Abstract

The high-frequency electromagnetic noise caused by a frequency converter power supply has become the main composition of the vibration and noise of frequency-converter-driven PMSMs. Determining how to reduce this kind of noise is very important to improve motor performance. This paper analyzes the frequency characteristics of the high-frequency noise generated by an inverter, using the magnetic circuit analysis and Maxwell tensor methods. The switching frequency and the natural frequencies of the main modes are optimized according to the modal characteristics of the motor in order to reduce the vibration and noise of the motor. The results show that the high-frequency electromagnetic vibration and noise generated by the inverter is mainly caused by the high-frequency switching harmonic current. The frequencies of the vibration and noise are related to the switching frequency and the modulation wave frequency. At the same time, the simulation calculation of the natural frequencies of the main modes and the noise spectrum obtained from the experiment provide direction for the optimization of the vibration noise near the switching frequency. The switching frequency optimization and the natural frequency optimization based on the main modes of the motor can effectively reduce vibration and noise. This work has certain reference significance for the design of low-noise PMSMs.

1. Introduction

Today, a variety of compressors are used in all walks of life, including in facilities closely related to our daily lives, such as air conditioners and refrigerators. With the continuous development and maturity of permanent magnet motor technology, the number of compressors driven by variable frequency permanent magnet motors is increasing. However, compressor noise still exists, and this seriously affects people’s working and living environments. The medium- and low-frequency noise of compressors is mainly generated by the non-motor part, while the high-frequency noise is mainly generated by the permanent magnet motor driven by frequency conversion. The high-frequency electromagnetic noise generated by a permanent magnet motor is more uncomfortable, and the suppression of this noise has become a problem worth discussing.

As the source of electromagnetic noise, electromagnetic force is the main research object of electromagnetic noise. At present, the main electromagnetic force analysis methods are the magnetic circuit analysis and the Maxwell tensor method. Some scholars have used these electromagnetic force analysis methods to analyze the electromagnetic force expressions of motors with different structures, including built-in PMSMs, solid PMSMs and convex synchronous motor structures [1,2,3,4]. Considering that the magnitude and distribution of electromagnetic force are affected by various structures on the magnetic circuit, the influence of air-gap deformation, the auxiliary slot, the fractional slot and the concentrated winding structure on the electromagnetic force has been deeply explored [5,6,7,8]. At the same time, the electromagnetic force is mainly determined by the current and the magnetic field, so different control strategies, such as weak magnetic field control, id = 0 control and maximum torque current ratio control, have different effects on electromagnetic noise [9,10].

The high-frequency electromagnetic noise near the switching frequency, which is also called sideband noise, is a major problem in the electromagnetic noise of PMSMs. Sideband noise is caused by harmonic currents generated by the frequency converter. In view of the formation reason of such harmonic currents, W. Deng obtained the expression of harmonic currents from the perspective of power electronics [11,12].

Based on the generation principle of sideband noise, a large number of studies have optimized the harmonic current generated by an inverter drive from the perspective of the modulation method so as to reduce the sideband noise near the switching frequency. Currently, the optimization methods include the random pulse width modulation (RPWM) method [13], pseudo-random triangular pulse width modulation (PTPWM) technology [14], random hysteresis current control pulse width modulation (RHCC-PWM) technology [15], random asymmetric carrier pulse width modulation (RACPWM) technology [16], etc. All these methods are based on the concept of switching frequency randomization, which means that the electromagnetic vibration noise in a narrow frequency range is dispersed to a larger frequency range so as to reduce the maximum noise level near the switching frequency. However, the randomization of the switching frequency must increase the frequency range of the switching harmonic electromagnetic forces, which makes it easier for these high-frequency electromagnetic forces to act on the natural frequencies and produce large vibration and noise. This effect is not discussed in these articles.

Since the electromagnetic vibration noise of a motor decreases with an increase in the electromagnetic force frequency, carrier phase shift technology has become another main method to optimize sideband noise [17,18,19]. Its operating principle is to increase the equivalent switching frequency by adding an extra modulation circuit and to reduce the sideband noise interval in the observation frequency interval (0~20,000 Hz). However, this method inevitably brings a higher cost and a higher switching loss.

In recent years, the optimization of the sideband noise of PMSMs has been carried out mainly from the perspective of control, and the high-frequency harmonic current generated by the inverter is optimized to reduce the high-frequency vibration noise. However, electromagnetic noise is not only related to the electromagnetic force, but it also has an inseparable connection with the structural mode of the motor itself. This paper mainly optimizes the sideband noise of PMSMs from the perspective of mode. On the one hand, the selection of the switching frequency is optimized according to the natural frequencies of the main modes. On the other hand, the switching frequency is adapted by optimizing the natural frequencies of the main modes.

The research steps of this paper are shown in Figure 1. Firstly, the influence of the frequency converter power supply on the air-gap flux density is discussed using the magnetic circuit analysis method. The frequency law of high-frequency electromagnetic force under a frequency converter power supply is analyzed using the Maxwell tensor method. The above analysis results are verified using Maxwell software, with an SPMSM used in the compressor. The correctness of the theory is also verified by experiments.

Figure 1.

Vibration and noise research process.

