1. Introduction

The Food and Agriculture Organization of the United Nations (FAO) estimates that livestock emissions represent approximately 7.1 Gt of CO

2eq. per year [

1]. The mitigation of greenhouse gas (GHG) emissions is one of the greatest challenges for the livestock sector in the context of climate change. It can be estimated that livestock accounts for 14.5–16.5% of GHG emissions related to human activities [

1,

2,

3]. Slightly different estimates can be found in other sources [

3,

4,

5], but the level is similar, and the differences are most often the result of a different emission calculation methodology.

Even small upward revisions to the percentage can make a difference to the social and political structure of the livestock emissions problem. Especially in view of the ongoing calls to reduce the livestock sector, this issue is very important to livestock farmers and consumers [

6]. Since the current trend, with the increasing demand for food [

7,

8], is to increase the unit efficiency of livestock production (without increasing the herd), it may have a smaller impact on reducing GHG emissions than a general reduction in livestock production (and thus reducing food supply) [

1,

3,

5,

9].

It should be noted that 1/5 of all GHG emissions from above mentioned production comes from milk production [

1,

2,

3,

10]. This industry, therefore, causes some of the largest emissions among livestock production. Since much more than 3/4 of GHG emissions are generated even before the milk leaves the farm, this serves as a signal to look for techniques to reduce air pollution of this type in the proper management of the farm [

11,

12,

13,

14].

The most significant GHG emissions from dairy cows that contribute to global warming are carbon dioxide (CO

2) (related to fossil fuel consumption and land use change), methane (CH

4) (which is a physiological consequence of enteric fermentation and manure) and nitrous oxide (N

2O) (from manure management, fertilization and the process of nitrification and denitrification) [

15,

16].

To assess the impact of individual emissions on global warming, “carbon dioxide equivalent” is used to calculate global warming potential [

11]. In this respect, the methane generated on the farm is a gas 25–28 times more harmful than the equivalent of carbon dioxide (CO

2) [

17,

18,

19], while nitrous oxide (N

2O) is even 265–298 times greater than CO

2eq [

18,

19,

20,

21]. Emissions from inappropriate manure management alone are very high; up to 50% of the N

2O generated worldwide could have been avoided if the manure had not been left on pastures [

22,

23]. Nitrate leaching and ammonia leakage during field use, as well as improper storage and direct emissions, are also strongly related to this.

The impact of animal nutrition, as well as manure farming (including feed residue), on emissions is quite complex and difficult to quantify. The economic and ecological effect includes the carbon footprint of the above-mentioned activities. In the case of manure management, the situation is different; each of its conversions, or its appropriate protection during storage, brings measurable benefits in reducing greenhouse gas (and ammonia) emissions from animal production [

24,

25,

26,

27]. It should be noted that improper manure storage not only increases CH

4, N

2O, CO

2 and NH3 emissions, but also leads to a loss of nutrients. Such action directly results in fertilization and ecological losses (excessive emissions, leaching), but indirectly in its price decrease. Higher doses per hectare are necessary [

28,

29,

30].

This article presents possible scenarios for the use of cow manure as fertilizer or as a substrate for a biogas plant on the example of a typical, medium-sized farm in Poland. The first solution is a typical approach in Europe–in total, 1.4 billion tons of livestock manure were produced annually in the European Union and the United Kingdom in 2016–2019 [

26,

31], the second is gaining more and more importance due to better fertilizer quality of the digestate and lower GHG emissions before and after fertilization [

26,

27,

32].

In Europe, almost 70% of all manure is generated by only 6 countries (Germany, Spain, Italy, France, Poland and the United Kingdom), of which as many as 3/4 comes from cows [

31]. The problem of emissions from manure is continually growing in the entirety of Europe, the reason being the constantly growing demand for meat and dairy products. This problem will particularly affect the countries of eastern Europe, where 61% of all manure is produced and stored in a traditional way; solid manure or farmyard manure (i.e., mixed feces, urine and straw) ends up in uncompacted and uncovered piles/heaps [

33]. Improper and/or long-term storage of manure, as well as its direct application to fields, can cause significant negative economic, ecological and even social effects [

6,

10,

30,

34]. One of the most effective methods of reducing the above-mentioned negative effects is the processing of manure by anaerobic digestion (and then using the digestate as a valuable fertilizer) [

6,

10,

27,

32,

35,

36,

37,

38,

39]. Methane fermentation, and, most of all, the need for a very short storage time, enables the reduction of GHG emissions related to manure management by several dozen percent [

2,

6,

27,

36]. In addition, the production of biofuel (biogas or biomethane) can be effectively used for the production of heat and electricity, and thus reduce overall emissions from farms that utilize this biofuel instead of fossil fuels [

10,

35,

40,

41,

42,

43]. Noteworthy are the reports in the literature according to which the use of digestate in crops increases their yields [

44,

45,

46,

47,

48,

49]. Another advantage is the inhibitory nature of the digestate for some harmful plant pathogens (including bacteria and fungi) and insects [

50,

51,

52]. Field studies, including those carried out over a period of several years in fully functional fields, have shown that the addition of digestate increases plant resistance to diseases [

42,

49,

50].

In addition, this article presents a simple analysis of the results developed for 2021 and in the same period in 2022 (during the energy and indirect fertilization crisis) on the example of the same farm. Prices for energy, fertilizers and, consequently, food, have risen sharply over the past two years and appear to continue to rise after Russia’s invasion of Ukraine. The disruptions caused by Russia’s war in Ukraine highlighted the intertwined nature of global energy, fertilizer and food supply chains as both countries play a key role in world supply. Globally connected supply chains and food markets are closely related to inputs (i.e., agrochemicals, fertilizers, fuel, feed, capital and labor) [

53,

54,

55]. According to the World Food Program, the number of people suffering from severe food insecurity has more than tripled between 2017 and 2021, and could rise 17% to 323 million this year as a result of the war [

56].

The presented analyses include two approaches to the use of manure. The first is its periodic storage and subsequent fertilization of farmland, and the second is its direct use as a substrate in anaerobic digestion to produce biogas, and then the use of the digestate as a fertilizer. As part of the comparison of both approaches to manure management, differences in nitrous oxide and methane emissions were indicated, and energy and economic calculations were made for a functioning medium-sized cow farm. The paper compares the economic result we would obtain now and what was possible in the same period a year ago. At that time, two variants were analyzed: the first without the use of manure for energy purposes (without a biogas plant, and the second with a biogas installation based only on manure. This type of solution is recommended in the Strategic Plan for Poland as part of the reform of the common agricultural policy [

57] and is consistent with the postulates of mitigating EU climate change, including influencing the carbon dioxide emission trading system.

