Emerging Lignin-Based Materials in Electrochemical Energy Systems

Abstract

1. Introduction

2. Lignin and Industrial Lignin

2.1. Fundamental Structures of Lignin

2.2. Industrial Lignin from the Pulping Process

3. Lignin in Lithium Batteries (LIBs)

3.1. Lignin-Based Electrodes

3.2. Lignin-Based Gel Electrolytes

3.3. Lignin as Separators for LIBs

3.4. Lignin-Based Binders for LIBs

4. Lignin in Supercapacitors

4.1. Lignin-Based Electrodes for Supercapacitors

4.1.1. Lignin-Derived Electrodes for Double-Layer Capacitors

4.1.2. Lignin-Based Electrodes for Pseudocapacitors (PCs)

4.2. Lignin-Based Hydrogel Electrolytes

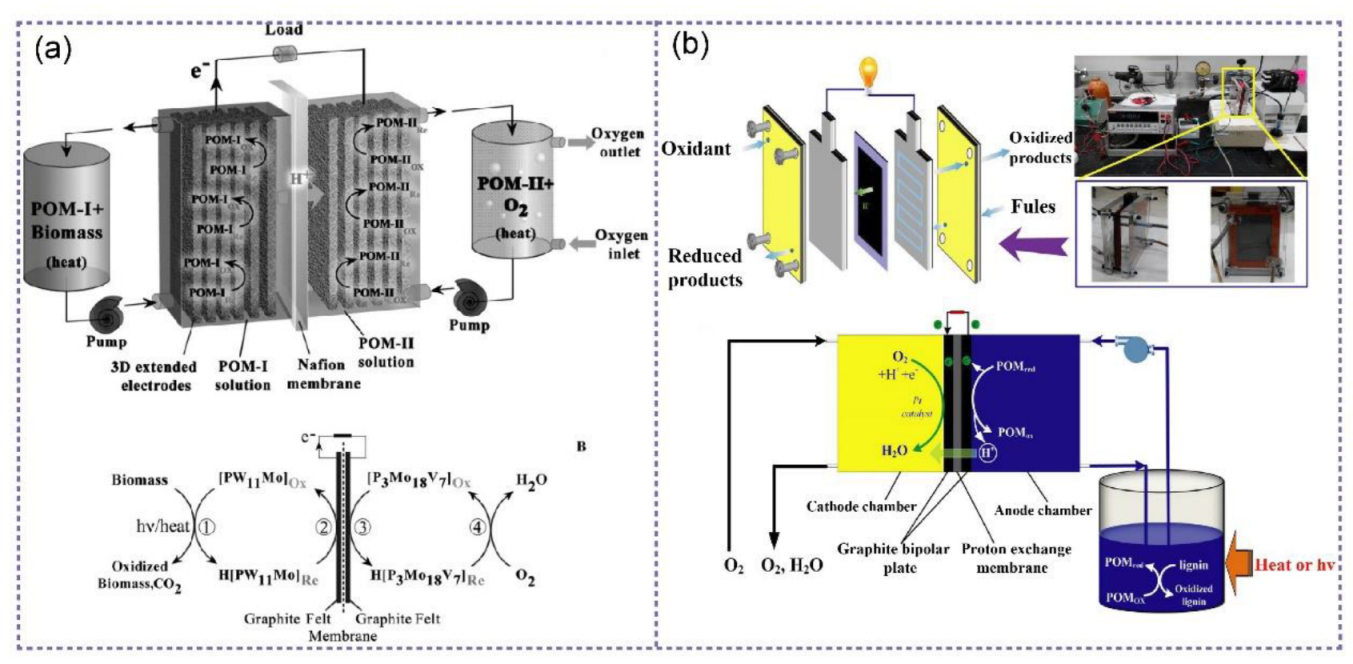

5. Lignin in Fuel Cells

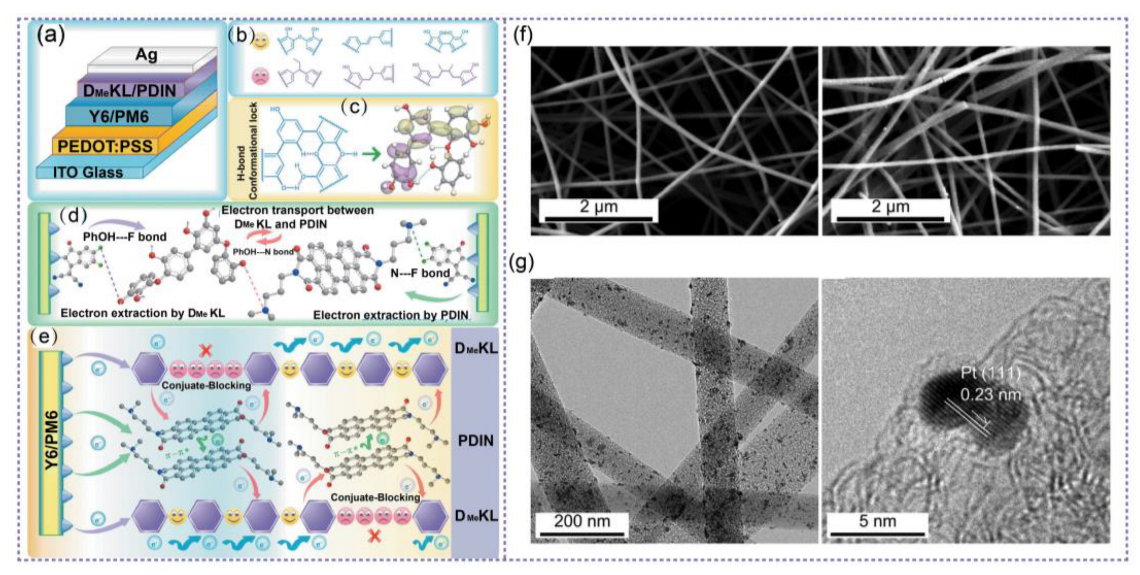

6. Lignin in Solar Cells

7. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Goodenough, J.B.; Kim, Y. Challenges for Rechargeable Li Batteries. Chem. Mater. 2010, 22, 587–603. [Google Scholar] [CrossRef]

