Review of the Chosen Methods of Producing Front Contacts to Transparent Conductive Oxides Layers in Photovoltaic Structures

Abstract

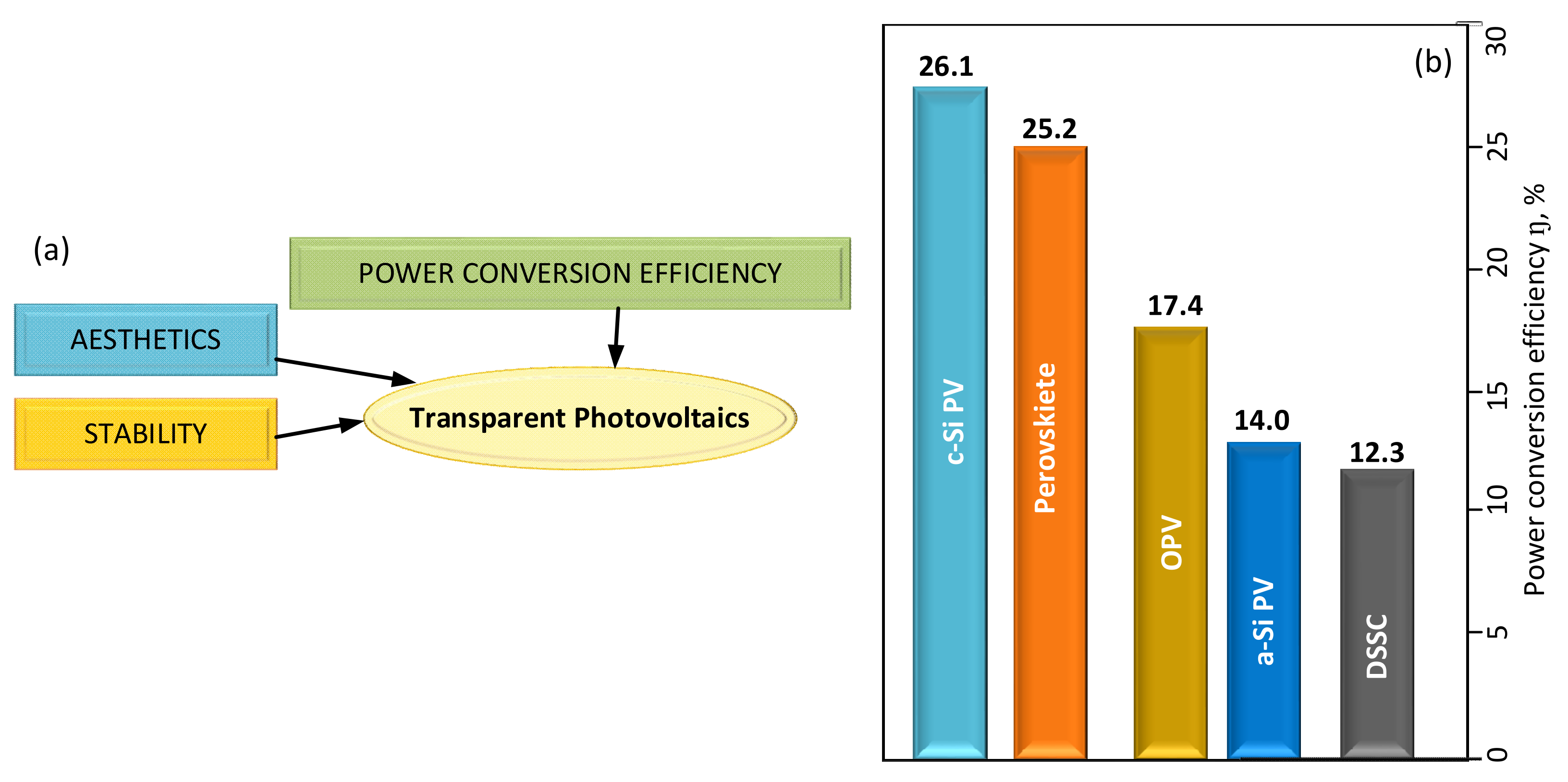

1. Introduction

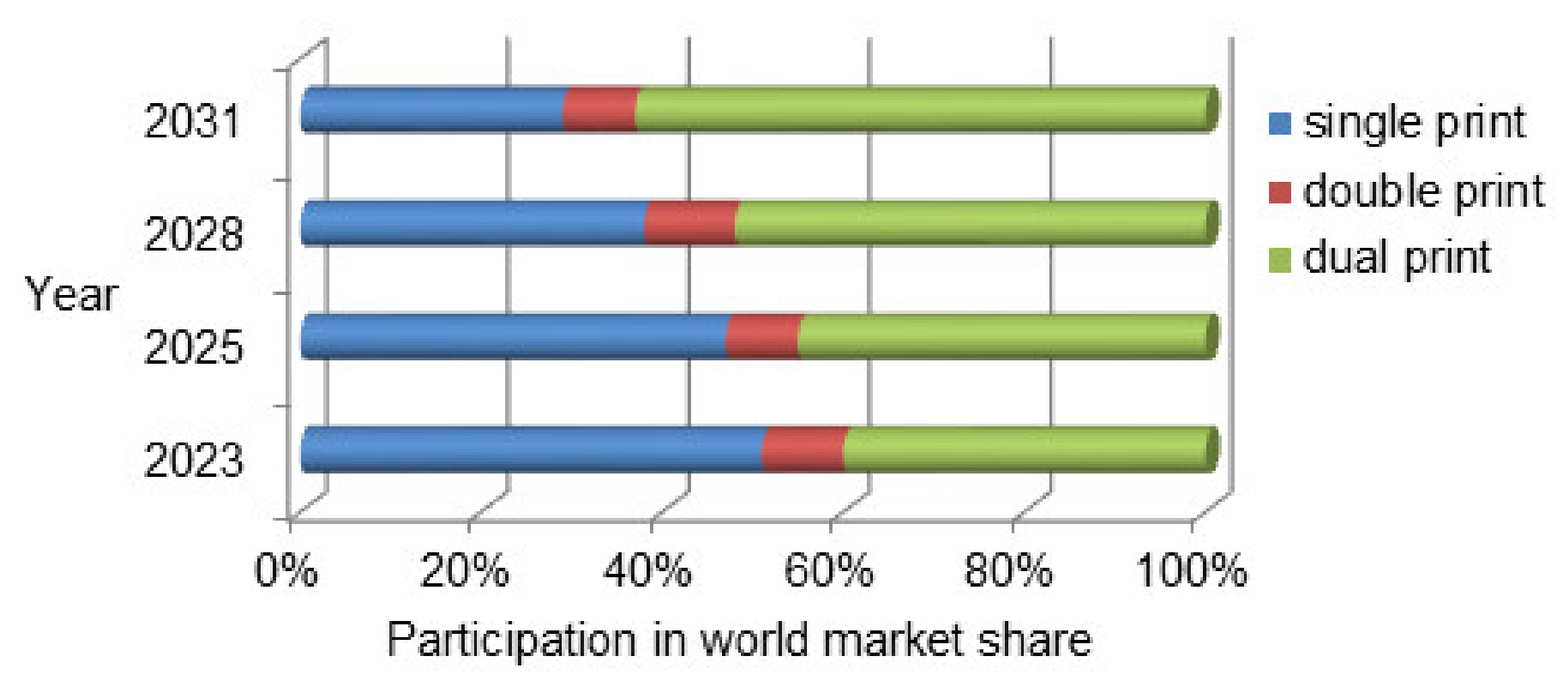

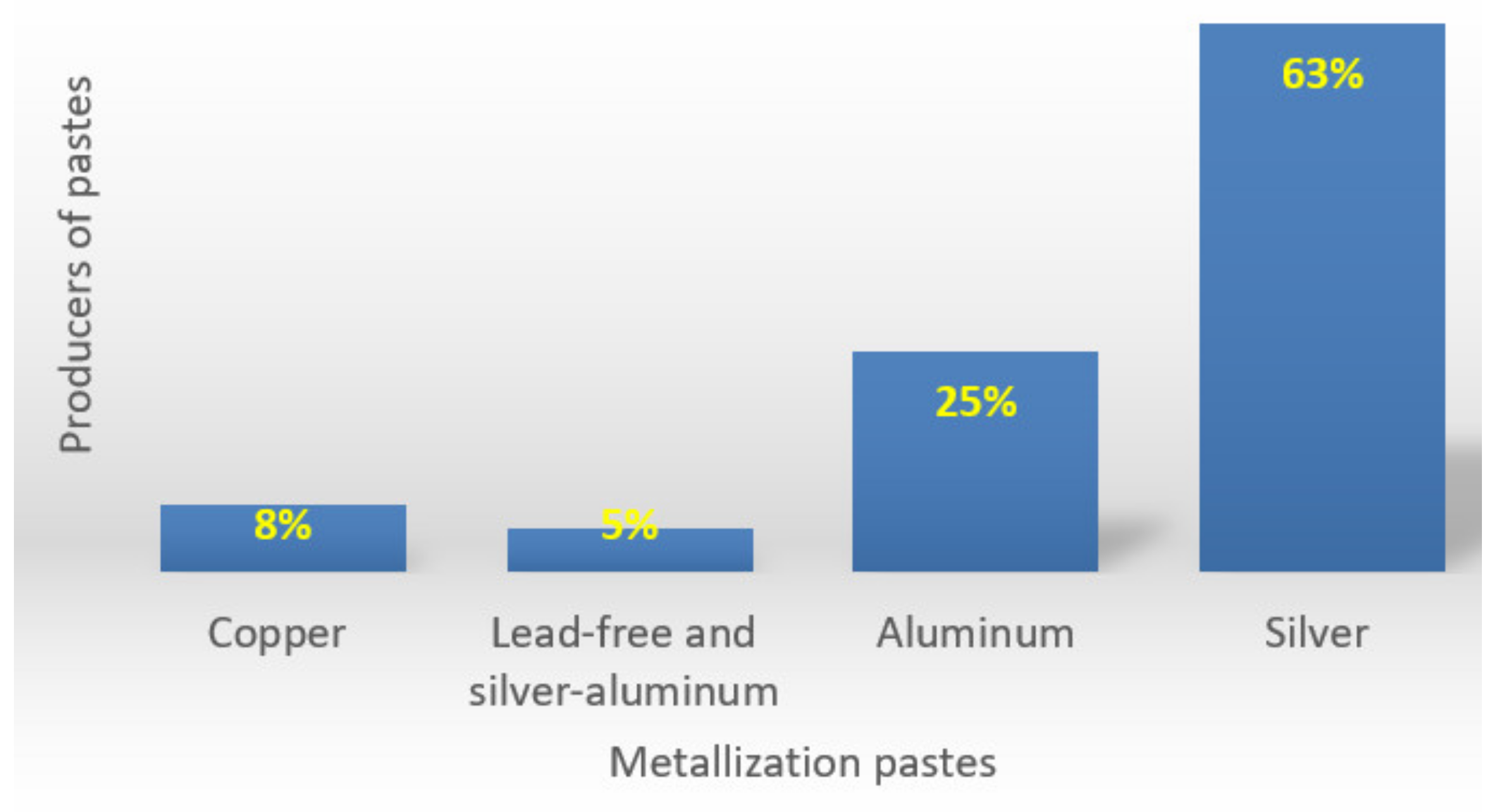

2. Metal Grids

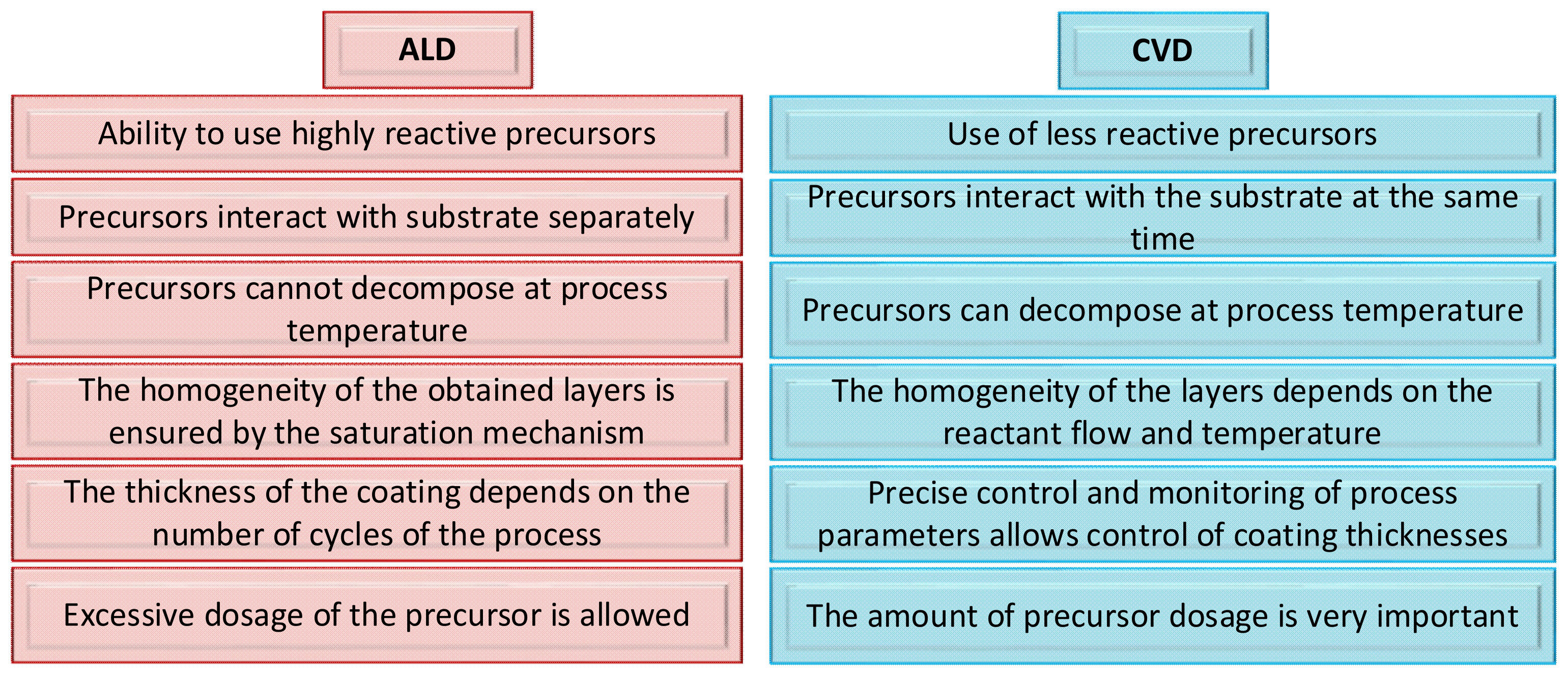

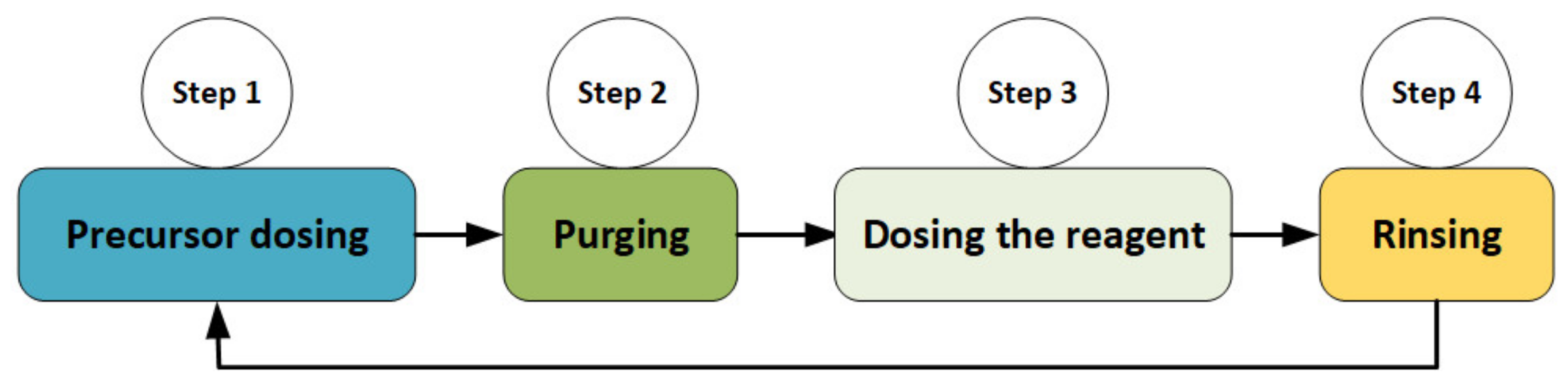

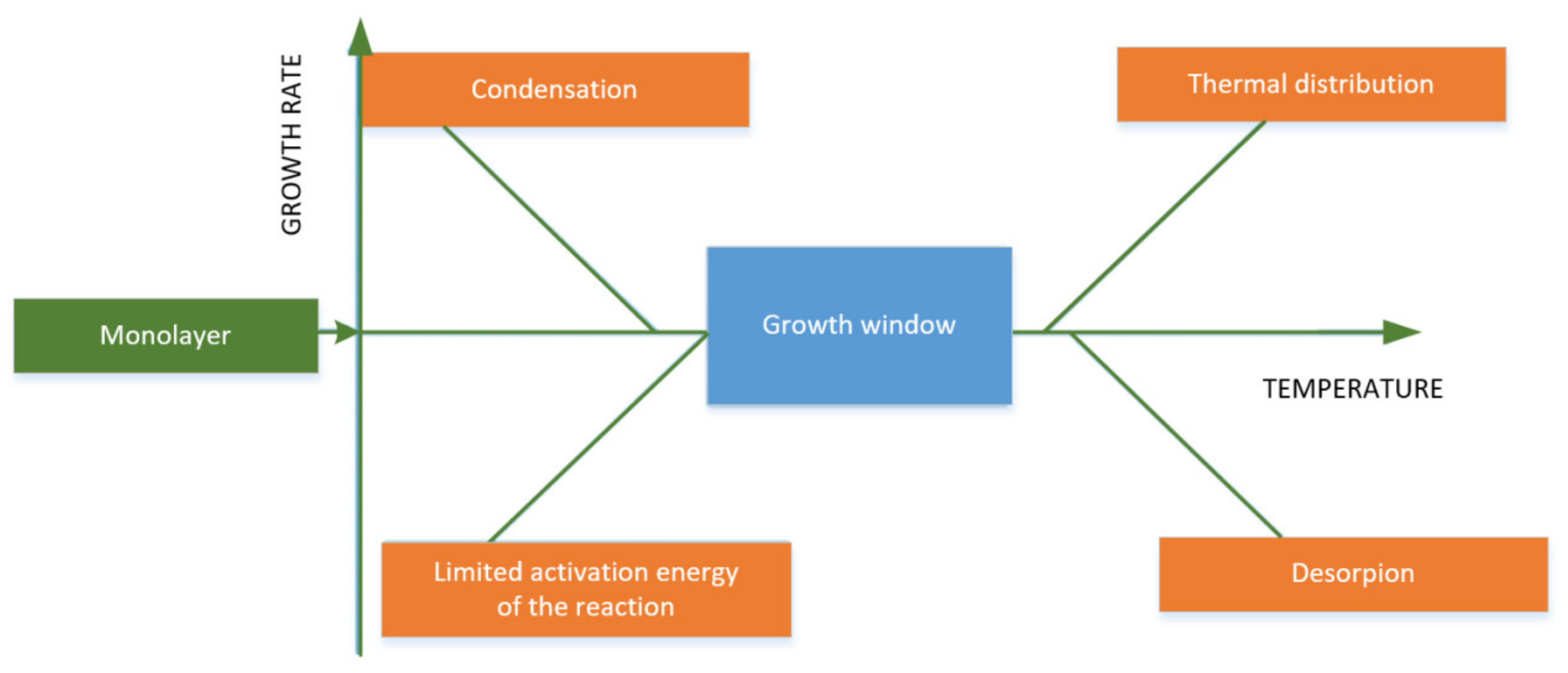