A new approach in this work was the economic balance of the investment in a biogas plant with a cogeneration installation for manure processing, in particular during the energy and fertilizer crisis (on a case study of a Polish dairy farm). Many investors, fearing an increase in the prices of materials and services, etc., wonder whether this type of investment makes sense. As the calculations for a medium-sized farm with dairy production have shown, these fears are not justified. In addition, owners of dairy farms should take into account the ecological aspect, which financially (and in terms of perspective and image) affects future benefits.

2. Materials and Methods

The materials and methods section is divided into 5 parts, as follows:

The subject and scope of the work and a description of the case study, for which two basic scenarios were presented to be considered in economic (and indirectly ecological) terms;

Methods and formulas for calculating methane and nitrous oxide emissions from manure (according to international guidelines, this was done using estimation methods for Polish farms);

Methods to calculate the carbon dioxide equivalent, emission fees and the adoption of current average energy prices, which are the basis for economic estimates;

Laboratory methods for determining biogas efficiency from manure samples taken from the barn according to international guidelines through periodic tests, the so-called batch culture;

Methods and formulas for calculating the estimated energy production as well as the thermal and electric power of a biogas plant with a cogeneration installation

2.1. Subject and Scope of the Work and a Description of the Case Study

This publication focuses on calculating energy, as well as economic values and greenhouse gas emissions. The input data, which constitute a case study, are taken from a breeding farm in Wielkopolska (Greater Poland) of an average size for the region. This paper presents the benefits of changing manure management directly as a fertilizer, compared to using it as a substrate for a biogas plant, and then applying the digestate as a fertilizer. As part of the calculations, it was shown what size the installation could be created with regard to the use of the entire mass of manure collected from the barns. The yield of heat and electricity was presented, as well as the expected reduction of GHG emissions converted into CO2 equivalent.

The case study is a farm near Poznań (Poland). The held livestock includes about 600 cows and an additional 900 sheep. The farm covers approximately 900 ha of arable land, almost half of which is intended for fodder purposes. It, in a traditional way for this part of Europe, manages manure directly as fertilizer. Its decision-makers are aware of other, more economically and ecologically effective solutions and are considering investing in biogas plants with the use of manure. This type of modernization and the search for new solutions are now often considered in similar farms throughout central and eastern Europe. The estimated calculations presented here may constitute concepts for future investment, especially in times of increasing energy (and indirectly fertilizing) challenges.

The case study farm is a cowshed feed feeding system operation. This type of feeding is associated with higher GHG and nitrogen emissions than a grazing system [

58,

59]. In simple terms, it consists of feeding cattle mainly with preserved grass silage and other additives. Everything that goes to the barn and is excreted by animals is first stored, and then usually transported to and spread upon fallow fields, but usually only twice a year (in spring and early summer), rarely at other times (in most central and eastern European countries, this is done from spring to autumn). This means that the manure is stored for a long time (often improperly), which generates economic losses (deterioration of its quality) and environmental losses (emissions of GHG and ammonia increase).

The present analyses only cover the issues of comparing the use of manure directly for fertilization and energy purposes (biogas production) and its impact on GHG emissions, without taking into account the issues of costs and emissions related to the transport of material, the costs of the built-up area (for a biogas plant or manure storage), etc.

This work considers two main scenarios of manure utilization:

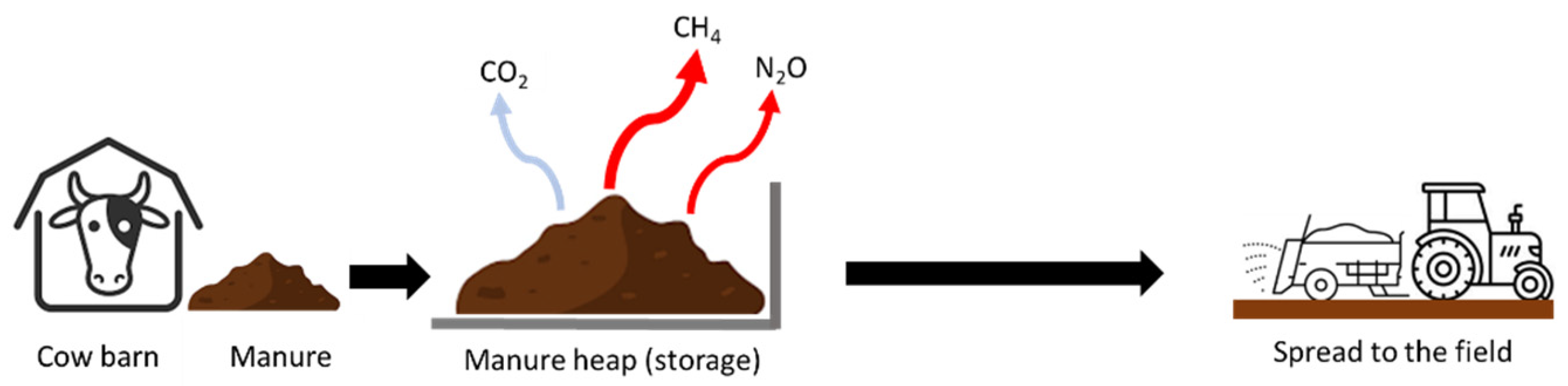

Scenario I: with manure storage on a heap and use at the right moment as a natural fertilizer (high GHG emissions). See

Figure 1.