Different from other studies, this paper uses the experimental results and the modal shapes, natural frequencies and vibration acceleration spectrum calculated by ANSYS simulation software to determine the main modal shapes and the natural frequencies. According to the natural frequencies of the main modes, the optimal switching frequency is determined with the minimum vibration radiation power as the criterion. Finally, according to the characteristic that the motor stator has a great influence on the overall motor mode, the distribution of the natural frequencies of the main modes is improved by optimizing the outer diameter of the motor stator. The results show that the selection of the switching frequency has a great influence on high-frequency electromagnetic vibration and noise, and the optimization of the switching frequency can greatly improve vibration and noise performance. At the same time, the vibration and noise performance can be optimized by properly optimizing the stator outer diameter and changing the natural frequencies of the main modes.

2. Research on Air-Gap Magnetic Field of SPMSM Powered by Frequency Converter

2.1. Analytical Analysis of Air-Gap Magnetic Field Driven by Frequency Conversion

At present, when analyzing the electromagnetic force of PMSMs, the magnetomotive force–magnetic conductivity method is often used at first to analyze the air-gap magnetic field, and its expression is as follows:

where is the air-gap flux density, is the air-gap magnetomotive force, and is the air-gap magnetoconductivity.

The air-gap magnetomotive force is related to the permanent magnet and the stator armature current. It can be regarded as the linear superposition of the permanent magnet magnetomotive force and the stator armature current magnetomotive force :

where the permanent magnet magnetomotive force is only related to its structure, material and other characteristics, and its result of Fourier decomposition can be expressed as follows:

When the rotor maintains synchronous speed, is both the spatial order and the time–frequency, , is the fundamental frequency, represents pole pairs, and is the mechanical angle.

When only the fundamental wave current exists in the stator armature, the magnetomotive force generated by the armature current maintains the same frequency, but its spatial order changes. When a sinusoidal voltage is used for the power supply, there is a harmonic current in the armature current, in addition to the fundamental current, and the magnetomotive force produced by the two currents has both time–frequency changes and spatial order changes:

where is the spatial order, and is the time–frequency. When , the corresponding formula in (4) represents the magnetomotive force generated by the fundamental current.

In Reference [20], when using a frequency converter power supply, in addition to fundamental frequency components and frequency-doubling components, the armature current increased the composition related to the switching frequency current. Based on the characteristics of frequency, the switching harmonic current can be divided into two parts. One part is the harmonic current on the switching frequency and its frequency doubling. The other part is the sideband harmonic current near the switching frequency and its frequency doubling. The composition proportion and distribution of the latter are much larger than those of the former. In fact, the former is mainly concentrated on the odd switching frequency, which means that it can be integrated with the latter to represent the switching harmonic current. Then, the magnetomotive force generated by the armature current powered by the frequency converter can be expressed as follows:

where , is the fundamental frequency, , and is the frequency of the switching harmonic current. The relationship between , and the switching frequency is as follows:

where is a positive integer, is a non-negative integer, and and have different parity. When is odd, can be zero, and the frequency is the odd times switching frequency if is zero. However, when is even, cannot be zero, so there are only sideband harmonic currents near even times switching frequencies.

The air-gap permeability is related to the equivalent air-gap thickness, which can be approximately expressed as follows:

where is the number of stator slots.

Substitute (5) and (3) into (2). The angular velocity in (3) maintains the synchronous angular velocity. By substituting (2) and (6) into (1), the formula of the air-gap flux field of an SPMSM powered by a frequency converter can be obtained:

①~⑥ in the formula correspond to the six formulas on the left of the equal sign in order. ③ and ⑥ make the air-gap flux density appear the switching harmonic components.

2.2. Simulation Verification of Air-Gap Flux Density Driven by Frequency Conversion

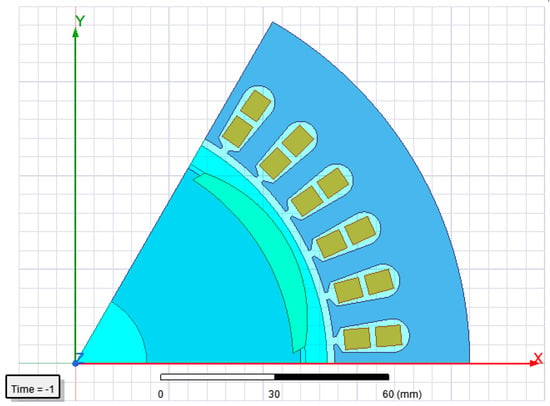

Taking a 25 kW SPMSM used for a compressor as an example, Maxwell simulation software is used to calculate the current and air-gap flux density of the motor under a frequency converter power supply. The related parameters of the SPMSM are shown in Table 1.

Table 1.

Main parameters of motor.

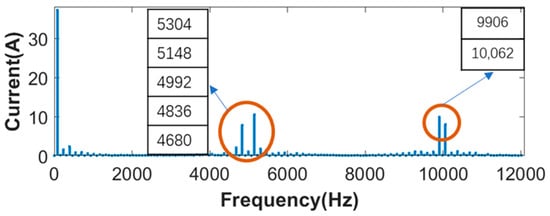

The simulation model of the SPMSM used in the compressors is shown in Figure 2. To calculate the current and air-gap flux density under the frequency converter power supply, the windings are connected to the SVPWM drive circuit. The switching frequency is 4992 Hz. To verify that the size and distribution of the high-frequency sideband harmonic current is greater than that of the harmonic current on the switching frequency and its frequency doubling, the A-phase current waveform is simulated, and Fourier decomposition is carried out to obtain the spectrum diagram. The results shown in Figure 3 fully prove that the high-frequency harmonic current generated under a frequency converter drive is mainly a high-frequency sideband harmonic current.

Figure 2.

Simulation model of motor.

Figure 3.

A-phase current spectrum under SVPWM drive.

