Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine

Abstract

1. Introduction

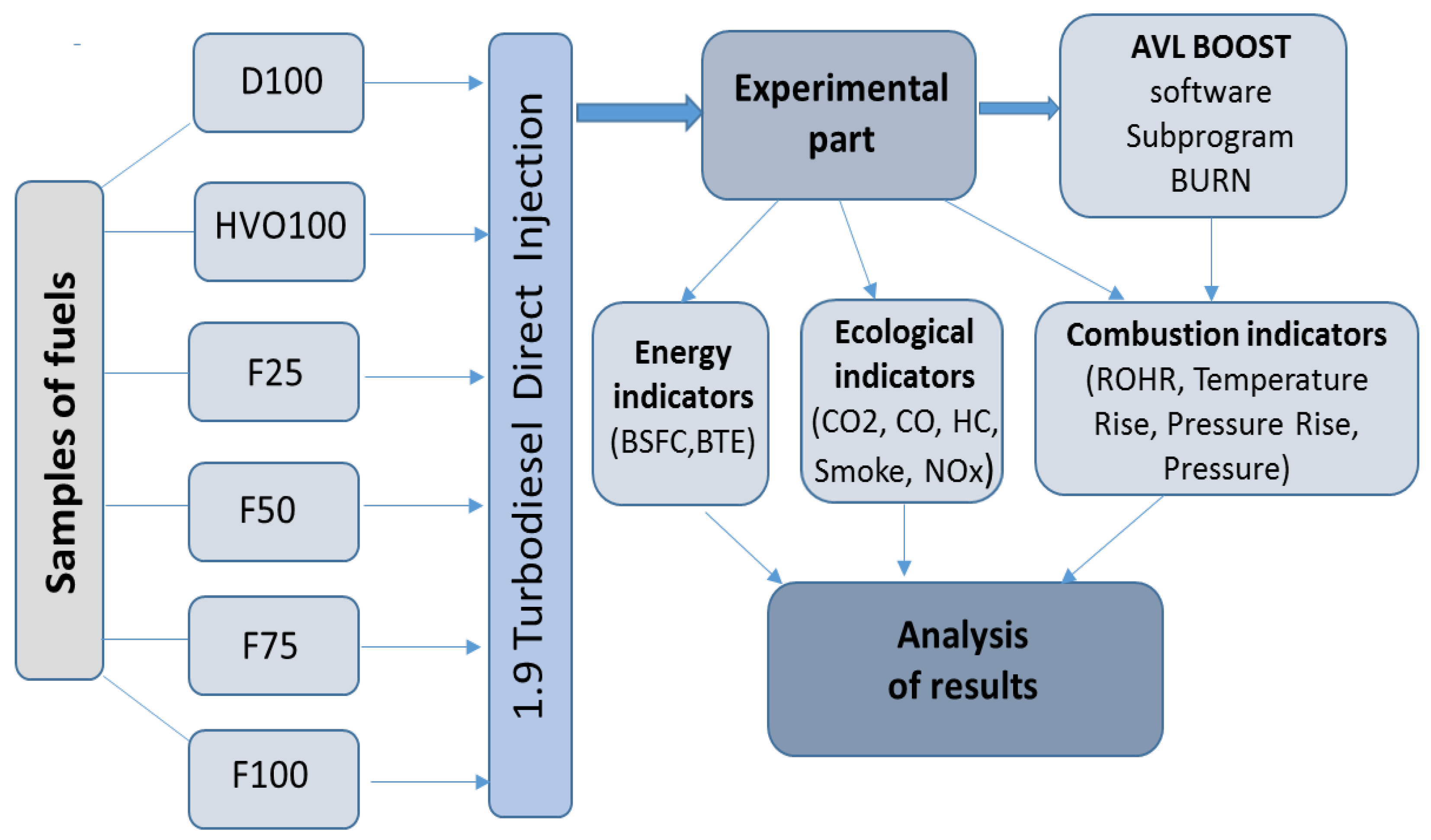

2. Methods and Materials

2.1. Fuel Preparation

2.2. Test Bench, Measuring Instruments, and Data Processing

2.3. Analysis of Experimental Results with the Use of AVL Boost Software

3. Results and Discussion

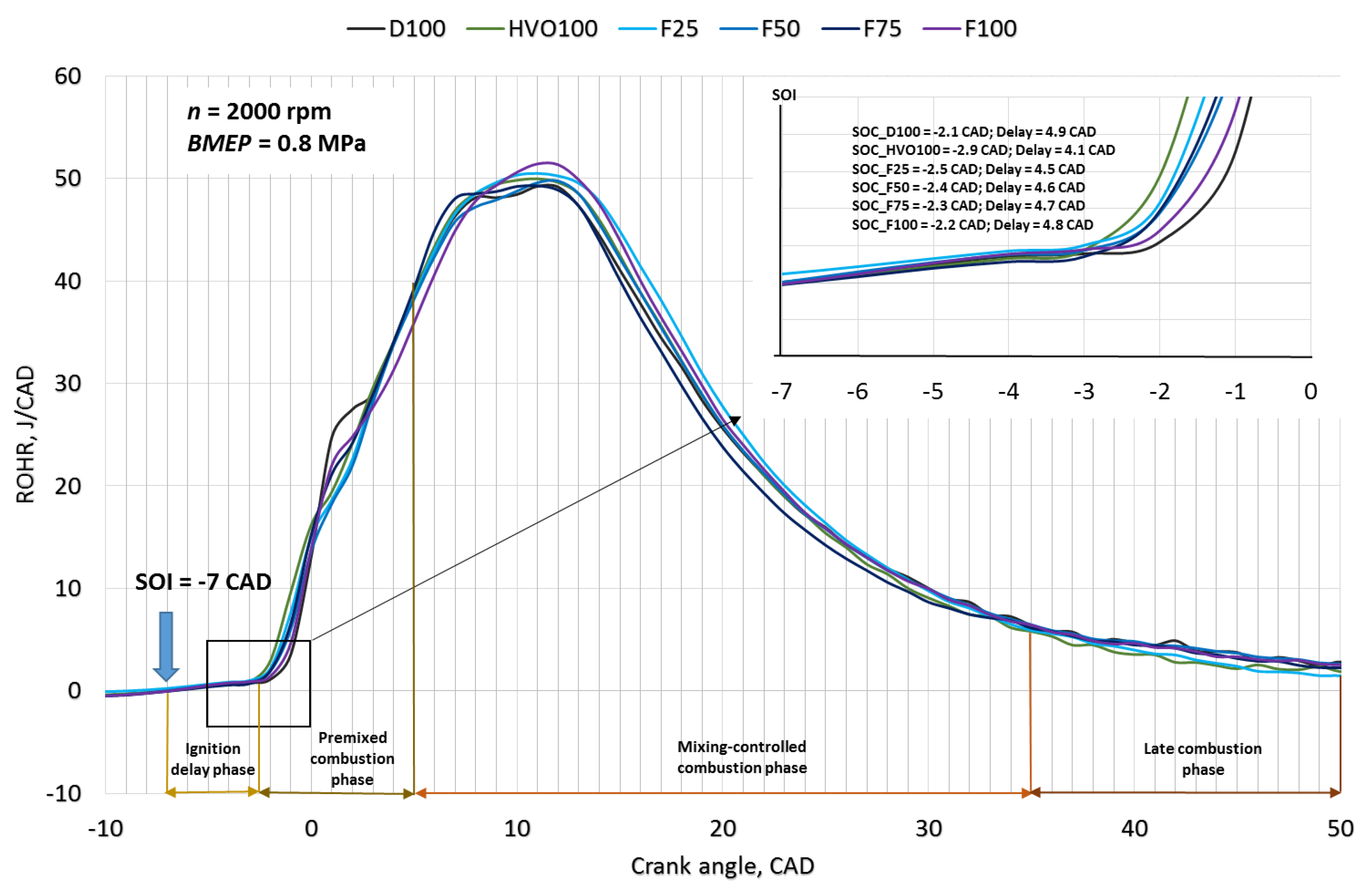

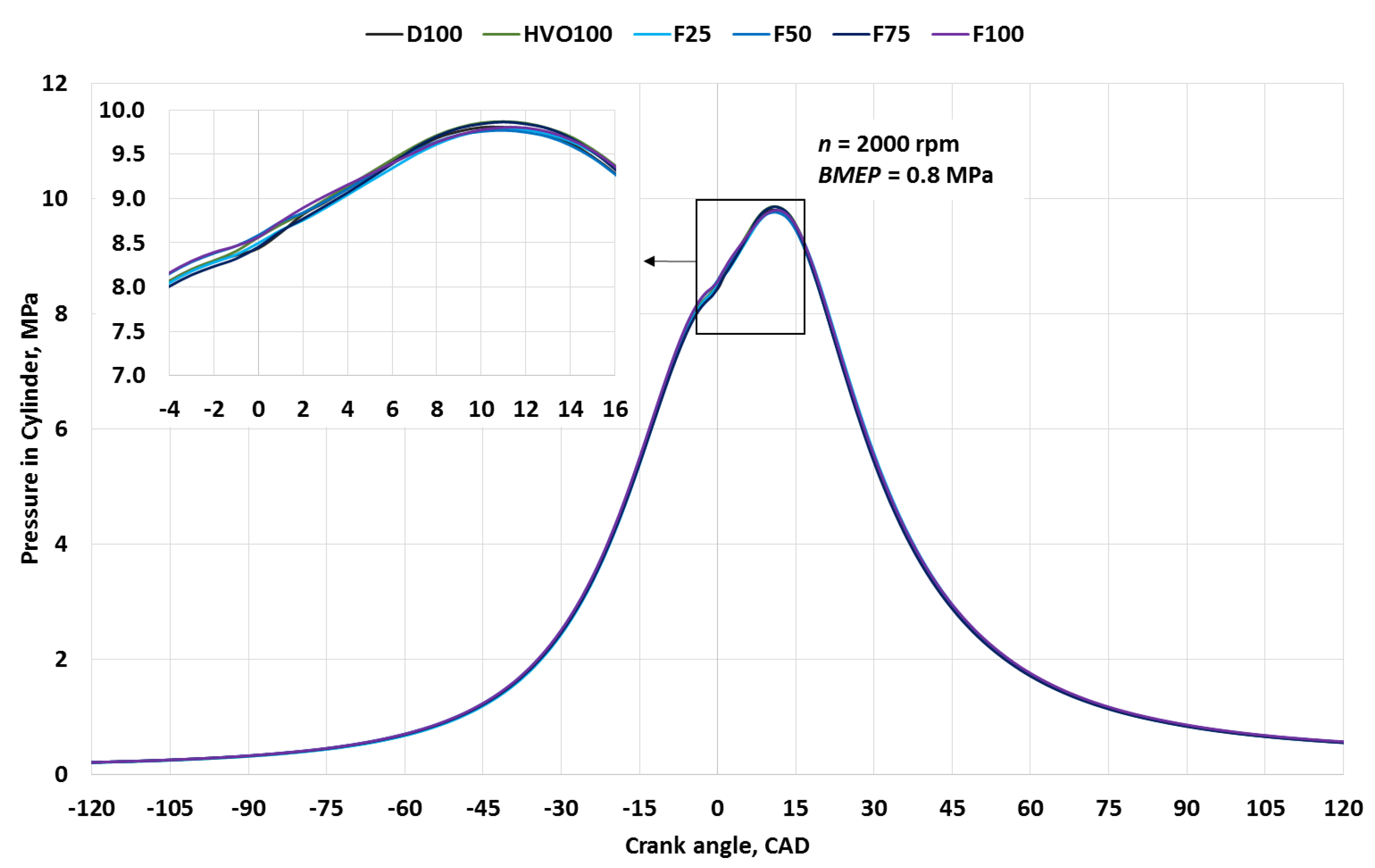

3.1. Indicators of Combustion

3.2. Ecological Indicators

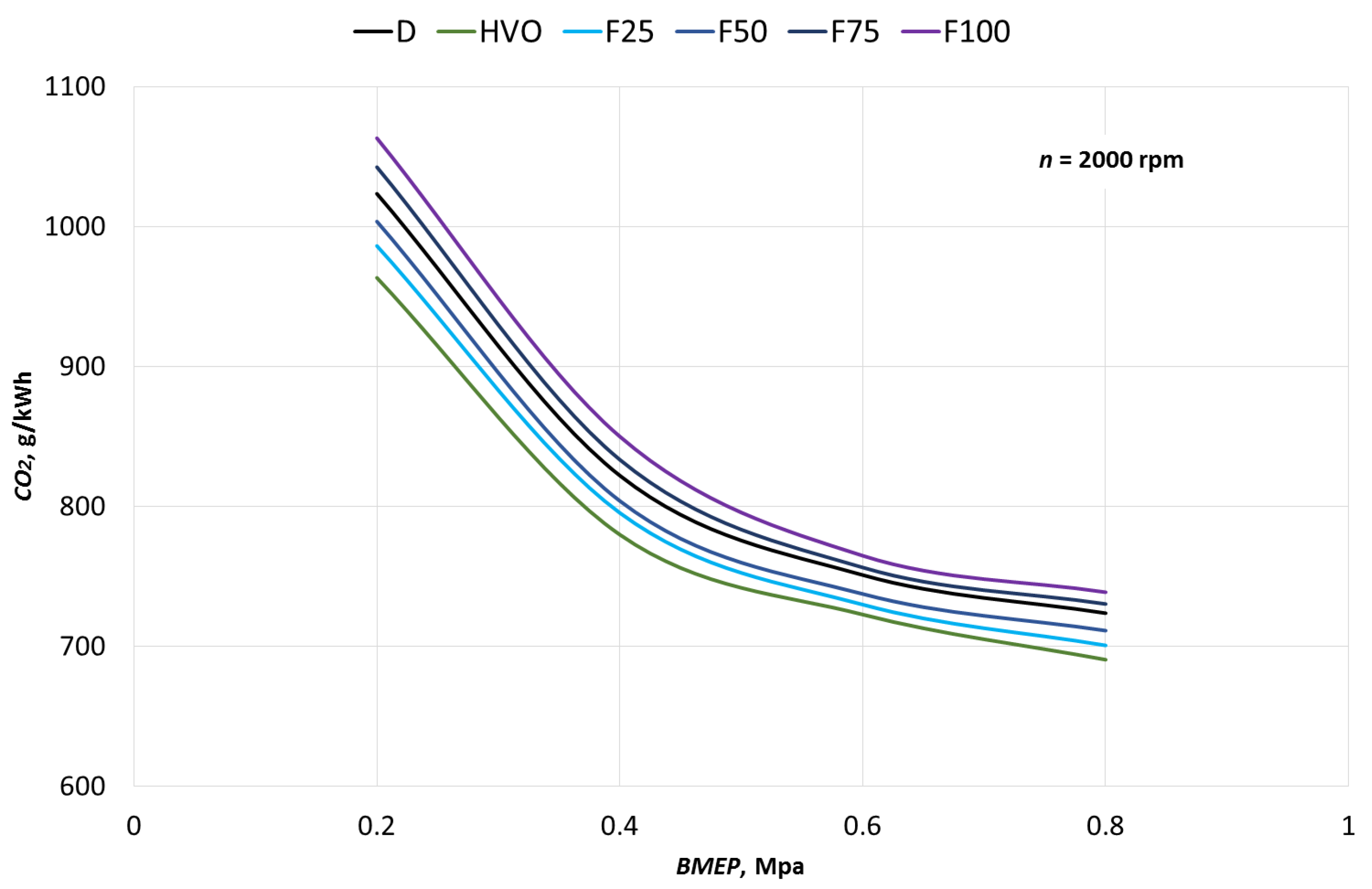

3.2.1. Emissions of Carbon Dioxide (CO2)

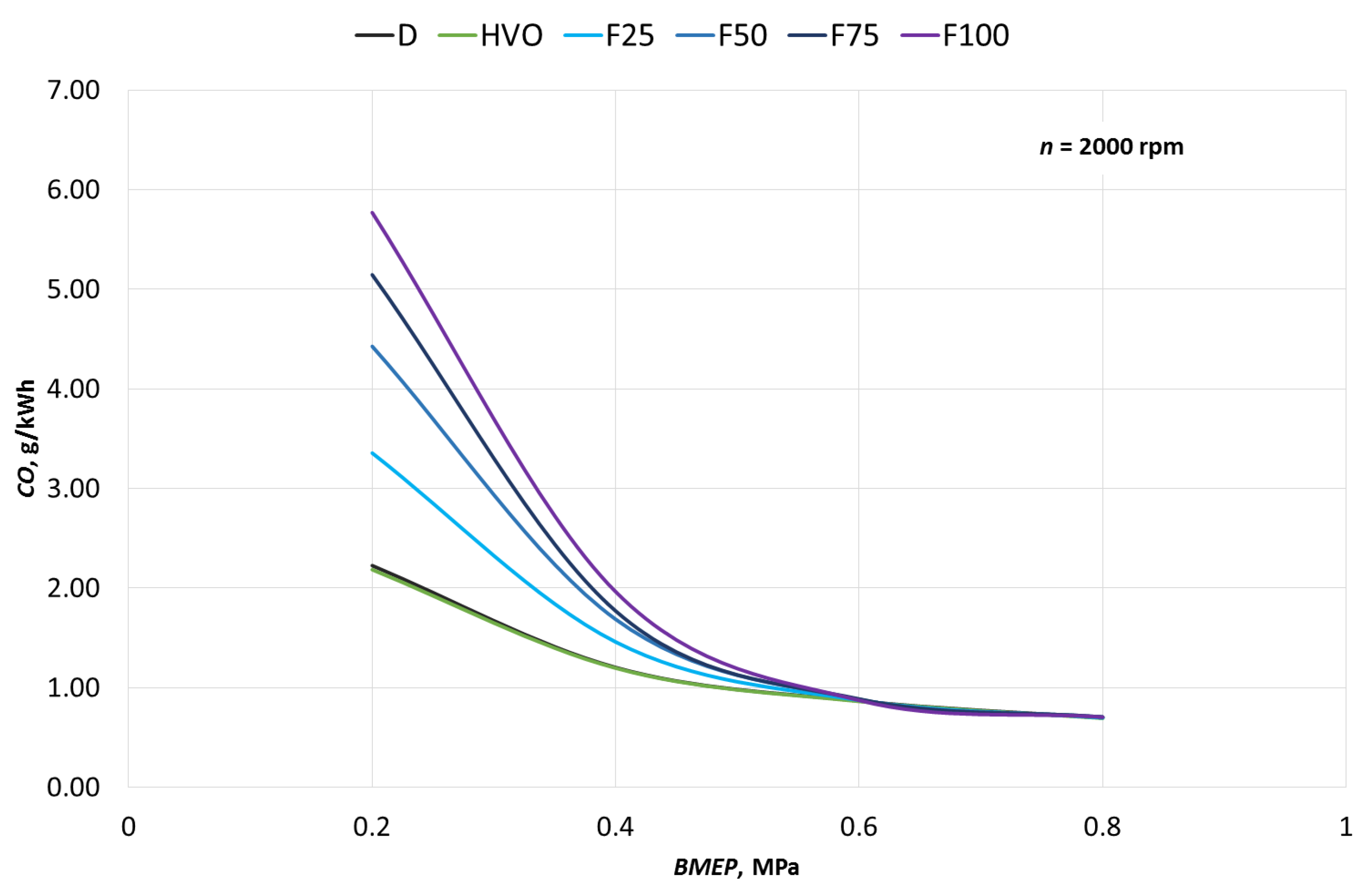

3.2.2. Emissions of Carbon Monoxide (CO)

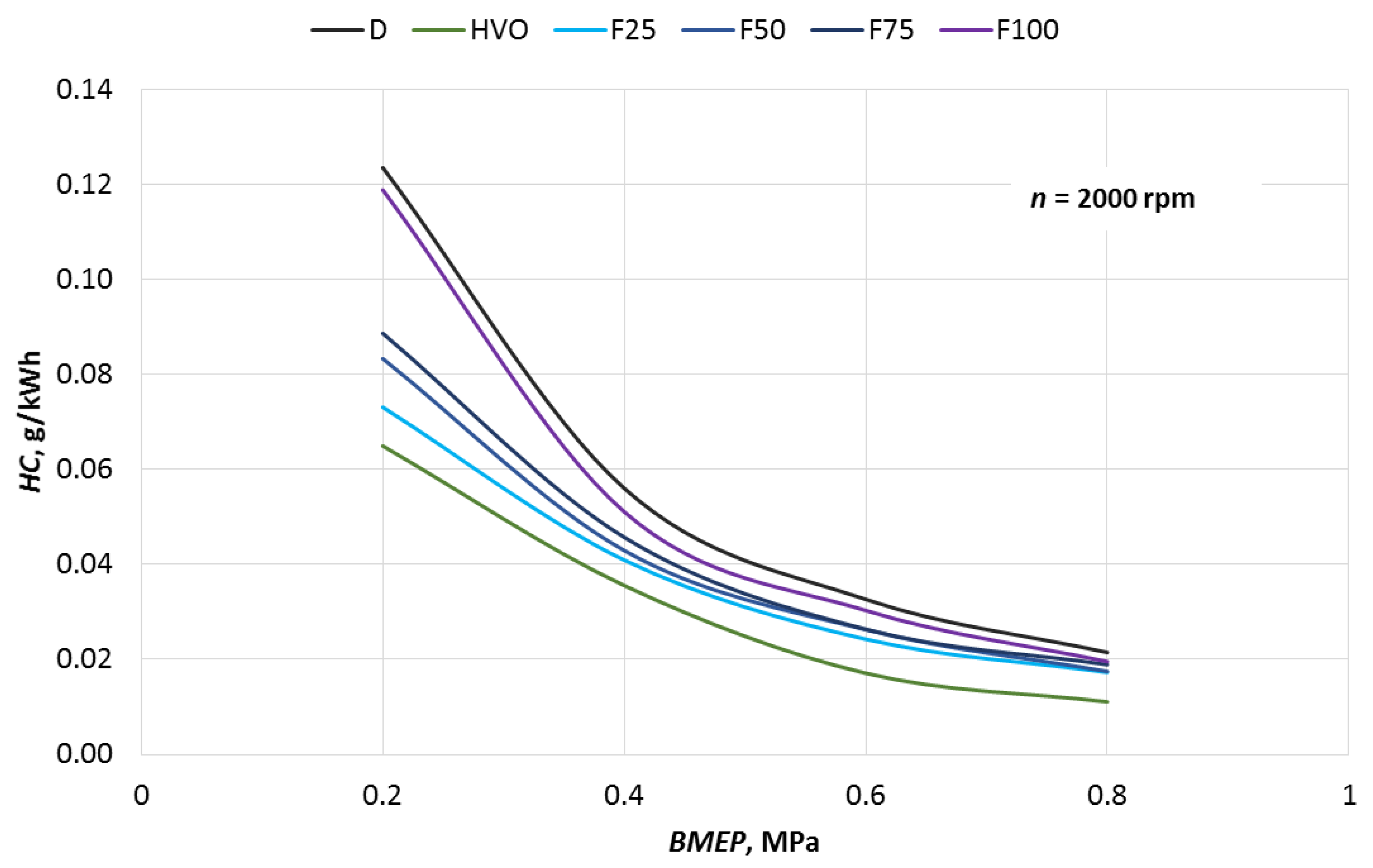

3.2.3. Emissions of Hydrocarbons (HC)

3.2.4. Smoke

3.2.5. Emissions of Nitrogen Oxide (NOx)

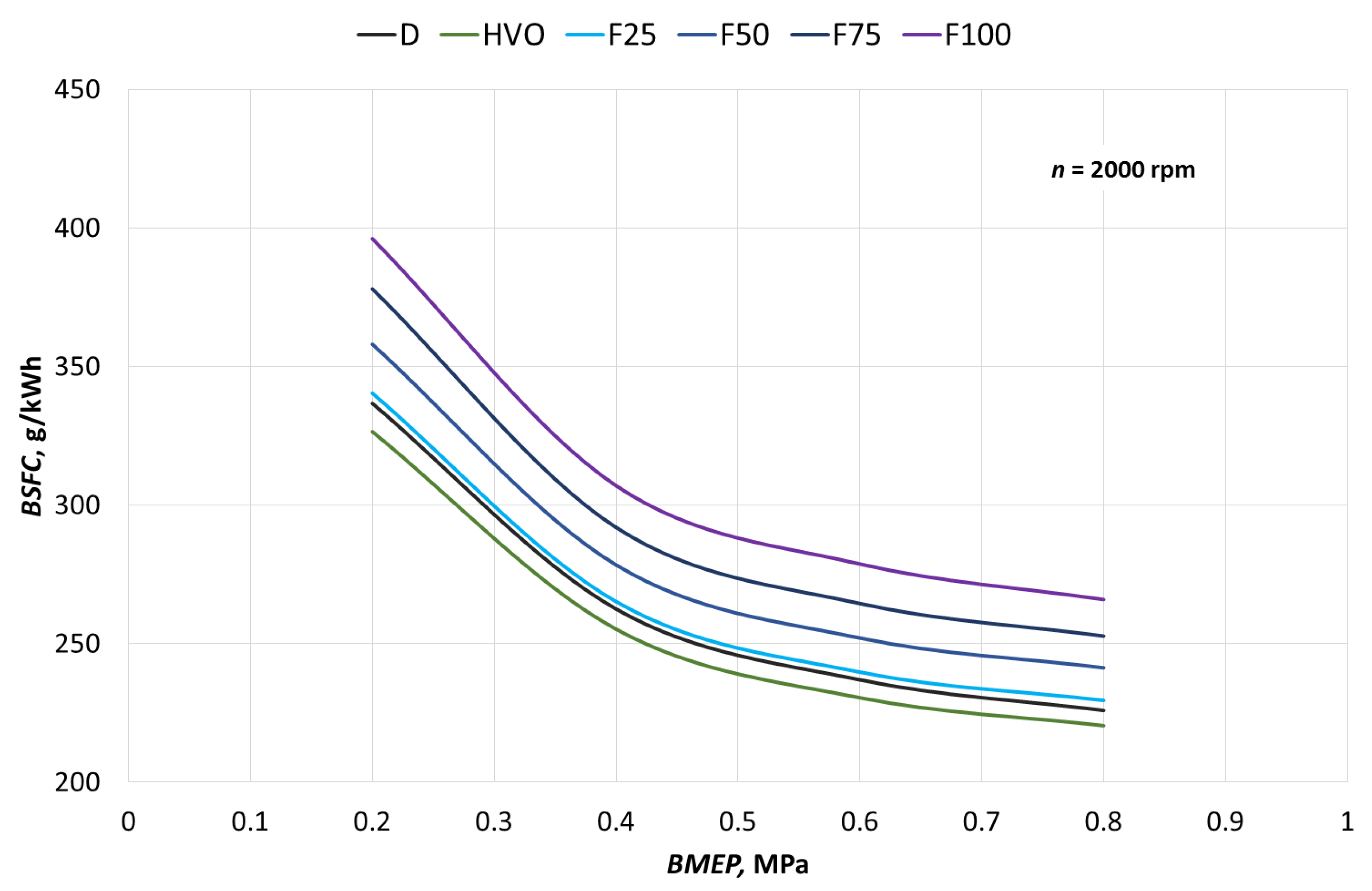

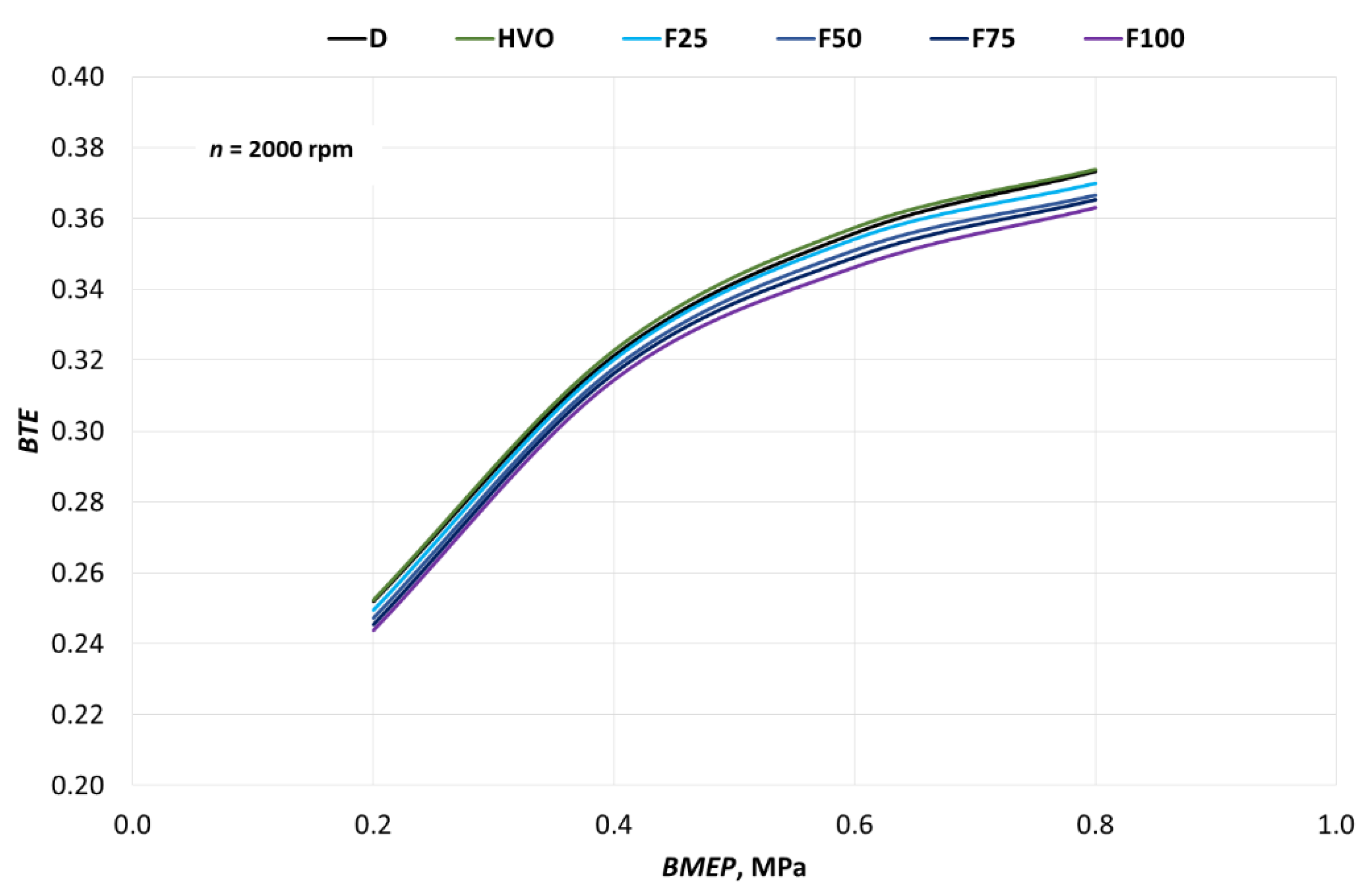

3.3. Energy Indicators

4. Conclusions

- The HVO compared to diesel fuel has ~1 CAD shorter ignition delay, ~20% lower ROHR during the premixed combustion phase, and slightly higher ROHR during the mixing-controlled combustion phase. The addition of pure fat to the mixtures increased the ignition delay phase compared to HVO, causing a shorter period of the premixed combustion phase and increasing ROHR at same time, but did not reach the level of diesel;

- CO2 emissions at all engine loads were reduced for HVO ~ 7% for F25 and F50 mixtures approximately by 3–5%, except F75 and F100, which were ~1.2% and ~2.8% higher than diesel fuel. This is mainly due to the specific fuel consumption and C/H ratio in fuels, as well as the efficiency of the mixing and combustion processes;

