Analysis of the Influence of System Parameters on Launch Performance of Electromagnetic Induction Coil Launcher

Abstract

:1. Introduction

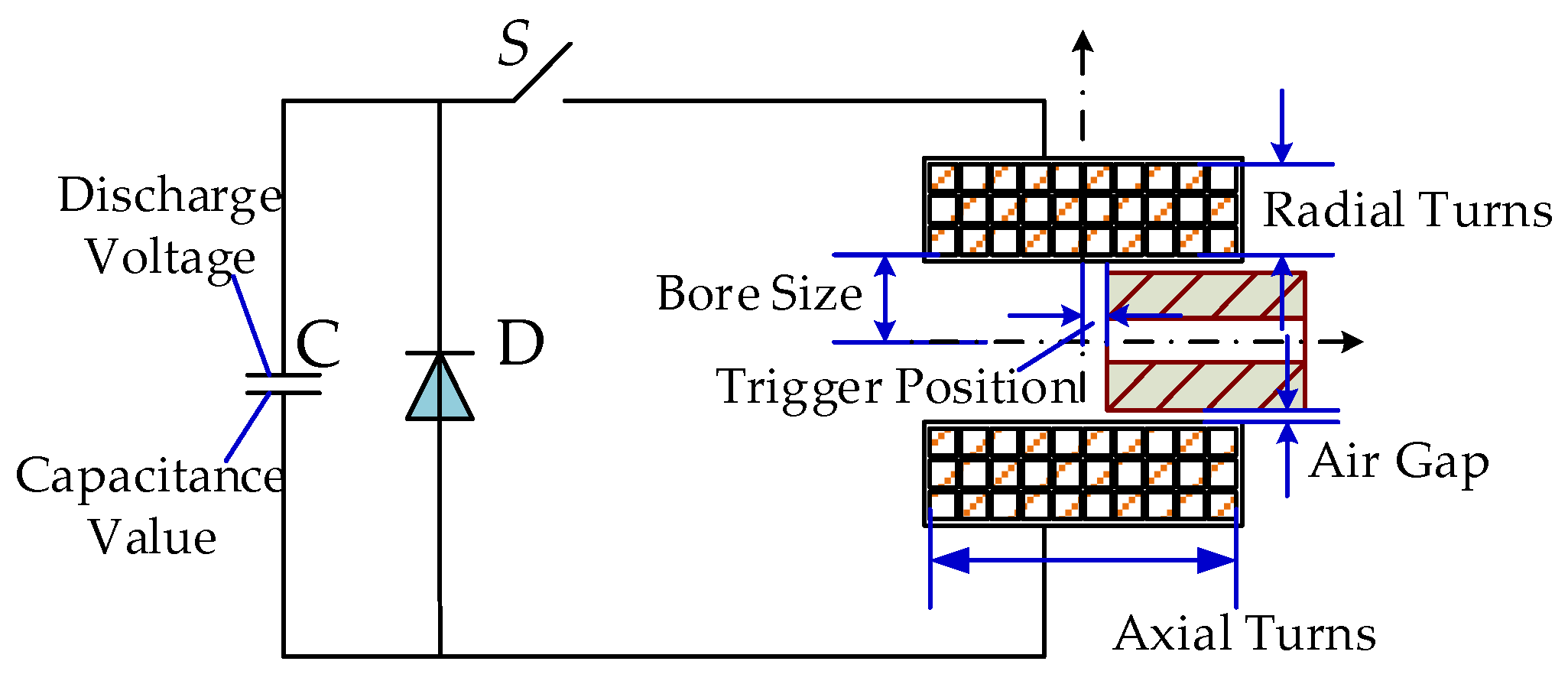

2. Launch Performance of EICL

3. System Parameters of EICL

4. Pulse Power Supply Parameters

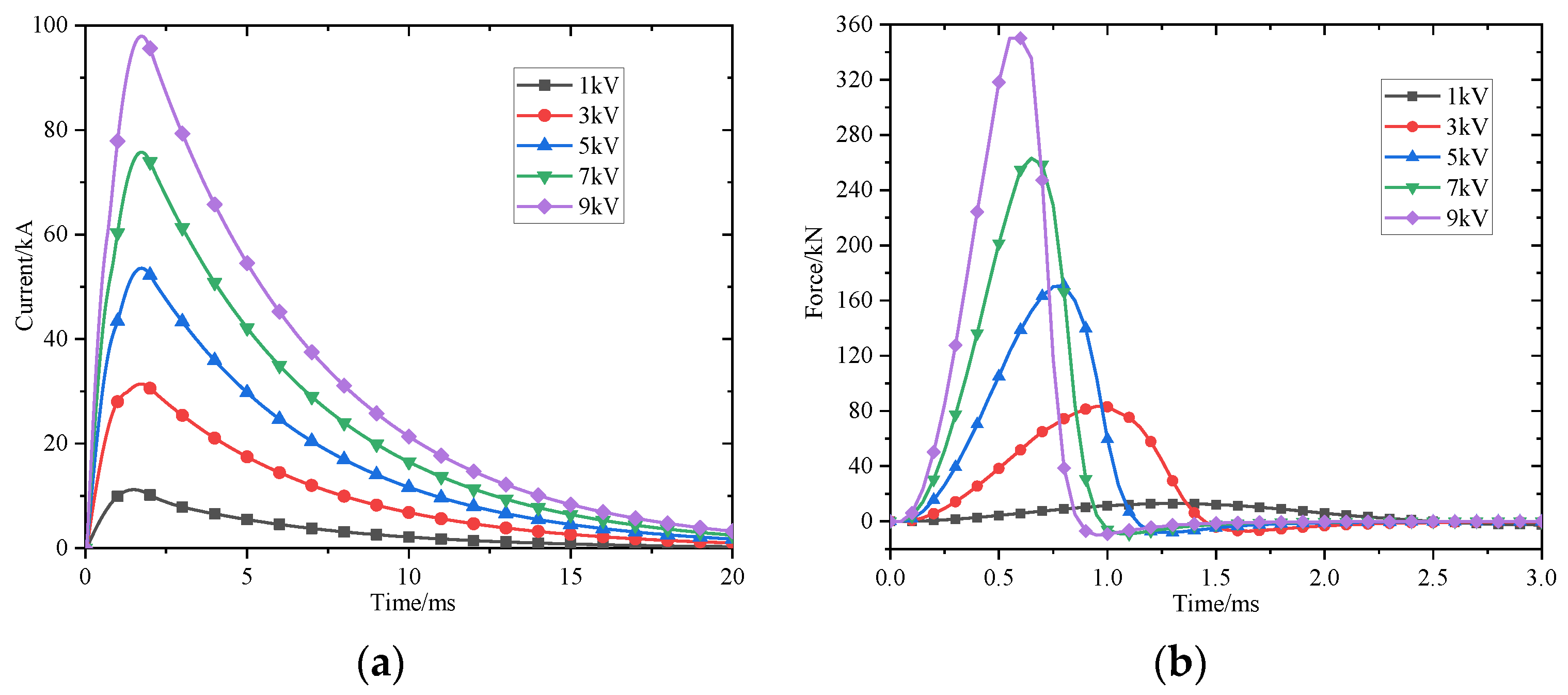

