1. Introduction

Nearly vertical and extremely thick coal seams are distributed in mining areas in Gansu, Xinjiang, and the southern part of China as well as in coal-producing areas such as Lorraine, France, and Asturias, Spain [

1,

2]. Intense geological movements caused the formation of regional fold and fault structures with large inclinations, among which some strata are vertical or overturned, forming nearly vertical coal seams with a strong residual tectonic stress state and complex coal-mining environments [

3]. Therefore, rock bursts occur in nearly vertical coal seam mines with shallow burial depths, such as the Gansu Yaojie Coal Mine, Xinjiang Tiechanggou Coal Mine, and Wudong Coal Mine [

4,

5,

6].

Compared with horizontal or gently inclined coal seams, nearly vertical and extremely thick coal seams result from unique rock deposition or geological tectonic movements, resulting in different deformation, destruction, energy distribution, and stress transfer characteristics [

7,

8]. Therefore, the rock burst mechanism of nearly vertical and extremely thick coal seams is different from that of horizontal or gently inclined seams.

A great deal of research has been carried out on rock burst problems of nearly vertical and extremely thick coal seams. He et al. [

9] revealed the evolution characteristics and laws of underground roadway excavation in nearly vertical coal seams through physical modeling experiments combined with infrared imaging and acoustic emission detection technology. Lai et al. [

10,

11] studied the roof deformation characteristics at a fully mechanized caving face in an extremely inclined and thick coal seam, established a mechanical model of the roof of the steeply inclined caving face, proposed that rock pillar instability is the main cause for rock burst in nearly vertical coal seams, and comprehensively analyzed the spatiotemporal evolution characteristics of the dynamic instability of a steeply inclined coal-rock mass in the Wudong Coal Mine [

12,

13]. Dou et al. [

6,

14] suggested that compared with horizontal coal seams, nearly vertical coal seams are under support pressure on both sides of the roof and floor and that stress concentration in such a coal mass is the cause of dynamic disasters. Lan Hang [

15] conducted a study on rock burst mechanisms during mining of a nearly vertical and extremely thick coal seam with the horizontal slicing method, analyzed the “pry bar effect” of goaf pillars on both sides of the coal mass, and obtained its expression. He et al. [

16,

17] studied rock burst mechanisms in steeply inclined and extremely thick coal seams, proposed that the combination of the high static stress of the coal mass and induced stress of the pillar failure led to the occurrence of rock bursts, and investigated the spatiotemporal evolution of microseismic and acoustic emissions for the early warning of rock bursts in steeply inclined mines. Wang et al. [

18] analyzed the process of mining steeply inclined and extremely thick coal seams, suggesting that coal seam roof fracture often causes rock burst failure in stope roadways during mining and that rock burst roadways consequently need to be reinforced. Cao et al. [

19] studied rock burst mechanisms in steeply inclined coal seams of the Yaojie No. 3 Mine and proposed that when the sum of static stress and dynamic stress exceeds the critical stress of the coal seam, rock burst failure occurs in the coal seam. Zhang et al. [

20] studied the energy distribution characteristics in the suspended roof structure of a steeply dipping and extremely thick coal seam in the Jingyuan Wangjiashan Coal Mine and concluded that the transfer and accumulation of elastic energy in the advanced top plate is the main cause of rock bursts in the roof. Zhang et al. [

21,

22] determined that rock bursts in the south mining area of the Wudong Coal Mine mainly occur in high-stress and high-stress-gradient zones with the geodynamic zoning method.

Although there have been some studies on the rock burst mechanisms of nearly vertical coal seams, due to the complexity of rock bursts and the particularity of the geological environment and mining conditions of the nearly vertical coal seams of the Wudong Coal Mine, research on the rock burst mechanism of these coal seams is still in progress, as further research is necessary. In this study, field testing, theoretical analysis, and numerical simulation methods are used to analyze the bending effect of the roof and the middle rock pillars of the nearly vertical extra-thick coal seams in the southern mining area of the Wudong Coal Mine, to study the elastic energy accumulation in the coal-rock mass, and to analyze the rock burst mechanism in terms of energy.

