Simulation-Based Fault Detection Remote Monitoring System for Small-Scale Photovoltaic Systems

Abstract

1. Introduction

2. Design of the Remote Monitoring System for Failure Detection

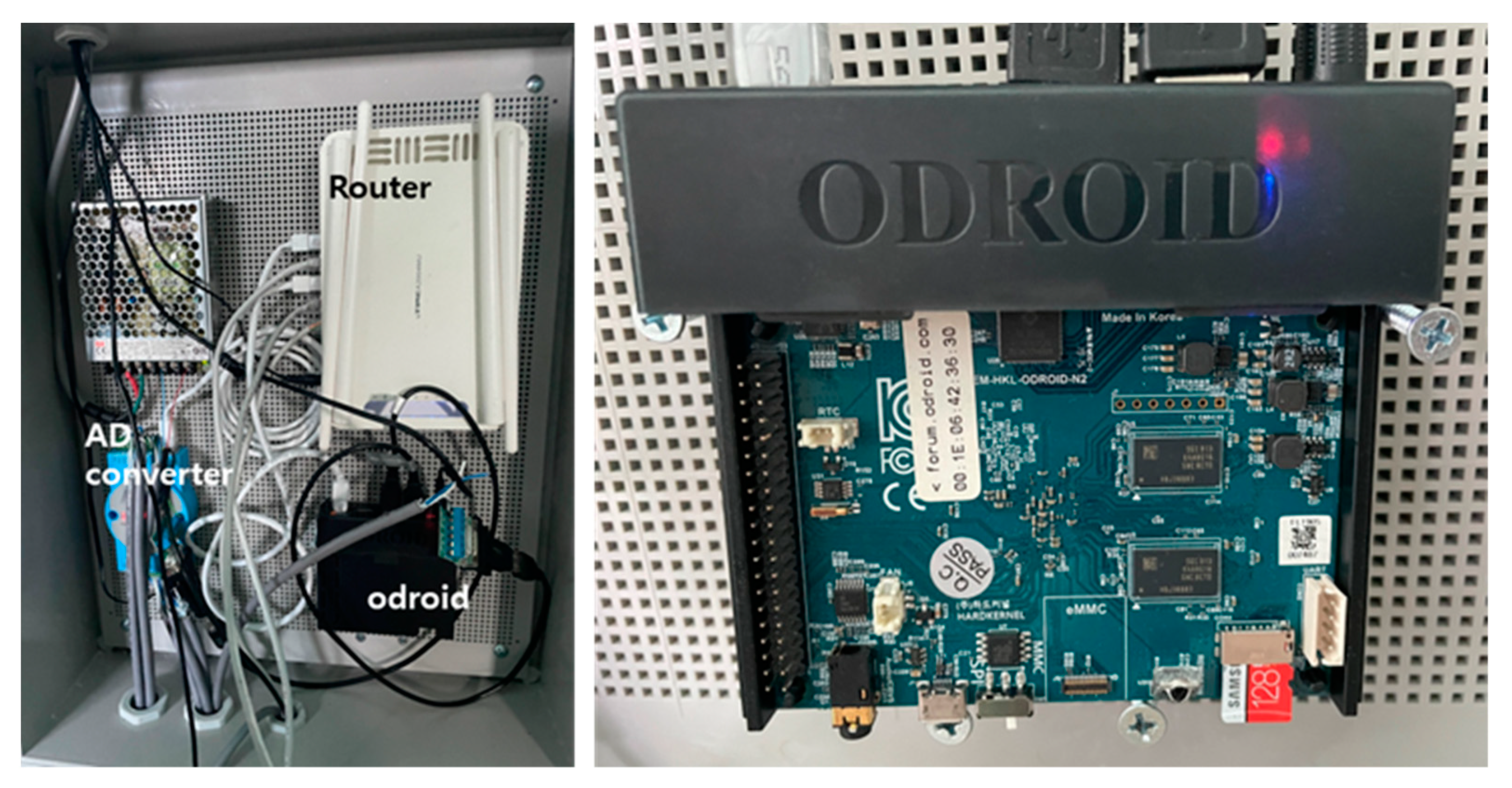

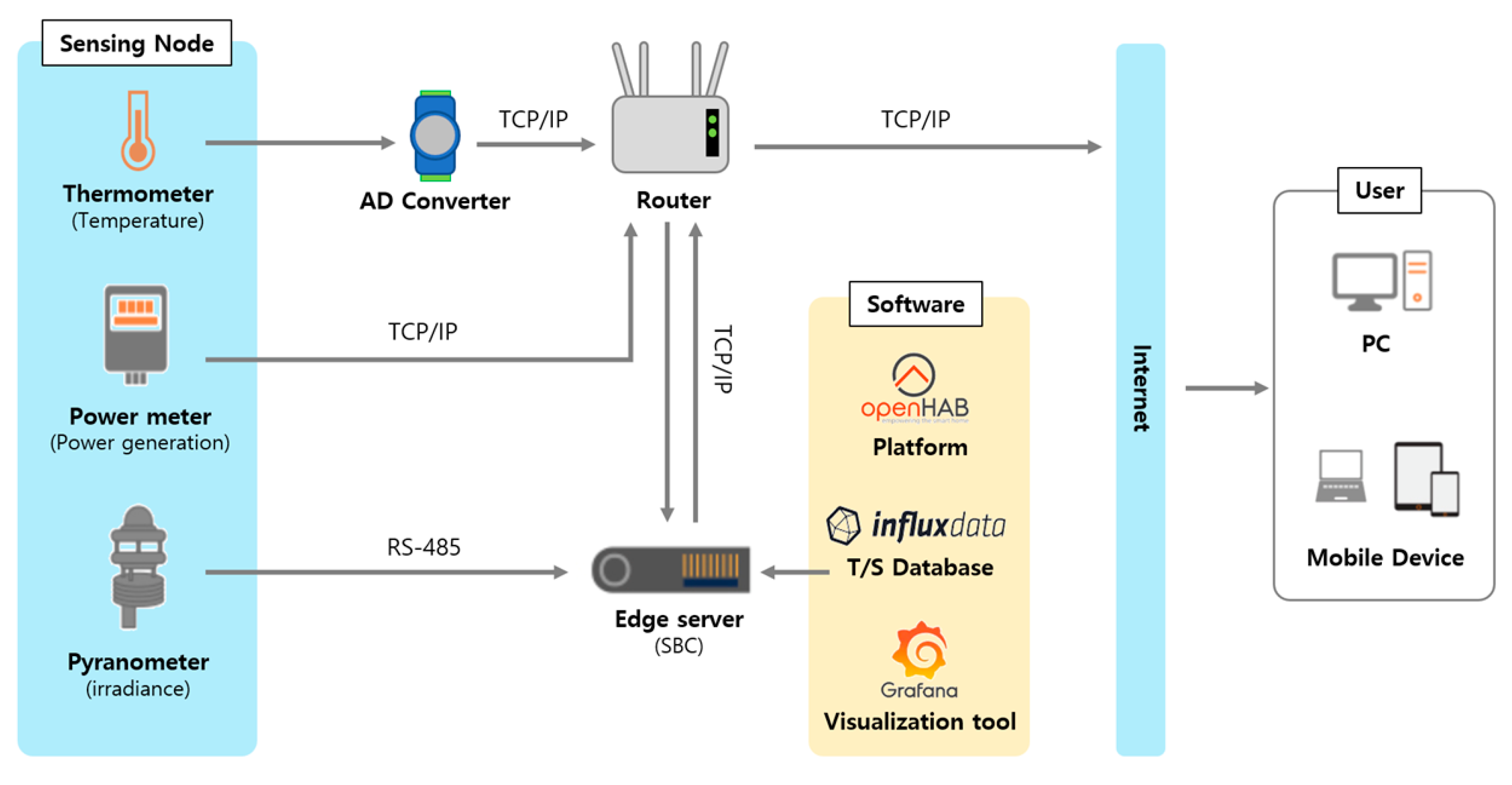

2.1. Data Server

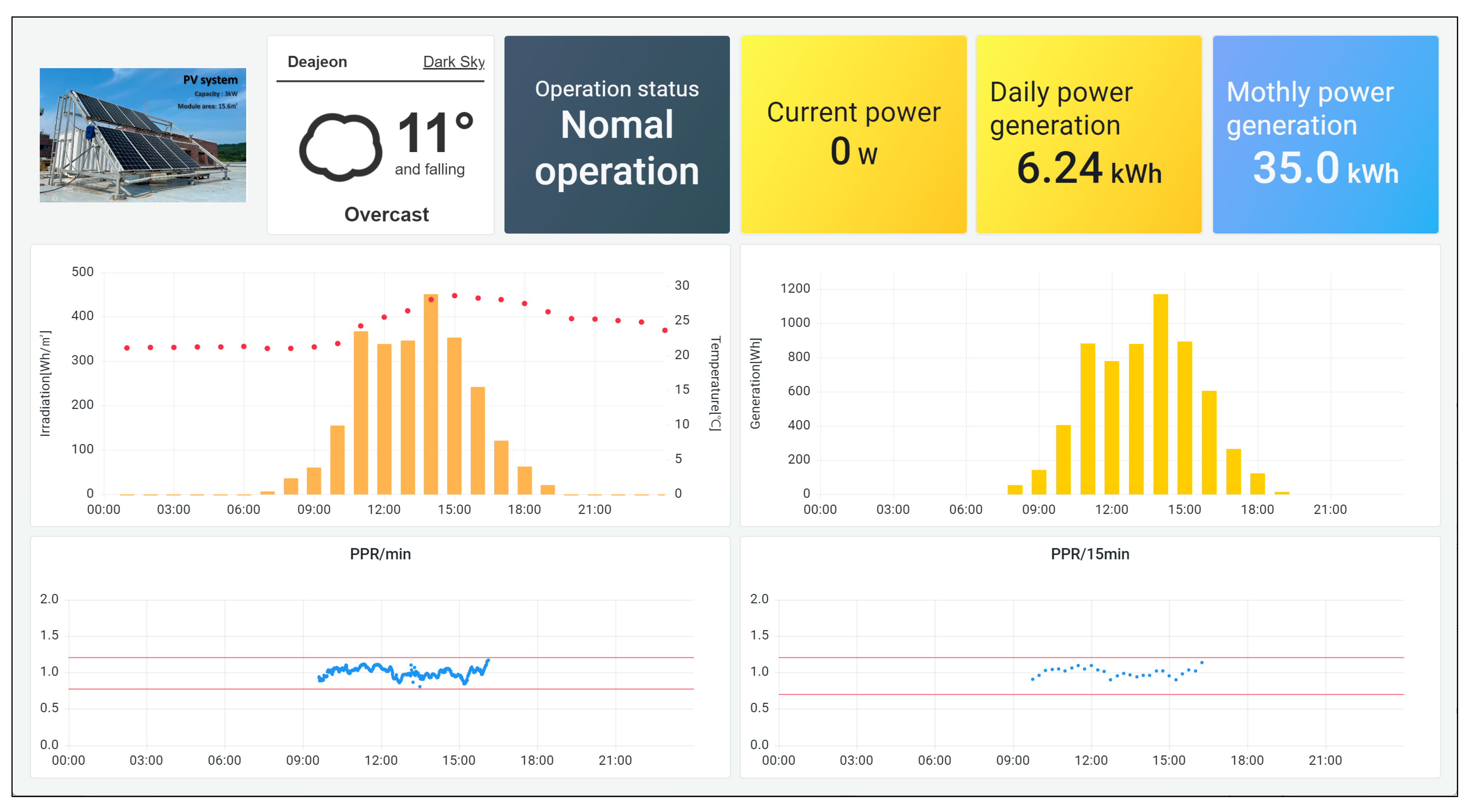

2.2. Building a Platform for the Monitoring System

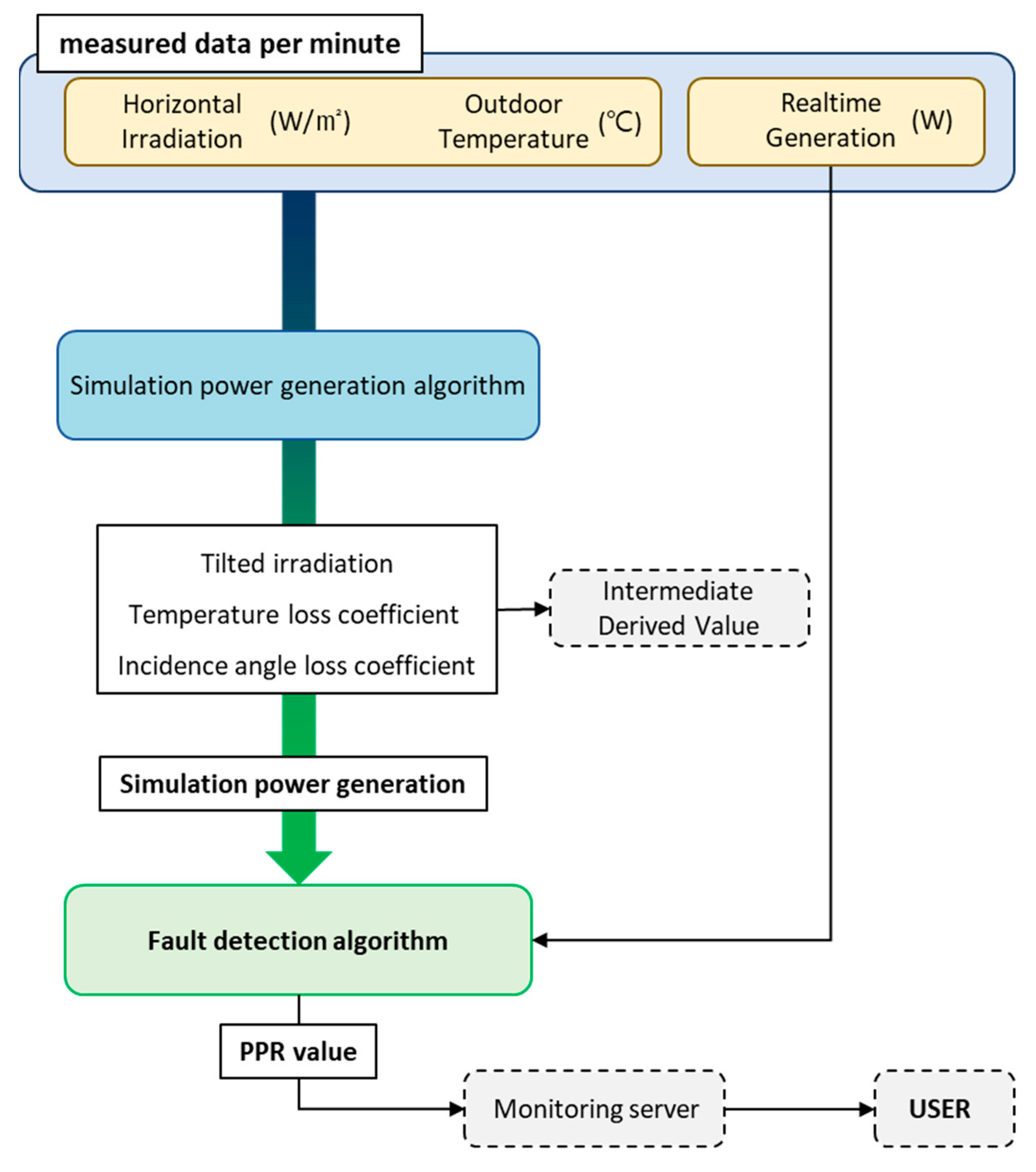

3. Simulation Algorithm

3.1. Simulation Generation Model

3.2. Failure Detection Algorithm

4. Establishment of the Remote Monitoring System for Solar Power Generation

4.1. PV Systems and Sensor Installation