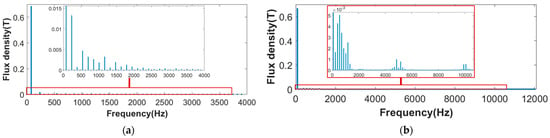

The air-gap flux density of the fundamental current drive and the SVPWM drive is simulated. Fourier decomposition is carried out to obtain the corresponding spectrum, as shown in Figure 4. Compared with the fundamental current drive, the air-gap flux density under the frequency converter drive produces a large number of harmonic components near the switching frequency and its frequency doubling. The frequencies of these harmonic components are the same as those of the sideband harmonic current.

Figure 4.

Spectrum of air-gap flux density: (a) fundamental current drive and (b) SVPWM drive.

3. Research on Electromagnetic Excitation Force of PMSM Powered by Frequency Converter

3.1. Analysis of Frequency Characteristics of High-Frequency Electromagnetic Force

The electromagnetic force density of the motor can be calculated according to the Maxwell tensor method, and the expression is as follows [3]:

In the formula, is the radial component of the air-gap flux density, and is the tangential component of the air-gap flux density. In order to facilitate an analytical analysis, and in general, the tangential component of the air-gap flux density is much smaller than the radial component, so the tangential component is ignored.

The analytical formula of the electromagnetic force density can be obtained by substituting (7) into (8). It is found that the three frequencies of the electromagnetic force density components related to formula ③ and formula ⑥ in the analytical formula can be expressed as follows:

In the formula, is a positive integer, and is a non-negative integer. and have the same parity.

The larger the and , the smaller the amplitude of the electromagnetic force at the corresponding frequency. Therefore, the frequencies of the main high-frequency electromagnetic force are near the switching frequency and its double frequency, such as , , , and .

3.2. Simulation and Verification of Frequency Characteristics of High-Frequency Electromagnetic Force

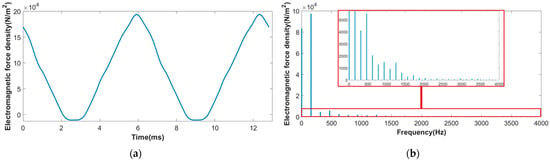

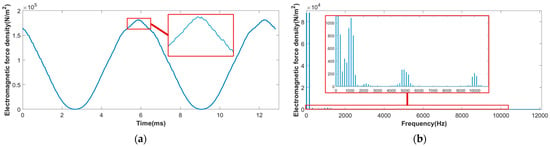

In order to highlight the influence of the frequency converter drive on the electromagnetic force, a simulation analysis on the electromagnetic force under the fundamental current power supply is carried out, and then Fourier decomposition is used to obtain the results, as shown in Figure 5. The air-gap flux density distribution produced by the permanent magnet is close to a sine wave due to the eccentric pole. Therefore, the electromagnetic force is basically concentrated in the low-frequency band, and the main components are constant quantity and double-frequency components.

Figure 5.

Electromagnetic force density under fundamental current power supply: (a) electromagnetic force density waveform and (b) spectrum diagram of electromagnetic force density.

Keeping the fundamental frequency current under the frequency converter drive and under the fundamental current drive the same, the time waveform of the electromagnetic force under the frequency converter drive at a certain point in the air-gap is calculated, as shown in Figure 6a. It is found that the area around the maximum amplitude of the waveform is obviously non-sinusoidal, and there are a large number of small burrs. Fourier decomposition is performed to obtain the spectrum, as shown in Figure 6b. Compared with the electromagnetic force spectrum diagram under the fundamental current drive, the electromagnetic force spectrum diagram under the frequency converter drive obviously adds a lot of electromagnetic force components to the high-frequency band. Their frequencies are 4758 Hz, 4914 Hz, 5070 Hz, 5226 Hz, 9828 Hz, 9984 Hz and 10,140 Hz, corresponding to the theoretical ,, and .

Figure 6.

Electromagnetic force density under frequency converter drive: (a) electromagnetic force density waveform and (b) spectrum diagram of electromagnetic force density.

4. Experimental Analysis of Vibration and Noise of Permanent Magnet Motor Used in Compressor

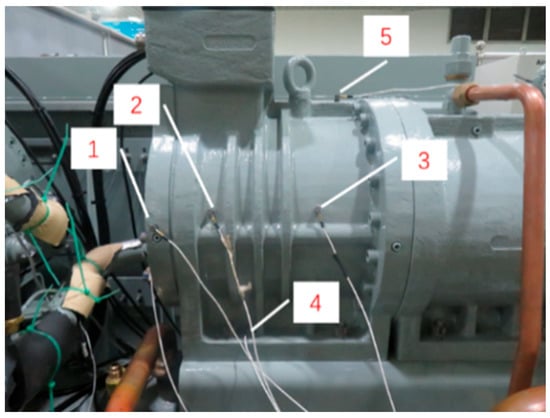

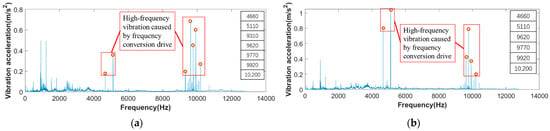

The multifunctional data acquisition system “SCADAS”, designed by Siemens, is used in the experiment to collect the vibration and noise data of the SPMSM of the marine compressor when it is powered by the frequency converter. The experimental motor and the positions of the acceleration sensor are shown in Figure 7. The vibration acceleration data of five parts are collected by the acceleration sensor, and five vibration acceleration spectrum diagrams are obtained, as shown in Figure 8.

