Studies on Water–Aluminum Scrap Reaction Kinetics in Two Steps and the Efficiency of Green Hydrogen Production

Abstract

1. Introduction

2. Materials and Methods

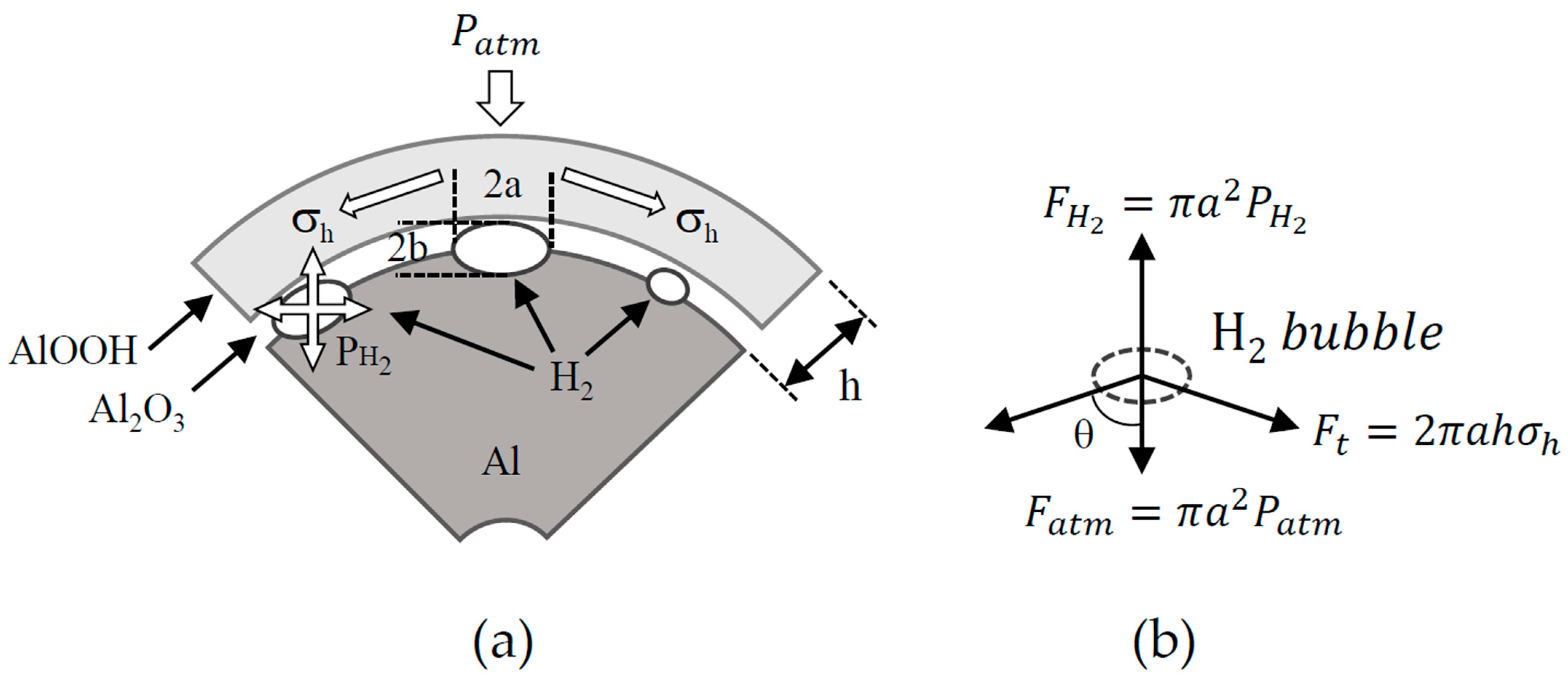

2.1. Aluminum Surface and Its Reaction with Water

2.2. The Role of the Alkali Promoter

2.3. Determining the Activation Energy

2.4. Reaction Kinetics in Two Steps

2.4.1. Surface Reaction Rate Step

2.4.2. Mass Transfer Rate Step

3. Materials and Methods

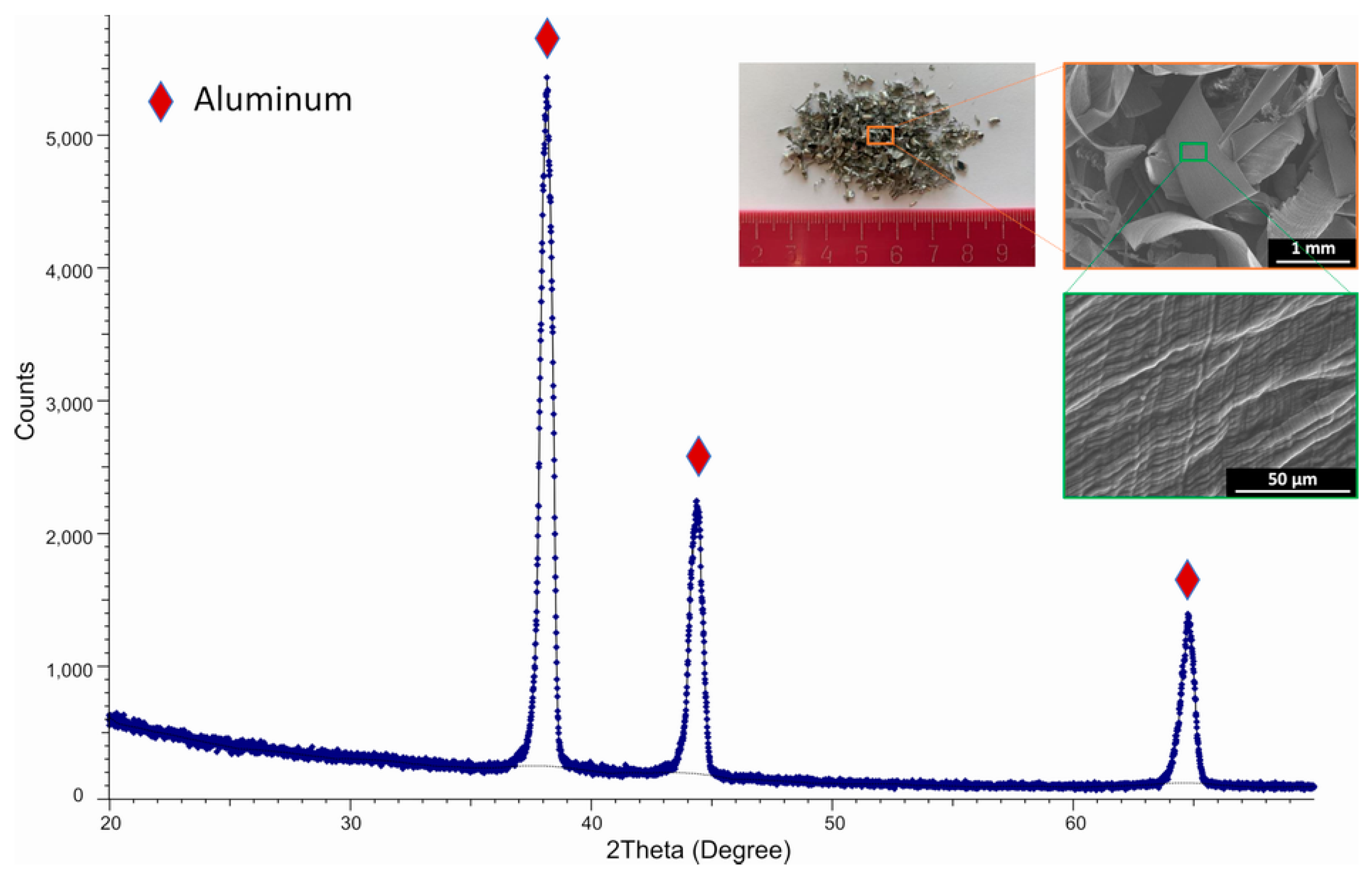

3.1. Experimental Sample

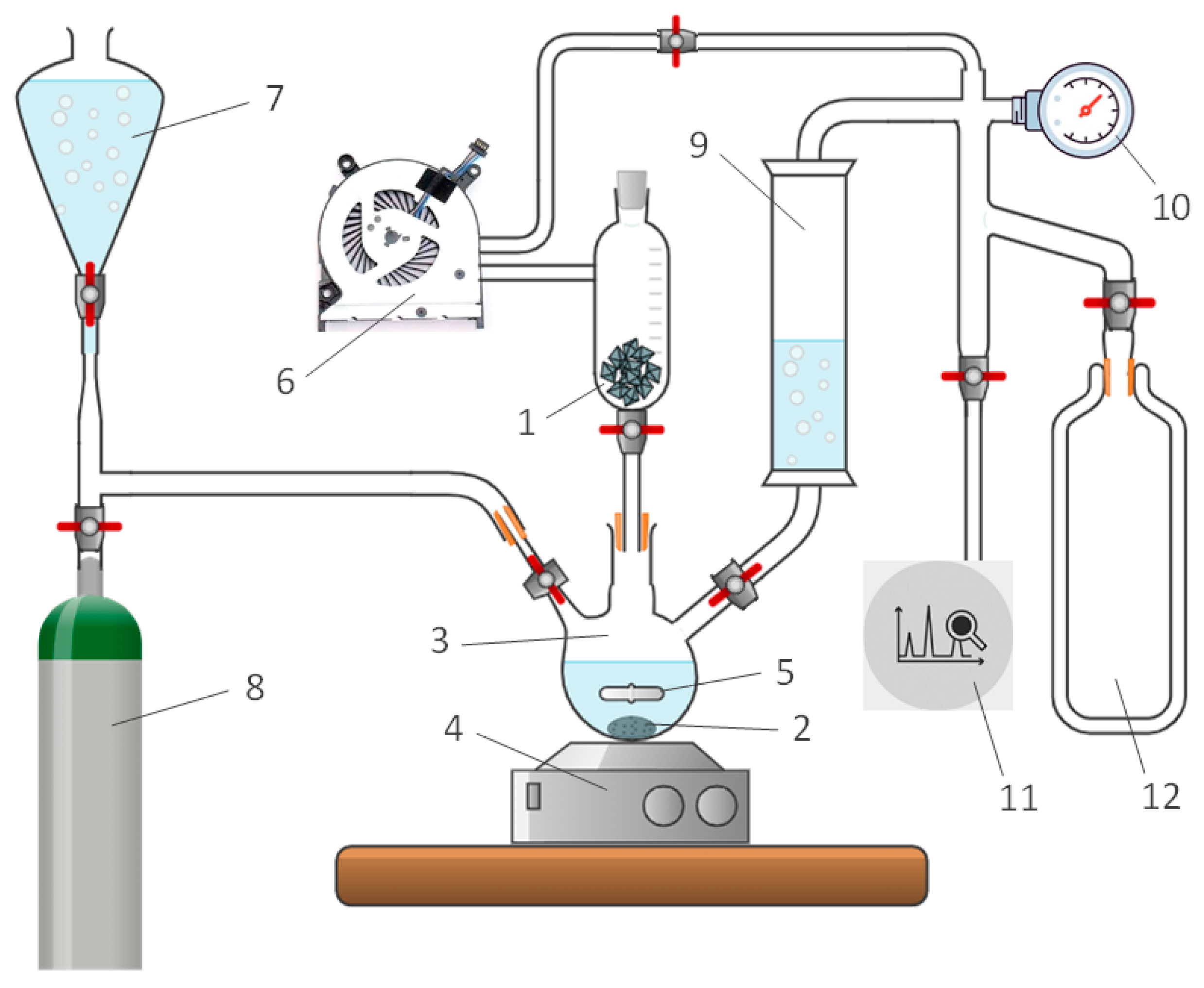

3.2. Experimental Setup

