Investigation of the Flow Intensity in an Inverted Seven-Point Well Pattern and Its Influence on the EOR Efficiency of S/P Flooding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

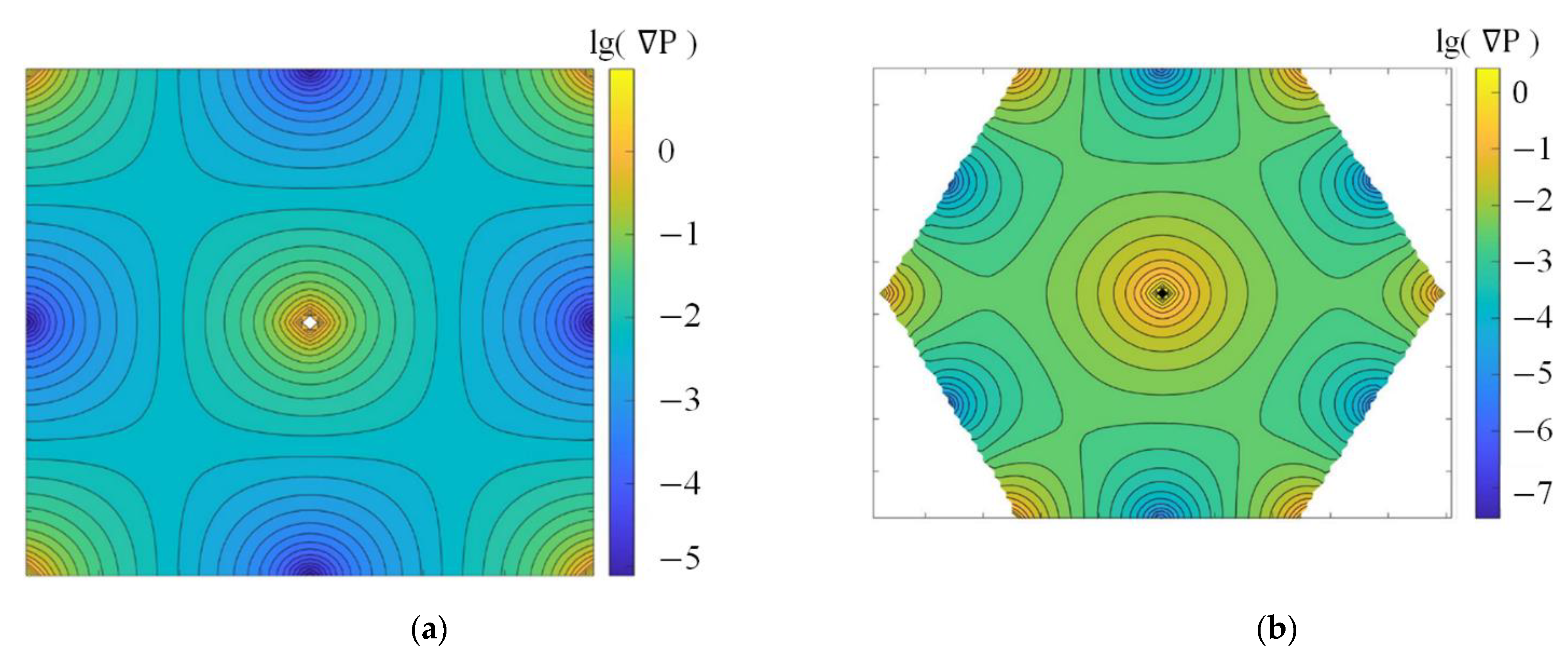

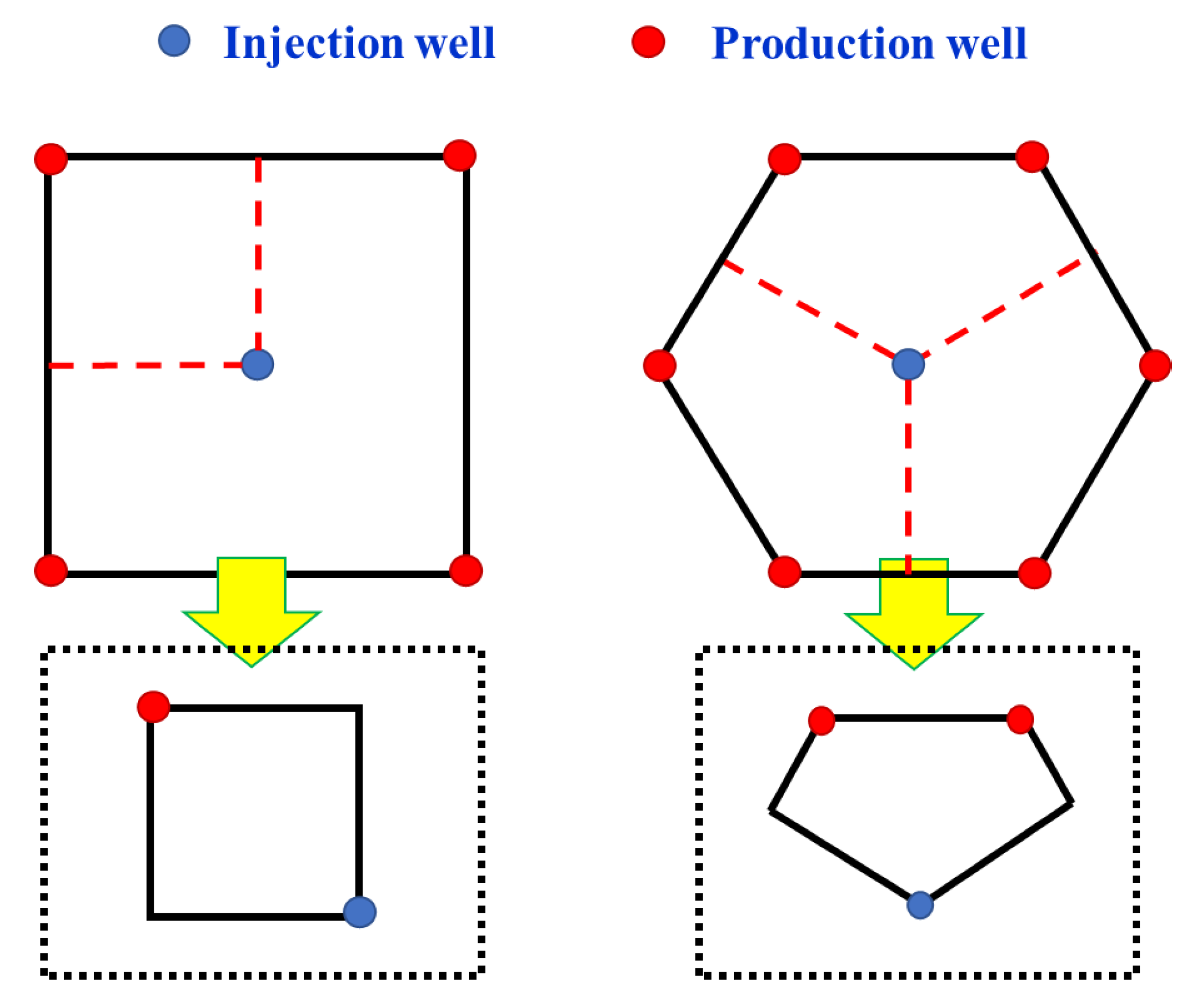

2.2. Calculation of the Flow Field Intensity of Inverted Seven-Spot Well Pattern

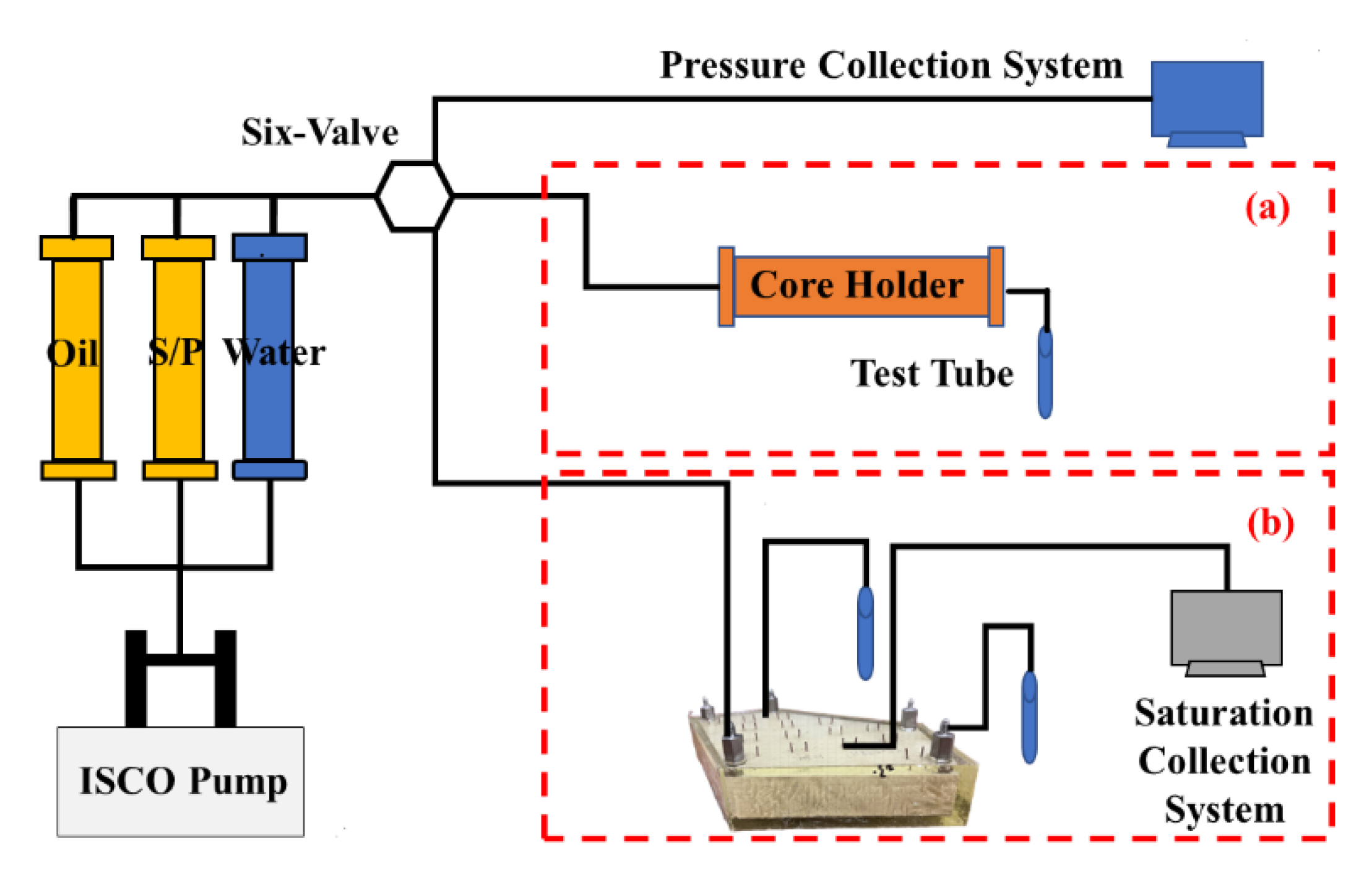

2.3. Effect of Flow Field Intensity on S/P Flooding

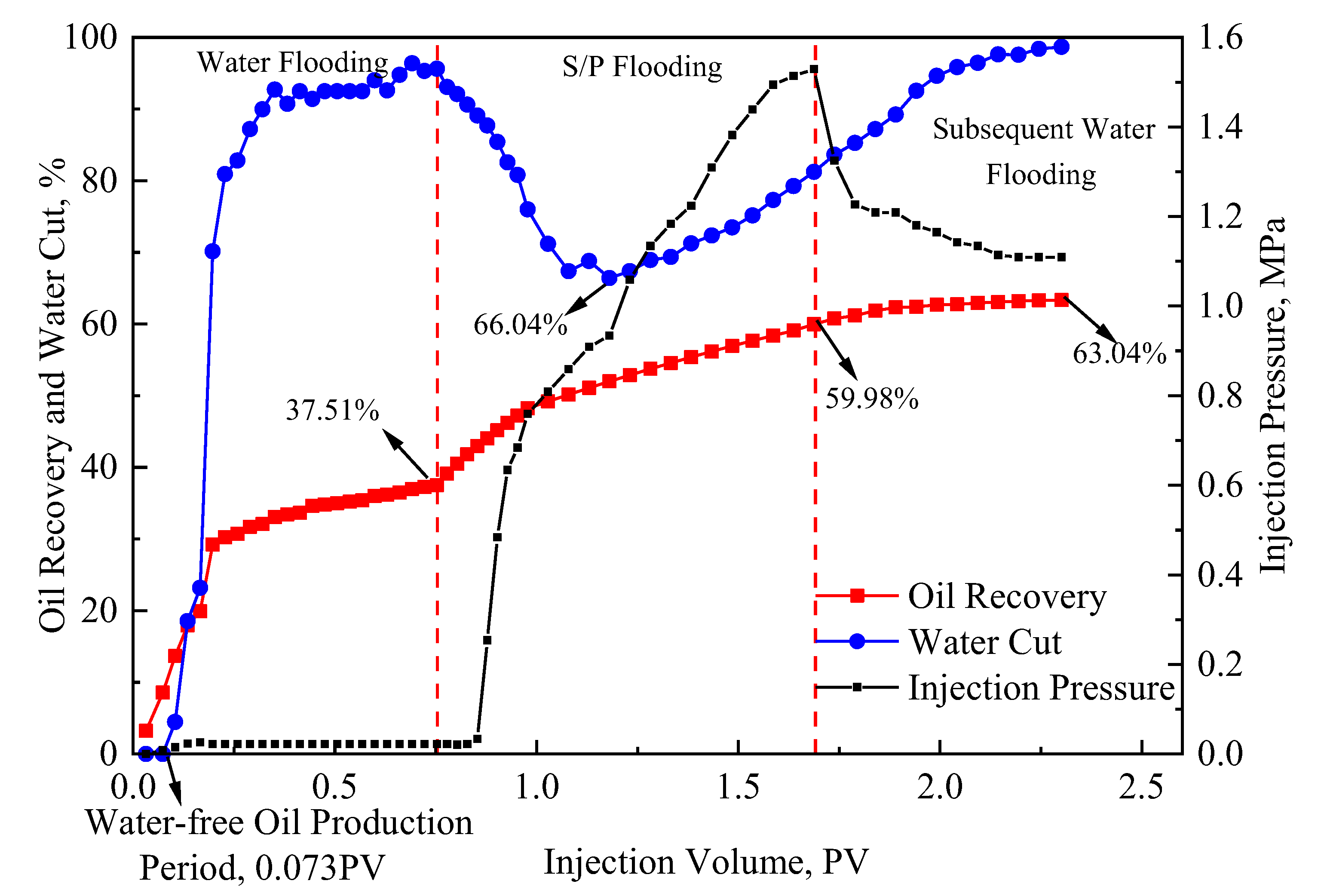

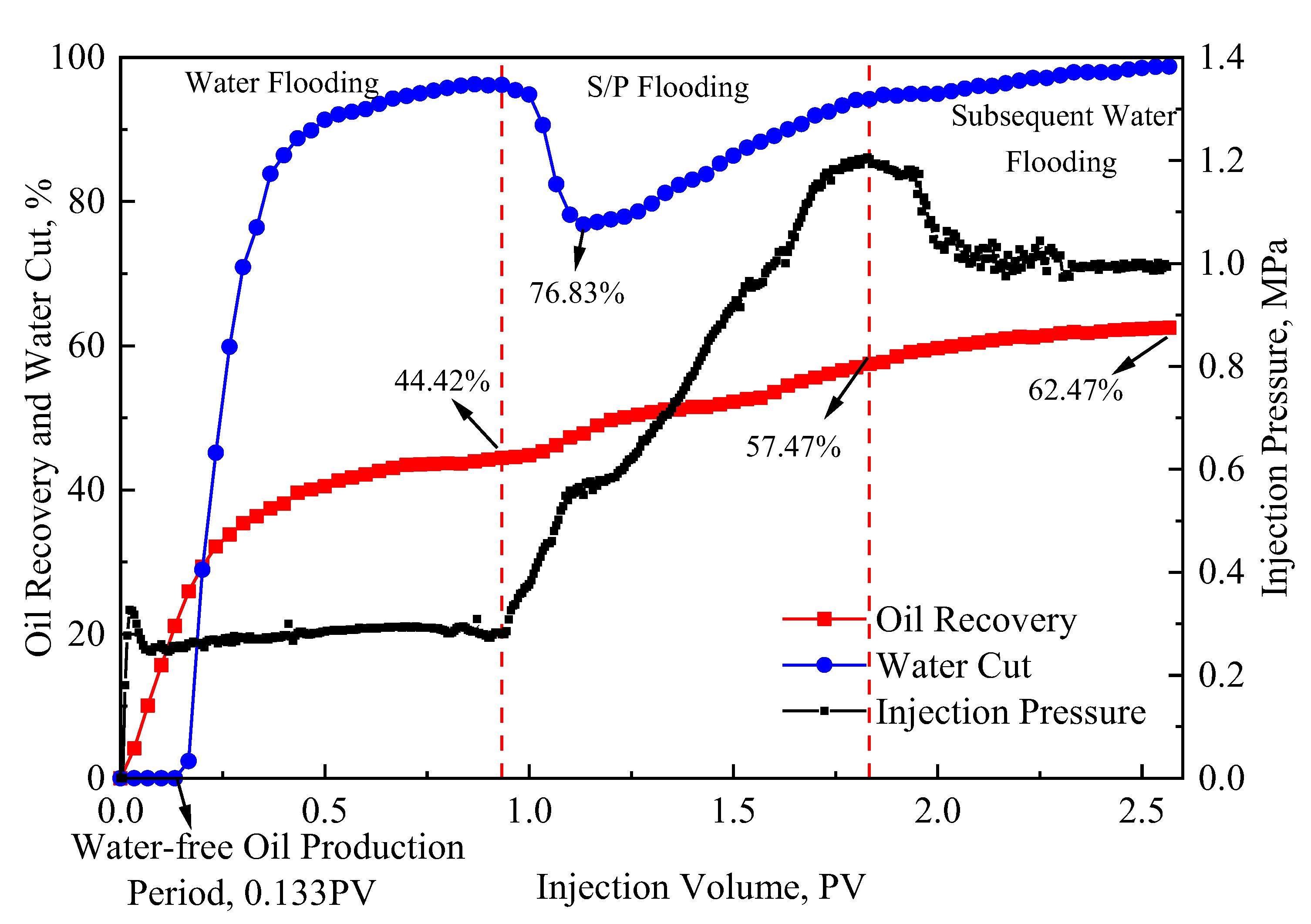

2.3.1. EOR Efficiency of S/P Flooding

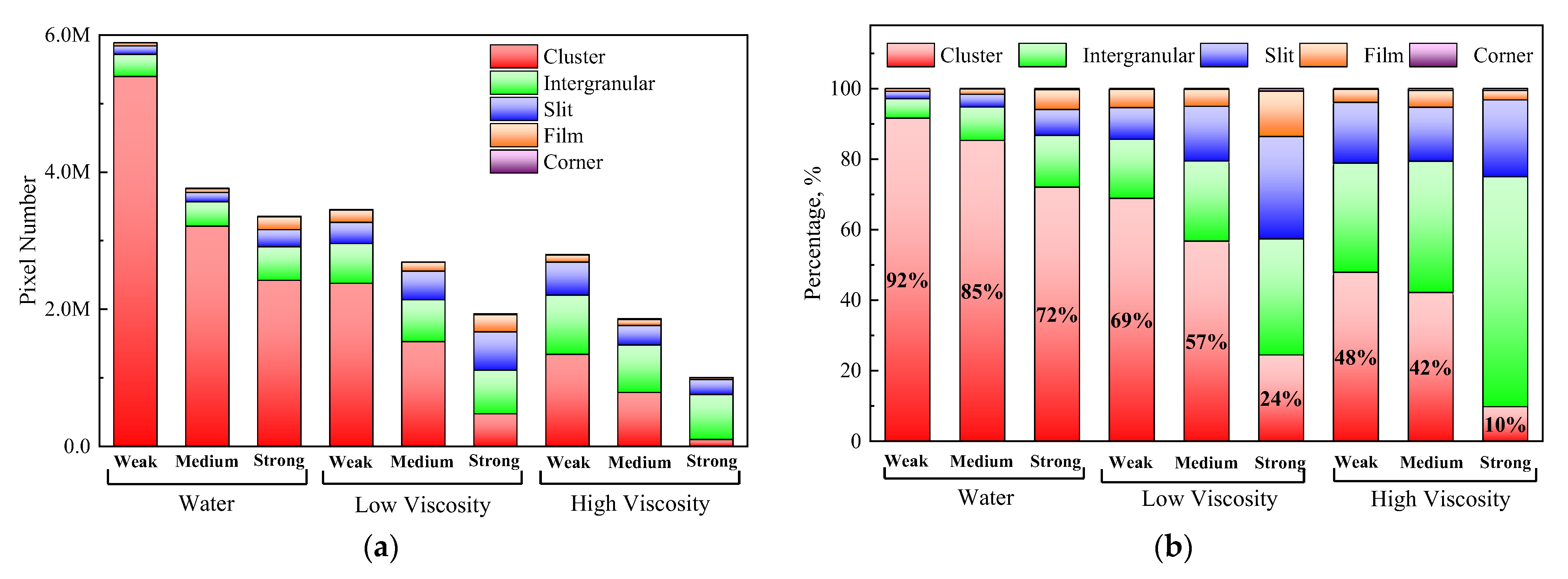

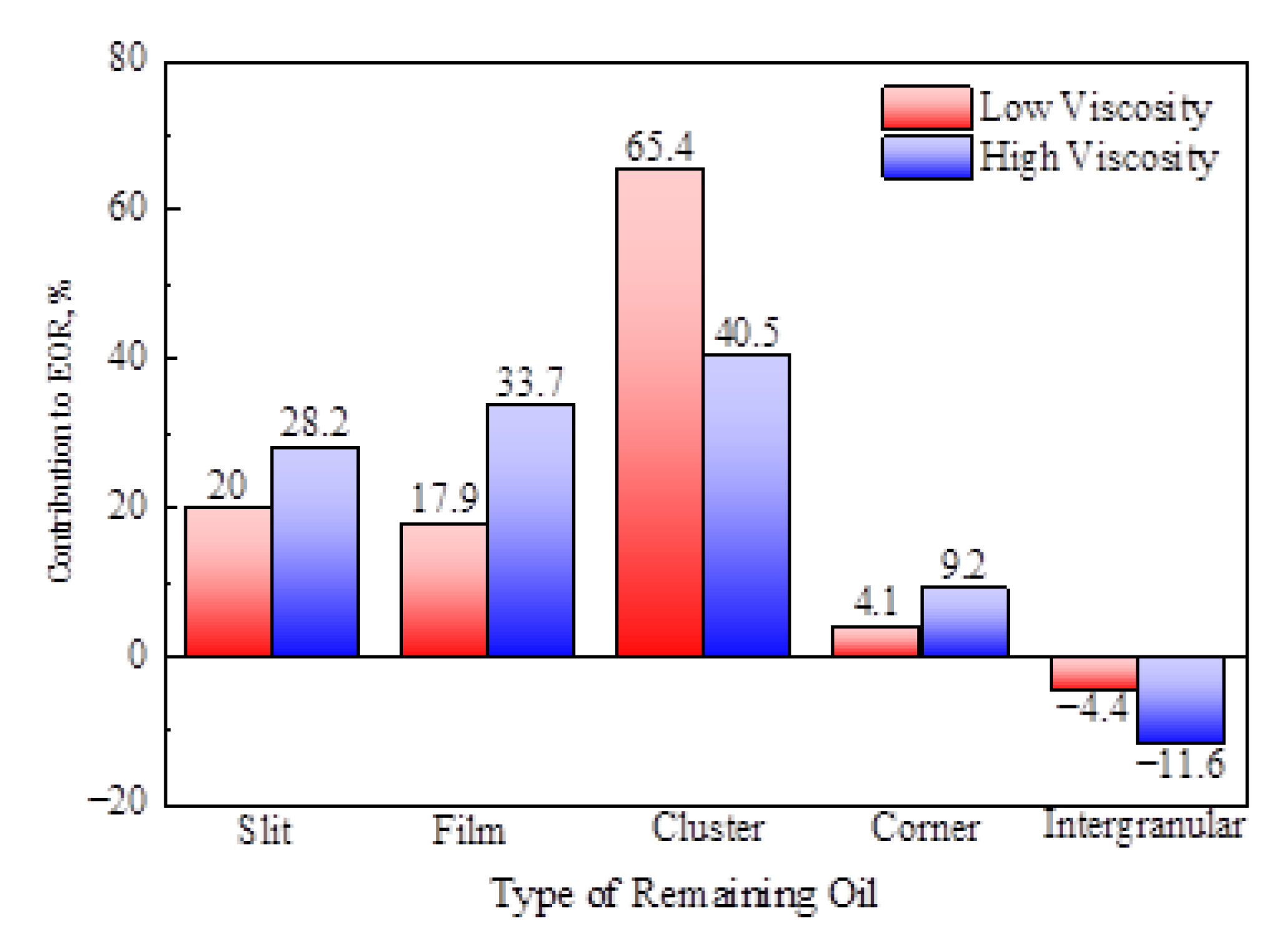

2.3.2. Occurrence Regularity of the Remaining Oil

2.4. EOR Efficiency of S/P Flooding in Reverted Seven-Spot Well Pattern

3. Results and Discussion

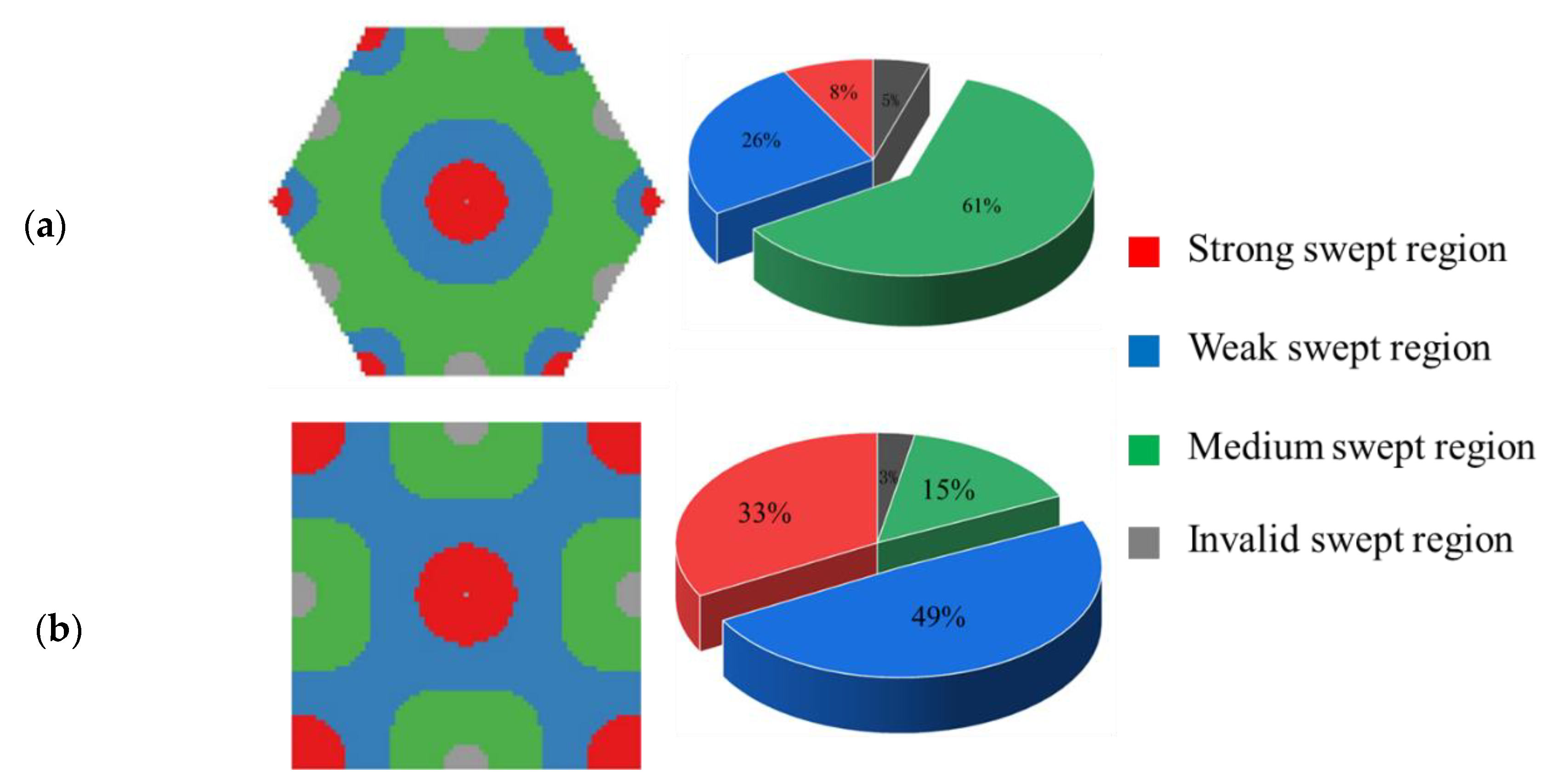

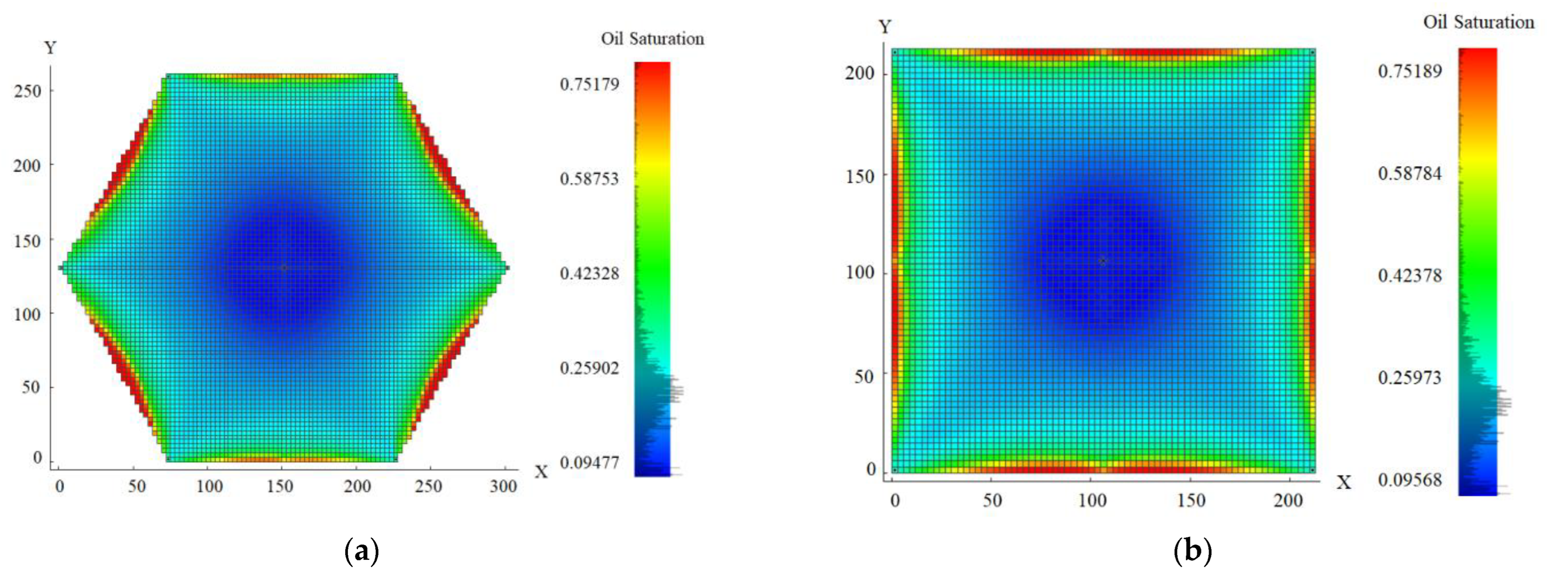