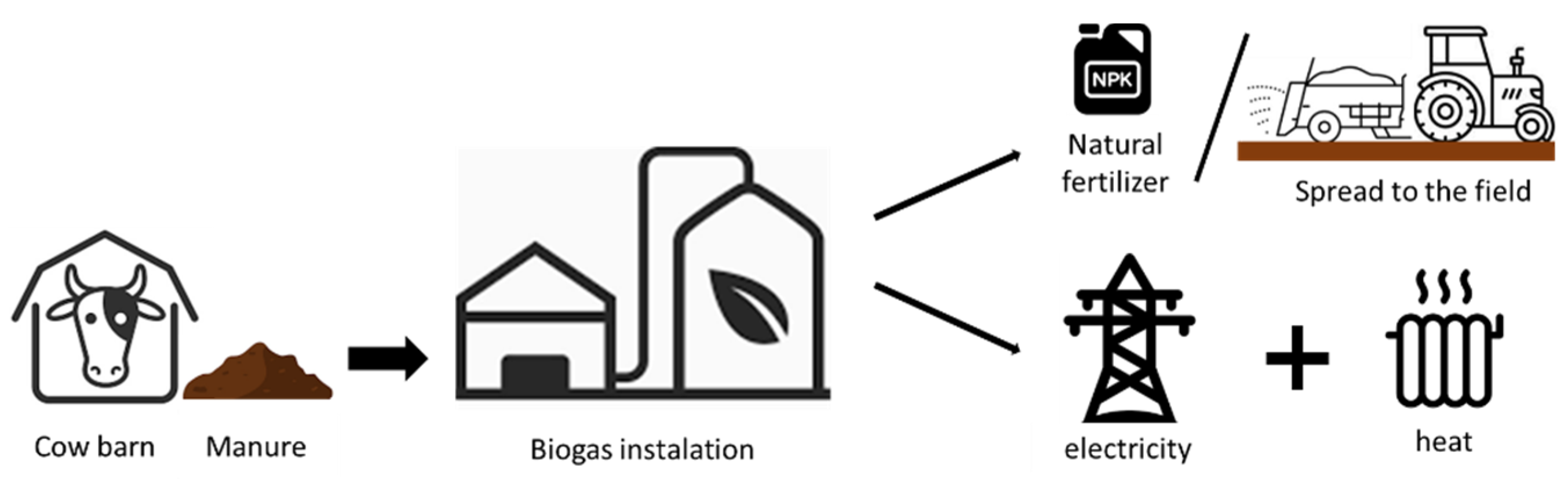

Scenario II: without manure storage, used as a substrate for biogas plants on an ongoing basis and then, in the form of digestate, used for fertilization (low GHG emissions and mainly related to CO

2; additional profits from energy sales (electricity and heat) and savings from lower fees for CO

2 equivalent emissions). See

Figure 2.

2.2. Determination of Direct CH4 and N2O Emissions from Manure

In order to calculate methane emissions from manure management, national values for the emission factors for dairy cows were used in accordance with the EU-wide Tier 2 methodology [

60]:

where:

EF—emission factor;

VS—mean daily amount of volatile excreted solids;

D/y—the number of days (in a year) used in the calculations;

BO—maximum CH4 production capacity of manure per animal and year;

CF—conversion from kg to m3;

MCF—methane conversion factor for manure management system (suitable for cool climate [

61]).

Volatile solids (VS) and the maximum CH

4 producing capacity (B

O) for cattle were adopted in accordance with the formulas from the international IPCC reports of 2006 and 2019 [

60,

61], as well as the national inventory report 2021 [

19]. As the calculations are made only for solid cow manure, the MS coefficient, the manure fraction of the livestock category, from the original formula was omitted. The calculations of methane emissions from manure per cow, as well as individual input factors are presented in

Table 1.

The MFC–methane conversion coefficient for solid manure management systems was adopted in accordance with the IPCC 2006 report for a cool climate of ≤10 °C (

Table 1, 0.17–2%) [

60]. The IPCC methodology [

60] was also used to calculate the direct emissions of nitrous oxide from cow manure, but the calculations are also based on values from Polish studies [

62,

63], in which

where:

N2OD (mm)—direct N2O emissions from cow manure (kg N2O/animal/year);

Nex—mean value of N excretion per animal and year;

EF3—emission factor for direct N2O emissions from solid cow manure;

CFN—conversion of (N2O−N) (mm) emissions to N2O (mm) emissions.

The parameters and factors for cattle for the estimation of N

2O emissions from manure are given in

Table 2.

Based on the IPCC guidelines, the Nex value for dairy cows was 70.26 kg N/head, assuming that the N retained by the animal (Nretention) was 0.2 [

60].

2.3. Determination of CO2 Equivalent, Emission Allowances and Energy Prices

The carbon dioxide equivalent for methane and nitrous oxide was adopted in accordance with the global warming potential (GWP), for methane wherein the factor was 25 and that for nitrous oxide, 298 [

