1. Introduction

The lead bismuth fast reactor (LBFR) has become one of the main development directions of the fourth-generation nuclear reactor because of its unique safety characteristics [

1]. Nowadays, building large nuclear reactors is not a favorable option, and hence the trend for developing small nuclear reactors (SMR) is increasing correspondingly [

2].

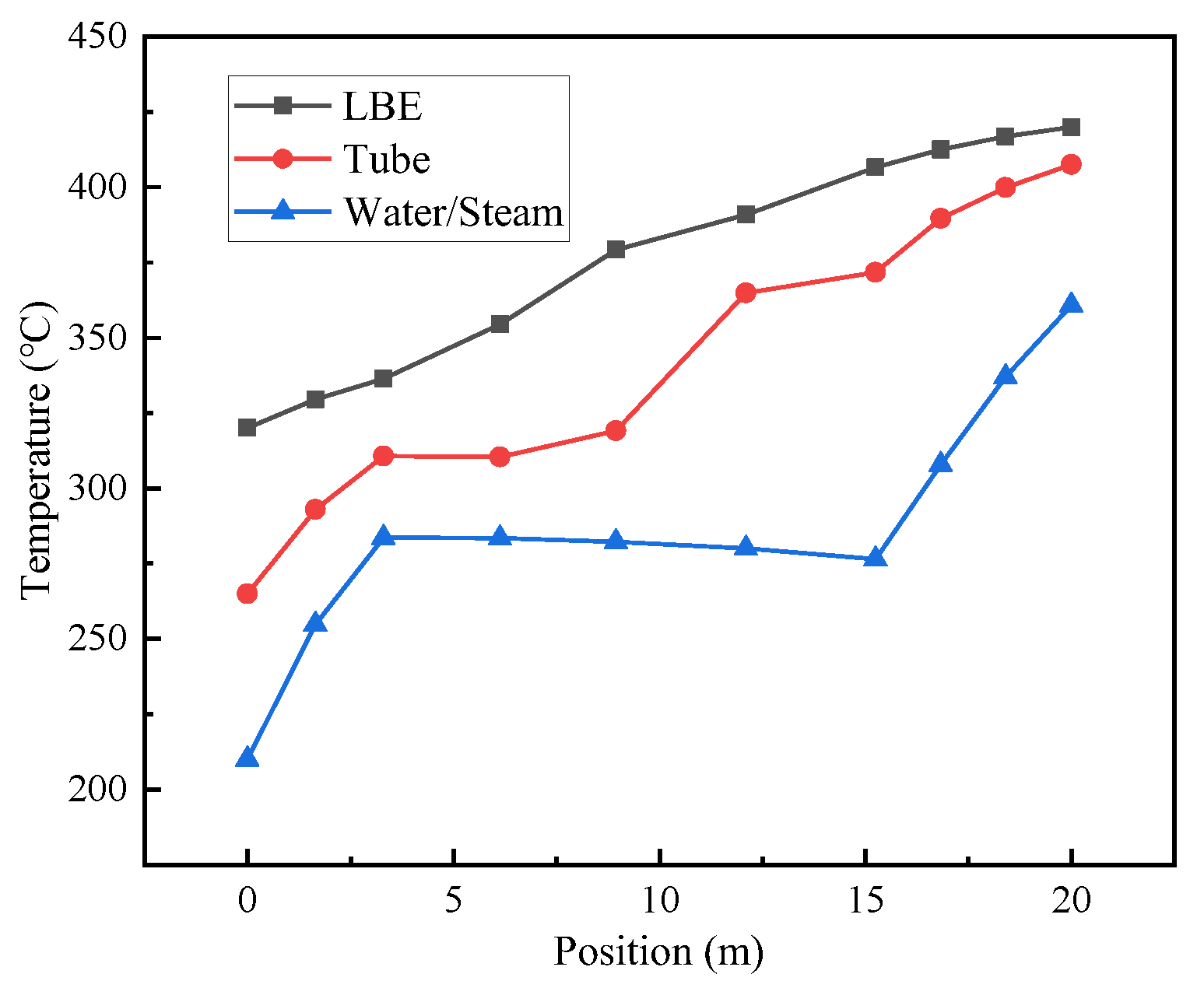

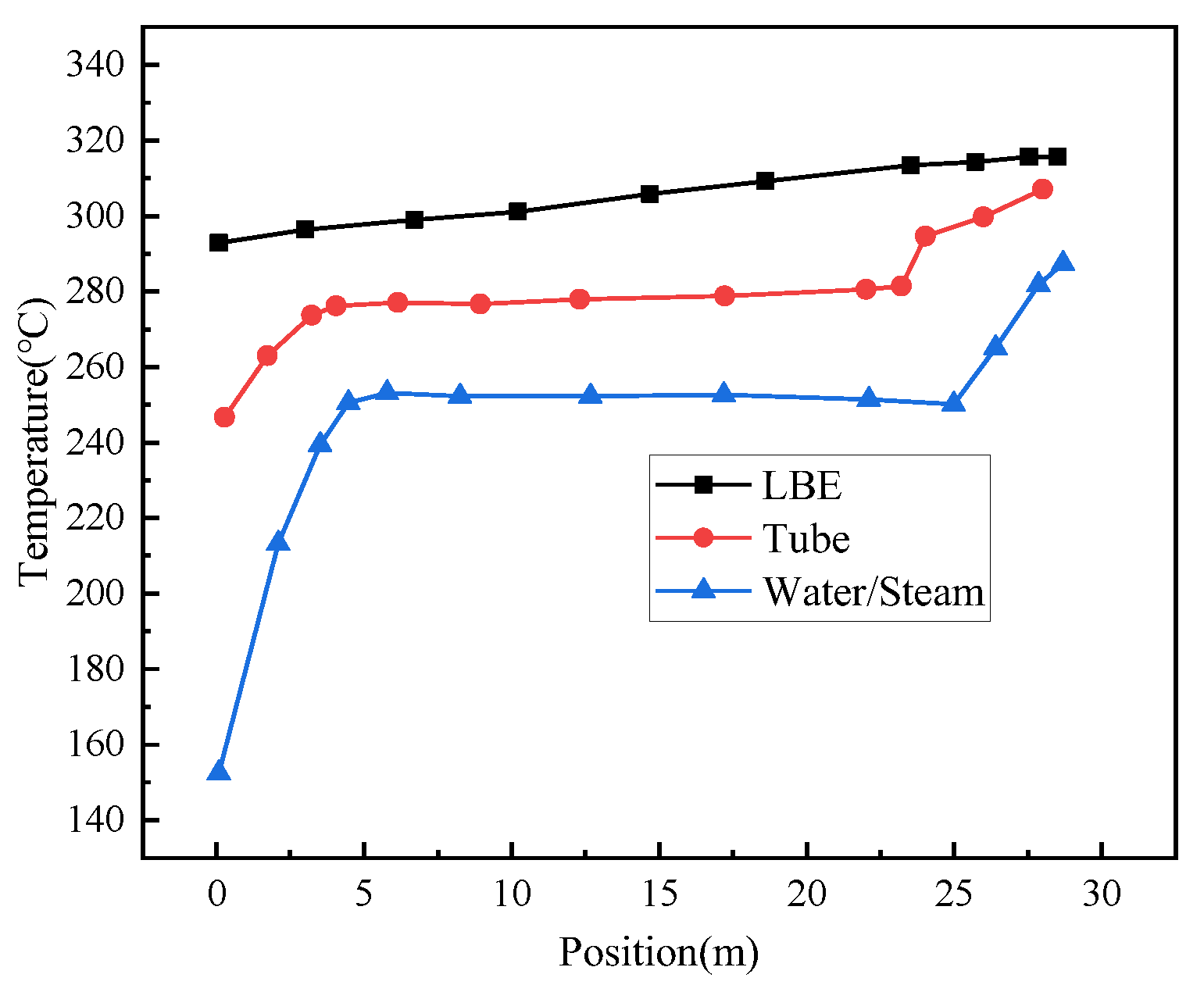

The once-through steam generator (OTSG), the key component of heat transfer in primary and secondary circuits, has been widely concerned in the small lead bismuth fast reactor (SLBFR) [

3]. However, the structure of OTSG is complex, and the feedwater at the secondary side has gone through subcooled region, boiling region and superheated region, so the properties of water/steam have changed greatly. The experimental method is limited by conditions and consumes a lot of manpower and material resources [

4,

5]. Therefore, most scholars use numerical calculation to study OTSG. However, the drastic property changes in water/steam in OTSG bring difficulties in modeling.