- Fadzillah, D.M.; Kamarudin, S.K.; Zainoodin, M.A.; Masdar, M.S. Critical challenges in the system development of direct alcohol fuel cells as portable power supplies: An overview. Int. J. Hydrogen Energy 2019, 44, 3031–3054. [Google Scholar] [CrossRef]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Hou, Y.; Li, Y.M.; Xiao, H.I. Heteroatom-doped porous carbon microspheres derived from ionic liquid-lignin solution for high performance supercapacitors. J. Colloid Interface Sci. 2022, 614, 566–573. [Google Scholar] [CrossRef]

- Wu, X.Y.; Jiang, J.H.; Wang, C.M.; Liu, J.; Pu, Y.Q.; Ragauskas, A.; Li, S.M.; Yang, B. Lignin-derived electrochemical energy materials and systems. Biofuel. Bioprod. Bior. 2020, 14, 650–672. [Google Scholar] [CrossRef]

- Zhu, J.D.; Yan, C.Y.; Zhang, X.; Yang, C.; Jiang, M.J.; Zhang, X.W. A sustainable platform of lignin: From bioresources to materials and their applications in rechargeable batteries and supercapacitors. Prog. Energy Combust. Sci. 2020, 76, 100788. [Google Scholar] [CrossRef]

- Cai, C.; Bao, Y.; Zhan, X.J.; Lin, X.L.; Lou, H.M.; Pang, Y.X.; Qian, Y.; Qiu, X. Recovering cellulase and increasing glucose yield during lignocellulosic hydrolysis using lignin-MPEG with a sensitive pH response. Green Chem. 2019, 21, 1141–1151. [Google Scholar] [CrossRef]

- Choi, J.H.; Jang, S.K.; Kim, J.H.; Park, S.Y.; Kim, J.C.; Jeong, H.; Kim, H.Y.; Choi, I.G. Simultaneous production of glucose, furfural, and ethanol organosolv lignin for total utilization of high recalcitrant biomass by organosolv pretreatment. Renew. Energy 2019, 130, 952–960. [Google Scholar] [CrossRef]

- Zakzeski, J.; Bruijnincx, P.C.A.; Jongerius, A.L.; Weckhuysen, B.M. The Catalytic Valorization of Lignin for the Production of Renewable Chemicals. Chem. Rev. 2010, 110, 3552–3599. [Google Scholar] [CrossRef]

- Rippert, P.; Puyaubert, J.; Grisollet, D.; Derrier, L.; Matringe, M. Tyrosine and Phenylalanine Are Synthesized within the Plastids in Arabidopsis. Plant Physiol. 2009, 149, 1251–1260. [Google Scholar] [CrossRef]

- Ten, E.; Vermerris, W. Recent developments in polymers derived from industrial lignin. J. Appl. Polym. Sci. 2015, 132, 42069. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the Conversion of Lignin to High-Value Polymeric Materials: Review and Perspective. Chem. Rev. 2016, 116, 2275–2306. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Kelley, S.S.; Venditti, R.A. Lignin-Based Thermoplastic Materials. ChemSusChem 2016, 9, 770–783. [Google Scholar] [CrossRef] [PubMed]

- Pu, Y.Q.; Cao, S.L.; Ragauskas, A.J. Application of quantitative P-31 NMR in biomass lignin and biofuel precursors characterization. Energy Environ. Sci. 2011, 4, 3154–3166. [Google Scholar] [CrossRef]

- Espinoza-Acosta, J.L.; Torres-Chavez, P.I.; Olmedo-Martinez, J.L.; Vega-Rios, A.; Flores-Gallardo, S.; Zaragoza-Contreras, E.A. Lignin in storage and renewable energy applications: A review. J. Energy Chem. 2018, 27, 1422–1438. [Google Scholar] [CrossRef]

- Beckham, G.T.; Johnson, C.W.; Karp, E.M.; Salvachua, D.; Vardon, D.R. Opportunities and challenges in biological lignin valorization. Curr. Opin. Biotechnol. 2016, 42, 40–53. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhao, X.C.; Wang, A.Q.; Huber, G.W.; Zhang, T. Catalytic Transformation of Lignin for the Production of Chemicals and Fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef]

- Pandey, M.P.; Kim, C.S. Lignin Depolymerization and Conversion: A Review of Thermochemical Methods. Chem. Eng. Technol. 2011, 34, 29–41. [Google Scholar] [CrossRef]

- Buranov, A.U.; Mazza, G. Lignin in straw of herbaceous crops. Ind. Crops Prod. 2008, 28, 237–259. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Alonso, D.M.; Wettstein, S.G.; Dumesic, J.A. Bimetallic catalysts for upgrading of biomass to fuels and chemicals. Chem. Soc. Rev. 2012, 41, 8075–8098. [Google Scholar] [CrossRef] [PubMed]