17,

18,

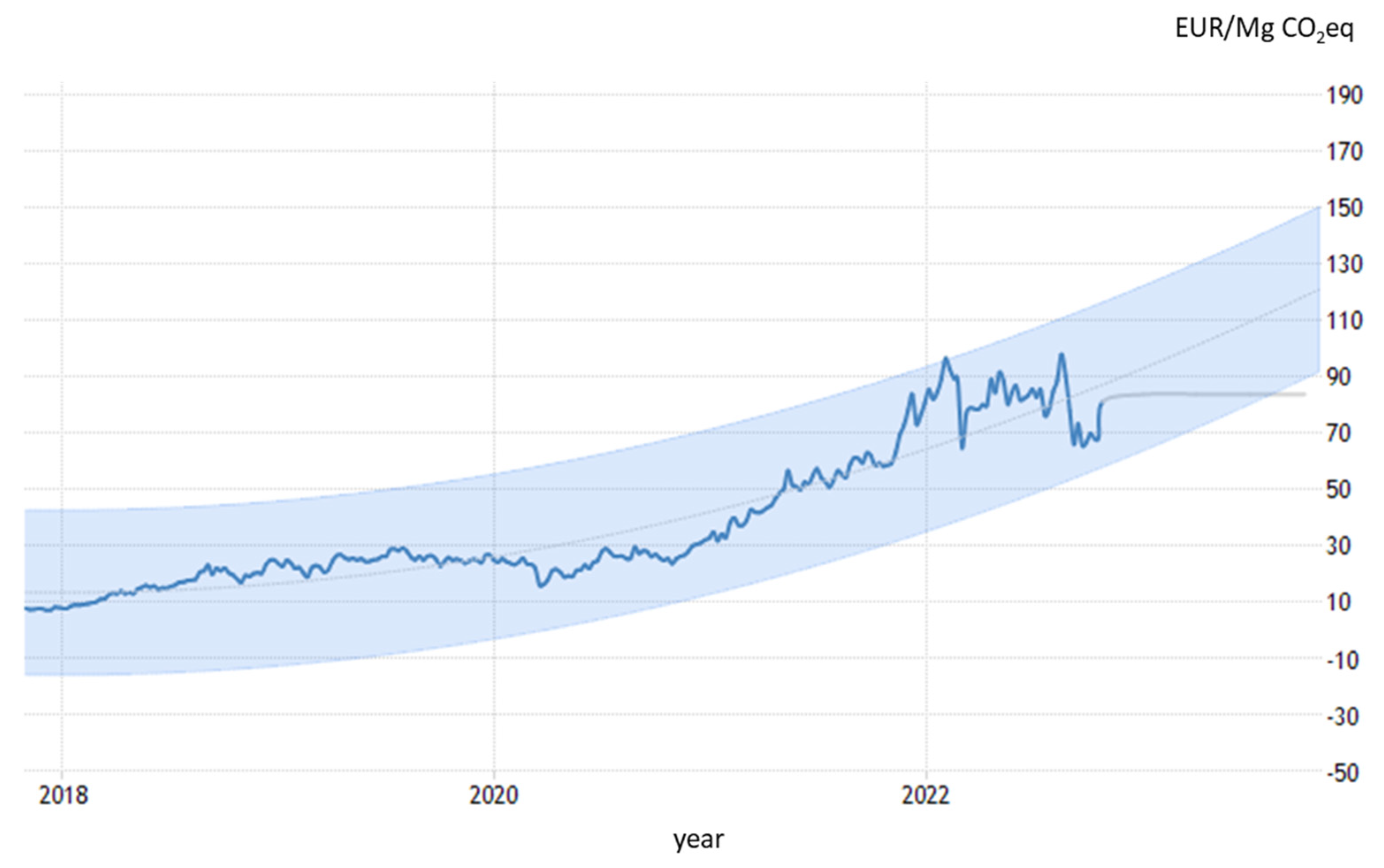

19]. In line with global macroeconomic models and Trading Economics analyst expectations, EU carbon permits are expected to reach EUR 83.74 by the end of this quarter, which is projected to remain somewhat fluctuant in the coming months [

64] (

Figure 3). The highest level of EUR 99.22 was achieved by carbon dioxide emission permits in the EU in August 2022 (

Figure 3).

The calculations assume the auction price of emission allowances from the market on 14 October 2022 amounted to EUR 68.12 per 1 for 1 Mg CO2eq.

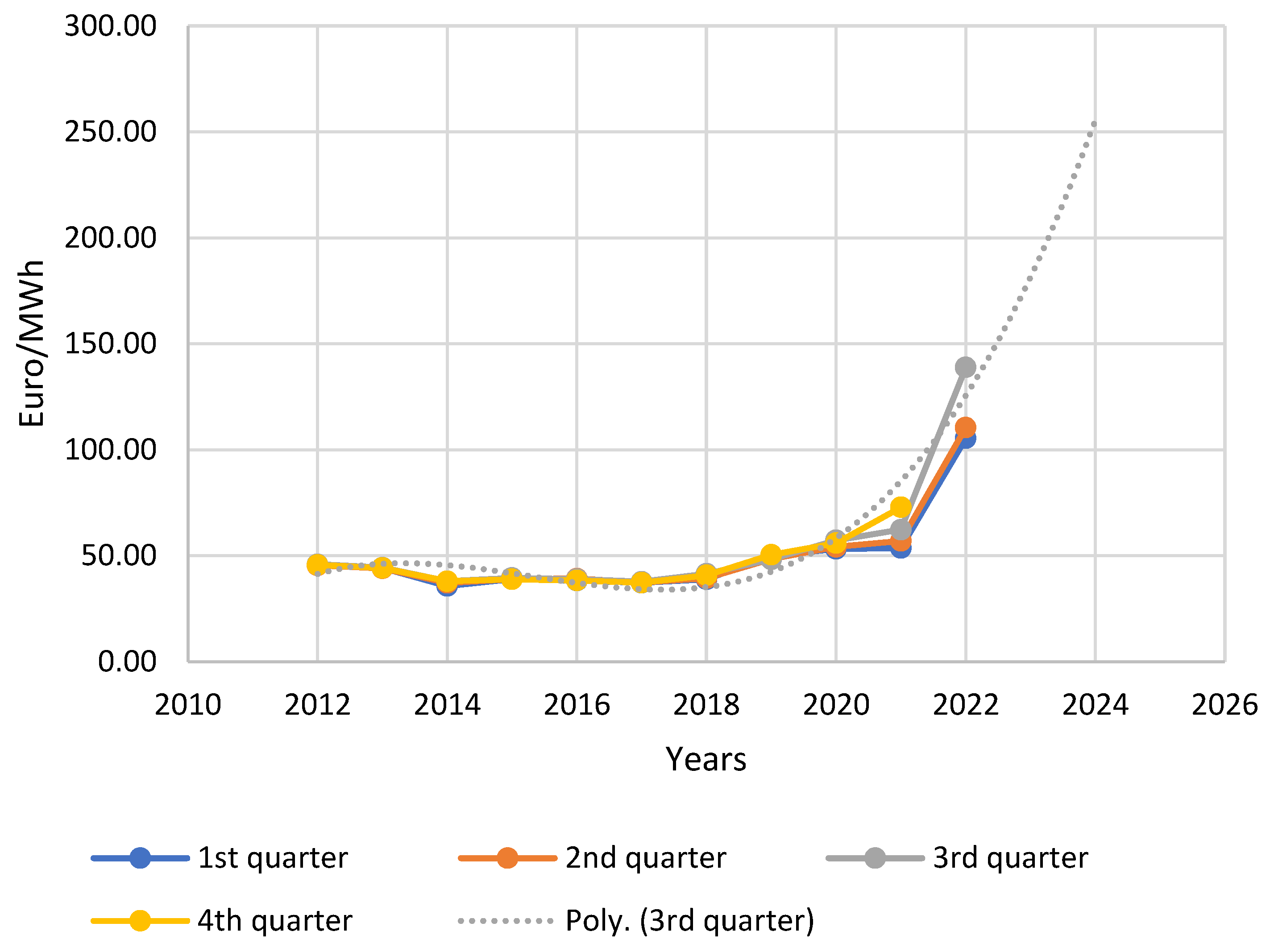

The Act of 20 February 2015 on renewable energy sources (the RES Act) caused the transition from the green certificate system to the auction system. In accordance with the law for new RES Installations, i.e., those that started generating electricity on or after 1 July 2016 (New Installations), the RES Act introduced new support regimes. This is a guaranteed electricity price in the form of feed-in tariffs (FiT) for small biogas plants (with a capacity of less than 0.5 MW) [

65]. Currently, this price is at the level of 157 per 1 MWh. At the market price in the third quarter of 2022, this is PLN 615.28/MWh [

66], which, at the average EUR exchange rate of PLN 4.83/EUR (as of 14 October 2022), is the equivalent of almost EUR 127.4. The guaranteed amount is therefore only approximately 23% higher than the market amount. It is not known how the situation will change after December 2022; from December 1, the maximum electricity price for sensitive entities and micro-, small- and medium-sized enterprises will be set at PLN 785/MWh, and for household consumers, after exceeding the consumption limits, at PLN 699/MWh–according to projections of the Ministry of Climate [

67]. Note: the prices of heat sold on the regional market are usually around EUR 22 per GJ.