4.1. Influence of the Discharge Voltage on the Launch Performance

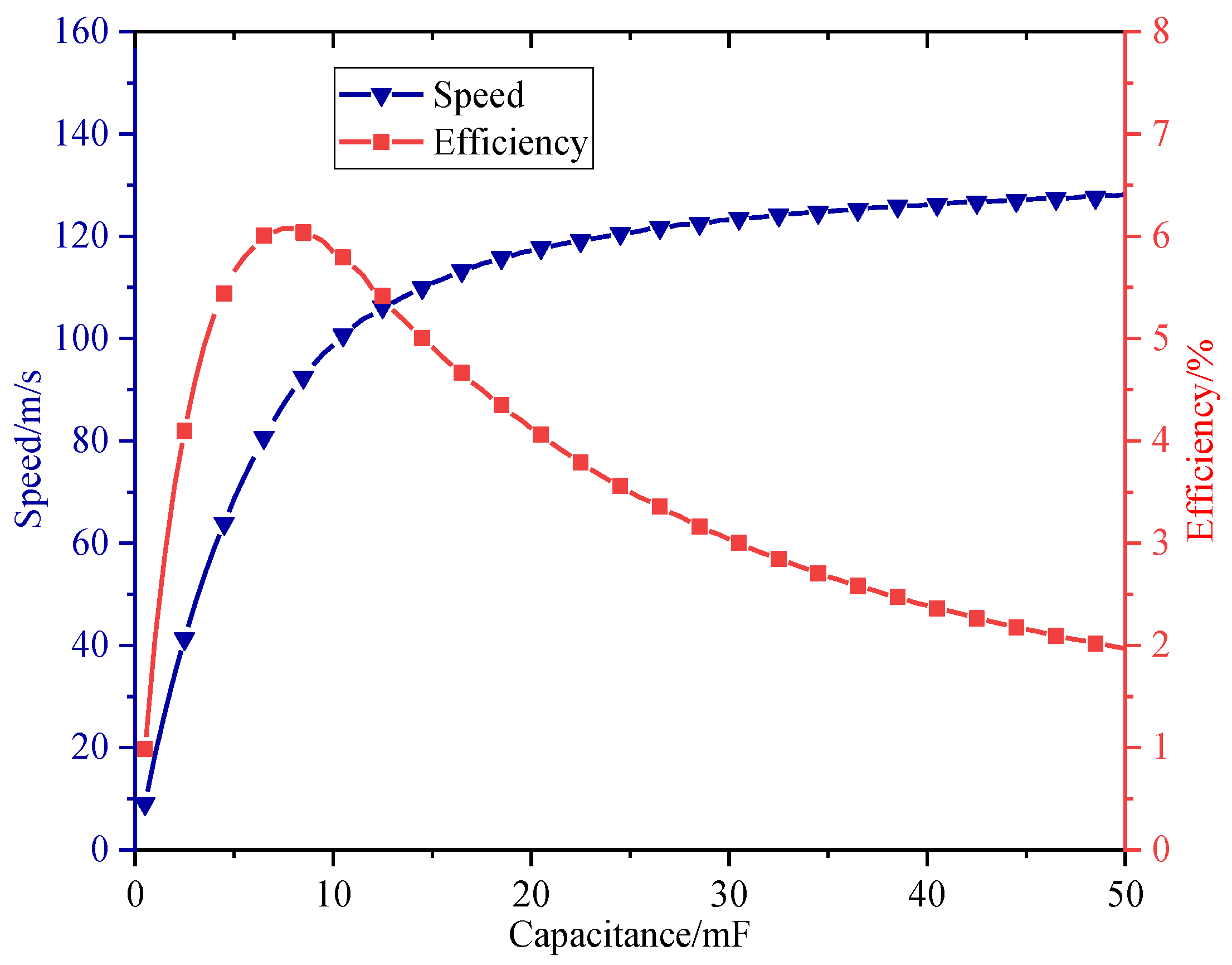

4.2. Influence of the Capacitance Value on the Launch Performance

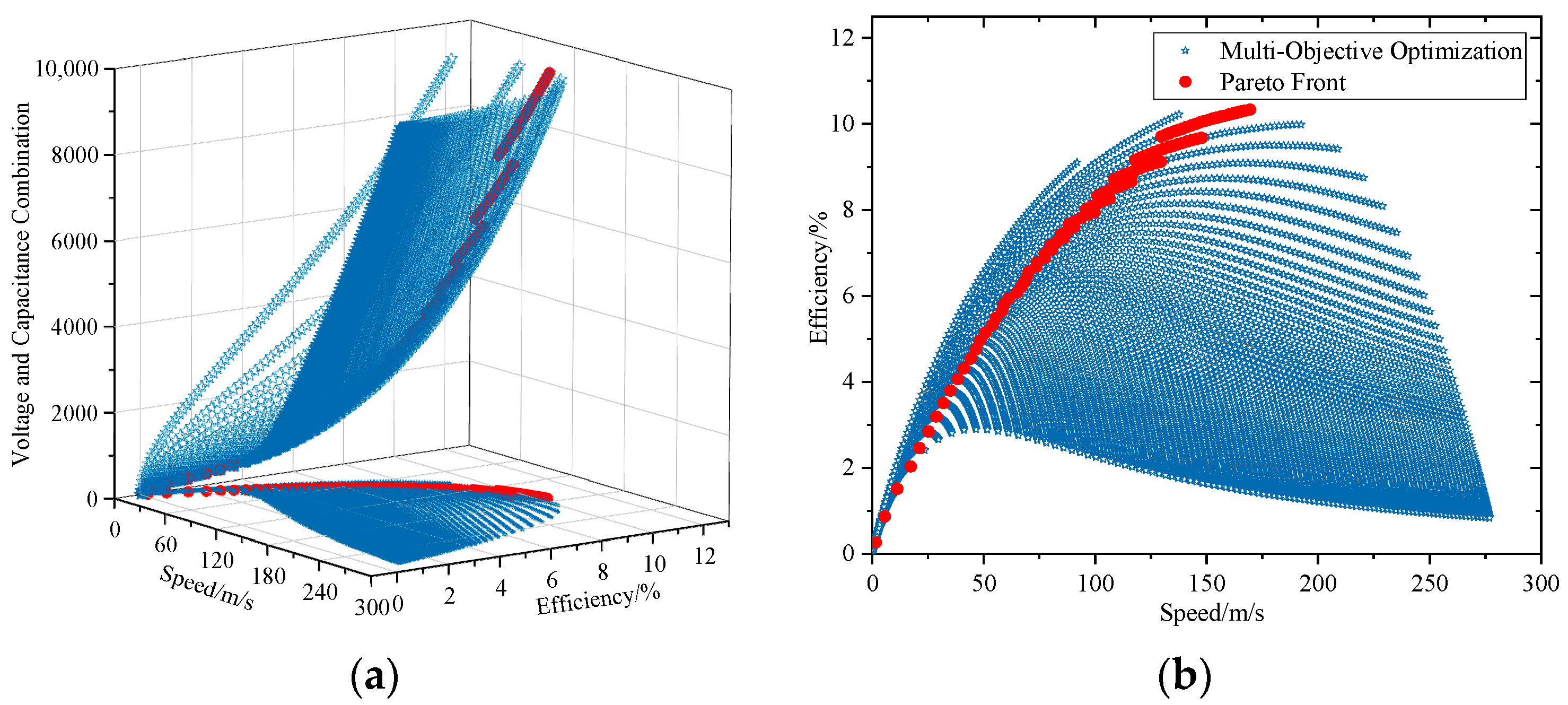

4.3. Influence of the Discharge Voltage and Capacitance Value Combination on the Launch Performance

5. Structural Parameters of EICL

