Optimizing Operation Strategy in a Simulated High-Proportion Wind Power Wind–Coal Combined Base Load Power Generation System under Multiple Scenes

Abstract

1. Introduction

1.1. Background

1.2. Literature Review

1.3. Research Contribution

- (1)

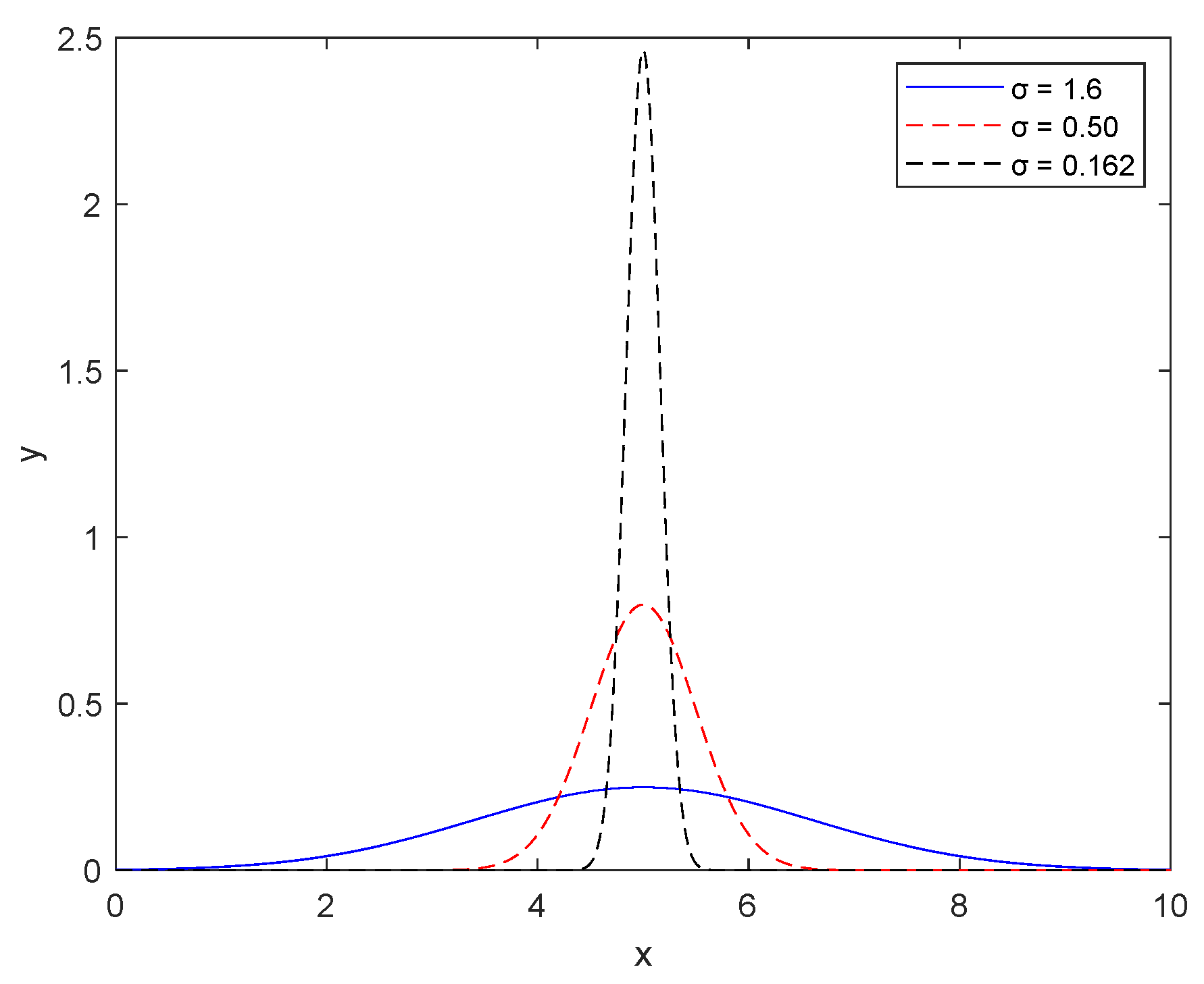

- A simulation model of the peak of the wind power curve was established based on the Gaussian distribution, which can simulate the peaks of different shapes, aiming at the peak characteristics of the power curve of the wind farm;

- (2)

- A decision-making model for unit operation strategy based on economic and environmental considerations was established, by researching the base load wind–coal combined power generation system with a high-proportion of wind power;

- (3)