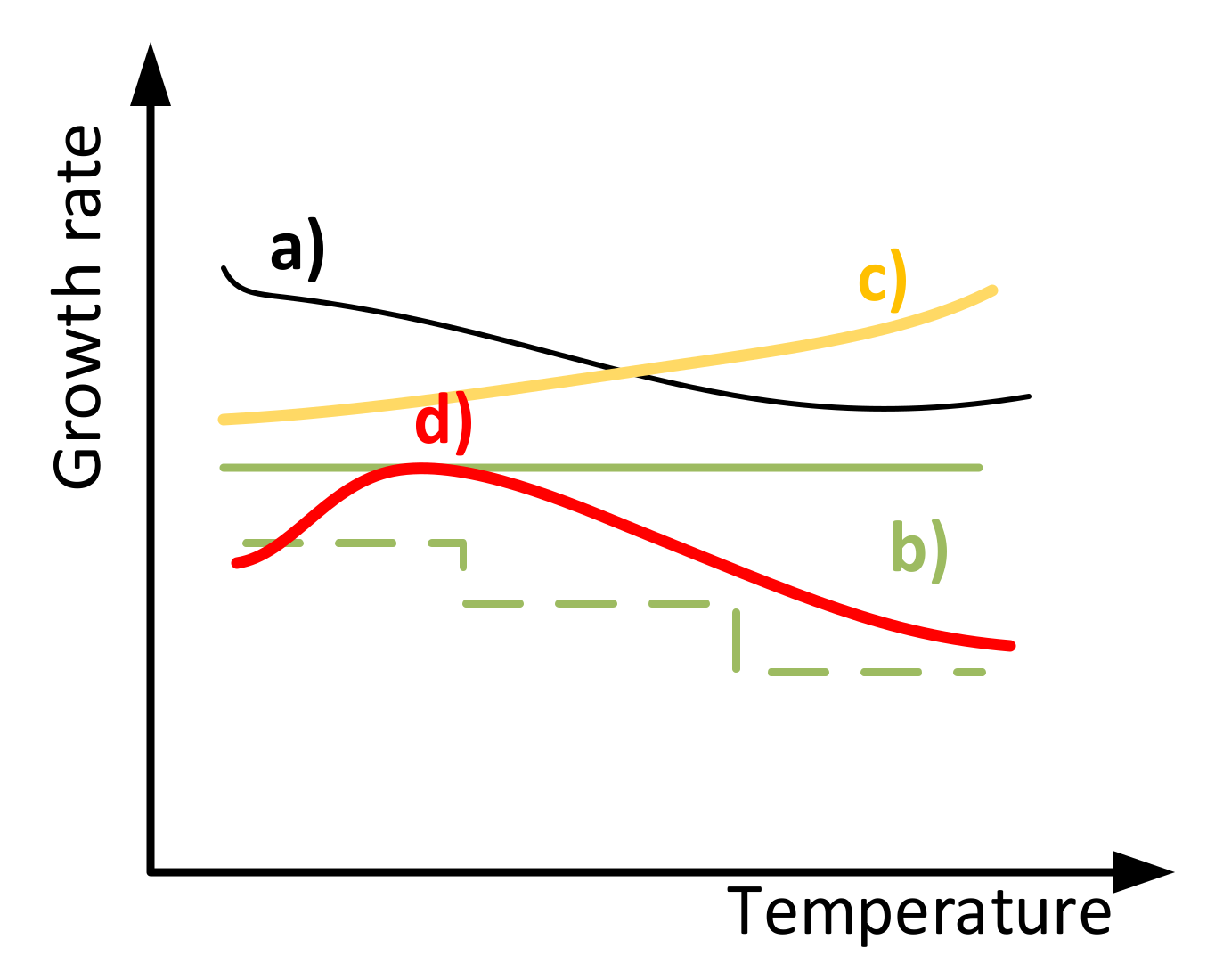

3. Application of ALD and PVD Methods

- Single elements, e.g., from group IV of the periodic table,

- Binary compounds, e.g., metal oxides,

- Multi -component compounds, e.g., hydroxyapatite.

- Volatility —gas pressure >0.1 Tr at <200 °C, liquid at evaporation temperature without decomposition,

- Reactivity —they can react quickly with the substrate and the other precursor in a self-limiting manner (most are air-sensitive),

- Stability -the precursor must retain physical and chemical properties at high temperatures,

- By -products-which should not react with the coating and be easy to remove from the reactor chamber,

- Availability at the lowest possible price.

- With a closed chamber system,

- With an open chamber system,

- With a semi-closed chamber system,

- With a semi-open chamber system.