- Vishtal, A.; Kraslawski, A. Challenges in Industrial Applications of Technical Lignins. Bioresources 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- Delmas, G.H.; Benjelloun-Mlayah, B.; Le Bigot, Y.; Delmas, M. Functionality of Wheat Straw Lignin Extracted in Organic Acid Media. J. Appl. Polym. Sci. 2011, 121, 491–501. [Google Scholar] [CrossRef]

- Laurichesse, S.; Averous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Solarte-Toro, J.C.; Alzate, C.A.C. The potential use of lignin as a platform product in biorefineries: A review. Renew. Sustain. Energy Rev. 2021, 138, 110688. [Google Scholar] [CrossRef]

- Gharehkhani, S.; Zhang, Y.Q.; Fatehi, P. Lignin-derived platform molecules through TEMPO catalytic oxidation strategies. Prog. Energy Combust. Sci. 2019, 72, 59–89. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and Application of Lignosulfonates and Sulfonated Lignin. ChemSusChem 2017, 10, 1861–1877. [Google Scholar] [CrossRef]

- Tribot, A.; Amer, G.; Alio, M.A.; de Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.D.; Callois, J.M.; Vial, C.; Michaud, P.; et al. Wood-lignin: Supply, extraction processes and use as bio-based material. Eur. Polym. J. 2019, 112, 228–240. [Google Scholar] [CrossRef]

- Kai, D.; Tan, M.J.; Chee, P.L.; Chua, Y.K.; Yap, Y.L.; Loh, X.J. Towards lignin-based functional materials in a sustainable world. Green Chem. 2016, 18, 1175–1200. [Google Scholar] [CrossRef]

- Zhou, W.P.; Zhang, H.; Chen, F.G. Modified lignin: Preparation and use in reversible gel via Diels-Alder reaction. Int. J. Biol. Macromol. 2018, 107, 790–795. [Google Scholar] [CrossRef]

- Bernardini, J.; Cinelli, P.; Anguillesi, I.; Coltelli, M.B.; Lazzeri, A. Flexible polyurethane foams green production employing lignin or oxypropylated lignin. Eur. Polym. J. 2015, 64, 147–156. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A.; Honarbakhsh-Raouf, A.; Nemati, F. The effect of soda bagasse lignin modified by ionic liquids on properties of the urea-formaldehyde resin as a wood adhesive. J. Adhes 2017, 93, 914–925. [Google Scholar] [CrossRef]

- Doherty, W.O.S.; Mousavioun, P.; Fellows, C.M. Value-adding to cellulosic ethanol: Lignin polymers. Ind. Crops Prod. 2011, 33, 259–276. [Google Scholar] [CrossRef]

- Lobato-Peralta, D.R.; Duque-Brito, E.; Villafan-Vidales, H.I.; Longoria, A.; Sebastian, P.J.; Cuentas-Gallegos, A.K.; Arancibia-Bulnes, C.A.; Okoye, P.U. A review on trends in lignin extraction and valorization of lignocellulosic biomass for energy applications. J. Clean. Prod. 2021, 293, 126123. [Google Scholar] [CrossRef]

- Deng, B.B.; Shen, L.; Liu, Y.A.; Yang, T.; Zhang, M.S.; Liu, R.J.; Huang, Z.H.; Fang, M.H.; Wu, X.W. Porous Si/C composite as anode materials for high-performance rechargeable lithium-ion battery. Chin. Chem. Lett. 2017, 28, 2281–2284. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Lu, Z.; Liu, J.; Bai, L.; Dong, J.; Nan, D. Constructing porous lignin-based carbon nanofiber anodes with flexibility for high-performance lithium/sodium-ion batteries. Mater. Today Sustain. 2022, 20, 100234. [Google Scholar] [CrossRef]

- Jo, G.; Jeon, H.; Park, M.J. Synthesis of Polymer Electrolytes Based on Poly(ethylene oxide) and an Anion-Stabilizing Hard Polymer for Enhancing Conductivity and Cation Transport. ACS Macro Lett. 2015, 4, 225–230. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, J.; Chong, C.B.; Yu, X.W.; Wanga, L.L.; Shi, Z.Q. An electrospun lignin/polyacrylonitrile nonwoven composite separator with high porosity and thermal stability for lithium-ion batteries. RSC Adv. 2015, 5, 101115–101120. [Google Scholar] [CrossRef]

- Yi, X.L.; He, W.; Zhang, X.D.; Yang, G.H.; Wang, Y.Y. Hollow mesoporous MnO/MnS/SiC/S-CN composites prepared from soda pulping black liquor for lithium-ion batteries. J. Alloys Compd. 2018, 735, 1306–1313. [Google Scholar] [CrossRef]

- Nowak, A.P.; Hagberg, J.; Leijonmarck, S.; Schweinebarth, H.; Baker, D.; Uhlin, A.; Tomani, P.; Lindbergh, G. Lignin-based carbon fibers for renewable and multifunctional lithium-ion battery electrodes. Holzforschung 2018, 72, 81–90. [Google Scholar] [CrossRef]

- Song, S.J.; Ma, F.W.; Wu, G.; Ma, D.; Geng, W.D.; Wan, J.F. Facile self-templating large scale preparation of biomass-derived 3D hierarchical porous carbon for advanced supercapacitors. J. Mater. Chem. A 2015, 3, 18154–18162. [Google Scholar] [CrossRef]

- Zhao, H.J.; Wang, Q.J.; Deng, Y.H.; Shi, Q.; Qian, Y.; Wang, B.B.; Lu, L.; Qiu, X.Q. Preparation of renewable lignin-derived nitrogen-doped carbon nanospheres as anodes for lithium-ion batteries. RSC Adv. 2016, 6, 77143–77150. [Google Scholar] [CrossRef]

