Visualizing Experimental Study of the Effect of Inclination Angle on the Melting Performance for an Energy Storage Tank

Abstract

:1. Introduction

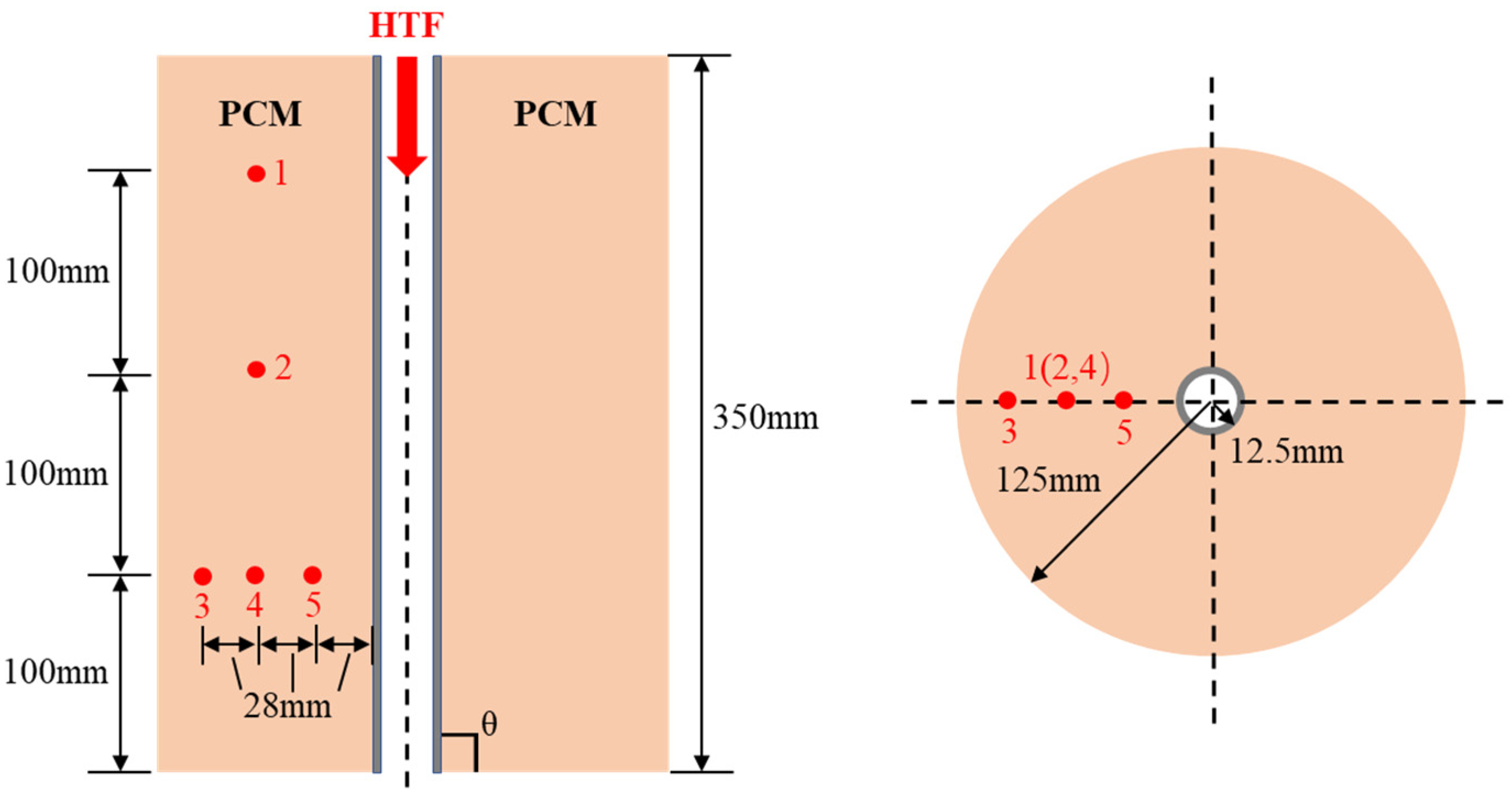

2. Experimental Design and Process