- CO emission at a low load for F100 increased by 160–60% compared to diesel fuel. The reason for this is a low fuel pressure, which, in turn, causes the formation of large droplets of high density and viscosity fuel, which burn much worse. Increasing the engine load significantly reduces the CO emissions of pure fat. HC emissions for HVO100, F25, F50, F75, and F100 were lower, opposite to fossil diesel fuel, respectively, ~45%, ~28%, ~23%, ~19%, and ~7%. This is explained by the simpler molecular structure of HVO and better injection and combustion properties. The fat changes the quality of the injection and the combustion deteriorates, especially at low loads;

- Smoke values, on average, decreased by 18% for HVO and 51%, 54%, 56%, and 59% for F25, F50, F75, and F100 compared to diesel fuel. The decrease in smoke emission for the mixtures can be explained by the high mass oxygen content in duck fat and the lower C/H ratio in HVO. Due to the fat additive, the worst fuel injection did not increase the smoke;

- The maximum difference of NOx emissions was observed between D and HVO and amounted to ~18%. By increasing to F100 emission of NOx, it remained 6% lower compared to diesel. It can be assumed that the maximum temperature rise during the combustion of diesel fuel is higher; therefore, the level of formation of nitrogen oxides for diesel is higher. Due to the worst fat injection, the maximum combustion temperature was lower compared to diesel;