- Li, Y.; Huang, Y.; Song, K.X.; Wang, X.F.; Yu, K.F.; Liang, C. Rice Husk Lignin-Derived Porous Carbon Anode Material for Lithium-Ion Batteries. Chemistryselect 2019, 4, 4178–4184. [Google Scholar] [CrossRef]

- Zhang, W.L.; Yin, J.; Lin, Z.Q.; Lin, H.B.; Lu, H.Y.; Wang, Y.; Huang, W.M. Facile preparation of 3D hierarchical porous carbon from lignin for the anode material in lithium ion battery with high rate performance. Electrochim. Acta 2015, 176, 1136–1142. [Google Scholar] [CrossRef]

- Yun, L.; Jia, M.Q.; Yang, H.H.; Zheng, H.Y.; Ao, H. Structural Characteristics and Electrochemical Performance of N,P- Codoped Porous Carbon as a Lithium-Ion Battery Anode Electrode. ACS Omega 2022, 38, 34109–34116. [Google Scholar]

- Chen, F.; Wu, L.; Zhou, Z.P.; Ju, J.J.; Zhao, Z.P.; Zhong, M.Q.; Kuang, T.R. MoS2 decorated lignin-derived hierarchical mesoporous carbon hybrid nanospheres with exceptional Li-ion battery cycle stability. Chin. Chem. Lett. 2019, 30, 197–202. [Google Scholar] [CrossRef]

- Wang, S.X.; Yang, L.P.; Stubbs, L.P.; Li, X.; He, C.B. Lignin-Derived Fused Electrospun Carbon Fibrous Mats as High Performance Anode Materials for Lithium Ion Batteries. ACS Appl. Mater. Interfaces 2013, 5, 12275–12282. [Google Scholar] [CrossRef]

- Tenhaeff, W.E.; Rios, O.; More, K.; McGuire, M.A. Highly Robust Lithium Ion Battery Anodes from Lignin: An Abundant, Renewable, and Low-Cost Material. Adv. Funct. Mater. 2014, 24, 86–94. [Google Scholar] [CrossRef]

- Yi, X.L.; He, W.; Zhang, X.D.; Yue, Y.Z.; Yang, G.H.; Wang, Z.Y.; Zhou, M.J.; Wang, L.Z. Graphene-like carbon sheet/Fe3O4 nanocomposites derived from soda papermaking black liquor for high performance lithium ion batteries. Electrochim. Acta 2017, 232, 550–560. [Google Scholar] [CrossRef]

- Niu, X.Y.; Zhou, J.Q.; Qian, T.; Wang, M.F.; Yan, C.L. Confined silicon nanospheres by biomass lignin for stable lithium ion battery. Nanotechnology 2017, 28, 405410. [Google Scholar] [CrossRef]

- Chou, C.Y.; Kuo, J.R.; Yen, S.C. Silicon-Based Composite Negative Electrode Prepared from Recycled Silicon-Slicing Slurries and Lignin/Lignocellulose for Li-Ion Cells. ACS Sustain. Chem. Eng. 2018, 6, 4759–4766. [Google Scholar] [CrossRef]

- Zhou, Z.P.; Chen, F.; Kuang, T.R.; Chang, L.Q.; Yang, J.T.; Fan, P.; Zhao, Z.P.; Zhong, M.Q. Lignin-derived hierarchical mesoporous carbon and NiO hybrid nanospheres with exceptional Li-ion battery and pseudocapacitive properties. Electrochim. Acta 2018, 274, 288–297. [Google Scholar] [CrossRef]

- Xi, Y.B.; Yang, D.J.; Liu, W.F.; Qin, Y.L.; Qiu, X.Q. Preparation of porous lignin-derived carbon/carbon nanotube composites by hydrophobic self-assembly and carbonization to enhance lithium storage capacity. Electrochim. Acta 2019, 303, 1–8. [Google Scholar] [CrossRef]

- Cheng, J.J.; Pan, Y.; Pan, J.A.; Song, H.J.; Ma, Z.S. Sulfur/bamboo charcoal composites cathode for lithium–sulfur batteries. RSC Adv. 2014, 5, 68–74. [Google Scholar] [CrossRef]

- Yuan, Y.; Haibo, L. In situ growth of CoO nanosheets on a carbon fiber derived from corn cellulose as an advanced hybrid anode for lithium-ion batteries. N. J. Chem. 2022, 46, 18664–18670. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, J.; Chen, X.; Zhang, M.; Huang, Q.; Du, X.; Liu, Y.; Li, X. Microtubular carbon fibers derived from bamboo and wood as sustainable anodes for lithium and sodium ion batteries. J. Porous Mater. 2019, 26, 1821–1830. [Google Scholar] [CrossRef]

- Chen, T.; Hu, J.Z.; Zhang, L.; Pan, J.; Liu, Y.Y.; Cheng, Y.T. High performance binder-free SiOx/C composite LIB electrode made of SiOx and lignin. J. Power Sources 2017, 362, 236–242. [Google Scholar] [CrossRef]

- Gong, S.D.; Huang, Y.; Cao, H.J.; Lin, Y.H.; Li, Y.; Tang, S.H.; Wang, M.S.; Li, X. A green and environment-friendly gel polymer electrolyte with higher performances based on the natural matrix of lignin. J. Power Sources 2016, 307, 624–633. [Google Scholar] [CrossRef]

- Wang, Q.J.; Song, W.L.; Fan, L.Z.; Song, Y. Facile fabrication of polyacrylonitrile/alumina composite membranes based on triethylene glycol diacetate-2-propenoic acid butyl ester gel polymer electrolytes for high-voltage lithium-ion batteries. J. Membr. Sci. 2015, 486, 21–28. [Google Scholar] [CrossRef]

