A Comprehensive Assessment of Products Management and Energy Recovery from Waste Products in the United States

Abstract

:1. Introduction

2. Materials and Methods

2.1. Product Classification and Sources Used

2.2. Changes in the Total Amount and Disposal Rates of Products Managed in the U.S.

2.3. Potential Contribution of Waste Products to the U.S. Energy Grid

- (i)

- WTE is a more preferable option for non-recyclable materials, compared to landfilling, according to the U.S. EPA hierarchy [1].

- (ii)

- The most successful paradigms of sustainable waste management achieved up to 60–70% recycling and the rest is used as fuel in WTE plants [29].

- (iii)

- Recent studies concluded that even if nations achieve ambitious recycling targets by 2035, there will still be a fraction of up to 30% at least, of residual materials, which should be used as fuels in WTE plants [30].

2.4. GHG Emissions from Waste Management in the U.S. and the EU

3. Results and Discussion

3.1. Management of Waste Products in the U.S.

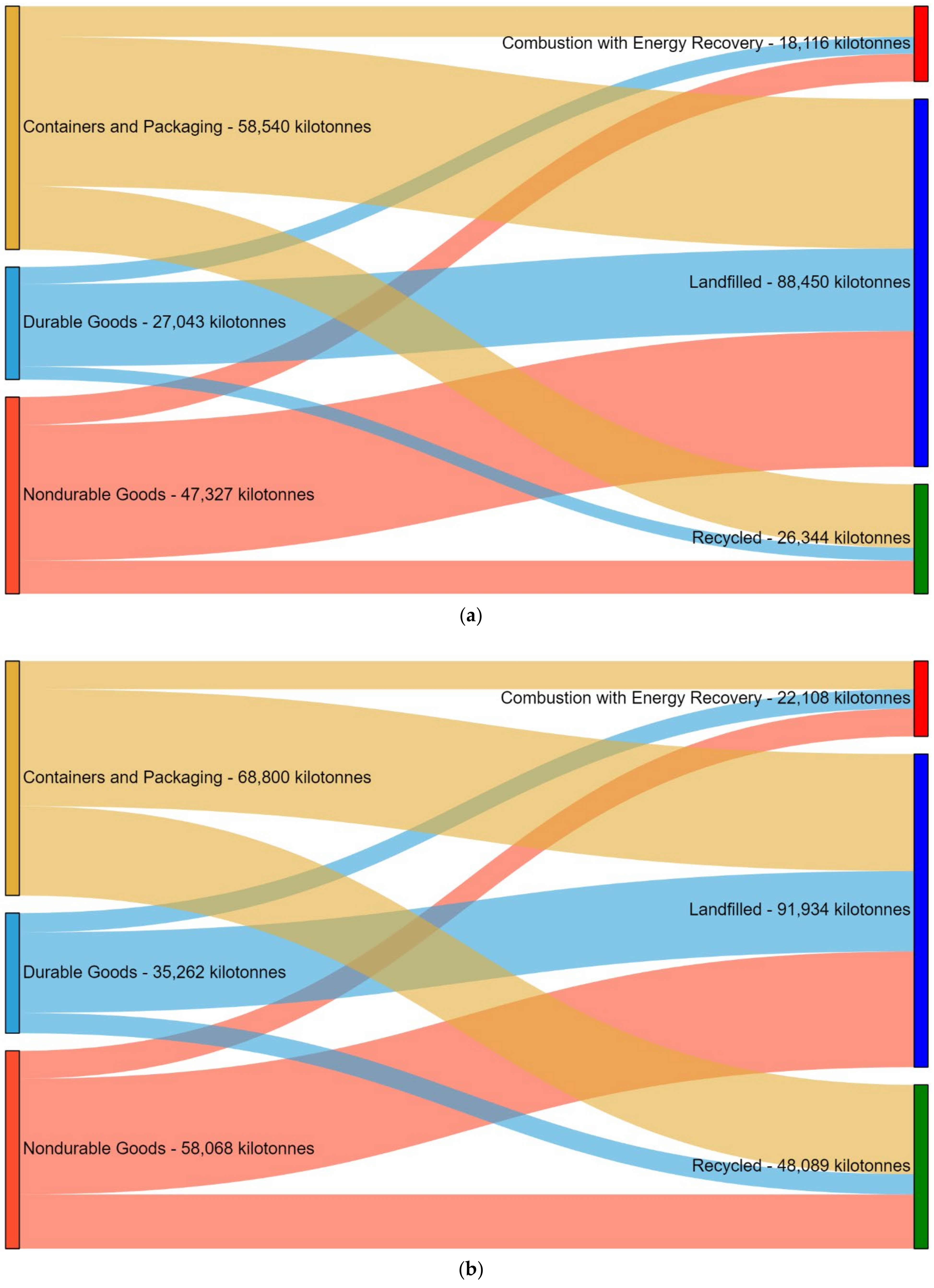

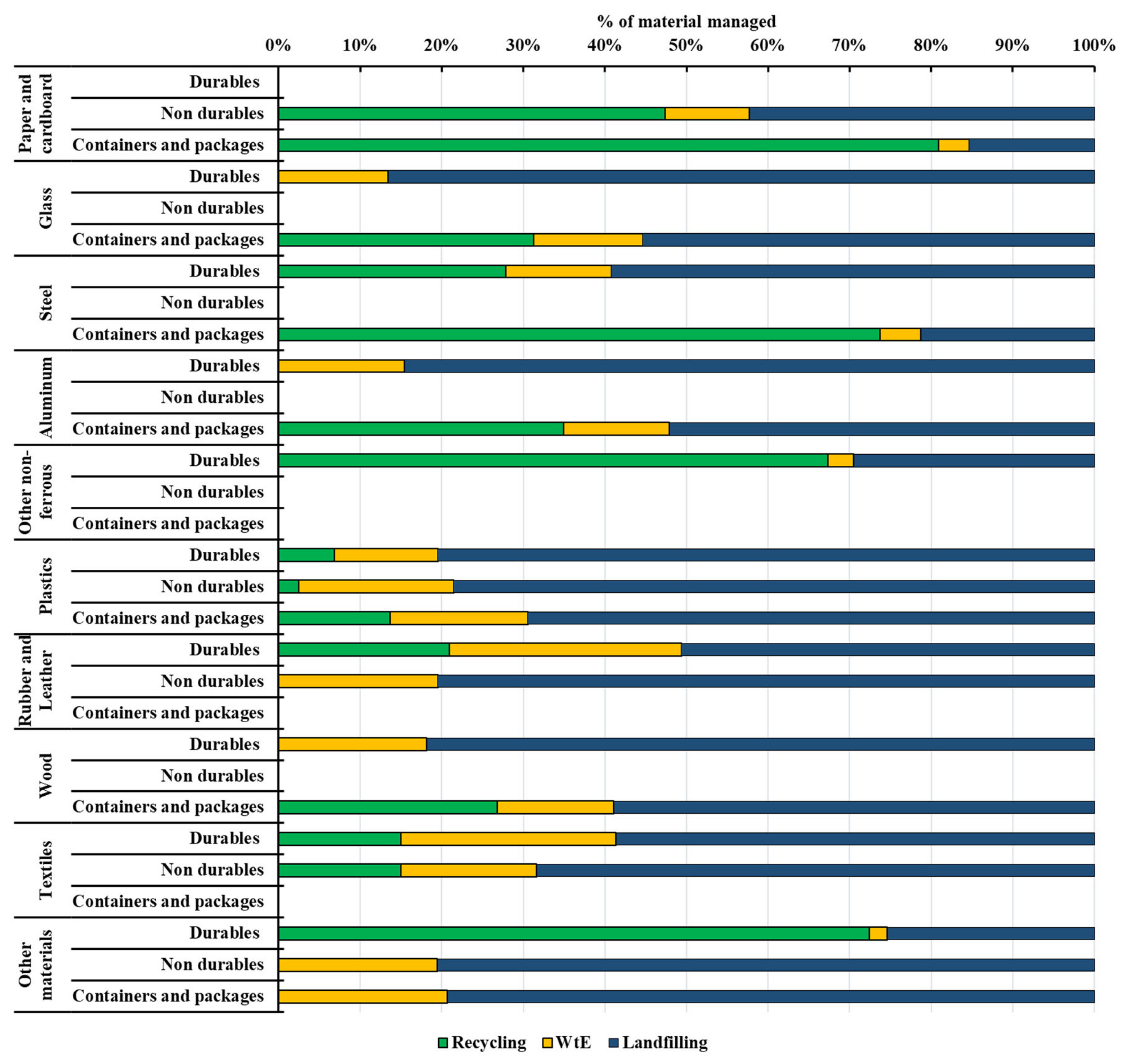

3.1.1. Generation and Management of Total Products in Durables, Non-Durables, and Containers and Packages in the U.S.

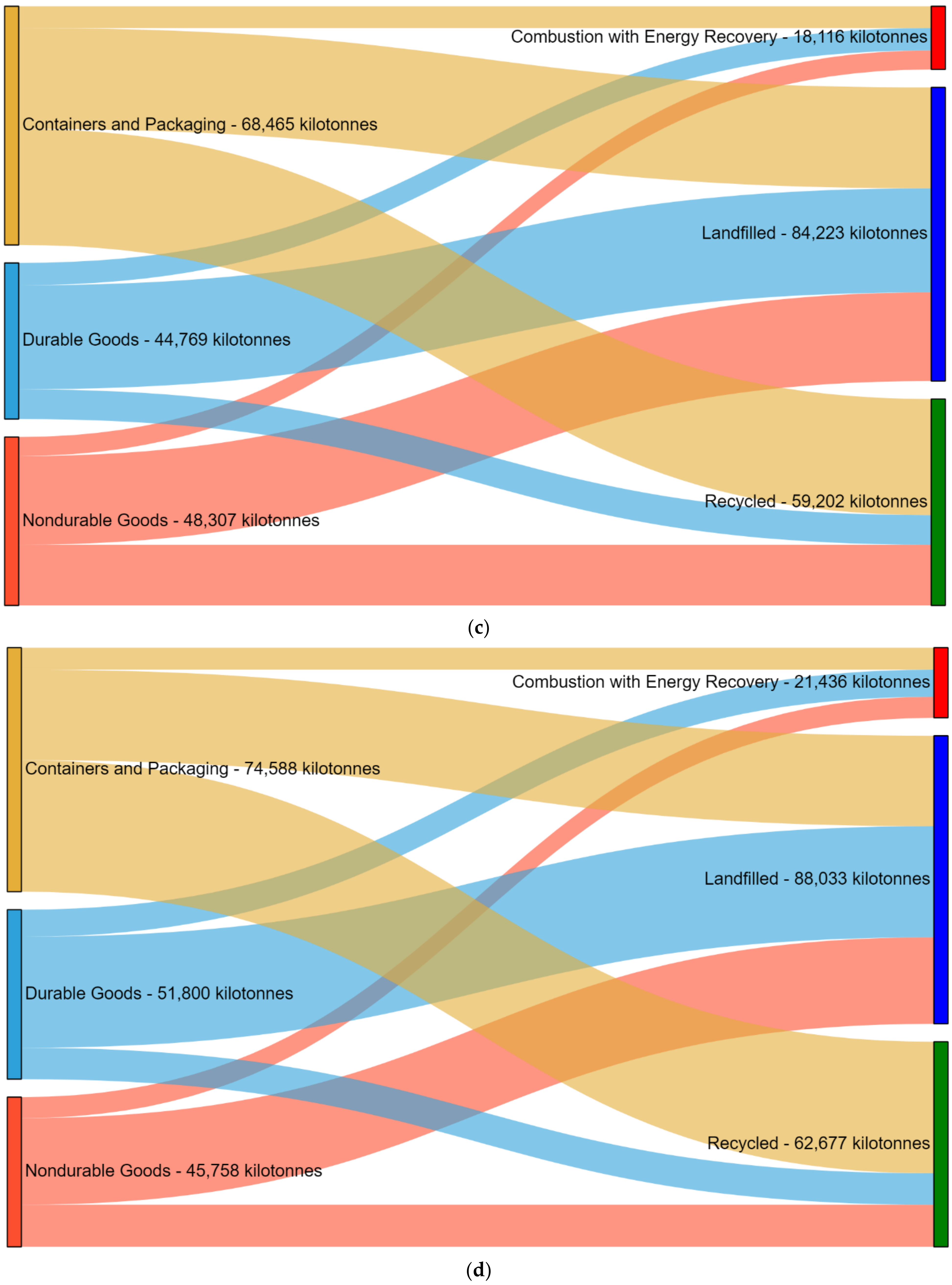

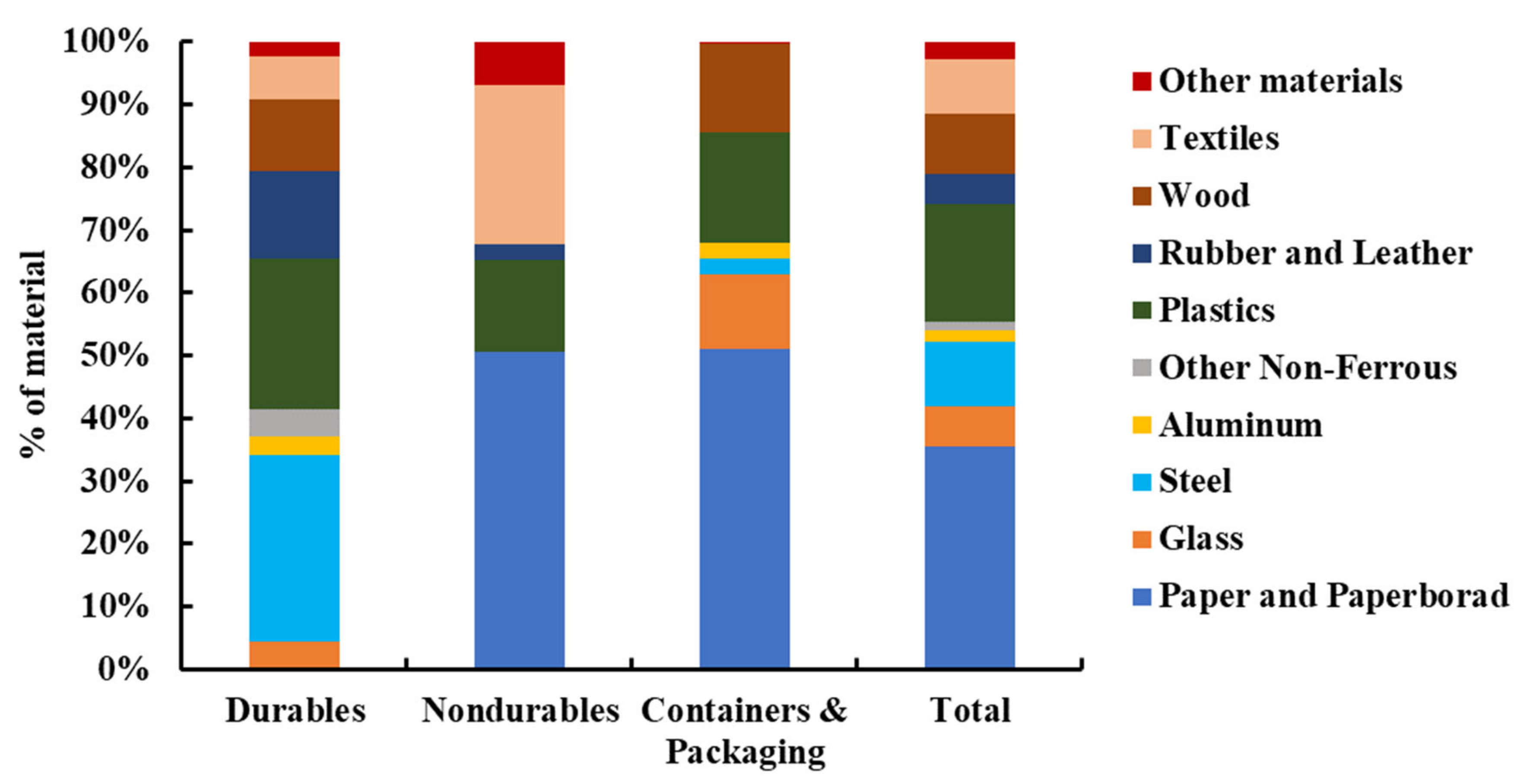

3.1.2. Composition of Durables, Non-Durables, and Containers and Packages, and Management of Materials Contained in Broad Categories