Figure 7.

Experimental motor (The numbers in figure are the testing point of vibration acceleration).

Figure 8.

Spectrum of vibration acceleration: (a) testing point 1, (b) testing point 2, (c) testing point 3, (d) testing point 4 and (e) testing point 5.

An analysis of the vibration acceleration spectrum of the five detection points shows that there are seven main high-frequency vibrations on the whole. Their frequencies are compared with the analytical theoretical values, as shown in Table 2. The actual mechanical rotation frequency measured in the experiment is 26 Hz, so the base frequency is 78 Hz, and the switching frequency is 4992 Hz. The error between the experimentally measured frequencies and the theoretic frequencies remains at about −2%. The main reason for this may be that the measurement accuracy of the mechanical rotation frequency is insufficient, resulting in the calculated switching frequency being higher than the actual value, but the error of the different compositions is similar. However, the measured values of each main vibration frequency can correspond to the theoretical compositions one by one, which proves the correctness of the analytical analysis of electromagnetic force when the frequency converter is driving.

Table 2.

Main vibration frequencies.

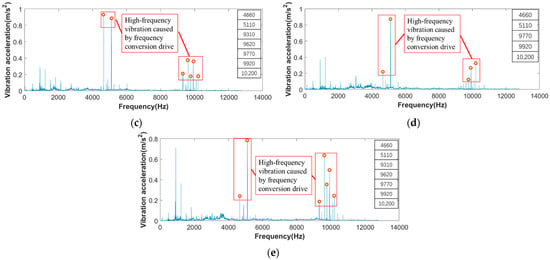

A-weighted noise levels near the exhaust port, near the middle of the motor side, near the suction port and near the suction flange were detected in the anechoic chamber, and spectrum diagrams of the four noise levels were obtained, as shown in Figure 9. The main noise frequencies in the spectrum diagrams of the four noise levels were summarized, and the average noise frequencies of the same compositions were calculated and compared with the theoretical frequencies obtained from the analytical analysis, as shown in Table 3. The measured rotation frequency was 26 Hz, the base frequency was 78 Hz, and the switching frequency was 4992 Hz.

Figure 9.

Spectrum diagram of noise level: (a) near the exhaust port, (b) near the middle of the motor side, (c) near the suction port and (d) near the suction flange.

Table 3.

Main noise frequencies.

Compared with the measurement of the vibration, the compressor is closer to the complete start when measuring the noise. The actual mechanical rotation frequency is closer to the rated speed, and the measured data error is smaller. The results of the noise level further prove the correctness of the analytical theory. At the same time, including the compositions in the vibration acceleration spectrum, the noise-level spectrum also contains , which is more consistent with the analytical theoretical results.

In addition, compared with the vibration acceleration spectrum, the noise-level spectrum clearly shows the vibration and noise characteristics of the motor. It is easier to observe the resonance band of the motor in the noise-level spectrum. For example, there is obviously a major natural frequency near 5000 Hz, which generally leads to a high noise level in the range of the resonance band. Based on this, the switching frequency and natural frequencies of the main modes can be changed to avoid these resonances and to reduce vibration noise near the switching frequency.

5. Structural Modal Analysis and Optimization of PMSM in Compressor

5.1. Finite Element Theory of Structural Mode

When the finite element method is used to analyze the vibration mode of a motor, the motion equation of the element body can be obtained according to the Lagrange function [21]:

where represents the mass matrix of the element body. represents the damping matrix of the element body. represents the stiffness matrix of the element body. represents the load matrix of the element body. represents the node displacement of the element body. represents the node velocity of the element body. represents the node acceleration of the element body.

The whole system can be regarded as a combination of multiple units. Therefore, by integrating all units of the whole system, the equation of the motion of the unit can be extended to that of the vibration system:

where is the mass matrix of the vibration system. is the damping matrix of the vibration system. is the stiffness matrix of the vibration system. is the node force vector of the vibration system. is the node displacement of the vibration system.

The vibration of the motor system at the natural frequency is close to undamped vibration, so the damping matrix and the node force vector in (11) can be set to 0. According to the differential equation theory, the solution of (11) can be expressed as follows:

where is the natural angular frequency of the mode. is the mode vector, representing the corresponding vibration mode of the natural frequency. Substituting Equation (12) into Equation (11), we obtain the following:

The eigenvalue of Equation (13) can be solved as follows:

The natural angular frequency is the characteristic value of the motion equation. is the natural vibration frequency of the motor. Corresponding to the natural frequency , the non-zero solution vector is the natural mode of vibration. It can also be seen from Equation (14) that an increase in stiffness can increase the natural frequency, while an increase in mass decreases the natural frequency.

5.2. Vibration Modal Characteristics of PMSM in Compressor

A permanent magnet synchronous motor is generally composed of an end cover, a stator core, a rotor, casing, winding, etc. The overall modal and natural frequencies of the motor are affected by each structure. The stator mass and stator stiffness are relatively large and concentrated so that the stator has a greater impact on the modes and the natural frequencies of the motor.