Many scholars have worked to simplify the model of OTSG [

6,

7,

8,

9]. The results show that the four regions model combined with the movable boundary method has high accuracy for OTSG [

10]. Unfortunately, the simplification and construction of the model make the difference between the model and the actual OTSG. Any parameter change affecting heat exchange and flow will lead to the change in feedwater demand. In addition, in order to simplify the calculation, many processes are not considered in the model. For example, factors such as the axial conduction of the tube, the heat exchange between the OTSG and the environment, etc., were not taken into account. So, the performance of the controller will worsen in industrial applications due to the model mismatch. Therefore, the robustness of the controller has also become the focus of current research [

11].

Advanced control algorithms such as DMC [

12] and MPC [

13] have fundamentally changed the essence of PID, which will lead to new standards in safety evaluation and many difficulties in industrial iteration. Fuzzy PID [

14], Adaptive PID [

15] and other PID-based control systems retain the lower logic of PID, but the parameters need to be adjusted according to the conditions, and the upper logic is still different from PID. IMC-PID calculates the parameters of PID by using the principle of IMC. It is not different from PID in application, so it is suitable for guiding and improving engineering controllers.

Garcia and Morari proposed an internal model control structure with model, control and feedback, called Internal Model Control (IMC) [

16]. It has attracted extensive attention because of its simple structure and strong robustness.

In nonlinear systems, Kazantzidou et al. [

17] studied the IMC for keeping and rudder roll stabilization for a surface marine craft. There is satisfactory roll reduction and the course-keeping is maintained in the presence of constant input disturbance. Singh et al. [

18] designed a 2-DOF IMC-PID for power system frequency modulation, but an extra degree of freedom is fixed to cancel the sequences of the added poles of the disturbances. Therefore, what needs to be designed and calculated is still the traditional IMC. Bhattacharjee et al. [

19] applied IMC to the artificial pancreas system. Through a feedforward control path to the online tuned IMC, it is proved that the online tuned IMC algorithm is able to compensate unannounced meal disorders with low infection of insulin does and reduces the risk of hyperglycemic events for different patient conditions. Li et al. [

20] used the GD-DE algorithm to optimize the parameters of the IMC controller of the nonlinear uncertain aeroelastic blade system. These studies have shown that even if there is a gap between the internal model of IMC and the actual controlled object, IMC still has a relatively satisfactory performance.

In process control, Mesbahr et al. [

21] present a general IMC structure with multiple degrees of freedom for the design of control systems with multiple objectives. The remarkable feature of the control structure is that the controllers can be designed independently of each other. Karan et al. [

22] studied the IMC of the system with integrated time-delayed processes (ITDP), and verified the IMC through experiments such as distillation tower and liquid storage tank. The controller output is calculated by computer simulation software, which is still a certain distance from the engineering control process. Through research on the biomass boiler, Schörghuber et al. [

23] found that IMC can greatly reduce the controller parameters and achieve satisfactory control performance. They promoted the industrial application of IMC through experimental research, but the inaccuracy of the model mentioned in the paper has not been studied in detail, especially when the model deviates from the steady-state point; the control effect should be the focus of future research.

In the context of nuclear reactors, Wang et al. [

24] designed the IMC power controller of pressurized water reactor (PWR) and optimized the parameters by the genetic algorithm. Zeng et al. [

25] designed the core power IMC-PID controller for a molten salt breeder reactor. Different from Wang’s work, Zeng used the particle swarm optimization algorithm to optimize the parameters of the approximated First Order Plus Dead Time (FOPDT) model rather than the controller parameters.

Due to the security of nuclear reactors, the method of on-line parameter tuning is unrealistic, and there is a certain error between the simulation model and the actual system. The study of model mismatch has great significance for the performance of IMC and engineering applications.

On the other hand, PID is still the main controller of industry because of its simple structure. In the field with high safety requirements, the combination of PID and advanced control method is also a transition form from traditional PID to advanced control method. Therefore, it is important for engineering applications to consider the combination of advanced control methods and PID and the influence of model mismatch on the controller performance.

In this work, firstly, the model of OTSG for SLBFR is established and verified. Then, the IMC and IMC-PID controller of OTSG feedwater are designed to control the lead bismuth eutectic (LBE) outlet temperature of OTSG. The temperature control process is simplified to three FOPDT models by different methods. The effectiveness of the approximate methods are proved by comparison with the nonlinear model. Finally, the performance of IMC-PID controller designed based on simplified FOPDT model is verified by a nonlinear model and non-minimum phase system, and the adaptability of IMC-PID to model mismatch is studied by adding nonlinear elements such as measurement noise and time delay. Finally, the performance of IMC-PID controller is studied when the model deviates from the steady state.