3.1.3. Generation of Specific Waste Products Contained in Durables, Non-Durables, Containers, and Packages in the U.S.

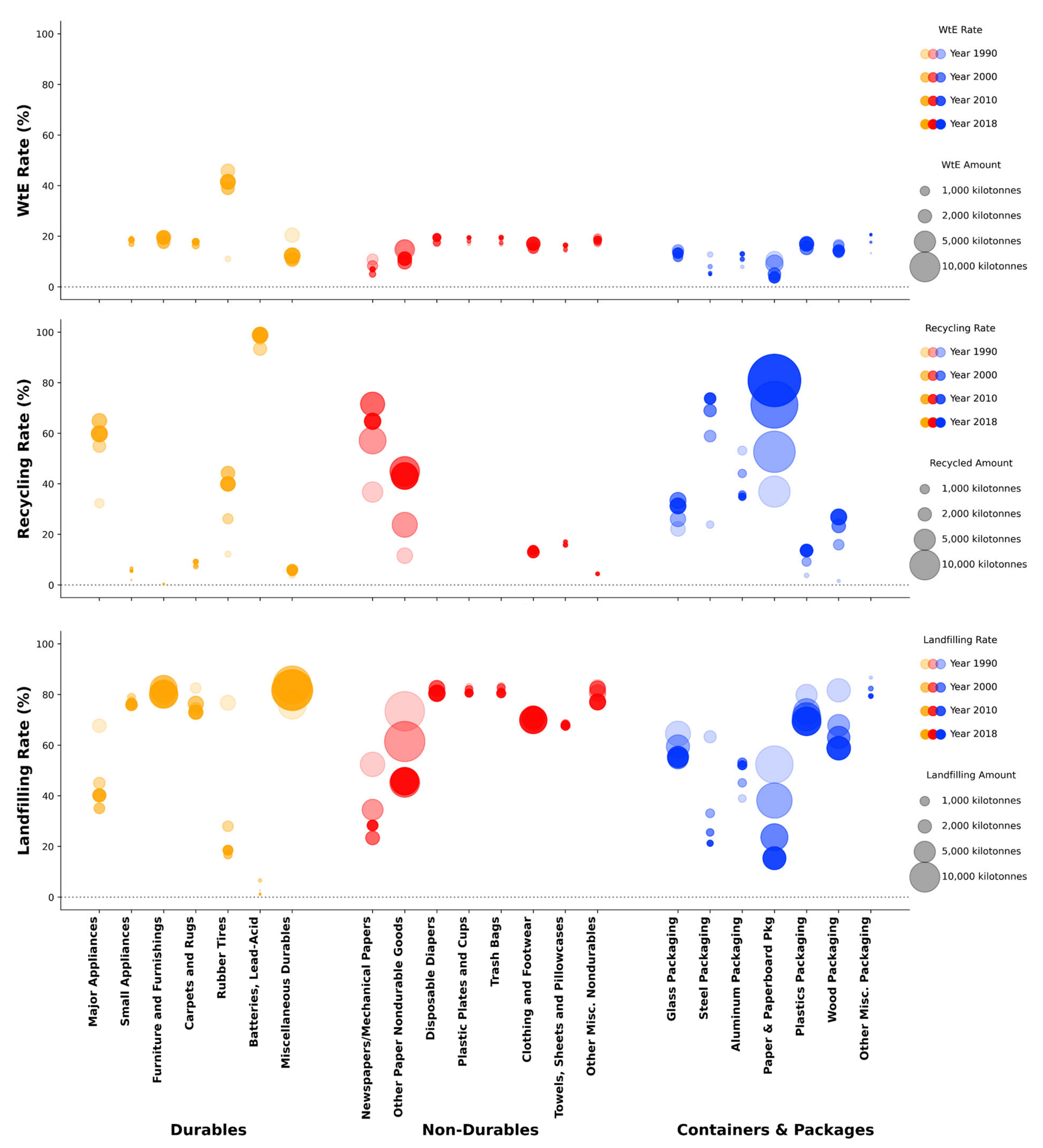

3.1.4. Change in the Disposal Rates of Specific Products Managed in the U.S.

Durables

Non-Durables

Containers and Packaging

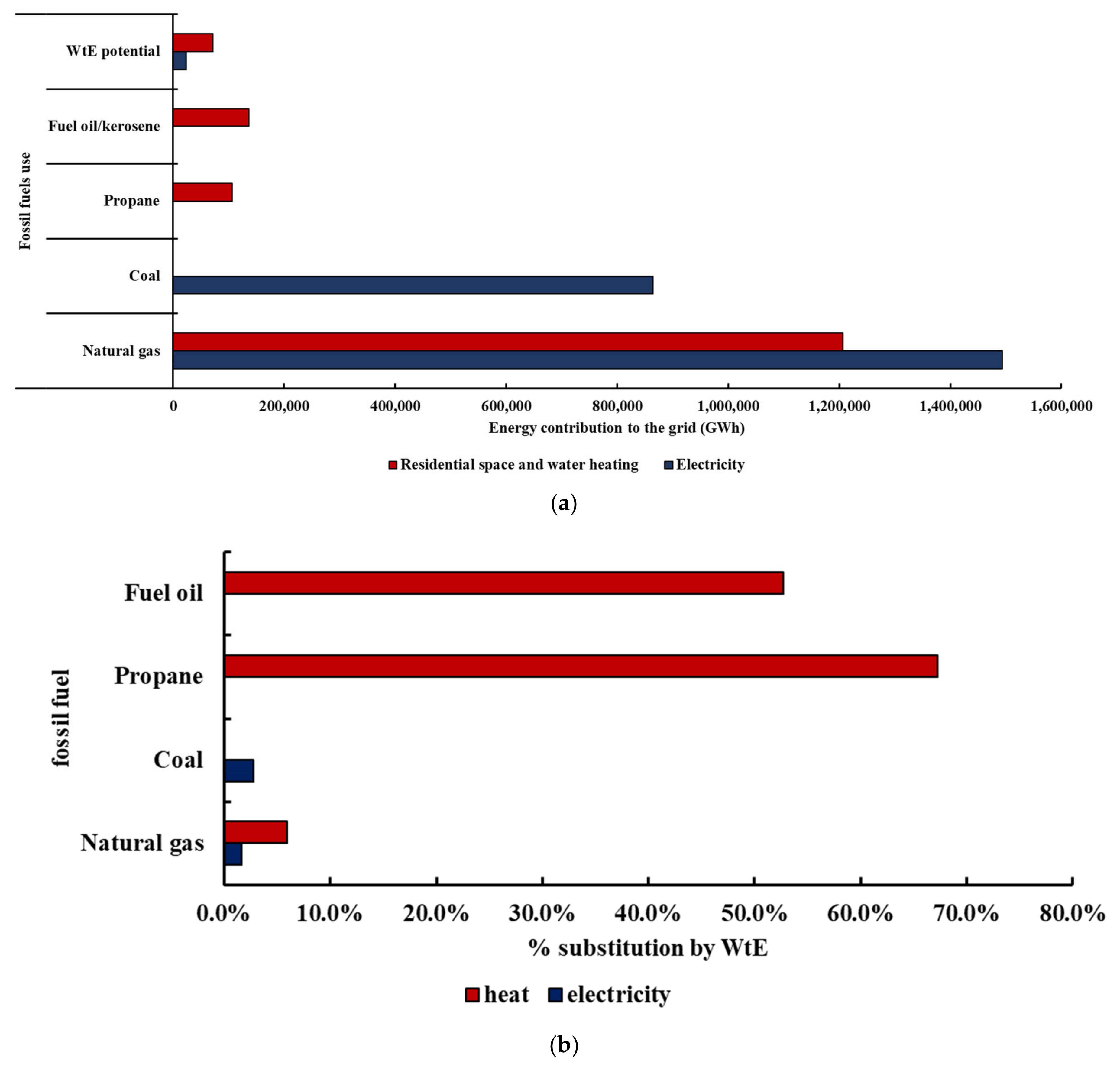

3.2. Potential Contribution of Waste Products to the U.S. Energy Grid

3.3. GHG Emissions from Waste Management in the U.S. and the EU

3.4. Practical Implications

4. Conclusions

- The amount of all durable products produced was increased, and most of the non-durable and packages and containers products indicated an increase during the 28-year period.

- The highest increase in the amounts of products recycled was observed with packaging and containers, which became the dominant method of managing such products in the U.S. in 2015. Non-durables and durables were mainly landfilled.

- Clothing and footwear, disposable diapers, plastic cups, trash bags, and other miscellaneous packaging are materials with negligible recycling rates during the 28-year period, and the only option to divert these materials from landfills is sophisticated WTE.

- On a conservative scenario, WTE can substitute either up to 2.8% of coal, or up to 1.6% of natural gas for electricity generation. However, WTE can substitute either up to 68% of propane, or 53% of fuel oil, or up to 6% of natural gas used for residential space and water heating.

- Over 85% of GHG emissions in the U.S. are associated with the landfilling of materials. The EU experience has shown that recycling and waste to energy are complementary in diverting materials from landfills, in enhancing energy security, and the associated GHG emissions, which includes both direct, such as the diversion of materials from landfills, and indirect benefits, such as the substitution of fossil fuels.

- Value-based life cycle models can be used to evaluate the contribution of waste materials in the U.S. economy, and to identify mutually beneficial opportunities with other sectors, such as energy and transportation. Result-based financing, such as environmental impact bonds, can be used to address the counterparty risks of the investment throughout the lifecycle of the project, along with public and private partnerships, which are associated with multiple benefits, such as a share of risk among the entities.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United States Environmental Protection Agency (USEPA). Sustainable Materials Management: Non-Hazardous Materials and Waste Management Hierarchy. Available online: https://www.epa.gov/smm/sustainable-materials-management-non-hazardous-materials-and-waste-management-hierarchy (accessed on 15 August 2022).