3.1. The Flow Intensity of the Reverted Seven-Spot Well Pattern

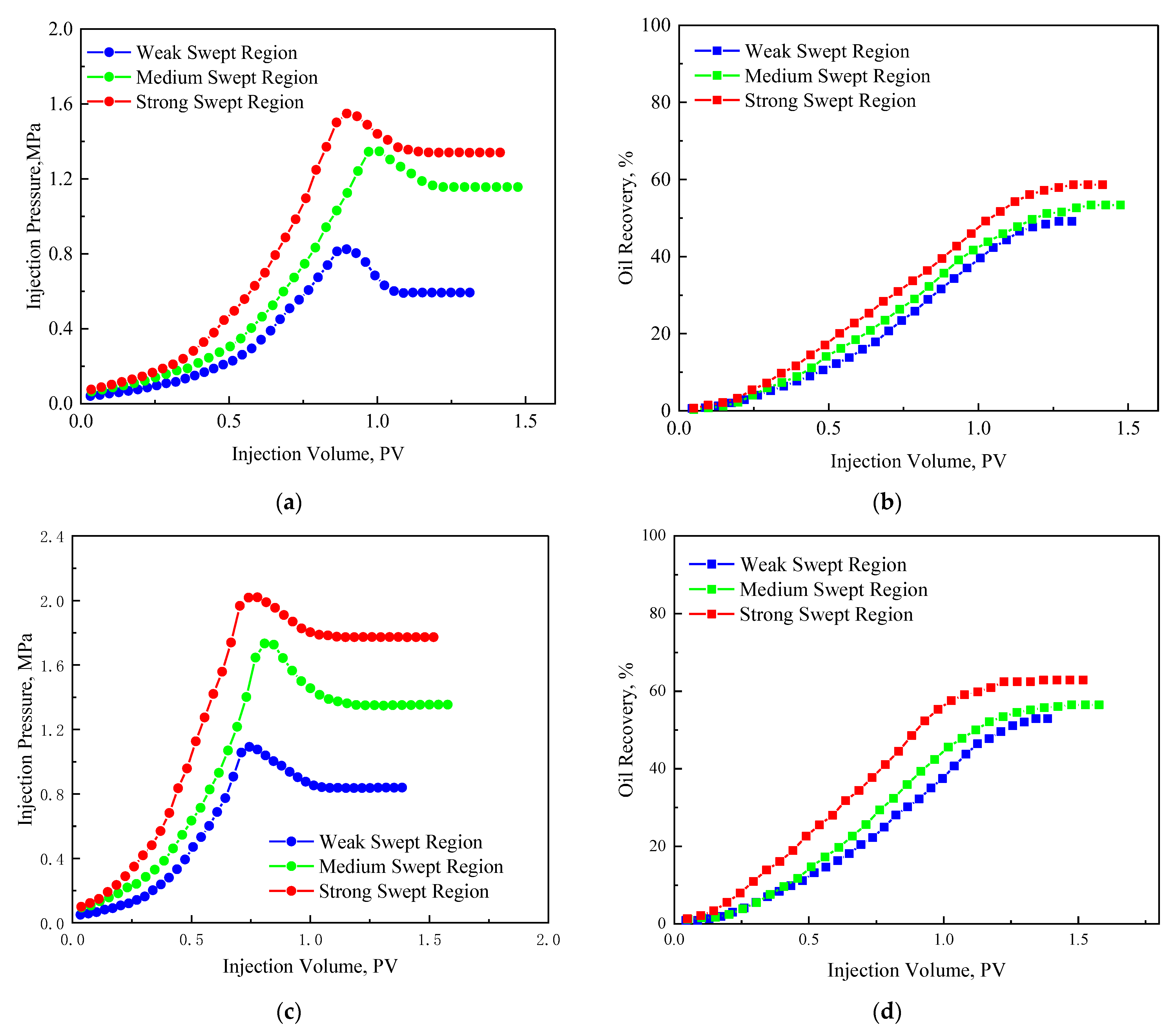

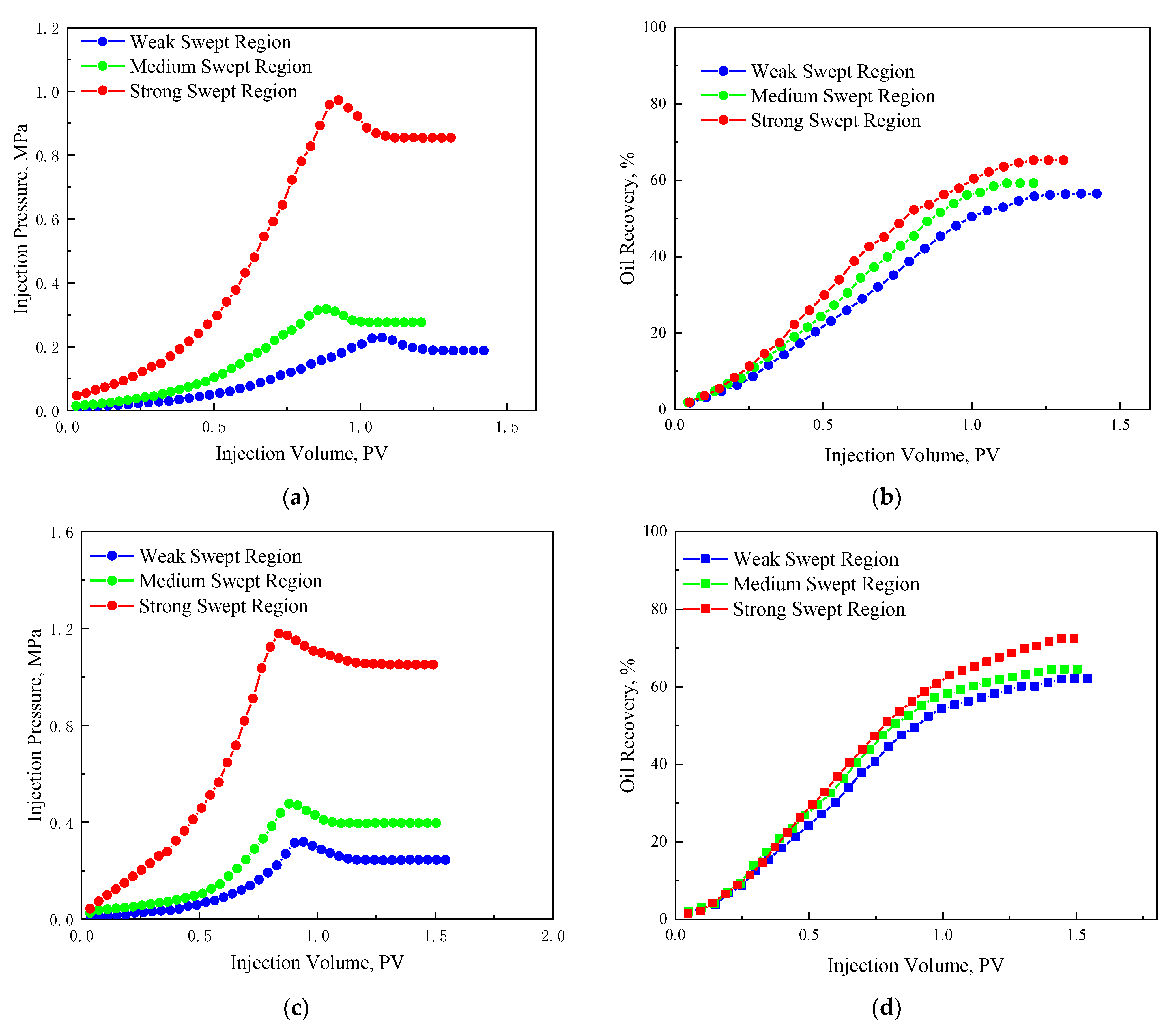

3.2. The Influence of Flow Intensity on the Oil Displacement Efficiency

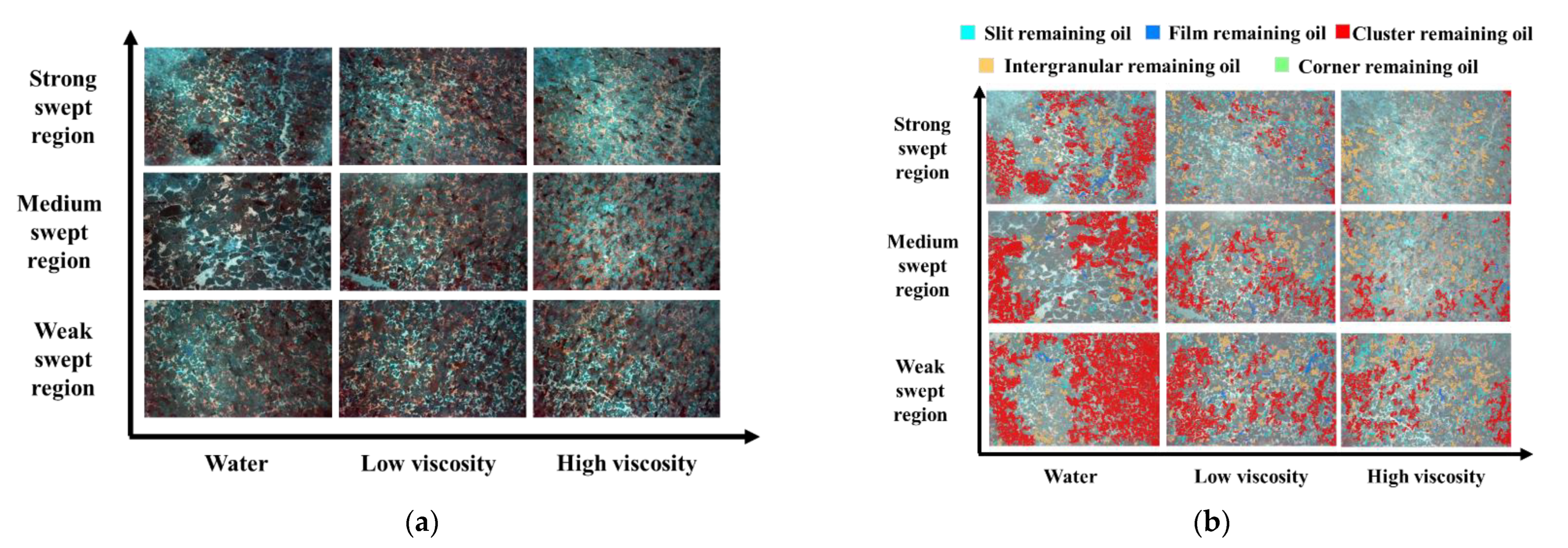

3.3. The Influence of Flow Intensity on the Occurrence of Remaining Oil

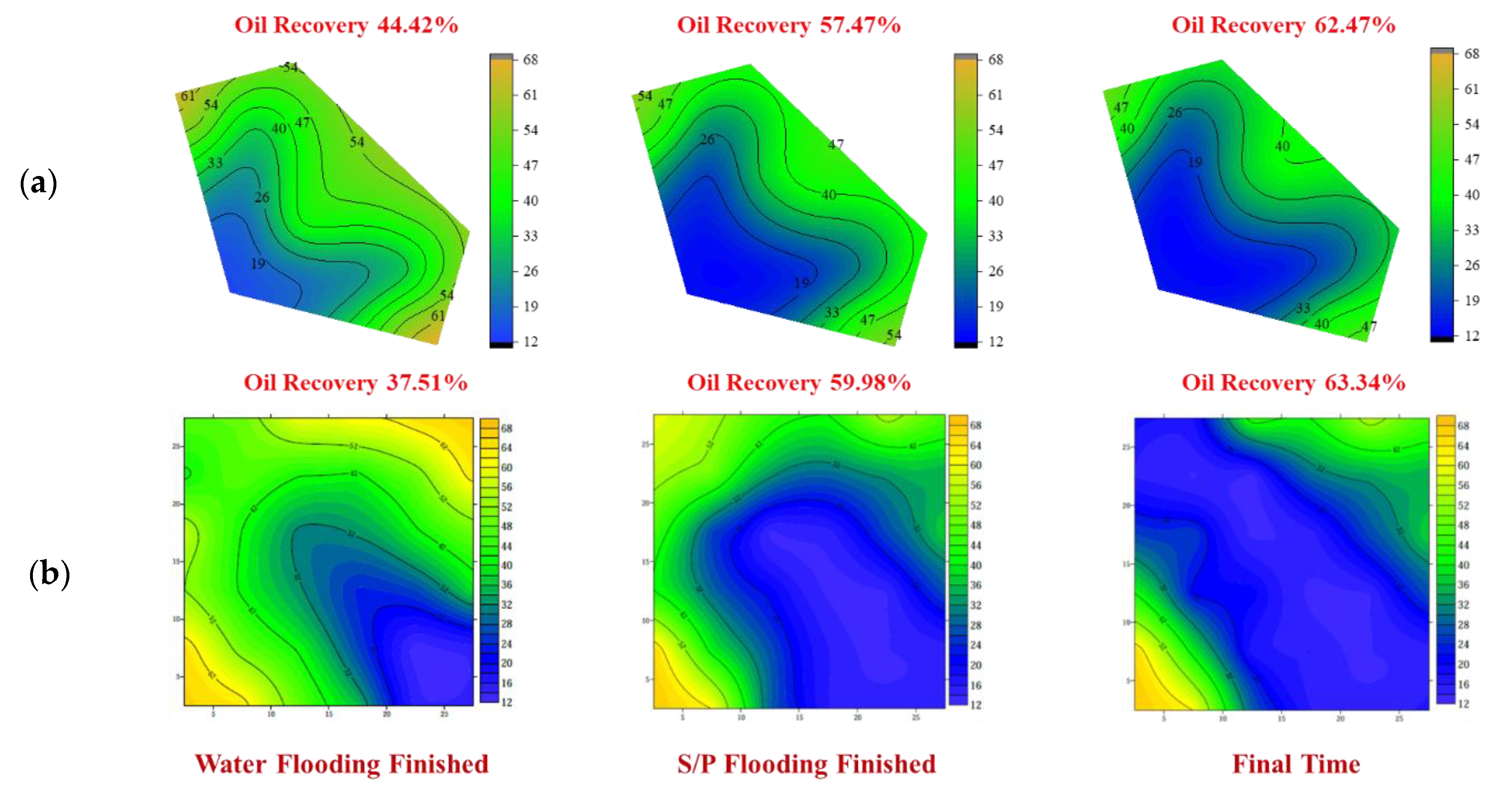

3.4. The EOR Efficiency of S/P Flooding in the Inverted Seven-Spot Well Pattern

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Conti, J.; Holtberg, P.; Diefenderfer, J.; LaRose, A.; Turnure, J.T.; Westfall, L. International Energy Outlook 2016 with Projections to 2040; USDOE Energy Information Administration (EIA): Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Jia, C.; Zou, C.; Yang, Z.; Zhu, R.; Chen, Z.; Zhang, B.; Jiang, L. Significant progress of continental petroleum geological theory in basins of Central and Western China. Pet. Explor. Dev. 2018, 45, 573–588. [Google Scholar] [CrossRef]