- Yang, P.T.; Zhang, P.; Shi, C.; Chen, L.X.; Dai, J.H.; Zhao, J.B. The functional separator coated with core-shell structured silica-poly (methyl methacrylate) sub-microspheres for lithium-ion batteries. J. Membr. Sci. 2015, 474, 148–155. [Google Scholar] [CrossRef]

- Li, L.Y.; Chen, Y.X.; Guo, X.D.; Zhong, B.H. Preparation of sodium trimetaphosphate and its application as an additive agent in a novel polyvinylidene fluoride based gel polymer electrolyte in lithium sulfur batteries. Polym. Chem. 2015, 6, 1619–1626. [Google Scholar] [CrossRef]

- Che, Q.T.; Zhu, Z.F.; Chen, N.; Zhai, X. Methylimidazolium group-Modified polyvinyl chloride (PVC) doped with phosphoric acid for high temperature proton exchange membranes. Mater. Des. 2015, 87, 1047–1055. [Google Scholar] [CrossRef]

- Rajeswari, N.; Selvasekarapandian, S.; Karthikeyan, S.; Prabu, M.; Hirankumar, G.; Nithya, H.; Sanjeeviraja, C. Conductivity and dielectric properties of polyvinyl alcohol-polyvinylpyrrolidone poly blend film using non-aqueous medium. J. Non-Cryst. Solids 2011, 357, 3751–3756. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Wang, A.L.; Liu, X.; Chan, J.; Wang, Z.N.; Zeng, Q.H.; Zhou, H.H.; Jiang, X.R.; Zhang, L.Y. Polymer-Laden Composite Lignin-Based Electrolyte Membrane for High-Performance Lithium Batteries. ACS Sustain. Chem. Eng. 2018, 6, 14460–14469. [Google Scholar] [CrossRef]

- Uddin, M.J.; Alaboina, P.K.; Zhang, L.F.; Cho, S.J. A low-cost, environment-friendly lignin-polyvinyl alcohol nanofiber separator using a water-based method for safer and faster lithium-ion batteries. Mater. Sci. Eng. B Solid State Mater Adv. Technol. 2017, 223, 84–90. [Google Scholar] [CrossRef]

- Dominguez-Robles, J.; Sanchez, R.; Diaz-Carrasco, P.; Espinosa, E.; Garcia-Dominguez, M.T.; Rodriguez, A. Isolation and characterization of lignins from wheat straw: Application as binder in lithium batteries. Int. J. Biol. Macromol. 2017, 104, 909–918. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Chen, K.; Ma, J.; Xu, G.J.; Dong, S.M.; Chen, B.B.; Li, J.D.; Chen, Z.; Zhou, X.H.; Cui, G.L. A biomass based free radical scavenger binder endowing a compatible cathode interface for 5 V lithium-ion batteries. Energy Environ. Sci. 2019, 12, 273–280. [Google Scholar] [CrossRef]

- Wang, D.; Lee, S.H.; Kim, J.; Park, C.B. “Waste to Wealth”: Lignin as a Renewable Building Block for Energy Harvesting/Storage and Environmental Remediation. ChemSusChem 2020, 13, 2807–2827. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.Y.; Xu, T.; Liu, K.; Zhang, M.; Liu, W.; Li, H.; Du, H.S.; Si, C.L. Lignin-based electrodes for energy storage application. Ind. Crops Prod. 2021, 165, 113425. [Google Scholar] [CrossRef]

- Long, C.; Zhuang, J.L.; Xiao, Y.; Zheng, M.T.; Hu, H.; Dong, H.W.; Lei, B.F.; Zhang, H.R.; Liu, Y.L. Nitrogen-doped porous carbon with an ultrahigh specific surface area for superior performance supercapacitors. J. Power Sources 2016, 310, 145–153. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, N.; Lei, S.W.; Yan, R.; Tian, X.D.; Wang, J.Z.; Song, Y.; Xu, D.F.; Guo, Q.G.; Liu, L. Promising biomass-based activated carbons derived from willow catkins for high performance supercapacitors. Electrochim. Acta 2015, 166, 1–11. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Lu, M.; Tao, P.Y.; Zhang, Y.J.; Gong, X.T.; Yang, Z.; Zhang, G.Q.; Li, H.L. Hierarchically porous and heteroatom doped carbon derived from tobacco rods for supercapacitors. J. Power Sources 2016, 307, 391–400. [Google Scholar] [CrossRef]

- Cai, Y.J.; Luo, Y.; Xiao, Y.; Zhao, X.; Liang, Y.; Hu, H.; Dong, H.W.; Sun, L.Y.; Liu, Y.L.; Zheng, M.T. Facile Synthesis of Three-Dimensional Heteroatom-Doped and Hierarchical Egg-Box-Like Carbons Derived from Moringa oleifera Branches for High-Performance Supercapacitors. ACS Appl. Mater. Interfaces 2016, 8, 33060–33071. [Google Scholar] [CrossRef] [PubMed]

- Zapata-Benabithe, Z.; Castro, C.D.; Quintana, G. Kraft lignin as a raw material of activated carbon for supercapacitor electrodes. J. Mater. Sci. Mater. Electron. 2022, 33, 7031–7047. [Google Scholar] [CrossRef]

- Zhang, W.L.; Zhao, M.Z.; Liu, R.Y.; Wang, X.F.; Lin, H.B. Hierarchical porous carbon derived from lignin for high performance supercapacitor. Colloids Surf. A 2015, 484, 518–527. [Google Scholar] [CrossRef]