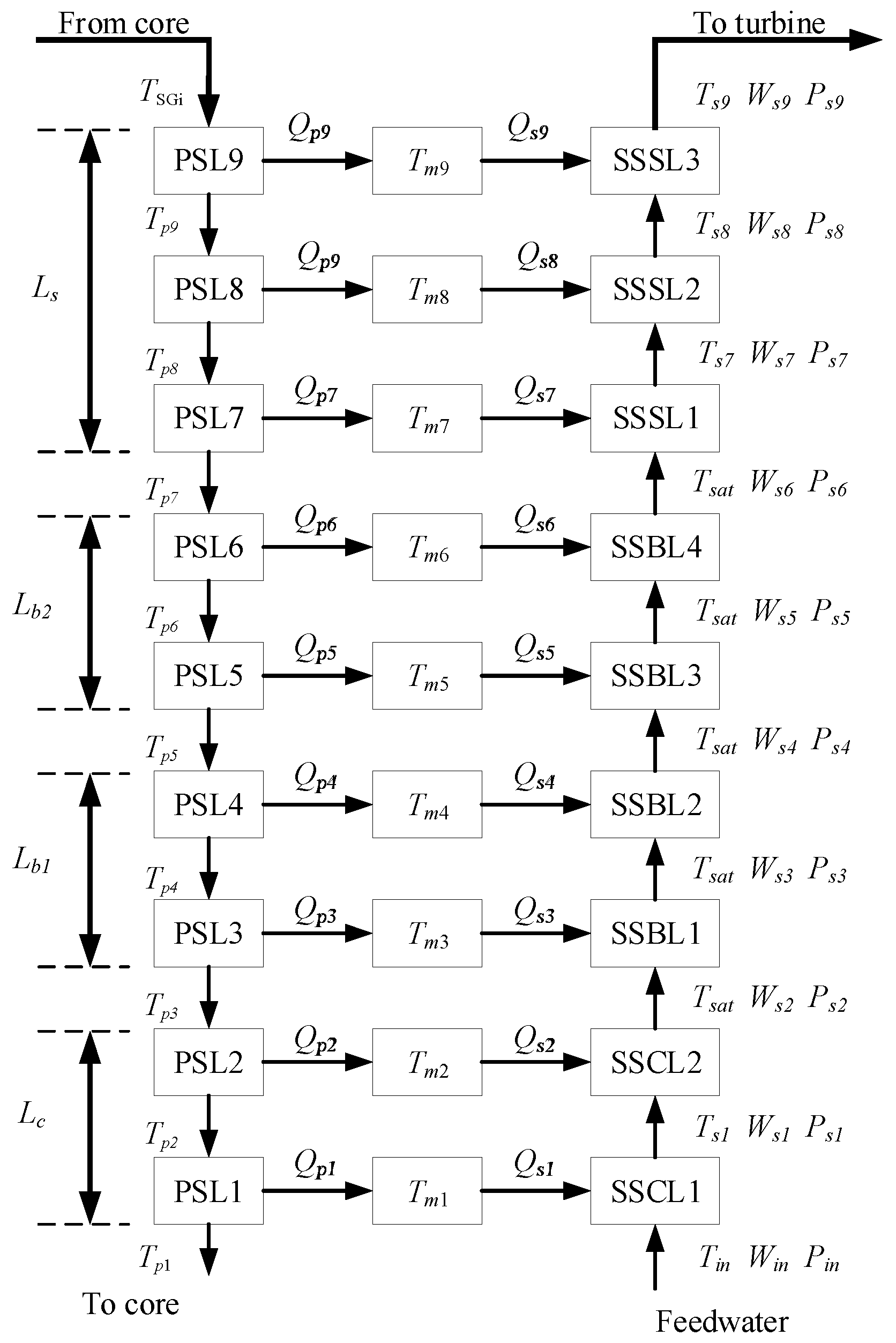

3. Controller Design and Simulation Platform Development

The LBE corrosivity causes the LBE flowrate change to be restricted by the primary loop, so it is not the best solution to adjust the LBE outlet temperature through the LBE flowrate. Adjusting the LBE outlet temperature through feedwater temperature must consider the rate of temperature change. Due to the large heat capacity of water and the faster response of the OTSG, adjusting the LBE outlet temperature through feedwater temperature cannot meet the needs of OTSG. The feedwater flowrate can be regulated by valves or pumps quickly, which is the best choice to control the LBE outlet temperature. Therefore, a flowrate controller is designed in this section.

This section contains two parts. Firstly, the principle and design method of IMC controller are introduced. Through the analysis of the characteristics of IMC, the IMC-PID is introduced, and the design method of IMC-PID controller is introduced.

3.1. IMC

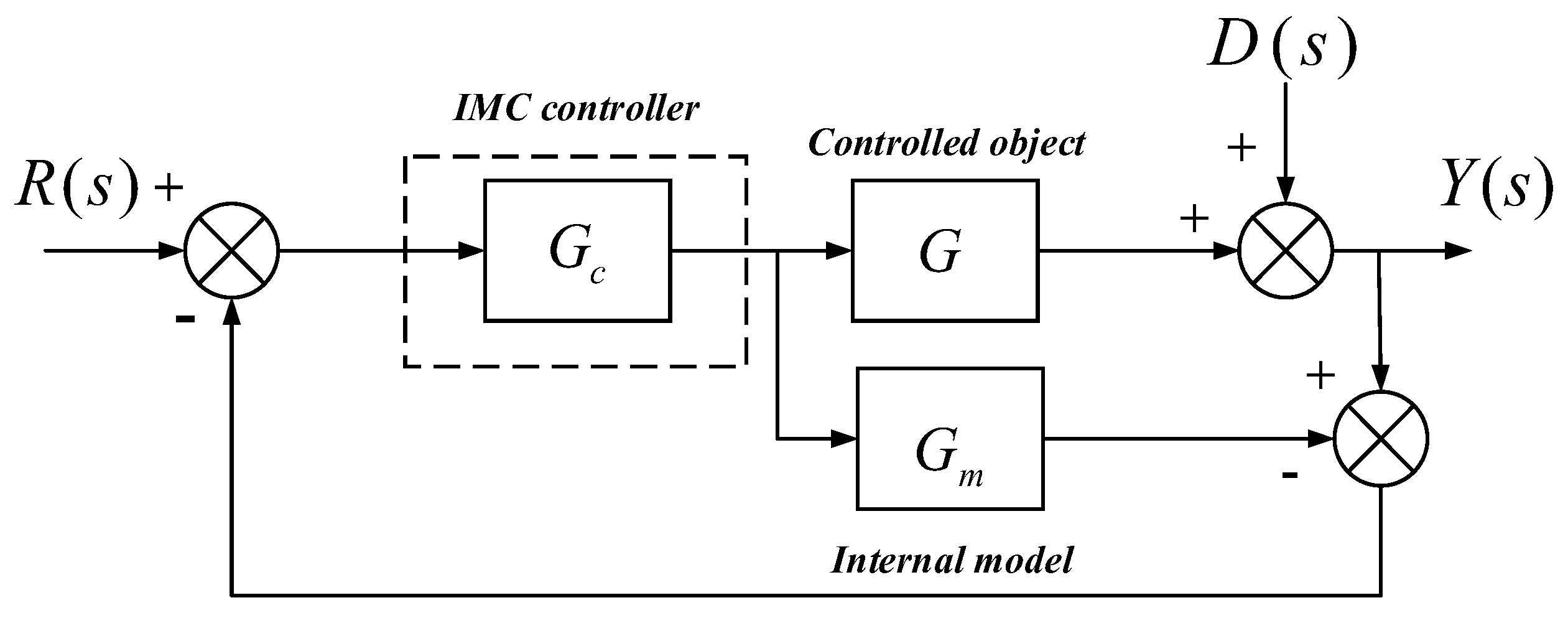

IMC is a control method based on internal model.

Figure 5 shows the general structure of the IMC controller, where

Gc is the IMC controller,

G is the controlled object,

Gm is the nominal model (internal model),

Y is the output of the controlled object,

D is the disturbance (including measurement noise) and

R is the reference of

Y. The output of the system can be expressed as:

It is not difficult to see from Equation (5) that when GcGm = 1, the system will achieve adequate anti-disturbance performance. At this time, if Gm = G, the system also has suitable tracking performance. Therefore, the controller is designed as follows:

Step 1: Let

. When

Gm(

s) has zeros in the right half plane of complex plane,

Gc(

s) will be unstable and difficult to achieve in engineering. So,

Gm(

s) can be expressed as:

where

is the non-minimum phase element of

Gm(

s) and

is the minimum phase part of

Gm(

s).

Step 2: If

is regular, then

Gc(

s) must be non-strictly regular. The robustness of IMC can be improved by including a low pass filter:

where

n is the order of the filter to ensure the regularity of

Gc(

s), so

n depends on

, and this parameter does not need to be tuned;

λ is a filter constant, which needs to be tuned for IMC. It can be seen from Equation (13) that only

λ needs to be tuned.

According to the OTSG model established in

Section 2, the transfer function from feedwater flow to outlet LBE temperature can be obtained. Due to the high order, the dominant pole method is used to reduce the order of the transfer function, and the reduced transfer function is (only 100% FP is given here, and other power levels can be found in the

Appendix A):

Gc(

s) designed according to the above steps is (

λ = 1 here, and the other calculation results can be found in the

Appendix A):