4. Results and Discussion

4.1. Experimental Parameters and Controls

4.1.1. Stirring Adjustment at the Surface Reaction Rate Step

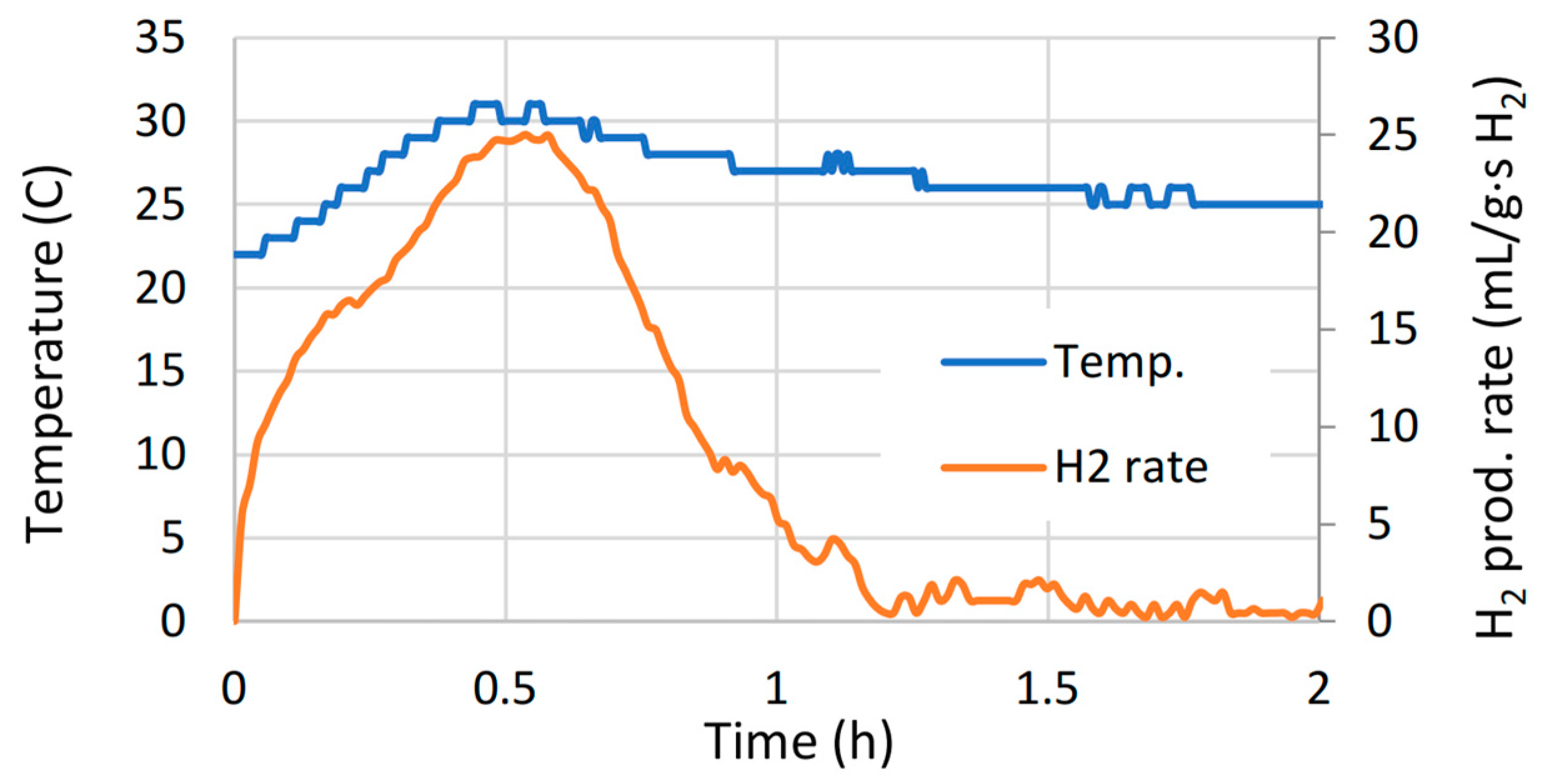

4.1.2. Temperature Control during Experiments

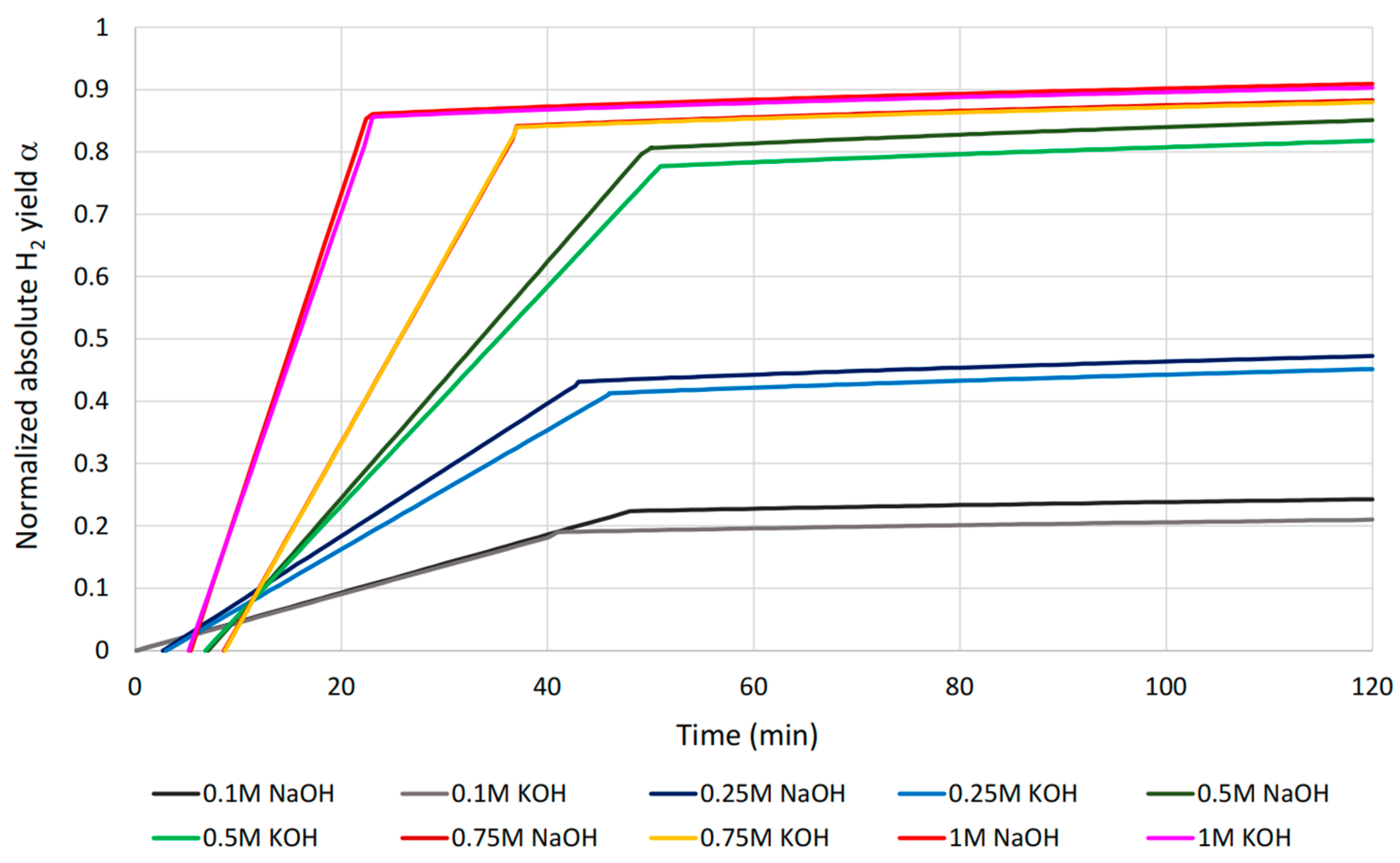

4.2. Normalized Cumulative Hydrogen Yield

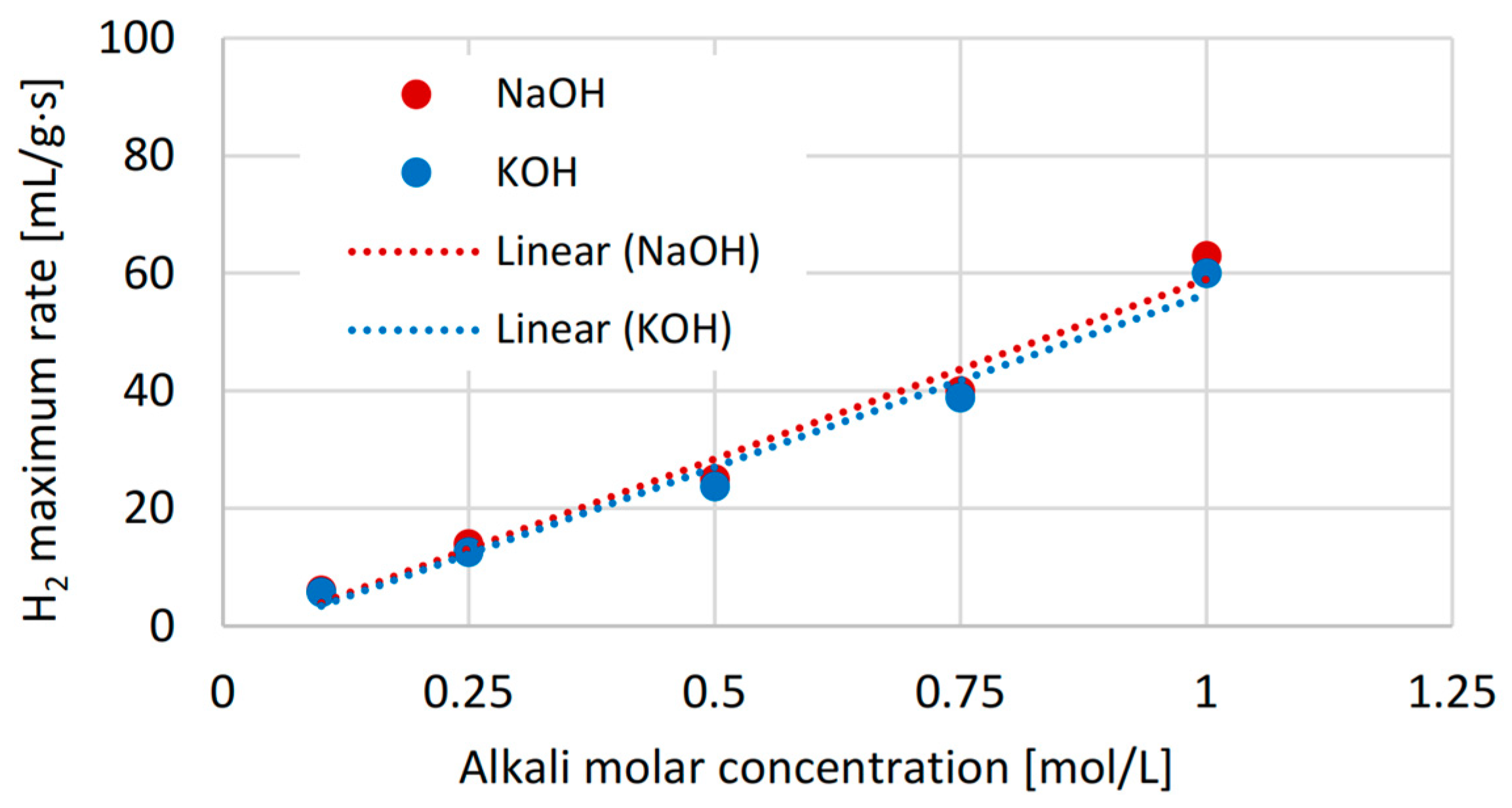

4.3. Hydrogen Production Rate

4.4. Linear Trendline Approximations and Their Compositions

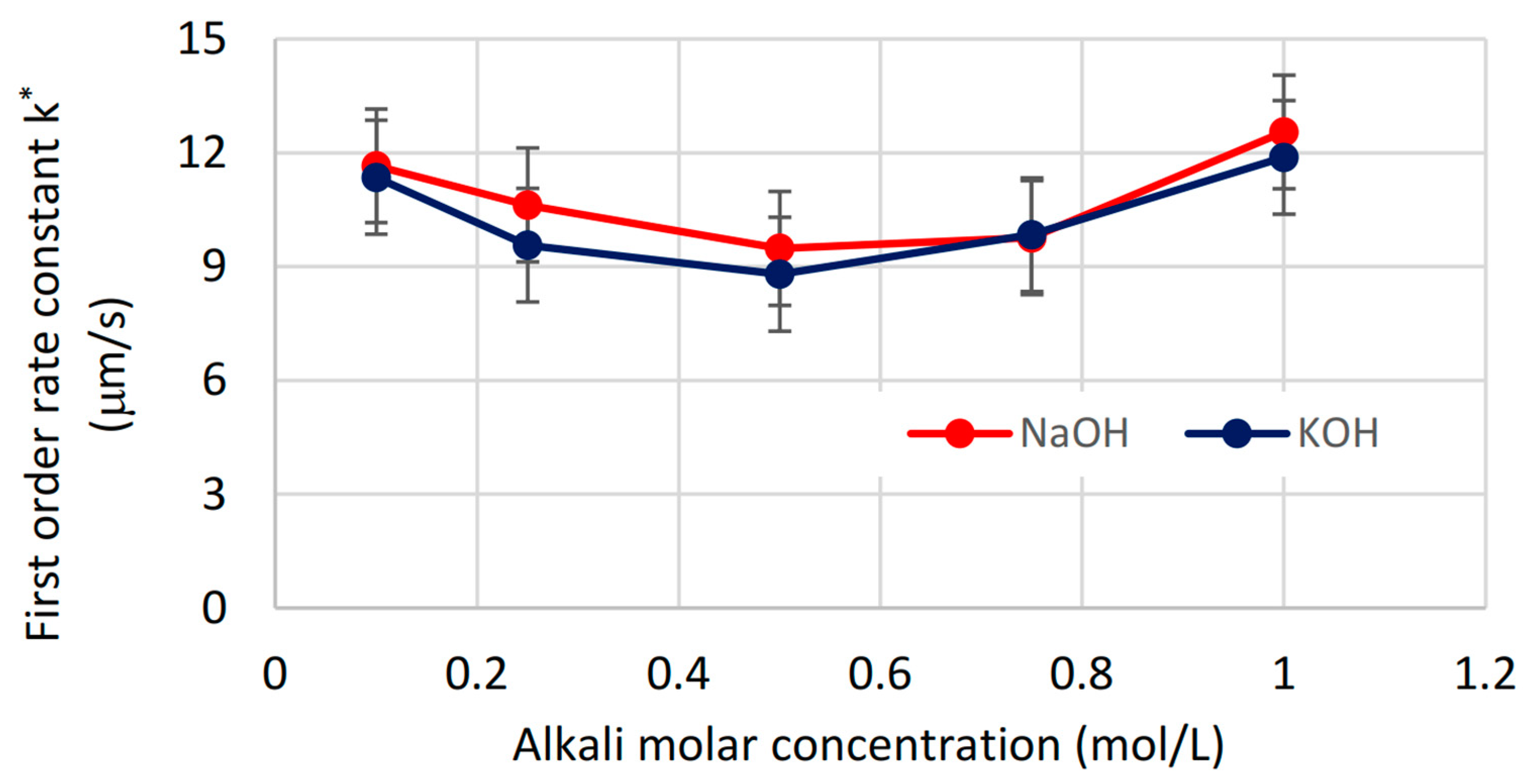

4.4.1. First-Order Rate Constant for Surface Reaction

4.4.2. Diffusion Coefficient of an Aqueous Reactant in the Byproduct Layer