- BSFC of pure HVO fuel was ~2.4% lower compared to conventional diesel due to 2.4% higher LHV. HVO fuel mixtures with a duck fat additive can only be used after heating them to 40–50 °C. With an increase in the concentration of fat to 100% in the HVO–fat mixtures, a proportional increase in the BSFC was observed on average up to 17.5% in comparison with conventional fossil diesel fuel due to the ~13% lower calorific value of the fat and slightly (2–3%) lower BTE for fat containing mixtures, due to their higher viscosity, and accordingly, poor atomization and combustion compared to diesel fuel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anifantis, A.S.; Colantoni, A.; Pascuzzi, S.; Santoro, F. Photovoltaic and Hydrogen Plant Integrated with a Gas Heat Pump for Greenhouse Heating: A Mathematical Study. Sustainability 2018, 10, 378. [Google Scholar] [CrossRef]

- Sarkan, B.; Skrucany, T.; Semanova, S.; Madlenak, R.; Kuranc, A.; Sejkorova, M.; Caban, J. Vehicle coast-down method as a tool for calculating total resistance for the purposes of type-approval fuel consumption. Sci. J. Sil. Univ. Technol.-Ser. Transp. 2018, 98, 161–172. [Google Scholar]

- Orynycz, O. Influence of tillage technology on energy efficiency of rapeseed plantation. Procedia Eng. 2017, 182, 532–539. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, X.; Zhang, X. The 2 °C Global Temperature Target and the Evolution of the Long-Term Goal of Addressing Climate Change—From the United Nations Framework Convention on Climate Change to the Paris Agreement. Engineering 2017, 3, 272–278. [Google Scholar] [CrossRef]