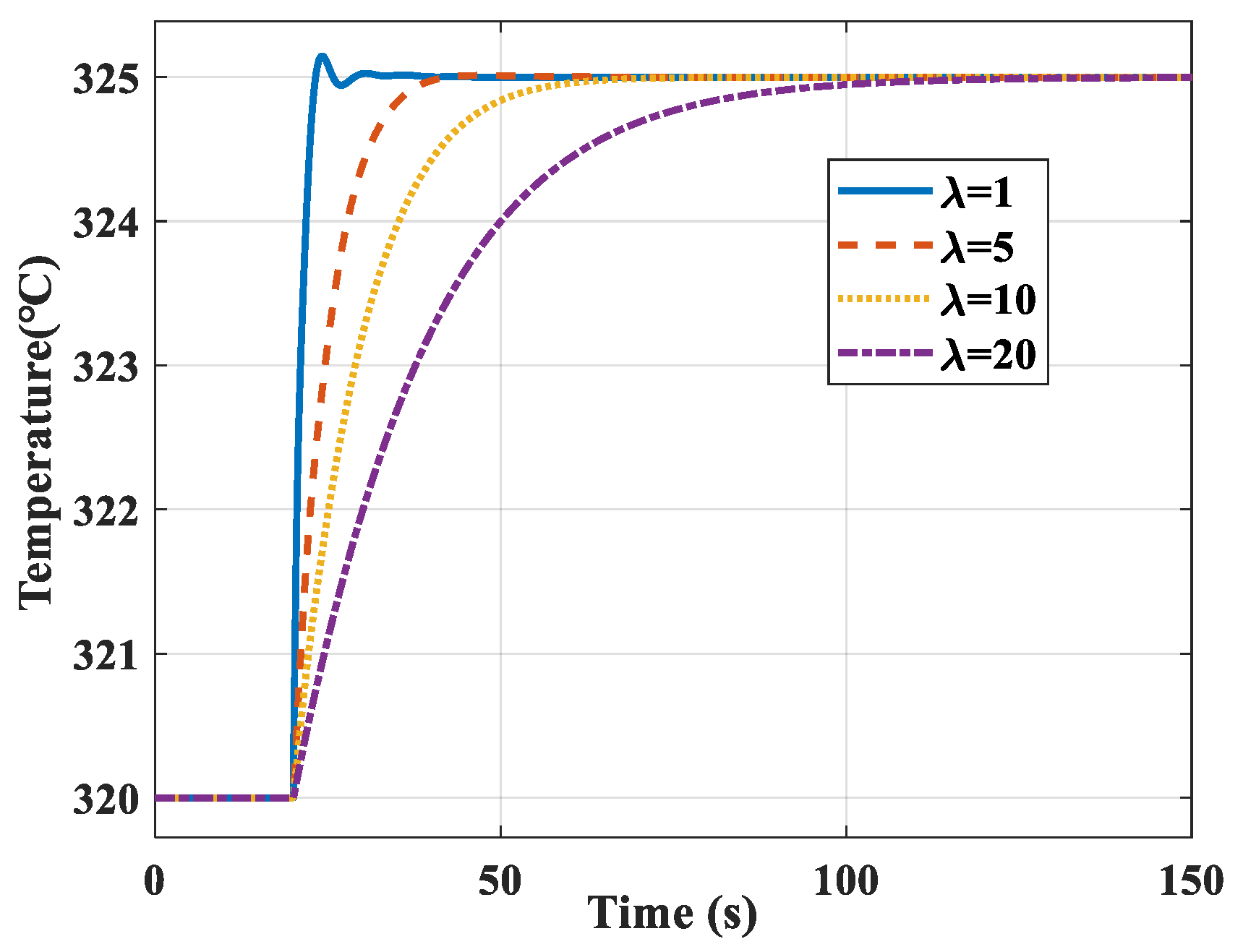

The step change in LBE outlet temperature reference is from 320 °C to 325 °C at 20 s.

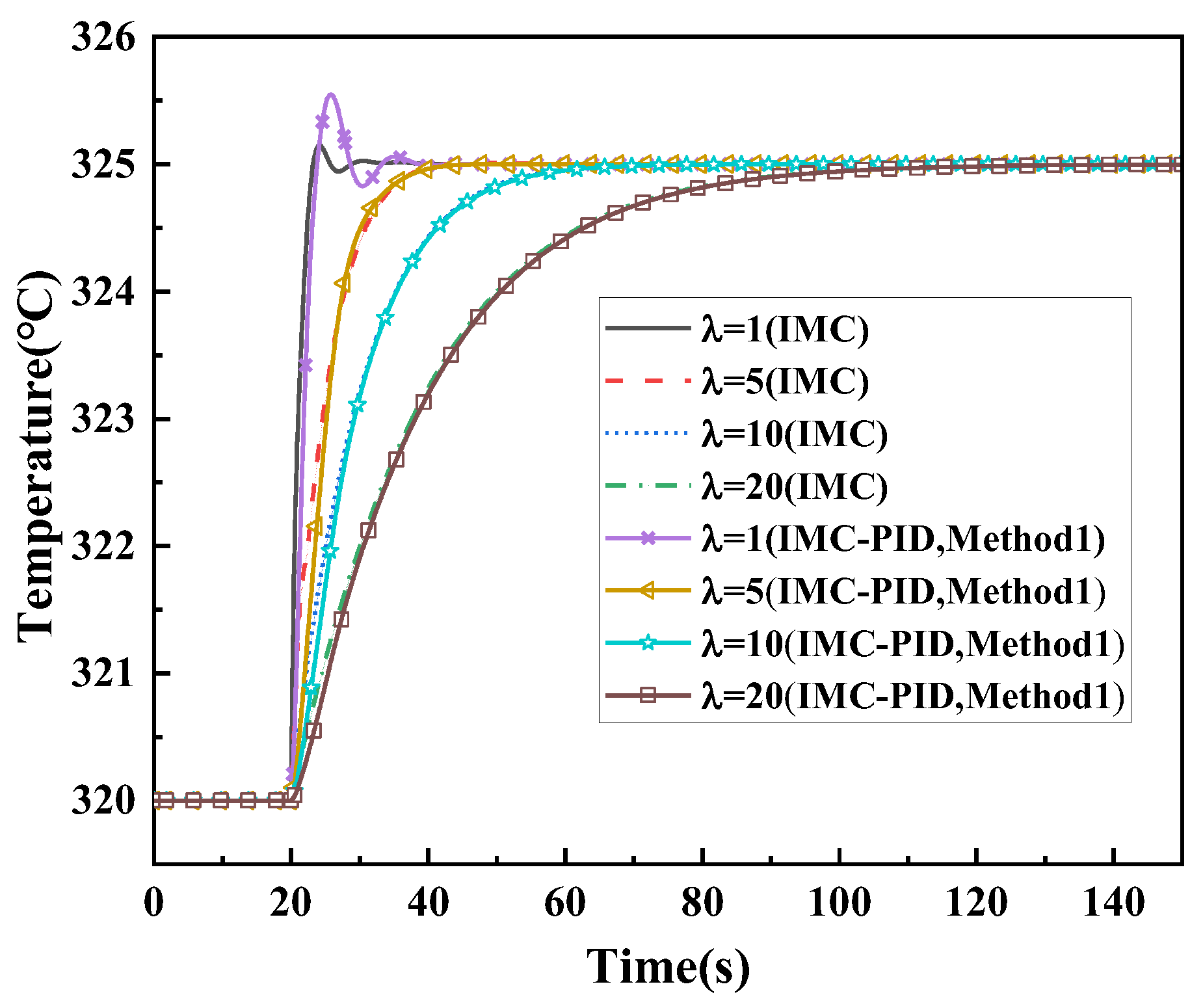

Figure 6 shows the performance of IMC with different controller parameters. Compared with PID, IMC parameter tuning is simple and clear. Single parameter adjustment avoids the possibility of more combinations. It can be seen from

Figure 6 that the impact of

λ on performance is intuitive. With the increase in

λ, the response of the system becomes slower, but a small

λ will cause the controller output to be aggressive.

In addition, it can be seen from Equation (15) that the order of IMC is higher than PID. With simple structure, principle and suitable control effect, traditional PID has become the most important controller in industry. So, combining the advantages of IMC and the easy implementation of PID is also an important direction of industrial controller research.

3.2. IMC-PID

The structure of the IMC-PID controller is shown in

Figure 7. Obviously, when

C in

Figure 7 is PID controller,

Figure 7 is transformed into traditional PID closed-loop control. Therefore, the key idea of the IMC-PID controller is to convert

C into PID equivalently.

From

Figure 7, the transfer function of

C can be obtained as:

The transfer function of traditional PID can be expressed as:

where

Kp,

Ki and

Kd are the coefficients of proportional, integral and differential elements, respectively. Since the differential element is difficult to realize, the third term in Equation (17) is usually used to approximate the ideal differential element, and

Td is the filter constant.

Usually, most of the controlled objects in industry can be represented by the FOPDT system, which can be expressed as follows:

The approximation process will bring errors to the model and make Gm(s) deviate from G. Therefore, in order to study the influence of model deviation on the effect of IMC-PID control, three different methods are used to approximate the transfer function.

3.2.1. Approximate Method of FOPDT

Method 1: Time domain response approximation method. By introducing the step signal and analyzing the output, the transfer function of the approximate FOPDT of the system is obtained. From Equation (18), the response of the system in the time domain can be derived:

When s = 0, can be obtained from . Then, by comparing the nonlinear model output y with the approximate model output , the parameters θ and T are identified.

Method 2: Derivative calculation method. The first and second derivatives of Equation (18) for

s are obtained:

Substitute

s = 0 into

G(

s) and

Gr(

s). Then, the left side of Equations (20) and (21) are equivalent as follows:

where the purpose of dividing

G(0) is to eliminate

e−θs; the calculation method of

K is the same as Method 1.

