Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification

Abstract

:1. Introduction

2. The Portuguese Water-and-Waste Sector

3. Potential Final Markets for Gasification-Based Sludge Valorization

3.1. Combined Heat and Power (CHP)

3.2. Hydrogen

3.3. Biomethane/Bio-SNG

4. Sewage-Sludge Production in Portugal and Potential Valorization Pathways

4.1. Base Scenarios and General Assumptions

- Reactor type: fluidized bed;

- Oxidant agent: air;

- Bed material: 60 wt.% sand + 40 wt.% alumina;

- Equivalence ratio: 0.3;

- Temperature: 850 °C;

- Syngas yield: 2.57 Nm3/kg daf [28].

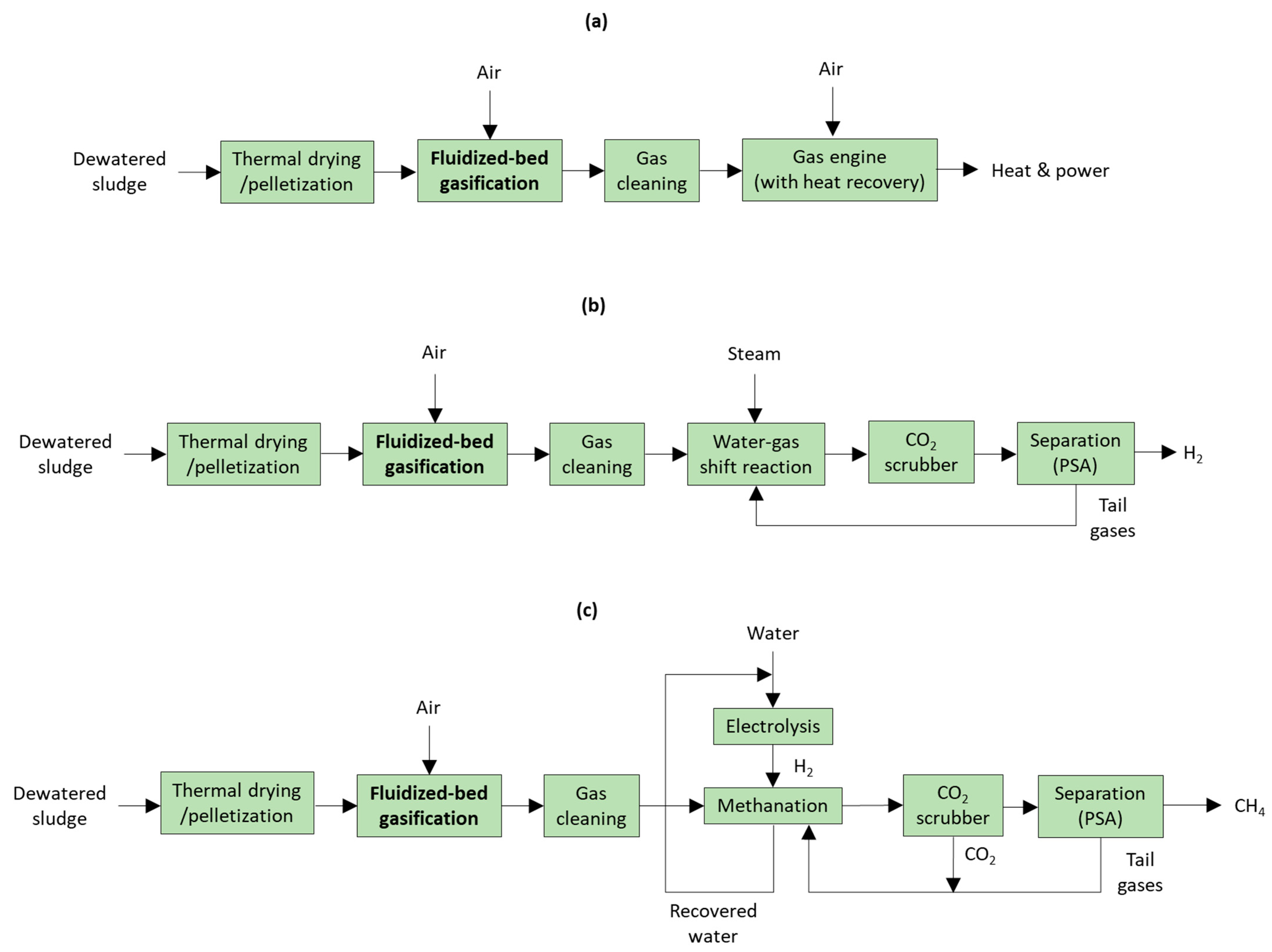

4.1.1. Base Scenario 1: Sludge to CHP

4.1.2. Base Scenario 2: Sludge to Hydrogen

4.1.3. Base Scenario 3: Sludge to Bio-SNG

4.1.4. Comparison of Technical, Economical, and Greenhouse-Gas-Emission Aspects between the Different Base Scenarios

5. Conclusions

- Recent national legislation and action plans (e.g., Decree-Law 60/2020, EN-H2 and RNC 2050) promoting decarbonization and the use of sustainable technologies for waste-biomass conversion into energy and renewable gases may be seen as an important opportunity to facilitate the establishment of gasification plants in the upcoming years;

- Companies working in the wastewater sector are interested in the implementation of technologies focused on in-house energy production due to the large energy demands associated with treatment processes. The AdP group is responsible for the most important companies in the sector, and it therefore presents good potential for the development of projects aiming to design and integrate new solutions for sludge valorization;

- Hydrogen and bio-SNG production from renewable sources is still scarce across Portugal. Currently, the supply of both gases is mainly covered by using fossil resources or importing them from other countries. Recognizing the relevant role of renewable gases in various economic domains (transport sector, grid injection, and industry), and the importance of decentralized energy production from low-carbon sources in the coming years, sludge gasification appears as a possible solution for wastewater-management entities to comply with the climate policies;

- The possible routes to generate advanced fuel products from the producer gas obtained by gasification include the following: gas or steam engines/turbines for CHP, water–gas shift reactors coupled with PSA separation for hydrogen, and electrolysis + methanation followed by PSA separation for bio-SNG;