2.4. Investigation of Biogas Efficiency

The methodology for testing the efficiency of biogas produced from substrates is based on the German guidelines contained in the standards DIN 38414/S8 [

49] and VDI 4630 [

50]. The cited guidelines are one of the basic methods of assessing biogas profitability. Our Laboratory of Ecotechnology is the first facility in the country to receive a certificate confirming the high quality of methane fermentation research, issued by the German organizations Verband Deutscher Landwirtschaftlicher Untersuchungs- und Forschungsanstalten–VDLUFA [

68] and Kuratorium für Technik und Bauwesen in der Landwirtschaft–KTBL [

69].

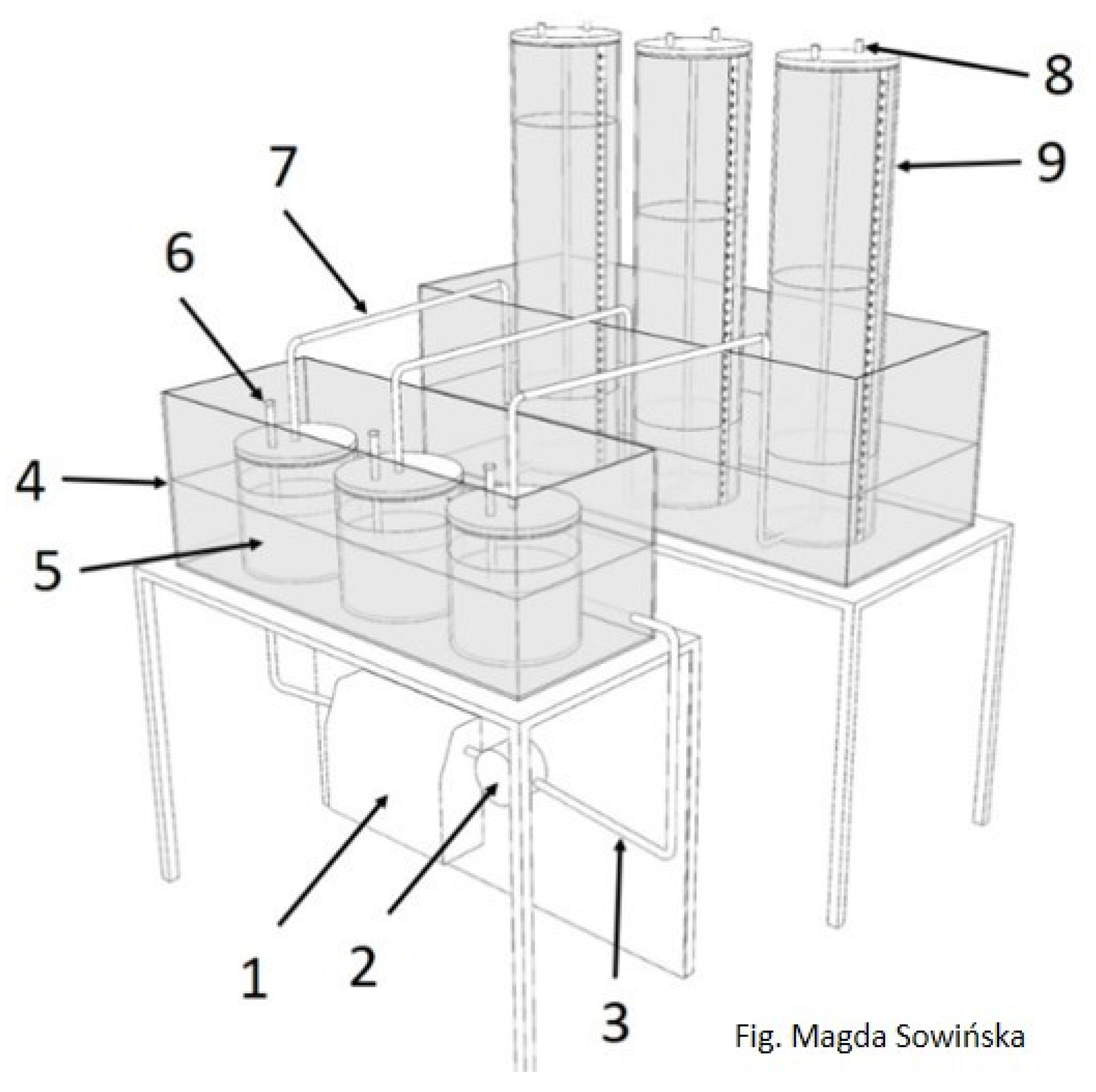

The volume of biogas and the share of methane produced from the collected manure samples were determined on the basis of batch culture studies at the Ecotechnology Laboratory of the University of Life Sciences in Poznań (PULS), one of the largest Polish biogas laboratories.

The biogas efficiency of cow manure was tested in a special 3-chamber reactor. Here, anerobic digestion processes take place in glass tubes (reactors with a capacity of 2 dm

3). A diagram of an exemplary 3-reactor station is shown in

Figure 4.

Each reactor has a constant temperature of approximately 39 °C due to the water bath. Each test is performed 3 times, always taking approximately 50 g of dry organic mass of the substrate and this being placed in reactors to which an inoculum of fermenting microorganisms is added. Control samples to compare the course and effects of fermentation are filled only with the inoculum and run for the same period of time, also in 3 replications. The bacterial inoculum is the liquid fraction of the digestate supplied from a properly working fermentation chamber. The volume of generated biogas from the reactors is read every 24 h. With the help of the Geotech GA5000 automatic multi-parameter device (QED Environmental Systems Ltd., Coventry, Uk), a qualitative analysis is then carried out, i.e., the proportion of basic gases (i.e., O2; CO2, CH4 and H2S, H2) is determined.