4.4.3. Reconstruction of the Hydrogen Yield via Numerically Obtained Values of k* and D

4.5. Economic Analysis

4.5.1. Profit Estimation of Performed Experiments

4.5.2. Open Problems of the Further Treatment of Aluminum Hydroxide

- Hydroxide salt make-up required between runs;

- Impurity levels of chemical elements within the solid aluminum hydroxide Al(OH)3 product and its general suitability for recycling/end use.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Calder, G.V.; Stark, T.D. Aluminum reactions and problems in municipal solid waste landfills. Pract. Period. Hazard. Toxic Radioact. Waste Manag. 2010, 14, 258–265. [Google Scholar] [CrossRef]

- International-aluminium.org. Primary Aluminium Production—International Aluminium Institute. Available online: https://international-aluminium.org/statistics/primary-aluminium-production/ (accessed on 29 January 2023).

- Martínez, S.S.; Benítes, W.L.; Gallegos, A.A.Á.; Sebastián, P.J. Recycling of aluminum to produce green energy. Sol. Energy Mater. Sol. Cells 2005, 88, 237–243. [Google Scholar] [CrossRef]

- Hiraki, T.; Akiyama, T. Exergetic life cycle assessment of new waste aluminium treatment system with co-production of pressurized hydrogen and aluminium hydroxide. Int. J. Hydrog. Energy 2009, 34, 153–161. [Google Scholar] [CrossRef]

- Razavi-Tousi, S.S.; Szpunar, J.A. Mechanism of Corrosion of Activated Aluminum Particles by Hot Water. Electrochim. Acta 2014, 127, 95–105. [Google Scholar] [CrossRef]

- Elsarrag, E.; Elhoweris, A.; Alhorr, Y. The production of hydrogen as an alternative energy carrier from aluminium waste. Energy Sustain. Soc. 2017, 7, 9. [Google Scholar] [CrossRef]

- Xuan, J.; Leung, M.K.H.; Leung, D.Y.C.; Ni, M. A review of biomass-derived fuel processors for fuel cell systems. Renew. Sustain. Energy Rev. 2009, 13, 1301–1313. [Google Scholar] [CrossRef]

- Amendola, S.C.; Sharp-Goldman, S.L.; Janjua, S.M.; Spencer, N.C.; Kelly, M.T.; Petillo, P.J.; Binder, M. A Safe, portable, hydrogen gas generator using aqueous borohydride solution and Ru catalyst. Int. J. Hydrog. Energy 2000, 25, 969–975. [Google Scholar] [CrossRef]

- Wang, E.D.; Shi, P.F.; Du, C.Y.; Wang, X.R. A mini-type hydrogen generator from aluminum for proton exchange membrane fuel cells. J. Power Sources 2008, 181, 144–148. [Google Scholar] [CrossRef]