- Song, Y.G.; Liu, J.L.; Sun, K.; Xu, W. Synthesis of sustainable lignin-derived mesoporous carbon for supercapacitors using a nano-sized MgO template coupled with Pluronic F127. RSC Adv. 2017, 7, 48324–48332. [Google Scholar] [CrossRef]

- Lim, G.H.; Lee, J.W.; Choi, J.H.; Kang, Y.C.; Roh, K.C. Efficient utilization of lignin residue for activated carbon in supercapacitor applications. Mater. Chem. Phys. 2022, 284, 126073. [Google Scholar] [CrossRef]

- Yi, Y.J.; Hou, Y.; Li, Y.M. Preparation of High Conductivity Hierarchical Porous Carbon Based on Sodium Lignosulfonate with Pre-crosslinking. Bioresources 2020, 15, 8995–9012. [Google Scholar] [CrossRef]

- Liu, W.S.; Yao, Y.M.; Fu, O.L.; Jiang, S.H.; Fang, Y.C.; Wei, Y.; Lu, X.H. Lignin-derived carbon nanosheets for high-capacitance supercapacitors. RSC Adv. 2017, 7, 48537–48543. [Google Scholar] [CrossRef]

- Herou, S.; Ribadeneyra, M.C.; Madhu, R.; Araullo-Peters, V.; Jensen, A.; Schlee, P.; Titirici, M. Ordered mesoporous carbons from lignin: A new class of biobased electrodes for supercapacitors. Green Chem. 2019, 21, 550–559. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, J.M.; Lei, E.; Ma, C.H.; Luo, S.; Wu, Z.W.; Li, W.; Liu, S.X. Effects of the Pore Structure of Commercial Activated Carbon on the Electrochemical Performance of Supercapacitors. J. Energy Storage 2022, 45, 103457. [Google Scholar] [CrossRef]

- Du, B.Y.; Zhu, H.W.; Chai, L.F.; Cheng, J.L.; Wang, X.; Chen, X.H.; Zhou, J.H.; Sun, R.C. Effect of lignin structure in different biomass resources on the performance of lignin-based carbon nanofibers as supercapacitor electrode. Ind. Crops Prod. 2021, 170, 113745. [Google Scholar] [CrossRef]

- Zhou, B.J.; Li, J.; Liu, W.; Jiang, H.M.; Li, S.B.; Tan, L.X.; Dong, L.C.; She, L.; Wei, Z.D. Functional-Group Modification of Kraft Lignin for Enhanced Supercapacitors. ChemSusChem 2020, 13, 2628–2633. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.L.; Cao, Y.H.; Wang, X.M.; Castro, M.A.; Luo, B.; Gu, Z.R.; Liu, J.; Hoefelmeyer, J.D.; Fan, Q.H. Rod-shape porous carbon derived from aniline modified lignin for symmetric supercapacitors. J. Power Sources 2016, 307, 462–467. [Google Scholar] [CrossRef]

- Milczarek, G.; Nowicki, M. Carbon nanotubes/kraft lignin composite: Characterization and charge storage properties. Mater. Res. Bull. 2013, 48, 4032–4038. [Google Scholar] [CrossRef]

- Leguizamon, S.; Diaz-Orellana, K.P.; Velez, J.; Thies, M.C.; Roberts, M.E. High charge-capacity polymer electrodes comprising alkali lignin from the Kraft process. J. Mater. Chem. A 2015, 3, 11330–11339. [Google Scholar] [CrossRef]

- Xu, H.L.; Jiang, H.; Li, X.W.; Wang, G.C. Synthesis and electrochemical capacitance performance of polyaniline doped with lignosulfonate. RSC Adv. 2015, 5, 76116–76121. [Google Scholar] [CrossRef]

- Ajjan, F.N.; Casado, N.; Rebis, T.; Elfwing, A.; Solin, N.; Mecerreyes, D.; Inganas, O. High performance PEDOT/lignin biopolymer composites for electrochemical supercapacitors. J. Mater. Chem. A 2016, 4, 1838–1847. [Google Scholar] [CrossRef]

- Lin, T.T.; Wang, W.D.; Lu, Q.F.; Zhao, H.B.; Zhang, X.Q.; Lin, Q.L. Graphene-wrapped nitrogen-containing carbon spheres for electrochemical supercapacitor application. J. Anal. Appl. Pyrolysis. 2015, 113, 545–550. [Google Scholar] [CrossRef]

- Yu, B.M.; Gele, A.; Wang, L.P. Iron oxide/lignin-based hollow carbon nanofibers nanocomposite as an application electrode materials for supercapacitors. Int. J. Biol. Macromol. 2018, 118, 478–484. [Google Scholar] [CrossRef]

- Shi, F.Y.; Tong, Y.; Li, H.S.; Li, J.J.; Cong, Z.Y.; Zhai, S.R.; An, Q.D.; Wang, K. Synthesis of oxygen/nitrogen/sulfur codoped hierarchical porous carbon from enzymatically hydrolyzed lignin for high-performance supercapacitors. J. Energy Storage 2022, 52, 104992. [Google Scholar] [CrossRef]

- Hu, P.Y.; Jin, H.; Wang, K.L.; Zhao, Z.Z.; Qu, W.D. Lignin-based carbon nanofibe rs: Morphologies, properties, and features as substrates for pseudocapacitor electrodes. Int. J. Biol. Macromol. 2021, 193, 519–527. [Google Scholar] [CrossRef] [PubMed]