- Regarding the potential of the sludge produced by the considered upstream management entities, the yearly production of CHP, hydrogen, and bio-SNG were estimated at 28,523 MWhe + 53,086 MWhth, 1245 t, and 7436 t, respectively;

- The heat generated by CHP plant configurations may be used for sludge drying before gasification; however, centralized gasification units seem to be the best option to convert sludge into heat and power due to the lower amounts of feedstock available for a decentralized strategy;

- The energy content of the generated bio-SNG is greater than the energy derived from hydrogen or CHP, thus showing the interesting potential for investors in using bio-SNG for injection in existing grid lines or transportation;

- Considering the potential of dewatered sludges for energy or renewable-fuel production through gasification, there is a strong opportunity for the development of projects across Portugal to produce added-value products, helping to achieve the national and international targets of decarbonization, and to fulfill European policies regarding waste valorization. These services may be possibly directed to feasibility studies, project planning, and economic and lifecycle-assessment studies of centralized or decentralized gasification units that are able to process large or local amounts of sludge.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Costa, A.; Cardoso, J.; Rosa, J.; Rodrigues, R.; Faroleiro, P.; Ruivo, F.; Videira, C.; Rosa, D.; Monte, M.; Santos, C.; et al. Relatório Anual dos Serviços de águas e Resíduos em Portugal 2020—Volume 1: Caraterização do Setor de águas e Resíduos; Entidade Reguladora dos Serviços de Águas e Resíduos: Lisbon, Portugal, 2021. [Google Scholar]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Gherghel, A.; Teodosiu, C.; De Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Guerra-Rodríguez, S.; Oulego, P.; Rodríguez, E.; Singh, D.N.; Rodríguez-Chueca, J. Towards the implementation of circular economy in the wastewater sector: Challenges and opportunities. Water 2020, 12, 1431. [Google Scholar] [CrossRef]

- Iticescu, C.; Georgescu, L.P.; Murariu, G.; Circiumaru, A.; Timofti, M. The characteristics of sewage sludge used on agricultural lands. AIP Conf. Proc. 2018, 2022, 020001. [Google Scholar]

- Eurostat—Your Key to European Statistics. Available online: https://ec.europa.eu/eurostat (accessed on 30 August 2022).