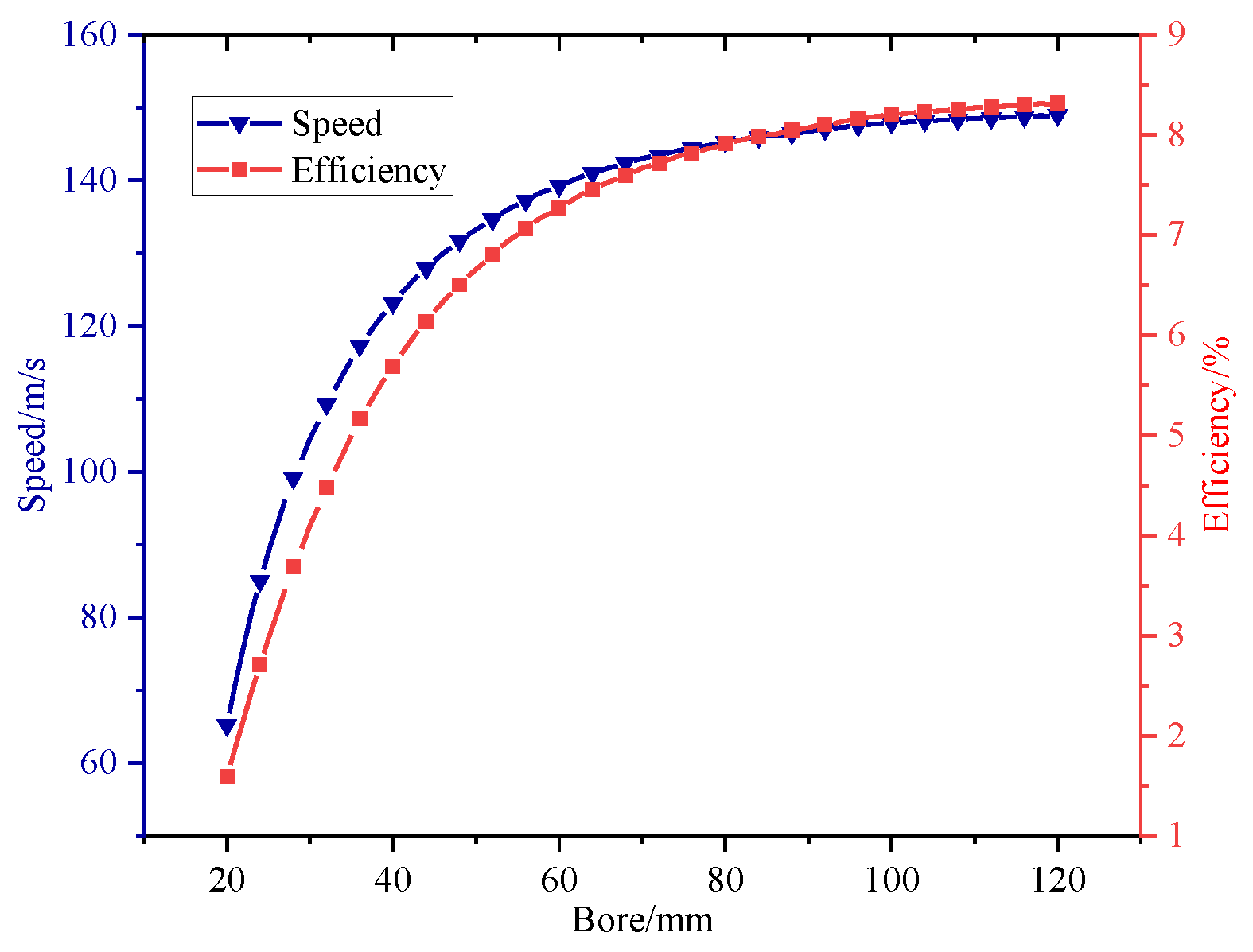

5.1. Influence of the Bore Size on the Launch Performance

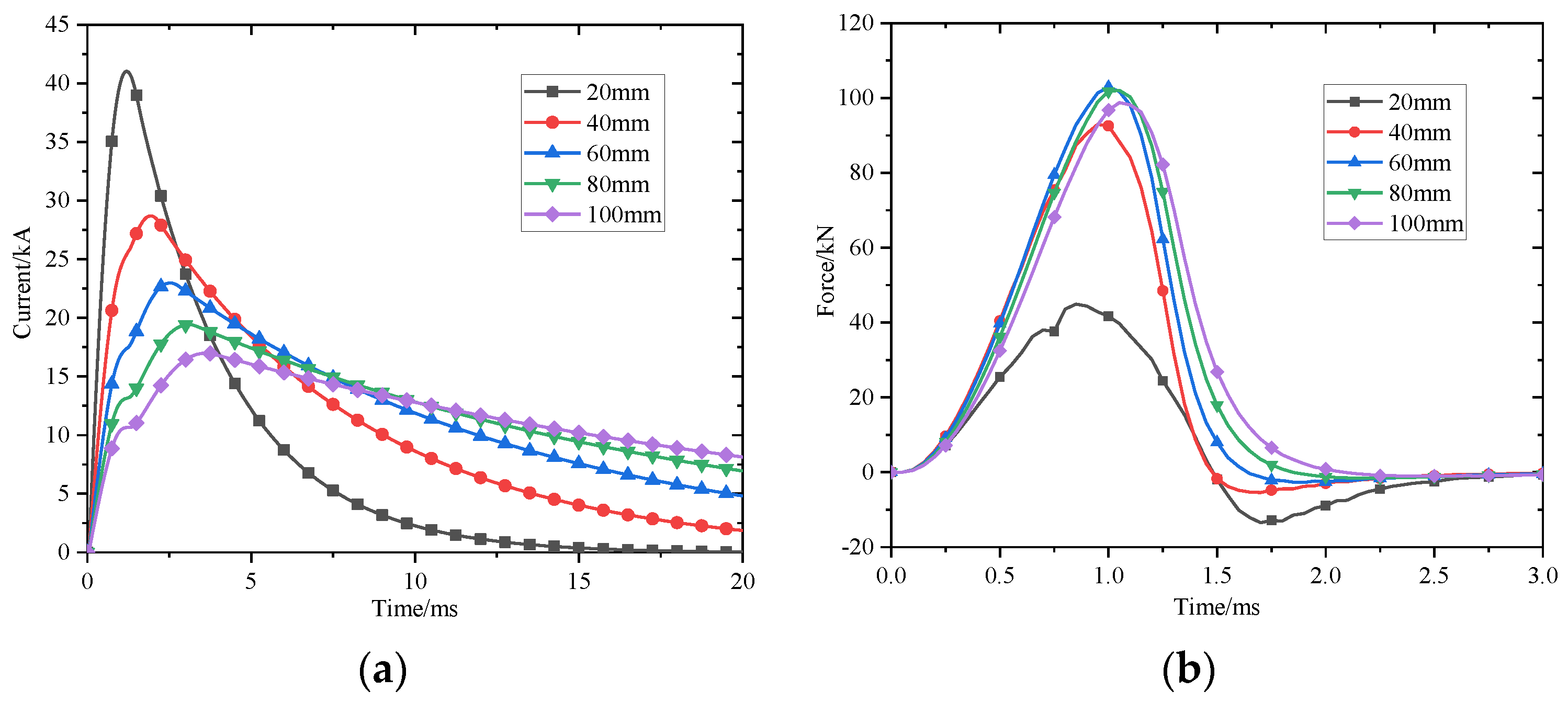

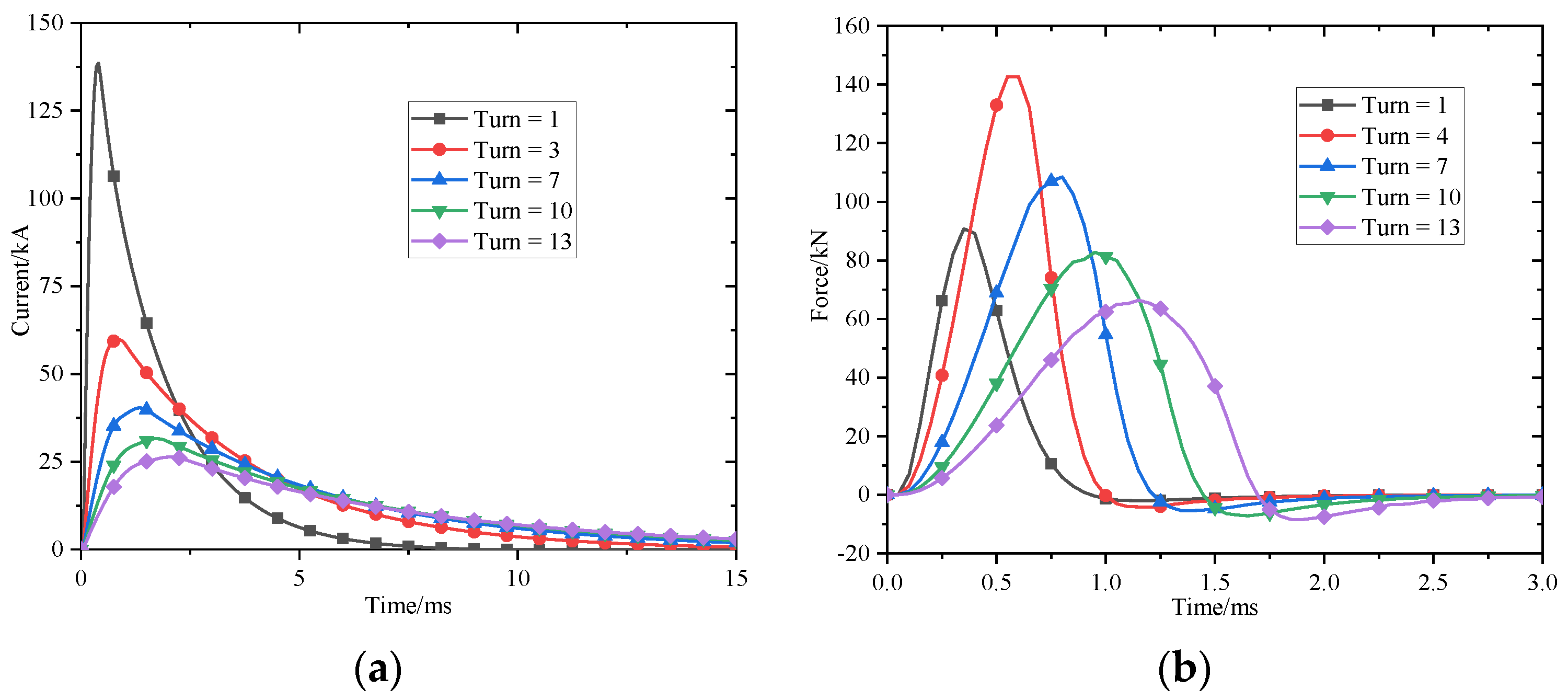

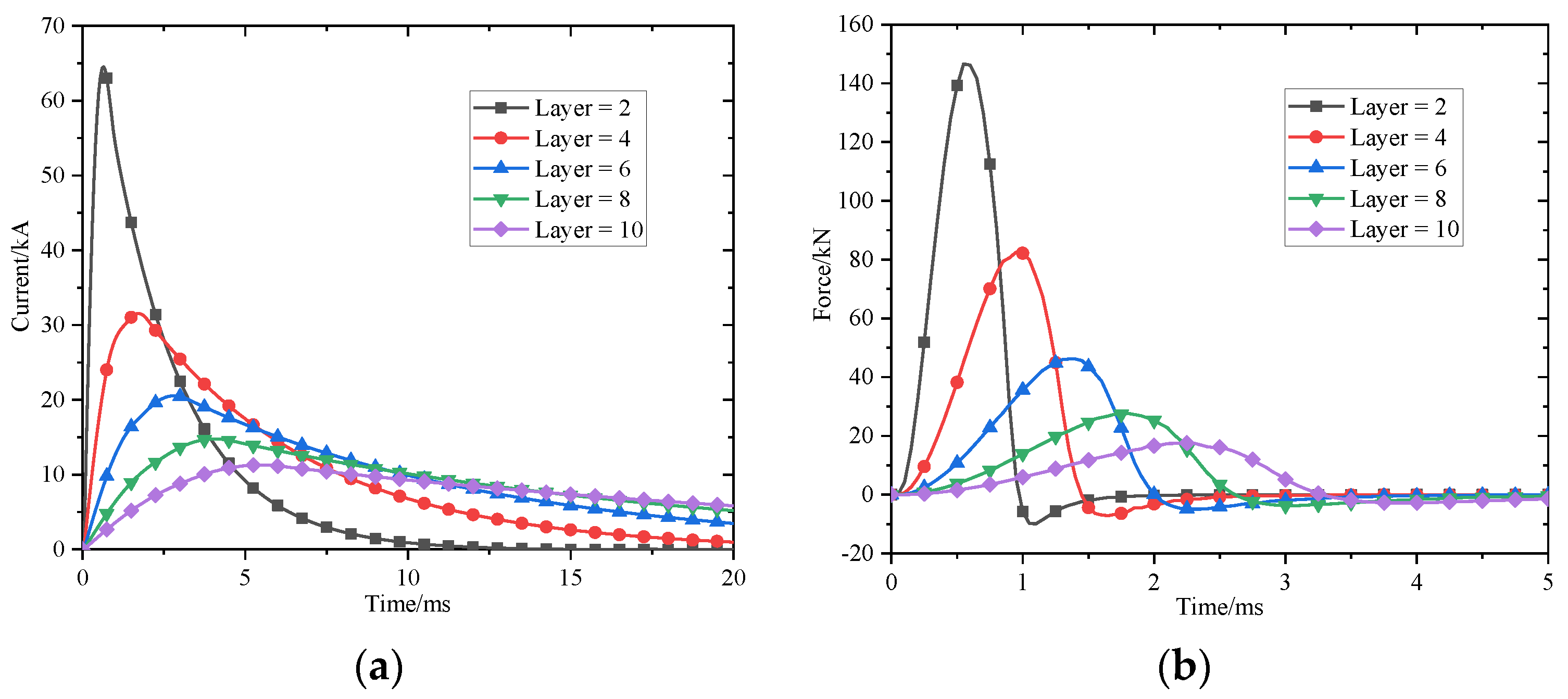

5.2. Influence of the Drive Coil Parameters on the Launch Performance

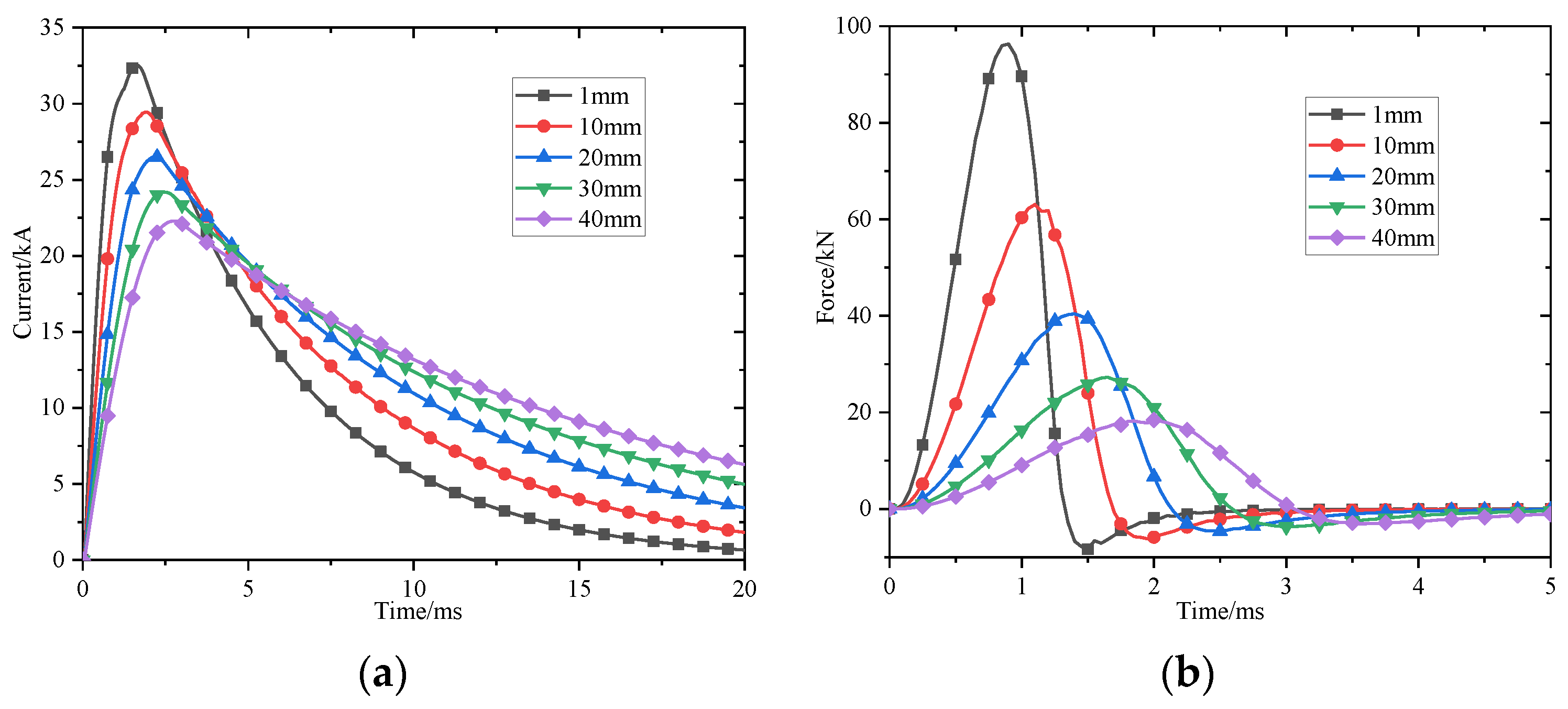

