1. Introduction

High energy demand and high reliability requirements increase the importance of distributed generation power systems for the stable and energetically safe operation of each sector of industry.

The increasing number of electricity sources that cannot be efficiently managed can create a risk of an imbalance between the production and consumption of electricity. It can result in a dangerous deviation of the grid frequency from the nominal value and the consequent breakdown of the power system into island systems or a complete power outage, i.e., a blackout.

To overcome these challenges, renewable energy sources (RES) based on distributed generation power systems can help to achieve energy autonomy of individual industrial units.

One of the highest energy-consuming processes in industry is the wastewater treatment (about 1% of the total energy consumption of a country in Europe and 4% in the USA [

1,

2]), and its energy demand is increasing considerably due to the introduction of more restrictive standards on the quality of water effluents, which require advanced technologies for pollutant removal.

Wastewater treatment plant (WWTP) electric energy accounts for 25–40% of total operating costs, of which 50 to 60% are connected to sludge treatment [

3]. Wastewater treatment plants are dependent on electricity supplies, and any a long-term outage can result in deteriorating quality of discharged wastewater and non-compliance with discharge limits.

In some WWTPs, the event of a power outage may cause the emergency discharge of wastewater directly to a recipient (usually a river) in 6–8 h. This discharge will occur immediately if there is heavy rainfall during this period. Exact data on the possible amount of untreated water discharged during a blackout are not available. They depend on the capacity and the usual amount of treated wastewater of each individual wastewater treatment plant. Longer power outages may result in significant river pollution and also technological difficulties in the WWTP, which can reduce treatment efficiency even after the end of the outage. The cause of this is sedimentation and decay of the activated sludge in the activation tank, which occurs after about 12–16 h. Without the supply of new wastewater not passing through the wastewater treatment plant equipment as a result of the blackout, the activated sludge would eventually die. When the function of the electrical distribution system is restored, the subsequent regeneration of the dead sludge would take approximately 3 weeks to achieve the ability to remove pollution [

4,

5].

There are a lot of wastewater pumping stations on the sewerage network. In the case of a blackout, untreated wastewater would flow directly from those stations into a recipient. This would occur after running out of the accumulation capacity of the pumping sumps and the gravitational part of the sewerage network after approximately 4–6 h. If the wastewater pumping stations do not have an emergency bypass to the recipient, the surroundings would be flooded in those 4–6 h. The extent would also depend on the intensity of possible precipitation. Flooding would lead to significant property damage in the area. In smaller sewerage systems, it is possible to ensure the removal of accumulated wastewater from pumping stations using special transport equipment to functional wastewater treatment plants. However, these have only limited capacity. However, the logical consequence of blackout can also be a significant decrease in wastewater production due to interruption of drinking water supply [

6,

7,

8].

Therefore, it is necessary to secure the supply of electricity for the wastewater treatment process by using local energy sources, including renewable ones, and ensuring the reliability of their power supply. The paper discusses the associated challenges and suggests directions based on Czech conditions.

Resilience to power outages can be improved by reducing energy needs and installing a local power source. For example, the Water and Sewer Department in Stockbridge, Massachusetts saved more than 60% in annual electric costs by installing electronic ballast lighting and heat pumps [

9]. Among the power sources that can be installed in WWTPs the most common solution involves diesel engine-generators. However, they can be used for small WWTPs and are sources of significant air pollution. Therefore, nowadays they are being replaced by renewable energy sources such as biogas and/or photovoltaics with or without battery storage [

10]. Biogas is the most frequently used renewable source in WWTPs [

10,

11]. The combined generation of heat and power from biogas is a very profitable technology for WWTPs [

12]. However, this technology is advantageous only for larger WWTPs [

13], and even their electricity production is only rarely sufficient to meet 100% of WWTP electricity consumption [

14]. However, the combination of biogas from sewage sludge and food waste can be enough to achieve energy-autonomy [

15]. This is described in detail in

Section 4. Therefore, it is important to find other renewable energy sources, not only for smaller WWTPs, but also for larger plants. Biogas as a combined heat and power source is described in more detail in

Section 3.1.

Other renewable energy sources can be generated from external sources or recovered from the energy embedded in wastewater [

16]. Among the external sources, mostly solar and wind power can be used [

1,

17]. These two sources are very dependent on WWTP location. To install wind power plants, various permissions are needed because they influence their surroundings, which is a big disadvantage. Solar power installed on the roofs of a WWTP could supply almost 80% of the electricity consumption of a WWTP located in China according to a theoretical study [

15]. Therefore, solar power has great potential and will be described in this article in more detail in

Section 3.3,

Section 3.4 and

Section 4. A small percentage of WWTPs can use hydropower [

16]. Hydropower technology uses energy from water flow. However, the available head (or pressure) and flow rate limit their use to a small number of locations [

16].

2. Wastewater as Part of the Critical Infrastructure Legislation in Czechia and Poland

In the Czech Republic, critical infrastructure (CI) includes elements for which disruption would have a serious impact on the security of the state, influence the basic living needs of the population, the health of people, or the economy of the state. In the field of water management, the following sectors are [

18]:

Drinking water and process water supply;

Securing and maintenance of surface and ground water;

Wastewater system (wastewater treatment plants, wastewater pumping stations).

Protection of critical infrastructure is a subject of critical management and must be ensured by preventive and mitigating measures, preparedness of services, resources, facilities and equipment for handling disasters and especially targeted attacks on critical infrastructure, as well as the ability to handle critical situations. Fast recovery should also be secured.

In the case of a lockdown, which can happen during an epidemic of some disease (e.g., COVID-19), elements of critical infrastructure should remain in operation.

In the Czech Republic, there is a ‘National Energy Resilience Program’ in which the so-called strategic objects are determined from the point of view of the power supply and are divided into four levels according to their priority of power supply. The highest priority level (1st level) includes objects for which interruption of power supply would mean interruption of drinking water supply, e.g., water treatment plants and water tower pumping stations. The second level includes wastewater treatment plants and wastewater pumping stations [

18].

Poland considers as critical infrastructure those physical or virtual systems that are important for securing necessary minimum of operation in economics and government. Water supply systems are among the elements of critical infrastructure in Poland in the area of water management.

The following sectors of water management are part of the critical infrastructure of the EU [

18]:

Compared to the EU, the Czech Republic has implemented a service of process water supply and a wastewater system. None of the CI facilities in the Czech Republic in the field of water management are of such international importance to be also part of European critical infrastructure [

19].