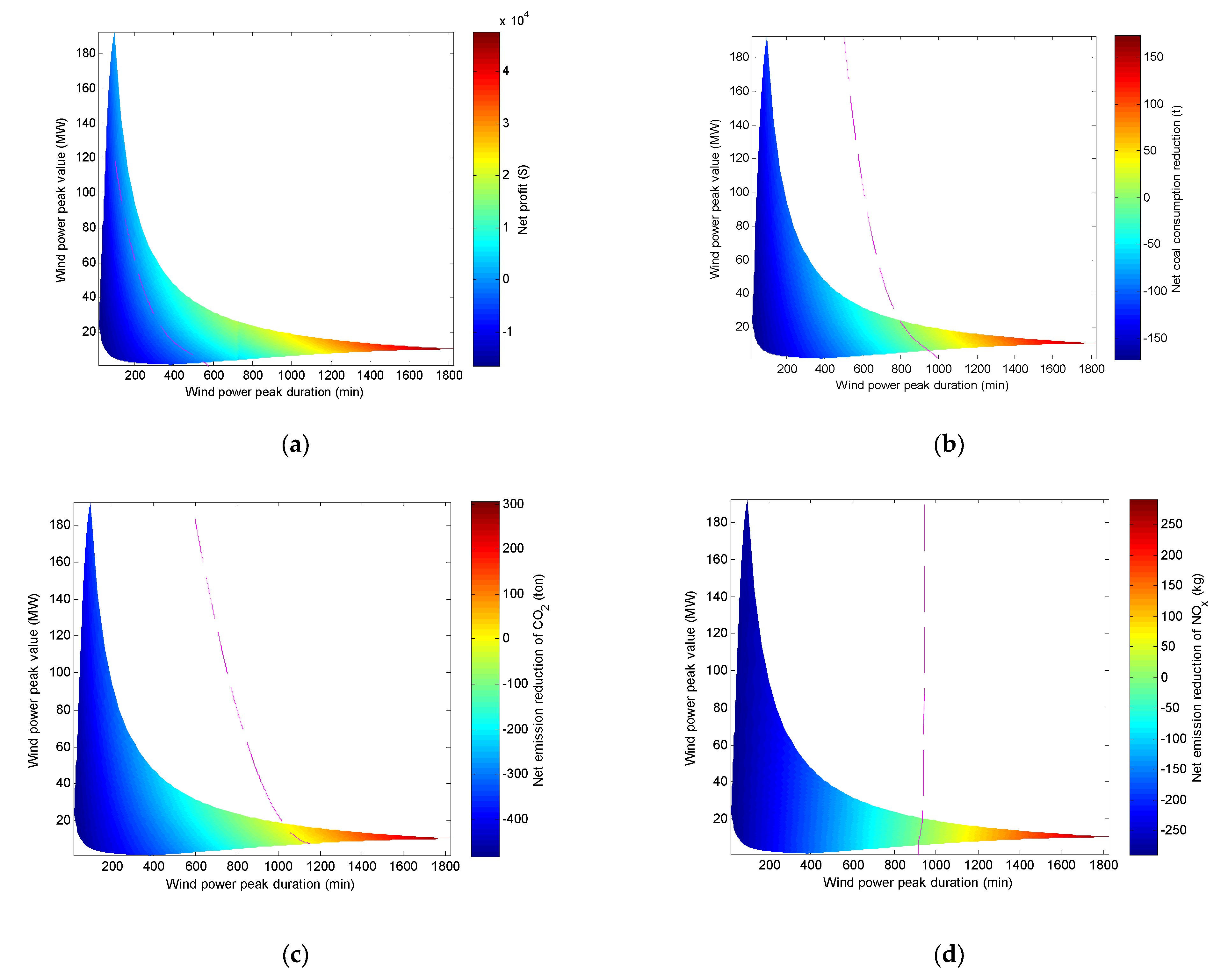

- The wind energy curtailment boundary with power generation costs, energy consumption, CO2 and pollutant emissions as the decision-making targets was determined based on simulations of wind power peaks on the base load wind–coal combined power generation system;

- (4)

- For the wind–coal combined base load power generation system based on the actual wind power curve, the optimal investment combination decision on the weekly scale unit was studied, and the optimal combination decision of the unit was achieved.