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—The Role of Waste-to-Energy in the Circular Economy; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- The White House. Joint US-EU Press Release on the Global Methane Pledge. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2021/09/18/joint-us-eu-press-release-on-the-global-methane-pledge/ (accessed on 15 August 2022).

- United States Environmental Protection Agency (USEPA). Overview of Greenhouse Gases. Available online: https://www.epa.gov/ghgemissions/overview-greenhouse-gases#methane (accessed on 15 August 2022).

- United States Environmental Protection Agency (USEPA). Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2019. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2019 (accessed on 15 August 2022).

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2021: The Physical Science Basis. Available online: https://www.ipcc.ch/report/ar6/wg1/#FullReport (accessed on 15 August 2022).

- Kumar, V.; Garg, N. National and Regional Waste Stream in the United States: Conformance and Disparity. Environ. Res. Infrastruct. Sustain. 2021, 1, 031002. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (USEPA). Advancing Sustainable Materials Management: Facts and Figures Report. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management (accessed on 15 August 2022).

- Tsiamis, D.A.; Torres, M.; Castaldi, M.J. Role of Plastics in Decoupling Municipal Solid Waste and Economic Growth in the U.S. Waste Manag. 2018, 77, 147–155. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Levis, J.W.; Barlaz, M.A. Development of Streamlined Life-Cycle Assessment for the Solid Waste Management System. Environ. Sci. Technol. 2021, 55, 5475–5484. [Google Scholar] [CrossRef]

- Levis, J.W.; Barlaz, M.A.; Decarolis, J.F.; Ranjithan, S.R. Systematic Exploration of Efficient Strategies to Manage Solid Waste in U.S Municipalities: Perspectives from the Solid Waste Optimization Life-Cycle Framework (SWOLF). Environ. Sci. Technol. 2014, 48, 3625–3631. [Google Scholar] [CrossRef]

- Pressley, P.N.; Levis, J.W.; Damgaard, A.; Barlaz, M.A.; DeCarolis, J.F. Analysis of Material Recovery Facilities for Use in Life-Cycle Assessment. Waste Manag. 2015, 35, 307–317. [Google Scholar] [CrossRef] [PubMed]

- Bourtsalas, A.C.; Seo, Y.; Tanvir Alam, M.; Seo, Y.C. The Status of Waste Management and Waste to Energy for District Heating in South Korea. Waste Manag. 2019, 85, 304–316. [Google Scholar] [CrossRef]