Method 3: Suboptimal order reduction method. This method can be obtained from Ref. [

33] and is not introduced here.

The transfer functions from feedwater flowrate to LBE outlet temperature approximated by three methods at 100% FP are shown in

Table 4. The transfer functions at the remaining power levels can be found in

Appendix A.

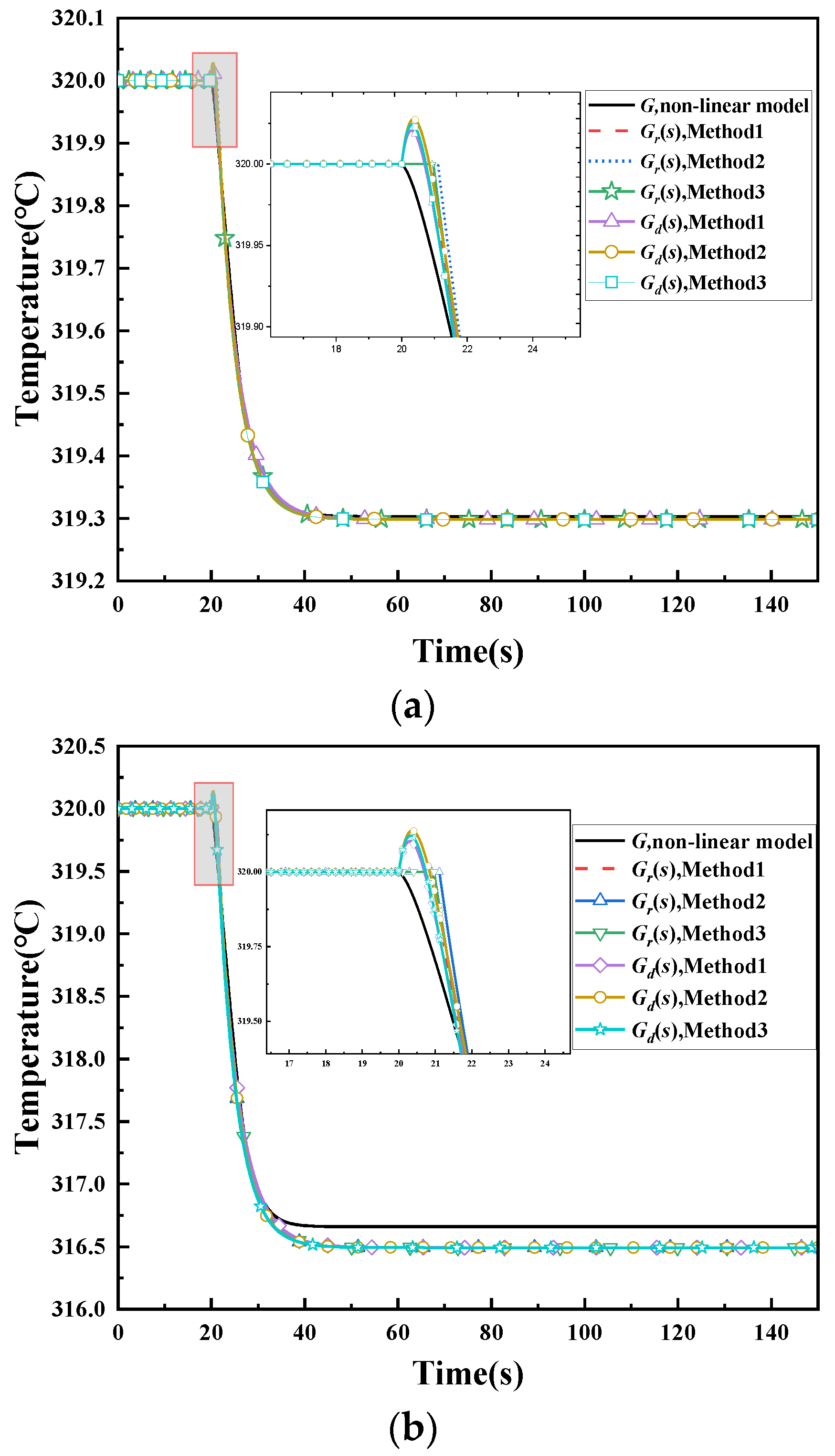

The OTSG operates stably at 100% FP at

t = 0. Then, the feedwater flowrate step changes +1% and +5% at

t = 20 s.

Figure 8 shows the output of nonlinear model, reduced order model and transfer function listed in

Table 4. It can be seen from

Figure 8 that the outputs of the models calculated by the three methods are consistent with the nonlinear model. Since the three methods calculate

K in the same way, the steady-state values of the three methods are equal. Comparing

Figure 8a,b, it can be found that the difference between the linear model and the nonlinear model increases with the deviation broadening from the steady state. The comparison showed that the output of Method 1 is closest to the nonlinear model, easy to calculate, and can be calculated by transfer function or fitted by system response curve, which is more convenient for engineering applications. Therefore, Method 1 is recommended. Ref. [

34] also provides a method to approximate the frequency domain characteristics of the system, but this method is limited by the characteristics of the controlled object and the calculation is complex, so it will not be introduced here.

3.2.2. Design of IMC-PID Controller

The approximate analysis of time delay terms is performed by the Pade method [

25]:

So, the IMC-PID controller is designed according to the method in

Section 3.1:

Gd(

s) calculated by the three methods is summarized in

Table 4. Then, substitute Equation (26) into Equation (16):

The parameters of the IMC-PID controller can be obtained by comparing Equations (27) and (17):

The parameters calculated by the three methods with

λ = 1 are listed in

Table 5.

3.3. Simulation Platform

MATLAB/Simulink is used to build the OTSG model and controller model.

Figure 9 shows the structure of the OTSG feedwater control simulation platform. In

Figure 9, module 1 is the reference, module 2 is IMC-PID controller, module 3 is IMC controller, module 4 is OTSG nonlinear model

G, module 5 is FOPDT model

Gr(

s), module 6 is non-minimum phase model

Gd(

s), module 7 is noise and switch and the module 8 is time delay and switch.

4. Results and Discussion

This section verifies the adaptability of IMC-PID to model mismatch under different controller parameters through four ways.

Section 4.1 tests the impact of three different approximation methods on IMC-PID.

Section 4.2 studies the performance of IMC-PID through the nonlinear model and non-minimum phase system.

Section 4.3 studies the performance of IMC-PID under different parameters. In

Section 4.4, the adaptability of IMC-PID to the time delay element under different parameters is studied. In

Section 4.5, the tracking ability of different controller parameters is studied through rapid load reduction.

4.1. Effect of Different Control Parameters

The step change in LBE outlet temperature reference is from 320 °C to 325 °C at 20 s, and the influence of different

λ values on the performance of IMC-PID controller is studied by comparing the system output.

Figure 10 shows the control performance of IMC and IMC-PID controller with different parameters.

It can be seen from

Figure 10 that with the increase in

λ, the adjustment time of the system gradually increases. At the same time, the output of IMC and IMC-PID are closer. This shows that as

λ increases, the robustness of the system gradually increases and the sensitivity to model mismatch gradually decreases.

It can be seen from Equation (14) that the filtering element introduces a pole with a value of and as the λ increases, the pole approaches the origin. This leads to the more obvious influence of pole on the system with the increase in λ, and gradually becomes the dominant pole of the system. Therefore, when λ is large, IMC-PID has the same performance with IMC.