- Furness, D.T.; Hoggett, L.A.; Judd, S.J. Thermochemical treatment of sewage sludge. Water Environ. J. 2000, 14, 57–65. [Google Scholar] [CrossRef]

- Anaerobic Digestion. Available online: http://www.eubia.org/cms/wiki-biomass/anaerobic-digestion (accessed on 1 September 2022).

- Alves, F. Avaliação do Potencial de Optimização Energética da Digestão Anaeróbia de Lamas de ETAR. Master’s Thesis, Instituto Superior de Engenharia de Lisboa, Lisbon, Portugal, 2018. [Google Scholar]

- Cao, L.; Yu, I.K.M.; Xiong, X.; Tsang, D.C.W.; Zhang, S.; Clark, J.H.; Hu, C.; Ng, Y.H.; Shang, J.; Ok, Y.S. Biorenewable hydrogen production through biomass gasification: A review and future prospects. Environ. Res. 2020, 186, 109547. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.L.; Zhao, X.Y.; Cao, J.P. Methanation of syngas from biomass gasification: An overview. Int. J. Hydrogen Energy 2020, 45, 4223–4243. [Google Scholar] [CrossRef]

- You, S.; Wang, W.; Dai, Y.; Tong, Y.W.; Wang, C.H. Comparison of the co-gasification of sewage sludge and food wastes and cost-benefit analysis of gasification- and incineration-based waste treatment schemes. Bioresour. Technol. 2016, 218, 595–605. [Google Scholar] [CrossRef]

- Singlitico, A.; Kilgallon, I.; Goggins, J.; Monaghan, R.F.D. GIS-based techno-economic optimisation of a regional supply chain for large-scale deployment of bio-SNG in a natural gas network. Appl. Energy 2019, 250, 1036–1052. [Google Scholar] [CrossRef]

- Binder, M.; Kraussler, M.; Kuba, M.; Luisser, M. Hydrogen from Biomass Gasification; International Environmental Agency: Paris, France, 2018. [Google Scholar]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction—Practical Design and Theory, 2nd ed.; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- International Environmental Agency. Outlook for Biogas and Biomethane. Prospects for Organic Growth; International Environmental Agency: Paris, France, 2020. [Google Scholar]

- Sülze Kopf Syngas Sewage Sludge Recycling. Available online: https://kopf-syngas.de/en (accessed on 1 February 2021).

- Portal da Entidade Reguladora dos Serviços de Água e Resíduos. Available online: https://www.ersar.pt/pt (accessed on 1 April 2021).

- Frade, J.V.; Lacasta, N.; Mendes, P.; Cardoso, P.; Trindade, I.; Newton, F.; Franco, P.; Serra, A.; Póvoa, C.; Narciso, F.; et al. PENSAAR 2020—Uma Estratégia ao Serviço da População: Serviços de Qualidade a um Preço Sustentável. Volume I; Agência Portuguesa do Ambiente; Ministério do Ambiente, Ordenamento do Território e Energia; Grupo Águas de Portugal: Amadora, Portugal; Lisbon, Portugal, 2015. [Google Scholar]

- Grupo Águas de Portugal. Annual Report & Accounts 2019; Grupo Águas de Portugal: Lisbon, Portugal, 2020. [Google Scholar]

- Estratégia Inovação 360°. Available online: https://www.adp.pt/pt/comunicacao/noticias/detalhe-da-noticia/?id=69&idn=404 (accessed on 1 April 2021).