2. Engineering Background

2.1. Geological and Mining Conditions

The south mining area of the Wudong Coal Mine is located in the south wing of the Badaowan syncline, the southeast section of the Huainan coalfield, exhibiting a monoclinal structure inclined to the south. The B1+2 and B3+6 coal seams (with average thicknesses of approximately 37 m and approximately 48 m, respectively, and an inclination of 87°) in the Lower Xishanyao Formation, which are nearly vertical and extremely thick coal seams, are mined simultaneously, as shown in

Figure 1. Mainly, sandstone with thin mudstone and coal layers is sandwiched between the two groups of coal seams, gradually thinning from east to west, with a thickness of 110~53 m. Upon completion of mining in the two groups of coal seams, loess and miscellaneous fill were used to backfill the mining goafs, and vertical rock pillars were formed in the nearly vertical rock layers between the two groups of coal seams; simultaneous mining was carried out in the two groups of coal seams. Taking the coal mine at the +475 level and a depth of approximately 375 m as the engineering background, this paper analyzes its rock burst mechanism.

Top-down mining was carried out in the nearly vertical coal seam of the mine using sublevel, fully mechanized top coal caving mining technology, with a mining level height of 25 m, a coal cutting height of 3 m, and a coal drawing height of 22 m. A mining roadway was excavated for the next level while mining was carried out at the current level. Mining roadways were arranged in the coal seams, as shown in

Figure 1. Upon completion of mining in the upper part, the mining goafs were backfilled with loess (but not fully filled). The strike length of the caving face of both the B1+2 and B3+6 coal seams was 2500 m. The shallow resources of the B3+6 coal seam at 100~1300 m were previously extracted by small coal mines, exhibiting insufficient mining and nonapparent surface subsidence, and boundary protection coal pillars were left on both sides of previous small coal mines above the current mining level. Rock bursts frequently occurred near the protection coal pillars.

2.2. Distribution Characteristics of Crustal Stress

Nearly vertical or steeply inclined coal seams are frequently formed during particular geological tectonic movements, and thus, their regional tectonic stresses are unique and closely related to the tectonic movements. Rock bursts occur at shallow mining depths of the mine, which must be related to its geological structure and crustal stress distribution. The studied mine is located in the second-level tectonic belt of the Tianshan latitudinal tectonic system, which is the secondary fault-fold zone of the second-level tectonic belt. The intense geologic process of the Tianshan orogeny and uplift of Mount Bogda promoted the compression of strata at the northern foot of the Tianshan Mountains, resulting in a series of faults and folds [

23,

24]. The southern mining area of the mine is located in the transition zone from the western to eastern sections on the north side of the Tianshan Mountains. There, the maximum horizontal principal stress is nearly S–N compressive stress. The hollow inclusion gauge method was used to measure the in situ crustal stress at the +475 level, obtaining a maximum horizontal principal stress

σH of 15.19 MPa, a minimum horizontal principal stress

σh of 10.38 MPa, and a vertical principal stress

σv of 8.18 MPa. The maximum horizontal principal stress was 1.9 times the vertical principal stress, indicating that horizontal tectonic stress is dominant in this area. The azimuth of the maximum horizontal principal stress was measured to be N21.6°W, approximately 82° from that of the working seams and stoping roadways.

The linear equations of the relationships between the crustal stresses and mining depth were regressed based on crustal stress test results.

The test results showed that the crustal stress field of the mine near the +475 level was such that σH > σh > σv. The maximum horizontal principal stress is nearly S–N compressive stress, oriented nearly 90° from the caving face strike, which has an extremely negative effect on the stability of the roadways and middle rock pillars.

3. Rock Burst Characteristics

The coal seams of the mine are nearly vertical and influenced by middle rock pillars and crustal stress. The dynamic release of rock bursts from coal seams has distinctive features.

(1) Dynamic phenomena occurred when mining was carried out at a certain depth. The frequency and energy of the dynamic phenomena increased significantly with increasing mining depth. The dynamic phenomena started when mining was carried out at the +545 level (a burial depth of approximately 300 m) and increased at the +522 level, with a low frequency and destructiveness. When the mining depth reached the +500 level, three larger dynamic phenomena appeared to severely damage the roadways, indicating that rock bursts were aggravated when a mining level was increased from a burial depth of 300 m to a burial depth of 350 m.

(2) Rock bursts frequently occurred below coal pillars. Two rock bursts and one rock burst occurred at the +500 level and +475 level, respectively, above which unmined coal pillars were left in the mining goaf of the B3+6 coal seam; that is, coal was not mined at the upper parts of these mining levels.