- Gai, W.Z.; Liu, W.H.; Deng, Z.Y.; Zhou, J.G. Reaction of Al powder with water for hydrogen generation under ambient condition. Int. J. Hydrog. Energy 2012, 37, 13132–13140. [Google Scholar] [CrossRef]

- Bunker, B.C.; Nelson, G.C.; Zavadil, K.R.; Barbour, J.C.; Wall, F.D.; Sullivan, J.P.; Windisch, C.F.; Engelhardt, M.H.; Baer, D.R. Hydration of Passive Oxide Films on Aluminum. J. Phys. Chem. B 2002, 106, 4705–4713. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Ferreira, J.M.F.; Tanaka, Y.; Ye, J. Physicochemical Mechanism for the Continuous Reaction of γ-Al2O3-Modified Aluminum Powder with Water. J. Am. Ceram. Soc. 2007, 90, 1521–1526. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Ferreira, J.M.F.; Sakka, Y. Hydrogen-generation materials for portable applications. J. Am. Ceram. Soc. 2008, 91, 3825–3834. [Google Scholar] [CrossRef]

- Omran, M.P.; Mousa Oskueyan, G.; Farhadi, M.; Sedighi, K. Design of Hydrogen Generator for on-Board Hydrogen Generation from Waste Aluminum Chips. In Proceedings of the 22th International Symposium on Transport Phenomena, TUDelft, The Netherlands, 8–11 November 2011; pp. 25–27. [Google Scholar]

- Levenspiel, O. Chemical Reaction Engineering, 3rd ed.; Wiley: New York, NY, USA, 1998; p. 704. [Google Scholar]

- Hiraki, T.; Takeuchi, M.; Hisa, M.; Akiyama, T. Hydrogen production from waste aluminum at different temperatures, with LCA. Mater. Trans. 2005, 46, 1052–1057. [Google Scholar] [CrossRef]

- Porciúncula, C.B.; Marcilio, N.R.; Tessaro, I.C.; Gerchmann, M. Production of hydrogen in the reaction between aluminum and water in the presence of NaOH and KOH. Braz. J. Chem. Eng. 2012, 29, 337–348. [Google Scholar] [CrossRef]

- Ambaryan, G.N.; Vlaskin, M.S.; Dudoladov, A.O.; Meshkov, E.A.; Zhuk, A.Z.; Shkolnikov, E.I. Hydrogen generation by oxidation of coarse aluminum in low content alkali aqueous solution under intensive mixing. Int. J. Hydrogen Energy 2016, 41, 17216–17224. [Google Scholar] [CrossRef]

- Soler, L.; Candela, A.M.; Macanás, J.; Muñoz, M.; Casado, J. In situ generation of hydrogen from water by aluminum corrosion in solutions of sodium aluminate. J. Power Sources 2009, 192, 21–26. [Google Scholar] [CrossRef]

- Soler, L.; Macanás, J.; Muñoz, M.; Casado, J. Aluminum and aluminum alloys as sources of hydrogen for fuel cell applications. J. Power Sources 2007, 169, 144–149. [Google Scholar] [CrossRef]

- Berna, X.S.; Genesca, M.M.; Daga-Monmany, J.M.; Mujal-Rosas, R. Analysis of Valorization Process of Aluminum Breakage Scraps to Obtain Green Hydrogen. Adv. Valuab. Met. Recycl. 2021, 11, 598. [Google Scholar]

- Brett, C.M.A.; Maria, A.N.A.; Brett, O. Principles, Methods, and Applications. Electrochemistry 1993, 67, 444. Available online: http://www.getcited.org/pub/102998784 (accessed on 29 January 2023).

- Haller, M.Y.; Amstad, D.; Dudita, M.; Bäuerle, Y. AlEnCycles—Aluminium-Redox-Cycles for the Production of Heat and Electricity for Buildings Based on Renewable Energies. Zenodo. Available online: https://zenodo.org/record/6393255#.ZBjQkMJBy70 (accessed on 20 March 2023).

- Soberanis, M.A.E.; Vales-Pinzón, C.; Hernández-Núñez, E.; Flota-Bañuelos, M.; Medina, J.; Quintal-Palomo, R.; San-Pedro, L.; Ruiz-Gómez, M. Temperature dependence on hydrogen production from hydrolysis reaction of recycled aluminum. Clean Techn Environ Policy 2023, 25, 35–49. [Google Scholar] [CrossRef]

- Moreno-Flores, R.; Loyola-Morales, F.; Valenzuela, E.; Sebastian, P.J. Design and performance evalu-ation of a prototype hydrogen generator employing hydrolysis of aluminum waste. Clean Techn Environ Policy 2023, 25, 747–753. [Google Scholar]

- Sodium Hydroxide/Caustic Soda Supplier & Distributor|Univar Solutions|Univar Solutions. Available online: https://www.univarsolutions.com/product-categories/essential-chemicals-ingredients/liquid-caustic-soda?hasprice=cspweb (accessed on 20 March 2023).

- Hydrogen Cost and Sales Prices|H2Valleys. Available online: https://h2v.eu/analysis/statistics/financing/hydrogen-cost-and-sales-prices (accessed on 20 March 2023).

