The development of the automotive sector is motivated by international environmental protection policies, focusing on low-carbon transportation. Recent years have seen an increase in the conversion of urban public transportation vehicles and private cars from fuel vehicles to electric vehicles (EVs) due to purchase subsidies for new energy vehicles and the widespread use of public charging stations [

1,

2]. The substantial market demand for pure electric vehicles encourages the quick advancement of battery technology. Moreover, lithium-ion battery (LIB) has high specific power and energy density, which has great potential to replace the internal combustion engine as the main power source of automobiles [

3,

4,

5]. However, the heat generated by the operation of LIB might significantly compromise the safety of EVs [

6,

7,

8,

9]. Continuous discharge causes the internal temperature of the battery to grow, which drastically reduces battery performance because the internal heat of the LIB pack cannot be dispersed over time. At the same time, constantly operating at high temperatures would cause thermal runaway in addition to accelerating battery degradation [

10,

11]. It has been found that ensuring that the LIB pack operates within the optimal temperature range of 15 °C to 35 °C and the temperature difference of the LIB pack is less than 5 °C will significantly lengthen the battery life [

12], [

13]. Therefore, in order to ensure that the battery functions in the optimal temperature range and avoid thermal runaway caused by excessive temperatures, it is necessary to establish an accurate prediction model of battery heat for monitoring the battery thermal state.

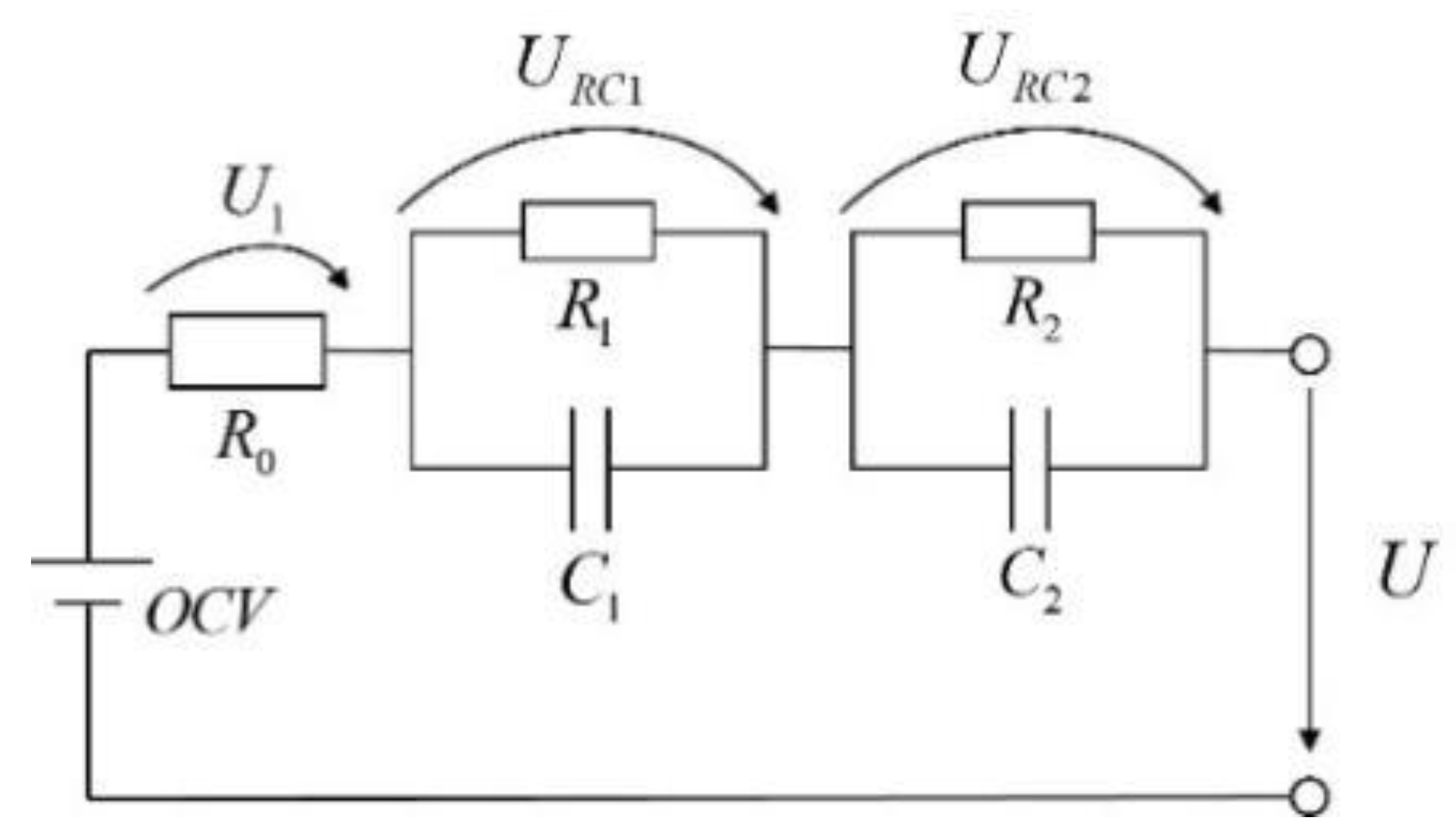

The most commonly used battery thermal models are the electrochemical–thermal coupling model, the thermal equivalent circuit model (TECM), and the data-based model [

14]. Xu et al. [

15] investigated the thermal runaway phenomenon of LIBs at high temperatures by developing an electrochemical–thermal coupling model that was used to analyze the heat generated by five different types of battery side reactions. However, in practice, the complexity of electrochemical reactions and the numerous sets of partial differential equations that must be calculated in the model lead to slow calculations that do not meet the needs of thermal management systems for real-time temperature estimation [

16,

17]. TECM is more concise in modeling and better suited for simulating the dynamic behavior of the battery than the electrochemical–thermal coupling model. It was discovered in [