A CI entity represents the operator of the critical infrastructure element if it is the operator of a European Critical Infrastructure element considered to be a European Critical Infrastructure entity. The CI entity is obliged to determine a special security employee who provides cooperation on behalf of the CI entity in the performance of tasks pursuant to the Crisis Act.

The CI entity is responsible for the protection of the CI element, and for this purpose, prepares a crisis preparedness plan of the CI entity. This plan identifies possible threats to the function of the CI element and sets out measures to protect it.

The operator of the wastewater system is therefore responsible for the system, including wastewater treatment plants and wastewater pumping stations, even in the case of a blackout. WWTPs face a fine for discharging polluted untreated wastewater.

3. Alternative Sources of Electricity as Solutions for Blackout in WWTPs

All water companies in the Czech Republic must ensure a supply of drinking water in the event of crises and emergencies. Therefore, they should have a Crisis Preparedness Plan. This must include a risk analysis, an assessment of the impact of risks on the company’s operations and tools for eliminating or at least mitigating these impacts. Because a blackout is already a real risk, most companies have developed a “Blackout Power Supply Plan”, with crisis response workflows. In recent years, some companies have also undergone regular exercises to check the readiness of processes and to verify plans and procedures. These practical exercises provide additional suggestions for improving technical measures and updating blackout plans.

Among the more important consequences of blackouts are threats to the process of water purification technology. This process is very demanding on electricity consumption. Pumps and other processes are very energy demanding, and is it possible, in the case of a long-lasting blackout, to choose which process is urgent and which can be reduced. The processes follow each other, and it is often not technologically possible to omit anything. Water may flow through the system by gravity, so that the flow is possible without pumps but this is not always the case.

From the point of view of electricity consumption, many WWTPs are not operated in an optimal energy mode. There are even several ways to improve the existing energy balance. This involves optimizing the consumption of individual electrical appliances (turbochargers, pumps, etc.), changing the technology, or increasing biogas production. Moreover, thermal energy can be used to run pumps, to heat buildings, to run technological processes, and for drying sludge [

20].

All alternative sources of electricity must be located in the WWTP area so that they can supply WWTP during a blackout. They must be able to go over to island operation, which means disconnection from the electrical distribution system, and they must be able work independently, regardless of the state of the electrical distribution system.

3.1. Diesel Engine-Generators

For smaller wastewater treatment plants, the most common solution is the use of petrol or diesel engine-generators. These can be stationary (generators with outputs of several tens of kVA are commonly used) or portable power generators of smaller output (a few kVA) in the case of the smallest WWTPs. Starting diesel engine-generators must be initiated from the outside. Therefore, each emergency power supply should include an automatic start switchboard that continuously monitors voltage parameters in the network and, at their out-of-tolerance values, automatically connects the voltage to the starter of the diesel engine-generator [

7].

In the case of large wastewater treatment plants (over 100,000 population equivalent PE), these would need to have a generator with large output power (e.g., 10 MVA). This is a very costly requirement, which may not be affordable. One option would be to connect multiple generator units at once. However, this is not an economic solution. Another option is to install a suitable spare power supply with the required power, ensuring function of at least part of the turbochargers. Then, the activated sludge would not decay immediately, but after, for example, 20 days. However, there would be a gradual suppression of biogas production in the digestion tanks. Due to the impossibility of maintaining the required temperature in the digestion tanks, biogas production would eventually stop completely [

4]. At present, diesel engine-generators are the most common equipment for securing an alternative source of electricity used at WWTPs, not only in the Czech Republic but also in Poland. Diesel engine-generators have many advantages; they are mobile, they can start operation immediately, their acquisition costs are not so high, and their operation is easy. However, there must be enough fuel available, which may not always be possible during a long-lasting blackout [

4].

3.2. Combined Heat and Power Units with the Use of Biogas

Another solution is the use of biogas as a fuel as combined heat and power source (CHP). Biogas in the WWTP is formed during the anaerobic digestion of sewage sludge. During a blackout, some WWTPs may switch to island operation for a certain period of time. During this time, they may produce electricity and heat from biogas for their own consumption and possibly other operations (e.g., WWTP in České Budějovice). The wastewater fed to the WWTP first undergoes mechanical pretreatment [

21]. Water free of coarse impurities flows into primary settling tanks. Here, sedimentable insoluble substances sediment. The captured primary sludge is then concentrated and discharged to digestion tanks where biogas is developed. From the primary settling tanks the wastewater flows to a selector before the anaerobic section of the activation process (biological treatment). As part of biological treatment, wastewater passes through anaerobic sections (without air access) and then aerobic sections (with the presence of oxygen). Air must be blown into the aerobic section using turbochargers, which is the most energy-demanding part of the WWTP. In both sections, bacteria are used that break down organic water pollution in their metabolism. After the activation process, a mixture of secondary sludge and wastewater flows into secondary settling tanks. Secondary sludge is drawn from the bottom of the tanks and treated wastewater goes through the overflow for drainage. The sludge in the digestion tanks is anaerobically stabilized. To improve the efficiency of biogas production, other materials can also be used [

22,

23]. The sludge in the digestion tanks must be heated to a temperature of approximately 38° C. The biogas produced is stored in gas tanks and gradually utilized. The digested sludge is then dehydrated, sanitized and can be used as fertilizer in agriculture [