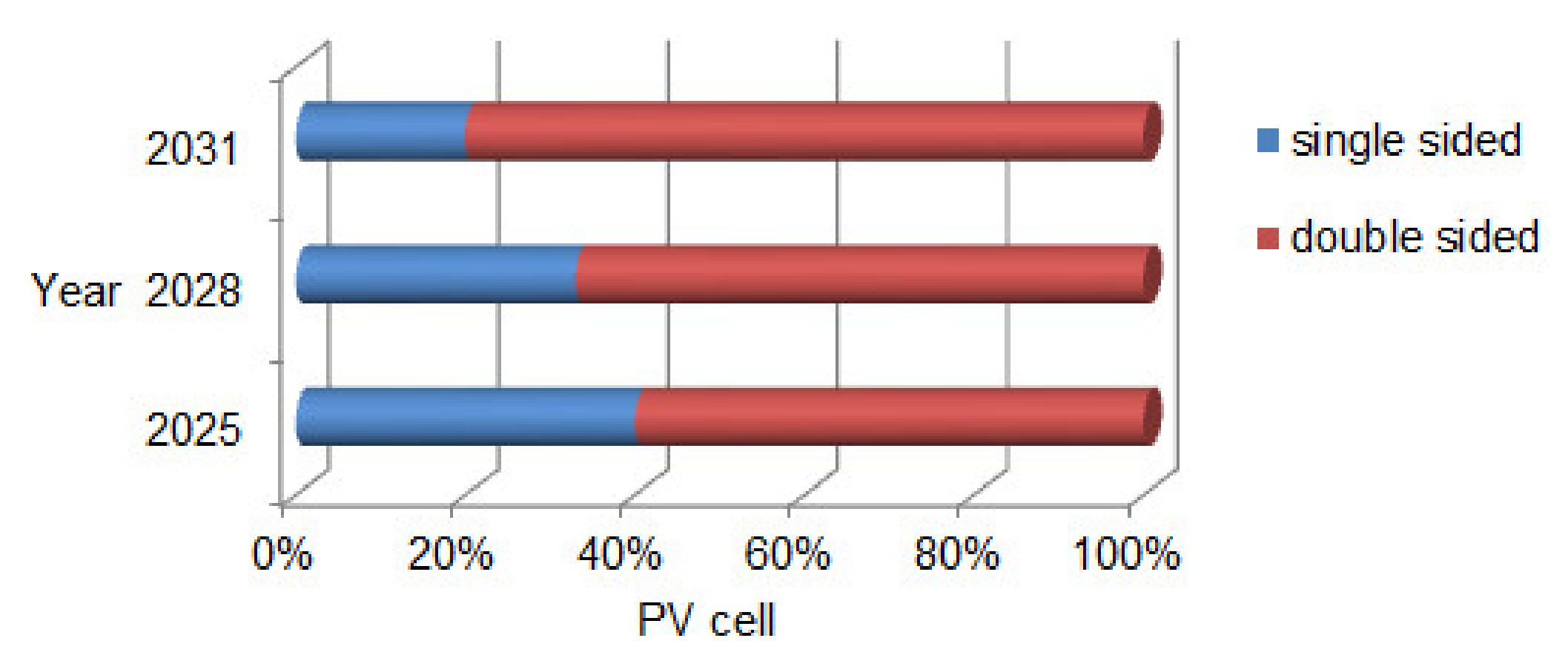

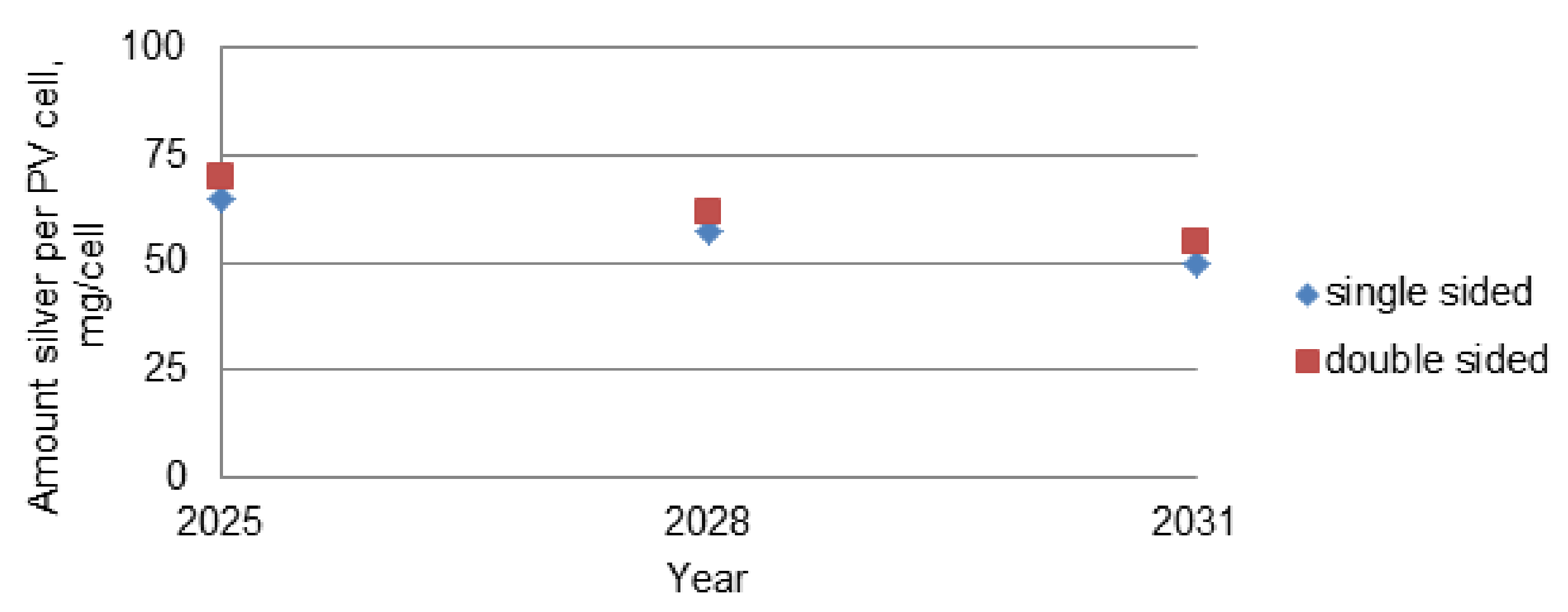

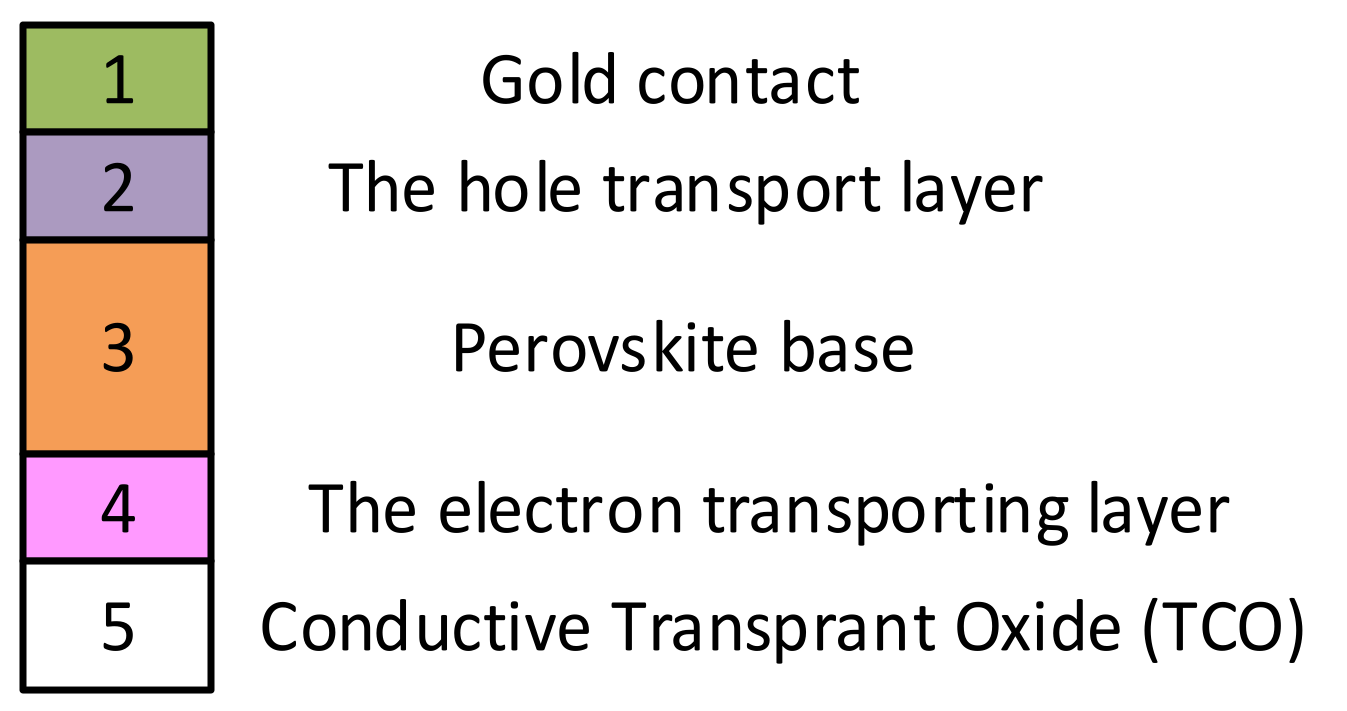

4. Use of TCO in a Photovoltaic Structure

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Znajdek, K.; Sibiński, M. Postępy w Fotowoltaice; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2021; pp. 60–74. (In Polish) [Google Scholar]

- Linie, których Nie widać Zrewolucjonizują Branżę Fotowoltaiczną. Available online: https://magazynfotowoltaika.pl/linie-ktorych-nie-widac-zrewolucjonizuja-branze-fotowoltaiczna (accessed on 22 August 2022).

- VDMA. International Technology Roadmap for Photovoltaics (ITRPV), 12th ed.; VDMA: Frankfurt, Germany, 2020. [Google Scholar]

- SolarPower Europe. Available online: https://www.solarpowereurope.org (accessed on 22 August 2022).

- Dobrzański, L.A.; Pakuła, D.; Staszuk, M. Chemical Vapor Deposition in Manufacturing. In Handbook of Manufacturing Engineering and Technology; Nee, A.Y.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; Chapter 30; pp. 2755–2803. [Google Scholar]

- Drive, P.H. Laser systems and Processes within Next Generation Photovoltaic Manufacturing Equipment. In Proceedings of the 4th Photovoltaic Manufacturing Technology Conference, Stuttgart, Semicon Europe, Stuttgart, Germany, 8–9 October 2008. [Google Scholar]

- Musztyfaga-Staszuk, M. SLS: One of the Modern Technologies of Laser Surface Treatment. Int. J. Thermophys. 2017, 38, 130. [Google Scholar] [CrossRef]

- Mertens, K. Photovoltaics: Fundamentals, Technology, and Practice, 2nd ed.; Wiley-Blackwell: Columbia, MD, USA, 2018. [Google Scholar]

- Cui, Z. Printed Electronics: Materials, Technologies and Applications; Higher Education Press: Beijing, China, 2016. [Google Scholar]

- Directive 2009/28/EC of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:140:0016:0062:en:PDF (accessed on 1 August 2022).