- Agência Portuguesa do Ambiente. Roteiro Para a Neutralidade Carbónica 2050 (RNC 2050)—Estratégia de Longo Prazo Para a Neutralidade Carbónica da Economia Portuguesa em 2050; Agência Portuguesa do Ambiente: Amadora, Portugal, 2019. [Google Scholar]

- Governo de Portugal. Resolução do Conselho de Ministros n.o 63/2020—Plano Nacional do Hidrogénio; Instituto Nacional Casa da Moeda: Lisbon, Portugal, 2020. [Google Scholar]

- Abad, A.V.; Dodds, P.E. Green hydrogen characterisation initiatives: Definitions, standards, guarantees of origin, and challenges. Energy Policy 2020, 138, 111300. [Google Scholar] [CrossRef]

- Biogasmove, um Projeto de Demonstração Tecnológica. Available online: https://dourogasrenovavel.pt/biogasmove/ (accessed on 28 July 2022).

- Dourogás GNV—A Bet on Sustainable Mobility. Available online: https://www.dourogasgnv.pt/en/ (accessed on 28 July 2022).

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Manyà, J.J.; Sánchez, J.L.; Gonzalo, A.; Arauzo, J. Air Gasification of Dried Sewage Sludge in a Fluidized Bed: Effect of the Operating Conditions and In-Bed Use of Alumina. Energy Fuels 2005, 19, 629–636. [Google Scholar] [CrossRef]

- Menin, L.; Vakalis, S.; Benedetti, V.; Patuzzi, F.; Baratieri, M. Techno-economic assessment of an integrated biomass gasification, electrolysis, and syngas biomethanation process. Biomass Convers. Biorefinery 2020, 11, 445–459. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, X.; Li, J.; Wang, Q.; Kang, Y.; Dong, Z.; Fan, X.; Liu, Z.; Zhang, Y.; Yang, Z.; et al. A novel thin-layer ash reciprocation heat recovery system for bottom ash from circulating fluidized bed boilers: Experimental study. Appl. Therm. Eng. 2021, 183, 116147. [Google Scholar] [CrossRef]

- Zsirai, I. Sewage sludge as renewable energy. J. Residuals Sci. Technol. 2011, 8, 165–179. [Google Scholar]

- Groß, B.; Eder, C.; Grziwa, P.; Horst, J.; Kimmerle, K. Energy recovery from sewage sludge by means of fluidised bed gasification. Waste Manag. 2008, 28, 1819–1826. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; Del Olmo, O.A. Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Adams, P.W.R.R.; McManus, M.C. Small-scale biomass gasification CHP utilisation in industry: Energy and environmental evaluation. Sustain. Energy Technol. Assess. 2014, 6, 129–140. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Available online: https://www.epa.gov (accessed on 30 March 2021).

- All Power Labs—130 kW Hybrid Biomass Microgrid. Available online: http://www.allpowerlabs.com/130kw-hybrid-microgrid (accessed on 30 March 2021).

- Chen, W.H.; Chen, C.Y. Water gas shift reaction for hydrogen production and carbon dioxide capture: A review. Appl. Energy 2020, 258, 114078. [Google Scholar] [CrossRef]

- Pal, D.B.; Chand, R.; Upadhyay, S.N.; Mishra, P.K. Performance of water gas shift reaction catalysts: A review. Renew. Sustain. Energy Rev. 2018, 93, 549–565. [Google Scholar] [CrossRef]

- Li, B.; He, G.; Jiang, X.; Dai, Y.; Ruan, X. Pressure swing adsorption/membrane hybrid processes for hydrogen purification with a high recovery. Front. Chem. Sci. Eng. 2016, 10, 255–264. [Google Scholar] [CrossRef]

- Feng, F.; Zhang, L.; Huang, S.; Feng, X.; Jin, L.; Zhang, P. Surface structure changes of nickel-based catalysts in the syngas methanation process. React. Kinet. Mech. Catal. 2020, 130, 229–240. [Google Scholar] [CrossRef]

- SysAdvance—Shaping the Future of Technology. Available online: https://sysadvance.com (accessed on 1 April 2021).