24,

25] or after the stabilization process for land rehabilitation [

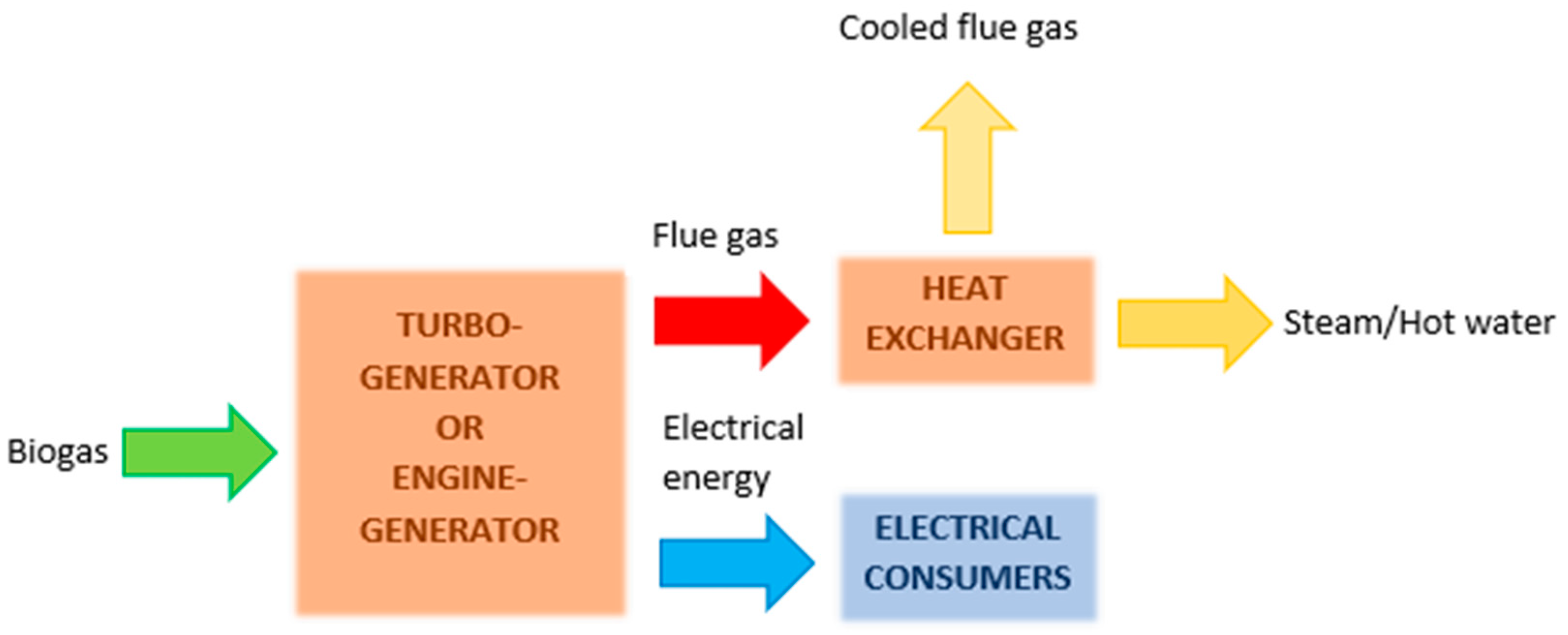

26]. Fortunately, biogas is no longer released into the atmosphere, and most WWTPs in the Czech Republic utilize it for combined heat and power production in cogeneration units. This produces heat that is consumed for in the WWTP technology for heating of digestion tanks, and for heating other objects within the WWTP. The cogeneration unit also produces electricity that the WWTP uses for its operation, and thus reduces operating costs. The overall efficiency of energy conversion contained in biogas is reported to be around 86% (36% electrical and 50% thermal). This varies slightly from manufacturer to manufacturer. A diagram of a cogeneration unit is presented in

Figure 1.

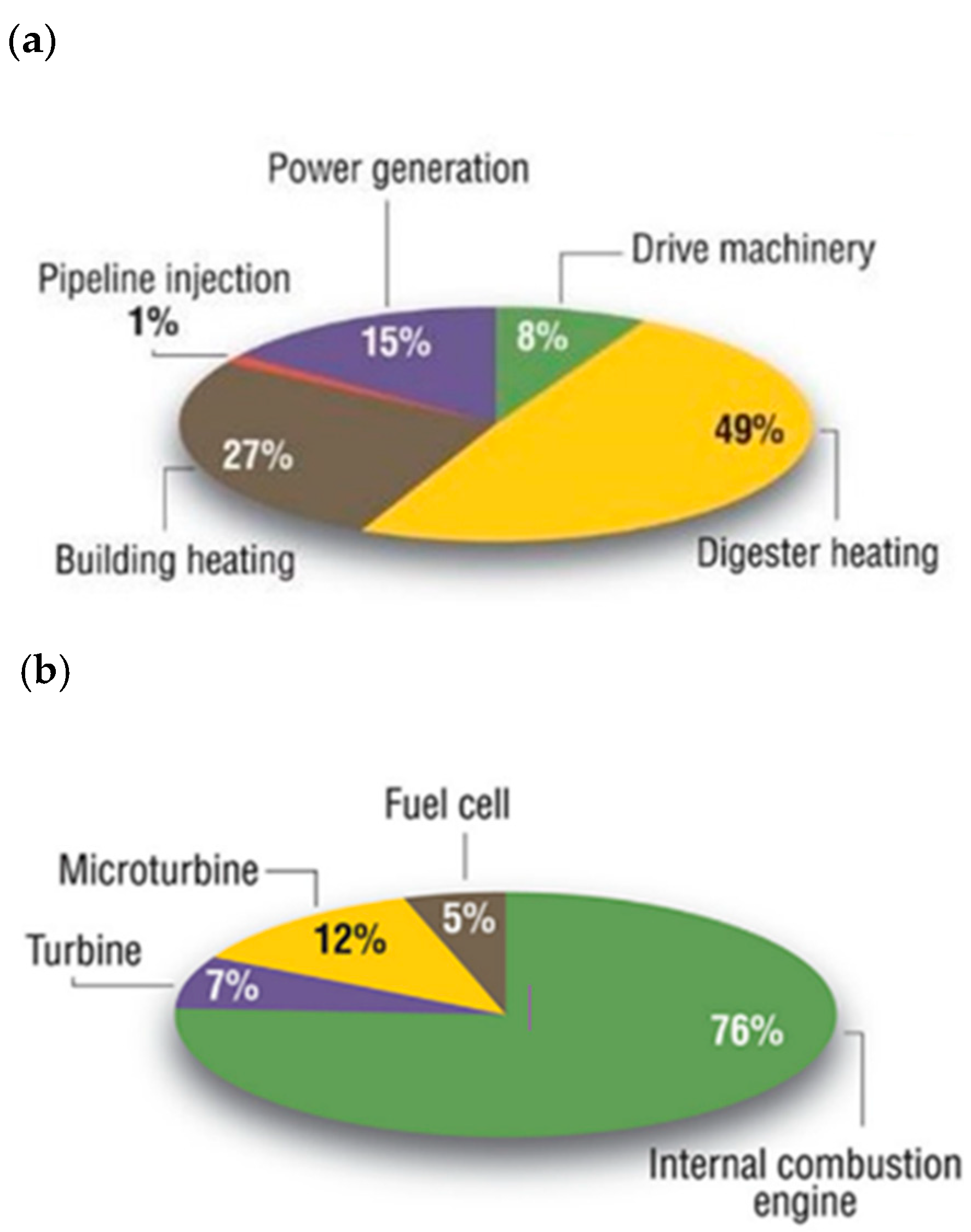

The power range of the cogeneration units is usually between hundreds of kW and units of MW. With increasing output power, unit costs for service and repairs decrease, and the electrical efficiency of cogeneration units increases. In contrast, the overall efficiency (the sum of electrical and thermal efficiency) remains more or less constant. Therefore, it is more advantageous to build only one large unit for biogas production than several smaller ones. This is currently the most common solution for biogas cogeneration units. The service life of the cogeneration unit engine is usually in the range of 6 to 8 years of continuous operation, but the service life is affected by the number of starts. According to statistics from WWTPs in the USA, 49% of the energy produced from biogas was used to heat digestion tanks and 27% was used to heat the building (