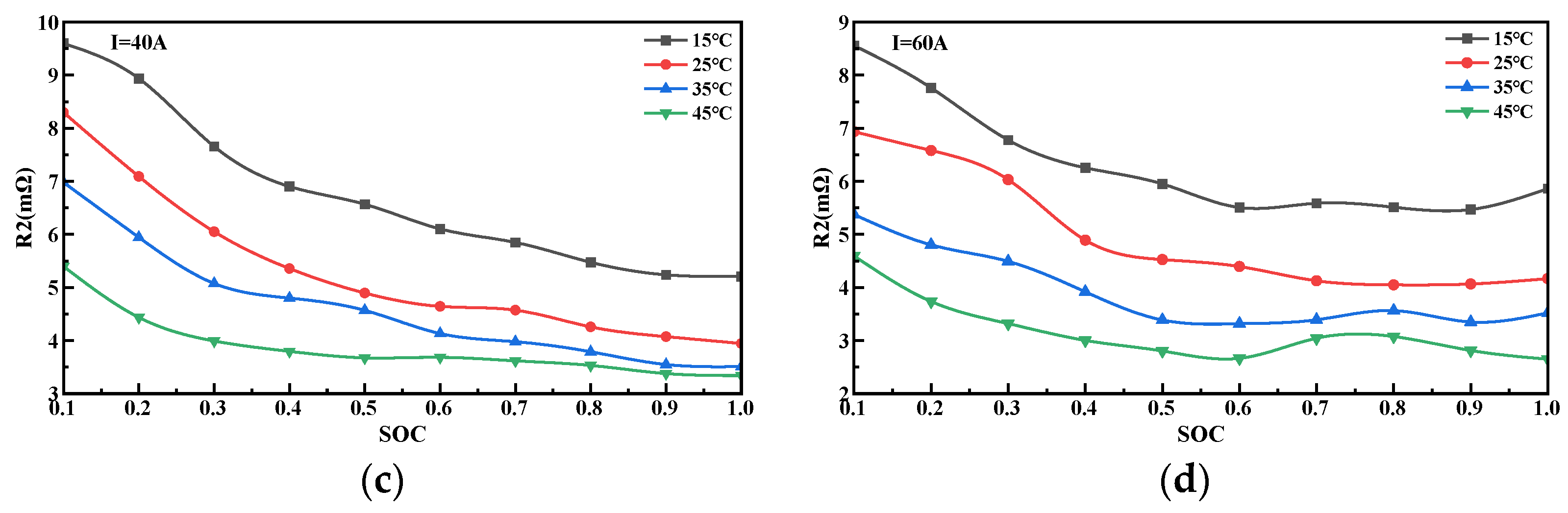

18] that one or two RC networks in the equivalent circuit were sufficient to satisfy the electrical behavior. It was unnecessary to use higher-order RC networks for greater accuracy, which would increase the model’s complexity and computation time. Nejad et al. [

19] compared equivalent circuit models of two cell types, LiFePO

4 and LiNMC, for different orders and found that the model with two RC circuits is preferable for describing the dynamic properties of the cell [

20,

21]. However, the temperature estimation model was not used in those studies. Geifes et al. [

22] developed a first-order thermal equivalent circuit model for small cells and experimentally tested its accuracy. Only estimating the temperature of the battery is insufficient in a practical BTMS application. For BTMS, a real-time model with a prediction function is required, which has contributed to the growth of data-driven battery thermal models. The data-driven model does not need to consider the battery’s physical parameters, but rather establishes a link between the input parameters and the battery’s output response using machine learning methods such as support vector machines [

23] or neural networks [

24]. The neural network model is more advantageous in establishing nonlinear dynamic relationships. Zhuang et al. [

25] proposed a battery prediction model by combining a lithium-ion equivalent circuit model with a fuzzy model. The battery temperature prediction model was able to obtain pack temperature information in advance to achieve active cooling of the battery. Kleiner et al. [

26] developed a 3D electro-thermal prediction model for prismatic cells and validated the model temperature prediction with laboratory scenarios. Xie et al. [

27] combined the dynamic resistance model with the current distribution model to propose a new electro-thermal model, and verified the accuracy of temperature prediction under the conditions of static and dynamic currents. However, general thermal models often use a feed-forward neural network (FFNN), which can only estimate the cell temperature and cannot feed the estimates back to the input for achieving multi-step heat prediction. In contrast, the NARX neural network is sufficient to achieve feed-forward estimation and feed-back prediction, and has a good advantage in solving the prediction problem of time series. Most of the literature on battery thermal modeling has only used simple constant current charge/discharge or standard driving cycle conditions to test the model’s accuracy, without fully considering the driver data in a real driving cycle as the input variables affecting the battery temperature for the study. Jafari et al. [

28] investigated the effect of driving style on battery capacity decay by using real-driving cycle data. Mudgal et al. [

29] found that aggressive driving behavior increases energy consumption by 5–33%. The increased energy consumption is used to cool the temperature rise caused by aggressive driving [

30]. Aggressive driving behavior increases the instantaneous current and leads to a rapid increase in battery temperature [

31], while gentle driving behavior enables a smooth discharge of the LIB and the internal temperature of the battery does not rapidly rise. However, there is little literature focused on the influence of driving behavior on the internal temperature of battery. As a consequence, research into the effect of driving behavior on battery heating is important.

