A Novel High-Speed Permanent Magnet Synchronous Motor for Hydrogen Recirculation Side Channel Pumps in Fuel Cell Systems

Abstract

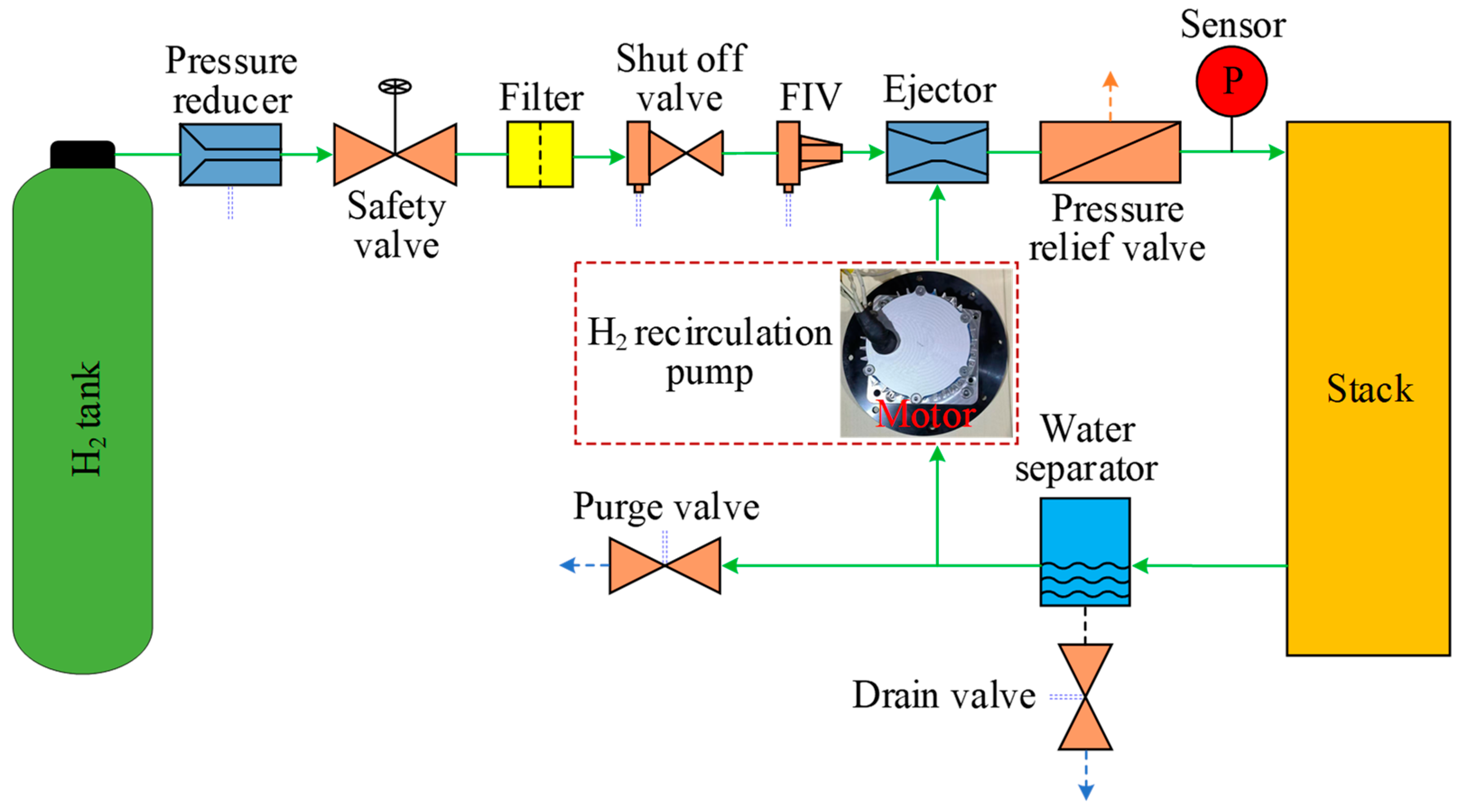

1. Introduction

- Wider operation range: pressure difference and flow rate;

- Cover low power system load working condition;

- Increased flexibility of shut-down procedure.