Figure 2a). Energy from biogas often provides WWTPs with the ability to cover all of their own heat consumption. This means that biogas is sometimes used only for heating [

27]. Electricity from biogas can be produced in a few ways. The most widely used method is the combustion of biogas in internal combustion engines (in the United States, it was 76% of the electricity produced from biogas in the WWTPs; see

Figure 2b). Another way is combustion in microturbines, which is still a new technology in many countries and apparently has great potential. The disadvantage compared to an internal combustion engine is the higher price and less experience with practical applications. The advantages are lower emissions and less maintenance due to the smaller number of moving parts, as well as smaller dimensions. Compared to conventional turbines, which are also used to produce electricity from biogas, microturbines have better efficiency [

27,

28].

Previously, anaerobic sludge digestion was considered a necessary evil associated with wastewater treatment, which drains up to 50% of the operating costs of the WWTP, and biogas was only used to heat buildings. However, the increase in the purchase prices of the electricity produced from RES has greatly favored these activities. Currently, approximately 20% of the total amount of biogas used for energy purposes comes from WWTPs with anaerobic digestion. The production of electricity by biogas combustion is not important for distribution system operators, but is very important for operators or owners of WWTPs. It is also an advantageous and efficient use of residual materials, which provides the WWTP with a certain degree of independence in the field of energy production. After the law on the support of electricity production from RES came into force, the process of biogas utilization in most WWTPs was optimized.

3.3. Solar Panels with Storage Systems

Another solution is to build a large number of solar panels near the plant in combination with high-capacity batteries. This is also very expensive, but such investments can be returned in a few years. An example of this solution is in Fayetteville, Arkansas, where a project exists that consists of three solar arrays with a total power of 10 MW, and two battery facilities with a capacity of 24 MWh, located near Fayetteville’s two wastewater treatment plants. The city spent EUR 791,000 for installation, but will save approximately EUR 200,000 a year. The two Fayetteville’s WWTPs consume approximately 67% of the city’s overall consumption. The new solar arrays cover approximately 103% of the wastewater treatment plants’ usage, increasing the city’s clean energy use from the current 16% to 72%. When electricity generated by the solar panels exceeds the consumption of the wastewater treatment plant, energy is distributed to the grid for use by cooperative members, or to the on-site battery storage systems that can be dispatched into the grid during peak usage periods when electricity use is most expensive. In addition, one product of the wastewater treatment process is biosolids—nutrient-rich organic materials which are processed in Fayetteville’s Biosolids Management facility into a Class A fertilizer [

29,

30].

3.4. Biogas and Solar Systems

An alternative source of electricity for WWTPs is the combination of two sources of renewable energy—biogas and solar panels, in which part of the WWTP energy consumption is covered using a cogeneration biogas unit and the rest is covered by solar panels. Due to the huge areas where WWTPs are located, it is not a problem to find a place for solar panels. For example, this can be the roofs of the operating facilities at the WWTP. Some WWTPs optimize biological processes and cover activation tanks. The roofs of these can also be a very convenient place to place solar panels. Another requirement involves suitable batteries to store the electricity produced. This concept works, for example, in Ridgewood, New Jersey (

Figure 3) [

31].

4. Energy Autonomy of WWTPs

The best preparation for a blackout is to have enough local production of electricity to allow disconnection from the distribution network. Wastewater treatment plants that generate at least as much energy as they need for their regular operations are classified as “energy-autonomous”. Complete heat autonomy is already being achieved by many plants, whereas complete energy autonomy today is achieved only by very advanced and sophisticated plants. Smaller WWTPs (up to 10,000 PE) can produce only about 35% of their own electricity consumption. However, large WWTPs (above 100,000 PE) have increased the efficiency of processes and can produce 68 to 100% of their own electricity consumption; only WWTPs with the most modern technologies achieve 100% [

32].

Electricity autonomy of WWTPs in the case of CHP use is presented in

Table 1, and electrical efficiency of CHP in

Table 2.

A very important parameter for achieving an energy autonomous WWTP is the electrical efficiency of CHP. The efficiency of biogas conversion of CHP technology has improved significantly in recent years. The thermal energy obtained from biogas is usually sufficient to meet the required heat for the WWTP, so it is important to focus on electrical efficiency. This can be greatly improved by replacing old equipment, which would also be beneficial from a long-term economic point of view. Deposits (e.g., from siloxanes) reduce efficiency, so another important thing is regular maintenance of the CHP [

32].

Another requirement for the WWTP to be able to cover its own electricity consumption is a reduction of this consumption. The largest proportion of electricity is consumed by turbochargers. The data from a model of a Czech wastewater treatment plant, which has a capacity over 100,000 PE, is presented in

Table 3.

In this case, turbochargers consume 45% of the electricity consumed by the WWTP. For other WWTPs, this can be up to 60% [

14]. Therefore, if the WWTP is to be energy-autonomous, it is necessary to reduce the consumption of turbochargers as much as possible. This can be accomplished by installing special advanced microsieving and filtration technologies.

4.1. Exsisting Examples of Energy-Autonomous Wastewater Treatment Plants

Some WWTPs are already energy-autonomous and do not have to be connected to the distribution system at all. This also means that blackouts have almost no effect on them. One example is a WWTP in Gera, Germany. This WWTP has a CHP unit (see

Figure 4) with a dual system to digest biowaste and sludge installed at the facility. Another example is a WWTP in Braunschweig, Germany. This WWTP uses biogas from co-digestion of sludge and biowaste (grease and oil), biogas from a nearby landfill, and methane from fermentation of green waste nearby. Both WWTPs are 100% autonomous in electricity use [

33,

34].