- Nazarko, J.; Czerewacz-Filipowicz, K.; Kuzmicz, A.K. Comparative analysis of the Eastern European countries as participants of the new silk road. J. Bus. Econ. Manag. 2017, 18, 1212–1227. [Google Scholar] [CrossRef]

- Stattman, S.L.; Gupta, A.; Partzsch, L.; Oosterveer, P. Toward Sustainable Biofuels in the European Union? Lessons from a Decade of Hybrid Biofuel Governance. Sustainability 2018, 10, 4111. [Google Scholar] [CrossRef]

- Ponte, S.; Daugbjerg, C. Biofuel sustainability and the formation of transnational hybrid governance. Environ. Politics 2015, 24, 96–114. [Google Scholar] [CrossRef]

- Fact Sheets on the European Union. Energy Policy: General Principles. Available online: https://www.europarl.europa.eu/factsheets/en/sheet/68/energy-policy-general-principles (accessed on 23 June 2022).

- Clean Energy for All Europeans Package. Available online: https://energy.ec.europa.eu/topics/energy-strategy/clean-energy-all-europeans-package_en (accessed on 23 June 2022).

- Renewable Energy Policies in a Time of Transition. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2018/Apr/IRENA_IEA_REN21_Policies_2018.pdf (accessed on 23 June 2022).

- Robaina, M.; Neves, A. Complete decomposition analysis of CO2 emissions intensity in the transport sector in Europe. Res. Transp. Econ. 2021, 90, 101074. [Google Scholar] [CrossRef]

- Mizik, T.; Gyarmati, G. Economic and Sustainability of Biodiesel Production—A Systematic Literature Review. Clean Technol. 2021, 3, 19–36. [Google Scholar] [CrossRef]