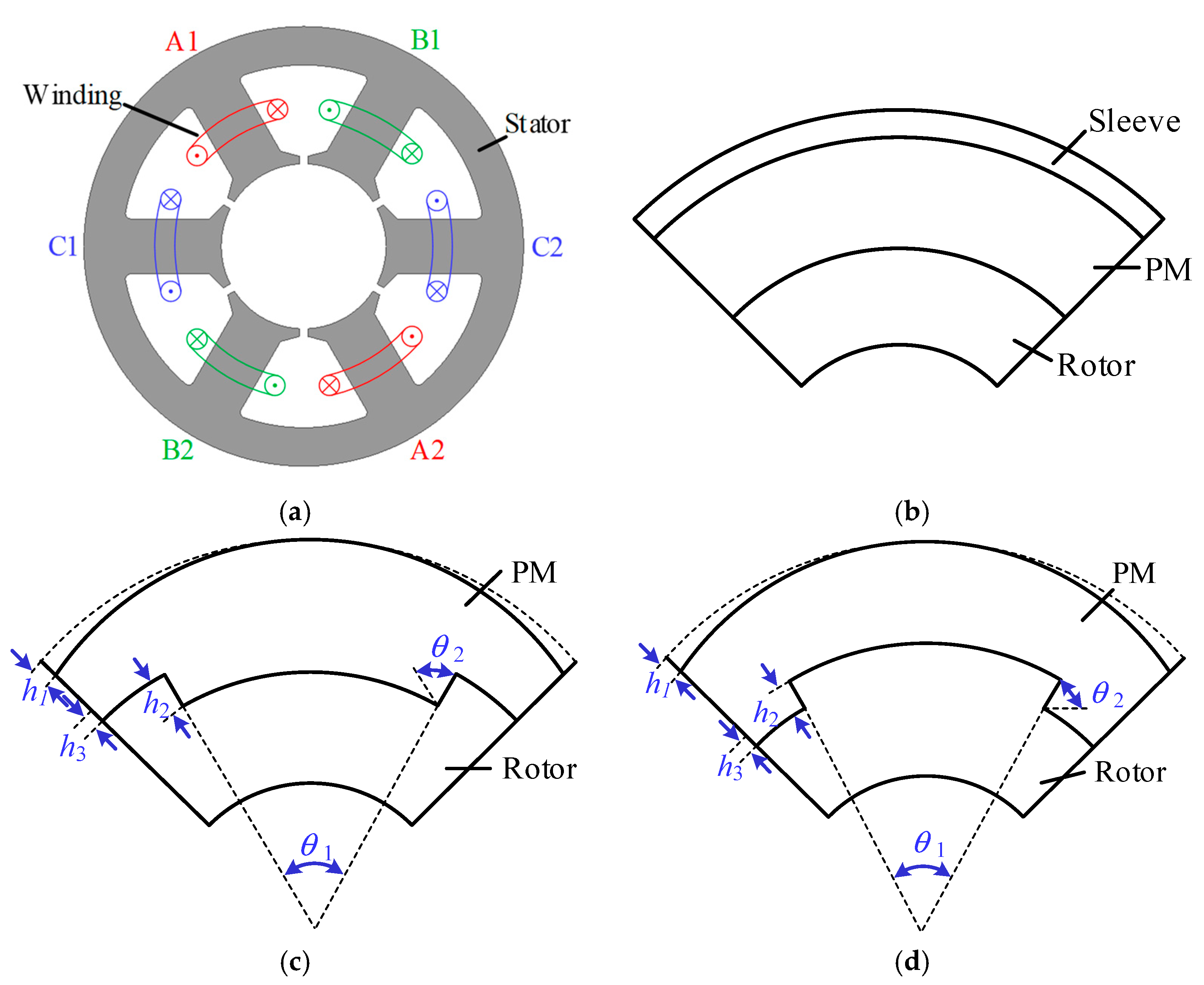

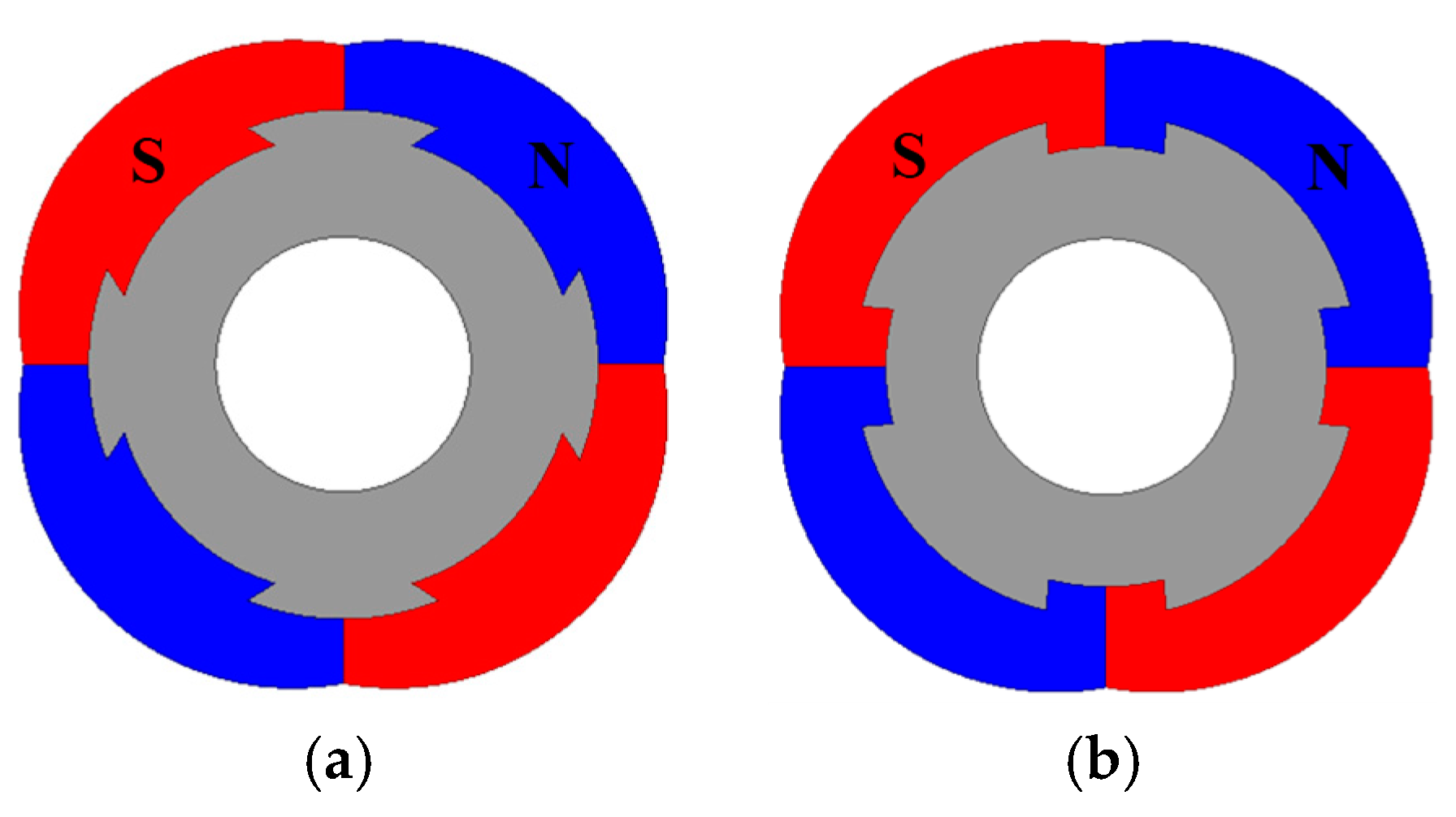

2. Motors with Different Rotors

3. Parametric Optimization of SIPM Motors

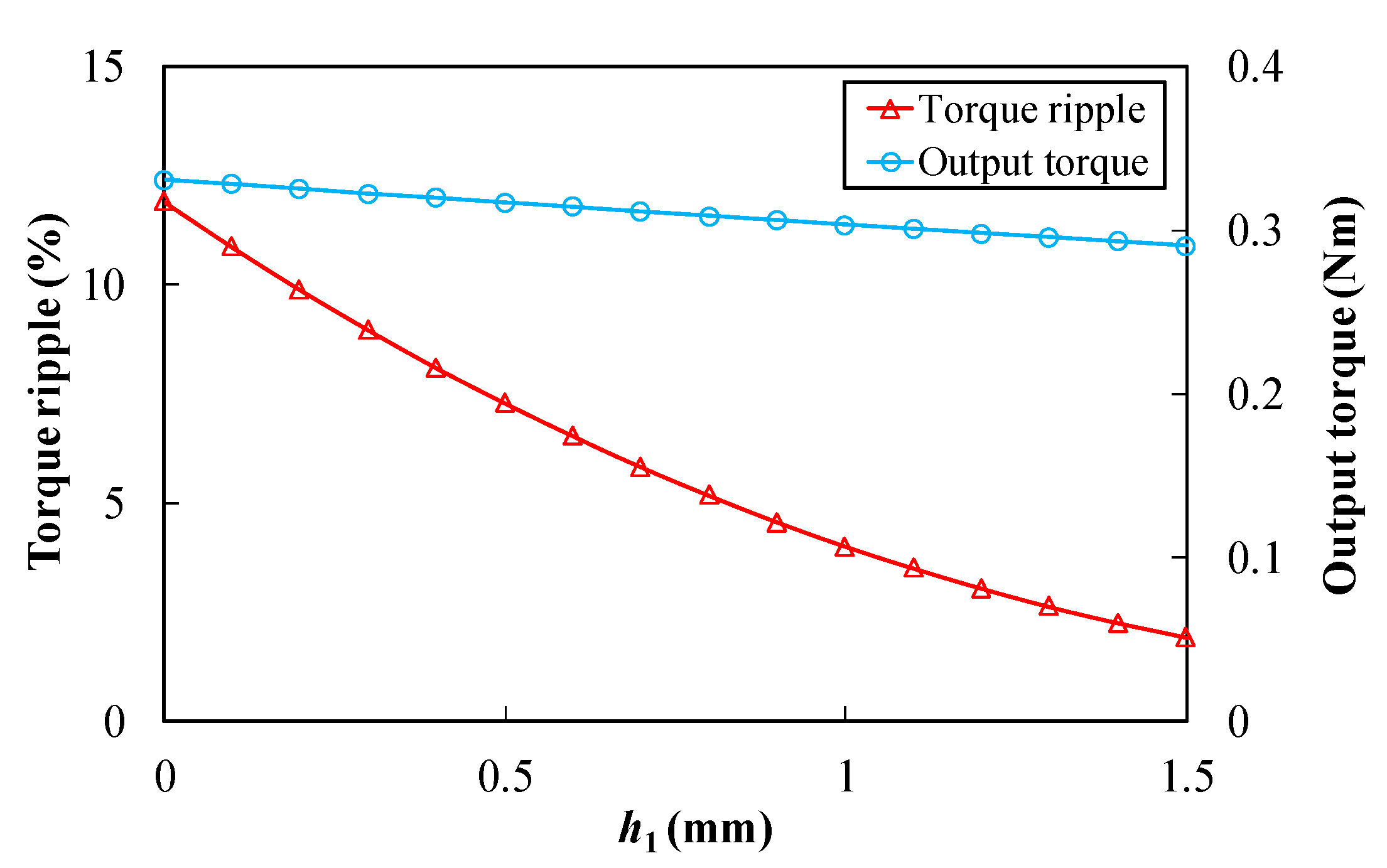

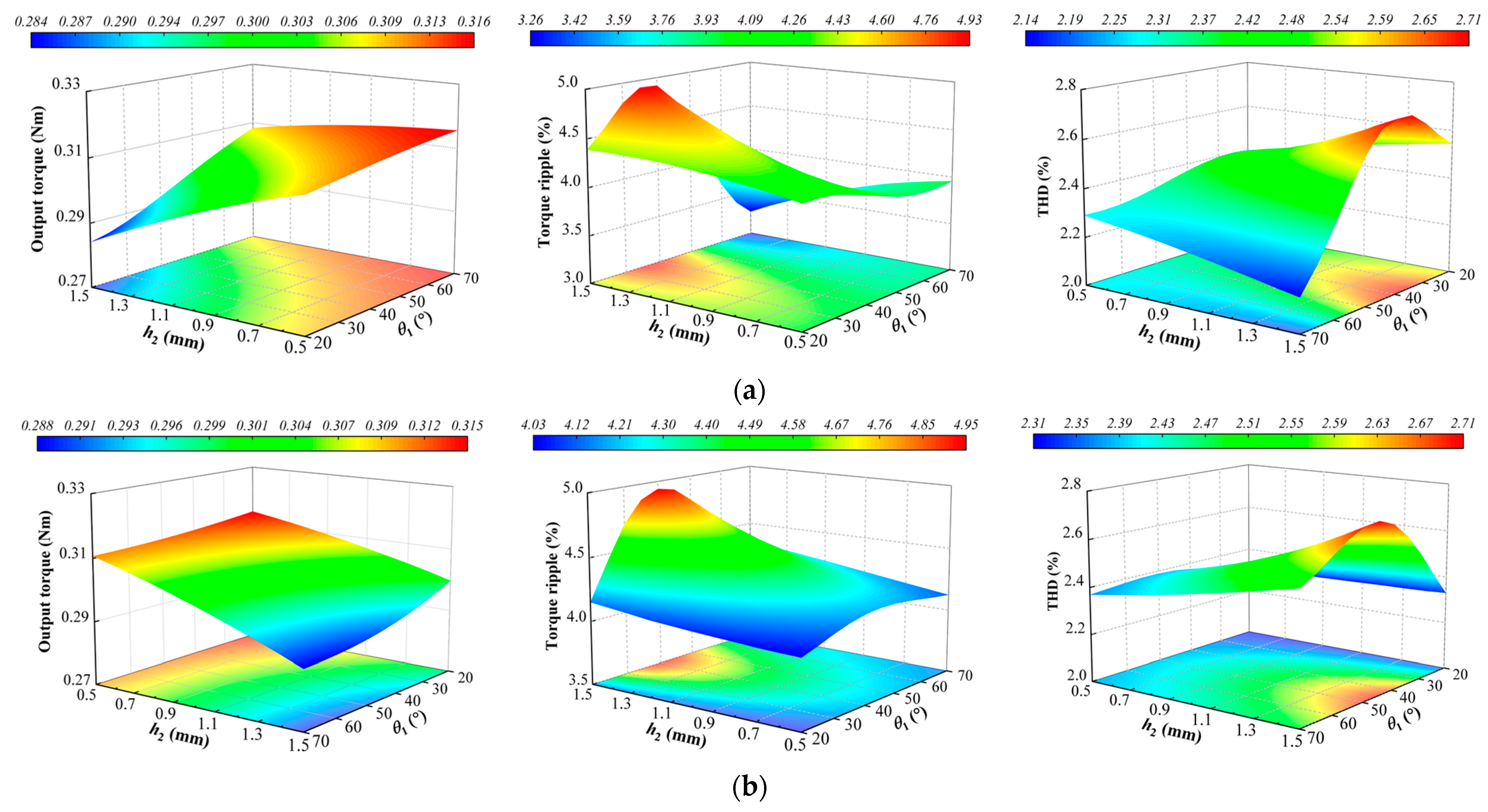