2. Wind Power Peak Curve Simulation Model

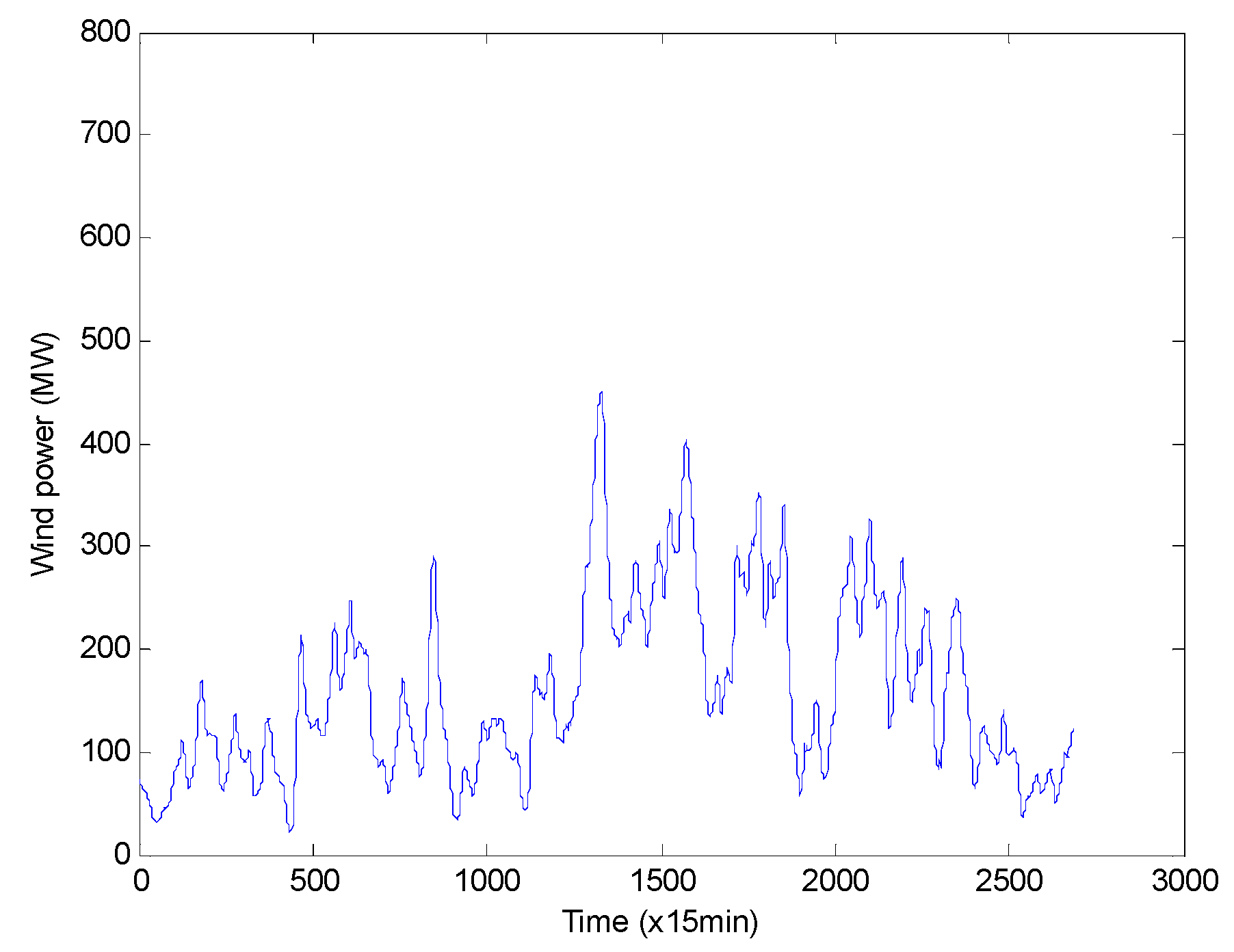

2.1. Analysis of Wind Power Peak Characteristics

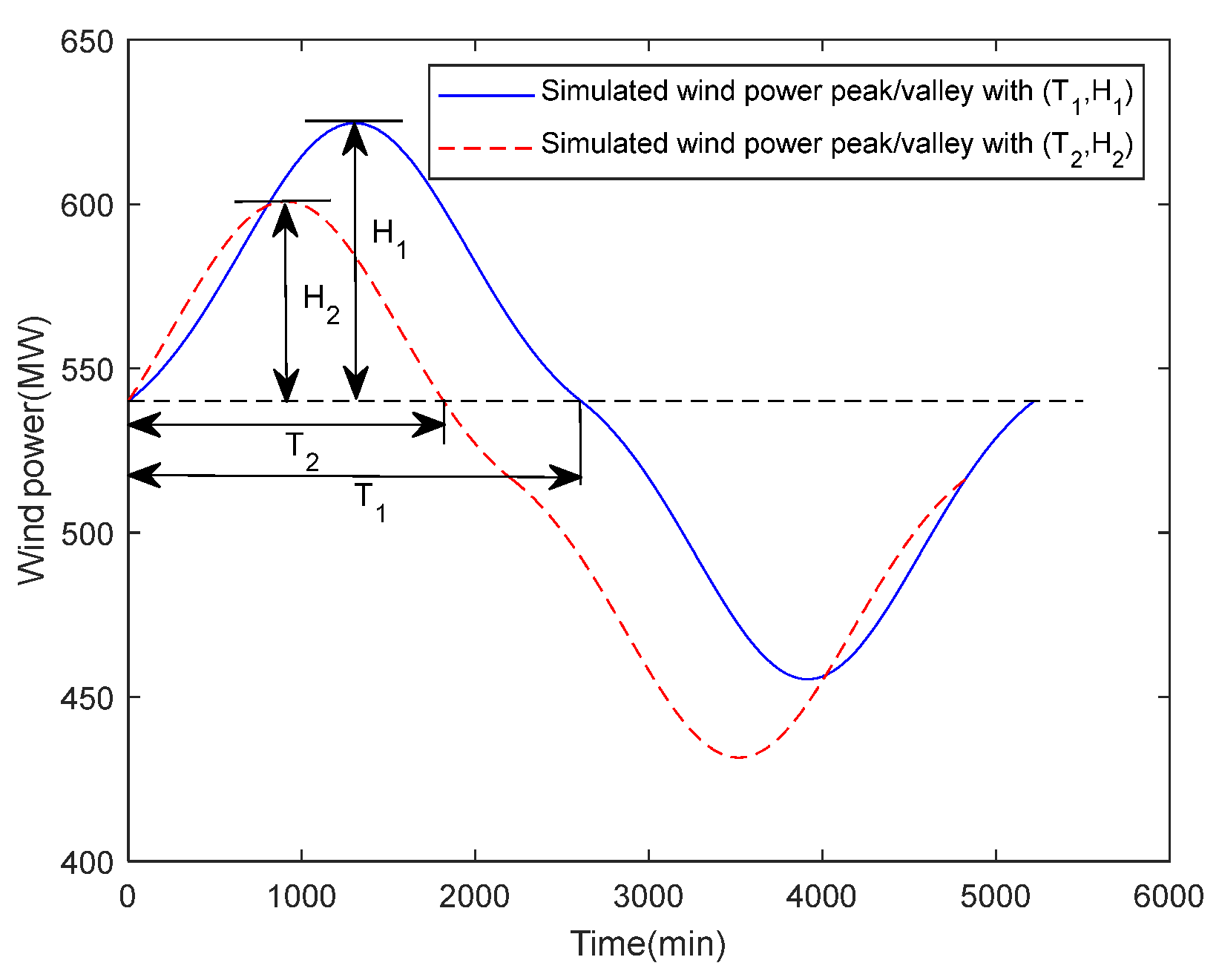

2.2. Simulation of Power Peak Curve of Wind Farm Based on Gaussian Distribution

3. Operation Strategy Decision Model of Wind–Coal Combined Power Generation System

3.1. Brief Introduction of Wind–Coal Combined Power Generation System

3.2. Operational Strategy

3.3. Unit Operation Strategy Decision Model

3.3.1. Wind Power Simulation of Wind Power Curve

3.3.2. Unit Operation Decision Model

Unit Operation Decision Criterion

- (1)

- Economic criteria

- (2)

- Environmental criteria

Coal-Fired Unit Operation Decision against a Wind Power Peak above 540 MW

- (1)

- Wind energy curtailment: a 300 MW and 600 MW unit operate together;

- (2)

- Without wind energy curtailment: a 300 MW unit undergoes shutdown and a 600 MW unit remains operational;

- (3)

- Without wind energy curtailment: a 600 MW unit undergoes shutdown and a 300 MW unit remains operational.

Coal-Fired Unit Operation Decisions against a Wind Power Peak above 240 MW

- (1)

- Wind energy curtailment: a 300 MW and 600 MW unit operate together;

- (2)

- Without wind energy curtailment: a 300 MW and 600 MW unit operate at a reduced load;

- (3)

- Without wind energy curtailment: a 300 MW unit undergoes shutdown and a 600 MW unit remains operational.