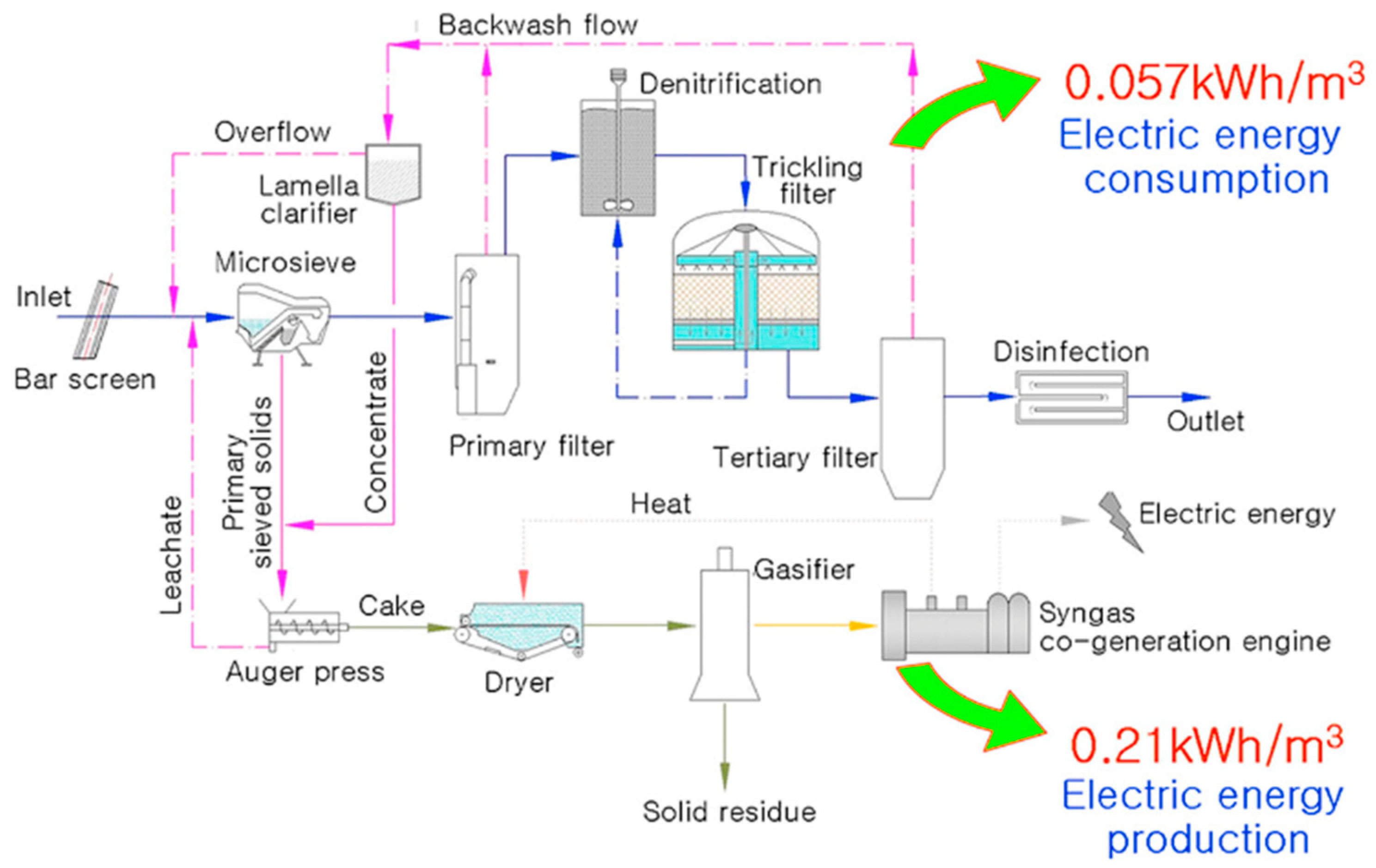

4.2. Theoretical Energy-Positive Wastewater Treatment Plants

Some calculations show that it is possible to produce even more electricity from biogas than the WWTP requires. The most important task is to reduce the consumption of aeration turbochargers as much as possible. This means eliminating aeration needs as much as possible. The first place where this can be done involves a big improvement in primary solids removal using advanced technologies during microsieving and filtration processes; for example, a proprietary rotating fabric belt MicroScreen and a proprietary Continuous Backwash Upflow Media Filter or cloth media filter. With these technologies, a reduction of 80–90% can be achieved in TTS (total suspended solids) and 60–70% in BOD5 (5-day biochemical oxygen demand). In the next step, a combination of low height trickling filters with encapsulated denitrification can be used for the removal of the remaining BOD and nitrogen. The primary solids removal process produces biosolids that can be dried by an auger press to about 55% solids, and then partially thermally dried to about 80% solids. In the end, biosolids are used in a gasifier for the co-production of thermal and electrical energy through syngas combustion in a co-generation engine. Alternatively, biosolids may undergo anaerobic digestion to produce biogas and then thermal and electric energy. The energy requirements for complete wastewater treatment per volume of inlet raw wastewater have been calculated at 0.057 kWh/m

3, (or 0.087 kWh/m

3, if UV disinfection has been selected). The potential for net electric energy production through gasification/co-generation per volume of inlet raw wastewater has been calculated at 0.172 kWh/m

3, or even 0.210 kWh/m

3, as presented in

Figure 5. If we are able to use such technologies in practical applications, then WWTP could be changed from a consumer to a producer of electricity [

14].