(3) Stoping roadways were seriously damaged on a large scale. The rock pressure occurred beyond burial depths of 200 m and 400 m during two rock burst events in roadways of the B3+6 coal seam at the +500 level, exhibiting various degrees of floor heave, sidewall heave, and roof settling in corresponding sections of both stoping roadways. In addition, the drivage roadways at the level of +475 m suffered different degrees of large deformation and damage (see

Figure 2).

4. Bending Effect of Middle Rock Pillars

Based on the unique geological conditions of the coal seams, a rock wall with a length of 2500 m and a height of 350 m, i.e., the middle rock pillars, was formed upon completion of mining in the B1+2 and B3+6 coal seams. The stability of middle rock pillars was greatly influenced by the fact that the mining goafs on both sides were not densely filled. Among the residual coal pillars in the overlying space of the B3+6 coal seam, the middle rock pillars were bent due to compression by the coal pillars and their initial 3° inclination angle. The mechanical behavior of the rock pillars was directly related to the stability of the underlying seams; thus, it is necessary to analyze the bending effect of rock pillars.

4.1. Energy Concentration in a Rock Pillar

When mining in coal seams, when both sides reach a certain depth, rock pillars can bend under their own gravity G and the lateral horizontal stress of coal pillars, as in the B3+6 coal seam, due to their own inclination. Here, the stress on rock pillars was analyzed to study the bending effect and energy concentration and distribution characteristics of the rock pillars. Since most rock bursts of the B3+6 coal seam occurred near coal pillars, middle rock pillars compressed by coal pillars above mining levels were studied. Assuming that fixed supports were arranged below the mining levels and that mining on both sides of rock pillars has been carried out to a certain depth, a model with rock pillars can be simplified as cantilever beams for calculation, as shown in

Figure 3.

Assuming that rock pillars have an inclination angle α and are subjected to gravity G in the vertical direction, compression force q1 of the B3+6 coal pillars in the horizontal direction, and lateral pressure q2 of backfill soil in the B1+2 mining goaf, both q1 and q2 linearly increase with the increase in mining depth. G is the gravity per unit length of the rock pillar, H is the vertical depth at the mining level, and L is the slant height of the rock pillars.

For a section with a length of

x at the top end of the cantilever beam, the section method is used to calculate the resultant force perpendicular to the beam at the location of

x:

where

. The equation of the bending moment is:

where

is the bulk density of middle rock pillars.

q1 is controlled by the maximum principal stress, with an angle of 82° from the strike of the coal seams and rock pillars:

q2 is the lateral pressure of the backfill soil in the B1+2 mining goaf,

where

is the bulk density of the backfill soil.

is Poisson’s ratio of the backfill soil.

This shows that the greater the mining depth

H, the greater the maximum value of

x and the greater the bending moment near the mining levels caused by the middle rock pillars, that is, the greater the bending effect. In addition, when

q1 increases, the bending effect of middle rock pillars increases. The increase in the mining depth and the inclination of the B3+6 roof toward the goaf will both cause an increase in

q1. When rock pillars are bent, elastic energy is concentrated in the rock mass. The amount of elastic energy in the rock pillars can be obtained from Equation (6).

where

E is the elastic modulus, and

I is the moment of inertia.

By substituting Equations (4) and (5) into Equation (6) and integrating, the rock pillar bending strain energy per unit length can be obtained from Equation (7).

Equation (7) indicates that the bending strain energy is related to the depth of mining, horizontal stress of the coal pillar, and inclination of the rock pillar. With the inclination unchanged, the bending strain energy of a rock pillar increases dramatically with the increases in the mining depth and coal pillar horizontal stress.

4.2. Energy Distribution Characteristics of a Rock Pillar

Based on the test results of the crustal stress and rock mechanical properties as well as the actual situation at the site, the values of each parameter in Equation (7) are given in

Table 1.