To ascertain the exact production of biogas from a given substrate, the results of each sample are recalculated by subtracting the volume of gas generated in the control experiments (wherein the substrate is only the inoculum). On this basis, further calculations are possible to estimate the energy efficiency of the future process and to determine operational guidelines.

2.5. Biogas Profitability

Profitability calculations are based on the use of manure directly as a fertilizing substance or as a sole or co-substrate in methane fermentation processing under thermophilic conditions. We assumed that the biogas plant in the case study will have a biogas storage facility and a cogeneration installation (CHP), i.e., it will burn the produced biogas in order to generate electricity and heat for sale.

The amount of electricity (Ee [MWh]) generated in the cogeneration installation formed from methane (contained in biogas) was determined in accordance with the formula:

where:

VCH4—volume of methane produced in the fermentation process (m3);

WCH4—energy value of methane contained in 1 m3;

Ƞe—electric efficiency of CHP unit.

The heat quantity (Et [MWh]) generated in the cogeneration installation was ascertained in accordance with the formula:

where:

VCH4—volume of methane produced in the fermentation process (m3);

WCH4—energy value of methane contained in 1 m3;

Ƞt—thermal efficiency of CHP unit.

The electricity produced by the cogeneration installation, operating for a certain number of hours a year, enables the estimation of the future electric power of the biogas plant (Pe [MW]) according to the formula:

where:

Ee—produced electricity per year;

t—operating time of the cogeneration installation in a year.

For thermal power (Pt [MW]), a similar equation was used:

where:

Et—produced heat per year;

t—operating time of the cogeneration installation in a year.

Heat production is usually presented using the unit–GJ. To express it in MWh, a conversion factor was adopted, which was–1 MWh equals 3.6 GJ.

Table 3 presents the coefficients adopted for energy calculations.

The electric and thermal efficiency of CHP unit indicators are not constant, but characteristic for a given installation and the operating regime of a biogas plant. For the sake of greater comparability, the values of 0.4 and 0.45 are given for them in

Table 3 (which is possible to achieve in most cases). The operating time of the CHP unit (t) depends mainly on the technology of generating individual components and the type of biogas plant equipment. First of all, this is related to the time needed to perform the annual component service. The operation time of individual biogas plants between servicing is quite varied and ranges from 7400 to 8400 h per year. As the case study assumes estimates for a technologically new biogas plant, the value in the upper range, i.e., 8200 h per year, was adopted.

3. Results

On a deliberate basis, some of the calculations presented in this work are similar or the same as in other publications. This is a deliberate action that allows a comparison of the results from the same season of 2021 and the current season of 2022 for similar technologies and working conditions.

3.1. Emission and Economic Calculations for Scenario I

For the purposes of the analysis of Scenario I—manure storage on a heap and use at the right moment as a natural fertilizer—calculations were used in accordance with formulas 1 and 2, assuming that the number of animals, i.e., dairy cows, was 600 units. The final results are shown in

Table 4.

According to the national fertilization plan for farmland, manure can only be applied from 1 March to 31 October. As spreading takes place only twice during this period due to the cultivation, it is kept in a heap on the farm almost the duration. The weight of fresh manure produced annually amounts to an average of approximately 12 thousand Mg (i.e., 55 kg/cow and per day). Due to the significant hydration of fresh manure (a mixture of feces, urine and litter), the emissions calculations refer to the solid manure fraction (assumptions in line with IPCC reports). According to this approach, for the above-mentioned period, emissions of carbon dioxide equivalent (as a sum corresponding to methane and nitrous oxide) would be approximately 183.4 Mg CO2eq (only from the solid part of the manure). Since nitrous oxide has a 10 times greater impact on global warming, with almost 10 times lower direct emissions than methane, their masses generated during the research period do not differ greatly from each other (approximately 85 and 99 Mg CO2eq/year, respectively).

3.2. Emission and Energy Calculations for Scenario II

Manure methane fermentation is usually quite uniform and takes about 20–24 days. The length of the fermentation process normally depends on the production technology, the type and method of laying the litter [

71] and the way of feeding the animals (type of diet) [

72]. However, the resulting product conventionally has a similar composition and is characterized by a high content of organic matter and nutrients.

The biogas and methane efficiency from the solid fraction of cow farmyard manure, as well as the basic results of the physico–chemical analysis, including the content of dry mass (TS) and organic dry mass (VS), as well as the elements of total carbon (C), total nitrogen (N) and their ratio generated in own laboratory and obtained from three different manure storage periods [

34,

36,

62], are given in

Table 5.

The first variant of Scenario II consisted in estimating only the yearly volume of biogas generated from the farm manure. In line with this assumption, we calculated that the annual amount of produced methane would exceed 549,011.1 m

3. This data is presented in

Table 6.

In the case of using a cogeneration unit (CHP) for the volume of methane produced, it is possible to determine the amount of annual electricity and thermal energy production using Formulas (3)–(6). The results are approximately 2189 MWh (at a capacity of 0.27 MW) and approximately 2462 MWh (at a power of 0.30 MW), respectively. These figures are listed in

Table 7.

3.3. Economic Calculations for Scenarios I and II in Years 2021–2022

It should be noted that the input values are mostly rounded in the tables, while the final values of the calculations result from the PLN to EUR conversion (and are not integers).

For the purposes of comparing the two seasons, input data (

Table 8) needed to prepare the final economic balance for the comparative years 2021 and 2022 are presented. 14 October in both years (2021 and 2022) was assumed as the comparative date (needed to determine the conversion rate to euro, amounts of subsidies in the FiT tariff, manure costs, etc.). The reference interest rates were taken from the official data of the National Bank of Poland [

73]. The volume of energy sold took into account the biogas plant’s own needs, which amounted to 8% for electricity (e.g., for powering installations, control, etc.) and 15% for heat (e.g., for heating fermenters and social rooms, etc.).

Based on the presented results, it can be concluded that the investment outlays for biogas plants were similar in 2021 and 2022, which is mainly due to the variability of the Euro exchange rate and the return (in October 2022) of the prices of many investment components to a level not much higher than in recent months of the previous year. In contrast, operating costs, mainly related to the operation and maintenance of the installation, increased significantly during the year by as much as EUR 4000. Moreover, amortization costs in 2022 increased significantly compared to the previous year, mainly due to the reference interest rate being almost 14 times higher (from 0.5% to 6.75%), year-on-year.