4. Results and Analysis

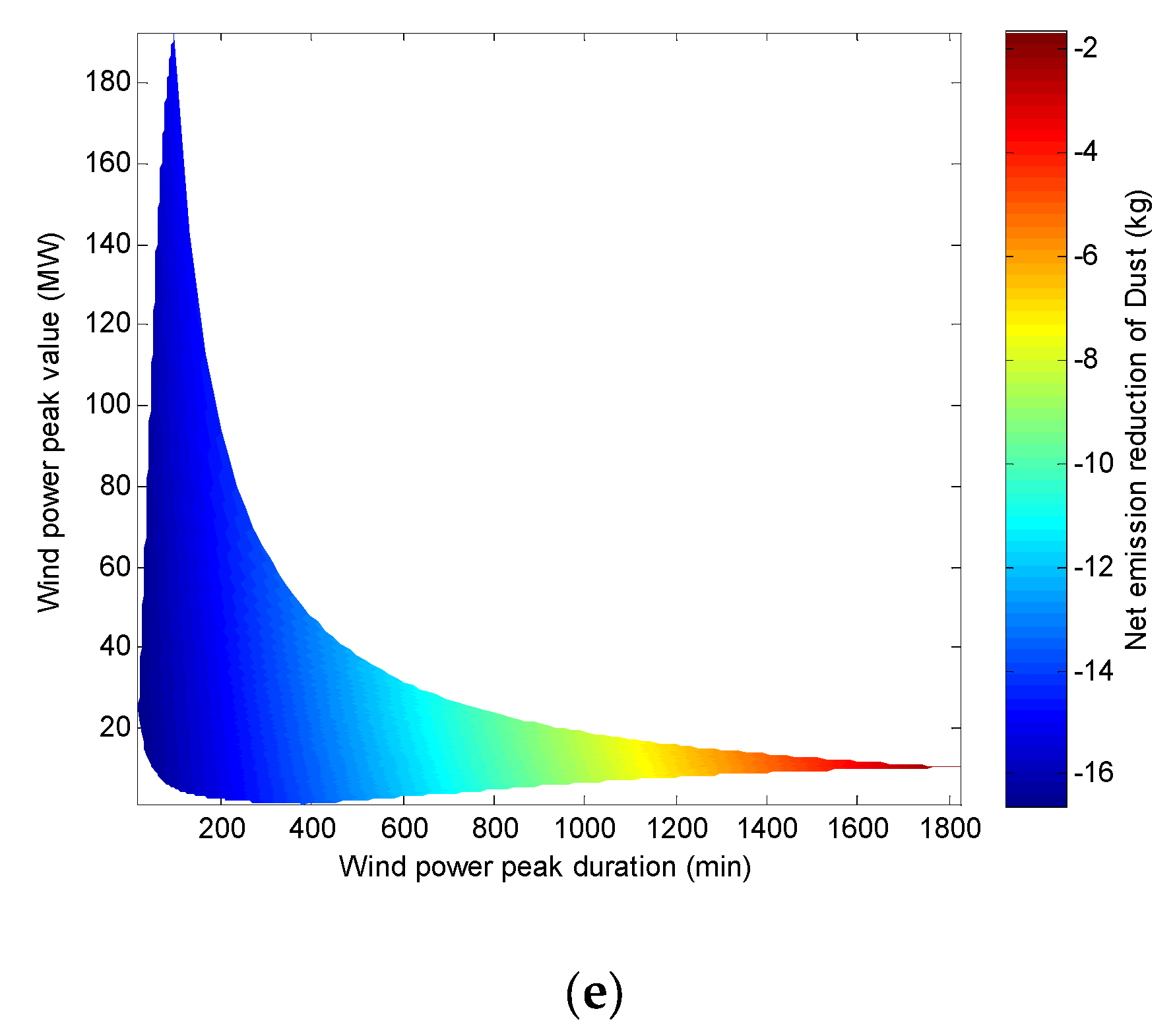

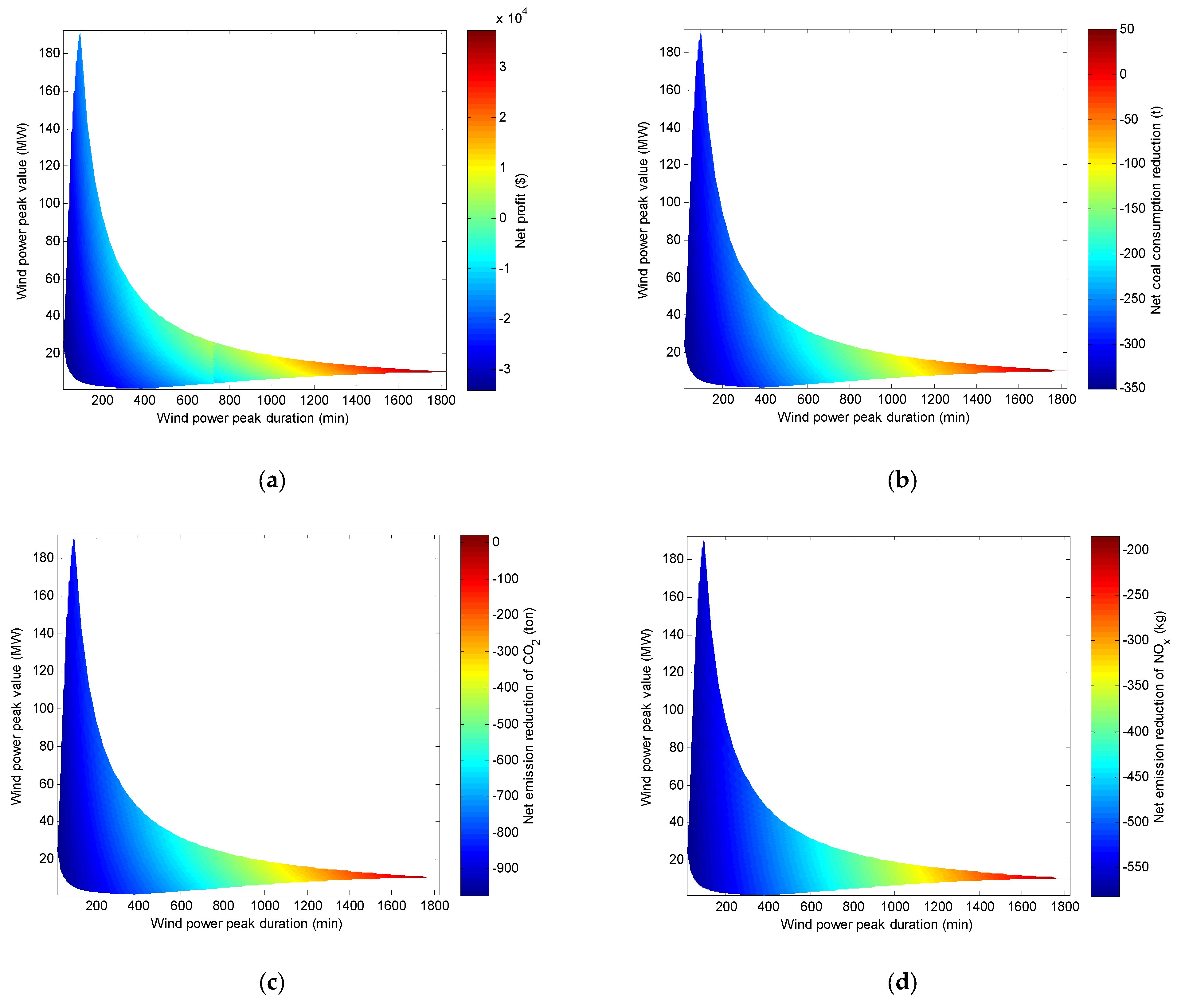

4.1. Wind Power Peaks above 540 MW

- (1)

- No wind energy curtailment mode 1 (300 MW unit start–stop peaking regulation)

- (2)

- No wind energy curtailment mode 2 (600 MW unit start and stop peaking regulation)