- European Climate Law. Available online: https://ec.europa.eu/clima/eu-action/european-green-deal/european-climate-law_en (accessed on 23 June 2022).

- Hazrat, M.A.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Rufford, T.E. Emission characteristics of waste tallow and waste cooking oil based ternary biodiesel fuels. Energy Procedia 2019, 160, 842–847. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Determination of a diesel engine operating parameters powered with canola, safflower and waste vegetable oil based biodiesel combination using response surface methodology (RSM). Fuel 2020, 270, 117496. [Google Scholar] [CrossRef]

- Emiroglu, A.O.; Keskin, A.; Sen, M. Experimental investigation of the effects of turkey rendering fat biodiesel on combustion, performance and exhaust emissions of a diesel engine. Fuel 2018, 216, 266–273. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Verma, T.N.; Shrivastava, P.; Rajak, U.; Dwivedi, G.; Jain, S.; Zare, A.; Shukla, A.K.; Verma, P. A comprehensive review of the influence of physicochemical properties of biodiesel on combustion characteristics, engine performance and emissions. J. Traffic Transp. Eng. 2021, 8, 510–533. [Google Scholar] [CrossRef]

- Szmigielski, M.; Zarajczyk, J.; Węgrzyn, A.; Leszczyński, N.; Kowalczuk, J.; Andrejko, D.; Krzysiak, Z.; Samociuk, W.; Zarajczyk, K. Testing the technological line for the production of alternative fuels. Przem. Chem. 2018, 97, 1079–1082. [Google Scholar]