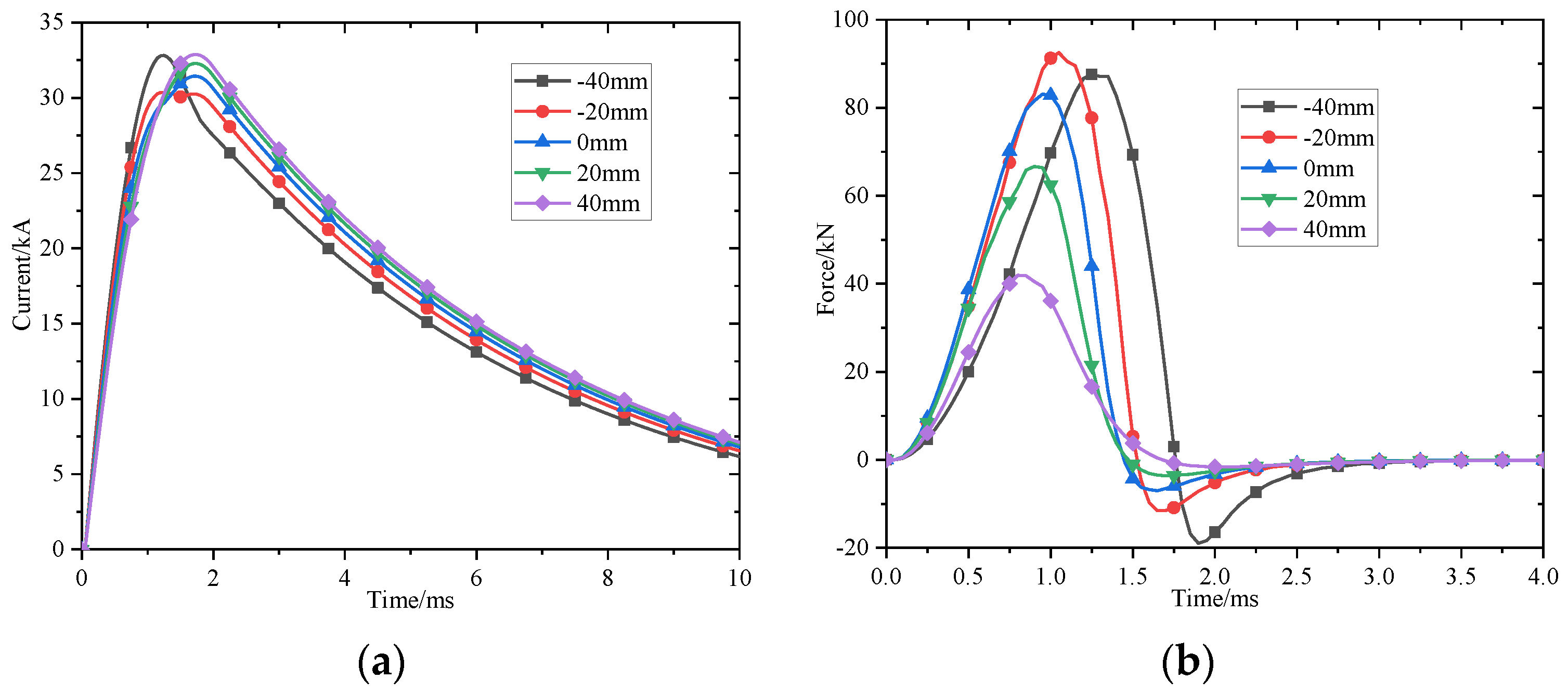

5.3. Influence of the Trigger Position on the Launch Performance

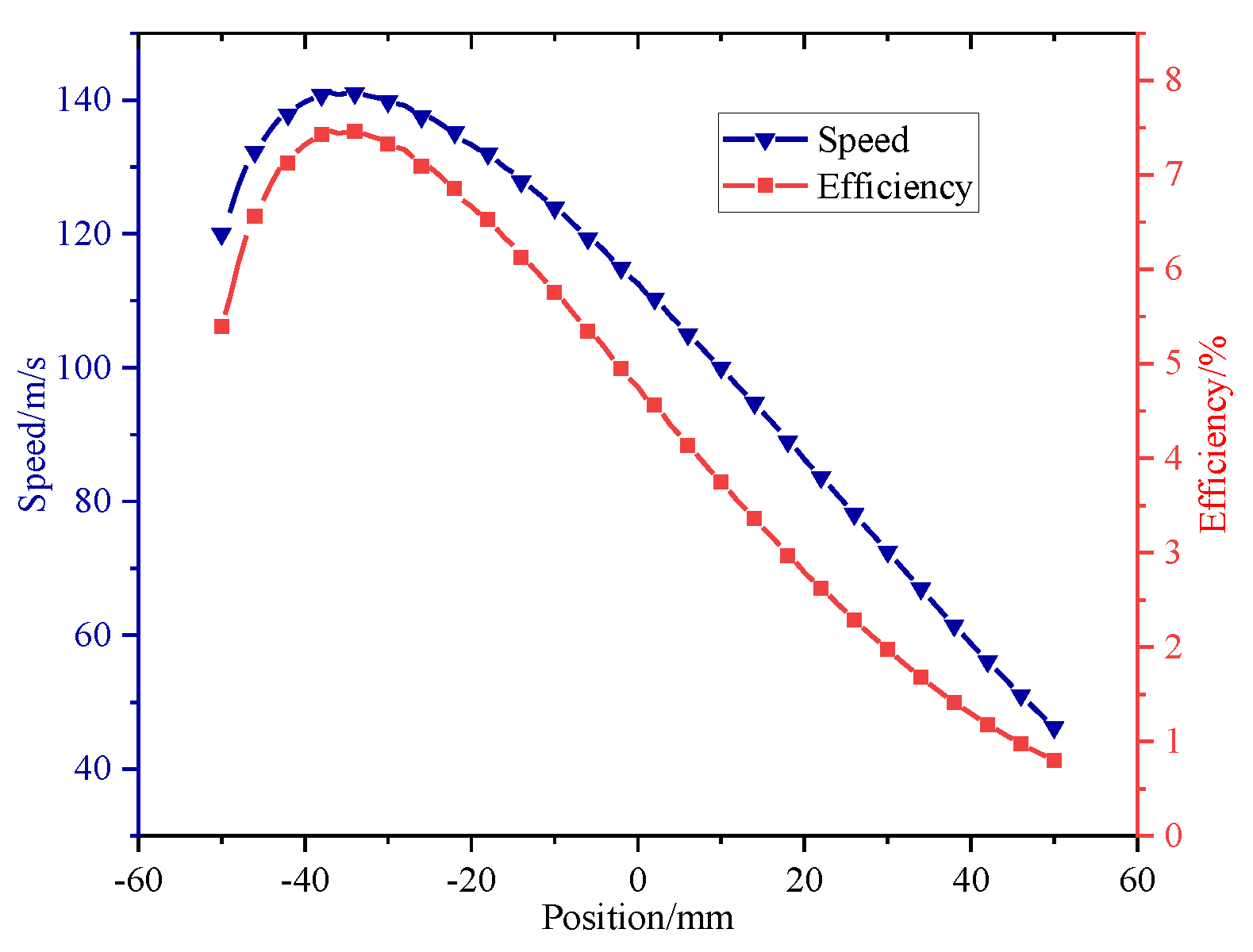

5.4. Influence of the Drive Coil Parameters and Trigger Position on the Launch Performance

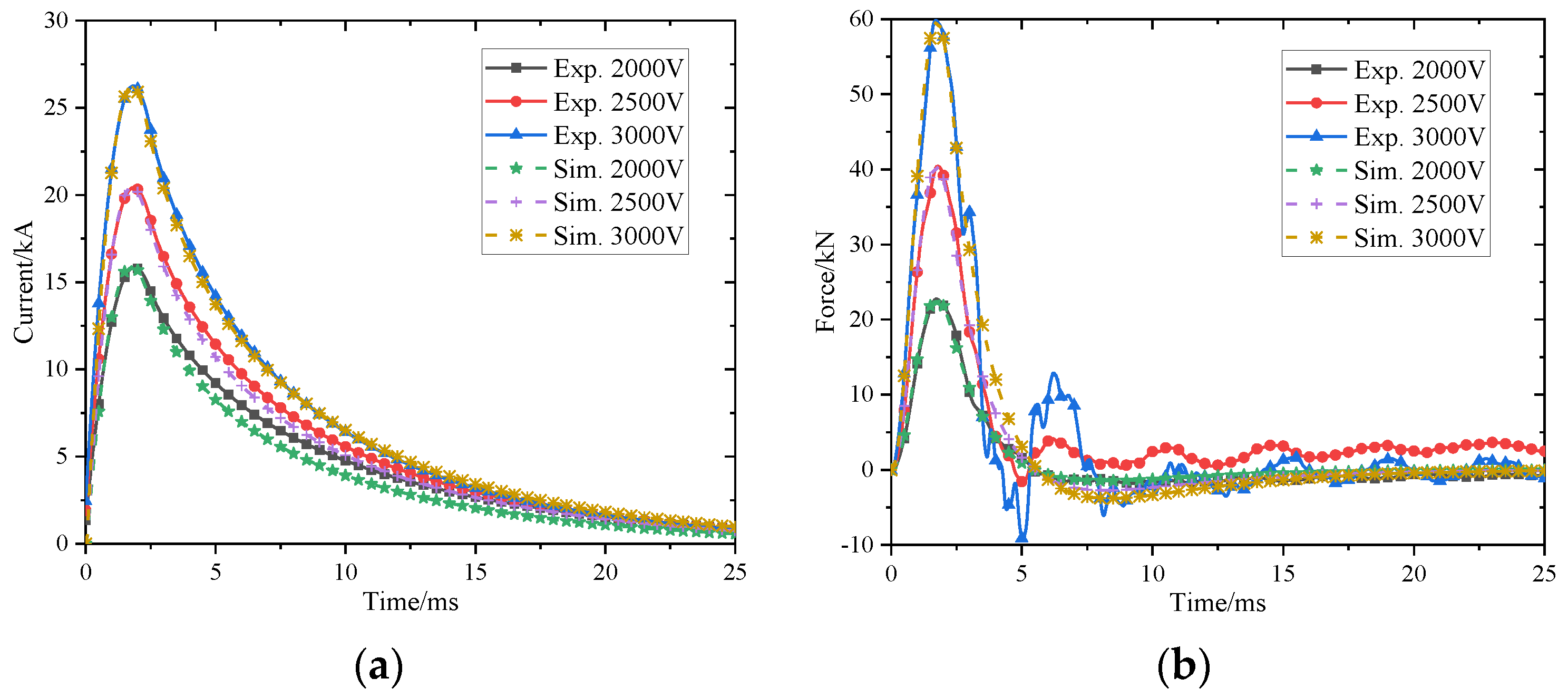

6. Experimental Verification

7. Conclusions

- (1)

- There is an optimal value for the discharge voltage under the premise of the capacitance value of the capacitor bank remaining unchanged.

- (2)

- There is also an optimal value for the capacitance value under the premise of the discharge voltage of the capacitor bank remaining unchanged.

- (3)

- The optimal solution of the Pareto front was obtained for the current parameter conditions.

- (4)

- For the single-stage EICL, the larger the bore size, the higher the launch performance.

- (5)

- There is an optimal number of turns of the winding in the axial and radial direction of the drive coil and an optimal trigger position for the launch performance.