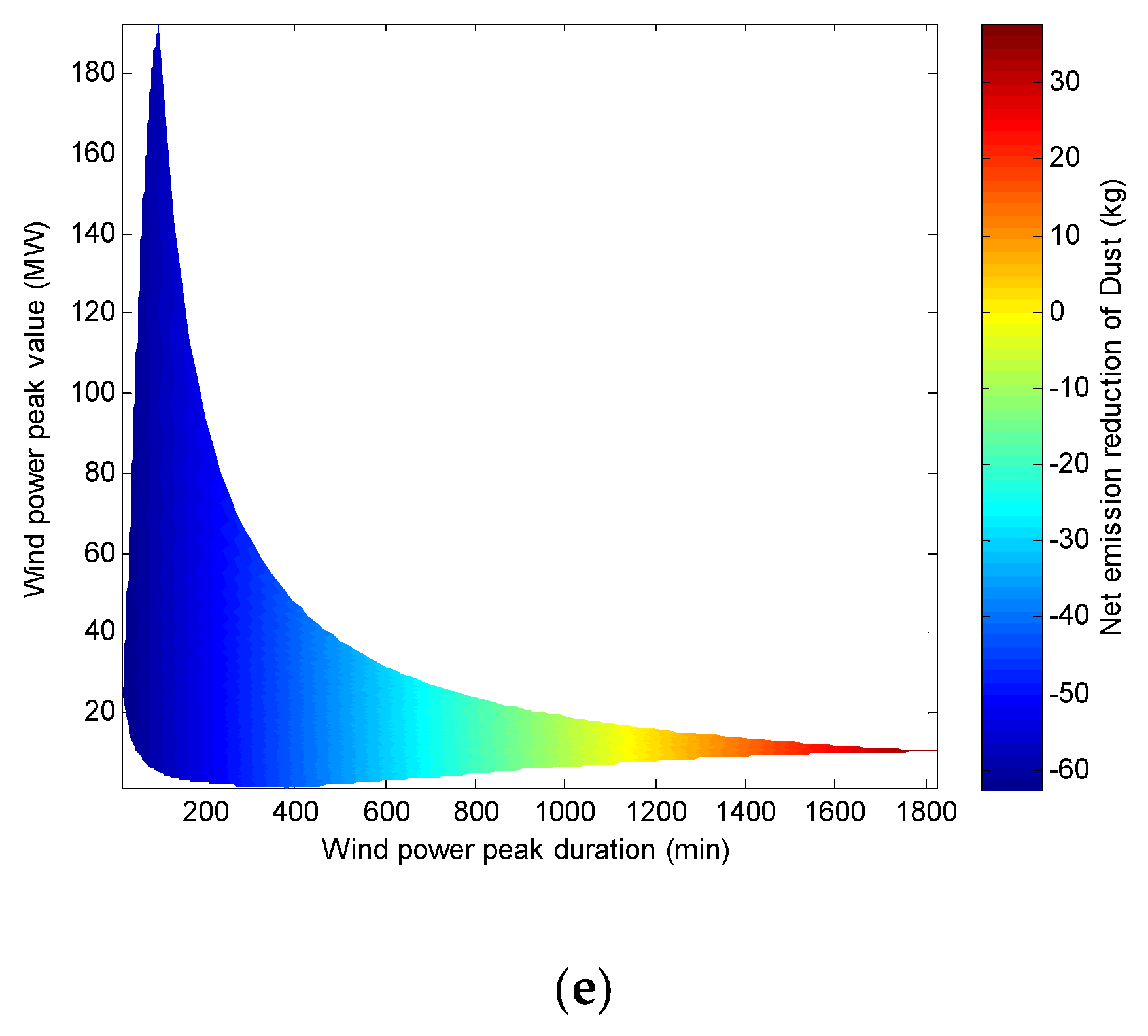

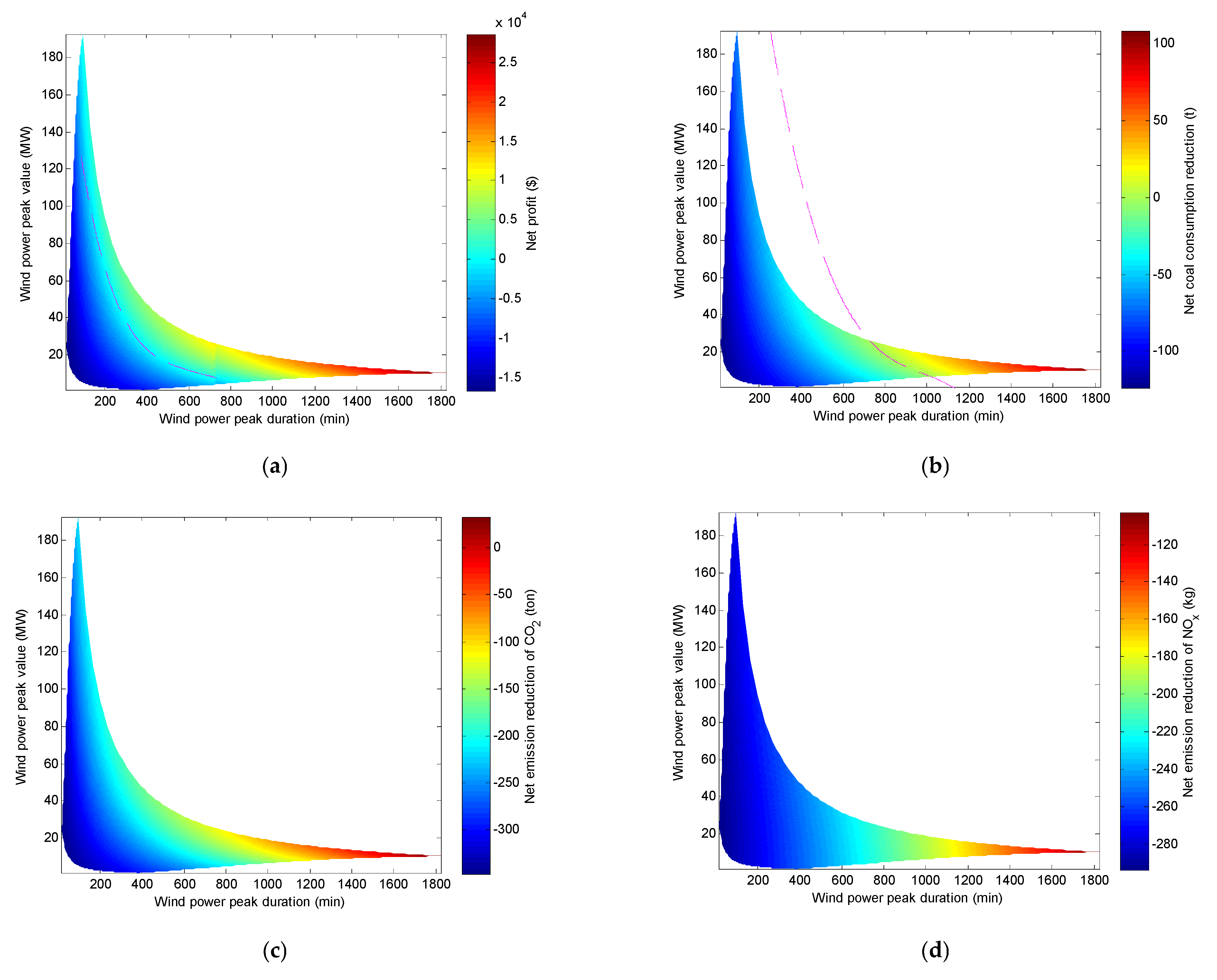

4.2. Wind Power Peaks above 240 MW

- (1)

- No wind energy curtailment (300 MW unit operates at 33% load, 600 MW unit operates for peak shaving)

- (2)

- No wind energy curtailment (300 MW unit undergoes shutdown, 600 MW unit operates for peak shaving)

4.3. Operational Strategy Decision of Weekly Scale Wind–Coal Power Generation System

5. Conclusions

- (1)

- According to the peak characteristics of the power curve of the wind farm, a simulation model of the peak of the wind power curve was established based on the Gaussian distribution, and the simulation of the peaks of different shapes was achieved by changing the parameter σ of the Gaussian distribution function;

- (2)

- Based on the research of a base load wind–coal combined power generation system with high-proportion wind power, a decision-making model of the unit operation strategy was established based on economic and environmental criteria. The decision objective function considered the costs and pollutant emissions increase caused by deep peak regulation and fast start-up and shutdown.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| μ | position parameter of Gaussian distribution |

| σ | shape parameter of Gaussian distribution |

| k | average slope of peak curve |

| T1 | lasting time of wind power peak |

| Pwind | capacity of wind power during the time period T1 |

| standard coal consumption rate | |

| Pel | active power, kW; |

| a, b and c | standard coal consumption rate coefficients. |

| thermal time constant of the unit; | |

| number of hours of downtime for the unit; | |

| Fi | fixed cost |

| Fs | total operation cost |

| λ | cost coefficient of wind energy curtailment |

| Ccoal | price of standard coal |

| total power generation cost under operation strategy 1 | |

| total power generation cost under operation strategy 2 | |

| net profit of strategy 2 relative strategy 1 | |

| total air pollutant emission under operation strategy 1 | |

| the total air pollutant emission under operation strategy 2 | |

| emission intensity of the ith air pollutant emission at active power | |

| active power of coal-fired unit | |

| Es | starting emission of certain air pollutant emissions from the unit |

| net air pollutant emission reduction |

References

- NDRC; SERC. Notification of The Renewable Energy Tariff Subsidy and Quota Trading Scheme. 2011. Available online: http://www.ndrc.gov.cn/fzgggz/jggl/zcfg/201102/t20110215_748295.html (accessed on 5 March 2020).