- Metz, A.; Fischer, M.; Trube, J. Crystalline silicon Technology—Current Status and Outlook. In International Technology Roadmap for Photovoltaics (ITRPV), 8th ed.; PV Manufacturing in Europe Conference Brussels; VDMA: Frankfurt, Germany, 2017. [Google Scholar]

- Mat Desa, M.K.; Sapeai, S.; Azhari, A.W.; Sopian, K.; Sulaiman, M.Y.; Amin, N.; Zaidi, S.H. Silicon back contact solar cell configuration: A pathway towards higher efficiency. Renew. Sustain. Energy Rev. 2016, 60, 1516–1532. [Google Scholar] [CrossRef]

- Kopecek, R.; Koduvelikulathu, L.J.; Cabrera, E.; Rudolph, D.; Buck, T. The technology with highest efficiency gain potential for c-Si cells. Photovolt. Int. 2015, 4, 52–60. [Google Scholar]

- Ralph, E.L. Recent advancements in low-cost solar cell processing. In Conference Record, Proceedings of the 11th IEEE Photovoltaic Specialists Conference, Scottsdale, AZ, USA, 6–8 May 1975; Institute of Electrical and Electronic Engineers: Piscataway, NJ, USA, 1975; pp. 315–316. [Google Scholar]

- Burgelman, M. Thin film solar cells by screen printing technology. In Proceedings of the Workshop Microtechnology and Thermal Problems in Electronics, Lodz, Poland, 21–27 September 1998; pp. 129–135. [Google Scholar]

- Shanmugama, V.; Cunnusamy, J.; Khanna, A.; Boreland, B.M.; Mueller, T. Optimisation of Screen-Printed Metallisation for Industrial High-Efficiency Silicon Wafer Solar Cells. Energy Procedia 2013, 33, 64–69. [Google Scholar] [CrossRef][Green Version]

- Hamer, D.W.; Biggers, J.V. Technologia Układów Scalonych Grubowarstwowych; WNT: Warsaw, Poland, 1976. (In Polish) [Google Scholar]

- Muszyfaga-Staszuk, M. New Copper-Based Composites for the Production of Silicon Photovoltaic Cells; WNT: Warsaw, Poland, 2019; (In Polish). ISBN 978-83-7880-626-4. [Google Scholar]

- Hannebauer, H.; Schimanke, S.; Falcon, T.; Altermatt, P.P.; Dullweber, T. Optimised stencil print for low Ag paste consumption and high conversion efficiencies. Energy Procedia 2015, 67, 108–115. [Google Scholar] [CrossRef][Green Version]

- Caballero, L.J. Contact Definition in industrial silicon solar cells. In Solar Energy; Rugescu, R.D., Ed.; IntechOpen: London, UK, 2010; pp. 375–398. [Google Scholar]

- Kofron, V.K. Photovoltaic Cell with Junction-Free Essentially-Linear Connections to Its Contacts. U.S. Patent 4,153,907, 8 May 1979. [Google Scholar]

- Neuhaus, A.R.; Bultman, J.H.; Tip, A.C.; Sinke, W.C. Metallisation patterns for interconnection through holes. Sol. Energy Sol. Cells 2001, 65, 347–353. [Google Scholar]

- Alemán, M.; Streek, A.; Regenfuβ, P.; Mette, A.; Ebert, R.; Exner, H.; Glunz, S.W.; Willeke, G. In Laser micro-sintering as a new metallisation technique for silicon solar cells. In Proceedings of the 21st European Photovoltaic Solar Energy Conference, Dresden, Germany, 4–8 September 2006. [Google Scholar]

- Edwards, M. Efficiencies of 22% at low cost: The future of mass-produced laser-doped selective emitter solar cells. Photovolt. Int. 2011, 1, 56–62. [Google Scholar]

- Hendell, R. Laser Applications in Solar Cell Manufacturing. In Focus: Laser Micro-Processing; Wiley-VCH: Weinheim, Germany, 2008. [Google Scholar]

- Dross, F.; Van, K.E.; Allebe, C.; Van der Heide, A.; Szlufcik, J.; Agostinelli, G.; Choulat, P.; Dekkers, H.F.W.; Beaucarne, G. Impact of Rear-Surface Passivation on MWT Performances. In Conference Record, Proceedings of the IEEE 4th World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 7–12 May 2006; Institute of Electrical and Electronic Engineers: Piscataway, NJ, USA, 2006. [Google Scholar]

- Kerscharer, E.V.; Beaucarne, G. Back-contact Solar Cells: A review. Progress in Photovoltaic: Research and application. Prog. Photovolt. Appl. 2005, 14, 107–123. [Google Scholar] [CrossRef]

- Gautero, L.; Hofmann, M.; Rentsch, J.; Lemke, A.; Mack, S.; Seiffe, J.; Nekarda, J.; Biro, D.; Wolf, A.; Bitnar, B.; et al. All-screen-printed 120-µm-thin large-area silicon solar cells applying dielectric rear passivation and laser-fired contacts reaching 18% efficiency. In Proceedings of the 34th IEEE Photovoltaic Specialists Conference (PVSC), Philadelphia, PA, USA, 7–12 June 2009. [Google Scholar]

- Neuhaus, D.H.; Münzer, A. Industrial silicon wafer solar cells. Adv. Opto Electron. 2007, 2007, 24521. [Google Scholar] [CrossRef]

- Nande, A.; Raut, S.; Dhoble, S.J. Energy Materials. In Perovskite Solar Cells; Dhoble, S.J., Thejo Kalyani, N., Vengadaesvaran, B., Arof, A.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Chapter 9; pp. 249–281. [Google Scholar]

- Yang, D.; Zhang, X.; Hou, Y.; Wang, K.; Ye, T.; Yoon, J.; Wu, C.; Sanghadasa, M.; Liu, S.; Priya, S. 28.3%-efficiency perovskite/silicon tandem solar cell by optimal transparent electrode for high efficient semitransparent top cel. Nano Energy 2021, 84, 105934. [Google Scholar] [CrossRef]

- Metallization Paste Manufacturers. Available online: https://www.enfsolar.com/directory/material/metallization_paste?tech=408 (accessed on 15 June 2022).

- TaiyangNews Provides Update on Latest Technical and Product Solutions to Contact All Types of Solar Cells. Available online: https://taiyangnews.info/reports/market-survey-metallization-pastes-201920/ (accessed on 10 April 2022).

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 2014, 17, 236–246. [Google Scholar] [CrossRef]

- Staszuk, M.; Pakuła, D.; Reimann, Ł.; Król, M.; Basiaga, M.; Mysłek, D.; Kří, A. Structure and Properties of ZnO Coatings Obtained by Atomic Layer Deposition (ALD) Method on a Cr-Ni-Mo Steel Substrate Type. Materials 2020, 13, 4223. [Google Scholar] [CrossRef] [PubMed]

- Lujala, V.; Skarp, J.; Tammenmaa, M.; Suntola, T. Atomic layer epitaxy growth of doped zinc oxide thin films from organometals. Appl. Surf. Sci. 1994, 82/83, 34–40. [Google Scholar] [CrossRef]

- Osadzanie Warstw Atomowych (ALD). Available online: http://www.eagle-regpot.eu/EfI/index.php?pid=33 (accessed on 1 August 2022).