4.2. Establishment of the Remote Monitoring System

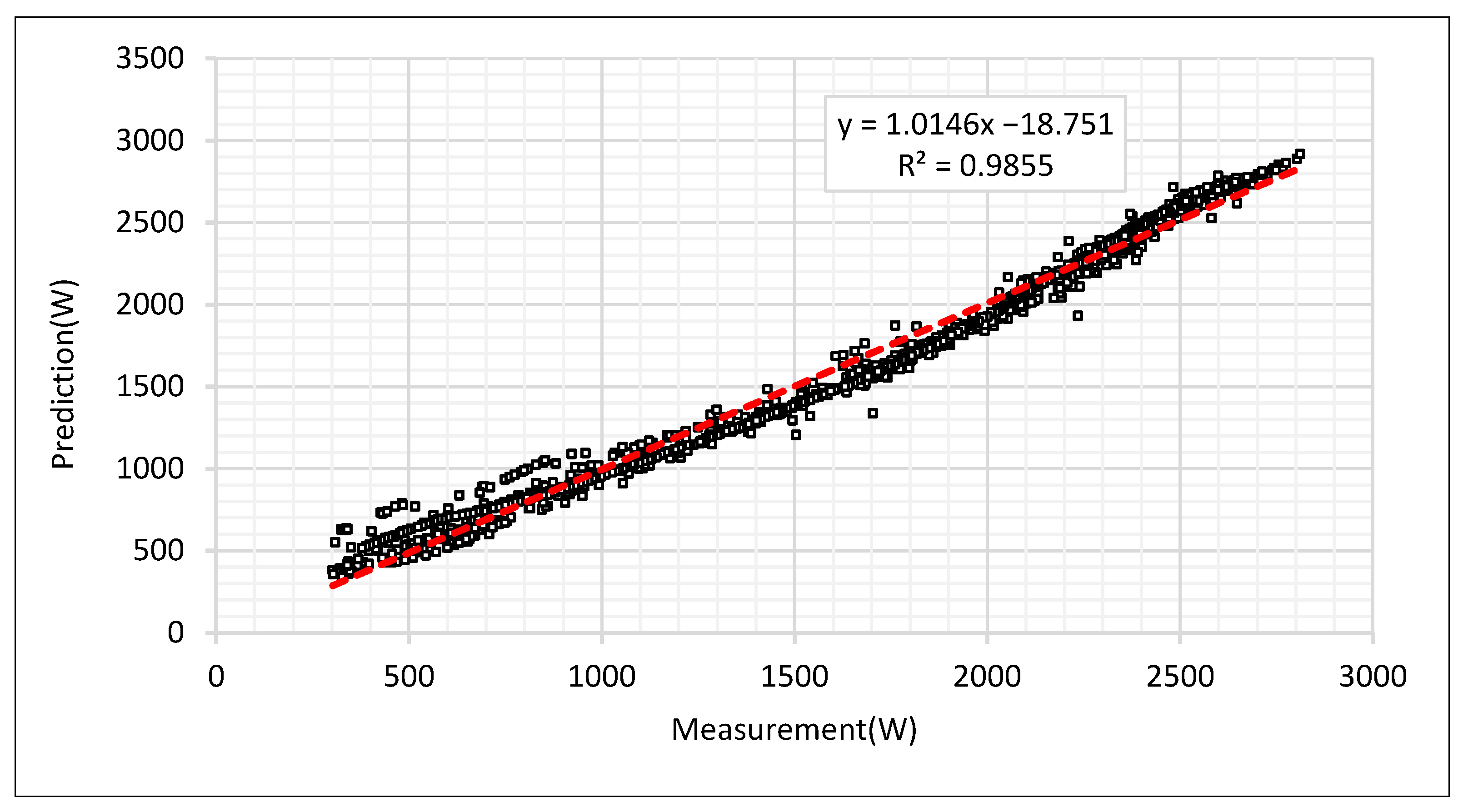

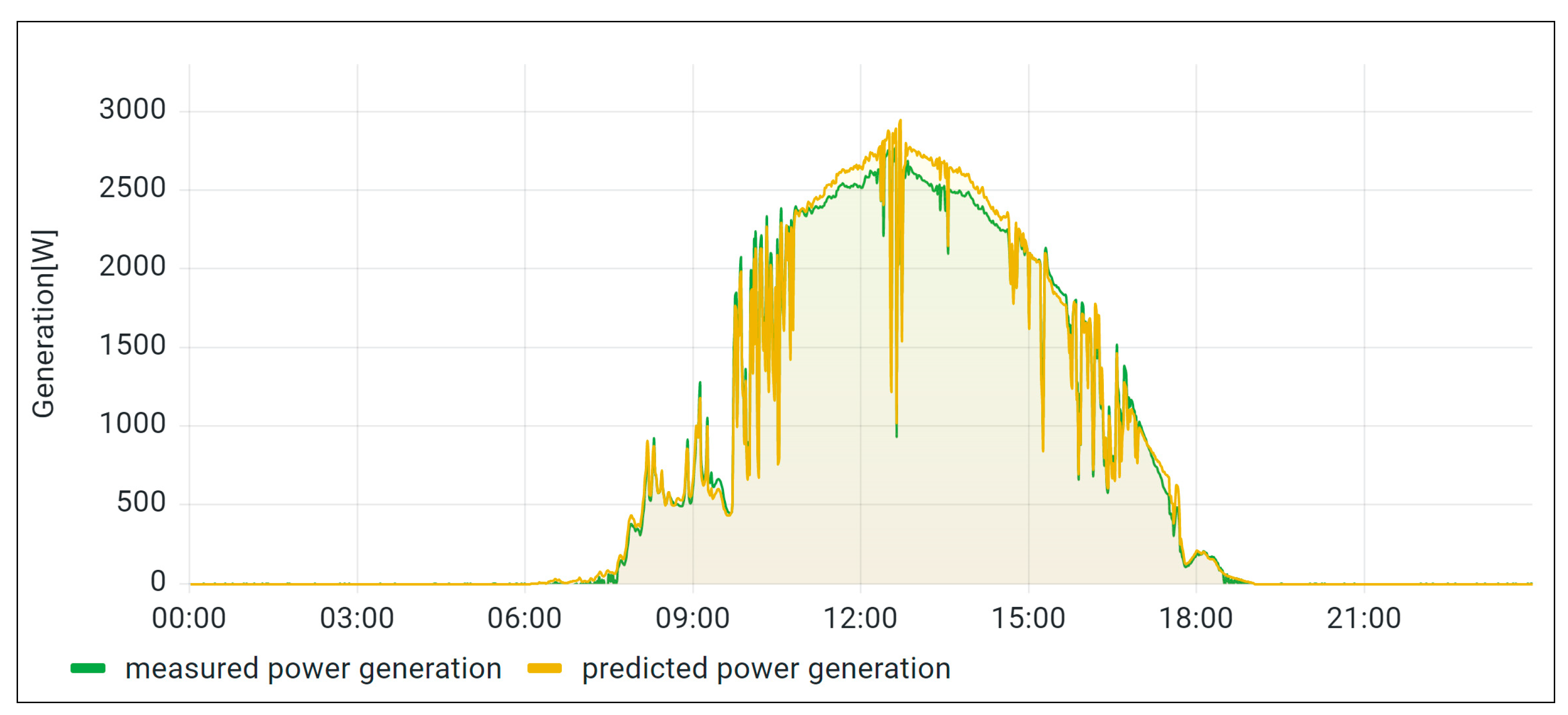

4.3. Validation of the Simulation Model

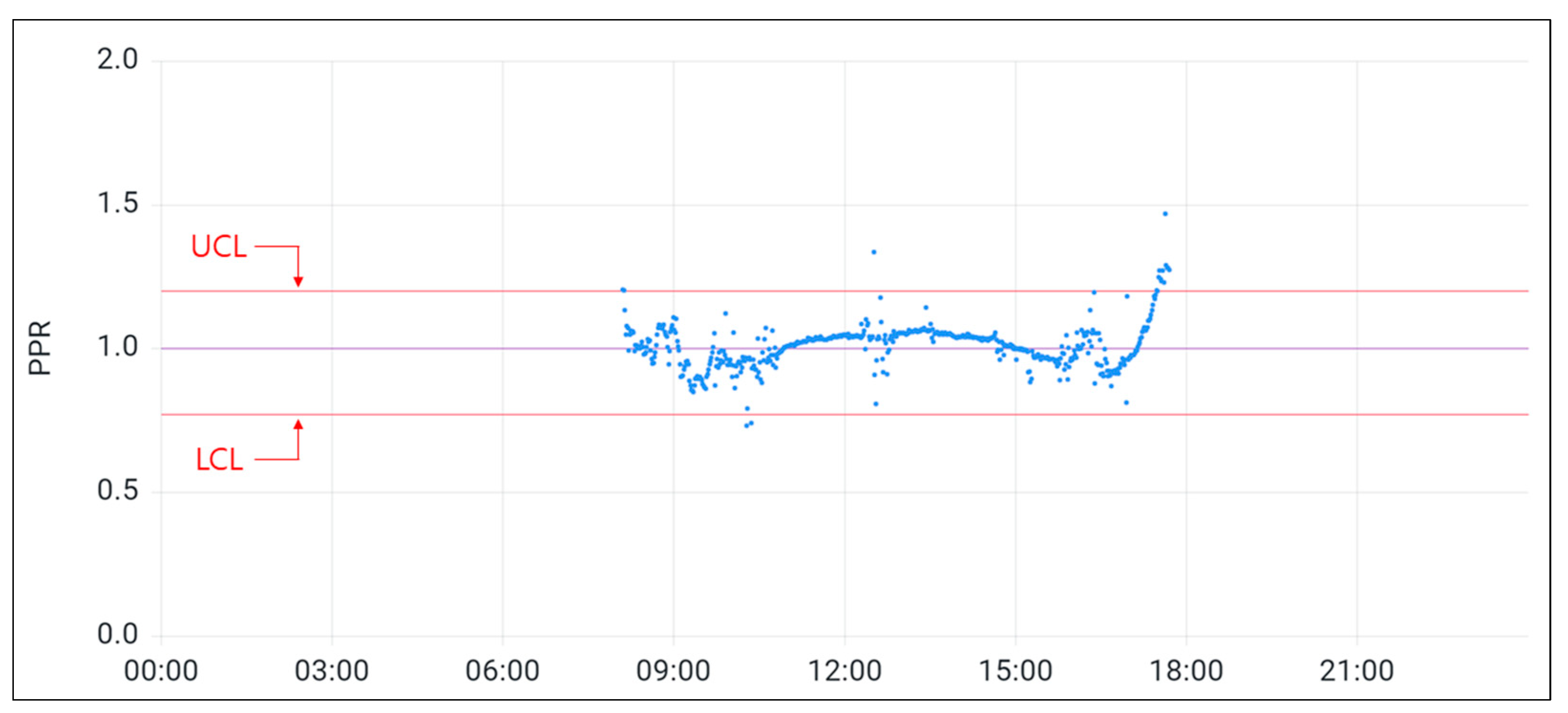

4.4. Control Limits

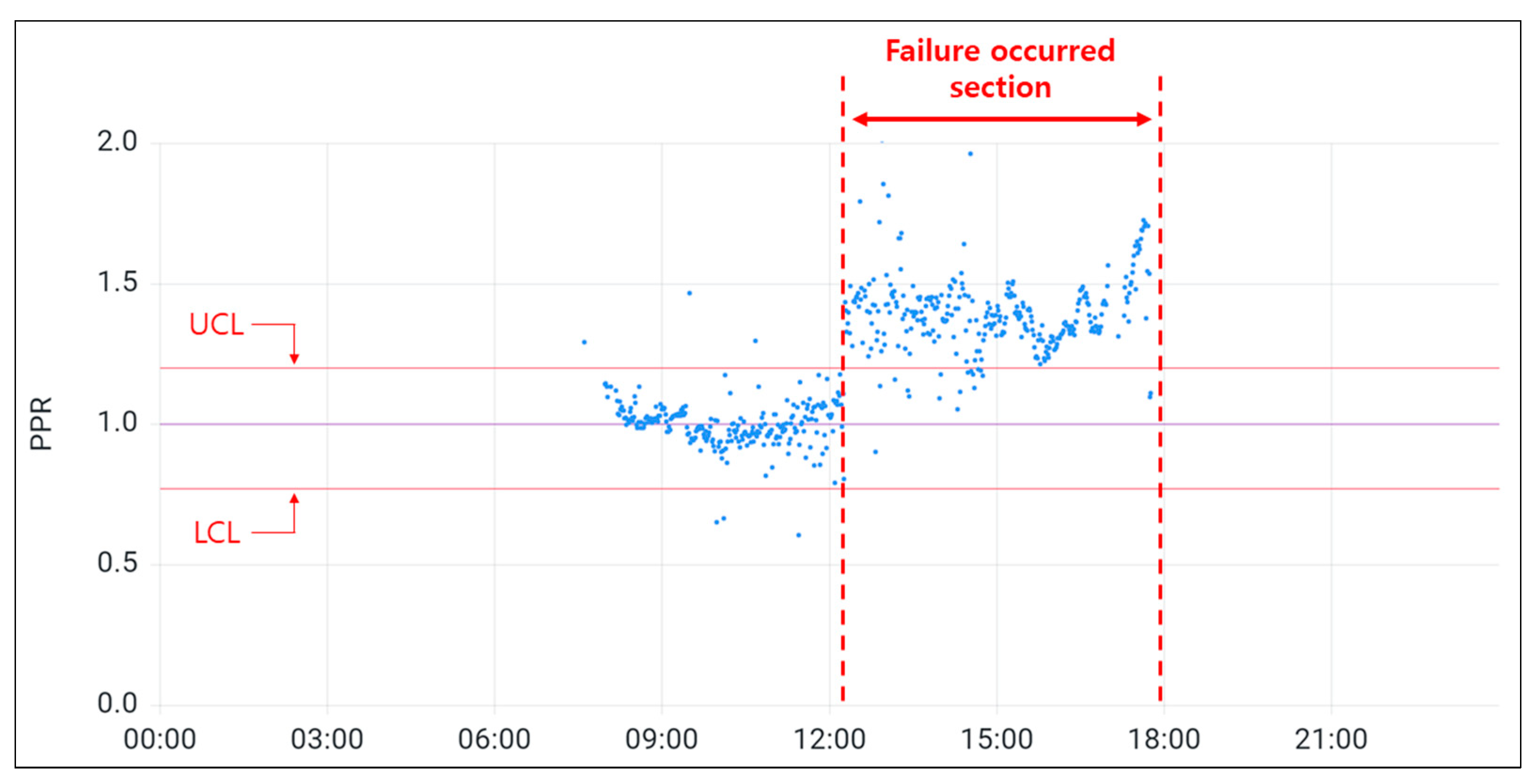

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Efficiency of the module (%) | |

| Reference efficiency of the module (%) | |

| Temperature coefficient | |

| PV module reference temperature (°C). | |

| Outside temperature (°C). | |

| Solar transmittance/absorption rate | |

| Heat loss coefficient | |

| Solar radiation intensity (W/m2) | |