3.1. Electromagnetic Optimization of SIPM

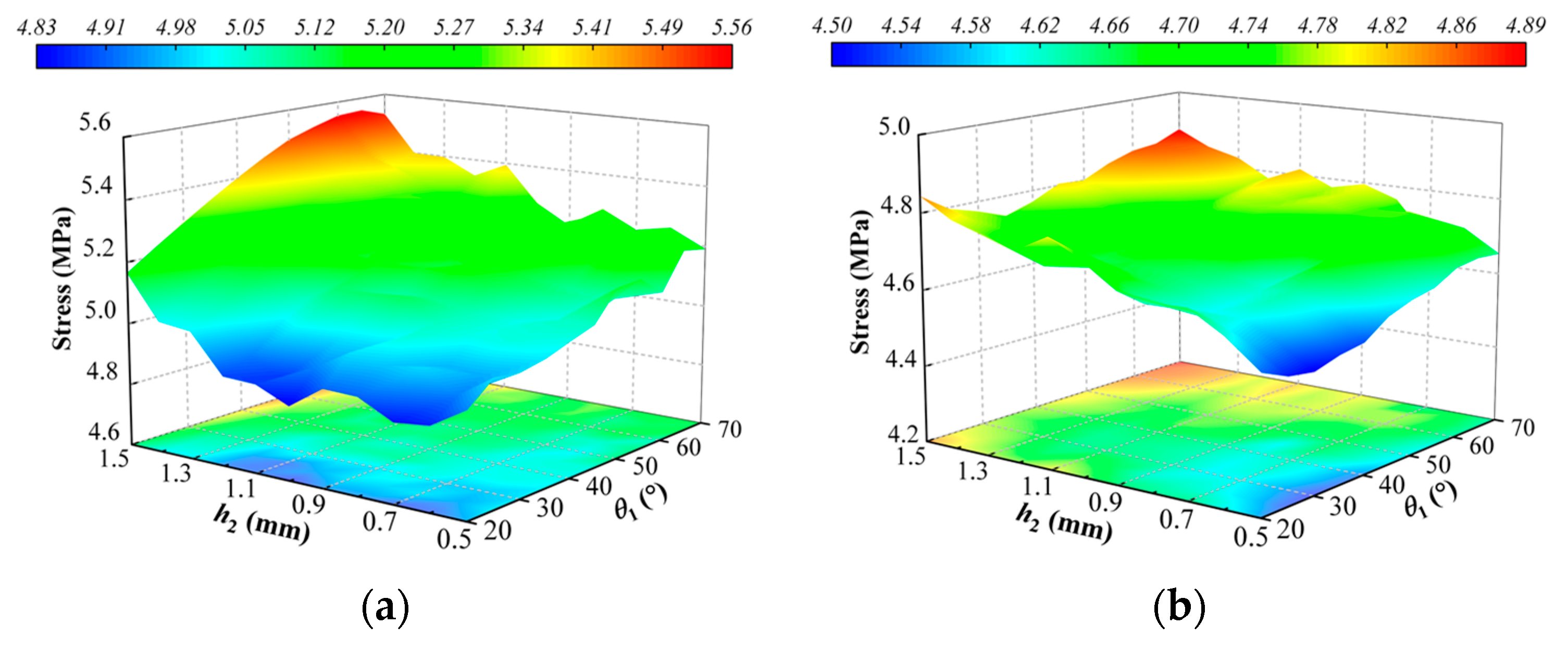

3.2. Mechanical Strength Optimization of SIPM

3.3. Optimization Result

4. Performance Analysis and Comparison