8. Recommendation

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Xiong, M.; Gong, Y.; Xiao, G.; Niu, X.; Huang, D. Study on Multi-Segment Asynchronous Induction Coilgun Launcher. IEEE Trans. Plasma Sci. 2019, 47, 4700–4707. [Google Scholar] [CrossRef]

- Zhang, T.; Li, H.; Zhang, C.; Wang, Q.; Zhai, L.; An, Y.; Chen, Y. Design and Simulation of a Multimodule Superconducting Inductive Pulsed-Power Supply Model for a Railgun System. IEEE Trans. Plasma Sci. 2019, 47, 1352–1357. [Google Scholar] [CrossRef]

- Yang, W.; Yao, L.; Fu, Z. Simulation of Dynamic and Electromagnetic Characteristics of a Superconductor Bulk in a Single-Stage Induction Coilgun. IEEE Trans. Plasma Sci. 2019, 47, 821–827. [Google Scholar] [CrossRef]

- Engel, T.G.; Rada, N.M. Time- and Frequency-Domain Characterization of Railgun Sliding Contact Noise. IEEE Trans. Plasma Sci. 2017, 45, 1321–1326. [Google Scholar] [CrossRef]

- Engel, T.G.; Neri, J.M.; Veracka, M.J. Characterization of the Velocity Skin Effect in the Surface Layer of a Railgun Sliding Contact. IEEE Trans. Magn. 2008, 44, 1837–1844. [Google Scholar] [CrossRef]

- Becherini, G.; Tellini, A.; Tellini, B.D. Electromagnetic and mechanical gyro stabilization in railgun launcher. In Proceedings of the 2004 12th Symposium on Electromagnetic Launch Technology, Snowbird, UT, USA, 25–28 May 2004; pp. 32–36. [Google Scholar]

- Pokryvailo, A. To the theory of parallel railgun driven by an inductive storage power supply. In Proceedings of the Digest of Technical Papers. 12th IEEE International Pulsed Power Conference. (Cat. No.99CH36358), Monterey, CA, USA, 27–30 June 1999; Volume 2, pp. 1345–1348. [Google Scholar]

- Song, M.G.; Lee, Y.; Kim, H.M.; Le, D.V.; Go, B.S.; Park, M.; Yu, I.K. Development and Experimental Results of a Three-Stage Induction Coilgun. IEEE Trans. Plasma Sci. 2019, 47, 2438–2444. [Google Scholar] [CrossRef]

- Li, J.; Cao, R.; Li, S. The Development of EML Technology in China. IEEE Trans. Plasma Sci. 2013, 41, 1029–1033. [Google Scholar]

- Rezal, M.; Iqbal, S.J.; Hon, K.W. Development of Magnetic Pulsed Launcher System using Capacitor Banks. In Proceedings of the 2007 5th Student Conference on Research and Development, Selangor, Malaysia, 11–12 December 2007; pp. 1–4. [Google Scholar]

- Guan, X.; Wang, S.; Guan, S.; Guo, D.; Liu, B. Study on the Best Trigger Position of Multistage Induction Coil Launcher. IEEE Trans. Plasma Sci. 2019, 47, 2419–2423. [Google Scholar] [CrossRef]

- Chen, H.; Nie, R.; Zhao, W. A Novel Tubular Switched Reluctance Linear Launcher With a Module Stator. IEEE Trans. Plasma Sci. 2019, 47, 2539–2544. [Google Scholar] [CrossRef]

- Perotoni, M.B.; Mergl, M.; Bernardes, V.A. Coilgun Velocity Optimization With Current Switch Circuit. IEEE Trans. Plasma Sci. 2017, 45, 1015–1019. [Google Scholar] [CrossRef]

- Winarno, B.; Putra, R.G.; Yuwono, I.; Gunawan, A.I.; Sumantri, B. Control of Velocity Projectile on Multistage Coil gun. In Proceedings of the 2018 International Conference on Applied Science and Technology (iCAST), Manado, Indonesia, 26–27 October 2018; pp. 24–29. [Google Scholar]

- Zhang, Y.; Gong, Y.; Xiong, M.; Niu, X.; Xiao, G. Study of a Multisection Synchronous Induction Coil Launcher. IEEE Trans. Plasma Sci. 2018, 46, 2959–2964. [Google Scholar] [CrossRef]

- Song, M.G.; Le, D.V.; Go, B.S.; Park, M.; Yu, I.K. Design of an Attractive Force Circuit of Pulsed Power System for Multistage Synchronous Induction Coilgun. IEEE Trans. Plasma Sci. 2018, 46, 3606–3611. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Yan, Z.; Jiang, M.; Liang, L. Experiment and Analysis on the New Structure of the Coilgun With Stepped Coil Winding. IEEE Trans. Plasma Sci. 2018, 46, 2170–2174. [Google Scholar] [CrossRef]

- Xiao-Cun, G.; Song-Cheng, L.; Jun-Yong, L.; Zhou, R. The Launch Performance Analysis of the Electromagnetic Coil Launcher Continuous Launch Process With Multiple Armature. IEEE Trans. Plasma Sci. 2017, 45, 1519–1525. [Google Scholar] [CrossRef]

- Citak, H.; Ege, Y.; Coramik, M. Design and Optimization of Delphi-Based Electromagnetic Coilgun. IEEE Trans. Plasma Sci. 2019, 47, 2186–2196. [Google Scholar] [CrossRef]

- Mascolo, L.; Stoica, A. Electro-Magnetic Launchers on the Moon: A Feasibility Study. In Proceedings of the 2018 NASA/ESA Conference on Adaptive Hardware and Systems (AHS), Edinburgh, UK, 6–9 August 2018; pp. 37–42. [Google Scholar]

- Inger, E. Electromagnetic Launching Systems to Geosynchronously Equatorial Orbit in Space and Cost Calculations. IEEE Trans. Plasma Sci. 2017, 45, 1663–1666. [Google Scholar] [CrossRef]

- Rivas-Camacho, J.L.; Ponce-Silva, M.; Olivares-Peregrino, V.H. Experimental results concerning to the effects of the initial position of the projectile on the conversion efficiency of a reluctance accelerator. In Proceedings of the 2016 13th International Conference on Power Electronics (CIEP), Guanajuato, Mexico, 20–23 June 2016; pp. 92–97. [Google Scholar]

- Yang, D.; Liu, Z.; Li-jia, Y.; Zhi, S.; Jian-Ming, O.; Yan-Pan, H. Research on energy conversion efficiency of helical coil electromagnetic launcher. In Proceedings of the 2014 17th International Symposium on Electromagnetic Launch Technology, San Diego, CA, USA, 7–11 July 2014; pp. 1–5. [Google Scholar]

- Khatibzadeh, A.; Besmi, M.R. Improve dimension of projectile for increasing efficiency of electromagnetic launcher. In Proceedings of the 4th Annual International Power Electronics, Drive Systems and Technologies Conference, Tehran, Iran, 13–14 February 2013; pp. 55–59. [Google Scholar]

- Liu, W.; Cao, Y.; Zhang, Y.; Wang, J.; Yang, D. Parameters Optimization of Synchronous Induction Coilgun Based on Ant Colony Algorithm. IEEE Trans. Plasma Sci. 2011, 39, 100–104. [Google Scholar] [CrossRef]

- Guo, L.; Guo, N.; Wang, S.; Qiu, J.; Zhu, J.G.; Guo, Y.; Wang, Y. Optimization for capacitor-driven coilgun based on equivalent circuit model and genetic algorithm. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, San Jose, CA, USA, 20–24 September 2009; pp. 234–239. [Google Scholar]

- Seog-Whan, K.; Hyun-Kyo, J.; Song-Yop, H. An optimal design of capacitor-driven coilgun. IEEE Trans. Magn. 1994, 30, 207–211. [Google Scholar] [CrossRef]

- Seog-Whan, K.; Hyun-Kyo, J.; Song-Yop, H. Optimal design of multistage coilgun. IEEE Trans. Magn. 1996, 32, 505–508. [Google Scholar] [CrossRef]