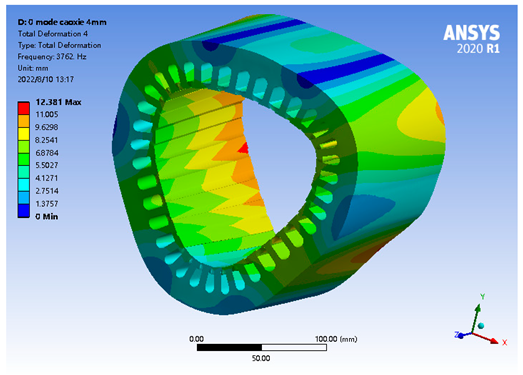

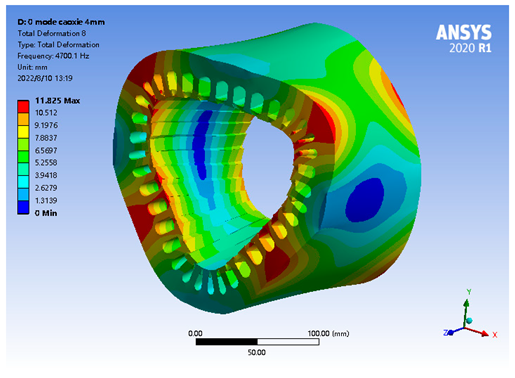

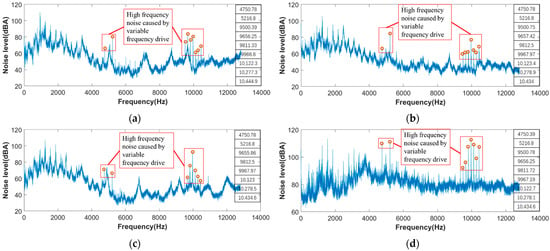

The modes of the motor stator have obvious characteristics because of its structural symmetry. In order to reflect the mode shape characteristics of the main vibration modes of the stator, the order of the stator mode is expressed as “Model (m, n)”, and its principle is shown in Figure 10. “m” is the order of the motor stator in the axial direction, and “n” is the order of the motor stator in the radial plane.

Figure 10.

Definition of mode order.

Considering the spatial distribution of the electromagnetic force, the order of the main stator vibration modes in the axial direction is zero. The modal characteristics are mainly reflected on the radial plane. Low-order modes on the radial plane are easily excited due to the large electromagnetic force corresponding to the spatial characteristics and natural frequencies of these modes. In addition, for modes whose order on the radial plane is more than one, the deformation quantity of the stator core is inversely proportional to the fourth square of spatial order under the same amplitude of electromagnetic force excitation [22]. So, vibration noise caused by low-order modes is more serious.