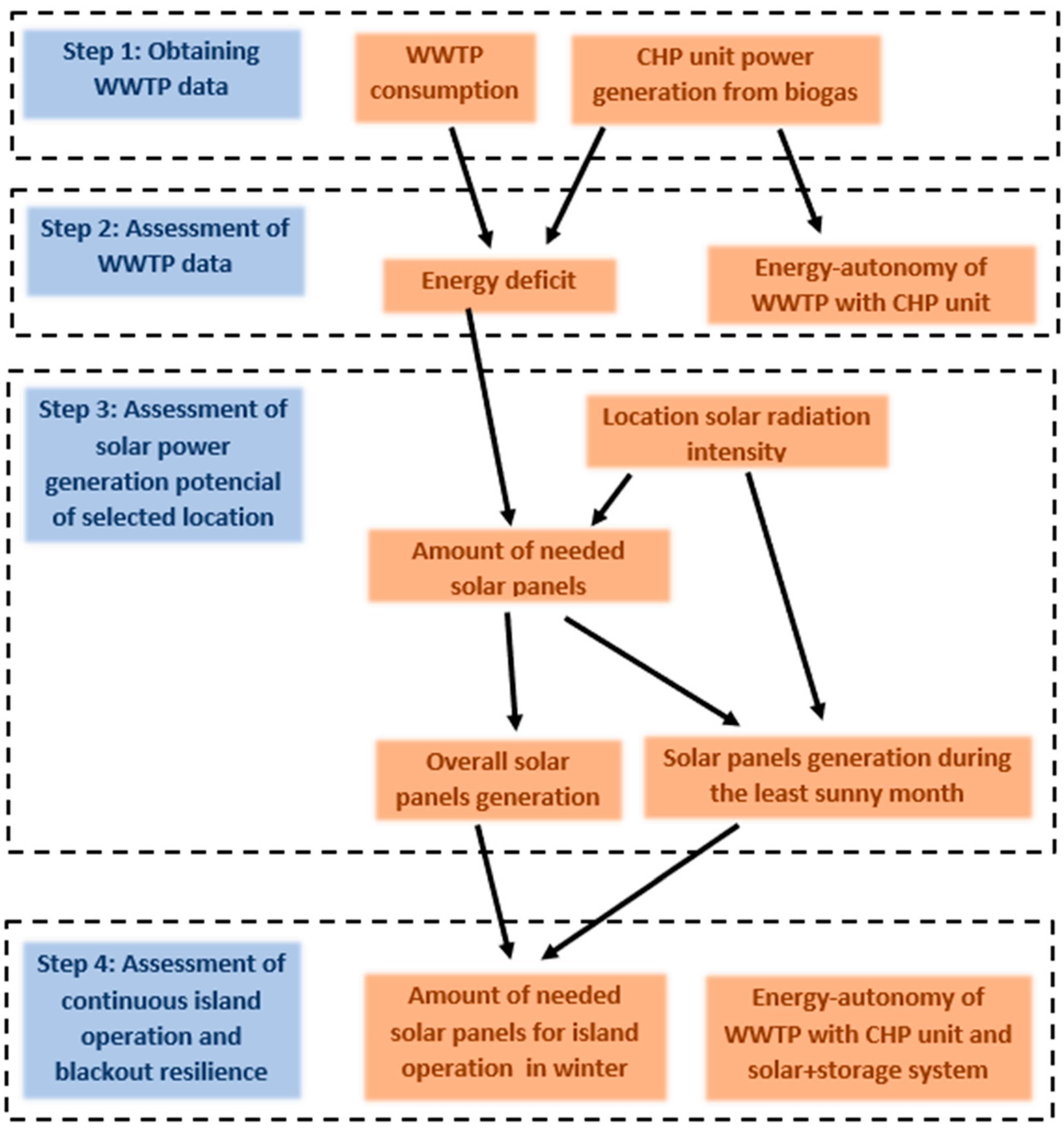

5. Methodology

An assessment of whether WWTP energy autonomy can be achieved with full resilience to blackouts, was carried out based on data from a Czech wastewater treatment plant located in the North Moravia region. For this WWTP, data were obtained about its electricity consumption and CHP biogas production for every month. The difference between these values defines an energy deficit that must be produced by solar panels. Calculations were made for three different locations:

Intentionally three locations with very different irradiances during the year were chosen. Irradiance data were obtained from the Photovoltaic Geographical Information System [

35]. In the Czech Republic, there are very challenging conditions for the use of solar power with storage as an independent source of energy because in winter months irradiance is very low. Northern Italy is a much better region when considering the use of solar power. However, there is also a big difference between solar panel energy production in the summer and winter months. By contrast, Egypt has almost unchanging high irradiance during the year, which means it is a very good location for the production of solar power.

The number of solar panels needed to produce the same amount of electricity as the consumption of WWTP (when subtracting production from CHP units) can be calculated as follows:

where E

DEF is the production deficit in kWh calculated as the difference between the electricity consumption of the WWTP and the production of biogas in the CHP unit, and E

P is the electricity production of one panel per year in a selected location. Then the needed area for those solar panels is calculated as:

where Ap is the area of one solar panel (1.63 m

2). The next step is to select the worst month in a year in terms of irradiance. This month is January [

35]. In January, the average 1 day energy deficit in our case study was 6450 kWh. This value is then compared with the daily production of solar panels, which can be calculated as follows:

where

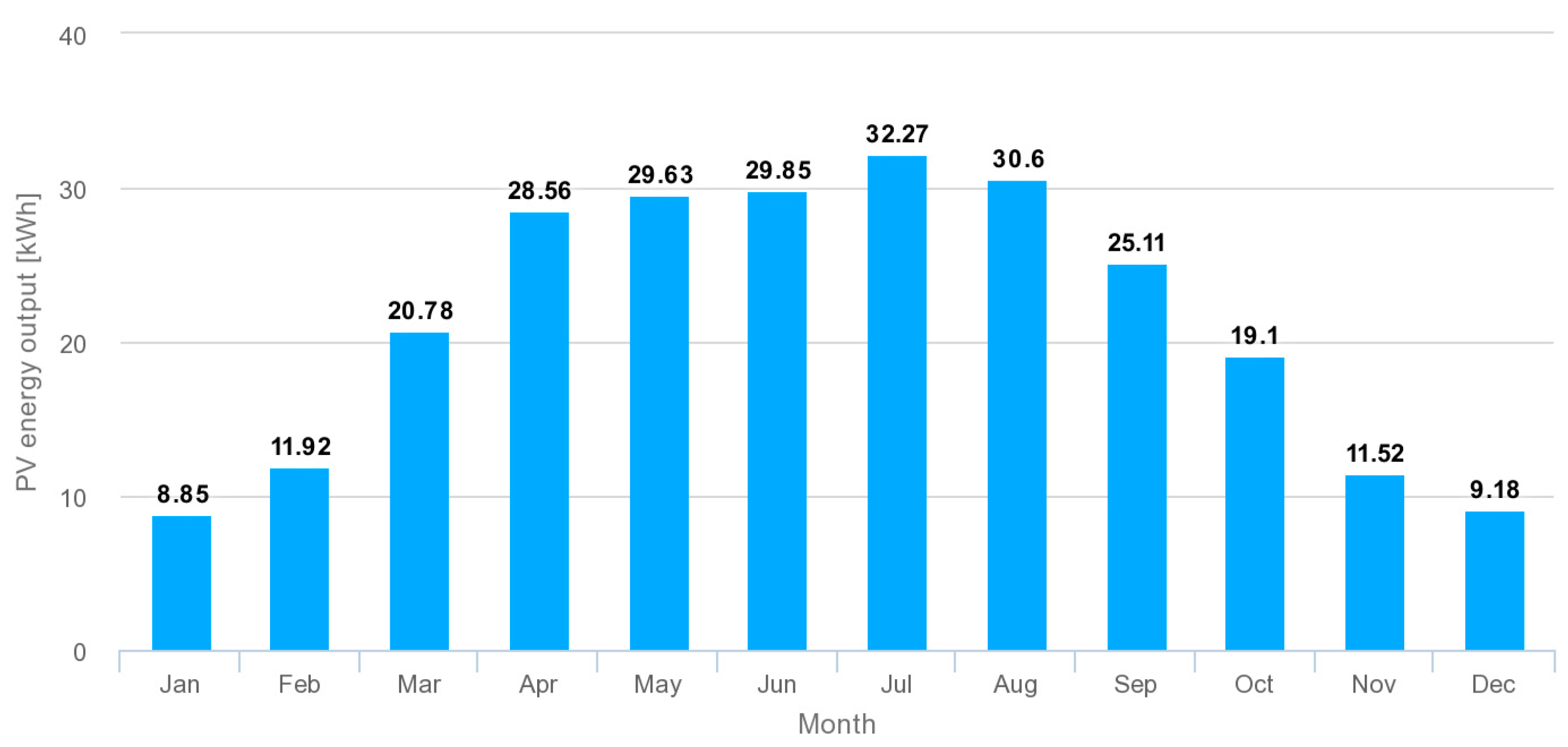

is the electricity production for 1 month by one solar panel in the selected location in January (8.85 kWh for Czech Republic), which has 31 days.

This value will always be lower than the energy deficit, which means that the site would need more solar panels or have a large number of batteries to store surplus energy produced in summer. This number can be unrealistically high, as can be seen in results for the Czech WWTP.

Therefore, the number of solar panels needed for sufficient electricity production in January is calculated as:

where

is the average 1 day energy deficit in kWh. It must be added that for the appropriate function of the energy-autonomy system, enough batteries must be installed.

The assessment process of the method is depicted in

Figure 6.

6. Results and Discussion

Based on data from a Czech wastewater treatment plant (the model WWTP) a calculation of energy system options was made (

Table 4). This WWTP has about 160,000 population equivalent, average consumption is 2673 MWh/y and its cogeneration production from biogas is 728 MWh/y. Therefore, the WWTP has 36.5% energy-autonomy. Solar panels can be installed on the roofs of WWTP’s buildings (cca 2000 m

2) and unused grass areas (6000 m

2). In the case of roofing activation tanks, which would provide additional benefits for their operation in winter, the roofs of these tanks (5000 m

2) can also be used for solar panels.

6.1. Results for North Moravia Region, Czech Republic

If we consider a standard solar panel available on the market that has 250 Wp capacity, an area of 1.63 m

2, and which costs EUR 160, its production can be calculated as 267.23 kWh/y for Central European conditions. The calculation was made for the local actinometrical station for the city of Opole, Poland [

36]. A photovoltaic geographical information system provided the calculations for the location of our model WWTP [

35]. This value was 257.37 kWh/y, which is very similar to the value for Opole.

The model WWTP´s consumption is larger than its production by 1945 MWh/y. Therefore, 4935 solar panels with an area of 8043 m

2 would be needed to produce the required energy, as shown in

Table 5.

Our model WWTP has enough available area for the solar panels to produce the required production. Therefore, it is possible for this WWTP to produce during a year the same amount of electricity as it consumes.

It is important to add that the consumption of WWTPs does not change much during the day, while the production of solar panels, of course, changes considerably during the day and is zero at night. This means that this combination is not sufficient for continuous operation without connection to the distribution system. However, in the case of a blackout lasting several days, the treatment plant could continue to operate, with some consumption being reduced during the night (for example, turbochargers).

The WWTP in Fayetteville is lacking biogas utilization but it has an electricity storage system. For our model WTTP, we can combine biogas CHP, solar panels and batteries. based on the example of the WWTP in Fayetteville, if a large number of solar panels are installed in the form of solar arrays, the price per panel decreases. In Fayetteville, five times more power was installed than the required power of the model Czech WWTP. If we use the principle of similarity, we can estimate that the required 4934 panels for our model WWTP would cost only EUR 100,000, even with the installation of 3 MWh batteries. This would be enough for 10 h of average operation of the WWTP. This means that it is enough to supply the WWTP at night when the solar panels are not producing electricity. In addition, if we consider solar panel production as shown in

Figure 7, and biogas CHP production, the WWTP model WWTP would be able to stay in full operation independently of the distribution network from April to September.

The situation in March and October would be uncertain. If a blackout occurred in these months, production would be sufficient during sunny days but not during cloudy days. In December and January, both the production from biogas and solar panels would be the lowest. However, even in those months, thanks to batteries, the WWTP would be able to stay in full operation during a blackout for at least 24 h. Continuous island operation would not be possible during winter months. For this type of operation, the number of needed solar panels would be over 20,000 panels, and most of them would be unused during summer. The amount of installed battery capacity would also be enormously high.