- Woolcock, P.J.; Brown, R.C. A review of cleaning technologies for biomass-derived syngas. Biomass Bioenergy 2013, 52, 54–84. [Google Scholar] [CrossRef]

- Calbry-Muzyka, A.S.; Gantenbein, A.; Schneebeli, J.; Frei, A.; Knorpp, A.J.; Schildhauer, T.J.; Biollaz, S.M.A. Deep removal of sulfur and trace organic compounds from biogas to protect a catalytic methanation reactor. Chem. Eng. J. 2019, 360, 577–590. [Google Scholar] [CrossRef]

- Roche, E.; De Andrés, J.M.; Narros, A.; Rodríguez, M.E. Air and air-steam gasification of sewage sludge. The influence of dolomite and throughput in tar production and composition. Fuel 2014, 115, 54–61. [Google Scholar] [CrossRef]

- Liu, H.; Hu, H.; Luo, G.; Li, A.; Xu, M.; Yao, H. Enhancement of hydrogen production in steam gasification of sewage sludge by reusing the calcium in lime-conditioned sludge. Int. J. Hydrogen Energy 2013, 38, 1332–1341. [Google Scholar] [CrossRef]

- De Andrés, J.M.; Narros, A.; Rodríguez, M.E. Behaviour of dolomite, olivine and alumina as primary catalysts in air-steam gasification of sewage sludge. Fuel 2011, 90, 521–527. [Google Scholar] [CrossRef]

- Elsner, W.; Wysocki, M.; Niegodajew, P.; Borecki, R. Experimental and economic study of small-scale CHP installation equipped with downdraft gasifier and internal combustion engine. Appl. Energy 2017, 202, 213–227. [Google Scholar] [CrossRef]

- Lui, J.; Paul, M.C.; Sloan, W.; You, S. Techno-economic feasibility of distributed waste-to-hydrogen systems to support green transport in glasgow. Int. J. Hydrogen Energy 2022, 47, 13532–13551. [Google Scholar] [CrossRef]

- Michailos, S.; Walker, M.; Moody, A.; Poggio, D.; Pourkashanian, M. Biomethane production using an integrated anaerobic digestion, gasification and CO2 biomethanation process in a real waste water treatment plant: A techno-economic assessment. Energy Convers. Manag. 2020, 209, 112663. [Google Scholar] [CrossRef]

- Ramachandran, S.; Yao, Z.; You, S.; Massier, T.; Stimming, U.; Wang, C.H. Life cycle assessment of a sewage sludge and woody biomass co-gasification system. Energy 2017, 137, 369–376. [Google Scholar] [CrossRef] [Green Version]

- Greenhouse Gas Protocol. Available online: https://ghgprotocol.org/ (accessed on 1 September 2022).

- Waste Water Treatment Plants Are Using Gasification for Energy. Available online: https://www.wastetoenergysystems.com/waste-water-treatment-plant-across-the-globe-use-gasification-for-energy/ (accessed on 1 September 2022).

| Management Entity | Type of System | Amount (t/y) |

|---|---|---|

| Águas do Tejo Atlântico | Upstream | 162,551 |

| TRATAVE | Upstream | 53,765 |

| Águas do Centro Litoral | Upstream | 50,409 |

| Águas do Algarve | Upstream | 45,902 |

| Águas do Norte (multimunicipal concession) | Upstream | 37,821 |

| Águas do Porto | Downstream | 26,428 |

| Águas do Vale do Tejo | Upstream | 21,639 |

| SIMDOURO | Upstream | 20,959 |

| Aquanena | Downstream | 19,881 |

| SMAS de Almada | Downstream | 16,511 |

| SIMARSUL | Upstream | 14,361 |

| Águas de Barcelos | Downstream | 9886 |

| AGERE | Downstream | 9615 |

| Águas de Valongo | Downstream | 9135 |

| Indaqua Matosinhos | Downstream | 6754 |

| Águas do Sado | Downstream | 6452 |

| Águas Públicas do Alentejo | Upstream | 6325 |

| SMAS de Viseu | Downstream | 4606 |

| SMAS de Sintra | Downstream | 4450 |

| SMAS de Caldas da Rainha | Downstream | 4304 |

| Águas de Santo André | Upstream | 4298 |

| EMAS de Beja | Downstream | 4140 |

| Águas da Figueira | Downstream | 4114 |

| Compound | Concentration (vol.%) |

|---|---|

| H2 | 8.67 |

| N2 | 62.69 |

| CO | 8.81 |

| CH4 | 2.20 |

| CO2 | 15.61 |

| C2H4 | 1.69 |

| C2H6 | 0.04 |

| C2H2 | 0.09 |

| H2S | 0.20 |

| Management Entity (AdP Group) | Mass of Sludge (t/y daf) | Syngas (t/y) | Syngas (×1000 Nm3/y) |