2.1. Experiment Setup

2.2. Phase Change Material

3. Results and Discussion

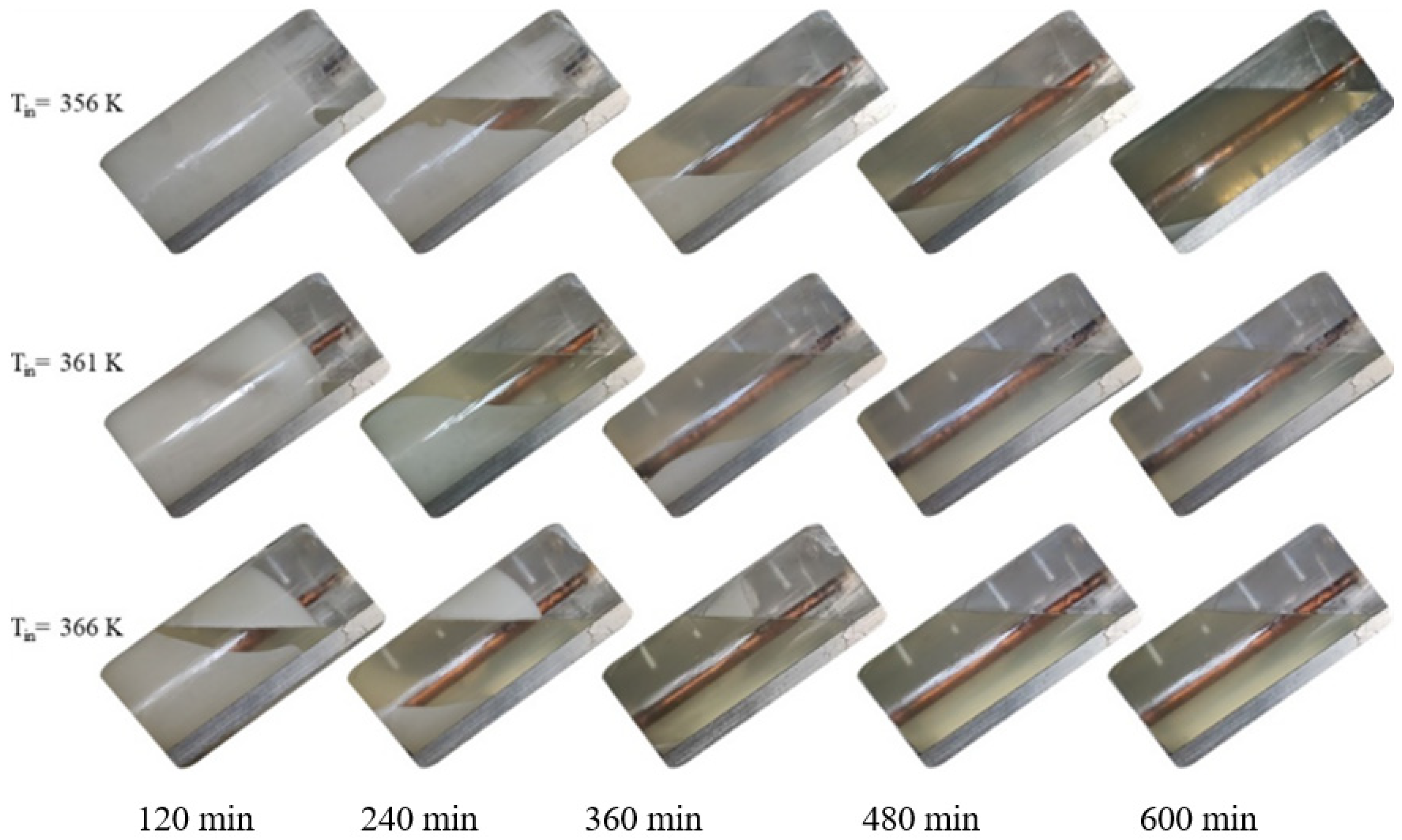

3.1. Liquid Fraction of PCM

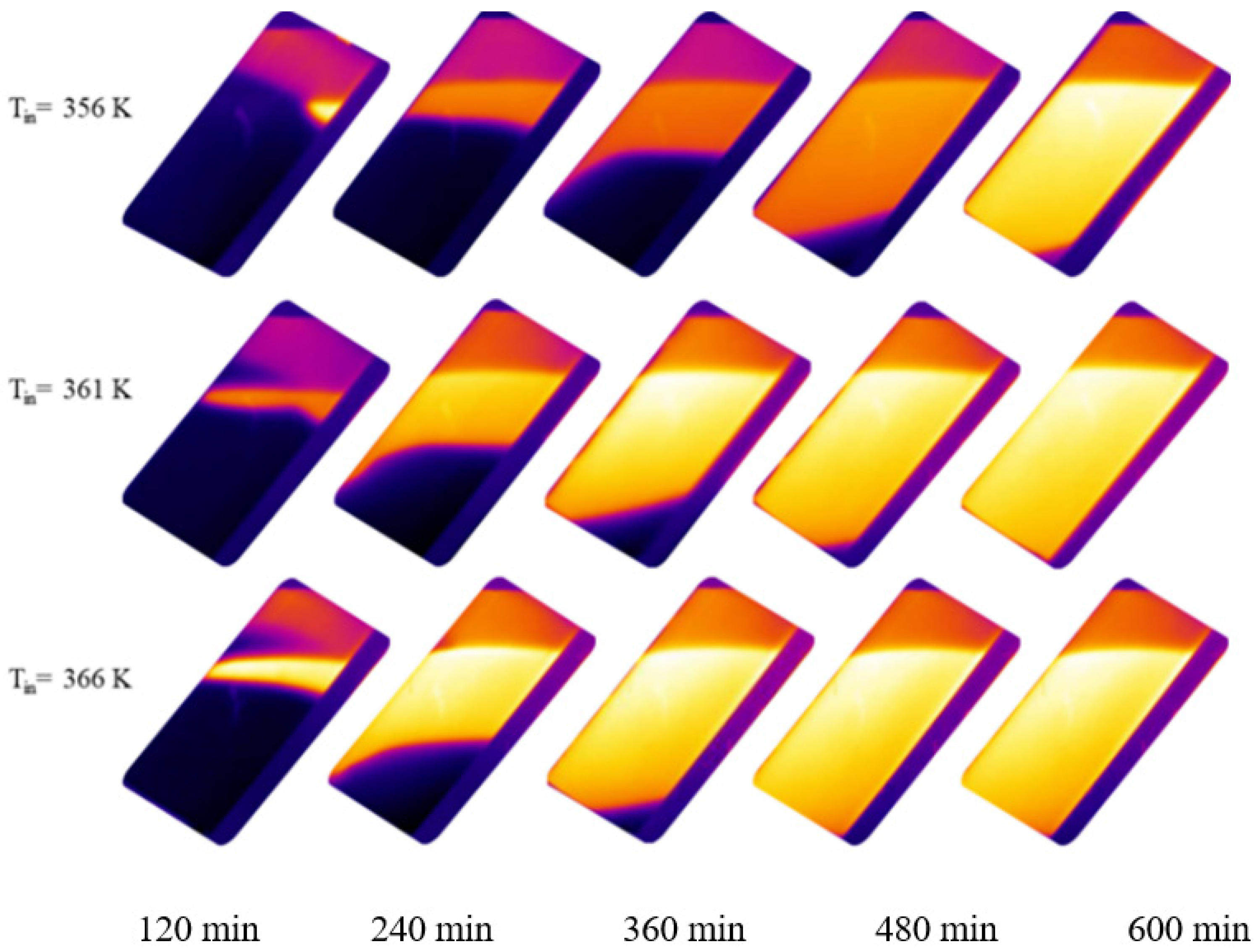

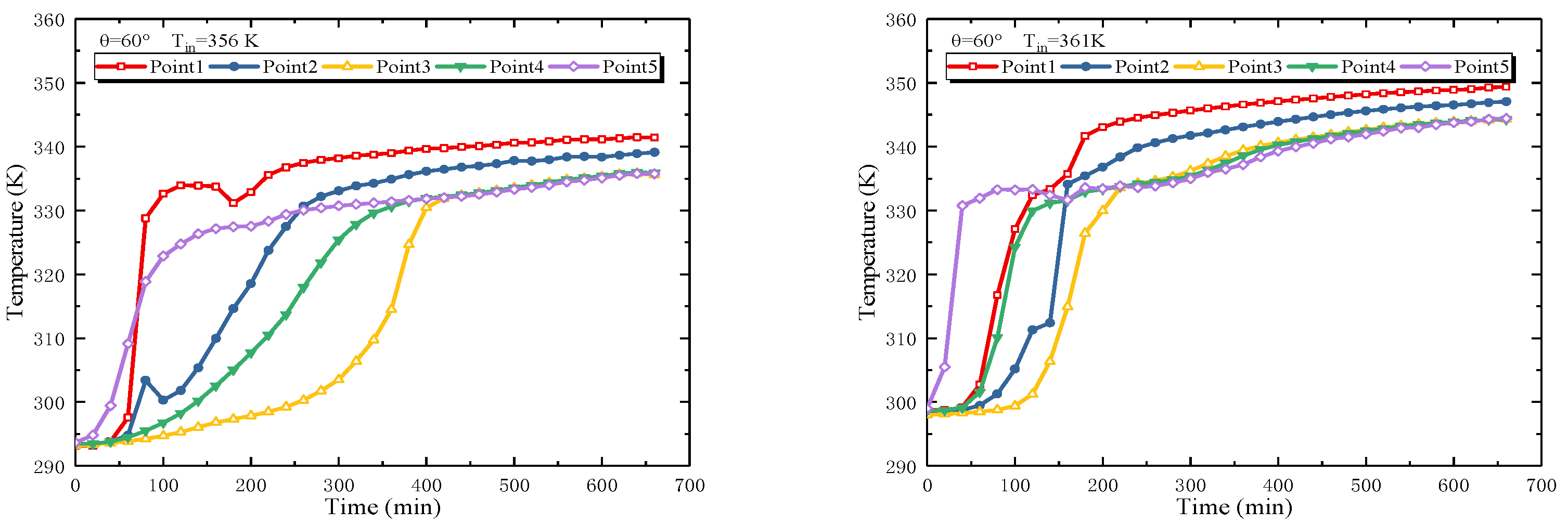