- NDRC; NEA. The 13th FYP Power Development Planning. 2016. Available online: https://zfxxgk.ndrc.gov.cn/web/fileread.jsp?id=240 (accessed on 5 March 2020).

- NEA; NDRC. Guidance on The Implementation of the 13th Five-Year Plan for Renewable Energy Development. 2017. Available online: http://zfxxgk.nea.gov.cn/auto87/201707/t20170728_2835.htm (accessed on 5 March 2020).

- Yuan, J.H. Wind energy in China: Estimating the potential. Nat. Energy 2016, 1, 16095. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, Y. Peak energy consumption and CO2 emissions in China. Energy Policy 2014, 68, 508–523. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, Y. China’s 2020 clean energy target: Consistency, pathways and policy implications. Energy Policy 2014, 65, 692–700. [Google Scholar] [CrossRef]

- Yuan, J.; Lei, Q.; Xiong, M.; Guo, J.S.; Hu, Z. The prospective of coal power in China: Will it reach a plateau in the coming decade. Energy Policy 2016, 98, 495–504. [Google Scholar] [CrossRef]

- Denny, E.; O’Malley, M. Wind generation, power system operation, and emissions reduction. IEEE Trans. Power Syst. 2006, 21, 341–347. [Google Scholar] [CrossRef]

- Katzenstein, W.; Jay, A. Air emissions due to wind and solar power. Environ. Sci. Technol. 2009, 43, 253–258. [Google Scholar] [CrossRef]

- Valentino, L.; Valenzuela, V.; Botterud, A. System-wide emissions implications of increased wind power penetration. Environ. Sci. Technol. 2012, 46, 4200–4206. [Google Scholar] [CrossRef]

- Zhao, X.L.; Liu, S.W.; Yan, F.G.; Yuan, Z.Q.; Liu, Z.W. Energy conservation, environmental and economic value of the wind power priority dispatch in China. Renew. Energy 2017, 111, 666–675. [Google Scholar] [CrossRef]

- Oates, D.L.; Jaramillo, P. Production cost and air emissions impacts of coal cycling in power systems with large-scale wind penetration. Environ. Res. Lett. 2013, 8, 024022–024028. [Google Scholar]

- Lu, X.; McElroy, M.B.; Chen, X. Opportunity for offshore wind to reduce future demand for coal-fired power plants in China with consequent savings in emissions of CO2. Environ. Sci. Technol. 2014, 48, 14764–14771. [Google Scholar] [CrossRef]

- Gonzalez-Salazara, M.A.; Kirsten, T.; Prchlik, L. Review of the operational flexibility and emissions of gas- and coal-fired power plants in a future with growing renewables. Renew. Sustain. Energy Rev. 2018, 82, 1497–1513. [Google Scholar] [CrossRef]

- Yang, H.; Liang, R.; Yuan, Y.; Chen, B.; Xiang, S.; Liu, J.; Ackom, E. Distributionally robust optimal dispatch in the power system with high penetration of wind power based on net load fluctuation data. Appl. Energy 2022, 313, 118813–118828. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Han, Y.; Zhao, Q.; Fang, X.; Cao, Z. Robust and opportunistic scheduling of district integrated natural gas and power system with high wind power penetration considering demand flexibility and compressed air energy storage. J. Clean. Prod. 2020, 256, 120456–120474. [Google Scholar] [CrossRef]

- NREL. The Western Wind and Solar Integration Study 2; NREL/TP-5500-55888; National Renewable Energy Laboratory: Golden, CO, USA, 2013. [Google Scholar]

- Frade, P.M.; Pereira, J.P.; Santana, J.J.E.; Catalão, J.P.S. Wind balancing costs in a power system with high wind penetration—Evidence from Portugal. Energy Policy 2019, 132, 702–713. [Google Scholar] [CrossRef]

- Dong, Y.; Jiang, X.; Liang, Z.; Yuan, J. Coal power flexibility, energy efficiency and pollutant emissions implications in China: A plant-level analysis based on case units. Resour. Conserv. Recycl. 2018, 134, 184–195. [Google Scholar] [CrossRef]

- Dong, Y.; Jiang, X.; Ren, M.; Yuan, J. Environmental implications of China’s wind-coal combined power generation system. Resour. Conserv. Recycl. 2019, 142, 24–33. [Google Scholar] [CrossRef]

- Kubik, M.L.; Coker, P.J.; Barlow, J.F. Increasing thermal plant flexibility in a high renewables power system. Appl. Energy 2015, 154, 102–111. [Google Scholar] [CrossRef]

- Hübel, M.; Meinke, S.; Andrén, M.T.; Wedding, C.; Nocke, J.; Gierow, C.; Funkquist, J. Modelling and simulation of a coal-fired power plant for start-up optimization. Appl. Energy 2017, 208, 319–331. [Google Scholar] [CrossRef]

- Wang, W.; Liu, J.; Zeng, D.; Niu, Y.; Cui, C. Modeling for condensate throttling and its application on the flexible load control of power plants. Appl. Therm. Eng. 2016, 95, 303–310. [Google Scholar] [CrossRef]

- Wang, W.; Li, L.; Long, D.; Liu, J.; Zeng, D.; Cui, C. Improved boiler-turbine coordinated control of 1000 MW power units by introducing condensate throttling. J. Process Control. 2017, 50, 11–18. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, D. An improved coordinated control technology for coal-fired boiler-turbine plant based on flexible steam extraction system. Appl. Therm. Eng. 2017, 125, 1047–1060. [Google Scholar] [CrossRef]

- Garbrecht, O.; Bieber, M.; Kneer, R. Increasing fossil power plant flexibility by integrating molten-salt thermal storage. Energy 2017, 118, 876–883. [Google Scholar] [CrossRef]

- Richter, M.; Oeljeklaus, G.; Görner, K. Improving the load flexibility of coal-fired power plants by theintegration of a thermal energy storage. Appl. Energy 2019, 236, 607–621. [Google Scholar] [CrossRef]

- Wolfersdorf, C.; Boblenz, K.; Pardemann, R.; Meyer, B. Syngas-based annex concepts for chemical energy storage and improving flexibility of pulverized coal combustion power plants. Appl. Energy 2015, 156, 618–627. [Google Scholar] [CrossRef]

- Mahdia, F.P.; Vasanta, P.; Kallimanib, V. A holistic review on optimization strategies for combined economic emission dispatch problem. Renew. Sustain. Energy Rev. 2018, 81, 3006–3020. [Google Scholar] [CrossRef]