From the investor’s point of view, the most important calculations are in

Table 9. This table includes calculations of costs and revenues, as well as the final profit after tax (18%).

Comparing the streams of costs and revenues, these two components increased their value in direct proportion to both scenarios over the year, for Scenario I, by about 60,000 euros, and for Scenario II, by about EUR 185,000. In turn, the difference in revenues per year is approximately 34,000 and 74,000 for Scenarios I and II, respectively. Profit in Scenario I for the following years amounts to approximately EUR 7300, and for Scenario II–approximately EUR 47,500.

This meant a significantly better financial result in the perspective of 10 years. Indeed, the investment in a biogas plant in 2021 would theoretically have a chance to pay back after approximately 9 years. Of note, the same investment made a year later would be paid off 3 years earlier (the payback period being approximately 6 years). Hence, for both scenarios (SI and SII), the more economically justified solution is to invest in biogas plants and use digestate for fertilization purposes, rather than to practice manure storage and periodic fertilization. The increase in revenues related to the selection of the 2nd year-on-year scenario was as much as 29%.

If, on the other hand, the fees for the annual production of carbon equivalent were taken into account, then the total costs in Scenario I would include a fee for 183.4 Mg CO

2eq, with the cost of emission allowances being EUR 61.41 and 68.12 for 1 Mg CO

2eq (for 2021 and 2022, respectively). In the period of mutually exclusive aspects—the energy crisis and the need to protect the climate—calculations were made taking into account additional costs incurred by the livestock farm related to the payment of emission allowances. This is found in

Table 10.

In 2021, the fees related to carbon emissions allowances would cause losses of over EUR 11,000, and almost EUR 12,500 in 2022. Such large fees would translate into a greater difference in profits each year, in the case of the construction of a biogas plant in 2021, by over EUR 16,500, and in 2022, by over EUR 57,700, i.e., by approximately 13.8% and 37.5%, respectively.

4. Discussion

Solutions based on technologically advanced manure management methods are gaining more and more importance, especially in the developing eastern (and partly central) part of Europe in terms of their contribution to achieving climate neutrality by 2050.

Table 11 presents the practices limiting CH

4 and N

2O emissions in descending order. Primary ways of mitigating emissions include replacing fossil fuel usages, avoiding CH

4, N

2O leakage from manure, producing green fertilizers to replace chemicals, applying high carbon fertilizers, enhancing soil carbon storage and utilizing carbon capture and storage.

According to many studies carried out on the mitigation of greenhouse gas emissions (refs. [

6,

27] and MilKey + MELS projects [

74,

75]), the most effective treatments (compared to many months of storage and transport of raw manure to the field) are primarily: anaerobic digestion (highly advanced technology, relatively expensive investment, but with a fast payback period) or frequent removal and daily spread (simple method, very time-consuming and inconvenient, rarely possible due to the method of cultivation). The first three practices listed in the table have one thing in common, namely the quick removal of manure from the barn and its quickest management.

The aspect of mitigating emissions through increased productivity can be quite controversial. On the one hand, it may mean reducing or not increasing the herd, but on the other hand, it is directly related to the unit milk production per cow. This solution, in turn, causes higher feed consumption by cows, which results in higher intestinal methane (CH

4) emissions [

11].

Composting methods are fairly simple to use and almost completely eliminate the formation of CH

4. However, the situation is different in the case of N

2O and odorogenic ammonia, which are released in significant amounts. There are also studies which indicate that in manure storage, less greenhouse gases (GHG) may be emitted in total than from composting, even 2.7 times less [

76,

77]. However, composting and storage conditions are so different that studies can be found in which N

2O and CH

4 emissions were significantly higher from stored manure (without aeration and shifting) than from composted manure [

32]. Still, the composting process has some advantages; part of the generated energy can be recovered [

78,

79] and, at the same time, additives reducing emissions can be used that increase the fertilizing quality of the compost [

80,

81,

82].

Although the most promising technology, especially in the case of GHG emissions from the solid fraction or farmyard manure (mixture of feces, urine and straw), seems to be anaerobic digestion, it is not the most efficient substrate in itself, as its biogas productivity is low [

83,

84]. Several scientific reports indicate a low efficiency of methane fermentation in relation to manure. This is due to the lack of easily decomposed substances at this stage, as these have already been used up by the microbes in the cow rumen. It can be assumed that up to 50% of the solids are undigested elements containing mainly cellulose, hemicellulose and lignin [

83], which are difficult to decompose during methane fermentation [

85,

86].

Due to these aspects, manure is also often combined with other agricultural waste or by-products. The easy and energetically justified use of straw as a co-substrate for biogas plants in particular is often indicated, e.g., corn straw [

43,

87,

88,

89], cereal straw [

34,

90] or other. This type of additive has the great advantage that it is readily available and does not enter into a sharp conflict between fuel or food production [

40,

91]. Therefore, clear indications from an energy and ecological point of view exist for the use of manure in anaerobic digestion processes. Nevertheless, in order to make a decision to start an investment, the overriding motivator is economic calculation.

This publication attempts to calculate the power, electricity and heat production of a biogas plant with a cogeneration unit, together with an estimate of the avoided greenhouse gas emissions that would take place during traditional manure management. The outcome of our work demonstrates that, in using manure for biogas purposes, it is possible to generate annual revenues in the amount of EUR 7300 to even more than EUR 47,500 (if the investment started in 2021 or 2022, respectively). This means 30% more profit per year. For the same period, but taking into account the emission rights, the above-mentioned profit would increase to approximately EUR 16.6 thousand and EUR 57.7 thousand which, in terms of percentage, is 13.7% to 37.6%, respectively, for the years 2021 and 2022.

In this study, only the current prices and fees are included in the presented publications. However, based on the current prices and forecast—the dotted line in the chart (

Figure 5)—we should expect even higher electricity prices, and, therefore, greater profits from investment in a biogas plant with a cogeneration unit (producing, among other products, electricity).