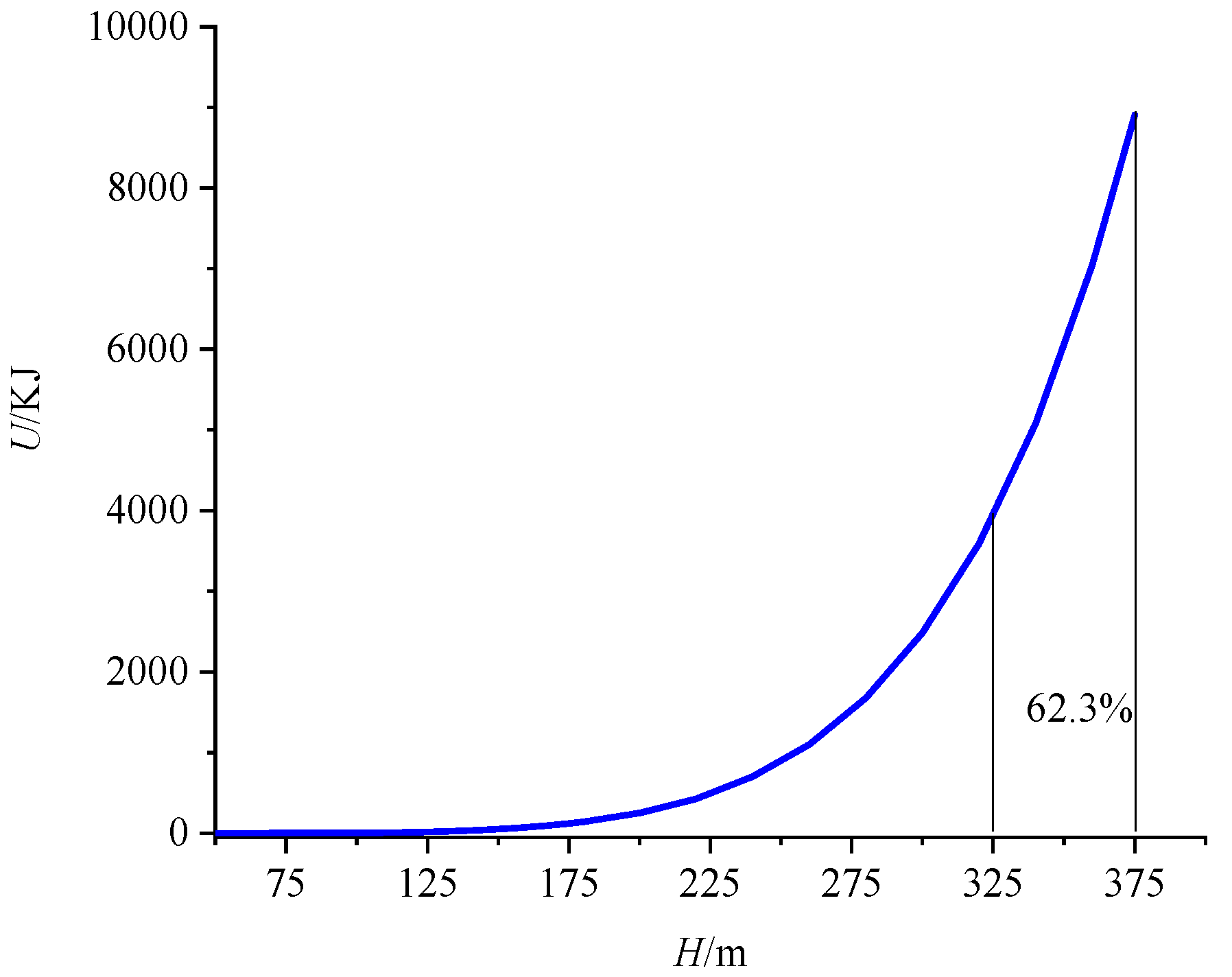

By substituting the above values into Equation (7), the distribution characteristic curves of the bending strain energy U of nearly vertical rock pillars can be obtained, as shown in

Figure 4.

Under the action of horizontal asymmetric loads and gravity, bending strain energy is stored in rock pillars during mining and nonlinearly distributed with the increase in the mining depth of rock pillars. The greater the mining depth, the faster the strain energy increases. Taking the +475 level as an example, the mining depth was 375 m, and the bending energy was mainly concentrated within 50 m above the mining level, reaching 62.3% of the total bending strain energy. When rock pillars were inclined to the side of the B1+2 mining goaf, their cantilever length increased with the increase in mining depth, and some bending elastic energy accumulated in the rock pillars. In the case of local instability upon intense mining disturbances, the threshold of system dynamic instability was easily reached, resulting in rock bursts.