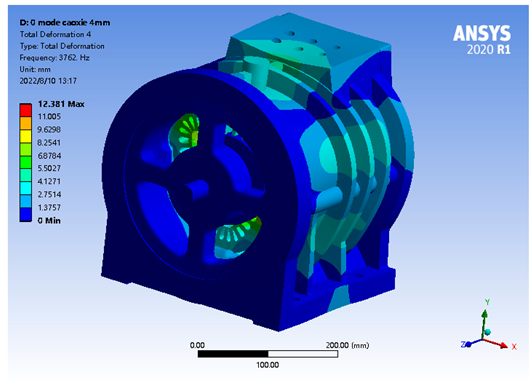

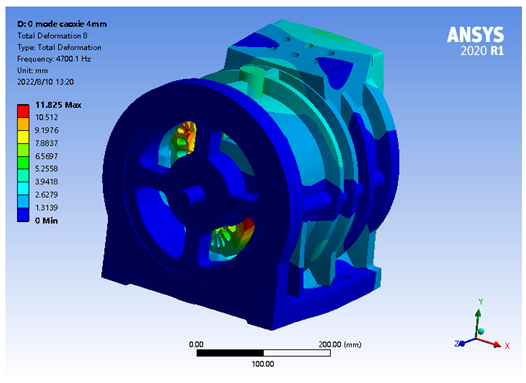

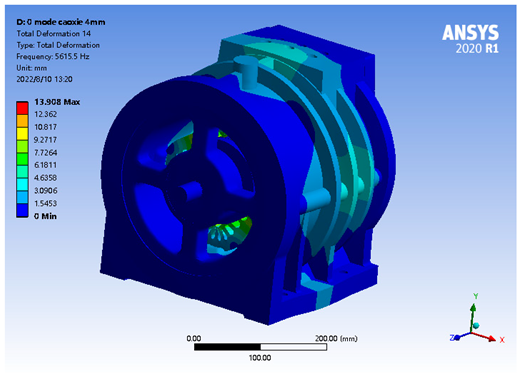

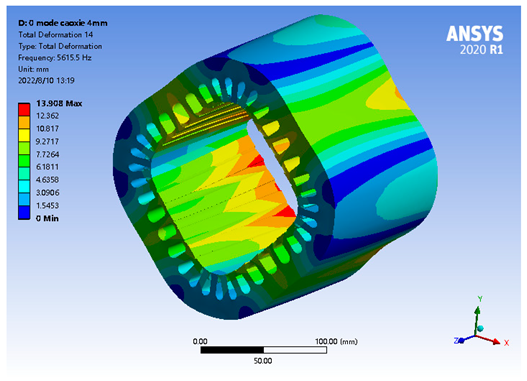

5.3. Simulation Calculation and Optimization of Natural Frequency

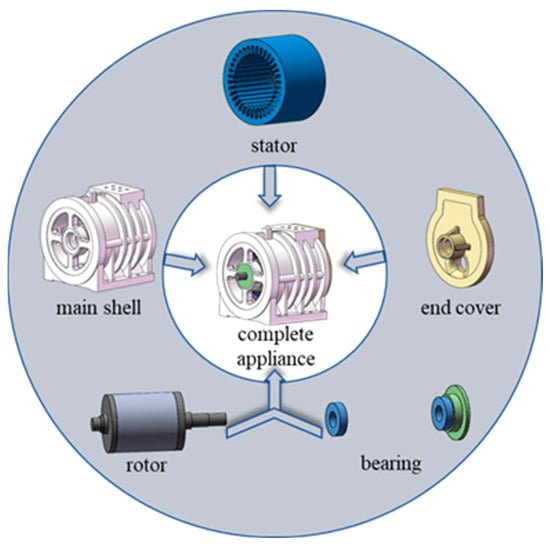

Based on the frequency characteristics of the high-frequency electromagnetic force caused by the frequency conversion drive and the natural frequencies of the main motor modes obtained from the simulation calculations or experiments, the switching frequency or the structure can be optimized to avoid the switching harmonic frequency. For the PMSM in this paper, the whole motor (including the stator, rotor, bearing, end cover and main housing) is modeled, as shown in Figure 11. In order to restore the experimental conditions more realistically, the simulation uses the same fixed position as the assembly and assumes that the stiffness of the fixed position is sufficient to use completely fixed conditions.

Figure 11.

Simulation model.

All the natural frequencies and mode shapes can be obtained by calculating the modes of the machine alone. However, it is difficult to excite many modes considering the spatial characteristics of electromagnetic force excitation. Furthermore, it is difficult to screen out the main mode shapes and natural frequencies from a large number of modes. Therefore, it is necessary to screen the natural frequencies and modes of the main modes through a harmonic response simulation.

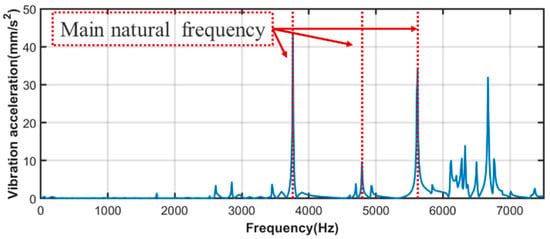

In order to avoid the high-frequency electromagnetic force affecting the selection and judgment of the main natural frequencies in the simulation, an alternating current input is used in the electromagnetic part of the simulation. The vibration acceleration of the motor-housing surface obtained from the simulation is shown in Figure 12. The results show that there are three natural frequencies that have a great influence on the motor vibration near the switching frequency.

Figure 12.

Simulation results of vibration acceleration on shell surface.

Then, according to the results obtained from the mode simulation, the mode shapes and natural frequencies of the main vibration modes can be determined by comparing the frequencies, as shown in Table 4. According to the main vibration mode shapes obtained from the simulation, the main vibration modes of the motor are determined to a large extent by the mode shapes of the motor stator.

Table 4.

Mode shapes and natural frequencies of main modes.

At the same time, compared with Model (1,3), the vibration acceleration on Model (0,3) and Model (0,4) is significantly larger, which is in line with the distribution law of electromagnetic force. The vibration acceleration of Model (0,3) is greater than that of Model (0,4), which confirms the relationship between the vibration deformation size and the mode order in the radial plane.

In order to improve the vibration and noise near the switching frequency, on the one hand, the switching frequency can be set in the frequency interval far from the main natural frequencies. According to the frequency characteristics of the electromagnetic force near the switching frequency, the frequency interval needs at least 6 times the fundamental frequency range. For the PMSM studied in this paper, according to the vibration acceleration spectrum obtained from the simulation, it is most appropriate to set the switching frequency between Model (0,3) and Model (1,3). Considering that Model (0,3) is more easily excited than Model (1,3), the switching frequency is biased toward Model (1,3), that is, about 4300 Hz.

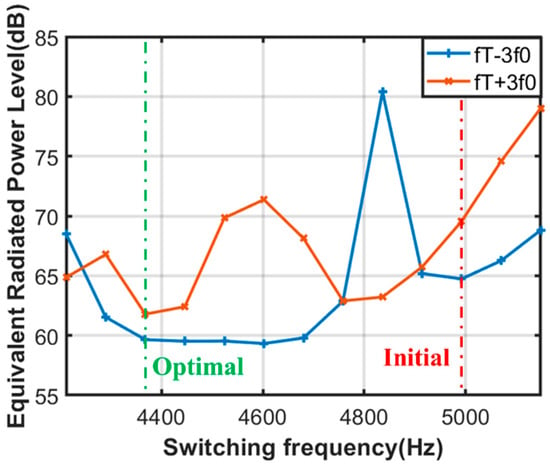

In order to verify the above point of view, an equivalent vibration radiation power at and at different switching frequencies is simulated. The step size of the switching frequency is the fundamental frequency, namely, 78 Hz, so 13 groups of switching frequencies from 54 to 66 times the fundamental frequency are simulated.

Figure 13 shows the equivalent vibration radiation power variations at and under different switching frequencies. The result shows that, when the switching frequency is 4368 Hz (that is, 56 times the fundamental frequency), the equivalent vibration radiation power at and is the minimum. This is not much different from the previous estimate of 4300 Hz. Compared with the initial switching frequency, the optimized switching frequency reduces the equivalent vibration radiation power at by nearly 5 dB and the equivalent vibration radiation power at by nearly 8 dB.

Figure 13.

Switching frequency optimization.