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A comprehensive review of physicochemical properties, production process, performance and emissions characteristics of 2nd generation biodiesel feedstock: Jatropha curcas. Fuel 2021, 285, 119110. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Natsios, I.; Dimaratos, A.; Katsaounis, D.; Samaras, Z.; Bezergianni, S.; Lehto, K. Hydrotreated Vegetable Oil (HVO) and Effects on Emissions of a Passenger Car Diesel Engine. Front. Mech. Eng. 2018, 4, 7. [Google Scholar] [CrossRef]

- Rimkus, A.; Vipartas, T.; Matijošius, J.; Stravinskas, S.; Kriaučiūnas, D. Study of Indicators of CI Engine Running on Conventional Diesel and Chicken Fat Mixtures Changing EGR. Appl. Sci. 2021, 11, 1411. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Ahmed, C.M.S.; Canchola, A.; Chen, J.Y.; Li, C.; Johnson, K.C.; Durbin, T.D.; Lin, Y.H.; Karavalakis, G. Effects of hydrogenated vegetable oil (HVO) and HVO/biodiesel blends on the physicochemical and toxicological properties of emissions from an off-road heavy-duty diesel engine. Fuel 2022, 323, 124283. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Fayaz, H. Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew. Sustain. Energy Rev. 2013, 18, 211–245. [Google Scholar] [CrossRef]

- Stopka, O.; Stopková, M.; Pečman, J. Application of Multi-Criteria Decision Making Methods for Evaluation of Selected Passenger Electric Cars: A Case Study. Commun. Sci. Lett. Univ. Zilina 2022, 24, A133–A141. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O. Bioenergy and Biofuels. Sustainability 2021, 13, 9972. [Google Scholar] [CrossRef]

- Lópeza, E.M.T.; Mauricioa, W.H.B.; Oliveraa, C.A.C.; Floresa, J.W.V.; Alfaroa, E.G.B.; Gonzales, L.G.V. Comparison of Biodiesel Extracted from Pork and Duck Fat. Chem. Eng. Trans. 2021, 87, 505–510. [Google Scholar] [CrossRef]

- Kinnal, N.; Sujaykumar, G.; D’costa, S.W.; Girishkumar, G.S. Investigation on Performance of Diesel Engine by Using Waste Chicken Fat Biodiesel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012012. [Google Scholar] [CrossRef]

- Ramalingam, S.; Rajendran, S.; Ganesan, P.; Govindasamy, M. Effect of Operating Parameters and Antioxidant Additives with Biodiesels to Improve the Performance and Reducing the Emissions in a Compression Ignition Engine—A Review. Renew. Sustain. Energy Rev. 2018, 81, 775–788. [Google Scholar] [CrossRef]

- Caban, J.; Jandacka, J.; Nieoczym, A.; Holubcik, M.; Vrabel, J. Preliminary Studies of Fuel Briquettes from Wood Waste. Engineering for Rural Development. Available online: https://www.tf.llu.lv/conference/proceedings2021/Papers/TF293.pdf (accessed on 23 June 2022).

- Kumar, M.S.; Jaikumar, M. A Comprehensive Study on Performance, Emission and Combustion Behavior of a Compression Ignition Engine Fuelled with WCO (Waste Cooking Oil) Emulsion as Fuel. J. Energy Inst. 2014, 87, 263–271. [Google Scholar] [CrossRef]

- Mikulski, M.; Duda, K.; Wierzbicki, S. Performance and Emissions of a CRDI Diesel Engine Fuelled with Swine Lard Methyl Esters–Diesel Mixture. Fuel 2016, 164, 206–219. [Google Scholar] [CrossRef]

- Elkelawy, M.; Alm-Eldin Bastawissi, H.; Esmaeil, K.K.; Radwan, A.M.; Panchal, H.; Sadasivuni, K.K.; Ponnamma, D.; Walvekar, R. Experimental studies on the biodiesel production parameters optimization of sunflower and soybean oil mixture and DI engine combustion, performance, and emission analysis fueled with diesel/biodiesel blends. Fuel 2019, 255, 115791. [Google Scholar] [CrossRef]

- Kanthasamy, S.; Karthick, A.; Ramalingam, V.; Praveen, M.V.J. Performance and emission characteristics of diesel engine fueled with ternary blends of linseed and rubber seed oil biodiesel. Fuel 2021, 285, 119255. [Google Scholar] [CrossRef]

- Ghazali, W.N.M.W.; Mamat, R.; Masjuki, H.H.; Najafi, G. Effects of biodiesel from different feedstocks on engine performance and emissions: A review. Renew. Sustain. Energy Rev. 2015, 51, 585–602. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Shafay, A.S.; Abu Hashish, H.M. Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds. Process Saf. Environ. Prot. 2021, 147, 518–526. [Google Scholar] [CrossRef]

- Sen, M.; Emiroglu, A.O.; Keskin, A. Production of biodiesel from broiler chicken rendering fat and investigation of its effects on combustion, performance, and emissions of a diesel engine. Energy Fuels 2018, 32, 5209–5217. [Google Scholar] [CrossRef]

- Ge, S.; Brindhadevi, K.; Xia, C.; Elesawy, B.H.; Elfasakhany, A.; Unpaprom, Y.; Doan, H.V. Egg shell catalyst and chicken waste biodiesel blends for improved performance, combustion and emission characteristics. Fuel 2021, 306, 121633. [Google Scholar] [CrossRef]

- Karmakar, A.; Karmakar, S.; Mukherjee, S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour. Technol. 2010, 101, 7201–7210. [Google Scholar] [CrossRef]

- Du, E.; Cai, L.; Huang, K.; Tang, H.; Xu, X.; Tao, R. Reducing viscosity to promote biodiesel for energy security and improve combustion efficiency. Fuel 2018, 211, 194–196. [Google Scholar] [CrossRef]

- Keskin, A.; Şen, M.; Emiroğlu, A.O. Experimental studies on biodiesel production from leather industry waste fat and its effect on diesel engine characteristics. Fuel 2020, 276, 118000. [Google Scholar] [CrossRef]

- Milojevic, S.; Savić, S.; Marić, D.; Stopka, O.; Krstić, B.; Stoja, B. Correlation between Emission and Combustion Characteristics with the Compression Ratio and Fuel Injection Timing in Tribologically Optimized Diesel Engine. Teh. Vjesn. 2022, 29, 1210–1219. [Google Scholar]

- Alptekin, E.; Canakci, M.; Ozsezen, A.N.; Turkcan, A.; Sanli, H. Using Waste Animal Fat Based Biodiesels–Bioethanol–Diesel Fuel Blends in a DI Diesel Engine. Fuel 2015, 157, 245–254. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljkovic, V.B.; Hung, Y.-T. Waste Animal Fats as Feedstocks for Biodiesel Production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef]

- El-Shafay, A.S.; Ağbulut, Ü.; Attia, E.-A.; Touileb, K.L.; Gad, M.S. Waste to Energy: Production of Poultry-Based Fat Biodiesel and Experimental Assessment of Its Usability on Engine Behaviors. Energy 2022, 262, 125457. [Google Scholar] [CrossRef]

- Karuppan, D.; Muthu Manokar, A.; Vijayabalan, P.; Sathyamurthy, R.; Madhu, B.; Mageshbabu, D.; Bharathwaaj, R.; Jenoris Muthiya, S. Experimental Investigation on Pressure and Heat Release HCCI Engine Operated with Chicken Fat Oil/Diesel-Gasoline Blends. Mater. Today Proc. 2020, 33, 437–444. [Google Scholar] [CrossRef]