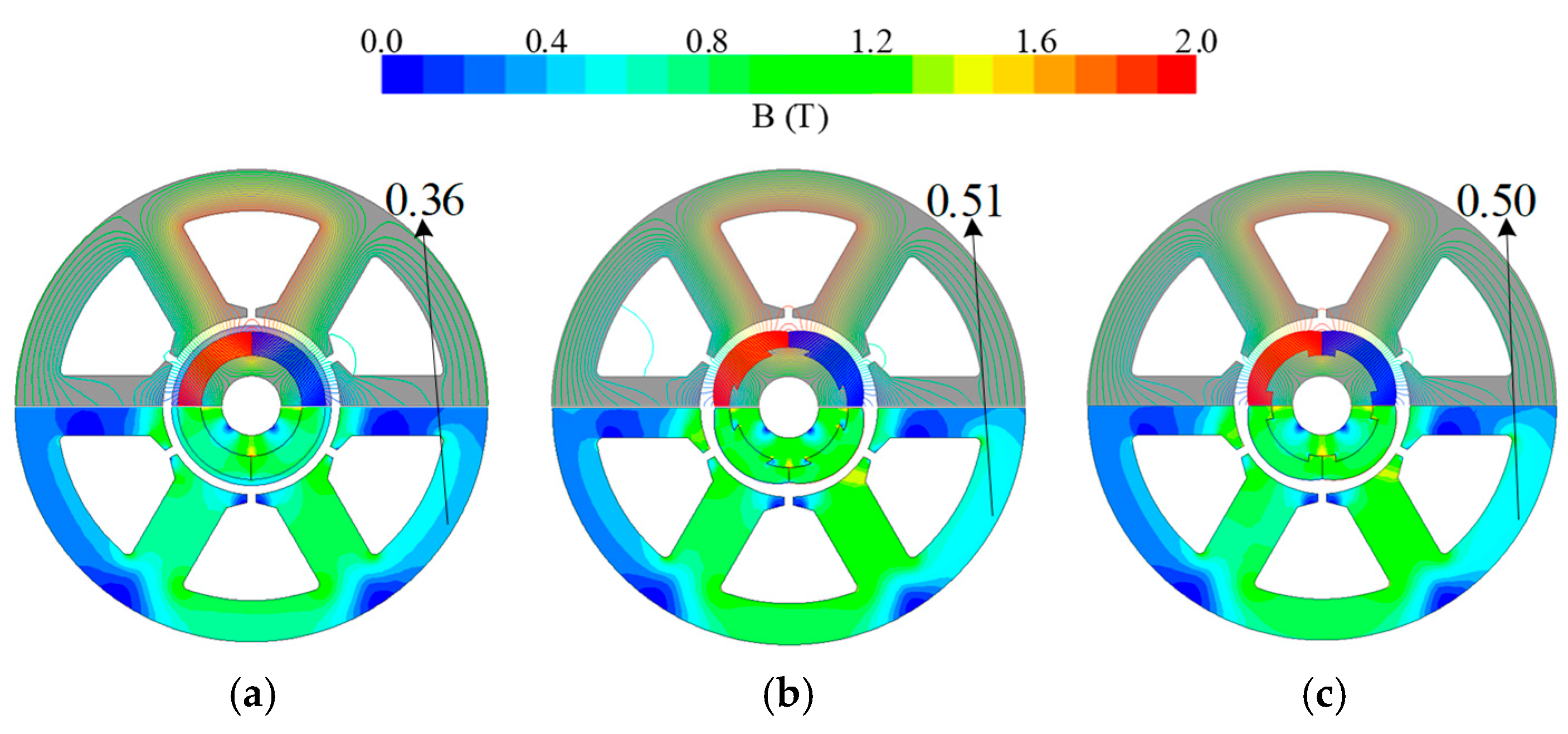

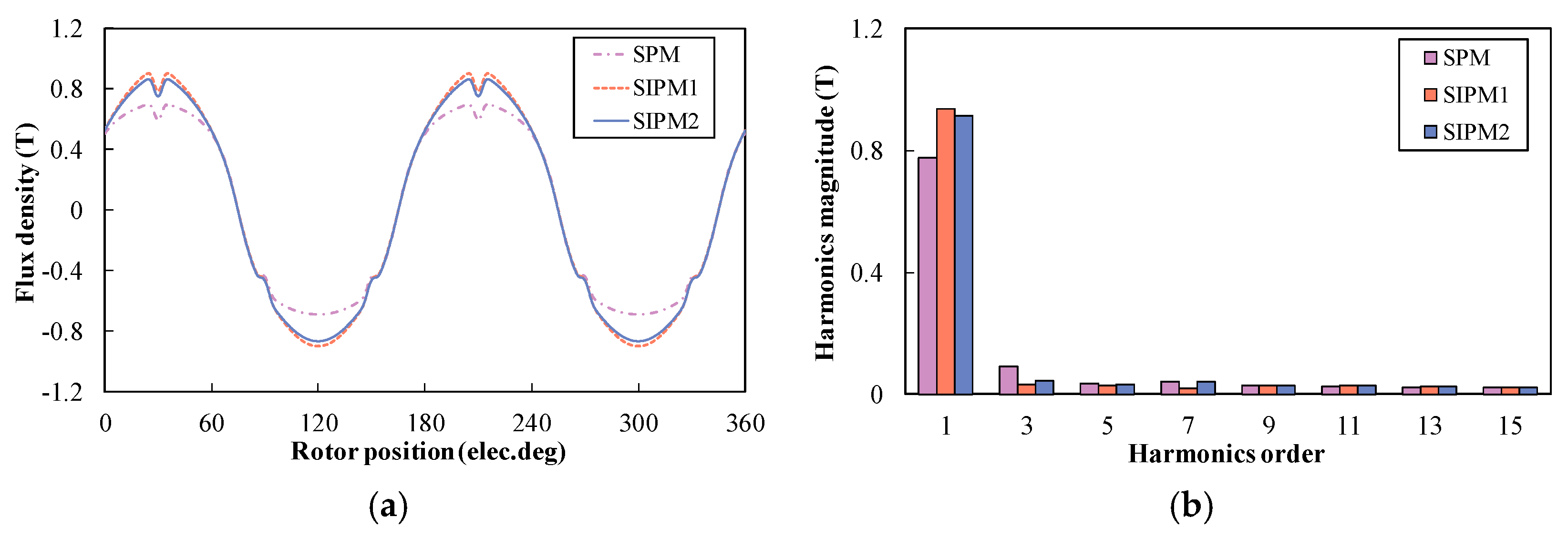

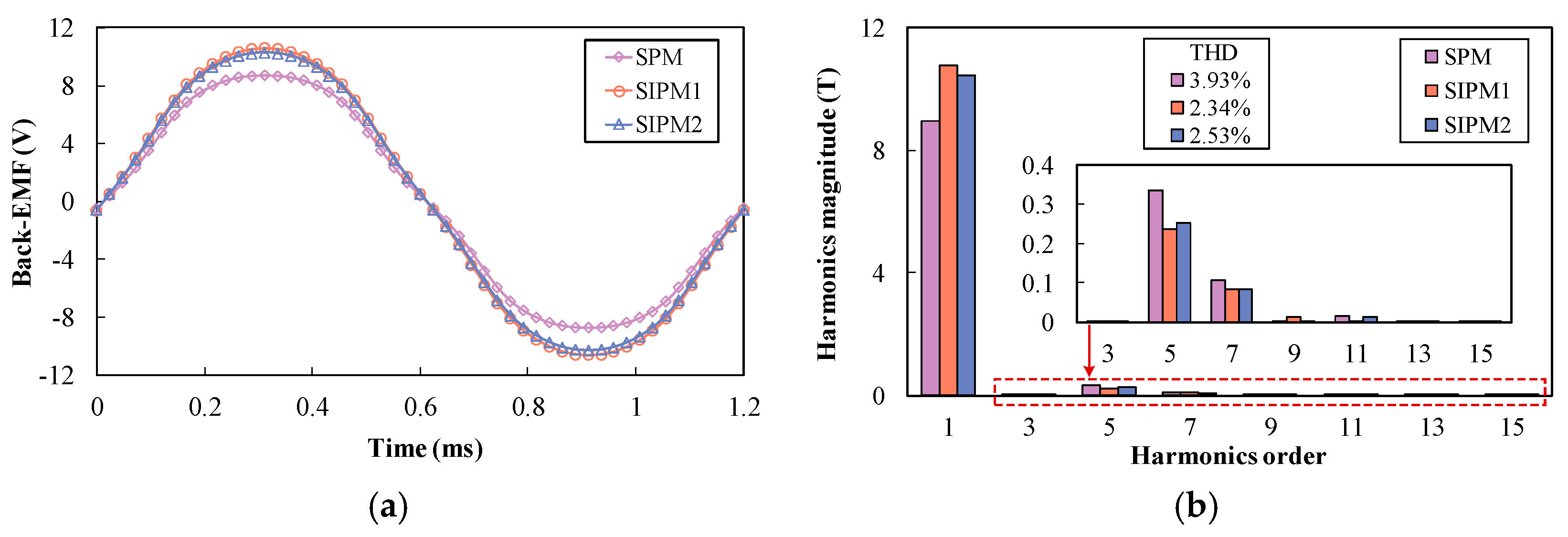

4.1. No-Load Airgap Flux Density and Back-EMF

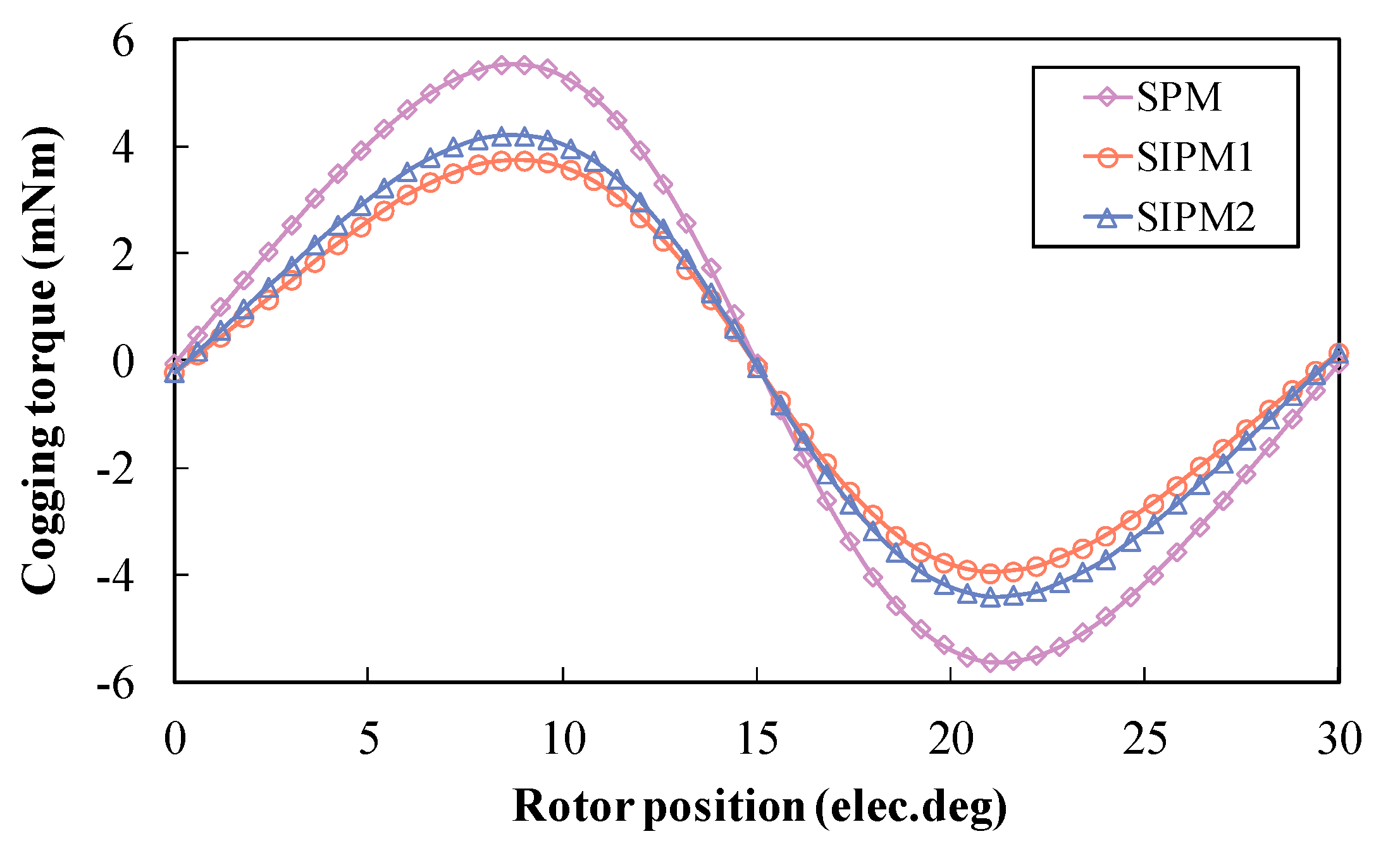