4.3. Stress Distribution Characteristics in Coal Seams under the Bending Effect of Rock Pillars

To study the bending effect of rock pillars on the stress distribution characteristics of coal seams, FLAC 3D software is used for numerical simulation calculation. Based on in situ mining conditions, a three-dimensional geological calculation model is established. The x, y, and z lengths of the model are 676 m, 500 m, and 556 m, respectively, as shown in

Figure 5. Both the bottom and y direction displacements of the model are fixed. According to crustal stress test results, stress conditions are applied in the x direction of the model to two boundaries, and self-weight stress is obtained in the vertical direction. The mechanical parameters of each rock stratum are determined based on laboratory test results, as shown

Table 2. The Mohr–Coulomb criterion is used in the model.

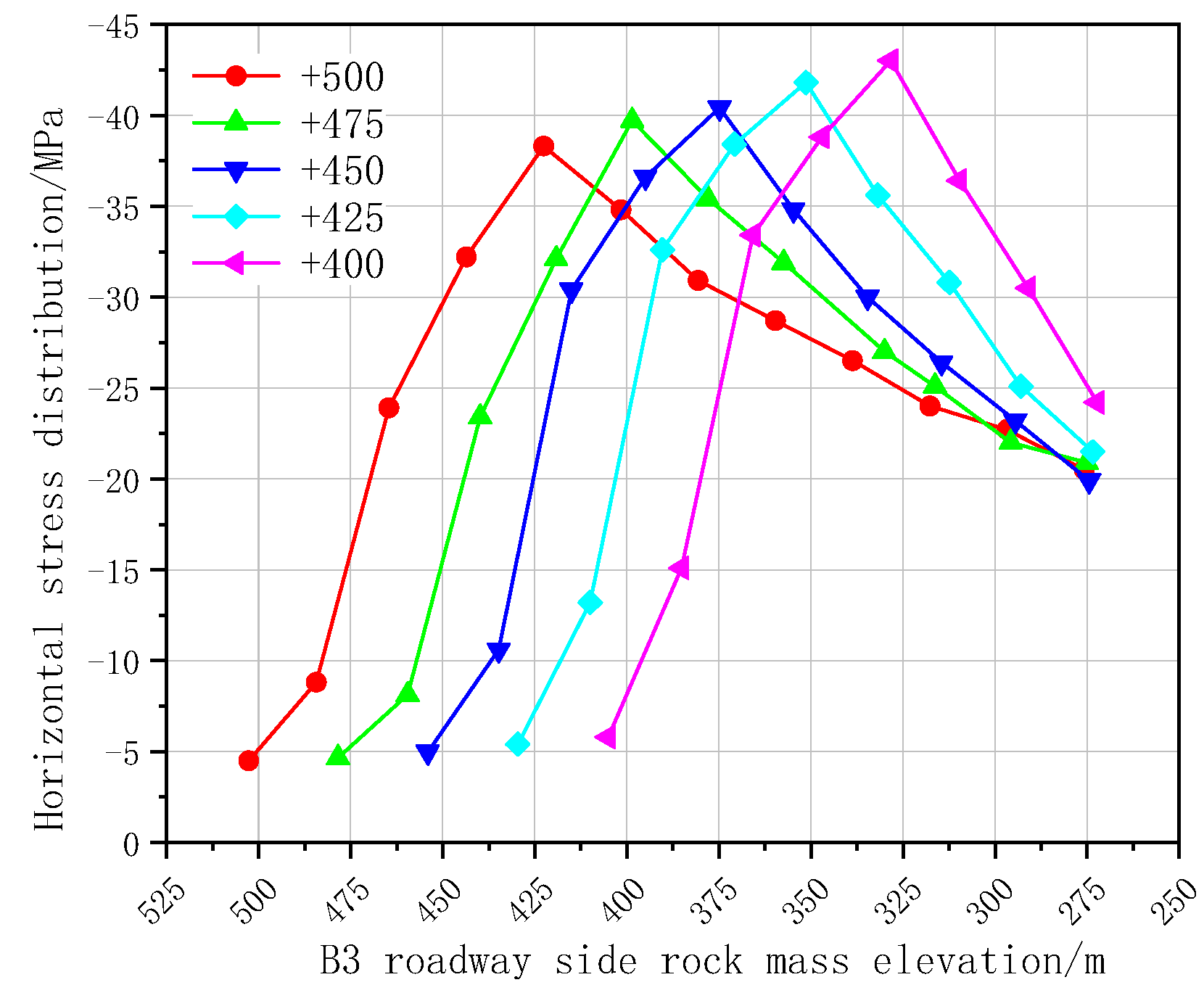

When the model simulates mining at the +475 level, equilibrium is calculated based on the initial conditions, and the horizontal stress distribution in the coal-rock mass under static force is obtained, as shown in

Figure 6.