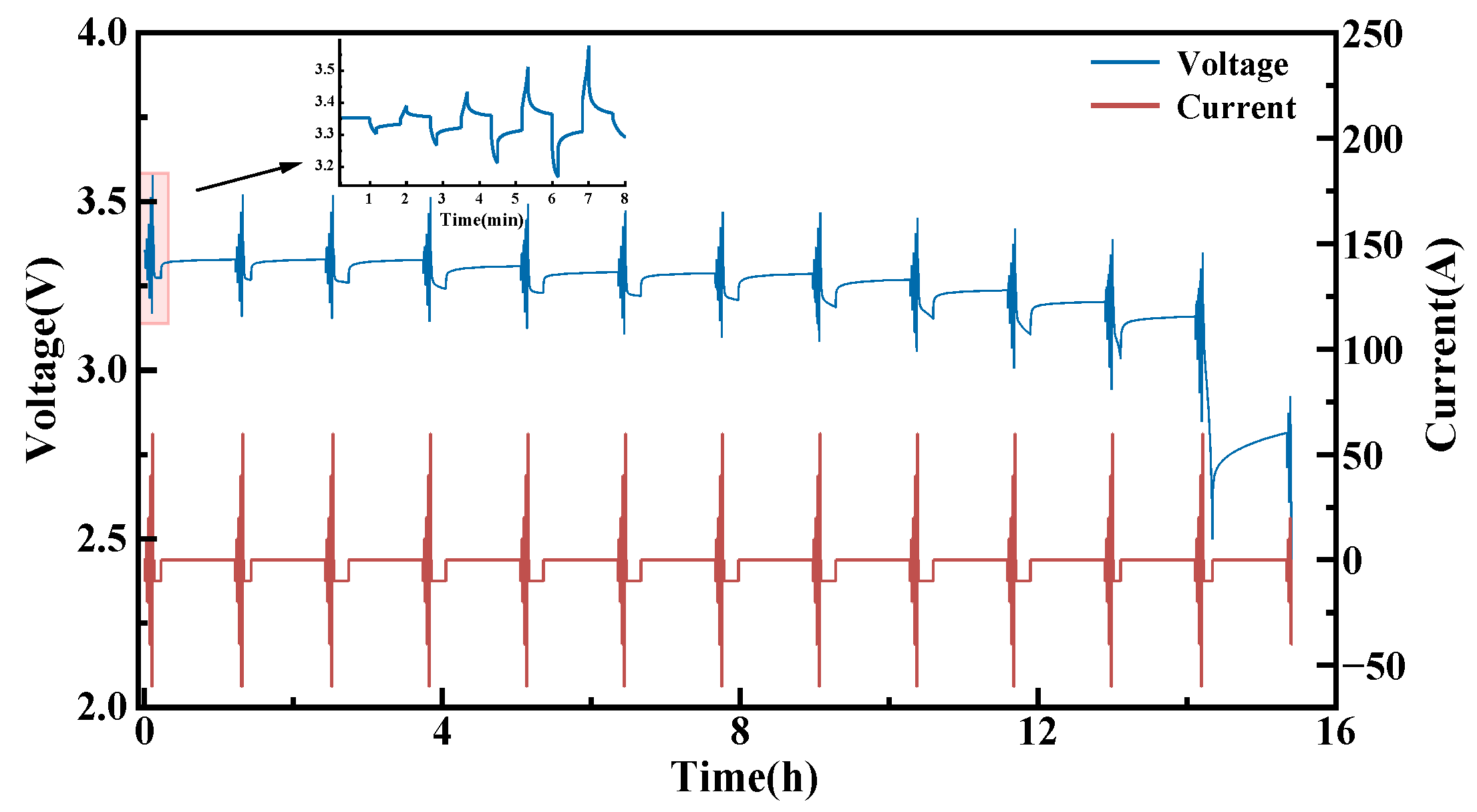

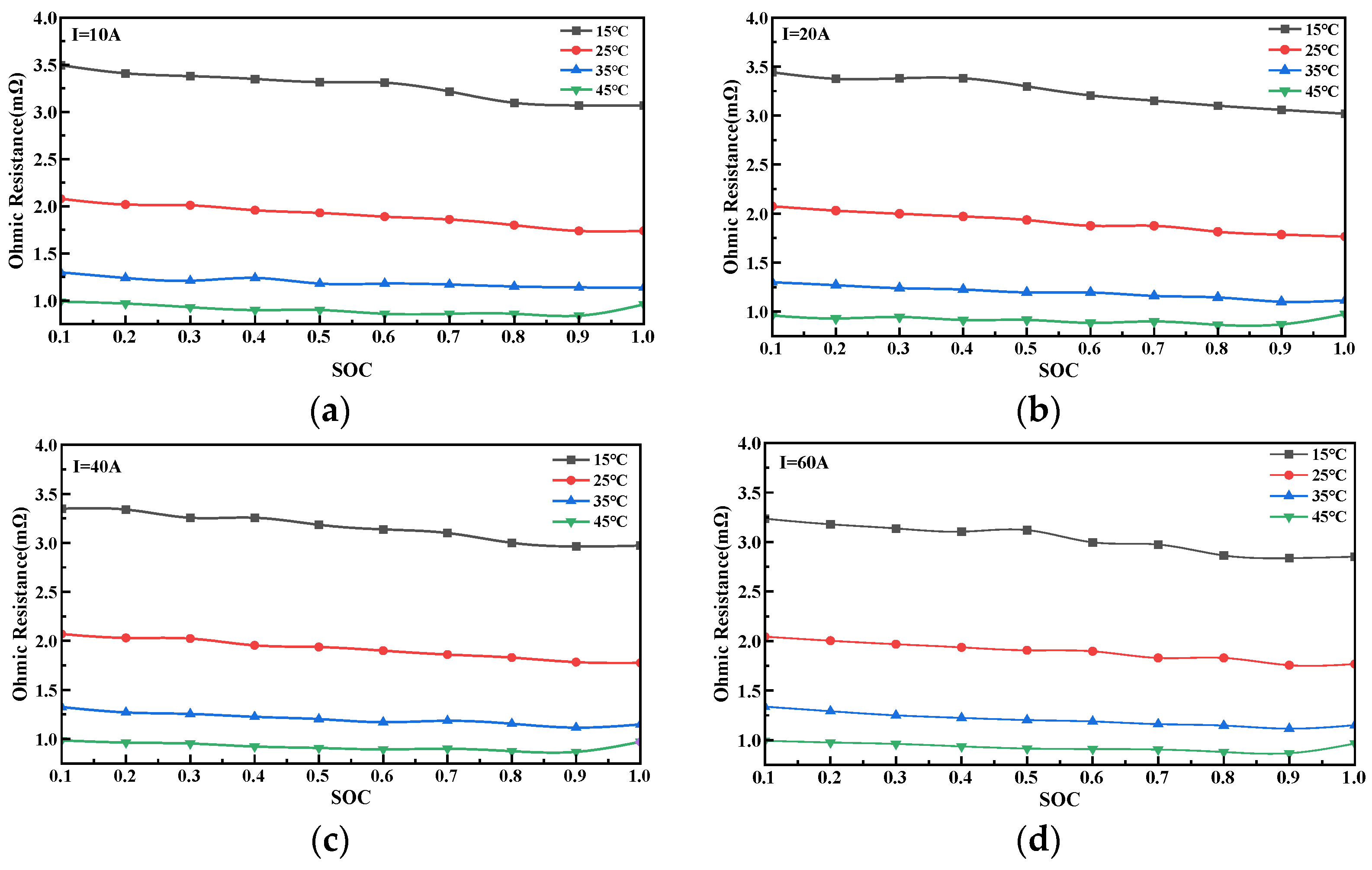

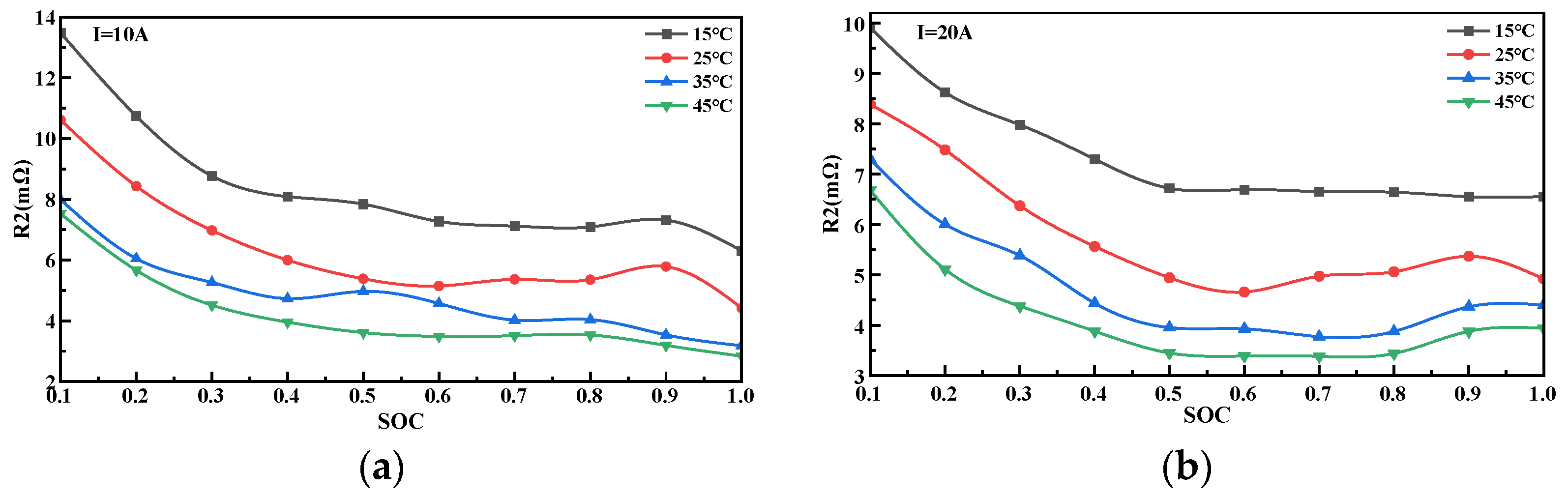

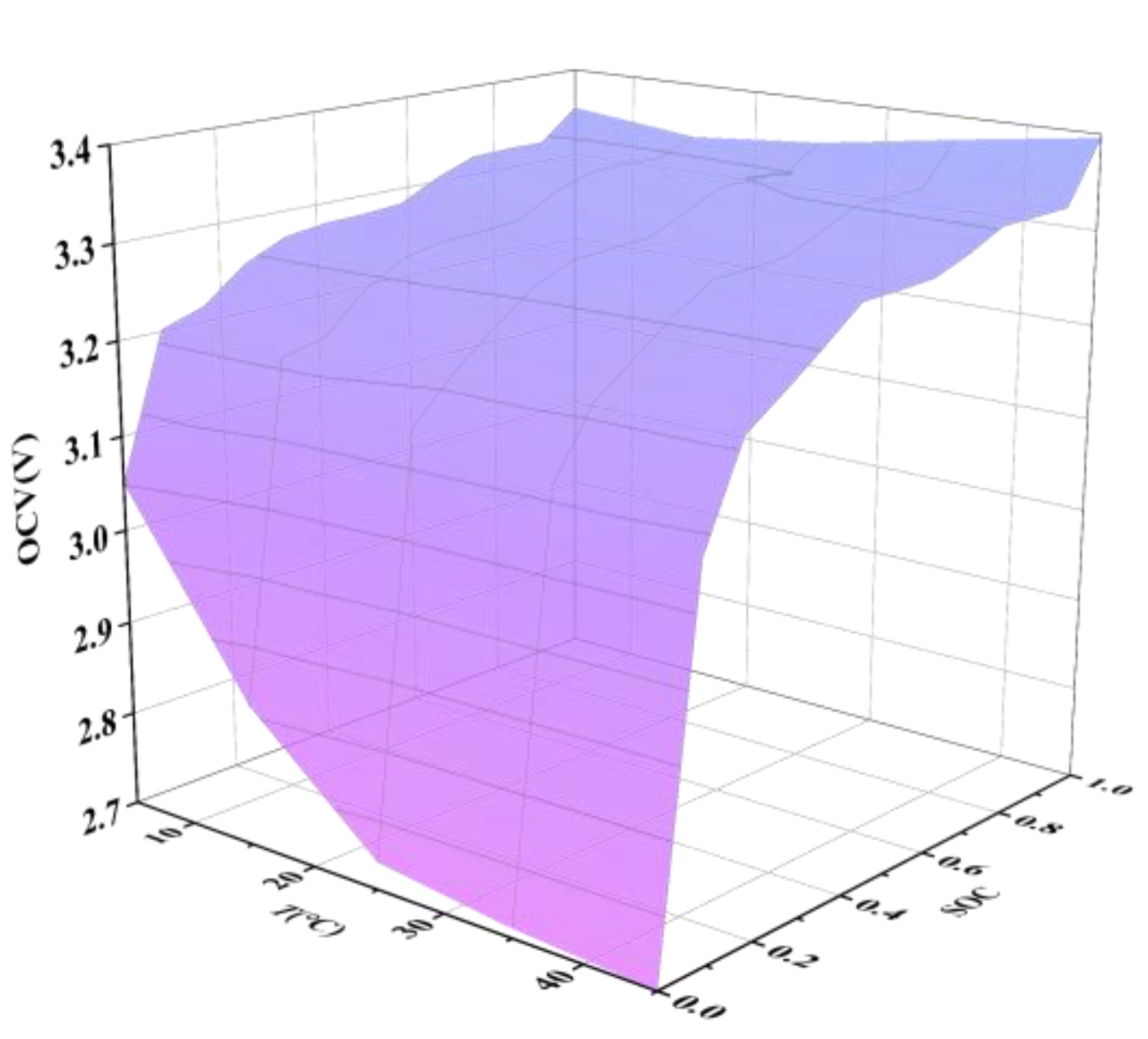

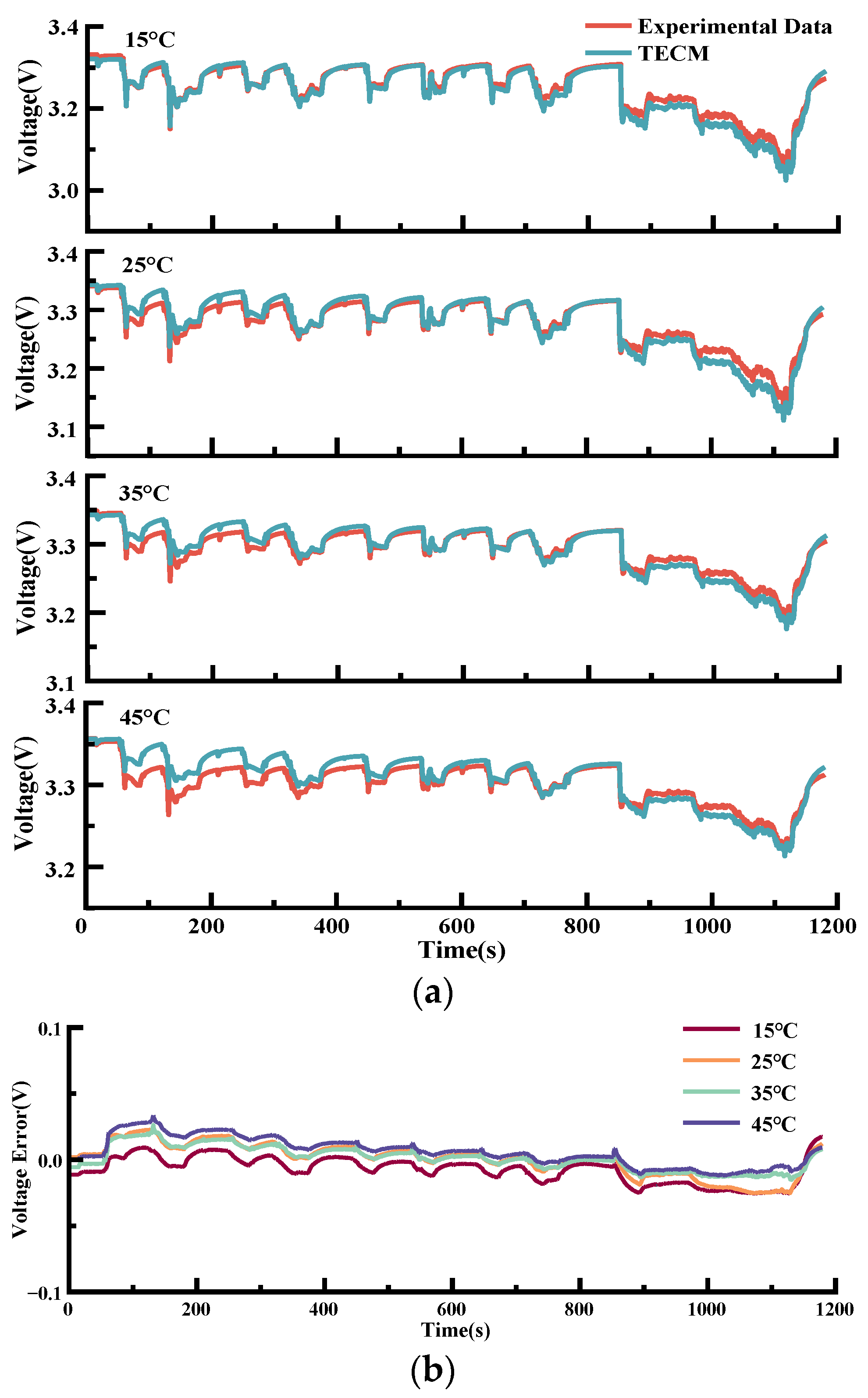

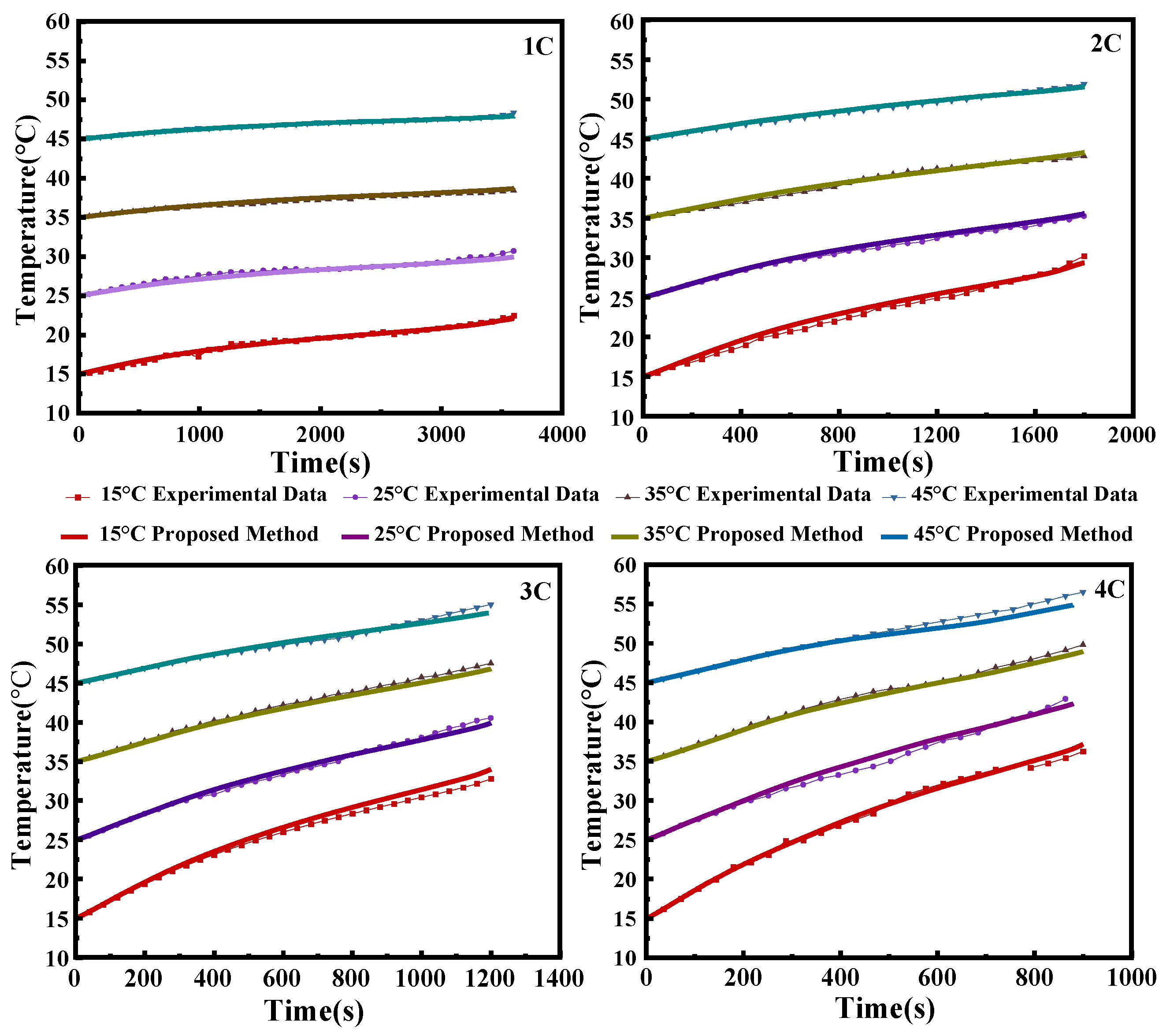

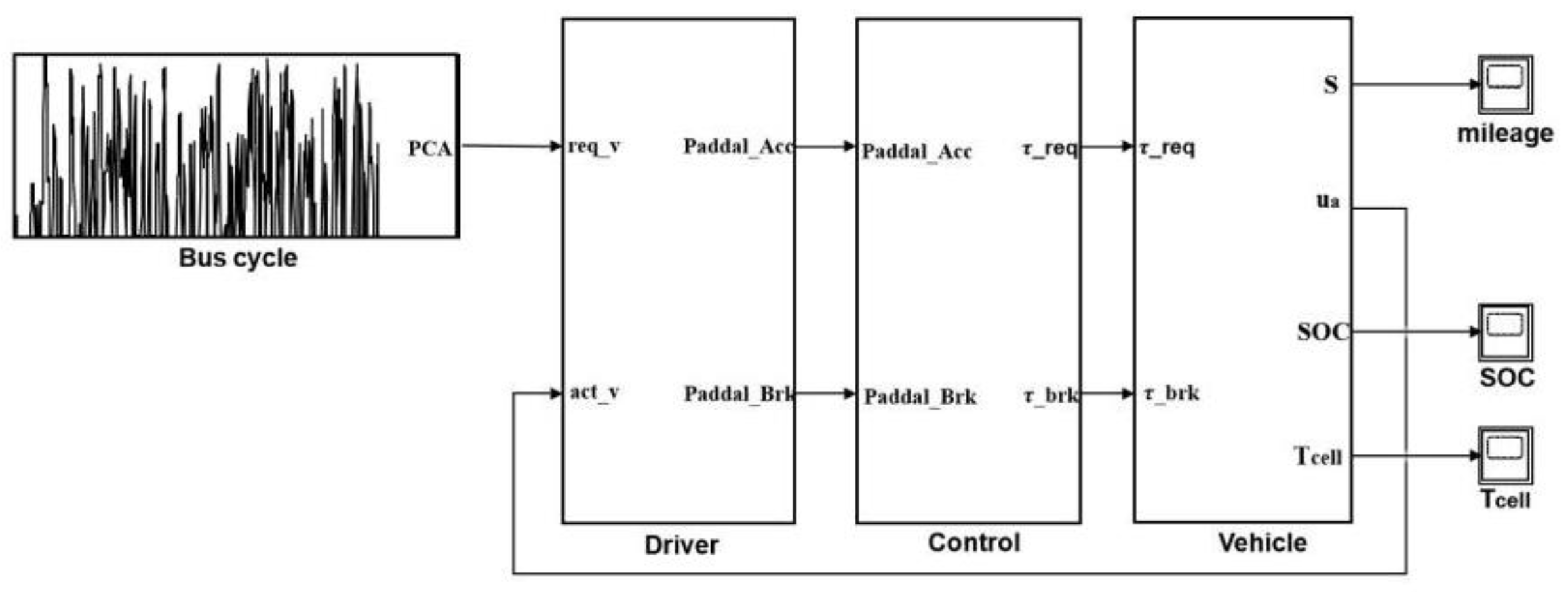