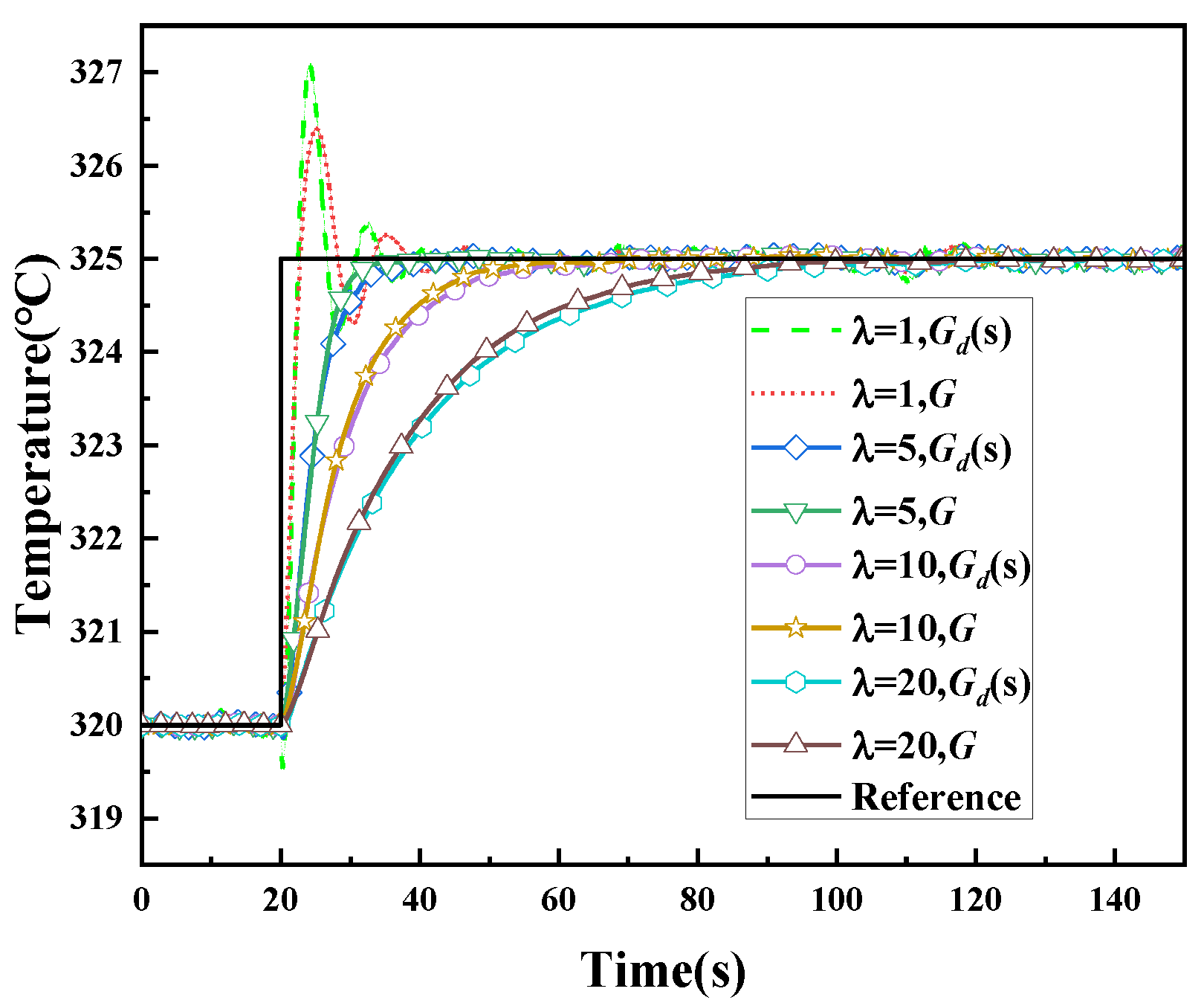

Figure 11 shows the performance of IMC-PID controller parameters calculated by three methods. It can be seen from

Figure 11 that the performance of the IMC-PID controller obtained by the three methods gradually disappears with the increase in

λ. The results are consistent with those in

Figure 8, which show that with the increase in

λ, the system will become insensitive to model mismatch.

As can be seen in

Figure 11, the transfer functions obtained by the three approximate methods can describe the characteristics of the system approximately, and the performance of the controllers designed by the three methods is not different, especially when

λ is large. Therefore, the results of Method 1 are used for subsequent analysis in this paper.

4.2. Effect of Model Mismatch

According to the established controlled object, the controller performance will be poor due to the model mismatch in practical application. Therefore, it is important to study the influence of the controller parameters on model mismatch. It may be assumed that the nonlinear model

G established in

Section 2.1 is the actual controlled object 1,

Gd(

s) in

Table 4 is the actual controlled object 2, and

Gr(

s) is the model established by simulation calculation.

Gr(

s) ignores the nonlinearity of

G and the non-minimum phase characteristics in

Gd(

s).

Unfortunately, industrial processes use the system identification method to obtain the system transfer function and design the controller. At the same time, for the convenience of controller design, the system is usually approximated as FOPDT, such as Gr(s), to replace G, thereby ignoring the nonlinearity of original system G and the non-minimum phase characteristic of Gd(s). This is consistent with our assumption.

Figure 12 shows the control performance of IMC and IMC-PID on models

Gd(

s) under different parameters when the LBE outlet temperature reference of the OTSG has a +5 °C step change. The control performance of IMC-PID on nonlinear model

G is shown in

Figure 10.

By comparing

Figure 10 and

Figure 12, it can be found that the approximation of the time delay element using first-order Pade is very effective in

Section 3.2.2. When the controlled object is a minimum phase system, IMC-PID can realize fast regulation without overshoot. When the controlled object is a non-minimum phase system, the control performance of IMC-PID deteriorates slightly. With the increase in

λ, the output of IMC-PID controller is gradually conservative and insensitive to non-minimum phase characteristics. It can be seen from

Figure 10 that with the increase in

λ, the system is also no longer sensitive to the disturbance of the internal model (model mismatch and non-minimum phase characteristics).

4.3. Effect of Measurement Noise on Control Performance

To simulate the sensor measurement noise, 0.25% of the measurement noise is added to the output of the controlled object.

Figure 13 shows the performance of IMC-PID under different control parameters. As can be seen from

Figure 13, when

λ = 1, the system responds quickly, but it is also more sensitive to measurement noise. When

λ = 20, the measurement noise has little effect on the performance of the IMC-PID controller. The effect of the controller on

G,

Gr(

s) and

Gd(

s) is consistent. In addition, the results show that the PID controller with appropriate parameters can also achieve the effect of disturbance rejection. Moreover,

λ plays the same role in IMC and IMC-PID controller. Therefore, tuning the PID controller by the IMC method is helpful for practical applications. Three parameters of PID that need to be tuned are simplified to one, which is convenient for design and tuning.

4.4. Influence of Time Delay Element

Based on

Section 4.3, a time delay element is added to simulate the time of signal transmission and controller output.

Figure 14 shows the performance of the IMC-PID controller with different parameters when there is a 1 s delay from error generation to controller output.

It can be seen from

Figure 14 that when

λ = 1, the performance of the controller is further deteriorated than in

Figure 11, resulting in large overshoot. Comparing

Figure 10,

Figure 11,

Figure 12,

Figure 13 and

Figure 14, it can be found that the smaller filter parameters are sensitive to model mismatch caused by nonlinear elements, non-minimum phase elements, noise and time delay, which can be regarded as the model mismatch between the actual model and the simulation model for controller design. It can be found that the larger filter parameters sacrifice certain sensitivity, but the robustness is strengthened. From

Figure 14, it can be found that the impact of the introduced element in this paper on the performance of IMC-PID with

λ = 20 can be ignored. Therefore, if there is a model mismatch problem in the controller design, it is inappropriate to only use load tracking as the evaluation index of the controller, and the optimization of the controller is likely to be futile.

Although the increase in λ will make the IMC-PID controller insensitive to model mismatch, it will also cause the controller output to be too conservative, resulting in poor control performance.