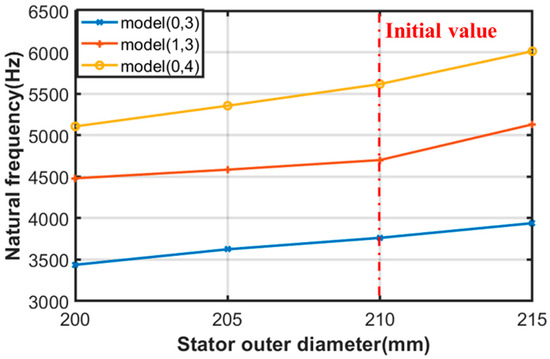

On the other hand, by improving the structural parameters of the motor, the natural frequencies of the main modes can be changed to avoid the switching frequency. Considering that the mode of the motor is mainly related to the motor stator, the natural frequencies of the main modes can be changed by changing the stator yoke thickness appropriately.

Figure 14 shows the natural frequencies of the main modes under different stator outer diameters. The results show that the natural frequencies of the main modes greatly increase with an increase in the stator yoke thickness. Figure 15 shows the equivalent vibration radiation power at and under different stator outer diameters, where the switching frequency is always 4992 Hz.

Figure 14.

Natural frequencies of main modes under different stator outer diameters.

Figure 15.

Stator outer diameter optimization.

By observing Figure 14 and Figure 15, it can be seen that, when the stator outer diameter decreases, the natural frequency of Model (0,4) decreases and gradually approaches the switching frequency. At this time, the electromagnetic force at and is distributed near Model (0,4), which causes a lot of vibration. Relative to the initial outer diameter, the increase in the vibrational radiation under the smaller outer diameter caused by the proximity of Model (0,4) to the main high-frequency electromagnetic force can reach about 30 dB.

When the stator outer diameter increases, the natural frequencies of Model (0,4) and Model (1,3) increase. The natural frequency of Model (0,4) gradually becomes far away from the main high-frequency electromagnetic force. However, the natural frequency of Model (1,3) gradually becomes close to the main high-frequency electromagnetic force. Due to the existence of many similar modes near Model (1,3), it is difficult to simply describe the influence of the natural frequency variation caused by the stator outer diameter variation on the vibration. Therefore, it is necessary to optimize the stator outer diameter within a certain range. For example, when the stator outer diameter is 213 mm, the vibration situation is better than that when the stator outer diameter is 210 mm.

At the same time, a decrease in the switching frequency leads to an increase in the electromagnetic force interval in the frequency range of human hearing, resulting in more noise. Therefore, the optimization of the above two aspects can be combined. The switching frequency can be optimized after the natural frequencies are increased. However, limited by the control method, the optimization step of the switching frequency can only be based on the fundamental frequency. The fine tuning of the natural frequencies can make up for this defect. Therefore, the joint optimization method of the switching frequency and the mode can be established in the following work.

6. Summary

In this paper, the high-frequency electromagnetic vibration and noise of an SPMSM used in a compressor powered by a frequency converter is analyzed using an analytical method. The theory is verified by simulations and experiments. At the same time, the vibration and noise are optimized by using the mode theory. Finally, the following conclusions are drawn:

- (1)

- The air-gap flux density harmonics of an SPMSM driven by SVPWM are mainly caused by the sideband harmonic current. The frequencies of the harmonic components of these air-gap flux densities are the same as those of the sideband harmonic current, which can be expressed as , where is the switching frequency, is the fundamental frequency, is a positive integer, is a non-negative integer, and and have different parity.

- (2)

- When the SPMSM is powered by the frequency converter, there is a large high-frequency vibration noise near the switching frequency and its frequency doubling. The main vibrational noise frequency can be expressed as , where is a positive integer, is a non-negative integer, and and have the same parity.

- (3)

- The mechanical vibration characteristics of the whole motor can be determined by the noise spectrum obtained from the experiment. Cooperating with the harmonic response simulation and modal simulation, the main modal shapes can be determined, and their natural frequency ranges can be basically located from the noise spectrum.

- (4)

- According to the response spectrum of the motor vibration, the high-frequency sideband noise near the switching frequency can be improved by optimizing the switching frequency. Considering that the stator has a great influence on the modes of the whole motor, the high-frequency sideband noise near the switching frequency can also be improved by optimizing the stator outer diameter.

Different from most current studies on switching harmonic noise, this paper not only analyzes the characteristics of electromagnetic force but also focuses on the important influence of the motor vibration response characteristics on the switching harmonic noise. On the basis of an electromagnetic analysis and a modal analysis, the switching harmonic noise is optimized to reduce it. However, from the simulation results, it can be judged that the optimization of the switching frequency or the natural frequency alone has certain limitations. Determining how to combine the two optimization methods in order to form a new optimization method and apply it to practical engineering will become the next research direction.

Author Contributions

Writing—original draft, J.S.; review and revision, J.M. and L.Q.; methodology, Y.F.; investigation, Z.Z. and B.L.; data curation, B.X. and C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China under grants 51977193 and 51827810.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liao, C.; Jiang, W.; Zhang, Z. Analysis of Electromagnetic Vibration Characteristics of an Interior Permanent Magnet Synchronous Motor. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Lu, Y.; Li, J.; Qu, R.; Ye, D.; Lu, H.; Sun, J.; Ge, M.; Xu, H. Electromagnetic Force and Vibration Analysis of Permanent-Magnet-Assisted Synchronous Reluctance Machines. IEEE Trans. Ind. Appl. 2018, 54, 4246–4256. [Google Scholar] [CrossRef]

- Zhang, Y.; Geng, H.; Zhou, J.; Yu, L. Analysis of Electromagnetic Force Waves of Solid Cylindrical Permanent Magnet Synchronous Motors. In Proceedings of the 2018 IEEE International Conference on Mechatronics and Automation (ICMA), Changchun, China, 5–8 August 2018; pp. 689–694. [Google Scholar] [CrossRef]