- Wojcik, A.; Kiecana, M.; Kopalko, K.; Godlewski, M.; Guziewicza, E.; Yatsunenko, S.; ÃLusakowska, E.; Minikayev, R.; Paszkowicza, W.; Swiatek, K.; et al. Magnetic, structural, and optical properties of low-temperature ZnMnO grown by atomic layer epitaxy; Proceedings of the XXXIV International School of Semiconducting Compounds. Acta Phys. Pol. A 2005, 108, 915–921. [Google Scholar] [CrossRef]

- Robertson, J. High dielectric constant oxides. Eur. Phys. J. Appl. Phys. 2004, 28, 265–291. [Google Scholar] [CrossRef]

- Boryło, P.; Szindler, M.; Lukaszkowicz, K. Various Applications of Multifunctional Thin Films with Specific Properties Deposited by the ALD Method; Trans Tech Publications: Wollerau, Switzerland, 2019; pp. 111–123. [Google Scholar]

- Provine, J.; Rincon, M. Atomic Layer Deposition: Introduction to the Theory and Cambridge Nanotech Savannah & Fiji; Stanford University: Stanford, CA, USA, 2012. [Google Scholar]

- Poortmans, J.; Pieters, P.; Baert, K. Exploiting the microelectronics toolbox to boost Si PV manufacturing. Photovolt. Int. 2011, 3, 102–110. [Google Scholar]

- Grochowski, J.; Guziewicz, M.; Borysiewicz, M. Analiza transmisji optycznej półprzewodnikowych warstw NiO osadzanych metodą magnetronowego rozpylania katodowego. Elektron. Konstr. Technol. Zastos. 2011, 52, 7. (In Polish) [Google Scholar]

- Lee, K.; Kim, N.; Kim, K.; Um, H.-D.; Jin, W.; Choi, D.; Park, J.; Park, K.J.; Lee, S.; Seo, K. Neutral-Colored Transparent Crystalline Silicon Photovoltaics. Joule 2020, 4, 235–246. [Google Scholar] [CrossRef]

- Fraunhofer Institute for Solar Energy Systems (ISE). Photovoltaics Report; Prepared with support of PSE Conferences &Consulting GmbH; Fraunhofer Institute for Solar Energy Systems: Freiburg im Breisgau, Germany, 2021. [Google Scholar]

- NREL-Led Research into Perovskite-Silicon Tandem Cells Shows New Path to Take. Available online: https://www.nrel.gov/news/program/2020/nrel-led-research-into-perovskite-silicon-tandem-cells-shows-new-path.html (accessed on 11 August 2022).

- Kryłow, J.; Oleński, J.; Sawicki, Z.; Tumański, A. Domieszkowanie Półprzewodników, Procesy Technologiczne w Elektronice Półprzewodnikowej; WN: Warsaw, Poland, 1980. (In Polish) [Google Scholar]

- Vlooswijk, A. Growth & Characterisation of p-Type Transparent Oxide Semiconductors. Master’s Thesis, Applied Physics, Inorganic Materials Science, Faculty of Science and Technology, University of Twente, Enschede, The Netherlands, February 2005. [Google Scholar]

- Klein, E.; Hubert, K.; Paul, O.; Ruther, P. Low-temperature plasma annealing of sputtered indium tin oxide for transparent and conductive thin-films on glass and polymer substrates. Thin Solid Films 2020, 693, 137715. [Google Scholar] [CrossRef]

- Hamberg, I.; Granqvist, C.G. Evaporated Sn-doped In2O3 films: Basic optical properties and applications to energy-efficient windows. J. Appl. Phys. 1986, 60, R123–R159. [Google Scholar] [CrossRef]

- Laist, J.W. Copper, Silver and Gold, 2nd ed.; D. van Nostrand Company: Toronto, ON, Canada, 1954. [Google Scholar]

- Ross, R.B. Copper Cu. In Metallic Materials Specification Handbook; Springer: Boston, MA, USA, 1992. [Google Scholar]

- Bartsch, J.; Mondon, A.; Bayer, K.; Schetter, C.; Hörteis, M.; Glunz, S.W. Quick Determination of Copper-Metallization Long-Term Impact on Silicon Solar Cells. J. Electrochem. Soc. 2010, 157, H942. [Google Scholar] [CrossRef]

- Minami, T. Present status of transparent conducting oxide thin-film development for Indium-Tin-Oxide (ITO) substitutes. Thin Solid Films 2008, 516, 5822–5828. [Google Scholar] [CrossRef]

- Tak, Y.H.; Kim, K.B.; Park, H.G.; Lee, K.H.; Lee, J.R. Criteria for ITO (indium-tin-oxide) thin film as the bottom electrode of an organic light-emitting diode. Thin Solid Films 2002, 411, 12–16. [Google Scholar] [CrossRef]

- Song, P.K.; Akao, H.; Kamei, M.; Shigesato, Y.; Yasui, I. Preparation and crystallisation of tin-doped and undoped amorphous indium oxide films deposited by sputtering. Jpn. J. Appl. Phys. 1999, 38, 5224–5226. [Google Scholar] [CrossRef]

- Nam, E.; Kang, Y.; Son, D.; Jung, D.; Hong, S.; Kim, Y.S. Electrical and surface properties of indium tin oxide (ITO) films by pulsed DC magnetron sputtering for organic light-emitting diode as anode material. Surf. Coat. Technol. 2010, 205, S129–S132. [Google Scholar] [CrossRef]

- Minami, T.; Sonohara, H.; Kakumu, T.; Takata, S. Physics of very thin ITO conducting films with high transparency prepared by DC magnetron sputtering. Thin Solid Films 1995, 270, 37–42. [Google Scholar] [CrossRef]

- Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photonics 2012, 6, 809. [Google Scholar] [CrossRef]

- Sun, L.; Grant, J.T.; Jones, J.G.; Murphy, N.R. Tailoring electrical and optical properties of Al-doped ZnO thin films grown at room temperature by reactive magnetron co-sputtering: From bandgap to near-infrared. Opt. Mater. 2018, 84, 146–157. [Google Scholar] [CrossRef]

- Ellmer, K.; Bikowski, A. Intrinsic and extrinsic doping of ZnO and ZnO alloys. J. Phys. D Appl. Phys. 2016, 49, 413002. [Google Scholar] [CrossRef]

- Wu, Y.; Potts, S.; Hermkens, P.; Knoops, H.; Roozeboom, F.; Kessels, W. Enhanced doping efficiency of Al-doped ZnO by atomic layer deposition using dimethyl aluminium isopropoxide as an alternative aluminium precursor. Chem. Mater. 2013, 25, 4619–4622. [Google Scholar] [CrossRef]

- Knoops, H.C.; Loo, B.W.; Smit, S.; Ponomarev, M.V.; Weber, J.-W.; Sharma, K.; Kessels, W.M.; Creatore, M. Optical modeling of plasma-deposited ZnO films: Electron scattering at different length scales. J. Vac. Sci. Technol. 2015, 33, 021509. [Google Scholar] [CrossRef]

- Zhang, H.; Li, X.; Fang, Z.; Yao, R.; Zhang, X.; Deng, Y.; Lu, X.; Tao, H.; Ning, H.; Peng, J. Highly conductive and transparent AZO films fabricated by PLD as source/drain electrodes for TFTs. Materials 2018, 11, 2480. [Google Scholar] [CrossRef] [PubMed]

- Shahid, M.; Deen, K.; Ahmad, A.; Akram, M.; Aslam, M.; Akhtar, W. Formation of Al-doped ZnO thin films on glass by sol-gel process and Characterisation. Appl. Nanosci. 2016, 6, 235–241. [Google Scholar] [CrossRef]

- Islam, M.R.; Rahman, M.; Farhad, S.; Podder, J. Structural, optical and photocatalysis properties of sol-gel deposited Al-doped ZnO thin films. Surf. Interfaces 2019, 16, 120–126. [Google Scholar] [CrossRef]

- Nasiri, M.; Rozati, S. Muscovite mica as a flexible substrate for transparent conductive AZO thin films deposited by spray pyrolysis. Mater. Sci. Semicond. Process. 2018, 81, 38–43. [Google Scholar] [CrossRef]

- Stapiński, T.; Godlewski, M.; Jakubowska, M.; Marszałek, K.; Pietruszka, R.; Panek, P.; Soliński, B.; Soliński, I.; Turoń, K.; Wróblewski, G. Materiały i Metody Optymalizacji Budowy Ogniw i Paneli Fotowoltaicznych; AR TOP: Kraków, Poland, 2014; pp. 15–77. [Google Scholar]