- Zhiqiang, F.; Zihui, F.; Wei, H.; Jiangping, L.; Wei, Q.; Bo, Z. Exploration of the Daqing Oilfield for 50 years: A great practice of continental origin petroleum theory. Chin. J. Geol. 2009, 44, 349–364. [Google Scholar]

- Liu, Z.; Chai, M.; Chen, X.; Hejazi, S.H.; Li, Y. Emulsification in a microfluidic flow-focusing device: Effect of the dispersed phase viscosity. Fuel 2021, 283, 119229. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Chen, X.; Chen, Y.; Lyu, J.; Sui, M. The Optimal Initiation Timing of Surfactant-Polymer Flooding in a Waterflooded Conglomerate Reservoir. SPE J. 2021, 26, 1–14. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Liu, Z.; Liu, R.; Liu, W.; Zhang, H. Effects of molecular structure of polymeric surfactant on its physico-chemical properties, percolation and enhanced oil recovery. J. Ind. Eng. Chem. 2021, 101, 165–177. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Luan, H.; Gao, W.; Guo, Y.; Chen, Y. Pore scale and macroscopic visual displacement of oil-in-water emulsions for enhanced oil recovery. Chem. Eng. Sci. 2019, 197, 404–414. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Liu, Z.; Li, X.; Zhang, J.; Zhang, H. Core- and pore-scale investigation on the migration and plugging of polymer microspheres in a heterogeneous porous media. J. Pet. Sci. Eng. 2020, 195, 107636. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Liu, Z.; Zhang, J.; Chen, C.; Ma, M. Investigation on matching relationship and plugging mechanism of self-adaptive micro-gel (SMG) as a profile control and oil displacement agent. Powder Technol. 2020, 364, 774–784. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Liu, Z.; Zhang, J.; Li, X.; Zhang, H. Mechanism Investigation and Optimization of Conformance Control by Polymer Microsphere in Heterogeneous Offshore Oil Fields. In Offshore Technology Conference Asia; OnePetro: Kuala Lumpur, Malaysia, 2020. [Google Scholar] [CrossRef]

- Kong, D.; Li, Y.; Yu, M.; Ma, R.; Guo, H.; Peng, Y.; Xu, S.; Yan, H. Experimental investigation on block and transport characteristics of foam in porous media for enhanced oil recovery processes. Colloids Surf. A Physicochem. Eng. Asp. 2019, 570, 22–31. [Google Scholar] [CrossRef]

- Jones, S.; van der Bent, V.; Farajzadeh, R.; Rossen, W.; Vincent-Bonnieu, S. Surfactant screening for foam EOR: Correlation between bulk and core-flood experiments. Colloids Surf. A Physicochem. Eng. Asp. 2016, 500, 166–176. [Google Scholar] [CrossRef]

- Gupta, A.; Pandey, A.; Kesarwani, H.; Sharma, S.; Saxena, A. Automated determination of interfacial tension and contact angle using computer vision for oil field applications. J. Pet. Explor. Prod. Technol. 2022, 12, 1453–1461. [Google Scholar] [CrossRef]

- Kesarwani, H.; Khan, F.; Tandon, A.; Azin, R.; Osfouri, S.; Sharma, S. Performance improvement of the surfactant polymer flooding using bio synthesized calcium carbonate nanoparticles: An experimental approach. Arab. J. Sci. Eng. 2022, 1–18. [Google Scholar] [CrossRef]

- Tandon, A.; Khan, F.; Shukla, R.; Saxena, A.; Sharma, S.; Biswas, K.G. 3-D Micromodel for Visualization & Experimental Analysis of Flow Behavior, Surface Tension and Polymer Concentration on Enhanced Oil Recovery. In Offshore Technology Conference Asia; OnePetro: Kuala Lumpur, Malaysia, 2022. [Google Scholar] [CrossRef]

- Jie-Cheng, C. Field test performance of alkaline surfactant polymer flooding in Daqing oil field. Acta Pet. Sin. 2002, 23, 37. [Google Scholar] [CrossRef]

- Onwunalu, J.E.; Durlofsky, L. A new well-pattern-optimization procedure for large-scale field development. SPE J. 2011, 16, 594–607. [Google Scholar] [CrossRef]

- Humphries, T.D.; Haynes, R.D.; James, L.A. Simultaneous and sequential approaches to joint optimization of well placement and control. Comput. Geosci. 2014, 18, 433–448. [Google Scholar] [CrossRef]

- Gu, H.; Yang, R.; Guo, S.; Guan, W.; Yue, X.; Pan, Q. Study on Reservoir Engineering: ASP Flooding Pilot Test in Karamay Oilfield. In SPE International Oil and Gas Conference and Exhibition in China; OnePetro: Beijing, China, 1998. [Google Scholar] [CrossRef]

- Liu, F.; Wu, X.; Zhou, W. Application of Well Pattern Adjustment for Offshore Polymer Flooding Oilfield: A Macro-Scale and Micro-Scale Study. Chem. Technol. Fuels Oils 2020, 56, 441–452. [Google Scholar] [CrossRef]