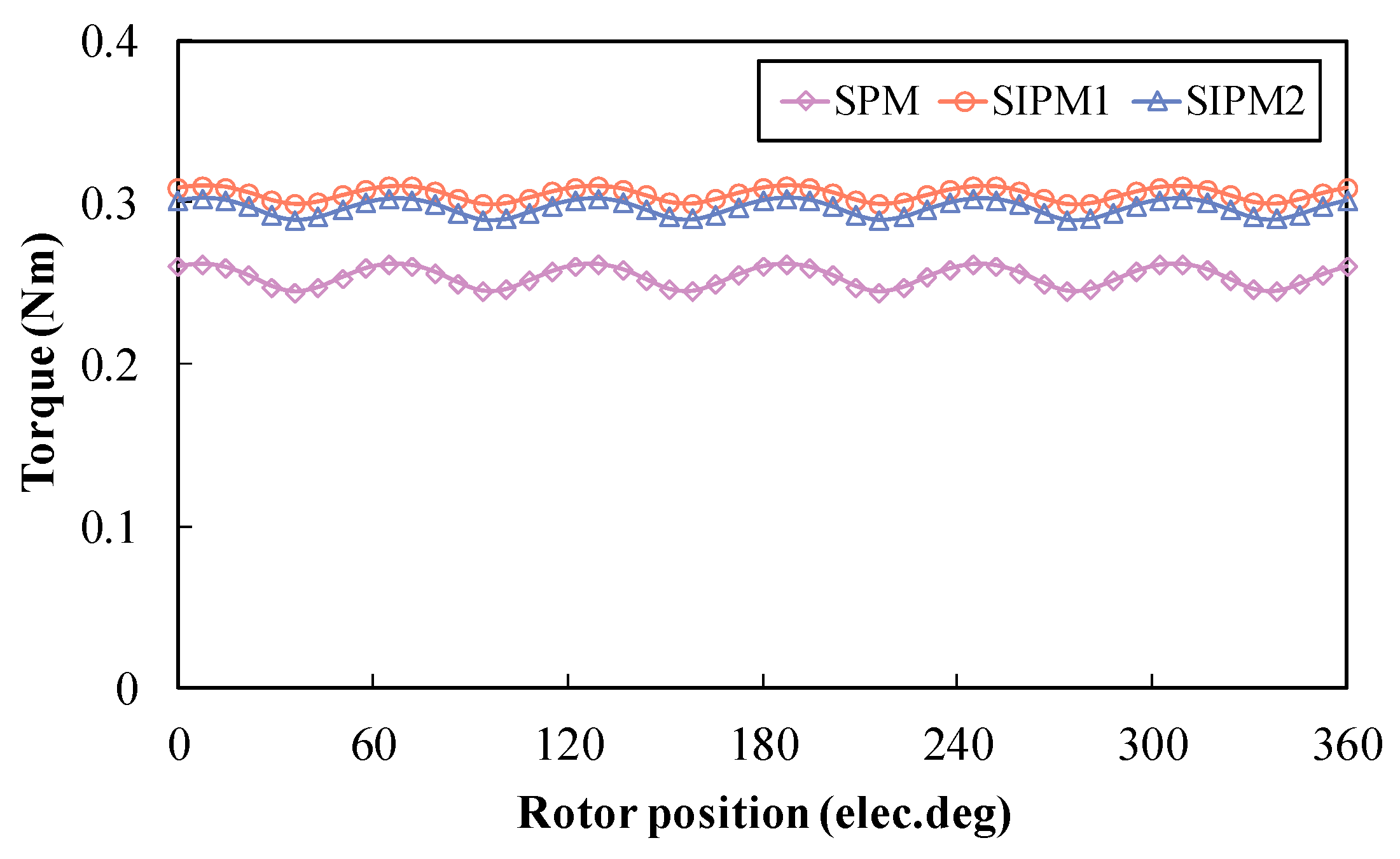

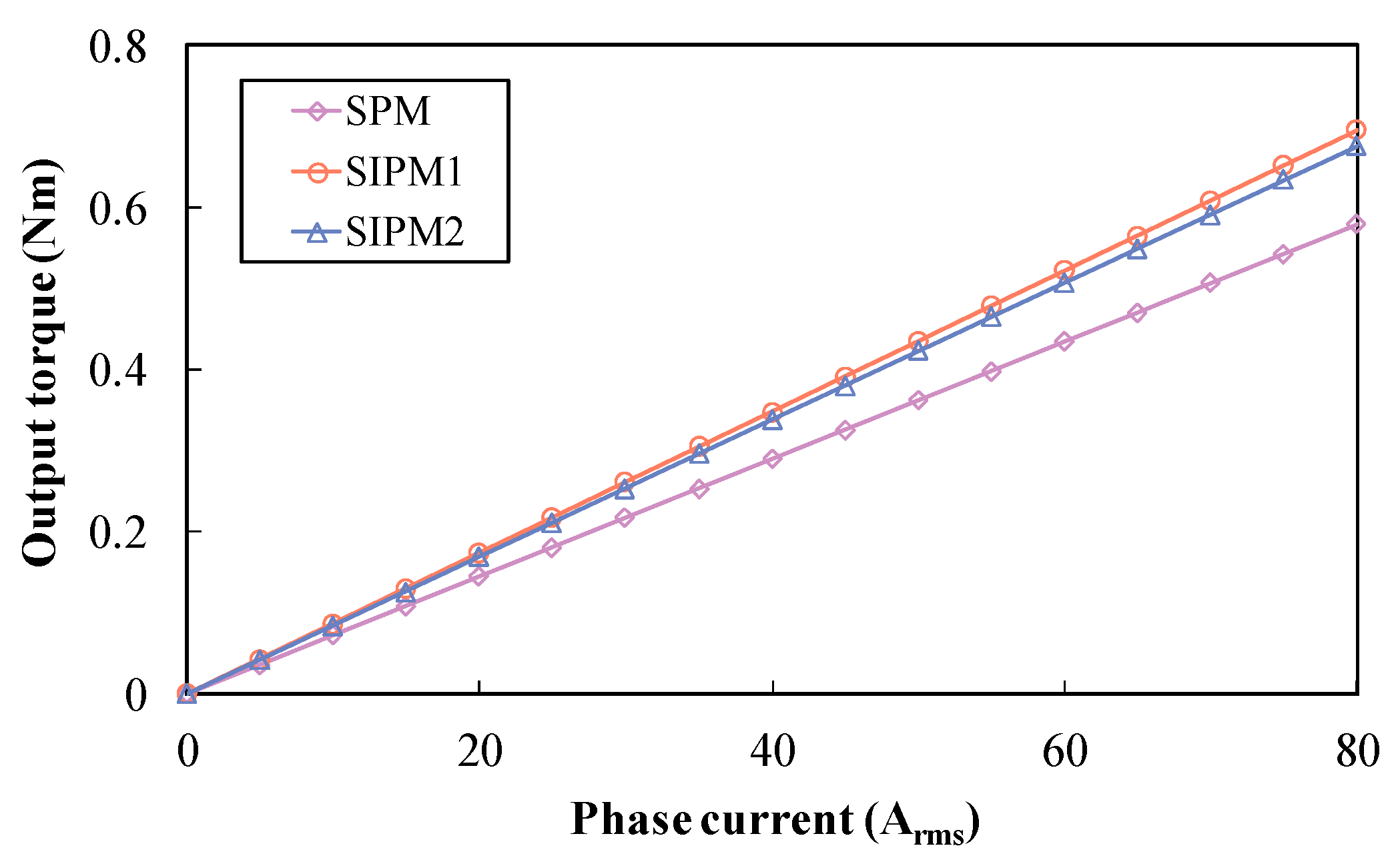

4.2. Output Torque Characteristics

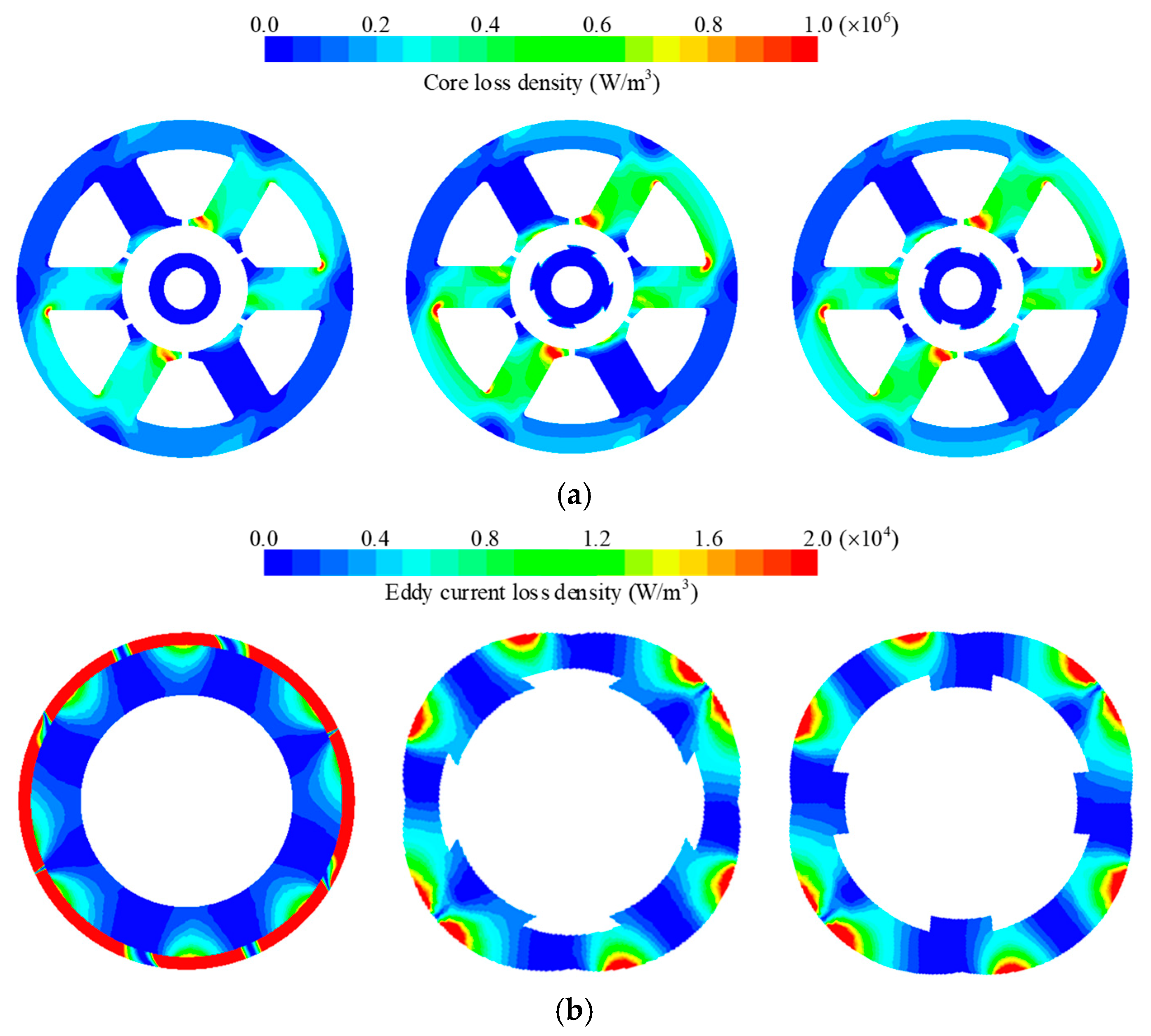

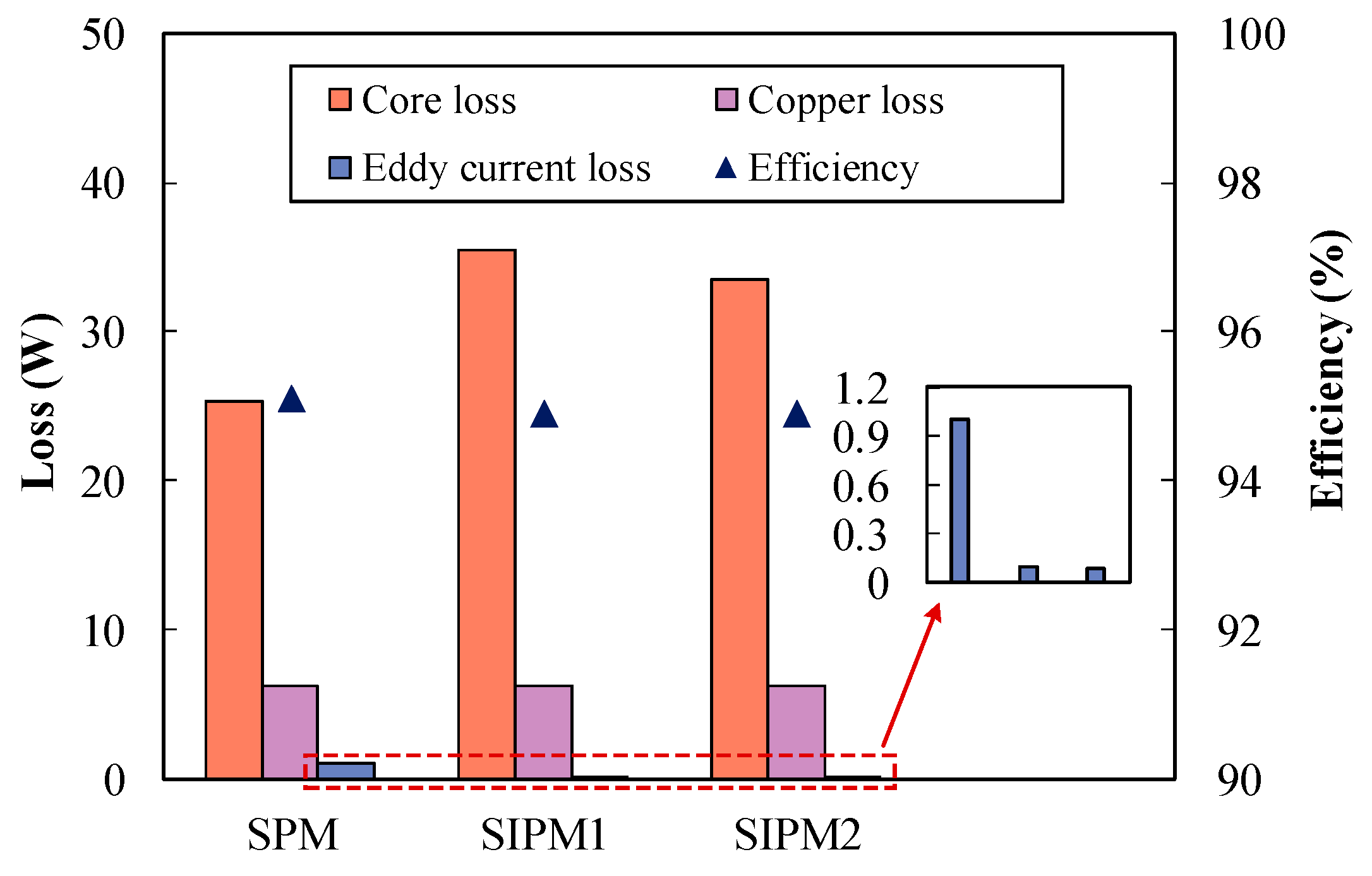

4.3. Energy Loss and Efficiency