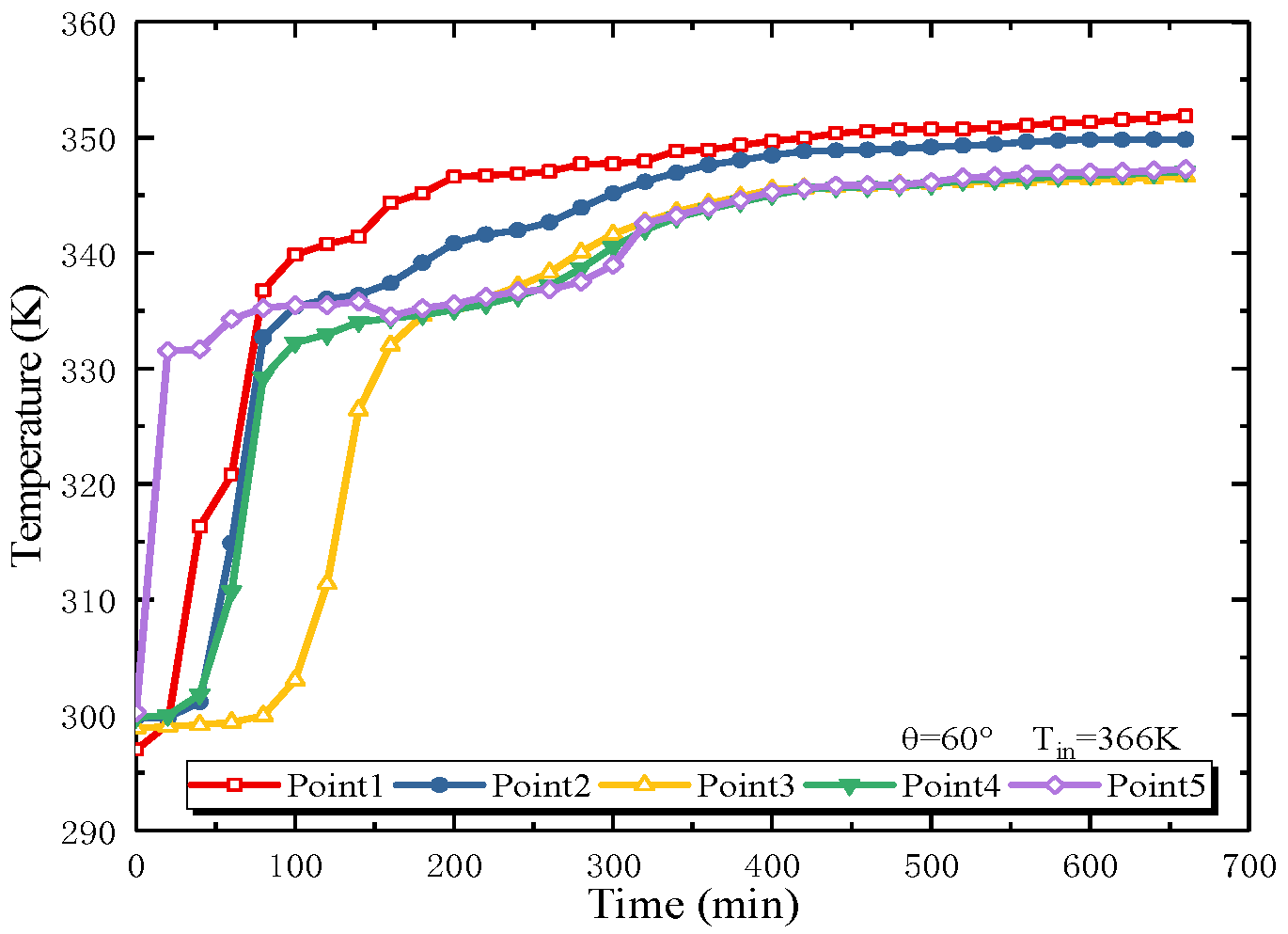

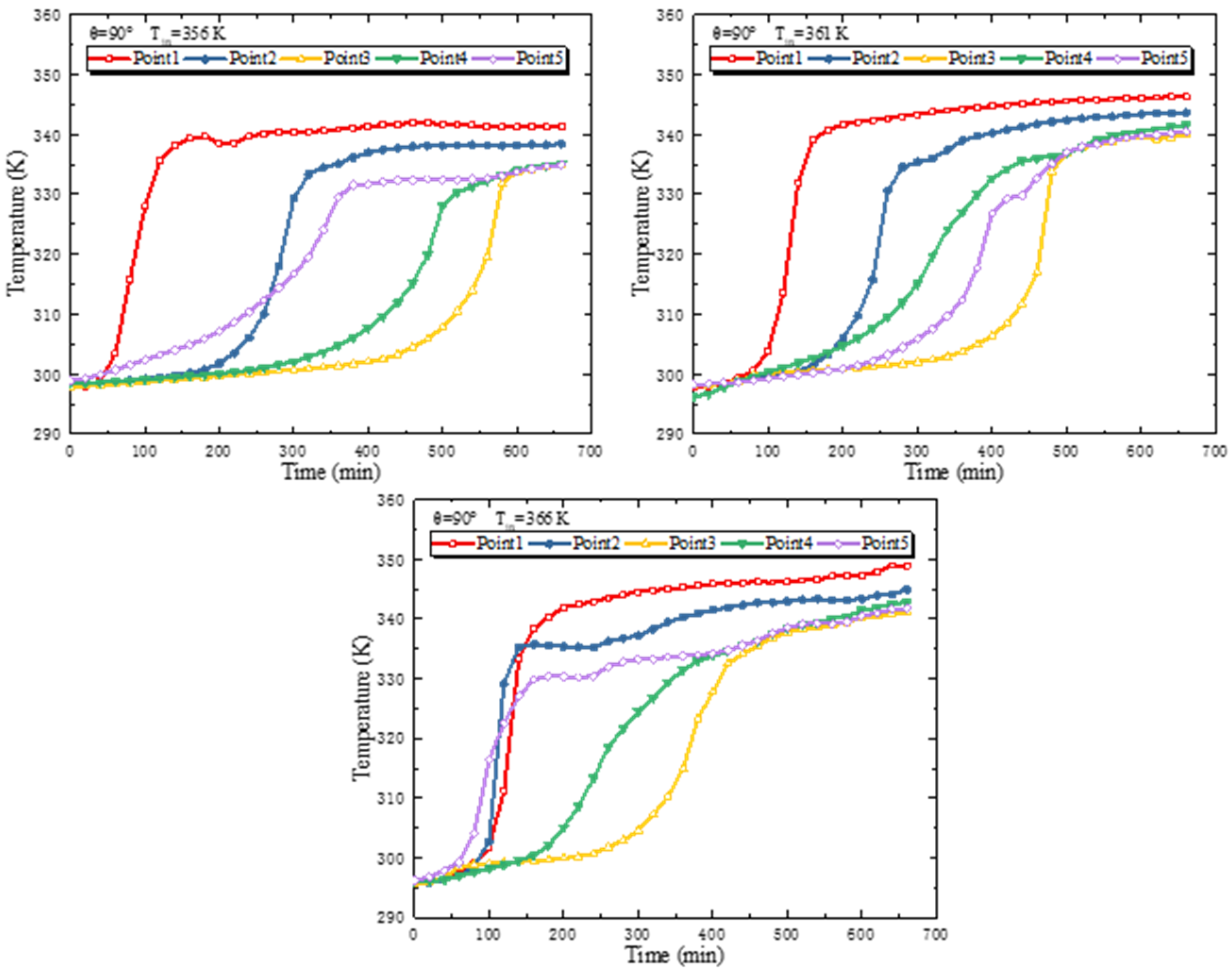

3.2. Temperature Distribution of PCM in the Tank

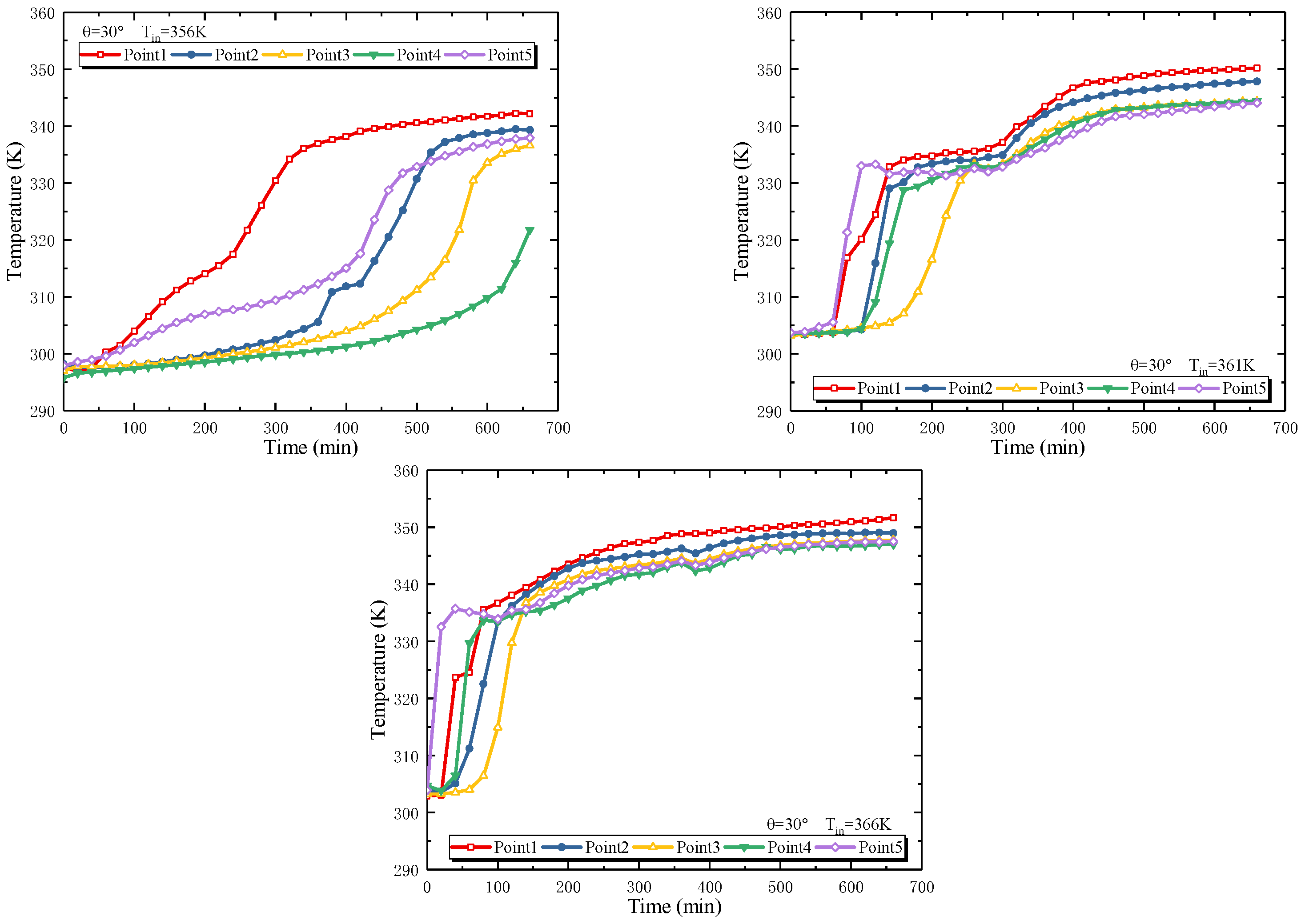

3.3. Temperature Change of Five Testing Points

4. Conclusions

- (1)

- According to the experimental photographs, a novel phenomenon of the tank was observed; that is, the beginning stage of melting appeared in the middle of the tank. The melting time of paraffin wax was also quite different at different inlet water temperatures. When the inlet temperature increased from 356 K to 366 K, the rate of the rise in temperature of the phase change material increased greatly. When the inclination angle was 30°, the time required for the paraffin wax to reach the melting-point temperature at the third measurement point was shortened by 75%, and the time required for the paraffin wax to reach the melting point at measurement point 1 was shortened by 76.5%.