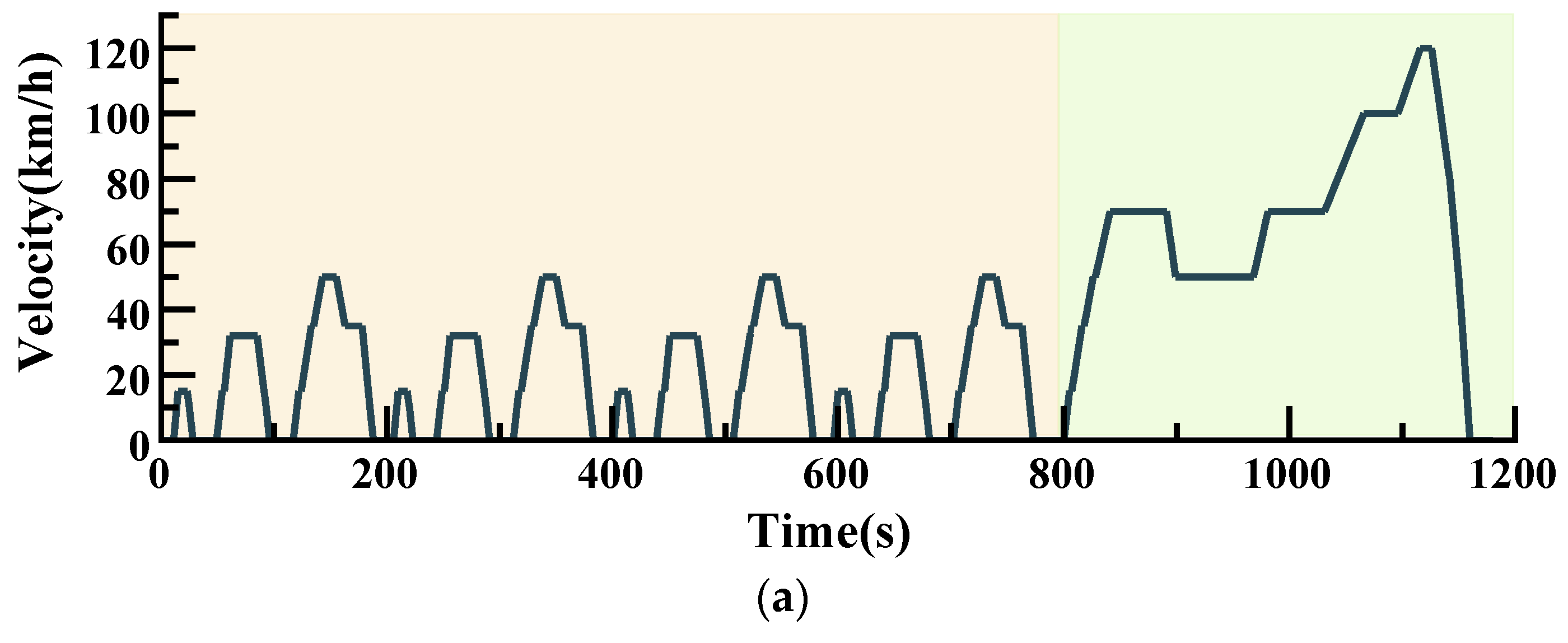

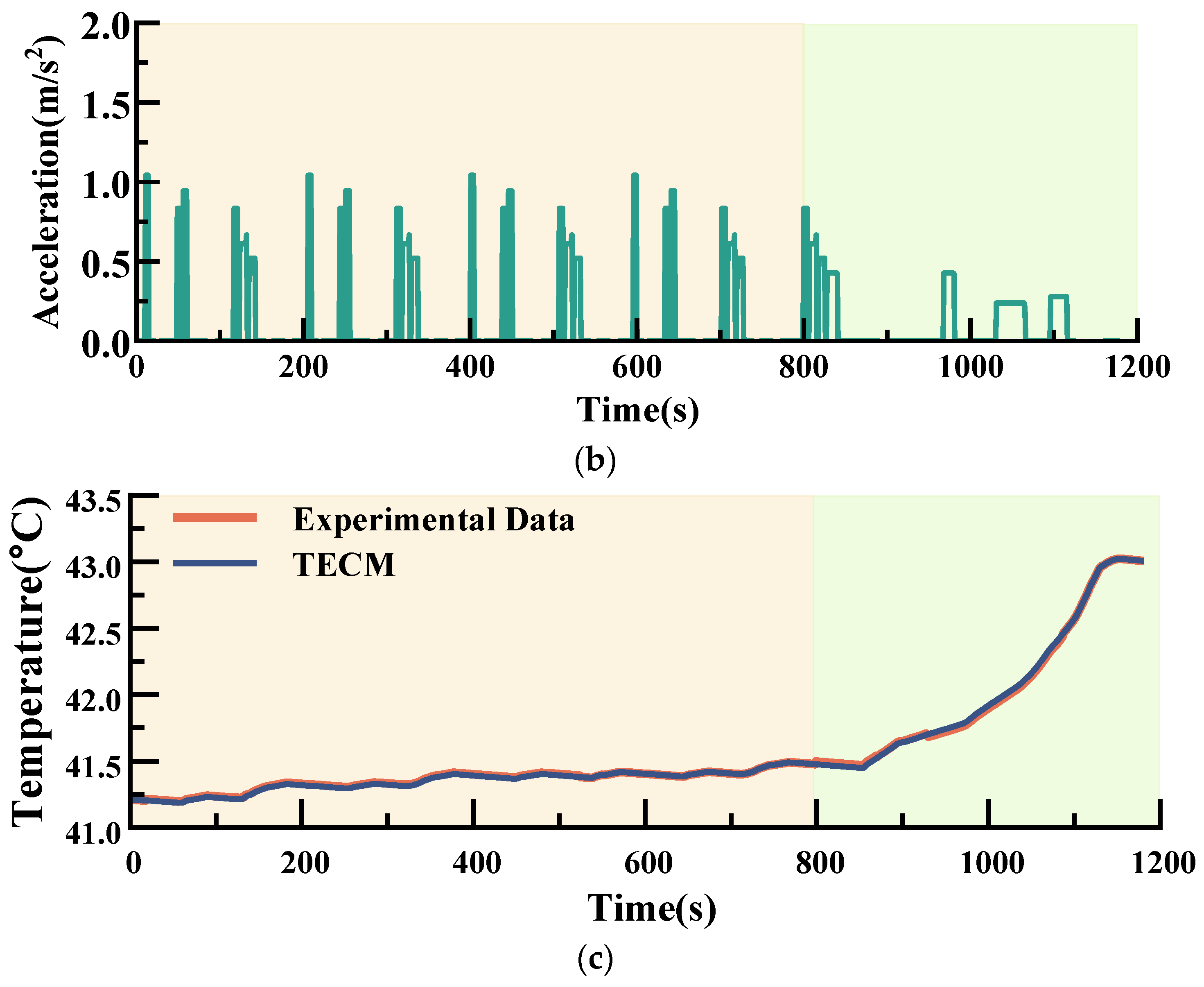

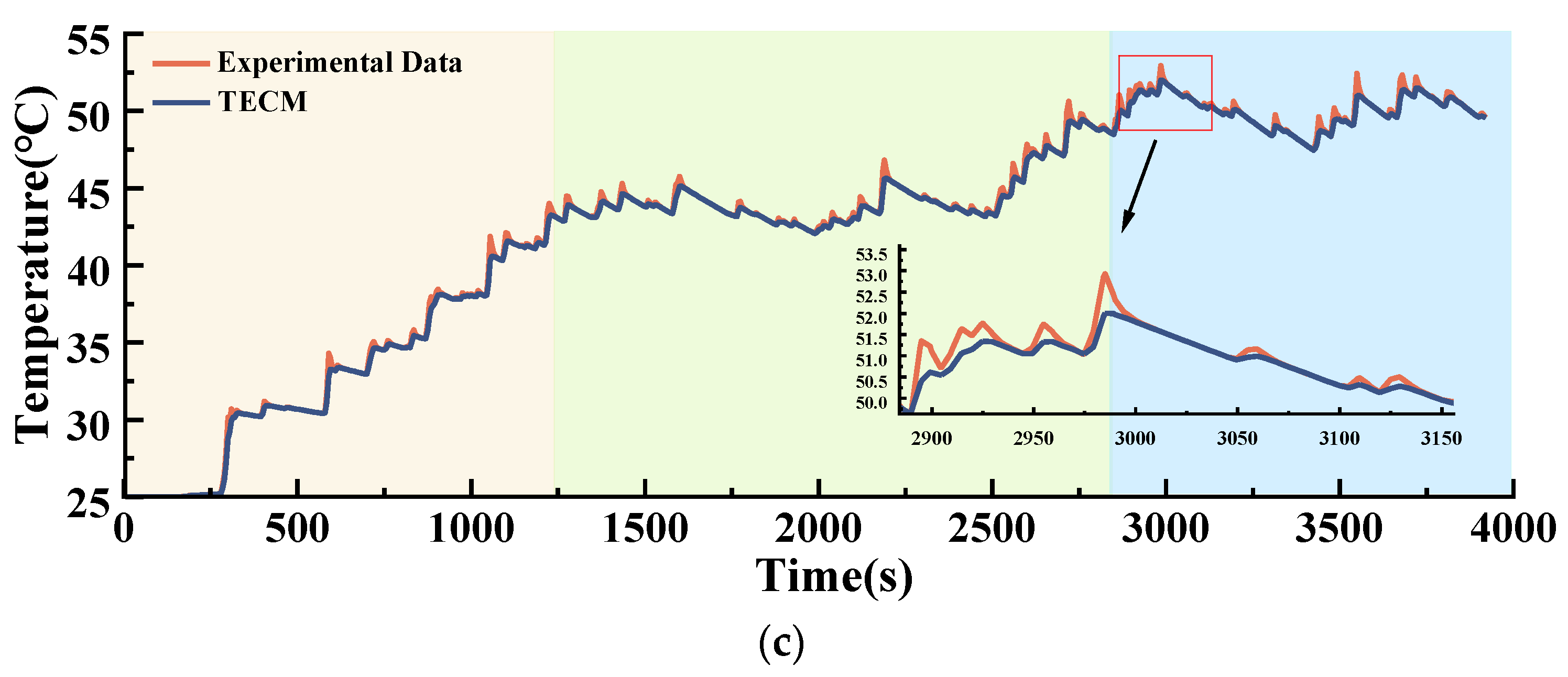

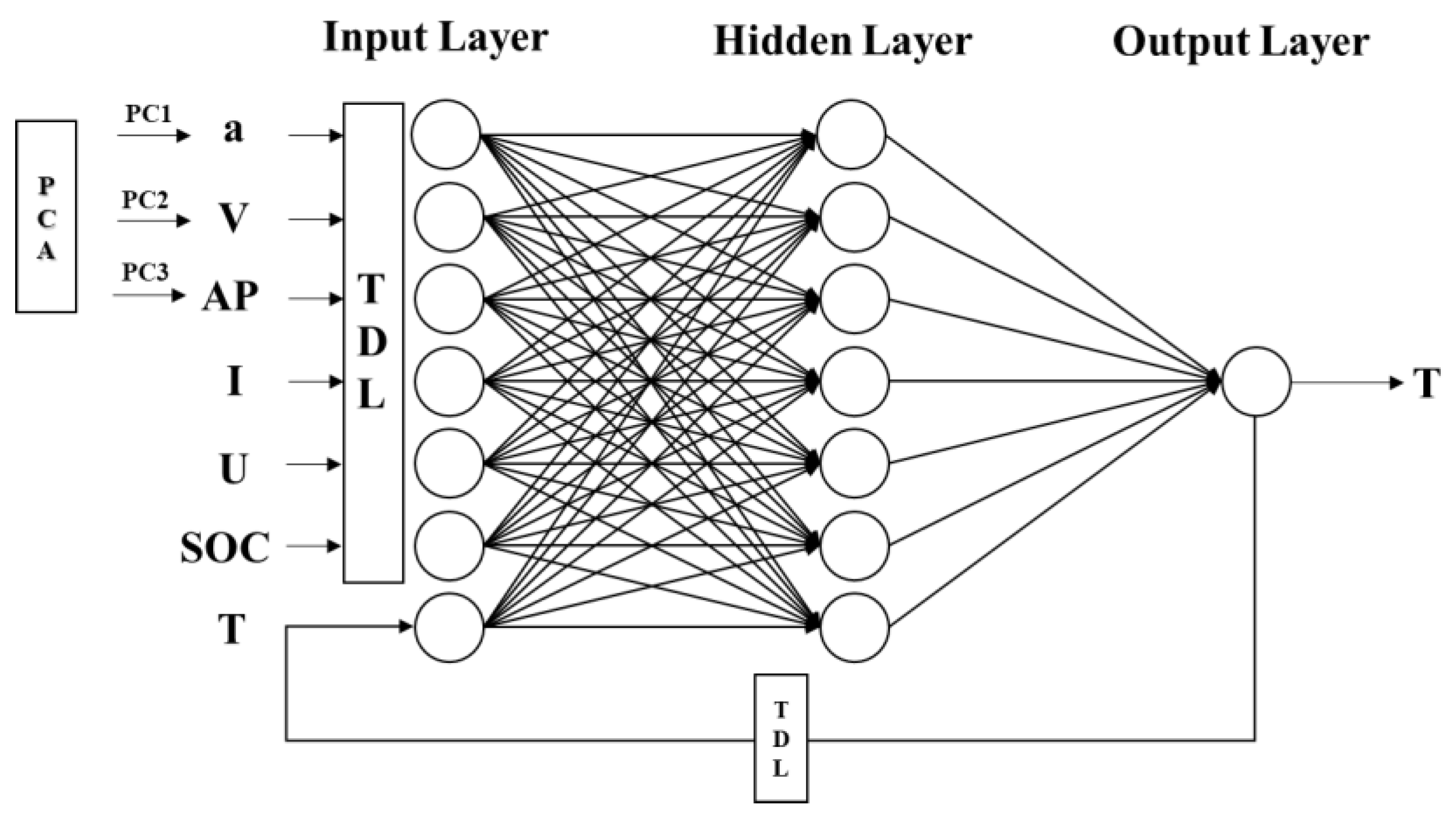

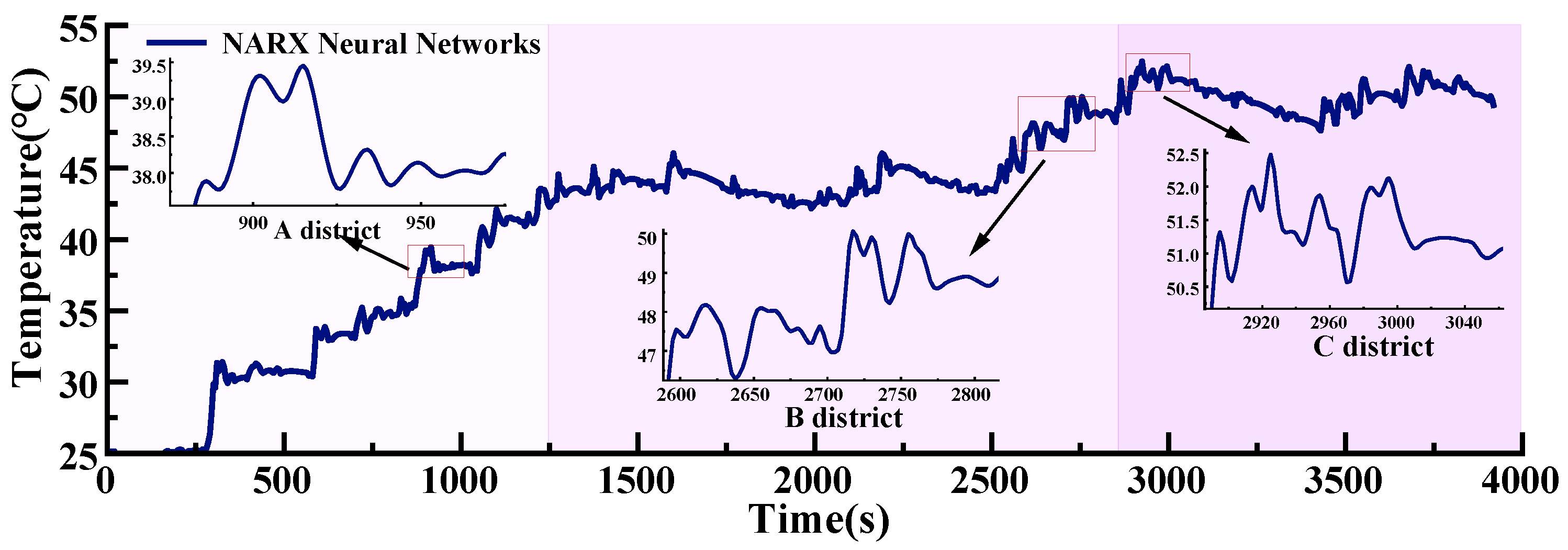

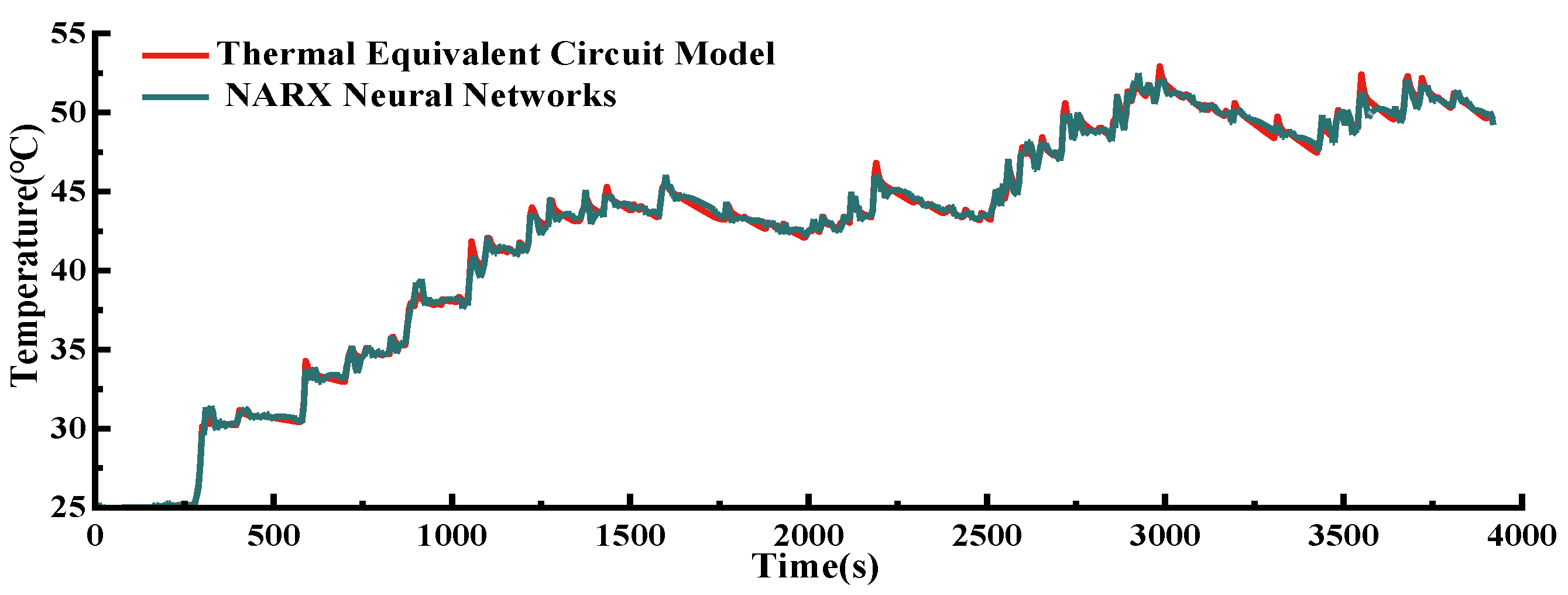

To fill this void, the influence of driving behavior parameters on battery temperature is investigated in this study. Based on actual driving cycles, TECM and ANN thermal models with driver behavior parameters as input are proposed and built in MATLAB/Simulink software. In terms of driving behavior, ambient temperature, state of charge (SOC), discharge rate, and other factors, the effects of battery temperature and internal physical parameters on battery performance are examined. The two proposed models’ temperature prediction results are compared in terms of calculation speed and accuracy.

The remaining sections of this article are structured as follows: In

Section 2, a TECM based on a LiFePO

4 cell with a total capacity of 20 Ah is established; In

Section 3, the PCA method is used to obtain the primary parameters describing the driver behavior by reducing the data dimension of the collected driver behavior data; The EV model is established and the temperature prediction of TECM and ANN models influenced by driving behavior is analyzed in

Section 4;

Section 5 is the summary and prospect of this article.