| Direct irradiance ratio | |

| Horizontal direct irradiance (W/m2) | |

| Horizontal sky scattering irradiance (W/m2) | |

| Ground reflectance | |

| Incident angle modifier of direct irradiance | |

| Incident angle modifier of sky scattering | |

| Incident angle modifier of ground reflectance | |

| PV module Installation Slope Angle (°) | |

| Incident angle correction coefficient | |

| Incident angle of the PV module for each component of solar radiation (°) | |

| ω | Time angle (°) |

| δ | Solar declination (°) |

| φ | Latitude (°) |

| Incident angle of direct irradiance | |

| Incident angle of sky scattering | |

| Incident angle of ground reflectance | |

| Operating efficiency reflecting the system loss (%) | |

| Installation area of the PV module (m2) |

References

- Silvestre, S.; da Silva, M.A.; Chouder, A.; Guasch, D.; Karatepe, E. New procedure for fault detection in grid-connected PV systems based on the evaluation of current and voltage indicators. Energy Convers. Manag. 2014, 86, 241–249. [Google Scholar] [CrossRef]

- Park, Y.; Kang, G.; Ju, Y.; Kim, S.; Ko, S.; Jang, G. The monitoring system of photovoltaic module using fault diagnosis sensor. J. Korean Sol. Energy Soc. 2016, 36, 91–100. [Google Scholar] [CrossRef][Green Version]