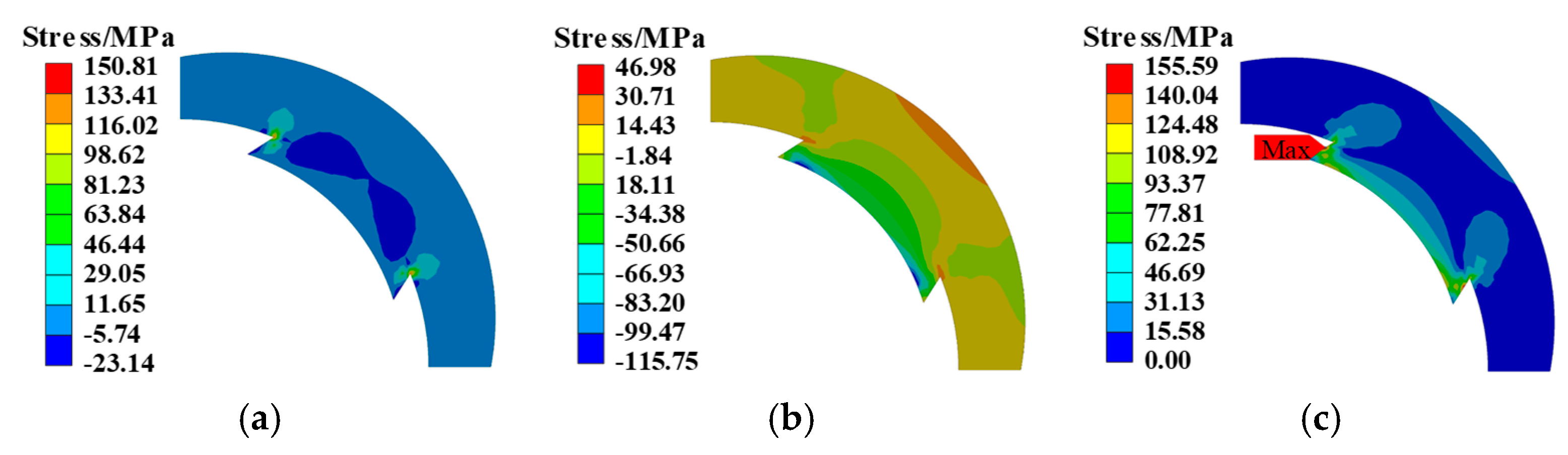

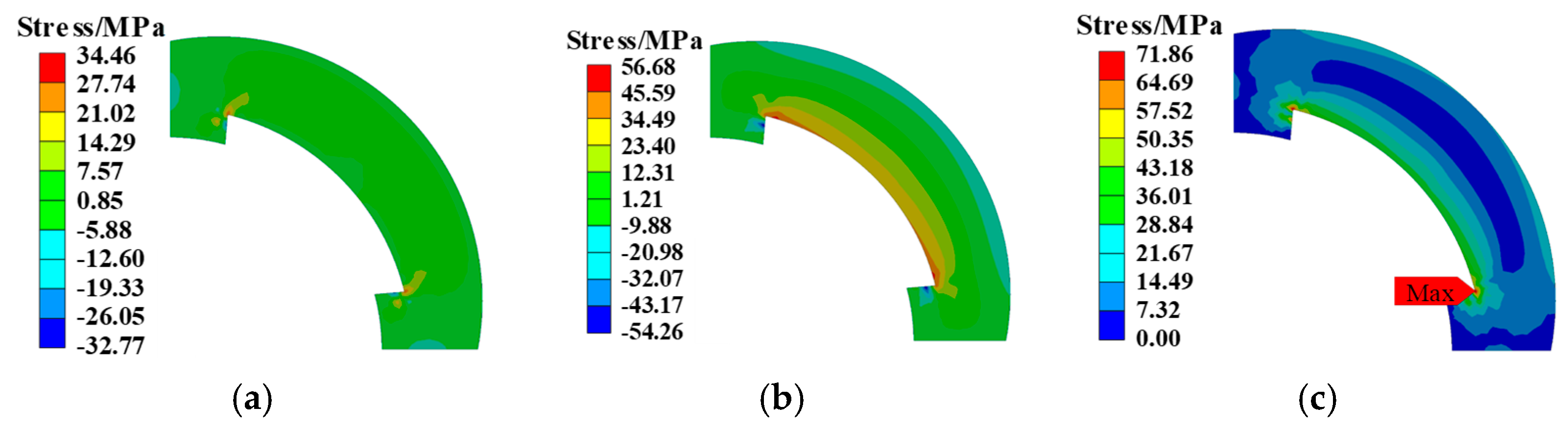

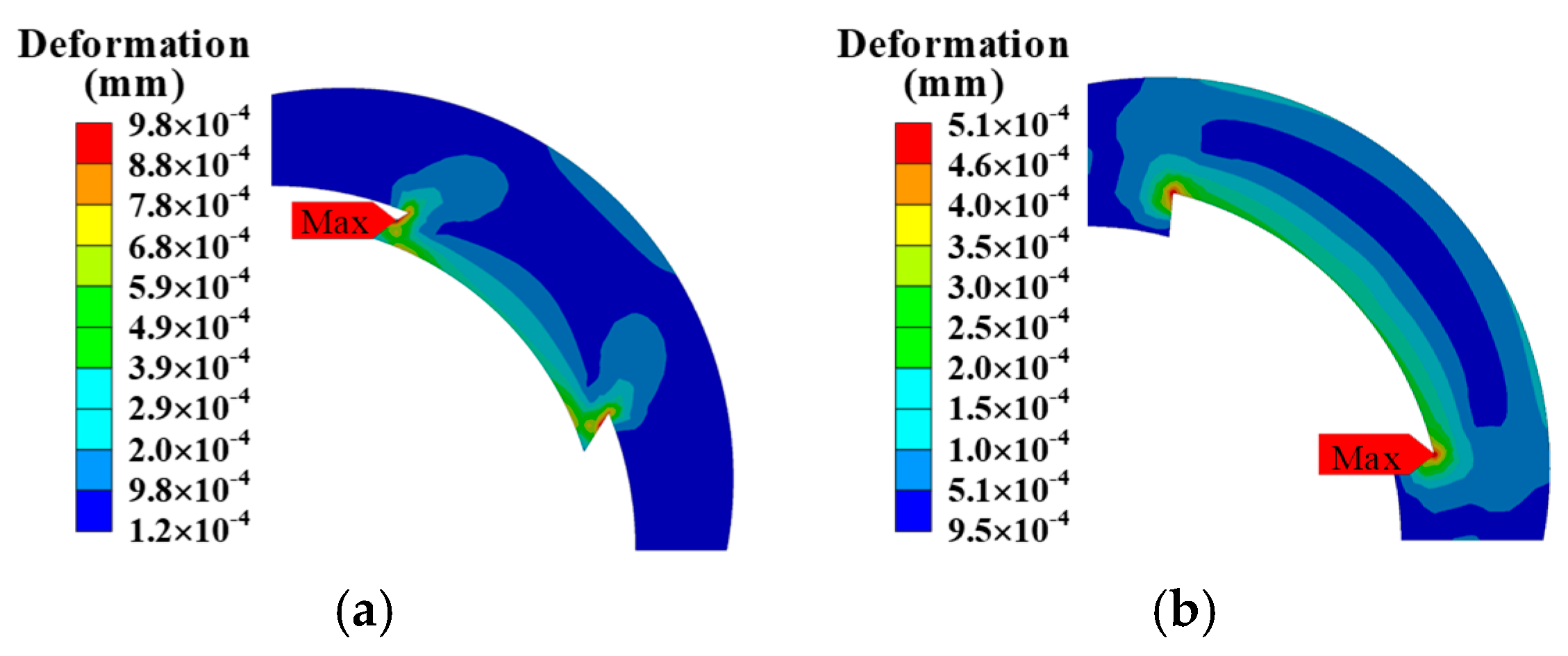

4.4. Mechanical Strength

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luo, X.; Pan, L.; Yang, J. Mineral Resource Constraints for China’s Clean Energy Development under Carbon Peaking and Carbon Neutrality Targets: Quantitative Evaluation and Scenario Analysis. Energies 2022, 15, 7029. [Google Scholar] [CrossRef]