- Lugand, T.; Schwery, A. Comparison between the Salient-Pole Synchronous Machine and the Doubly Fed Induction Machine with Regard to Electromagnetic Parasitic Forces and Stator Vibrations. IEEE Trans. Ind. Appl. 2017, 53, 5284–5294. [Google Scholar] [CrossRef]

- Chai, F.; Li, Y.; Pei, Y.; Yu, Y. Analysis of Radial Vibration Caused by Magnetic Force and Torque Pulsation in Interior Permanent Magnet Synchronous Motors Considering Air-Gap Deformations. IEEE Trans. Ind. Electron. 2019, 66, 6703–6714. [Google Scholar] [CrossRef]

- Ting, D.; Ruiqing, W.; Jicheng, Z.; Kun, L. Influence of auxiliary slot on electromagnetic vibration in PMSM with similar slot and pole number. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Xia, Z.P.; Wu, L.J.; Jewell, G.W. Analytical Modeling and Finite-Element Computation of Radial Vibration Force in Fractional-Slot Permanent-Magnet Brushless Machines. IEEE Trans. Ind. Appl. 2010, 46, 1908–1918. [Google Scholar] [CrossRef]

- Min, S.G.; Sarlioglu, B. Modeling and Investigation on Electromagnetic Noise in PM Motors with Single- and Double-Layer Concentrated Winding for EV and HEV Application. IEEE Trans. Transp. Electrif. 2018, 4, 292–302. [Google Scholar] [CrossRef]

- Chen, S.; Ding, S.; Shen, S.; Dai, Y.; Yang, Z.; Zhang, J. Influence of Field Weakening Control on Electromagnetic Force and Electromagnetic Vibration of SPMSMs. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress & Exposition—Asia (ECCE-Asia), Singapore, 24–27 May 2021; pp. 221–225. [Google Scholar] [CrossRef]

- Han, Z.; Liu, J. Comparative Analysis of Vibration and Noise in IPMSM Considering the Effect of MTPA Control Algorithms for Electric Vehicles. IEEE Trans. Power Electron. 2021, 36, 6850–6862. [Google Scholar] [CrossRef]

- Deng, W.; Huang, J.; Qian, Z.; Qian, C.; Zhong, D. A Random Pulse Position-Based Selective Noise Cancellation Modulation Method for SVPWM Driven PMSMs. IEEE Trans. Energy Convers. 2022, 37, 2190–2198. [Google Scholar] [CrossRef]

- Deng, W.; Zuo, S. Analysis of the Sideband Electromagnetic Noise in Permanent Magnet Synchronous Motors Generated by Rotor Position Error. IEEE Trans. Ind. Electron. 2022, 69, 4460–4471. [Google Scholar] [CrossRef]

- Pindoriya, R.M.; Rajpurohit, B.S.; Kumar, R. A Novel Application of Harmonics Spread Spectrum Technique for Acoustic Noise and Vibration Reduction of PMSM Drive. IEEE Access 2020, 8, 103273–103284. [Google Scholar] [CrossRef]

- Pindoriya, R.M.; Gautam, G.; Rajpurohit, B.S. A Novel Application of Pseudorandom-Based Technique for Acoustic Noise and Vibration Reduction of PMSM Drive. IEEE Trans. Ind. Appl. 2020, 56, 5511–5522. [Google Scholar] [CrossRef]

- Pindoriya, R.M.; Yadav, A.K.; Rajpurohit, B.S.; Kumar, R. A Novel Application of Random Hysteresis Current Control Technique for Acoustic Noise and Vibration Reduction of PMSM Drive. In Proceedings of the 2020 IEEE Industry Applications Society Annual Meeting, Detroit, MI, USA, 10–16 October 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, H. Random Asymmetric Carrier PWM Method for PMSM Vibration Reduction. IEEE Access 2020, 8, 109411–109420. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Huang, H.; Zou, J. Vibration Reduction for Dual-Branch Three-Phase Permanent Magnet Synchronous Motor with Carrier Phase-Shift Technique. IEEE Trans. Power Electron. 2020, 35, 607–618. [Google Scholar] [CrossRef]

- Jiang, D.; Liu, K.; Liu, Z.; Wang, Q.; He, Z.; Qu, R. Four-Module Three-Phase PMSM Drive for Suppressing Vibration and Common-Mode Current. IEEE Trans. Ind. Appl. 2021, 57, 4874–4883. [Google Scholar] [CrossRef]

- Ji, Z.; Cheng, S.; Lv, Y.; Wang, D.; Sun, W.; Li, X. The Mechanism for Suppressing High-Frequency Vibration of Multiphase Surface Permanent Magnet Motors via PWM Carrier Phase Shifting. IEEE Trans. Power Electron. 2021, 36, 10504–10513. [Google Scholar] [CrossRef]

- Mu, Y. Study on Influence of Harmonic Suppression and Spread Spectrum Modulation on Vibration and Noise of PMSM. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar]

- Wang, S.; Hong, J.; Sun, Y.; Cao, H. Exciting Force and Vibration Analysis of Stator Permanent Magnet Synchronous Motors. IEEE Trans. Magn. 2018, 54, 8108205. [Google Scholar] [CrossRef]

- Timar, P.; Fazekas, A.; Kiss, J.; Miklos, A.; Yang, S. Noise and Vibration of Electrical Machines; Elsevier: New York, NY, USA, 1989. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).