- Lee, J.; Kim, K.; Park, S.; Byun, H.; Shim, K.; An, B. IoT-based mobile smart monitoring system for solar power generation. J. Inst. Electron. Inf. Eng. 2017, 54, 1175–1184. [Google Scholar]

- Hazra, A.; Das, S.; Basu, M. An efficient fault diagnosis method for PV systems following string current. J. Clean. Prod. 2017, 154, 220–232. [Google Scholar] [CrossRef]

- Ko, S.W.; So, J.H.; Hwang, H.M.; Ju, Y.C.; Song, H.J.; Shin, W.G.; Kang, G.H.; Choi, J.R.; Kang, I.C. The monitoring system with PV module-level fault diagnosis algorithm. J. Korean Sol. Energy Soc. 2018, 38, 21–28. [Google Scholar] [CrossRef]

- Hu, A.; Sun, Q.; Liu, H.; Zhou, N.; Tan, Z.; Honglu Zhu, H. A novel photovoltaic array outlier cleaning algorithm based on sliding standard deviation mutation. Energies 2019, 12, 4316. [Google Scholar] [CrossRef]

- Cho, K.; Kim, E.; Lee, D.; Lee, M.; Park, J. Development of fault diagnosis program for reducing power loss cost of the photovoltaic power system using actual operation data. Trans. Korean Inst. Electr. Eng. 2020, 69, 1682–1688. [Google Scholar] [CrossRef]

- Dhanraj, J.A.; Mostafaeipour, A.; Velmurugan, K.; Techato, K.; Chaurasiya, P.K.; Solomon, J.M.; Gopalan, A.; Phoungthong, K. An effective evaluation on fault detection in solar panels. Energies 2021, 14, 7770. [Google Scholar] [CrossRef]

- Madeti, S.R.K. A monitoring system for online fault detection in multiple photovoltaic arrays. Renew. Energy Focus 2022, 41, 160–178. [Google Scholar] [CrossRef]

- Hong, Y.Y.; Pula, R.A. Methods of photovoltaic fault detection and classification: A review. Energy Rep. 2022, 8, 5898–5929. [Google Scholar] [CrossRef]

- Kang, S.Y.; Lee, I.W. Implementation of Real-Time Monitoring System for Maintenance of PV Generation System; Korea Institute of Communication Sciences: Seoul, Republic of Korea, 2019; pp. 91–92. [Google Scholar]