Figure 6 shows that in a static pressure state, stress concentration areas occurred within 50~70 m below the +475 level, and the horizontal stress reached approximately 35 MPa. Compared with the stress of the primary rock, the stress concentration coefficient reached 2.4. Stress was concentrated across two coal seam groups, the roof and floor, and the middle rock pillars. The main reasons for this are as follows. First, this stratum had a dip angle of 87° and was nearly vertical. Unlike a gently inclined coal seam roof, the B3+6 coal seam roof would not periodically collapse with continued coal seam mining but formed a large roof stratum with a height of 375 m, bent, and tilted to the B3+6 goaf, exerting a strong compression effect on the unmined coal seam at the bottom. Second, the in situ stress was relatively high, with a nearly vertical angle to the strike of the stratum, which increased the inclination of the B3+6 coal seam roof rock to the goaf, aggravated the compression effect on the coal seam, and was conducive to stress accumulation after coal mining. Third, the middle rock pillars formed a vertical rock wall after mining on both sides, which exerted a bending effect under the action of the asymmetrical horizontal stress on both sides of the rock pillars, a back bending effect, and violent compression on the B3+6 coal seam. Under the bidirectional compression of the B3+6 coal seam roof and middle rock pillars, the stress of the coal-rock mass within 50 m below the mining level was high. Moreover, it can be predicted that the stress concentration coefficient in the stress concentration zones will increase with increasing mining depth.

Figure 7 shows the distribution curves of horizontal stress at the junction of the B3+6 coal seam and middle rock pillars at the +500~+400 mining levels; due to reverse bending and compression of the rock pillars, the horizontal stress in the coal mass below the mining level increased sharply, reaching a peak approximately 50 m below the mining level. With the increase in mining level, the peak stress increased. At the +400 mining level, the peak horizontal stress was approximately 45 MPa. Clearly, the bending effect of the middle rock pillars induced a large concentration of stress below the mining level, resulting in a substantial accumulation of elastic energy in the coal-rock mass. Meanwhile, as mining was carried out in stages, in which each mined section was 25 m high, the roadway for the next section was prepared in a high stress environment, and the stress was redistributed after roadway drivage, further increasing the roadway surrounding rock stress. Under these conditions, instability was more likely to occur under horizontal mining disturbances.

5. Energy Mechanism of Rock Burst Instability

The instantaneous release of a considerable amount of energy accumulated in a coal-rock mass causes rock burst disasters. A coal-rock mass exhibits quasistatic deformation before rock burst and returns to a new equilibrium after rock burst. The Dirichlet criterion is generally used to determine the stability of the equilibrium state of a deformation system. This criterion holds that the system is in stable equilibrium at the minimum total potential energy but in an unstable equilibrium at the maximum total potential energy [

25].

Surrounding rock undergoes elastic deformation under stress; thus, elastic energy accumulates in rock, which plays an important role in the mechanical behavior of rock. The energy consumed by rock failure is entirely derived from the elastic deformation energy accumulated in rock at earlier stages. In the case of a large elastic deformation energy at earlier stages, residual energy will be released in the form of kinetic energy upon rock failure. The elastic energy accumulated at earlier stages is equal to the work done by external forces or corresponding displacements [

26]. Such energy drives rock dynamic phenomena.

Research has shown that when the initial speed of a crushed coal-rock mass ejected into free space does not exceed 1 m/s, rock bursts do not occur. Rock bursts are more likely to occur when this initial speed is at least 10 m/s. When a rock burst occurs, the required energy comprises the energy for crushing the coal-rock mass per unit and the minimum kinetic energy for ejecting the crushed material. When the amount of elastic energy accumulated per unit of coal-rock mass exceeds the sum of the two, rock burst may occur [

22]. Therefore, the critical energy density when rock burst occurs is described by Equation (8).