- Suhel, A.; Abdul Rahim, N.; Abdul Rahman, M.R.; Bin Ahmad, K.A. Engine’s Behaviour on Magnetite Nanoparticles as Additive and Hydrogen Addition of Chicken Fat Methyl Ester Fuelled DICI Engine: A Dual Fuel Approach. Int. J. Hydrog. Energy 2021, 46, 14824–14843. [Google Scholar] [CrossRef]

- Raman, A.L.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Ghobadian, B.; Tavakoli-Hashjin, T.; Mohtasebi, S.S.; Rezaei-Asl, A.; Azadbakht, M. Characterization of Engine’s Combustion-Vibration Using Diesel and Biodiesel Fuel Blends by Time-Frequency Methods: A Case Study. Renew. Energy 2016, 95, 422–432. [Google Scholar] [CrossRef]

- Cheikh, K.; Sary, A.; Khaled, L.; Abdelkrim, L.; Mohand, T. Experimental Assessment of Performance and Emissions Maps for Biodiesel Fueled Compression Ignition Engine. Appl. Energy 2016, 161, 320–329. [Google Scholar] [CrossRef]

- Shah, P.R.; Ganesh, A. A comparative study on influence of fuel additives with edible and non-edible vegetable oil based on fuel characterization and engine characteristics of diesel engine. Appl. Therm. Eng. 2016, 102, 800–812. [Google Scholar] [CrossRef]

- Stone, R. Intergovernmental Panel on Climate Change. Summary for Policymakers. In Climate Change 2013—The Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 1–30. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties, and specifications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Rosman, N.A.; AbdulKareem-Alsultan, G.; Mastuli, M.S.; Lee, H.V.; Nabihah-Fauzi, N.; Lokman, I.M.; Alharthi, F.A.; Alghamdi, A.A.; Aisyahi, A.A.; et al. Production of Renewable Diesel from Jatropha Curcas Oil via Pyrolytic-Deoxygenation over Various Multi-Wall Carbon Nanotube-Based Catalysts. Process Saf. Environ. Prot. 2020, 142, 336–349. [Google Scholar] [CrossRef]

- Selvam, D.J.P.; Vadivel, K. Performance and Emission Analysis of DI Diesel Engine Fuelled with Methyl Esters of Beef Tallow and Diesel Blends. Procedia Eng. 2012, 38, 342–358. [Google Scholar] [CrossRef]

- Gad, M.S.; EL-Seesy, A.I.; Hashish, H.M.A.; He, Z.; Alshaer, W.G. Combustion and emissions aspects of a diesel engine working with sheep fat oil biodiesel-diesel blends. Case Stud. Therm. Eng. 2021, 26, 101162. [Google Scholar] [CrossRef]

- Krishania, N.; Rajak, U.; Chaurasiya, P.K.; Singh, T.S.; Birru, A.K.; Verma, T.N. Investigations of spirulina, waste cooking and animal fats blended biodiesel fuel on auto-ignition diesel engine performance, emission characteristics. Fuel 2020, 276, 118123. [Google Scholar] [CrossRef]

- Goga, G.; Chauhan, B.S.; Mahla, S.K.; Cho, H.M. Performance and emission characteristics of diesel engine fueled with rice bran biodiesel and n-butanol. Energy Rep. 2019, 5, 78–83. [Google Scholar] [CrossRef]

- Jayabal, R.; Thangavelu, L.; Subramani, S. Combined Effect of Oxygenated Additives, Injection Timing and EGR on Combustion, Performance and Emission Characteristics of a CRDi Diesel Engine Powered by Sapota Biodiesel/Diesel Blends. Fuel 2020, 276, 118020. [Google Scholar] [CrossRef]

- Barrios, C.C.; Domínguez-Sáez, A.; Martín, C.; Álvarez, P. Effects of animal fat based biodiesel on a TDI diesel engine performance, combustion characteristics and particle number and size distribution emissions. Fuel 2014, 117, 618–623. [Google Scholar] [CrossRef]

- Graboski, M.S.; McCormick, R.L.; Alleman, T.L.; Herring, A.M. Impact of biodiesel source material and chemical structure on emissions of criteria pollutants from a heavy-duty engine. Environ. Sci. Technol. 2001, 35, 1742–1747. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Shameer, P.M. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 2018, 83, 2970–2992. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N.; Pugazhendhi, A. Performance and emission analysis of a diesel engine using hydrogen enriched n-butanol, diethyl ester and Spirulina microalgae biodiesel. Fuel 2020, 271, 117645. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Badruddin, I.A.; Mahlia, T.M.I.; Masjuki, H.H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 2012, 16, 4. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. A comprehensive review of biodiesel as an alternative fuel for compression ignition engine. Renew. Sustain. Energy Rev. 2016, 57, 799–821. [Google Scholar] [CrossRef]

- Rao, K.; Ramakrishna, A.; Rao, P. Effect of fuel injection pressure on performance and emission characteristics of DI-CI engine fueled with chicken fat biodiesel. Int. J. Heat Technol. 2013, 71, 53–59. [Google Scholar]

- Mohiddin, M.N.; Saleh, A.A.; Reddy, A.N.R.; Hamdan, S. A Study on Chicken Fat as an Alternative Feedstock: Biodiesel Production, Fuel Characterisation, and Diesel Engine Performance Analysis. Int. J. Automot. Mech. Eng. 2018, 15, 5535–5546. [Google Scholar] [CrossRef]

- Kanthasamy, P.; Selvan, V.A.M. FTIR and GCMS analysis on useful methyl ester compound from industrial waste animal fleshing oil (WAFO). Mater. Today Proc. 2021, 46, 10072–10078. [Google Scholar] [CrossRef]

- Kirubakaran, M.; Selvan, V.A.M. Experimental investigation on the effects of micro eggshell and nano-eggshell catalysts on biodiesel optimization from waste chicken fat. Bioresour. Technol. Rep. 2021, 14, 100658. [Google Scholar] [CrossRef]

- Kirubakaran, M.; Selvan, V.A.M. Biodiesel Prod. Waste Chick. Oil Using Nanoeggshell Heterog. Catal. Isopropyl Ether Cosolvent. Environ. Qual. Manag. 2020, 31, 51–64. [Google Scholar] [CrossRef]

- Kanthasamy, P.; Selvan, V.A.M.; Shanmugam, P. Investigation on the performance, emissions and combustion characteristics of CRDI engine fuelled with tallow methyl ester biodiesel blends with exhaust gas recirculation. J. Therm. Anal. Calorim. 2020, 141, 2325–2333. [Google Scholar] [CrossRef]

- Kirubakaran, M.; Selvan, V.A.M. Eggshell as heterogeneous catalyst for synthesis of biodiesel from high free fatty acid chicken fat and its working characteristics on a CI engine. J. Environ. Chem. Eng. 2018, 6, 4490–4503. [Google Scholar] [CrossRef]

- Abed, K.A.; El Morsi, A.K.; Sayed, M.M.; El Shaib, A.A.; Gad, M.S. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Jayaprabakar, J.; Dawn, S.S.; Ranjan, A.; Priyadharsini, P.; George, R.J.; Sadaf, S.; Rajha, C.R. Process optimization for biodiesel production from sheep skin and its performance, emission and combustion characterization in CI engine. Energy 2019, 174, 54–68. [Google Scholar] [CrossRef]

- ISO 21748:2017; Guidance for the Use of Repeatability, Reproducibility and Trueness Estimates in Measurement Uncertainty Evaluation. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/71615.html (accessed on 14 October 2022).

- JCGM 100:2008; Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement. JCGM: Geneva, Switzerland. Available online: https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf/cb0ef43f-baa5-11cf-3f85-4dcd86f77bd6 (accessed on 14 October 2022).