- Zhao, X.L.; Wu, L.L.; Zhang, S.F. Joint environmental and economic power dispatch considering wind power integration: Empirical analysis from Liaoning Province of China. Renew. Energy 2013, 52, 260–265. [Google Scholar] [CrossRef]

- El-Keib, A.; Ding, H. Environmentally constrained economic dispatch using linear programming. Electr. Power Syst. Res. 1994, 29, 155–159. [Google Scholar] [CrossRef]

- Chen, J.F.; Chen, S.D. Multi-objective power dispatch with line flow constraints using the fast Newton-raphson method. IEEE Trans. Energy Convers. 1997, 12, 86–93. [Google Scholar] [CrossRef]

- Wang, K.P.; Yuryevich, J. Evolutionary-programming-based algorithm for environmentally-constrained economic dispatch. IEEE Trans. Power Syst. 1998, 13, 301–306. [Google Scholar] [CrossRef]

- Das, D.B.; Patvardhan, C. New multi-objective stochastic search technique for economic load dispatch. IEEE Proc. Gener. Transm. Distrib. 1998, 145, 747–752. [Google Scholar] [CrossRef]

- Song, Y.H.; Wang, G.S.; Wang, P.Y.; Johns, A.T. Environmental/economic dispatch using fuzzy logic controlled genetic algorithms. IEEE Proc. Gener. Transm. Distrib. 1997, 144, 377–382. [Google Scholar] [CrossRef]

- Kumar AI, S.; Dhanushkodi, K.; Kumar, J.J.; Paul, C.K.C. Particle swarm optimization solution to emission and economic dispatch problem. In Proceedings of the TENCON 2003 Conference on Convergent Technologies for the Asia-Pacific Region, Bangalore, India, 15–17 October 2003; pp. 435–439. [Google Scholar]

- Basu, M. A simulated annealing-based goal-attainment method for economic emission load dispatch of fixed head hydrothermal power systems. Int. J. Electr. Power Energy Syst. 2005, 27, 147–153. [Google Scholar] [CrossRef]

- Apostolopoulos, T.; Vlachos, A. Application of the firefly algorithm for solving the economic emissions load dispatch problem. Int. J. Comb. 2011, 2011, 523806. [Google Scholar] [CrossRef]

- Dixit, G.P.; Dubey, H.M.; Pandit, M.; Panigrahi, B.K. Artificial bee colony optimization for combined economic load and emission dispatch. In Proceedings of the Sustainable Energy and Intelligent Systems, International Conference on: IET, Chennai, India, 20–22 July 2011; pp. 340–345. [Google Scholar]

- Ramesh, B.; Chandra Jagan Mohan, V.; Veera Reddy, V.C. Application of bat algorithm for combined economic load and emission dispatch. J. Electr. Eng. 2013, 13, 214–219. [Google Scholar]

- Roy, P.K.; Bhui, S. A multi-objective hybrid evolutionary algorithm for dynamic economic emission load dispatch. Int. Trans. Electr. Energy Syst. 2016, 26, 49–78. [Google Scholar] [CrossRef]

- Zhang, H.; Yue, D.; Xie, X.; Hu, S.; Weng, S. Multi-elite guide hybrid differential evolution with simulated annealing technique for dynamic economic emission dispatch. Appl. Soft Comput. 2015, 34, 312–323. [Google Scholar] [CrossRef]

- Younes, M.; Khodja, F.; Kherfane, R.L. Multi-objective economic emission dispatch solution using hybrid FFA (firefly algorithm) and considering wind power penetration. Energy 2014, 67, 595–606. [Google Scholar] [CrossRef]

- Sayah, S.; Hamouda, A.; Bekrar, A. Efficient hybrid optimization approach for emission constrained economic dispatch with nonsmooth cost curves. Int. J. Electr. Power Energy Syst. 2014, 56, 127–139. [Google Scholar] [CrossRef]

- Hooshmand, R.A.; Parastegari, M.; Morshed, M.J. Emission, reserve and economic load dispatch problem with non-smooth and non-convex cost functions using the hybrid bacterial foraging-Nelder-Mead algorithm. Appl. Energy 2012, 89, 443–453. [Google Scholar] [CrossRef]

- Roselyn, J.P.; Devaraj, D.; Dash, S.S. Economic Emission OPF Using Hybrid GA-Particle Swarm Optimization. In International Conference on Swarm, Evolutionary, and Memetic Computing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 167–175. [Google Scholar]

- Hota, P.; Barisal, A.; Chakrabarti, R. Economic emission load dispatch through fuzzy based bacterial foraging algorithm. Int. J. Electr. Power Energy Syst. 2010, 32, 794–803. [Google Scholar] [CrossRef]

- Ramadan, A.; Ebeed, M.; Kamel, S.; Agwa, A.M.; Tostado-Véliz, M. The Probabilistic Optimal Integration of Renewable Distributed Generators Considering the Time-Varying Load Based on an Artificial Gorilla Troops Optimizer. Energies 2022, 15, 1302. [Google Scholar] [CrossRef]

- Kuo, C.C. Wind energy dispatch considering environmental and economic factors. Renew. Energy 2010, 35, 2217–2227. [Google Scholar] [CrossRef]

- Bishop, C. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- NB/T 31110-2017; Technical Rule for Active Power Regulation and Control of Wind Farm. National Energy Administration: Beijing, China, 2017.

- Soliman, S.A.H.; Mantawy, A.A.H. Modern Optimization Techniques with Applications in Electric Power Systems; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

| Wind Farm Installed Capacity (MW) | 10 min Active Power Variation Upper Limit (MW) | 1 min Active Power Variation Upper Limit (MW) |

|---|---|---|

| <30 | 10 | 3 |

| 30~150 | Installed capacity/3 | Installed capacity/10 |

| >150 | 50 | 15 |

| No. | Theory Wind Power (MW) | Coal-Fired Power (MW) | Coal-Fired Units Input Strategy 1 | Coal-Fired Units Input Strategy 2 |

|---|---|---|---|---|

| 1 | 0~240 | 600~840 | 600 MW + 300 MW | |

| 2 | 240~540 | 300~600 | 600 MW + 300 MW | 600 MW |

| 3 | 540~630 | 210–300 | 300 MW | 600 MW |

| 4 | 630~735 | 105~210 | 300 MW |

| Boundary Points | Duration (min) | Height (MW) | Power Quantity (MW·h) | Cost for Wind Energy Curtailment (×105 $) | Cost for Mode 1 (×105 $) |

|---|---|---|---|---|---|

| 1 | 563 | 2.9 | 17.58 | 1.7934 | 1.7933 |

| 2 | 440 | 11.16 | 50.63 | 1.4230 | 1.4227 |

| 3 | 331 | 24.42 | 79.63 | 1.0937 | 1.0933 |

| 4 | 194 | 65.18 | 115.53 | 0.6815 | 0.6811 |

| Boundary Points | Duration (min) | Height (MW) | Power Generation Quantity (MW·h) | Coal Consumption for Wind Power Curtailment Mode (×103 t) | Coal Consumption for Mode 1 (×103 t) |