- Changmai, P.; Deka, S.; Kumar, S.; Babu, T.S.; Aljafari, B.; Nastasi, B. A Critical Review on the Estimation Techniques of the Solar PV Cell’s Unknown Parameters. Energies 2022, 15, 7212. [Google Scholar] [CrossRef]

- Wei, D.; He, H.; Cao, J. Hybrid electric vehicle electric motors for optimum energy efficiency: A computationally efficient design. Energy 2020, 203, 117779. [Google Scholar] [CrossRef]

- Li, Z.; Khajepour, A.; Song, J. A comprehensive review of the key technologies for pure electric vehicles. Energy 2020, 182, 824–839. [Google Scholar] [CrossRef]

- Beik, O.; Schofield, N. High-Voltage Hybrid Generator and Conversion System for Wind Turbine Applications. IEEE Trans. Ind. Electron. 2017, 65, 3220–3229. [Google Scholar] [CrossRef]

- Ismagilov, F.R.; Vavilov, V.E.; Miniyarov, A.H.; Urazbakhtin, R.R. Super high-speed electric motor with amorphous magnetic circuit for the hydrogen fuel cell air supply system. Int. J. Hydrogen Energy 2018, 43, 11180–11189. [Google Scholar] [CrossRef]

- Golovanov, D.; Gerada, D.; Sala, G.; Degano, M.; Trentin, A.; Connor, P.H.; Xu, Z.; La Rocca, A.; Galassini, A.; Tarisciotti, L.; et al. 4-MW Class High-Power-Density Generator for Future Hybrid-Electric Aircraft. IEEE Trans. Transp. Electrif. 2021, 7, 2952–2964. [Google Scholar] [CrossRef]

- Dadvar, M.; Afshari, E. Analysis of design parameters in anodic recirculation system based on ejector technology for PEM fuel cells: A new approach in designing. Int. J. Hydrogen Energy 2014, 39, 12061–12073. [Google Scholar] [CrossRef]

- Hong, Z.; Li, Q.; Han, Y.; Shang, W.; Zhu, Y.; Chen, W. An energy management strategy based on dynamic power factor for fuel cell/battery hybrid locomotive. Int. J. Hydrogen Energy 2018, 43, 3261–3272. [Google Scholar] [CrossRef]

- Shen, J.; Hao, H.; Yuan, C. FEA study on circumferential grooves on rotor retaining sleeve of high-speed pm brushless motors. Proc. Chin. Soc. Electr. Eng. 2012, 12, 53–60. [Google Scholar]

- Binder, A.; Schneider, T.; Klohr, M. Fixation of buried and surface mounted magnets in high-speed permanent magnet synchronous motors. In Proceedings of the Fourtieth IAS Annual Meeting. Conference Record of the 2005 Industry Applications Conference, Hong Kong, China, 2–6 October 2005; Volume 42, pp. 1031–1037. [Google Scholar] [CrossRef]

- Li, C.; Wang, K.; Liu, C. Torque Improvement and Cost Reduction of Permanent Magnet Motors With a Dovetailed Consequent-Pole Rotor. IEEE Trans. Energy Convers. 2018, 33, 1628–1640. [Google Scholar] [CrossRef]

- Rao, J.; Qu, R.; Ma, J.; Xu, W. Investigate the influence of magnetic bridge design on mechanical strength and electromagnetic characteristics in high speed IPM motors. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 22–27. [Google Scholar] [CrossRef]

- Arumugam, P.; Xu, Z.; La Rocca, A.; Vakil, G.; Dickinson, M.; Amankwah, E.; Hamiti, T.; Bozhko, S.; Gerada, C.; Pickering, S.J.; et al. High-Speed Solid Rotor Permanent Magnet Motors: Concept and Design. IEEE Trans. Transp. Electrif. 2016, 2, 391–400. [Google Scholar] [CrossRef]

- Liu, Y.; Ou, J.; Schiefer, M.; Breining, P.; Grilli, F.; Doppelbauer, M. Application of an Amorphous Core to an Ultra-High-Speed Sleeve-Free Interior Permanent-Magnet Rotor. IEEE Trans. Ind. Electron. 2018, 65, 8498–8509. [Google Scholar] [CrossRef]

- Jun, H.-W.; Lee, J.; Lee, H.-W.; Kim, W.-H. Study on the Optimal Rotor Retaining Sleeve Structure for the Reduction of Eddy-Current Loss in High-Speed SPMSM. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Zhao, W.; Lipo, T.A.; Kwon, B.-I. Optimal Design of a Novel Asymmetrical Rotor Structure to Obtain Torque and Efficiency Improvement in Surface Inset PM Motors. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Zubkov, Y.V.; Vereshagin, V.E. Designing of High Speed Permanent Magnet Electric Motors with Rotor Strength Verification. In Proceedings of the 2021 International Ural Conference on Electrical Power Engineering (UralCon), Magnitogorsk, Russia, 24–26 September 2021; pp. 414–418. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, Z.Q.; Ombach, G. Torque Enhancement of Surface-Mounted Permanent Magnet Motor Using Third-Order Harmonic. IEEE Trans. Magn. 2014, 50, 104–113. [Google Scholar] [CrossRef]

- Du, Z.S.; Lipo, T.A. High Torque Density and Low Torque Ripple Shaped-Magnet Motors Using Sinusoidal Plus Third Harmonic Shaped Magnets. IEEE Trans. Ind. Appl. 2019, 55, 2601–2610. [Google Scholar] [CrossRef]

| Parameter | SPM | SIPM1 | SIPM2 |

|---|---|---|---|

| Value | |||

| Number of slots | 6 | ||

| Number of poles | 4 | ||

| Stator outer diameter (mm) | 80 | ||

| Stator inner diameter (mm) | 30 | ||

| Air-gap length (mm) | 1.5 | ||

| Rotor outer diameter (mm) | 28.5 | ||

| Stack length (mm) | 30 | ||

| Sleeve thickness (mm) | 1 | 0 | |

| PM thickness (mm) | 4 | - | |

| DC Voltage (V) | 24 | ||

| Rated phase current (Arms) | 35 | ||

| Rated speed (r/min) | 25,000 | ||

| Parameter | Rotor Core | PM |

|---|---|---|

| Density (kg/m3) | 7650 | 7650 |

| Young’s modulus (GPa) | 210 | 160 |

| Poisson ratio | 0.27 | 0.24 |

| CTE(μm/m/°C) | 12 | 12 |

| Tensile strength (MPa) | 450 | 80 |

| Parameter | SIPM1 | SIPM2 |

|---|---|---|

| Value | ||

| θ1 (°) | 55 | 60 |

| θ2 (°) | 40 | 10 |

| h1 (mm) | 1 | |

| h2 (mm) | 1 | 1.2 |

| h3 (mm) | 0.5 | 0.9 |

| Characteristic | SPM | SIPM1 | SIPM2 |

|---|---|---|---|

| Tout (Nm) | 0.254 | 0.311 | 0.297 |

| Tout (%) | 100 | 122.4 | 116.9 |

| ΔTpk-pk (Nm) | 0.017 | 0.012 | 0.013 |

| Tc (mNm) | 5.54 | 3.75 | 4.21 |

| Tripple (%) | 6.7 | 3.8 | 4.4 |

| Vpm (cm3) | 7.9 | 7.9 | 7.9 |

| ηpm (Nm/cm3) | 0.032 | 0.039 | 0.038 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, K.; Liu, Y.; Wei, Z.; Yang, J.; Guo, B. A Novel High-Speed Permanent Magnet Synchronous Motor for Hydrogen Recirculation Side Channel Pumps in Fuel Cell Systems. Energies 2022, 15, 8913. https://doi.org/10.3390/en15238913

Ma K, Liu Y, Wei Z, Yang J, Guo B. A Novel High-Speed Permanent Magnet Synchronous Motor for Hydrogen Recirculation Side Channel Pumps in Fuel Cell Systems. Energies. 2022; 15(23):8913. https://doi.org/10.3390/en15238913

Chicago/Turabian StyleMa, Kang, Ye Liu, Ziqiang Wei, Jianfei Yang, and Baocheng Guo. 2022. "A Novel High-Speed Permanent Magnet Synchronous Motor for Hydrogen Recirculation Side Channel Pumps in Fuel Cell Systems" Energies 15, no. 23: 8913. https://doi.org/10.3390/en15238913

APA StyleMa, K., Liu, Y., Wei, Z., Yang, J., & Guo, B. (2022). A Novel High-Speed Permanent Magnet Synchronous Motor for Hydrogen Recirculation Side Channel Pumps in Fuel Cell Systems. Energies, 15(23), 8913. https://doi.org/10.3390/en15238913