The energy of a rock mass can be expressed by the strain energy index of the rock mass and calculated by quantification based on the strain energy density. Assuming that a cube with a side length of

a is taken from the surrounding rock in mining space, which is internally isotropic with principal stresses of

σ1,

σ2, and

σ3; corresponding strains of

ε1,

ε2, and

ε3; and an elastic modulus of

K, according to the theory of elastic mechanics [

14], the equation of the strain energy density of an elastic element body under the action of a three-dimensional principal stress state is obtained as follows:

Based on the numerical simulation results in

Section 4.3, the values of

σ1,

σ2, and

σ3 at each node in the maximum stress concentration plane were obtained, and the strain energy density of the coal-rock mass at each node in the plane was calculated by Equation (9). Then, Surfer software was used to draw a three-dimensional diagram of the energy density, as shown in

Figure 8. Test results of the coal-rock physico-mechanical properties showed that the strength of the B3+6 coal seam was 13.65 MPa, the elastic modulus

E was 2008 MPa, and the natural density was 1371 kg/m

3. Calculated by Equation (8), the critical energy density of rock burst in the Wudong Coal Mine was 1.15 × 10

5 J/m

3. The energy density of the coal mass in high-stress zones exceeded the critical energy density when rock burst occurred. Meanwhile, the system became unstable as a large amount of elastic energy accumulated in the middle rock pillars and both sides of the coal mass under the bending effect.

Therefore, a higher stress existed in the zones below the mining levels under the action of static pressure, and a large amount of elastic energy was accumulated in the coal mass. The mine employed fully mechanized mining technology appropriate for a tall mining height. During mining, strong disturbances occurred and had a great effect on the stability of the B3+6 roof, middle rock pillars, and high-stress coal mass. The coal mass was under high-stress conditions and was in the process of dynamic loading and unloading, which easily caused rock bursts.

6. In Situ Microseismic Monitoring

The mine was equipped with an ARAMIS microseismic monitoring system to further analyze the activity of coal seams and assess the stability of rock pillars. By projecting microseismic events that occurred over a period of time onto a plane, the relationship between microseismic activity and stoping space can be clearly reflected. A total of 189 microseismic events near the B3+6 stoping face were recorded in 10 days, averaging 19 microseismic events a day, thus showing a relatively high frequency.

Figure 9 is a plane projection of the microseismic events with energies greater than 10

4 J, showing that microseismic events mainly concentrated near stoping faces.

Figure 10 shows that all microseismic events occurred vertically near mining levels, the vast majority of which were distributed within 50 m from the mined coal mass, while there were almost no microseismic events in other zones. Moreover, microseismic events developed as the mining in the caving face progressed, indicating that the rock pillars with a considerable amount of bending strain energy were unstable under the effect of mining dynamic disturbances and that rock bursts were prone to occur during stoping with dynamic loading and unloading.

7. Conclusions

(1) The nearly vertical coal seams of the Wudong Coal Mine are located in a unique tectonic stress field at the northern foot of the Tianshan Mountains. The angle between the horizontal maximum principal stress and the strike of the coal seam and the middle rock pillars is 82°, and the in situ stress has a great influence on the stability of the coal seam. The middle rock pillars are bent toward the B1+2 goaf due to the horizontal pushing action of the B3+6 high-stress coal pillars, a large amount of bending energy is accumulated near the mining level, and the rock pillars are in an unstable state.

(2) The B3+6 coal seams are subject to inclination extrusion of the roof and reverse bending extrusion of the middle rock pillars, resulting in stress concentration approximately 50 m below the mining level. The concentration factor is approximately 2.4, causing a large amount of elastic energy to accumulate in the coal and rock mass. The energy principle and numerical calculation results indicate that in the B3+6 stress concentration zone, the energy density of the coal mass reached or exceeded the critical energy density before the rock burst occurred, and the coal mass was in unstable equilibrium, which easily caused instability failure.

(3) The vertical segmented top coal-mining process greatly disturbs the B3+6 coal and rock mass, which is under high-stress conditions. This disturbance constitutes the dynamic load condition for inducing rock burst. In situ microseismic test results show that high-energy microseismic events were mainly concentrated in the middle rock pillars near the mining levels and in the coal mass in the high-stress concentration zones, indicating that rock bursts were prone to occur in the middle rock pillars where a high amount of energy had been concentrated under mining disturbances.