- Ryu, C. Potential of Municipal Solid Waste for Renewable Energy Production and Reduction of Greenhouse Gas Emissions in South Korea. J. Air Waste Manag. Assoc. 2010, 60, 176–183. [Google Scholar] [CrossRef] [PubMed]

- Thermelis, N.J.; Kim, Y.H.; Brady, M.H. Energy Recovery from New York City Municipal Solid Wastes. Waste Manag. Res. 2002, 20, 223–233. [Google Scholar] [CrossRef]

- Danish Energy Agency. Regulation and Planning of District Heating in Denmark; Danish Energy Agency: København, Denmark, 2016. [Google Scholar]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal Solid Waste Management and Waste-to-Energy in the Context of a Circular Economy and Energy Recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Tunesi, S. LCA of Local Strategies for Energy Recovery from Waste in England, Applied to a Large Municipal Flow. Waste Manag. 2011, 31, 561–571. [Google Scholar] [CrossRef]

- Kaplan, P.O.; Decarolis, J.; Thorneloe, S. Is It Better to Burn or Bury Waste for Clean Electricity Generation? Environ. Sci. Technol. 2009, 43, 1711–1717. [Google Scholar] [CrossRef] [PubMed]

- Varjani, S.; Shahbeig, H.; Popat, K.; Patel, Z.; Vyas, S.; Shah, A.V.; Barceló, D.; Hao Ngo, H.; Sonne, C.; Shiung Lam, S.; et al. Sustainable Management of Municipal Solid Waste through Waste-to-Energy Technologies. Bioresour. Technol. 2022, 355, 127247. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A Review of Technologies and Performances of Thermal Treatment Systems for Energy Recovery from Waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (USEPA). Guide to the Facts and Figures Report about Materials, Waste and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/guide-facts-and-figures-report-about#Products (accessed on 15 August 2022).

- United States Environmental Protection Agency (USEPA). Advancing Sustainable Materials Management: 2018 Fact Sheet; United States Environmental Protection Agency (USEPA): Washington, DC, USA, 2020.

- Holoviews Sankey Element. Available online: https://holoviews.org/reference/elements/bokeh/Sankey.html (accessed on 15 August 2022).

- Bokeh Bokeh Documentation. Available online: https://docs.bokeh.org/en/latest/ (accessed on 15 August 2022).

- Matplotlib Matplotlib: Visualization with Python. Available online: https://matplotlib.org/ (accessed on 15 August 2022).

- United States Energy Information Administrtion. Residential Energy Consumption Survey (RECS). Available online: https://www.eia.gov/consumption/residential/index.php (accessed on 15 August 2022).

- United States Energy Information Administration. Units and Calculators Explained Energy Conversion Calculators. Available online: https://www.eia.gov/energyexplained/units-and-calculators/energy-conversion-calculators.php (accessed on 15 August 2022).

- Eurostat Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Waste_treatment (accessed on 15 August 2022).

- CEWEP (Confederation of European Waste-to-Energy Plants). Circular Economy Calculation Tool. Available online: https://www.cewep.eu/circular-economy-calculations-2/ (accessed on 15 August 2022).

- Themelis, N.J.; Elena, M.; Barriga, D.; Estevez, P.; Velasco, M.G. Guidebook for the Application of Waste to Energy Technologies in Latin America and the Caribbean; Earth Engineering Center, Columbia University: New York, NY, USA, 2013. [Google Scholar]

- United States Environmental Protection Agency (USEPA). National Overview: Facts and Figures on Materials, Wastes and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 15 August 2022).

- United States Environmental Protection Agency (USEPA). Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2019; United States Environmental Protection Agency (USEPA): Washington, DC, USA, 2021; Volume April. Available online: https://www.epa.gov/sites/default/files/2021-04/documents/us-ghg-inventory-2021-main-text.pdf (accessed on 15 August 2022).

- Eurostat Municipal Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics#Municipal_waste_treatment (accessed on 15 August 2022).

- Eurostat Climate Change—Driving Forces. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Climate_change_-_driving_forces#Emissions_from_waste (accessed on 15 August 2022).

- Anshassi, M.; Smallwood, T.; Townsend, T.G. Life Cycle GHG Emissions of MSW Landfilling versus Incineration: Expected Outcomes Based on US Landfill Gas Collection Regulations. Waste Manag. 2022, 142, 44–54. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Themelis, N.J.; Sun, K.; Bourtsalas, A.C.; Huang, Q.; Zhang, Y.; Wu, Z. Current Influence of China’s Ban on Plastic Waste Imports. Waste Dispos. Sustain. Energy 2019, 1, 67–78. [Google Scholar] [CrossRef]

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese Import Ban and Its Impact on Globalplastic Waste Trade. Sci. Adv. 2018, 4, eaat0131. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, L.; Lim, M.K.; Chen, W.Q.; Sutherland, J.W. Structure of the Global Plastic Waste Trade Network and the Impact of China’s Import Ban. Resour. Conserv. Recycl. 2020, 153, 104591. [Google Scholar] [CrossRef]

- Sovacool, B.K. Exploring and Contextualizing Public Opposition to Renewable Electricity in the United States. Sustainability 2009, 1, 702–721. [Google Scholar] [CrossRef]

- Gandy, M. Political Conflict over Waste-to-Energy Schemes. The Case of Incineration in New York. Land Use Policy 1995, 12, 29–36. [Google Scholar] [CrossRef]

- Quicker, P.; Consonni, S.; Grosso, M. The Zero Waste Utopia and the Role of Waste-to-Energy. Waste Manag. Res. 2020, 38, 481–484. [Google Scholar] [CrossRef]