The prices of CO

2eq emission allowances also influence the profit from biogas plants, albeit to a lesser extent than the prices of electricity generation. According to

Figure 3 (presented earlier), despite the upward trend, one should not expect such large fluctuations in value as seen recently (stabilizing mechanisms are to be introduced), contrary to the forecasts described in other work [

62]. This is not certain, however, as there has been a significant volatility of these fees in recent years; at the beginning of 2021, the entitlements were at the level of approximately EUR 31 (after 3 months, already newly valued at approximately 49), and a year later they tripled their value, being 99.22 in August of 2022 [

64]). Any longer-term growth, or even stabilization (the outcome being that the difference between the cost of energy and allowances will increase) gives additional economic benefits to an investor owning a biogas plant.

A similar study [

62], based on similar calculations, also demonstrated that the use of manure for biogas purposes will bring more benefits on all levels than its traditional use. The revenues generated in those calculations differed between Scenarios I and II by approximately EUR 150,000. Even with a computing power of approximately 0.12 MW, which is more than two times less than in the case of discussed in this publication (0.27 MW), it was possible to achieve very high revenues of EUR 215 thousand. This is over EUR 70,000 a year more than in the calculation from this publication (EUR 144,851). However, in the previous one, insurance and tax costs were not taken into account at this stage, which would have resulted in an approximately similar amount. In the case of Scenario II described therein (0.5 MW), or with the addition of cereal straw, the gross profit amounted to approximately EUR 518,000. However, this value is difficult to compare because it involved almost twice the size of a biogas plant, and this generated proportionally higher income at a slightly higher cost. In this publication, based on the same farm size, quite similar costs were assumed for electricity and heat, as well as manure and digestate. In the case discussed above, the power of this biogas plant with a cogeneration unit was calculated at 500 kW and the profitability analyses assumed revenues from milk production. Moreover, the input to the biogas plant was partly straw. However, the amounts provided for service and depreciation were quite similar to those adopted for 2021 in these calculations (they differed by approximately EUR 1000 and EUR 7000, respectively).

As there are no standardized data in the literature that could be easily and unequivocally compared, e.g., GHG emissions per 1 m

3 or 1 Mg of cow manure, it was necessary in the current publication to use international IPCC methodology [

61] and national indicators [

19]. The reason for this approach is the large diversity and number of factors influencing the emissions from the farmyard manure, including physico–chemical properties and qualitative composition of the manure, temperature and humidity of the outside air (surrounding the stored manure), as well as the intensity and speed of wind, the type and speed of natural crust formation on the surface of the stored manure, as well as the length of the storage period and the number of transports to the field [

69].

Publications containing data on GHG emissions are proof of the correctness of the above statements. Although, as in the current publication, they also confirm the benefits of using anaerobic digestion processes together with a cogeneration unit for efficient manure management, the data on individual emissions are specific to each case.

The estimated annual GHG emission of the entire farm was from 2.5 to 5.8 Mg CO

2eq per cow [

92,

93], while in the current publication, with the total emission from the farmyard manure (a mixture of feces, urine and straw), it was approximately 0.3 Mg CO

2eq per head of cattle. This is about 10 times less, but enteric fermentation and other indirect emissions were not included here. The differences in intestinal and other emissions in relation to the emissions from manure account for about a dozen percent [

94,

95], which would confirm the correctness of the estimates adopted in this study only for the lower values from the range given above. Even higher values can be found in other studies. For example, in “Recording Dairy Cattle Methane Emission for Genetic Evaluation” [

96], the given figure is 15 m

3 CH

4/Mg of manure (manure emission is 20% of biogas efficiency). Such a conversion factor would suggest a multiple lowering of the total value per carbon dioxide equivalent, both for the current publication and the previously cited data. However, it should be noted that the data is often given for cow manure, without specifying what type of manure it is (solid or liquid fraction; a mixture of feces, urine and straw, etc.). The lack of such a description means that the comparisons in the emissions generated are very rough. More unequivocal results are obtained from the conversion of the total values of CH-C emissions, which, in the studies [

97], were determined on average at approximately 0.54 kg C/Mg, which would mean approximately 0.6% in relation to the initial weight of the stored manure. This value would give the result for the input data of this work to be about 2.8 Mg CH

4/year. The total mass of methane calculated was less than 3.4 Mg/year, which could be considered an acceptable amount.

When using the above advanced conversion factor in other sources, a fairly wide range of CH

4–C losses during manure storage can be found. Values therein are between 0.4% and 9.7% of the initial carbon content in cattle feces [

98]. The results of the current calculation fall within the above range. The same authors of the studies, however, present results which show that most of the experiments indicate a much narrower range, namely 1.8–4.4%. Additionally, the authors found that only the initial phase of the method of covering and compacting manure heaps is relevant for methane emissions [

98]. Much more effective is frequent rotation and thus aeration and loosening of the heap (free access of oxygen to the entire volume of the manure), which allows only approximately 0.5% loss of the starting carbon content in the manure [

32,

99].

Apart from the several factors mentioned earlier [

100,

101,

102], the possibility of complete or partial decomposition of antibiotics contained in manure as a result of methane fermentation deserves special attention. There are indications that direct application of manure, usually containing some amounts of antibiotics used in animal production, results in an uncontrolled release of drugs into the environment. This phenomenon is considered to be the main cause of the formation of the so-called “super worms” resistant to all known antibiotics [

34].

5. Conclusions

Based on the presented calculations and considerations, the following conclusions can be drawn:

1. A more advantageous solution for manure management is its direct use in a biogas plant with a cogeneration unit, and then the use of the digestate for fertilization purposes (Scenario II);

2. The benefits resulting from the above-mentioned solution relate to all the considered aspects, i.e., economic, energy and ecological;

3. The energy (and fertilizer) crisis resulted in a significant increase in the prices of energy and fertilizers, which caused the payback period for Scenario II to shorten from 9 to 6 years during the calculation year. Moreover, the revenues from this would increase by over EUR 70,000 (compared to the investment in 2021);

4. With a further increase in energy prices, an even shorter payback period can be assumed, regardless of the amount of emission allowances;

5. Maintaining a herd at a level of 600 dairy cows with a guarantee of return on investment of less than 10 years, without the need to add other substrates, and regardless of the crisis situation in Europe, is viable;

6. As biogas is a biofuel that enables GHG reductions, calculating avoided emissions can be an important aspect in determining the LCA or carbon footprint of dairy products;

7. A biogas plant, as a renewable energy source, fully complies with the idea of sustainable development and should be considered as a possible source of energy diversification in times of energy crisis.