|---|---|---|---|---|---|

| 1 | 948 | 6.24 | 60.14 | 1.7978 | 1.7969 |

| 2 | 899 | 10.25 | 89.24 | 1.7052 | 1.7046 |

| 3 | 856 | 14.80 | 115.53 | 1.6231 | 1.6228 |

| 4 | 823 | 19.44 | 136.01 | 1.5595 | 1.5594 |

| Boundary Points | Duration (min) | Height (MW) | Power Generation Quantity (MW·h) | Emitted CO2 for Wind Energy Curtailment (×103 t) | Emitted CO2 for Mode 1 (×103 t) |

|---|---|---|---|---|---|

| 1 | 1141 | 7.88 | 87.34 | 5.0557 | 5.0573 |

| 2 | 1075 | 10.48 | 107.31 | 4.8731 | 4.8724 |

| 3 | 1063 | 14.02 | 129.92 | 4.7111 | 4.7120 |

| 4 | 1022 | 18.66 | 149.99 | 4.5301 | 4.5290 |

| Boundary Points | Duration (min) | Height (MW) | Power Quantity (MW·h) | Emitted NOx for Wind Energy Curtailment Mode (kg) | Emitted NOx for Mode 1 (kg) |

|---|---|---|---|---|---|

| 1 | 916 | 6.24 | 58.21 | 750.3547 | 750.3201 |

| 2 | 922 | 10.00 | 89.24 | 754.6157 | 755.2209 |

| 3 | 929 | 16.00 | 136.01 | 761.4154 | 762.4493 |

| 4 | 931 | 19.42 | 146.01 | 761.8848 | 762.9060 |

| Decision Strategy | Net Revenue (×104 $) | Standard Coal (t) | CO2 (t) | NOx (kg) | Dust (kg) | |

|---|---|---|---|---|---|---|

| Decision point a | Strategy 2 | 9.534 | 252.4 | 574.4 | 95.1 | 3.6 |

| Strategy 3 | 9.265 | 175.1 | 283.1 | −155.7 | −18.5 | |

| Decision point b | Strategy 2 | 112.207 | 2967.2 | 6967.0 | 268.7 | 57.9 |

| Strategy 3 | 120.92 | 3427.7 | 7929.0 | 566.9 | 58.9 | |

| Decision point c | Strategy 2 | 52.074 | 1436.3 | 3358.7 | 207.9 | 27.1 |

| Strategy 3 | 54.246 | 1505.1 | 3398.5 | 217.2 | 13.1 | |

| Strategies | a | b | c | Coal Consumption (t) | CO2 (t) | NOx (kg) | Dust (kg) |

|---|---|---|---|---|---|---|---|

| 1 | a1 | b1 | c1 | 16,226.2 | 38,033.0 | 4417.8 | 591.0 |

| 2 | a1 | b1 | c2 | 14,789.9 | 34,674.3 | 4209.9 | 563.7 |

| 3 | a1 | b1 | c3 | 14,721.1 | 34,634.5 | 4200.6 | 577.7 |

| 4 | a1 | b2 | c1 | 13,259.0 | 31,066.0 | 4149.1 | 533.1 |

| 5 | a1 | b2 | c2 | 11,822.7 | 27,707.3 | 3941.2 | 505.8 |

| 6 | a1 | b2 | c3 | 11,753.9 | 27,667.5 | 3931.9 | 519.8 |

| 7 | a1 | b3 | c1 | 12,798.5 | 30,104.0 | 3850.9 | 532.2 |

| 8 | a1 | b3 | c2 | 11,362.2 | 26,745.3 | 3643.0 | 504.8 |

| 9 | a1 | b3 | c3 | 11,293.4 | 26,705.5 | 3633.7 | 518.8 |

| 10 | a2 | b1 | c1 | 15,973.8 | 37,458.6 | 4322.7 | 587.4 |

| 11 | a2 | b1 | c2 | 14,537.5 | 34,099.9 | 4114.8 | 560.1 |

| 12 | a2 | b1 | c3 | 14,468.7 | 34,060.1 | 4105.5 | 574.1 |

| 13 | a2 | b2 | c1 | 13,006.6 | 30,491.6 | 4054.0 | 529.5 |

| 14 | a2 | b2 | c2 | 11,570.3 | 27,132.9 | 3846.1 | 502.2 |

| 15 | a2 | b2 | c3 | 11,501.5 | 27,093.1 | 3836.8 | 516.2 |

| 16 | a2 | b3 | c1 | 12,546.1 | 29,529.6 | 3755.8 | 528.5 |

| 17 | a2 | b3 | c2 | 11,109.8 | 26,170.9 | 3547.9 | 501.2 |

| 18 | a2 | b3 | c3 | 11,041.0 | 26,131.1 | 3538.6 | 515.2 |

| 19 | a3 | b1 | c1 | 16,051.1 | 37,749.9 | 4573.5 | 609.6 |

| 20 | a3 | b1 | c2 | 14,614.8 | 34,391.2 | 4365.6 | 582.3 |

| 21 | a3 | b1 | c3 | 14,546.0 | 34,351.4 | 4356.3 | 596.3 |

| 22 | a3 | b2 | c1 | 13,083.9 | 30,782.9 | 4304.8 | 551.7 |

| 23 | a3 | b2 | c2 | 11,647.6 | 27,424.2 | 4096.9 | 524.4 |

| 24 | a3 | b2 | c3 | 11,578.8 | 27,384.4 | 4087.6 | 538.4 |

| 25 | a3 | b3 | c1 | 12,623.4 | 29,820.9 | 4006.6 | 550.7 |

| 26 | a3 | b3 | c2 | 11,187.1 | 26,462.2 | 3798.7 | 523.4 |

| 27 | a3 | b3 | c3 | 11,118.3 | 26,422.4 | 3789.4 | 537.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Dong, Y.; Du, Y.; Yuan, J.; Fang, F. Optimizing Operation Strategy in a Simulated High-Proportion Wind Power Wind–Coal Combined Base Load Power Generation System under Multiple Scenes. Energies 2022, 15, 8004. https://doi.org/10.3390/en15218004

Yu Q, Dong Y, Du Y, Yuan J, Fang F. Optimizing Operation Strategy in a Simulated High-Proportion Wind Power Wind–Coal Combined Base Load Power Generation System under Multiple Scenes. Energies. 2022; 15(21):8004. https://doi.org/10.3390/en15218004

Chicago/Turabian StyleYu, Qingbin, Yuliang Dong, Yanjun Du, Jiahai Yuan, and Fang Fang. 2022. "Optimizing Operation Strategy in a Simulated High-Proportion Wind Power Wind–Coal Combined Base Load Power Generation System under Multiple Scenes" Energies 15, no. 21: 8004. https://doi.org/10.3390/en15218004

APA StyleYu, Q., Dong, Y., Du, Y., Yuan, J., & Fang, F. (2022). Optimizing Operation Strategy in a Simulated High-Proportion Wind Power Wind–Coal Combined Base Load Power Generation System under Multiple Scenes. Energies, 15(21), 8004. https://doi.org/10.3390/en15218004