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H.; Pham, V.V. Perspective Review on Municipal Solid Waste-to-Energy Route: Characteristics, Management Strategy, and Role in Circular Economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Waste to Energy Considerations for Informed Decision-Making; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- Powell, J.T.; Townsend, T.G.; Zimmerman, J.B. Estimates of Solid Waste Disposal Rates and Reduction Targets for Landfill Gas Emissions. Nat. Clim. Chang. 2016, 6, 162–165. [Google Scholar] [CrossRef]

- Themelis, N.J.; Bourtsalas, A.C. Methane Generation and Capture of U.S. Landfills. J. Environ. Sci. Eng. A 2021, 10, 199–206. [Google Scholar] [CrossRef]

- Staley, B.; Kantner, D. Quantification of Municipal Solid Waste Management in the United States—With Comparative Analysis to Other Estimates. Multidiscip. J. Waste Resour. Residues 2018, 3, 167–170. [Google Scholar] [CrossRef]

- Sauve, G.; Van Acker, K. The Environmental Impacts of Municipal Solid Waste Landfills in Europe: A Life Cycle Assessment of Proper Reference Cases to Support Decision Making. J. Environ. Manag. 2020, 261, 110216. [Google Scholar] [CrossRef]

- Mühle, S.; Balsam, I.; Cheeseman, C.R. Comparison of Carbon Emissions Associated with Municipal Solid Waste Management in Germany and the UK. Resour. Conserv. Recycl. 2010, 54, 793–801. [Google Scholar] [CrossRef]

- Habib, K.; Schmidt, J.H.; Christensen, P. A Historical Perspective of Global Warming Potential from Municipal Solid Waste Management. Waste Manag. 2013, 33, 1926–1933. [Google Scholar] [CrossRef]

- EUR-Lex Access to European Union Law Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control) Text with EEA Relevance. Available online: http://data.europa.eu/eli/dir/2010/75/oj (accessed on 15 August 2022).

- Department for Environment Food & Rural Affairs. Energy from Waste A Guide to the Debate; Department for Environment Food & Rural Affairs: London, UK, 2014.

- Scharff, H. Landfill Reduction Experience in The Netherlands. Waste Manag. 2014, 34, 2218–2224. [Google Scholar] [CrossRef]

- Gharfalkar, M.; Court, R.; Campbell, C.; Ali, Z.; Hillier, G. Analysis of Waste Hierarchy in the European Waste Directive 2008/98/EC. Waste Manag. 2015, 39, 305–313. [Google Scholar] [CrossRef]

- Castillo-Giménez, J.; Montañés, A.; Picazo-Tadeo, A.J. Performance and Convergence in Municipal Waste Treatment in the European Union. Waste Manag. 2019, 85, 222–231. [Google Scholar] [CrossRef]

- Marconsin, A.F.; Rosa, D.D.S. A Comparison of Two Models for Dealing with Urban Solid Waste: Management by Contract and Management by Public-Private Partnership. Resour. Conserv. Recycl. 2013, 74, 115–123. [Google Scholar] [CrossRef]

- Tičar, B.; Zajc, K. Public-Private Partnerships in Slovenia: Recent Developments and Perspectives. Rev. Cent. East Eur. Law 2010, 35, 191–215. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G.; Chang, N. Bin Solid Waste Management in European Countries: A Review of Systems Analysis Techniques. J. Environ. Manag. 2011, 92, 1033–1050. [Google Scholar] [CrossRef] [PubMed]

- Thermelis, N.J.; Ma, W. Waste to Energy (WTE) in China: From Latecomer to Front Runner. Waste Dispos. Sustain. Energy 2021, 3, 267–274. [Google Scholar] [CrossRef]

- van Ewijk, S.; Stegemann, J.A. Recognising Waste Use Potential to Achieve a Circular Economy. Waste Manag. 2020, 105, 1–7. [Google Scholar] [CrossRef]

- Fiorentino, G.; Ripa, M.; Protano, G.; Hornsby, C.; Ulgiati, S. Life Cycle Assessment of Mixed Municipal Solid Waste: Multi-Input versus Multi-Output Perspective. Waste Manag. 2015, 46, 599–611. [Google Scholar] [CrossRef]

- Tejaswini, M.S.S.R.; Pathak, P.; Ramkrishna, S.; Ganesh, P.S. A Comprehensive Review on Integrative Approach for Sustainable Management of Plastic Waste and Its Associated Externalities. Sci. Total Environ. 2022, 825, 153973. [Google Scholar] [CrossRef]

- Allesch, A.; Brunner, P.H. Material Flow Analysis as a Decision Support Tool Forwaste Management: A Literature Review. J. Ind. Ecol. 2015, 19, 753–764. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD). Material Resources, Productivity and the Environment: Key Findings; OECD: Paris, France, 2011. Available online: http://www.oecd.org/greengrowth/MATERIAL_RESOURCES,_PRODUCTIVITY_AND_THE_ENVIRONMENT_key_findings.pdf (accessed on 15 August 2022).

- Fernández-González, J.M.; Grindlay, A.L.; Serrano-Bernardo, F.; Rodríguez-Rojas, M.I.; Zamorano, M. Economic and Environmental Review of Waste-to-Energy Systems for Municipal Solid Waste Management in Medium and Small Municipalities. Waste Manag. 2017, 67, 360–374. [Google Scholar] [CrossRef]

- Thorneloe, S.A.; Weitz, K.; Jambeck, J. Application of the US Decision Support Tool for Materials and Waste Management. Waste Manag. 2007, 27, 1006–1020. [Google Scholar] [CrossRef] [Green Version]

- Makarichi, L.; Techato, K.A.; Jutidamrongphan, W. Material Flow Analysis as a Support Tool for Multi-Criteria Analysis in Solid Waste Management Decision-Making. Resour. Conserv. Recycl. 2018, 139, 351–365. [Google Scholar] [CrossRef]

- Buttol, P.; Masoni, P.; Bonoli, A.; Goldoni, S.; Belladonna, V.; Cavazzuti, C. LCA of Integrated MSW Management Systems: Case Study of the Bologna District. Waste Manag. 2007, 27, 1059–1070. [Google Scholar] [CrossRef] [PubMed]