- Li, W.W.; Gao, F.X.; Wang, X.Q.; Zhang, N.; Ma, M.M. Strong and Robust Polyaniline-Based Supramolecular Hydrogels for Flexible Supercapacitors. Angew. Chem. Int. Ed. 2016, 55, 9196–9201. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Zhang, X.; Li, C.; Sun, X.Z.; Meng, Q.H.; Ma, Y.W.; Wei, Z.X. Chemically Crosslinked Hydrogel Film Leads to Integrated Flexible Supercapacitors with Superior Performance. Adv. Mater. 2015, 27, 7451. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhong, M.; Shi, F.K.; Liu, X.Y.; Tang, Z.J.; Wang, Y.K.; Huang, Y.; Hou, H.Q.; Xie, X.M.; Zhi, C.Y. An Intrinsically Stretchable and Compressible Supercapacitor Containing a Polyacrylamide Hydrogel Electrolyte. Angew. Chem. Int. Ed. 2017, 56, 9141–9145. [Google Scholar] [CrossRef]

- Park, J.H.; Rana, H.H.; Lee, J.Y.; Park, H.S. Renewable flexible supercapacitors based on all-lignin-based hydrogel electrolytes and nanofiber electrodes. J. Mater. Chem. A 2019, 7, 16962–16968. [Google Scholar] [CrossRef]

- Liu, T.; Ren, X.L.; Zhang, J.M.; Liu, J.; Ou, R.X.; Guo, C.G.; Yu, X.Y.; Wang, Q.W.; Liu, Z.Z. Highly compressible lignin hydrogel electrolytes via double-crosslinked strategy for superior foldable supercapacitors. J. Power Sources 2020, 449, 227532. [Google Scholar] [CrossRef]

- Lima, R.B.; Raza, R.; Qin, H.Y.; Li, J.B.; Lindstrom, M.E.; Zhu, B. Direct lignin fuel cell for power generation. RSC Adv. 2013, 3, 5083–5089. [Google Scholar] [CrossRef]

- Shewa, W.A.; Lalman, J.A.; Chaganti, S.R.; Heath, D.D. Electricity production from lignin photocatalytic degradation byproducts. Energy 2016, 111, 774–784. [Google Scholar] [CrossRef]

- Liu, W.; Mu, W.; Deng, Y.L. High-Performance Liquid-Catalyst Fuel Cell for Direct Biomass-into-Electricity Conversion. Angew. Chem. Int. Ed. 2014, 53, 13558–13562. [Google Scholar] [CrossRef]

- Zhao, X.B.; Zhu, J.Y. Efficient Conversion of Lignin to Electricity Using a Novel Direct Biomass Fuel Cell Mediated by Polyoxometalates at Low Temperatures. ChemSusChem 2016, 9, 197–207. [Google Scholar] [CrossRef]

- Li, Y.D.; Liu, T.F.; Qiu, X.Q.; Zhou, Y.H.; Li, Y. Enhancing Efficiency and Durability of Inverted Perovskite Solar Cells with Phenol/Unsaturated Carbon-Carbon Double Bond Dual-Functionalized Poly(3,4-ethylenedioxythiophene) Hole Extraction Layer. ACS Sustain. Chem. Eng. 2019, 7, 961–968. [Google Scholar] [CrossRef]

- Thomas, J.P.; Leung, K.T. Mixed co-solvent engineering of PEDOT:PSS to enhance its conductivity and hybrid solar cell properties. J. Mater. Chem. A 2016, 4, 17537–17542. [Google Scholar] [CrossRef]

- Liu, D.Y.; Li, Y.; Yuan, J.Y.; Hong, Q.M.; Shi, G.Z.; Yuan, D.X.; Wei, J.; Huang, C.C.; Tang, J.X.; Fung, M.K. Improved performance of inverted planar perovskite solar cells with F4-TCNQ doped PEDOT:PSS hole transport layers. J. Mater. Chem. A 2017, 5, 5701–5708. [Google Scholar] [CrossRef]

- Xie, B.S.; Hou, Y.; Liu, C.; Li, Y.M. Hydrophobic magnetic bilayer micro-particles from OA@Lignin@Fe3O4 for high-efficient oil adsorption. Eur. Polym. J. 2022, 168, 111090. [Google Scholar] [CrossRef]

- Hu, H.C.; Xu, H.M.; Wu, J.Y.; Li, L.J.; Yue, F.X.; Huang, L.L.; Chen, L.H.; Zhang, X.Y.; Ouyang, X.H. Secondary Bonds Modifying Conjugate-Blocked Linkages of Biomass-Derived Lignin to Form Electron Transfer 3D Networks for Efficiency Exceeding 16% Nonfullerene Organic Solar Cells. Adv. Funct. Mater. 2020, 30, 2001494. [Google Scholar] [CrossRef]

- Ma, X.J.; Elbohy, H.; Sigdel, S.; Lai, C.L.; Qiao, Q.Q.; Fong, H. Electrospun carbon nano-felt derived from alkali lignin for cost-effective counter electrodes of dye-sensitized solar cells. RSC Adv. 2016, 6, 11481–11487. [Google Scholar] [CrossRef]

| Kraft Lignin | Lignosulfonate | Soda Lignin | Organosolv Lignin | |

|---|---|---|---|---|

| Extraction methods | NaOH, Na2S, 150–170 °C, 1–2 h | Sulfur dioxide (Na, Ca or Mg as counter ion), 125–150 °C, 1–5 h | NaOH or NaOH- anthraquinone, 140–170 °C, 1–2 h | Acetic acid/formic acid/water, 80–130 °C, 1–4 h |