|---|---|---|---|

| Águas do Tejo Atlântico | 20,228 | 64,858 | 51,986 |

| Águas do Centro Litoral | 6273 | 20,113 | 16,122 |

| Águas do Algarve | 5712 | 18,315 | 14,680 |

| Águas do Norte | 4707 | 15,091 | 12,096 |

| Águas do Vale do Tejo | 2693 | 8634 | 6920 |

| SIMDOURO | 2608 | 8363 | 6703 |

| SIMARSUL | 1787 | 5730 | 4593 |

| Águas de Santo André | 535 | 1715 | 1375 |

| TOTAL | 44,543 | 142,819 | 114,475 |

| Management Entity (AdP Group) | Potential Annual Electrical Output (MWhe/y) | Potential Annual Thermal Output (MWhth/y) | CHP-Estimated Electrical Output for 7500 h (MWe/y) |

|---|---|---|---|

| Águas do Tejo Atlântico | 12,953.28 | 23,653.81 | 1.73 |

| Águas do Centro Litoral | 4016.97 | 7335.33 | 0.54 |

| Águas do Algarve | 3657.81 | 6679.49 | 0.49 |

| Águas do Norte | 3013.86 | 5503.57 | 0.40 |

| Águas do Vale do Tejo | 1724.36 | 3148.83 | 0.23 |

| SIMDOURO | 1670.17 | 3049.88 | 0.22 |

| SIMARSUL | 1144.39 | 2089.76 | 0.15 |

| Águas de Santo André | 342.50 | 625.43 | 0.05 |

| TOTAL | 28,523.33 | 53,086.09 | 3.80 |

| Management Entity (AdP Group) | Annual-Hydrogen-Production Potential (×1000 Nm3/y) | Annual-Hydrogen-Production Potential (t/y) |

|---|---|---|

| Águas do Tejo Atlântico | 6478 | 565 |

| Águas do Centro Litoral | 2009 | 175 |

| Águas do Algarve | 1829 | 159 |

| Águas do Norte | 1507 | 132 |

| Águas do Vale do Tejo | 862 | 75 |

| SIMDOURO | 835 | 83 |

| SIMARSUL | 572 | 50 |

| Águas de Santo André | 171 | 15 |

| TOTAL | 14,265 | 1245 |

| Management Entity (AdP Group) | Annual Bio-SNG Production Potential (×1000 Nm3/y) | Annual Bio-SNG Production Potential (t/y) |

|---|---|---|

| Águas do Tejo Atlântico | 5142 | 3377 |

| Águas do Centro Litoral | 1595 | 1047 |

| Águas do Algarve | 1452 | 954 |

| Águas do Norte | 1196 | 786 |

| Águas do Vale do Tejo | 684 | 450 |

| SIMDOURO | 663 | 435 |

| SIMARSUL | 454 | 298 |

| Águas de Santo André | 136 | 89 |

| TOTAL | 11,323 | 7436 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, O.; Garcia, B.; Rijo, B.; Lourinho, G.; Nobre, C. Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification. Energies 2022, 15, 6600. https://doi.org/10.3390/en15186600

Alves O, Garcia B, Rijo B, Lourinho G, Nobre C. Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification. Energies. 2022; 15(18):6600. https://doi.org/10.3390/en15186600

Chicago/Turabian StyleAlves, Octávio, Bruno Garcia, Bruna Rijo, Gonçalo Lourinho, and Catarina Nobre. 2022. "Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification" Energies 15, no. 18: 6600. https://doi.org/10.3390/en15186600

APA StyleAlves, O., Garcia, B., Rijo, B., Lourinho, G., & Nobre, C. (2022). Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification. Energies, 15(18), 6600. https://doi.org/10.3390/en15186600