- Topare, N.S.; Jogdand, R.I.; Shinde, H.P.; More, R.S.; Khan, A.; Asiri, A.M. A short review on approach for biodiesel production: Feedstock’s, properties, process parameters and environmental sustainability. Mater. Today Proc. 2022, 57, 1605–1612. [Google Scholar] [CrossRef]

- Syed, A.; Quadri, S.A.P.; Rao, G.A.P.; Mohd, W. Experimental investigations on DI (direct injection) diesel engine operated on dual fuel mode with hydrogen and mahua oil methyl ester (MOME) as injected fuels and effects of injection opening pressure. Appl. Therm. Eng. 2017, 114, 118–129. [Google Scholar] [CrossRef]

- Sivalakshmi, S.; Balusamy, T. Influence of Ethanol Addition on a Diesel Engine Fuelled with Neem Oil Methyl Ester. Int. J. Green Energy 2012, 9, 218–228. [Google Scholar] [CrossRef]

- Bello, E.I.; Out, F.; Osasona, A. Cetane number of three vegetable oils, their biodiesels and blends with diesel fuel. J. Pet. Technol. Altern. Fuels 2012, 3, 52–57. [Google Scholar] [CrossRef]

- Knoth, G. Cetane Numbers-Heat of Combustion-Why Vegetable Oils and Their Derivatives Are Suitable as a Diesel Fuel, 1st ed.; The Biodiesel Handbook; AOCS Press: Champaign, IL, USA, 2005; pp. 4–16. [Google Scholar]

- Martinka, J.; Rantuch, P.; Wachter, I. Impact of Water Content on Energy Potential and Combustion Characteristics of Methanol and Ethanol Fuels. Energies 2019, 12, 3491. [Google Scholar] [CrossRef]

- Singer, A.; Schröder, O.; Pabst, C.; Munack, A.; Bünger, J.; Ruck, W.; Krahl, J. Aging studies of biodiesel and HVO and their testing as neat fuel and blends for exhaust emissions in heavy-duty engines and passenger cars. Fuel 2015, 153, 595–603. [Google Scholar] [CrossRef]

- Mofijur, M.; Hazrat, M.A.; Rasul, M.G.; Mahmudul, H.M. Comparative Evaluation of Edible and Non-edible Oil Methyl Ester Performance in a Vehicular Engine. Energy Procedia 2015, 75, 37–43. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Rapalis, P.; Skačkauskas, P. Research on the Combustion, Energy and Emission Parameters of Diesel Fuel and a Biomass-to-Liquid (BTL) Fuel Blend in a Compression-Ignition Engine. Energy Convers. Manag. 2015, 106, 1109–1117. [Google Scholar] [CrossRef]

- Abdulkadir, L.N.; Adisa, A.B.; Kyauta, E.E.; Raheem, M.A. Corrosion and Engine Test Analysis of Neem (Azadirachta indica) Oil Blends in a Single Cylinder, Four Stroke, and Air-cooled Compresion Ignition Engine. Am. J. Mech. Eng. 2014, 2, 151–158. [Google Scholar]

- Levine, F.; Kayea, R.V.; Wexler, R.; Sadvary, D.J.; Melick, C.; La Scala, J. Heats of Combustion of Fatty Acids and Fatty Acid Esters. J. Am. Oil Chem. Soc. 2014, 91, 235–249. [Google Scholar] [CrossRef]

- Duda, K.; Wierzbicki, S.; Śmieja, M.; Mikulski, M. Comparison of performance and emissions of a CRDI diesel engine fuelled with biodiesel of different origin. Fuel 2018, 212, 202–222. [Google Scholar] [CrossRef]

- Barua, P.; Hossain, N.; Chowdhury, T.; Chowdhury, H. Commercial Diesel Application Scenario and Potential of Alternative Biodiesel from Waste Chicken Skin in Bangladesh. Environ. Technol. Innov. 2020, 20, 101139. [Google Scholar] [CrossRef]

| Fuels | Density (kg/m3) at 15° | Viscosity (mm2/s) at 40° | Sulfur Content (mg/kg) | Water Content (mg/kg) | Total Contamination (mg/kg) | Cetane Number | Hydrogen % | Carbon % | Oxygen% | C/H% | LHV (MJ/kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Allowed value in accordance with quality standard EN 590 | |||||||||||

| 820–845 | 2–4.5 | ≤10 | ≤200 | ≤24 | ≥51 | ||||||

| D100 | 823.00 | 3.5 | 7.25 | 85 | 20 | 45 | 0.130 | 0.870 | 0.000 | 6.69 | 42.70 |

| Allowed value in accordance with quality standard EN 14214 | |||||||||||

| 860–900 | 3.5–5 | ≤10 | ≤500 | ≤24 | ≥51 | ||||||

| F25 | 800 | 4.7 | 4.52 | 690 | 43.27 | 72.04 | 0.146 | 0.827 | 0.027 | 5.64 | 42.40 |

| F50 | 831 | 9.8 | 4.87 | 770 | - | 67.19 | 0.141 | 0.804 | 0.055 | 5.70 | 40.70 |

| F75 | 867 | 18.8 | 5.21 | 925 | - | 62.34 | 0.136 | 0.782 | 0.082 | 5.77 | 39.00 |

| F100 | 908 | 34.8 | 5.31 | 1450 | - | 57.49 | 0.130 | 0.760 | 0.110 | 5.85 | 37.30 |

| Allowed value in accordance with the booklet information on Neste Renewable Diesel for HVO | |||||||||||

| 770–790 | 2–4 | ≤5 | ≤200 | ≤10 | >70 | ||||||

| HVO100 | 776.00 | 2.9 | 4.16 | 20 | 5.52 | 76.89 | 0.152 | 0.848 | 0.000 | 5.58 | 43.70 |

| Specification | Parameter |

|---|---|

| Engine | 1.9 Turbodiesel Direct Injection |

| Number of cylinders | 4 |

| Compression ratio | 19.5 |

| Stroke | 95.5 mm |

| Bore | 79.5 mm |

| Maximum power output | 66 kW at 4000 rpm |

| Maximum torque | 182 Nm at 2000–2500 rpm |

| Parameter | Standard Uncertainly u | Expanded Uncertainly U0.99 |

|---|---|---|

| ROHR, J/CAD | 0.003657 | 0.025 |

| Temperature rise K/deg | 0.002987 | 0.017 |

| Pressure rise in cylinder, MPa/deg | 0.005987 | 0.036 |

| Pressure in cylinder, MPa | 0.005745 | 0.034 |

| CO2, g/kWh | 0.000301 | 0.007 |

| CO, g/kWh | 0.000258 | 0.006 |

| HC, g/kWh | 0.006987 | 0.041 |

| Smoke, m−1 | 0.000249 | 0.005 |

| NOx, g/kWh | 0.007459 | 0.052 |

| BSFC, g/kWh | 0.005221 | 0.032 |

| BTE | 0.003698 | 0.025 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shepel, O.; Matijošius, J.; Rimkus, A.; Orynycz, O.; Tucki, K.; Świć, A. Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine. Energies 2022, 15, 7892. https://doi.org/10.3390/en15217892

Shepel O, Matijošius J, Rimkus A, Orynycz O, Tucki K, Świć A. Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine. Energies. 2022; 15(21):7892. https://doi.org/10.3390/en15217892

Chicago/Turabian StyleShepel, Oleksandra, Jonas Matijošius, Alfredas Rimkus, Olga Orynycz, Karol Tucki, and Antoni Świć. 2022. "Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine" Energies 15, no. 21: 7892. https://doi.org/10.3390/en15217892

APA StyleShepel, O., Matijošius, J., Rimkus, A., Orynycz, O., Tucki, K., & Świć, A. (2022). Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine. Energies, 15(21), 7892. https://doi.org/10.3390/en15217892