- Sarkar, S.; Rao, K.U.; Bhargav, J.; Sheshaprasad, S.; Anirudh, S.C.A. IoT Based Wireless Sensor Network (WSN) for Condition Monitoring of Low Power Rooftop PV Panels. In Proceedings of the 2019 IEEE 4th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Chennai, India, 21–23 November 2019; pp. 21–23. [Google Scholar]

- Mohamed, Z.; Yousry, A.; Abdullah, A.H.; Ihab, E.S. LabVIEW Based Monitoring System Applied for PV Power Station. In Proceedings of the 12th WSEAS International Conference on Automatic Control, Modelling and Simulation (ACMOS’10), Catania, Italy, 29–31 May 2010; pp. 65–70. [Google Scholar]

- Jürgen, S.; Dirk, P.; Ursula, E. Commissioning and operational control of photovoltaic power plants through online simulation. Energy Procedia 2014, 57, 152–160. [Google Scholar]

- Chouder, A.; Silvestre, S. Automatic supervision and fault detection of PV systems based on power loss analysis. Energy Convers. Manag. 2010, 51, 1929–1937. [Google Scholar] [CrossRef]

- Gokmen, N.; Karatepe, E.; Celik, B.; Silvestre, S. Simple diagnostic approach for determining of faulted PV modules in string based PV arrays. Sol. Energy 2012, 86, 3364–3377. [Google Scholar] [CrossRef]

- Silvestre, S.; Chouder, A.; Karatepe, E. Automatic fault detection in grid connected PV systems. Sol. Energy 2013, 94, 119–127. [Google Scholar] [CrossRef]

- Platon, R.P.; Martel, J.; Woodruff, N.; Chau, T.Y. Online fault detection in PV systems. IEEE Trans. Sustain. Energy 2015, 6, 1200–1207. [Google Scholar] [CrossRef]

- Evans, D.L. Simplified method for predicting photovoltaic array output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- PVsyst 7 Help: Array Thermal Losses. 2019. Available online: https://www.pvsyst.com/help/index.html?thermal_loss.htm (accessed on 12 September 2022).

- Erbs, D.; Klein, S.; Duffie, J. Estimation of the diffuse radiation fraction for hourly, daily and monthly-average global radiation. Sol. Energy 1982, 287, 293–302. [Google Scholar] [CrossRef]

- Reindl, D.T.; Beckman, W.A.; Duffie, J.A. Diffuse fraction correlations. Sol. Energy 1990, 45, 1–7. [Google Scholar] [CrossRef]

- Loutzenhiser, P.G.; Manz, H.; Felsmann, C.; Strachan, P.A.; Frank, T.H.; Maxwell, G.M. Empirical validation of models to compute solar irradiance on inclined surfaces for building energy simulation. Sol. Energy 2007, 81, 254–267. [Google Scholar] [CrossRef]

- John, A.; Duffie, J.A.; William, A.; Beckman, W.A. Solar Engineering of Thermal Process; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- NIST/SEMATECH e-Handbook of Statistical Methods. Available online: http://www.itl.nist.gov/div898/handbook/ (accessed on 12 September 2022).

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Garoudja, E.; Harrou, F.; Sun, Y.; Kara, K.; Chouder, A.; Silvestre, S. Statistical fault detection in photovoltaic systems. Sol. Energy 2017, 150, 485–499. [Google Scholar] [CrossRef]

- Pervaiz1, S.; Khan, H.A. Low irradiance loss quantification in c-Si panels for photovoltaic systems. J. Renew. Sustain. Energy 2015, 7, 013129. [Google Scholar] [CrossRef]

- OpenHAB. Available online: https://www.openhab.org/introduction.html (accessed on 12 September 2022).

| Installation Type | Thermal Loss Factor (W/m2 K) |

|---|---|

| Mounted modules with air circulation | 29 |

| Semi-integrated modules with air duct behind | 20 |

| Integrated modules with fully insulated back | 15 |

| Mean | Standard Deviations, σ | 3σ | |

|---|---|---|---|

| 0.99 | 0.07 | 0.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, H.-W.; Kim, I.-K.; Kim, J.-H.; Shin, U.-C. Simulation-Based Fault Detection Remote Monitoring System for Small-Scale Photovoltaic Systems. Energies 2022, 15, 9422. https://doi.org/10.3390/en15249422

Lim H-W, Kim I-K, Kim J-H, Shin U-C. Simulation-Based Fault Detection Remote Monitoring System for Small-Scale Photovoltaic Systems. Energies. 2022; 15(24):9422. https://doi.org/10.3390/en15249422

Chicago/Turabian StyleLim, Hee-Won, Il-Kwon Kim, Ji-Hyeon Kim, and U-Cheul Shin. 2022. "Simulation-Based Fault Detection Remote Monitoring System for Small-Scale Photovoltaic Systems" Energies 15, no. 24: 9422. https://doi.org/10.3390/en15249422

APA StyleLim, H.-W., Kim, I.-K., Kim, J.-H., & Shin, U.-C. (2022). Simulation-Based Fault Detection Remote Monitoring System for Small-Scale Photovoltaic Systems. Energies, 15(24), 9422. https://doi.org/10.3390/en15249422