- Lv, Q.A.; Li, Z.Y.; Lei, B.; Zhao, K.Y.; Zhang, Q.; Xiang, H.J.; Xie, S.S. Primary Structural Design and Optimal Armature Simulation for a Practical Electromagnetic Launcher. IEEE Trans. Plasma Sci. 2013, 41, 1403–1409. [Google Scholar]

- Zhang, Y.; Ruan, J.; Wang, Y.; Zhang, Y.; Liu, S. Armature Performance Comparison of an Induction Coil Launcher. IEEE Trans. Plasma Sci. 2011, 39, 471–475. [Google Scholar] [CrossRef]

- Dong, L.; Li, S.; Xie, H.; Zhang, Q.; Liu, J. Influence of Capacitor Parameters on Launch Performance of Multipole Field Reconnection Electromagnetic Launchers. IEEE Trans. Plasma Sci. 2018, 46, 2642–2646. [Google Scholar] [CrossRef]

- Abdo, T.M.; Elrefai, A.L.; Adly, A.A.; Mahgoub, O.A. Performance analysis of coil-gun electromagnetic launcher using a finite element coupled model. In Proceedings of the 2016 Eighteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 27–29 December 2016; pp. 506–511. [Google Scholar]

- Li, X.; Wang, Q.L.; Wang, H.S.; Chen, S.Z.; Liu, J.H. Performance of a Four-Section Linear Induction Coil Launcher Prototype. IEEE Trans. Appl. Supercond. 2014, 24, 1–5. [Google Scholar] [CrossRef]

- Du, Z.; Liu, S.; Ruan, J.; Yao, Y.; Zhang, Y.; Huang, G.; Liao, C. Performance Analysis of a Coil Launcher Based on Improved CFM and Nonoverlapping Mortar FEM. IEEE Trans. Plasma Sci. 2013, 41, 1070–1076. [Google Scholar]

- Guan, S.; Wang, D.; Guan, X.; Li, W.; Gao, T.; Qiu, L. Coupling Analysis and Research of Multistage SICL Based on Crowbar Circuit. IEEE Trans. Plasma Sci. 2020, 48, 3211–3219. [Google Scholar] [CrossRef]

| Launcher | Technical Characteristics | Research Status |

|---|---|---|

| Rail | Small mass, hyper speed, sliding electrical contact | Will be put into use |

| Reconnection | Non-contact, complex synchronous control technology | Application of basic research |

| Coil | Non-contact, large mass, high speed | Research on engineering development |

| Component | Unit | Value | |

|---|---|---|---|

| Armature | Material | Aluminum | |

| Outer radius | mm | 29.5 | |

| Inner radius | mm | 23.5 | |

| Length | mm | 200 | |

| Drive Coils | Material | Copper | |

| Inner radius | mm | 33.5 | |

| Outer radius | mm | 68.5 | |

| Length | mm | 102 | |

| Turns | 40 | ||

| Axial Turns | Length (mm) | Length/Inner Radius | Resistance (mΩ) | Velocity (m/s) |

|---|---|---|---|---|

| 1 | 10.2 | 0.304 | 1.5 | 64.04 |

| 2 | 20.4 | 0.609 | 3.0 | 101.18 |

| 3 | 30.6 | 0.913 | 4.5 | 113.16 |

| 4 | 40.8 | 1.218 | 6.0 | 116.26 |

| 5 | 51 | 1.522 | 7.5 | 116.24 |

| 6 | 61.2 | 1.827 | 9.0 | 116.02 |

| 7 | 71.4 | 2.131 | 10.5 | 115.29 |

| 8 | 81.6 | 2.436 | 12.0 | 114.23 |

| 9 | 91.8 | 2.740 | 13.5 | 113.41 |

| 10 | 102 | 3.045 | 15.0 | 112.01 |

| 11 | 112.2 | 3.349 | 16.5 | 111.87 |

| 12 | 122.4 | 3.654 | 18.0 | 110.67 |

| 13 | 132.6 | 3.958 | 19.5 | 109.95 |

| 14 | 142.8 | 4.263 | 21.0 | 109.48 |

| 15 | 153 | 4.567 | 22.5 | 108.23 |

| Radial Layers | Width (mm) | Width/Inner Radius | Resistance (mΩ) | Velocity (m/s) |

|---|---|---|---|---|

| 1 | 8.75 | 0.261 | 3.75 | 105.56 |

| 2 | 17.50 | 0.522 | 7.50 | 140.07 |

| 3 | 26.25 | 0.784 | 11.25 | 129.34 |

| 4 | 35.00 | 1.045 | 15.00 | 112.33 |

| 5 | 43.75 | 1.306 | 18.75 | 97.71 |

| 6 | 52.50 | 1.567 | 22.50 | 85.24 |

| 7 | 61.25 | 1.828 | 26.25 | 74.72 |

| 8 | 70.00 | 2.090 | 30.00 | 66.11 |

| 9 | 78.75 | 2.351 | 33.75 | 58.78 |

| 10 | 87.50 | 2.612 | 37.50 | 52.66 |

| 11 | 96.25 | 2.873 | 41.25 | 47.45 |

| 12 | 105.00 | 3.134 | 45.00 | 42.88 |

| 13 | 113.75 | 3.396 | 48.75 | 38.92 |

| 14 | 122.50 | 3.657 | 52.50 | 35.44 |

| 15 | 131.25 | 3.918 | 56.25 | 32.38 |

| Objective | Unit | Value |

|---|---|---|

| length | turn | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 |

| width | layer | 1, 2, 3, 4, 5, 6, 7, 8 |

| trigger position | mm | −50, −40, −30, −20, −10, 0, 10, 20, 30, 40, 50 |

| Component | Unit | Value | |

|---|---|---|---|

| Armature | Material | Aluminum | |

| Outer radius | mm | 29.5 | |

| Inner radius | mm | 23.5 | |

| Length | mm | 200 | |

| Trigger Position | mm | 0 | |

| Drive Coils | Material | Copper | |

| Inner radius | mm | 33.5 | |

| width | mm | 26.25 | |

| Length | mm | 91.8 | |

| Turns | 27 | ||

| Fiber Optical Sensor | Distance | mm | 80 |

| Numbers | 4 | ||

| No. | Capacitance /mF | Charge Voltage /kV | Peak Current /kA | Efficiency/% |

|---|---|---|---|---|

| 1 | 16 | 2.0 | 33.71 | 6.13 |

| 2 | 16 | 2.5 | 44.89 | 7.80 |

| 3 | 16 | 3.0 | 54.59 | 8.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, S.; Guan, X.; Wu, B.; Shi, J. Analysis of the Influence of System Parameters on Launch Performance of Electromagnetic Induction Coil Launcher. Energies 2022, 15, 7803. https://doi.org/10.3390/en15207803

Guan S, Guan X, Wu B, Shi J. Analysis of the Influence of System Parameters on Launch Performance of Electromagnetic Induction Coil Launcher. Energies. 2022; 15(20):7803. https://doi.org/10.3390/en15207803

Chicago/Turabian StyleGuan, Shaohua, Xiaocun Guan, Baoqi Wu, and Jingbin Shi. 2022. "Analysis of the Influence of System Parameters on Launch Performance of Electromagnetic Induction Coil Launcher" Energies 15, no. 20: 7803. https://doi.org/10.3390/en15207803

APA StyleGuan, S., Guan, X., Wu, B., & Shi, J. (2022). Analysis of the Influence of System Parameters on Launch Performance of Electromagnetic Induction Coil Launcher. Energies, 15(20), 7803. https://doi.org/10.3390/en15207803