| Isolation methods | Acid precipitation | Ultrafiltration | Acid precipitation | Antisolvent precipitation |

| Molecular weight (×103 g mol−1) | 1.0–6.0 | 15–50 | 0.8–3.0 | 0.5–5.0 |

| Polydispersity | 2.5–3.5 | 6.0–8.0 | 2.5–3.5 | 1.5–4.0 |

| Impurities (%) | Sulfur 1–3 | Sulfur 3–8 | Sulfur < 0.1% | ash < 10 |

| Tg (°C) | 140–150 | 130 | 140 | 90–110 |

| Solubility | Organic solvents and alkali | Water | Alkali | Organic solvents |

| Lignin Type | Lignin-Based Materials | SSA (m2 g−1) | Rate (A g−1) | Specific Capacitance (mA h g−1) | Ref. |

|---|---|---|---|---|---|

| KL | Carbon fibers | - | 0.1 C | 335 | [40] |

| SL | Hollow mesoporous spheres | - | 1 | 756 | [39] |

| AL | 3D hierarchical porous carbon | - | 0.2 | 470 | [44] |

| AL | N-doped carbon nanospheres | 419.2 | 0.06 | 225 | [42] |

| AL | 3D porous carbon | 167.5 | 0.2 | 469 | [43] |

| AL | N, P- codoped porous carbon | 675.4 | 1 | 1463.8 | [45] |

| LS | Hierarchical mesoporous carbon nanospheres | 462.8 | 0.1 | 520 | [46] |

| OSL | Carbon nanofibers | 381 | 2 | 200 | [47] |

| OSL | Carbon nanofibers | - | 0.015 | 193 | [48] |

| Lignin-Based Materials | Porogen | SSA (m2 g−1) | Rate (A g−1) | Specific Capacitance (mA h g−1) | Ref. |

|---|---|---|---|---|---|

| AL/MgO/G | Mg (NO3)2·6H2O | 628.09 | 2 C | 1064.7 | [36] |

| SL/Fe3O4 | FeCl3·6H2O and Fe (NO3)3·9H2O | - | 1 | 750 | [49] |

| AL/SiNPs | Self-assembly | - | 9 | 800 | [50] |

| AL/Si | Mixing mixture | - | 0.3 | 880 | [51] |

| LS/NiO | Ni (OH)2 | 851.8 | 0.1 | 863 | [52] |

| OSL/PEO | urea | 381 | 2 | 200 | [47] |

| EHL/CNTs | K2CO3 | 740 | 1 | 240 | [53] |

| Materials | Porogen | Electrolyte | Rate (A g−1) | Specific Capacitance (F g−1) | Ref. |

|---|---|---|---|---|---|

| AL | Freeze drying | 1 M H2SO4 | 0.5 | 281 | [74] |

| AL | KOH | 6 M KOH | 0.2 | 286.7 | [75] |

| AL | F127, MgO | 6 M KOH | 0.2 | 186.3 | [76] |

| KL | KOH | 1 M H2SO4 | 0.63 | 196.5 | [77] |

| LS | KOH | 6 M KOH | 0.5 | 305 | [78] |

| OL | KOH | 1 M TEABF4 | 1 mA cm−2 | 131 | [79] |

| OL | Self-assembly | 6 M KOH | - | 90 F cm−3 | [80] |

| Commercial AC | - | 6 M KOH | 1 | 139.35 | [81] |

| Materials | Porogen | Electrolyte | Rate (A g−1) | Specific Capacitance (F g−1) | Ref. |

|---|---|---|---|---|---|

| KL/PANI | 6 M KOH | 0.5 | 141.3 | [82] | |

| KL/Fe2O3 | - | 1 M H2SO4 | 0.5 | 390 | [83] |

| KL/aniline | KOH | 6 M KOH | 1 | 333 | [84] |

| KL/CNT | - | 1 M H2SO4 | 2.5 | 177 | [85] |

| AL/PPy | - | 0.5 M H2SO4 | 0.5 mA g−1 | 444 | [86] |

| LS/PANI | - | 1 M H2SO4 | 10 | 377.2 | [87] |

| LS/PEDOT | - | 0.1 M HClO4/acetonitrile | 1 | 170.4 | [88] |

| LS/PANI/GO | - | 6 M KOH | 0.5 | 266.7 | [89] |

| OL/Fe(acac)3 | - | 1 M Na2SO3 | 0.5 | 121 | [90] |

| EHL/urea | KOH | 6 M KOH | 0.5 | 318 | [91] |

| EHL/PANI | - | 0.5 M H2SO4 | 0.29 | 229 | [92] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, Y.; Zhuang, J.; Liu, C.; Lei, L.; He, S.; Hou, Y. Emerging Lignin-Based Materials in Electrochemical Energy Systems. Energies 2022, 15, 9450. https://doi.org/10.3390/en15249450

Yi Y, Zhuang J, Liu C, Lei L, He S, Hou Y. Emerging Lignin-Based Materials in Electrochemical Energy Systems. Energies. 2022; 15(24):9450. https://doi.org/10.3390/en15249450

Chicago/Turabian StyleYi, Yanjie, Jingshun Zhuang, Chao Liu, Lirong Lei, Shuaiming He, and Yi Hou. 2022. "Emerging Lignin-Based Materials in Electrochemical Energy Systems" Energies 15, no. 24: 9450. https://doi.org/10.3390/en15249450

APA StyleYi, Y., Zhuang, J., Liu, C., Lei, L., He, S., & Hou, Y. (2022). Emerging Lignin-Based Materials in Electrochemical Energy Systems. Energies, 15(24), 9450. https://doi.org/10.3390/en15249450