- (2)

- With the increase in the inclination angle, there was a big difference in the temperature at the measuring point. When the inclination angle increased from 30° to 60°, the rate of the rise in temperature at the same measuring point was further accelerated, and the phase transition temperature was reached in a shorter time. However, the time required for overall melting increased as the inclination angle increased. The heat storage time was longest when the tank was placed vertically.

- (3)

- As the inlet water temperature increased, the degree of influence on the temperature change of the paraffin in the tank became smaller and smaller. When the inlet water temperature was 356 K, the overall change trend of the temperature curve at all measuring points of the tank was quite different from that seen under the conditions of 361 K and 366 K. Taking a storage tank with a tilt of 60° as an example, when the temperature increases from 356 K to 361 K, the time required for all measuring points to reach the melting-point temperature is greatly shortened, and the time for measuring point 3 to reach the melting-point temperature is shortened by 45%. However, when the temperature continues to increase to 366 K, the change of the temperature curve is smaller.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, W.; Tao, L.; Han, L.; Sun, Y.; Campana, P.E.; Yan, J. Optimal analysis of a hybrid renewable power system for a remote island. Renew. Energy 2021, 179, 96–104. [Google Scholar]

- He, W.; Guo, R.; Liu, S.; Zhu, K.; Wang, S. Temperature gradient characteristics and effect on optimal thermoelectric performance in exhaust power-generation systems. Appl. Energy 2020, 261, 114366. [Google Scholar]

- Mao, Q.; Hu, X.; Li, T. Study on heat storage performance of a novel vertical shell and multi-finned tube tank. Renew. Energy 2022, 193, 76–88. [Google Scholar]

- Mao, Q. Recent developments in geometrical configurations of thermal energy storage for concentrating solar power plant. Renew. Sustain. Energy Rev. 2016, 59, 320–327. [Google Scholar]

- Kamidollayev, T.; Trelles, J.P.; Thakkar, J.; Kosny, J. Parametric Study of Panel PCM–Air Heat Exchanger Designs. Energies 2022, 15, 5552. [Google Scholar]

- Mao, Q.; Zhang, Y. Thermal energy storage performance of a novel three-PCM cascade tank in a high-temperature packed bed system. Renew. Energy 2020, 152, 110–119. [Google Scholar]

- Taler, D.; Sobota, T.; Jaremkiewicz, M.; Taler, J. Influence of the Thermometer Inertia on the Quality of Temperature Control in a Hot Liquid Tank Heated with Electric Energy. Energies 2020, 13, 4039. [Google Scholar]

- Mao, Q.; Li, Y.; Li, G.; Badiei, A. Study on the influence of tank structure and fin configuration on heat transfer performance of phase change thermal storage system. Energy 2021, 235, 121382. [Google Scholar]

- Mao, Q.; Hu, X.; Zhu, Y. Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger. Energies 2022, 15, 5682. [Google Scholar]

- Medrano, M.; Yilmaz, M.; Nogués, M.; Martorell, I.; Roca, J.; Cabeza, L. Experimental evaluation of commercial heat exchangers for use as PCM thermal storage systems. Appl. Energy 2009, 86, 2047–2055. [Google Scholar]

- Cui, H.; Yuan, X.; Hou, X. Thermal performance analysis for a heat receiver using multiple phase change materials. Appl. Therm. Eng. 2003, 23, 2353–2361. [Google Scholar]

- Khobragade, S.; Devanuri, J.K. Impact of inclination on the thermal performance of shell and tube latent heat storage system under simultaneous charging and discharging: Numerical investigation. Appl. Therm. Eng. 2022, 214, 118811. [Google Scholar]

- Maghrabie, H.M.; Attalla, M.; Mohsen, A.A. Performance of a shell and helically coiled tube heat exchanger with variable inclination angle: Experimental study and sensitivity analysis. Int. J. Therm. Sci. 2021, 164, 106869. [Google Scholar]