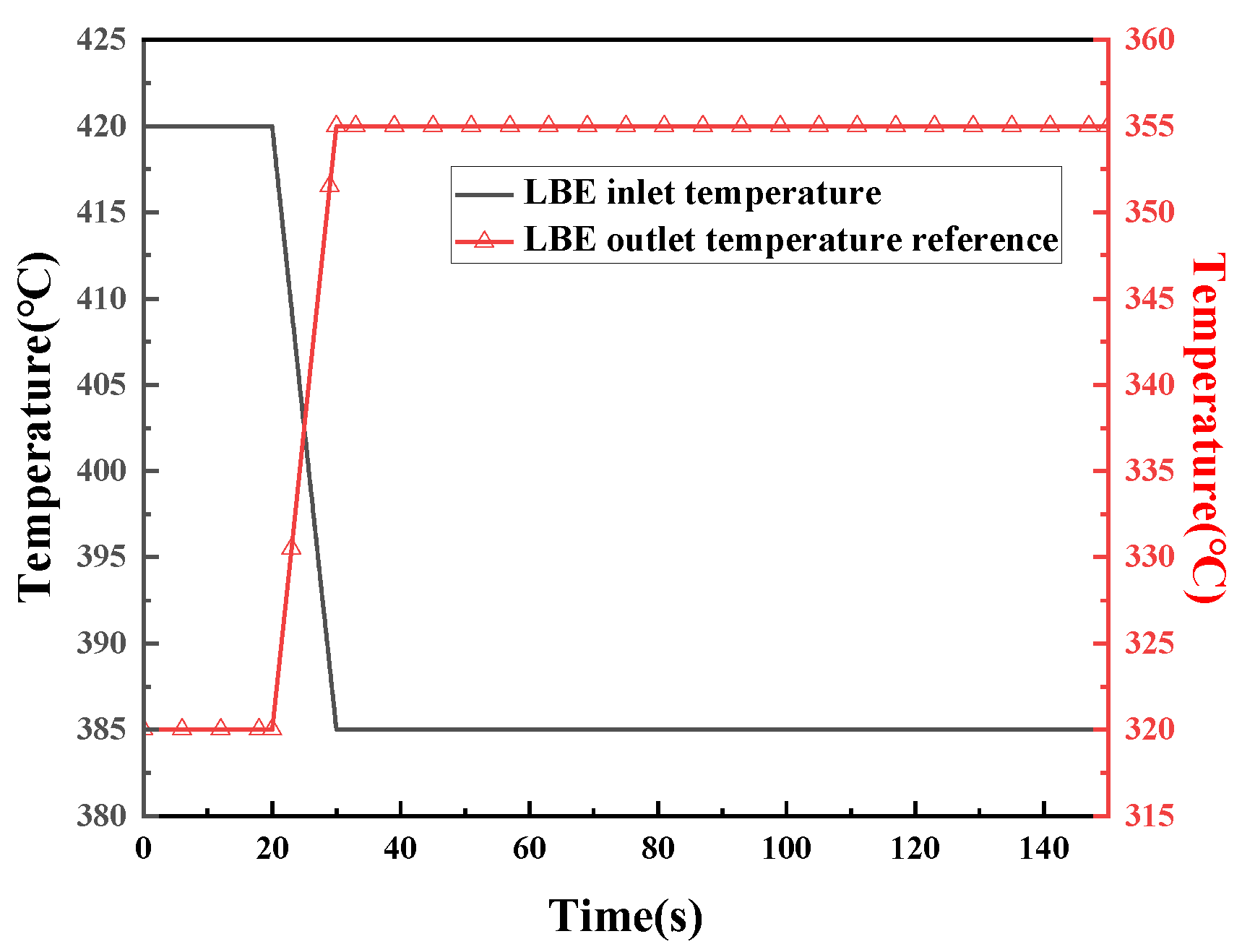

4.5. Rapid Power Changes

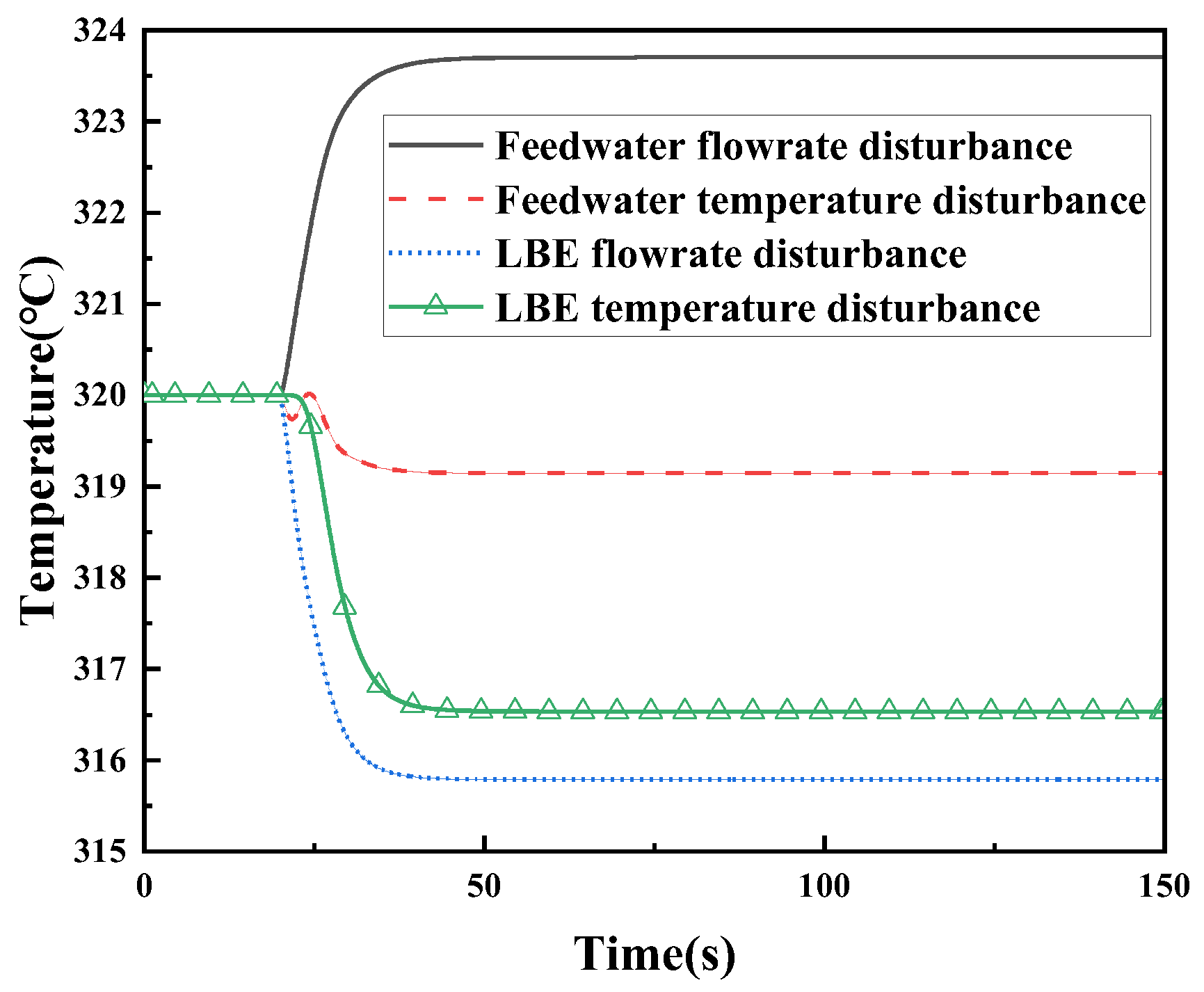

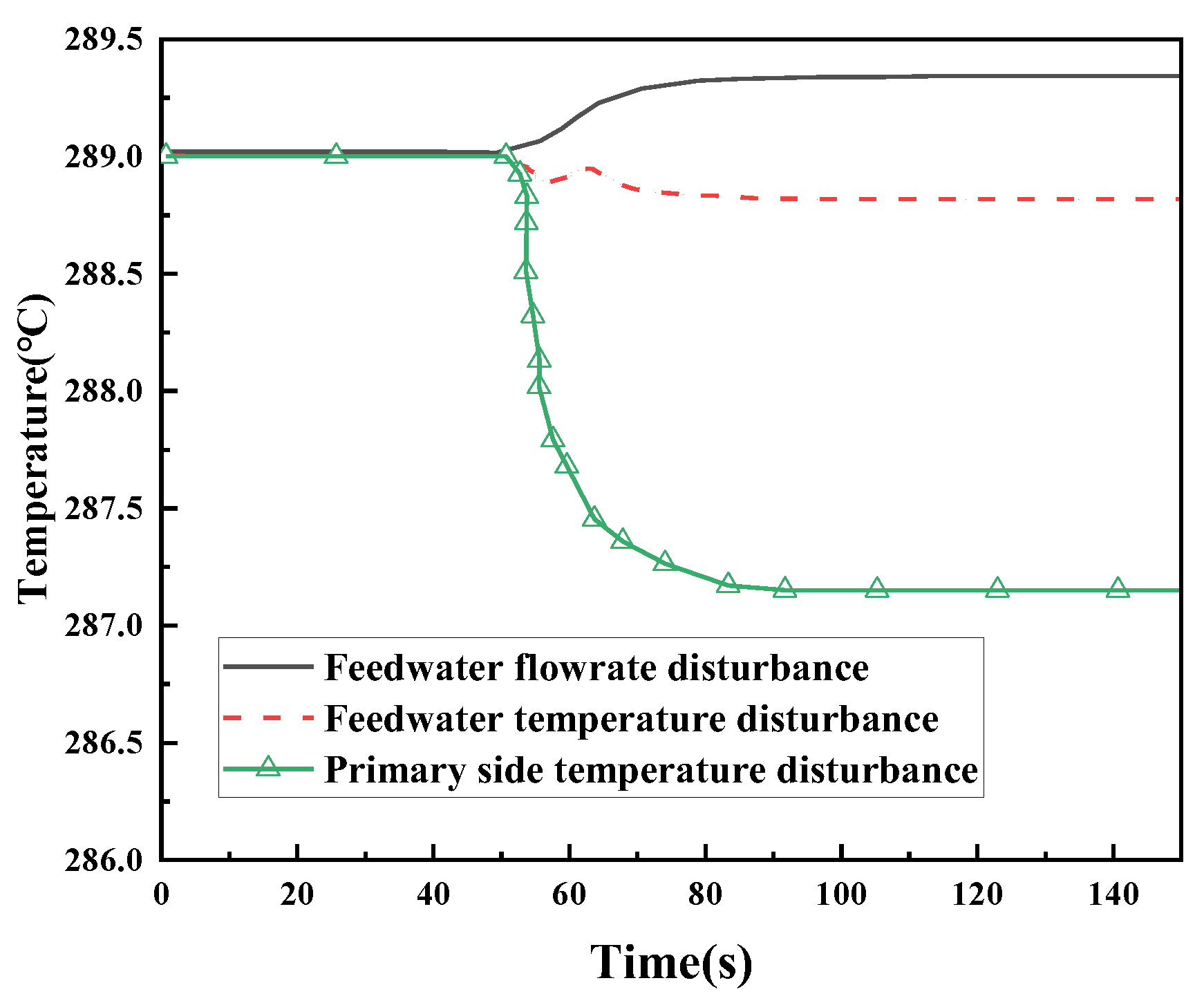

Rapid power changes usually occur in load rejection or emergency shutdown conditions. In these conditions, the powers of the primary and secondary loops of the nuclear reactor are reduced at the same time. Therefore, the input of OTSG and the reference change at the same time. This section simulates a rapid power drop from 100% FP to 30% FP. The change in LBE inlet temperature of OTSG due to the simultaneous power reduction on the primary side is shown in

Figure 15. At the same time, the OTSG feedwater control system needs to control the LBE outlet temperature to a reference curve to prevent the coolant temperature from introducing reactivity and causing the core power to change. The reference of LBE outlet temperature is shown in

Figure 15.

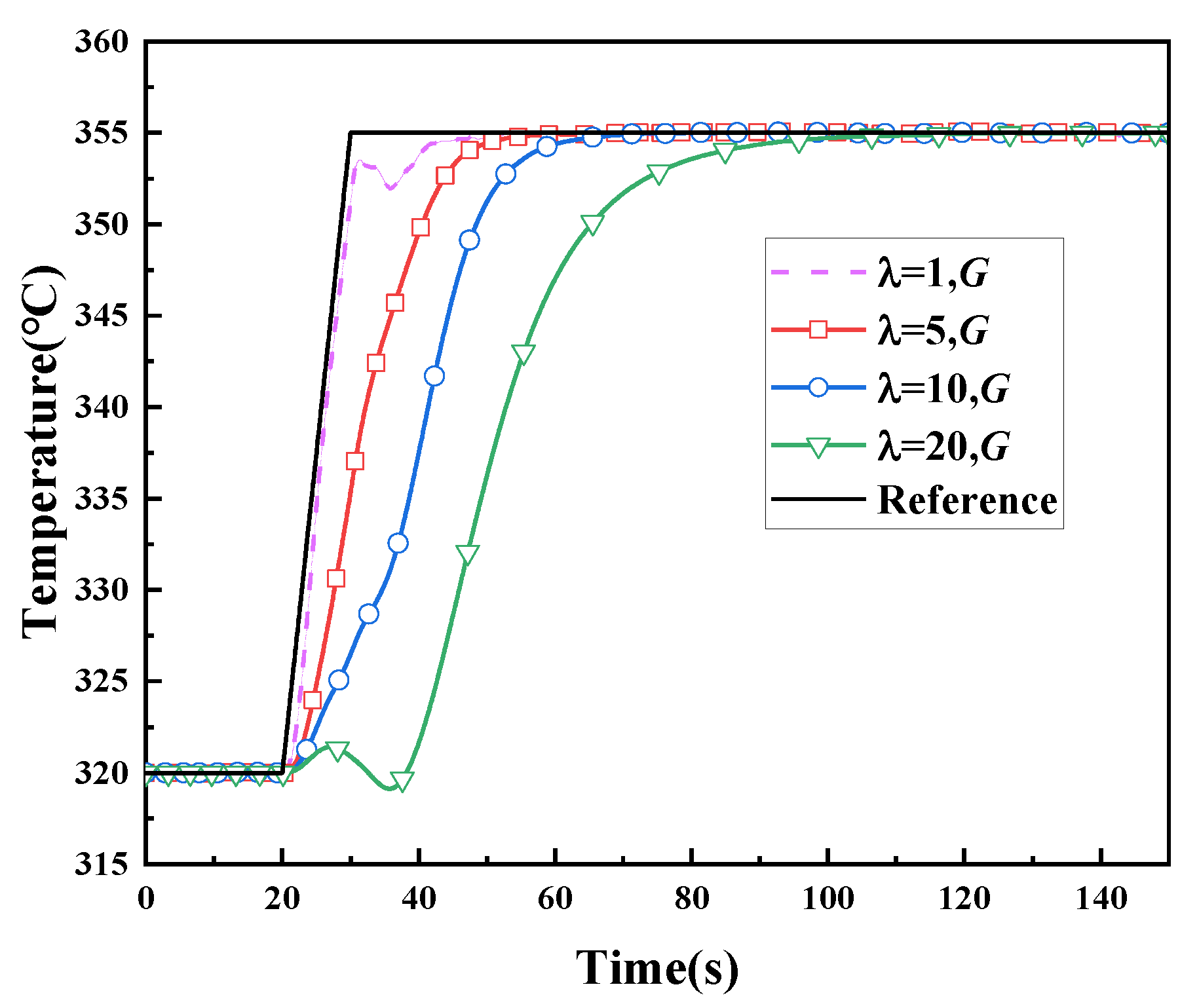

Figure 16 also shows the performance under different controller parameters. It can be seen from

Figure 16 that when

λ = 20, the system output fluctuates for a period of time, and even lower than the initial temperature. The reason is that the LBE flow velocity is restricted due to the corrosiveness. The change in LBE inlet temperature takes time to change the outlet temperature. As shown in

Figure 4, there is an obvious delay in the influence of LBE inlet temperature on LBE outlet temperature. At this time, the change in controller reference reduces the feedwater flowrate to increase the LBE outlet temperature. Subsequently, the influence of LBE inlet temperature change is transmitted to the OTSG outlet, resulting in the decrease in LBE outlet temperature, while the output of

λ controller is smaller and the LBE temperature decreases. When the

λ is small, the output of the system is large, and the disturbance of LBE at the inlet becomes less obvious. We can observe that the slopes of the four curves in

Figure 16 change at 30 s.

Based on the research of this paper, λ of IMC-PID feedwater controller for the presented OTSG of SLBFR is recommended to be between 5 and 10. This research on model mismatch has universality, and this method can be used to initialize other PID controller parameters in industrial processes.