- Gai, W.Z.; Wang, L.Y.; Lu, M.Y.; Deng, Z.Y. Effect of low concentration hydroxides on Al hydrolysis for hydrogen production. Energy 2023, 268, 126731. [Google Scholar] [CrossRef]

- Kanehira, S.; Kanamori, S.; Nagashima, K.; Saeki, T.; Visbal, H.; Fukui, T.; Hirao, K. Controllable hydrogen release via aluminum powder corrosion in calcium hydroxide solutions. J. Asian Ceram. Soc. 2013, 1, 296–303. [Google Scholar] [CrossRef]

- Zhu, Y.; Cooper, D.R. An Optimal Reverse Material Supply Chain for U.S. Aluminum Scrap. Procedia CIRP 2019, 80, 677–682. [Google Scholar] [CrossRef]

- Soo, V.K.; Peeters, J.R.; Compston, P.; Doolan, M.; Duflou, J.R. Economic and Environmental Evaluation of Aluminium Recycling based on a Belgian Case Study. Procedia Manuf. 2019, 33, 639–646. [Google Scholar] [CrossRef]

- Modaresi, R.; Müller, D.B. The role of automobiles for the future of aluminum recycling. Env. Sci. Technol. 2012, 46, 8587–8594. [Google Scholar] [CrossRef] [PubMed]

- Haller, M.Y.; Amstad, D.; Dudita, M.; Englert, A.; Häberle, A. Combined heat and power production based on renewable aluminium-water reaction. Renew. Energy 2021, 174, 879–893. [Google Scholar] [CrossRef]

- Gale, J.D.; Rohl, A.L.; Milman, V.; Warren, M.C. An ab Initio Study of the Structure and Properties of Aluminum Hydroxide: Gibbsite and Bayerite. J. Phys. Chem. B 2001, 105, 10236–10242. [Google Scholar] [CrossRef]

- Oxides and Hydroxides of Aluminum. WorldCat.org. Available online: https://www.worldcat.org/title/oxides-and-hydroxides-of-aluminum/oclc/18997314 (accessed on 18 March 2023).

| Elemental Composition | Concentration, % |

|---|---|

| Aluminum | 94.3 |

| Magnesium | 0.6 |

| Carbon | 5.0 |

| Oxygen | 0.1 |

| Al Chips 9 kg | Green H2 Sale 1 kg | Gibbsite Sale 26 kg | NaOH Price 26.6 kg 50 wt.% (aq) | NaOH Loss of 1.33% (with 1M NaOH) | Profit of Al Hydrolysis Process |

|---|---|---|---|---|---|

| EUR 0.5/kg·9 kg = EUR 4.5 | EUR 6 | EUR 0.2/kg·26 kg = EUR 5.2 | Chemical: EUR 547 | EUR 7.3 | EUR −0.6 |

| Technical: EUR 76 | EUR 1.0 | EUR 5.7 |

| NaOH Price 26.6 kg 50 wt.% (aq) | NaOH Loss of 1.33% (with 1M NaOH) | Profit of Al Hydrolysis Process with 1M | NaOH Loss of 1% (with 0.75M NaOH) | Profit of Al Hydrolysis Process with 0.75M | “Over-Profit” of Decreased NaOH Molarity vs. Overtime |

|---|---|---|---|---|---|

| Chemical: EUR 547 | EUR 7.3 | EUR −0.6 | EUR 5.5 | EUR 1.2 | EUR 3.6/h |

| Technical: EUR 76 | EUR 1.0 | EUR 5.7 | EUR 0.76 | EUR 5.9 | EUR 0.4/h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mezulis, A.; Richter, C.; Lesnicenoks, P.; Knoks, A.; Varnagiris, S.; Urbonavicius, M.; Milcius, D.; Kleperis, J. Studies on Water–Aluminum Scrap Reaction Kinetics in Two Steps and the Efficiency of Green Hydrogen Production. Energies 2023, 16, 5554. https://doi.org/10.3390/en16145554

Mezulis A, Richter C, Lesnicenoks P, Knoks A, Varnagiris S, Urbonavicius M, Milcius D, Kleperis J. Studies on Water–Aluminum Scrap Reaction Kinetics in Two Steps and the Efficiency of Green Hydrogen Production. Energies. 2023; 16(14):5554. https://doi.org/10.3390/en16145554

Chicago/Turabian StyleMezulis, Ansis, Christiaan Richter, Peteris Lesnicenoks, Ainars Knoks, Sarunas Varnagiris, Marius Urbonavicius, Darius Milcius, and Janis Kleperis. 2023. "Studies on Water–Aluminum Scrap Reaction Kinetics in Two Steps and the Efficiency of Green Hydrogen Production" Energies 16, no. 14: 5554. https://doi.org/10.3390/en16145554

APA StyleMezulis, A., Richter, C., Lesnicenoks, P., Knoks, A., Varnagiris, S., Urbonavicius, M., Milcius, D., & Kleperis, J. (2023). Studies on Water–Aluminum Scrap Reaction Kinetics in Two Steps and the Efficiency of Green Hydrogen Production. Energies, 16(14), 5554. https://doi.org/10.3390/en16145554