- Sorour, M.M.; Hassab, M.A.; Zaytoun, M.M.; Alnakeeb, M.A. The effect of inclination angle on the performance characteristic of a double-pipe latent heat storage unit. J. Energy Storage 2021, 34, 102202. [Google Scholar]

- Wang, Z.; Diao, Y.; Zhao, Y.; Chen, C.; Wang, T.; Liang, L. Effect of inclination angle on the charging process of flat heat pipe-assisted latent heat storage unit. J. Energy Storage 2021, 51, 104402. [Google Scholar]

- Karami, R.; Kamkari, B. Investigation of the effect of inclination angle on the melting enhancement of phase change material in finned latent heat thermal storage units. Appl. Therm. Eng. 2019, 146, 45–60. [Google Scholar]

- Zeng, S.; Chen, S.; Wu, G. Effect of inclination angle on the melting process of phase change materials in a square cavity under mechanical vibration. J. Energy Storage 2021, 36, 102392. [Google Scholar]

- Olimat, A.N.; Ismail, M.; Abu Shaban, N.; Al-Salaymeh, A. The effectiveness of the heat transfer fluid pipe orientation angle inside a latent heat thermal energy storage system. Case Stud. Therm. Eng. 2022, 36, 102174. [Google Scholar]

- Kousha, N.; Hosseini, M.J.; Aligoodarz, M.R.; Pakrouh, R.; Bahrampoury, R. Effect of inclination angle on the performance of a shell and tube heat storage unit—An experimental study. Appl. Therm. Eng. 2017, 112, 1497–1509. [Google Scholar]

- Huang, S.; Lu, J.; Li, Y. Numerical study on the influence of inclination angle on the melting behaviour of metal foam-PCM latent heat storage units. Energy 2022, 239, 122489. [Google Scholar]

- Variji, N.; Siavashi, M.; Tahmasbi, M.; Bidabadi, M. Analysis of the effects of porous media parameters and inclination angle on the thermal storage and efficiency improvement of a photovoltaic-phase change material system. J. Energy Storage 2022, 50, 104690. [Google Scholar]

- Pahamli, Y.; Hosseini, M.J.; Ranjbar, A.A.; Bahrampoury, R. Effects of nanoparticle dispersion and inclination angle on melting of PCM in a shell and tube heat exchanger. J. Taiwan Inst. Chem. Eng. 2017, 81, 316–334. [Google Scholar]

| Instrument | Model No. | Measuring Range | Accuracy | Photograph |

|---|---|---|---|---|

| Thermocouple | K-type | −70–600 °C | ±0.4% |  |

| Data logger | Fluke 2638A | −270–1372 °C | ±0.15 °C |  |

| Infrared thermal imager | Fluke Ti32 | −20–600 °C | ±0.1 °C |  |

| Turbine flow meter | - | 1–50 L/min | ±1% |  |

| HD camera | BCC 2000 | - | - |  |

| Property | Unit | Values |

|---|---|---|

| Latent heat | kJ/kg | 172.62 |

| Thermal conductivity | W/m·K | 0.186 |

| Solidus temperature | °C | 28.52 |

| Liquidus temperature | °C | 49.13 |

| Density (solid at 30 °C) | g/cm3 | 0.889 |

| Density (liquid at 70 °C) | g/cm3 | 0.790 |

| Specific heat capacity (solid at 30 °C) | kJ/kg·K | 7.103 |

| Specific heat capacity (liquid at 70 °C) | kJ/kg·K | 2.130 |

| Thermal expansion coefficient | 1/K | 0.0006 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, L.; Wu, H.; Mao, Q. Visualizing Experimental Study of the Effect of Inclination Angle on the Melting Performance for an Energy Storage Tank. Energies 2022, 15, 7394. https://doi.org/10.3390/en15197394

Peng L, Wu H, Mao Q. Visualizing Experimental Study of the Effect of Inclination Angle on the Melting Performance for an Energy Storage Tank. Energies. 2022; 15(19):7394. https://doi.org/10.3390/en15197394

Chicago/Turabian StylePeng, Li, Hongjun Wu, and Qianjun Mao. 2022. "Visualizing Experimental Study of the Effect of Inclination Angle on the Melting Performance for an Energy Storage Tank" Energies 15, no. 19: 7394. https://doi.org/10.3390/en15197394

APA StylePeng, L., Wu, H., & Mao, Q. (2022). Visualizing Experimental Study of the Effect of Inclination Angle on the Melting Performance for an Energy Storage Tank. Energies, 15(19), 7394. https://doi.org/10.3390/en15197394