- Sun, R.; Chen, Y.; Huang, Y.; Cao, G.; Huang, A.; Liu, L.; Liu, Z. Well Pattern Modification and Injection-Production Optimization for Extra-High Water Cut Oilfield. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Guangzhou, China, 2020; p. 012025. [Google Scholar] [CrossRef]

- Song, X.; Li, Y. Optimum development options and strategies for water injection development of carbonate reservoirs in the Middle East. Pet. Explor. Dev. 2018, 45, 723–734. [Google Scholar] [CrossRef]

- Bellout, M.C.; Ciaurri, D.E.; Durlofsky, L.J.; Foss, B.; Kleppe, J. Joint optimization of oil well placement and controls. Comput. Geosci. 2012, 16, 1061–1079. [Google Scholar] [CrossRef]

- Stahl, C.D. Areal sweepout of normal and inverted seven-spot and nine-spot patterns. Prod. Mon. 1967, 31 Pt. 2. [Google Scholar]

- Bellout, M.C.; Ciaurri, D.E.; Durlofsky, L.J.; Foss, B.; Kleppe, J. Sensitivity analysis of water-alternating-CO2 flooding for enhanced oil recovery in high water cut oil reservoirs. Comput. Fluids 2014, 99, 93–103. [Google Scholar] [CrossRef]

- Singhal, A. Physical model study of inverted seven-spot steamfloods in a pool containing conventional heavy oil. J. Can. Pet. Technol. 1980, 19, PETSOC-80-03-08. [Google Scholar] [CrossRef]

- Gazi, N.H.; Abdulla, F.; Al-Naqi, M.; Al-Kandari, I.; Dashti, L.; Al-Qattan, A.; Al-Farhan, F.A.; Maizeret, P.D. Design and Analysis of Interference Tests–Application to a Seven-Spot Inverted-Pattern Waterflood Pilot in the Wara Formation of the Greater Burgan Field, Kuwait. In SPE Middle East Oil and Gas Show and Conference; OnePetro: Kuala Lumpur, Malaysia, 2013. [Google Scholar] [CrossRef]

- Fan, H.; Wang, X.; Cao, W.; Yan, K.; Xie, K.; Lu, X.; He, M. Influence of Well Pattern Type on Remaining Oil Saturation and Distribution after Development. Energies 2022, 15, 2438. [Google Scholar] [CrossRef]

- Sheth, S.M.; Younis, R.M. Localized linear systems in sequential implicit simulation of two-phase flow and transport. SPE J. 2017, 22, 1542–1569. [Google Scholar] [CrossRef]

- Mirchi, V.; Sabti, M.J.; Piri, M.; Goual, L. Microscale Investigation of the Impact of Surfactant Structure on the Residual Trapping in Natural Porous Media. Ind. Eng. Chem. Res. 2019, 58, 9397–9411. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, S.; Zhang, Y.; Wang, R.; Luo, F. Prediction of Microscopic Remaining Oil Distribution Using Fuzzy Comprehensive Evaluation. Transp. Porous Media 2011, 89, 533–545. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, G.; Ma, K.; Song, Z.; Li, J.; Jiang, H. Influence factors and effect prediction model of the tertiary migrations of remaining oil. J. Pet. Explor. Prod. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Fang, H.; Xu, H.; Wang, Z.; Jiang, T.; Zhao, Y.; Li, J. Formation mechanism of the Donghe Sandstone residual oil zone in the Tarim Basin, NW China. J. Pet. Sci. Eng. 2018, 171, 1023–1032. [Google Scholar] [CrossRef]

- Zhang, L.; Yue, X.A.; Guo, F. Micro-mechanisms of residual oil mobilization by viscoelastic fluids. Pet. Sci. 2008, 5, 56–61. [Google Scholar] [CrossRef]

- Zhang, L.-j.; Yue, X.-a. Displacement of polymer solution on residual oil trapped in dead ends. J. Cent. South Univ. Technol. 2008, 15, 84–87. [Google Scholar] [CrossRef]

- Wenbin, G.; Yiqiang, L.; Shumei, H.; Deng, P.; Mingxi, L.; Cuo, G. Classification method of occurrence mode of remaining oil based on fluorescence thin sections. Acta Pet. Sin. 2020, 41, 1406. [Google Scholar] [CrossRef]

| Ions | HCO3− | Cl− | SO42− | Ca2+ | Mg2+ | N+, K+ | Total | pH |

|---|---|---|---|---|---|---|---|---|

| Concentration, mg/L | 1674.52 | 7388.7 | 22.26 | 208.06 | 27.04 | 5145.66 | 14,466.24 | 7.45 |

| Strong Swept Region | Medium Swept Region | Weak Swept Region | Invalid Swept Region |

|---|---|---|---|

| >0.2 MPa/m | 0.1–0.2 MPa/m | 0.03–0.1 MPa/m | <0.03 MPa/m |

| Number | Cores | Permeability, mD | Porosity, % | Viscosity, mPa·s | Injection Rate, mL/min | Process |

|---|---|---|---|---|---|---|

| 1 | Cylinder 1.5 cm × 30 cm | 50 | 23.52 | 18.5 | 0.05 | S/P flooding till the water cut is 98% |

| 2 | 50 | 23.21 | 18.5 | 0.1 | ||

| 3 | 50 | 24.02 | 18.5 | 0.3 | ||

| 4 | 50 | 23.67 | 37.6 | 0.05 | ||

| 5 | 50 | 23.69 | 37.6 | 0.1 | ||

| 6 | 50 | 23.36 | 37.6 | 0.3 | ||

| 7 | 300 | 24.69 | 18.5 | 0.05 | ||

| 8 | 300 | 25.23 | 18.5 | 0.1 | ||

| 9 | 300 | 24.60 | 18.5 | 0.3 | ||

| 10 | 300 | 24.26 | 37.6 | 0.05 | ||

| 11 | 300 | 24.19 | 37.6 | 0.1 | ||

| 12 | 300 | 25.06 | 37.6 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Que, T.; Chen, X.; Guan, D.; Yun, Q.; Luan, H.; Tang, X.; Cao, J.; Liu, Z.; Nie, X. Investigation of the Flow Intensity in an Inverted Seven-Point Well Pattern and Its Influence on the EOR Efficiency of S/P Flooding. Energies 2022, 15, 6632. https://doi.org/10.3390/en15186632

Que T, Chen X, Guan D, Yun Q, Luan H, Tang X, Cao J, Liu Z, Nie X. Investigation of the Flow Intensity in an Inverted Seven-Point Well Pattern and Its Influence on the EOR Efficiency of S/P Flooding. Energies. 2022; 15(18):6632. https://doi.org/10.3390/en15186632

Chicago/Turabian StyleQue, Tingli, Xin Chen, Dan Guan, Qingqing Yun, Huoxin Luan, Xuechen Tang, Jinxin Cao, Zheyu Liu, and Xiaobin Nie. 2022. "Investigation of the Flow Intensity in an Inverted Seven-Point Well Pattern and Its Influence on the EOR Efficiency of S/P Flooding" Energies 15, no. 18: 6632. https://doi.org/10.3390/en15186632

APA StyleQue, T., Chen, X., Guan, D., Yun, Q., Luan, H., Tang, X., Cao, J., Liu, Z., & Nie, X. (2022). Investigation of the Flow Intensity in an Inverted Seven-Point Well Pattern and Its Influence on the EOR Efficiency of S/P Flooding. Energies, 15(18), 6632. https://doi.org/10.3390/en15186632