- Feo, G.; De Malvano, C. The Use of LCA in Selecting the Best MSW Management System. Waste Manag. 2009, 29, 1901–1915. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Tang, Y.T.; Sun, Y.; He, J. Assessing the Transition of Municipal Solid Waste Management by Combining Material Flow Analysis and Life Cycle Assessment. Resour. Conserv. Recycl. 2022, 177, 105966. [Google Scholar] [CrossRef]

- Chan, K.S.; Chan, H.K.; Zhang, T.; Xu, M. Proceedings of the 2020 International Conference on Resource Sustainability—Sustainable Urbanisation in the BRI Era, IcRS Urbanisation 2020; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 9789811596049. [Google Scholar]

- Anshassi, M.; Laux, S.J.; Townsend, T.G. Approaches to Integrate Sustainable Materials Management into Waste Management Planning and Policy. Resour. Conserv. Recycl. 2019, 148, 55–66. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A.; Himanshu, H.; Stobernack, N. Economic and Environmental Life Cycle Assessment of Organic Waste Treatment by Means of Incineration and Biogasification. Is Source Segregation of Biowaste Justified in Germany? Sci. Total Environ. 2020, 721, 137731. [Google Scholar] [CrossRef] [PubMed]

- World Bank Group. Innovative Finance Solutions for Climate-Smart Infrastructure: New Perspectives on Results-Based Blended Finance for Cities; World Bank Group: Washington, DC, USA, 2019. [Google Scholar]

- European Commission Industrial Emissions Directive. Available online: https://ec.europa.eu/environment/industry/stationary/ied/legislation.htm (accessed on 15 August 2022).

- United States Environmental Protection Agency (USEPA). Leaching Environmental Assessment Framework (LEAF) Methods and Guidance. Available online: https://www.epa.gov/hw-sw846/leaching-environmental-assessment-framework-leaf-methods-and-guidance (accessed on 15 August 2022).

| Category | Product | Products Included |

|---|---|---|

| Durables | Major appliances or white goods | Refrigerators, washing machines, and water heaters |

| Small appliances | Toasters, hair dryers, and electric coffee pots | |

| Furniture and furnishings | Sofas, tables, chairs, and mattresses | |

| Carpets and rugs | N/A | |

| Rubber tires | N/A | |

| Batteries, lead acid | Automobiles, trucks, and motorcycles | |

| Miscellaneous durables | Electronics and consumer electronics such as television sets, videocassette recorders, personal computers, luggage, and sporting equipment | |

| Non-durables | Newspapers/mechanical paper | N/A |

| Other paper | Brochures, reports, menus, invitations, posters, photographic papers, cards, and games | |

| Disposable diapers | Infant diapers and adult incontinence products | |

| Plastic plates and cups | Plastic plates, cups, glasses, dishes and bowls, hinged containers, and other containers used in food service at home, in restaurants and other commercial establishments, and in institutional settings such as schools | |

| Trash bags | High-density polyethylene and low-density polyethylene for both indoor and outdoor use | |

| Clothing and footwear | Textiles, rubber and leather are the major material components of this category, with some plastics present as well | |

| Towels, sheets, and pillowcases | N/A | |

| Other miscellaneous non-durables | The primary material component is plastics, although some aluminum, rubber, and textiles are also present | |

| Containers and packaging | Glass packaging | Beer and soft drink bottles, wine and liquor bottles, as well as bottles and jars for food and juices, cosmetics, and other products |

| Steel packaging | Steel food cans and other cans, and other steel packaging (e.g., strapping, and steel barrels and drums) | |

| Aluminum packaging | Beer and soft drink cans (including all carbonated and non-carbonated soft drinks, tea, tonic, waters and juice beverages), other cans, and foil and closures (including semi-rigid foil containers, caps, closures, and flexible packaging) | |

| Paper and paperboard packaging | Corrugated boxes, milk and juice cartons, and other products packaged in gable top cartons and liquid food aseptic cartons, folding cartons (e.g., cereal boxes, frozen food boxes, some department store boxes), bags and sacks, wrapping papers, and other paper and paperboard packaging (primarily set-up boxes such as shoe, cosmetic, and candy boxes) | |

| Plastics packaging | Polyethylene terephthalate (PET) soft drink and water bottles, high-density polyethylene (HDPE) milk and water jugs, film products (including bags and sacks) made of low-density polyethylene (LDPE) and other containers and packaging (including clamshells, trays, caps, lids, egg cartons, loose fill, produce baskets, coatings, and closures) made up of polyvinyl chloride (PVC), polystyrene (PS), polypropylene (PP), and other resins. | |

| Wood packaging | Wood pallets and wood crates | |

| Other miscellaneous packaging | Bags made of textiles and small amounts of leather |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bourtsalas, A.C.; Shen, T.; Tian, Y. A Comprehensive Assessment of Products Management and Energy Recovery from Waste Products in the United States. Energies 2022, 15, 6581. https://doi.org/10.3390/en15186581

Bourtsalas AC, Shen T, Tian Y. A Comprehensive Assessment of Products Management and Energy Recovery from Waste Products in the United States. Energies. 2022; 15(18):6581. https://doi.org/10.3390/en15186581

Chicago/Turabian StyleBourtsalas, A. C. (Thanos), Tianxiao Shen, and Yixi Tian. 2022. "A Comprehensive Assessment of Products Management and Energy Recovery from Waste Products in the United States" Energies 15, no. 18: 6581. https://doi.org/10.3390/en15186581

APA StyleBourtsalas, A. C., Shen, T., & Tian, Y. (2022). A Comprehensive Assessment of Products Management and Energy Recovery from Waste Products in the United States. Energies, 15(18), 6581. https://doi.org/10.3390/en15186581