- Luque, A.; Hegedus, S. (Eds.) Handbook of Photovoltaic Science and Engineering; John Wiley & Sons, Ltd.: New York, NY, USA, 2003. [Google Scholar]

- Chae, J.; Kim, D.Y.; Kim, S.; Kang, M. Photovoltaic efficiency on dye-sensitised solar cells (DSSC) assembled using Ga-incorporated TiO2 materials. J. Ind. Eng. Chem. 2010, 16, 906–911. [Google Scholar] [CrossRef]

- Hossein-Babaei, F.; Amini, A. A breakthrough in gas diagnosis with a temperature-modulated generic metal oxide gas sensor. Sens. Actuators B Chem. 2012, 166–167, 419–425. [Google Scholar] [CrossRef]

- Khelladi, M.; Mentar, L.; Boubatra, M.; Azizi, A.; Kahoul, A. Early stages of cobalt electro-deposition on FTO and n-type Si substrates in sulphate medium. Mater. Chem. Phys. 2010, 122, 449–453. [Google Scholar] [CrossRef]

- Muthukumar, A. Fluorine-doped tin oxide (FTO) thin film as transparent conductive oxide (TCO) for photovoltaic applications. AIP Conf. Proc. 2013, 1512, 710. [Google Scholar]

- Nazeeruddin, M.K.; Baranoff, E.; Grätzel, M. Dye-sensitised solar cells: A brief overview. Sol. Energy 2011, 85, 1172–1178. [Google Scholar] [CrossRef]

- Kadam, A.N.; Chowdhury, S.R.; Bathula, C.; Kumar, N.; Kumar, V.; Jha, M.K.; Lee, S.-W.; Misra, M. A novel reduction approach for fabrication of transparent conducting fluorine and tin-doped indium oxide thin film with low sheet resistance. Ceram. Int. 2022, 48, 29307–29313. [Google Scholar] [CrossRef]

- Chen, Z.; Lai, J.; Shek, C. Multifractal spectra of scanning electron microscope images of SnO2 thin films prepared by pulsed laser deposition. Phys. Lett. 2005, 345, 218–223. [Google Scholar] [CrossRef]

- Fang, T.-H.; Chang, W.-J. Effect of freon flow rate on tin oxide thin films deposited by chemical vapour deposition. Appl. Surf. Sci. 2003, 220, 175–180. [Google Scholar] [CrossRef]

- Moholkar, A.; Pawar, S.; Rajpure, K.; Bhosale, C. Effect of solvent ratio on the properties of highly oriented sprayed fluorine-doped tin oxide thin films. Mater. Lett. 2007, 61, 3030–3036. [Google Scholar] [CrossRef]

- Napi, M.L.M.; Maarof, M.F.; Soon, C.F.; Nayan, N.; Fazli, F.I.M.; Hamed, N.K.A.; Mokhtar, S.M.; Seng, N.K.; Ahmad, M.K.; Suriani, A.B.; et al. Fabrication of fluorine-doped tin oxide (FTO) thin films using spray pyrolysis deposition method for transparent conducting oxide. J. Eng. Appl. Sci. 2016, 11, 8800–8840. [Google Scholar]

- Web of Science (Clarivate). Available online: https://www.webofscience.com/ (accessed on 7 September 2022).

- SCOPUS. Available online: https://www.scopus.com (accessed on 7 September 2022).

- Elsevier (Science Direct). Available online: https://www.sciencedirect.com/ (accessed on 7 September 2022).

- Indeksowanie Czasopism w Referencyjnych Bazach Danych. Available online: https://depot.ceon.pl/bitstream/handle/123456789/15614/Aneta_Drabek_Indeksowanie_czasopism_w_referencyjnych_bazach_danych.pdf?sequence=1&isAllowed=y (accessed on 6 September 2022).

- Boxwell, M. Solar Electricity Handbook: A Simple, Practical Guide to Solar Energy—Designing and Installing Solar Photovoltaic Systems, 2022 ed.; Greensteram Publishing: Birmingham, UK, 2022. [Google Scholar]

- Zalewski, E.F.; Geist, J. Solar cell spectral response characterisation. Appl. Opt. 1979, 18, 3942–3947. [Google Scholar] [CrossRef]

| No | Application Criteria | Specific Tasks to Be Performed |

|---|---|---|

| 1 | Absorber | Development of performed research on contamination and technical defects of modules/panels Development of thinner and larger wafer areas for more efficient use Development of new passivation techniques |

| 2 | Photovoltaic cells | Developing lower-cost manufacturing solar cells Designing high-precision equipment for accurate solar cell processing Improving anti-reflection layers and light-trapping in the solar cells |

| 3 | Metal grids (contacts) | Reducing surface recombination by minimizing contact surfaces and strong doping under contacts |

| 4 | Interconnection | Developing modern ways of joining solar cells |

| 5 | Packaging | Innovative drive to reduce optical losses Developing changes in the appearance of modules Improving inspection systems to detect defects, automatically record their identified class, and reduce them while maintaining high sensitivity, efficiency, and process performance Developing new materials to reduce the cost of creating modules while maintaining their operational reliability |

| 6 | Manufacturing | Ongoing innovation in commercially used products Introducing changes at every stage of production to improve the finished product |

| Pure Elements | Oxides | Nitrides | Sulfides | Carbides | Fluoride |

|---|---|---|---|---|---|

| C, Al, Si, Ti, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Mo, Ru, Rh, Pd, Ag, Sb, Ta, W, Os, Ir, Pt | Al2O3, TiO2, Ta2O5, Nb2O5, Zr O2, HfO2, SiO2, SnO2, In2O2, ZnO, MgO, La2O3, Y2O3, CeO2, Sc2O3, Cr2O3, Er2O3, VO2, B2O3, Co2O3, CuO, Fe2O3, NiO, Ga2O3, WO3,… | AlN, TaNx, NbN, TiN, MoN, ZrN, HfN, GaN, WxN, InN, … | ZnS, SrS, CaS, PbS, … | TiC, NbC, TaC, … | CaF2, SrF2, ZnF2, … |

| Issue Searched | Year | WOS | SCOPUS | ELSEVIER | |

|---|---|---|---|---|---|

| Transparent Conductive Oxides | 2012–2022 | 2382 | 814 | 4172 | 814 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musztyfaga-Staszuk, M.; Czupryński, A.; Radev, R. Review of the Chosen Methods of Producing Front Contacts to Transparent Conductive Oxides Layers in Photovoltaic Structures. Energies 2022, 15, 9026. https://doi.org/10.3390/en15239026

Musztyfaga-Staszuk M, Czupryński A, Radev R. Review of the Chosen Methods of Producing Front Contacts to Transparent Conductive Oxides Layers in Photovoltaic Structures. Energies. 2022; 15(23):9026. https://doi.org/10.3390/en15239026

Chicago/Turabian StyleMusztyfaga-Staszuk, Małgorzata, Artur Czupryński, and Rossen Radev. 2022. "Review of the Chosen Methods of Producing Front Contacts to Transparent Conductive Oxides Layers in Photovoltaic Structures" Energies 15, no. 23: 9026. https://doi.org/10.3390/en15239026

APA StyleMusztyfaga-Staszuk, M., Czupryński, A., & Radev, R. (2022). Review of the Chosen Methods of Producing Front Contacts to Transparent Conductive Oxides Layers in Photovoltaic Structures. Energies, 15(23), 9026. https://doi.org/10.3390/en15239026