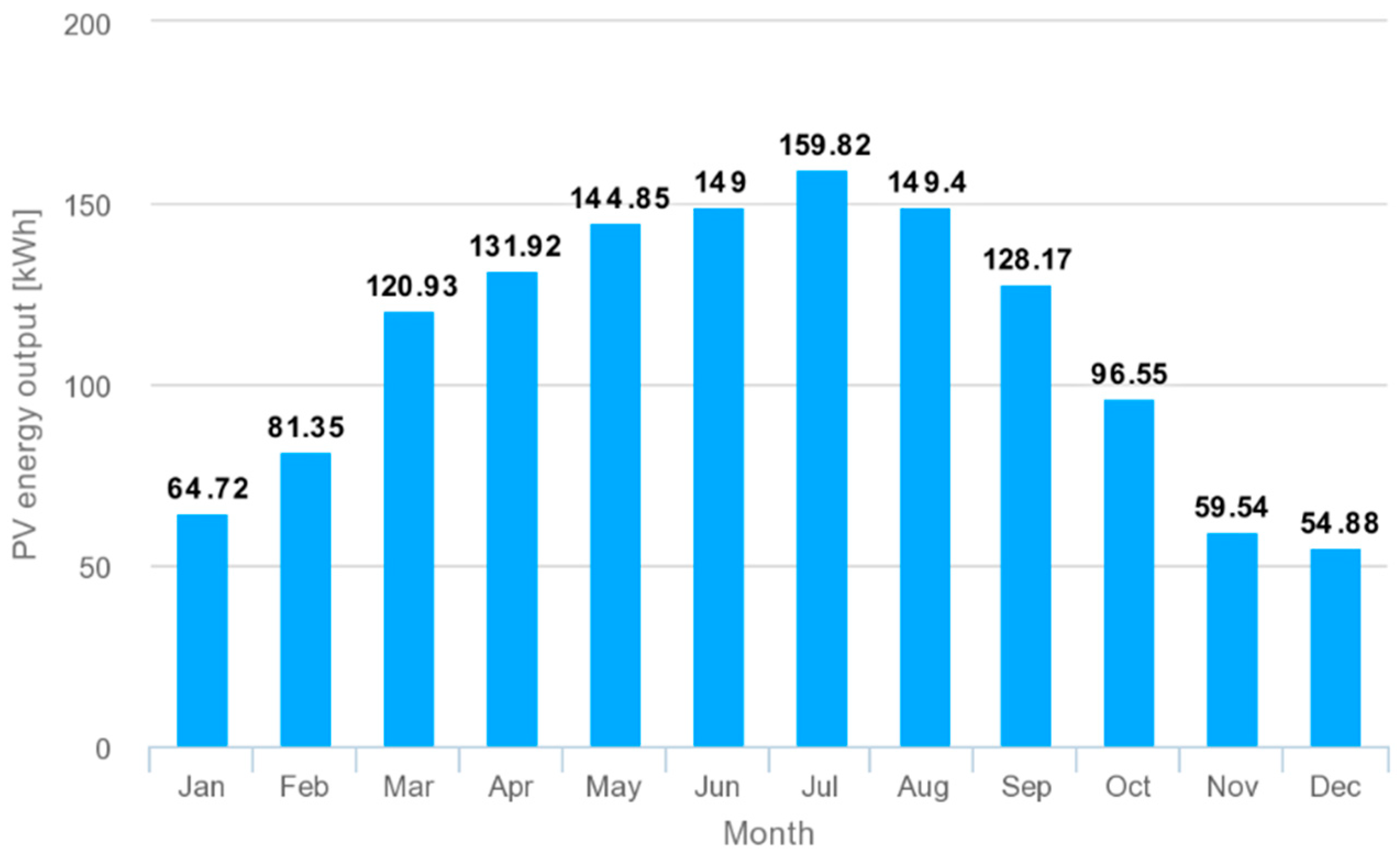

6.2. Results for North Italy Region

The solar radiation intensity is much more intensive in the northern Italy region, which means the number of solar panels needed is much lower compared to that of the Czech Republic (less than 1000 panels to meet 100% of the deficit energy). The yearly production from one solar panel was calculated at 1341 kWh, and even in winter months production is still quite high (64.72 kWh in January and 54.88 in December as can be seen in

Figure 8). For continuous island operation, about 3000 panels would be needed, which is an acceptable number.

6.3. Results for Cairo, Egypt

From the three selected locations, the best conditions for solar power use are in Cairo, Egypt. There, solar radiation intensity during the year varies little (from 131 to 163 kWh per panel, as can be seen in

Figure 9). Only about 700 panels are needed to be installed for WWTP yearly consumption, and 1480 panels would be needed for continuous island operation.

6.4. Overall Results

Calculations were made according to the relations presented in

Section 5 for three selected locations. Results are shown in

Table 5. Location greatly influences the possibility for use of solar power to achieve energy autonomy and the resilience of a WWTP to blackouts. Czechia has the most challenging conditions for the use of solar power. However, even there it is possible to install a sufficient number of solar panels to produce the needed electrical power to meet the yearly consumption of a WWTP. The WWTP would be able to operate in island operation even during a 24-h power outage. However, longer outages and continuous island operation is not possible during winter because the number of solar panels and batteries needed would be too high. In contrast, northern Italy has much better conditions and the needed number of solar panels (3090) would not be too high even for continuous island operation. Localities such as Egypt are very suitable for the use of solar power in WWTPs, where only 701 solar panels would be needed with an area of 1143 m

2, which is less than the area of the roofs of the WWTP buildings.

7. Technical Requirements for Island Operation

This section is placed before conclusion to add important information about the transition to island operation. Previous theoretical information and calculations were devoted to question concerning the possibly of operating a WWTP in an island operation. However, it is important to answer question about how this may be possible.

The most important thing during a blackout is for the WWTP to have its own source of electricity. In addition to a diesel generator, the above-mentioned renewable sources can be considered. However, the basic requirement for using an independent power source to secure power supply during a blackout is the possibility of island operation. The WWTP must be designed for disconnection from the distribution network [

37].

The transition to island operation is not a matter of course. In island operation, the balance between power sources and consumption must be ensured in the same way as in a conventional electricity grid. At the moment of a power outage, it is necessary to switch to island operation in a fraction of a second. A typical situation for the beginning of island operation is a lack of power. Therefore, it is necessary to disconnect some of the consumptions in order to bring the newly created island network into power balance. This is ensured by an automatic load shedding/application system that compares consumption with the power of sources and determines how much it will be necessary to reduce consumption. If possible, the reduction is performed according to the priorities determined, for example, from the analysis of smart meters [

38]. The frequency relay monitors the deviation of the network frequency from the nominal value and sends a signal to disconnect from the distribution network when the defined interval is exceeded. This procedure can be part of a multifunctional IED (intelligent electronic device).

Automatic transition to island operation can be realized on the basis of a 16-bit single-chip microprocessor. The microprocessor software contains several protection functions with the selective setting of various criteria. The microprocessor obtains information about the state of the AC network variables from analog inputs, and about the state of the switching elements from binary inputs. Another option is to attain automatic transition to island operation using a multifunction IED, which has all the required functions, with digital and analog inputs and outputs.

If conditions for island operation are met, the island is disconnected at the splitting point(s). If the fault is behind the splitting point (within the expected island operation of the WWTP), the island operation must not be activated, and local protection must ensure the elimination of the fault [

37].

During normal operation, the automatic load shedding/application system constantly monitors the consumption from the area of island operation and compares consumption with the power of sources that are located in island operation (e.g., a CHP unit for biogas in the case of a WWTP). Individual consumption processes are divided into categories according to their importance. If their total consumption is greater than the power of the CHP unit, then the less important consumption processes are included in a group for possible shutdown. Otherwise (in case of excess power) the generator is regulated, which reduces power and achieves the required power balance [

37].

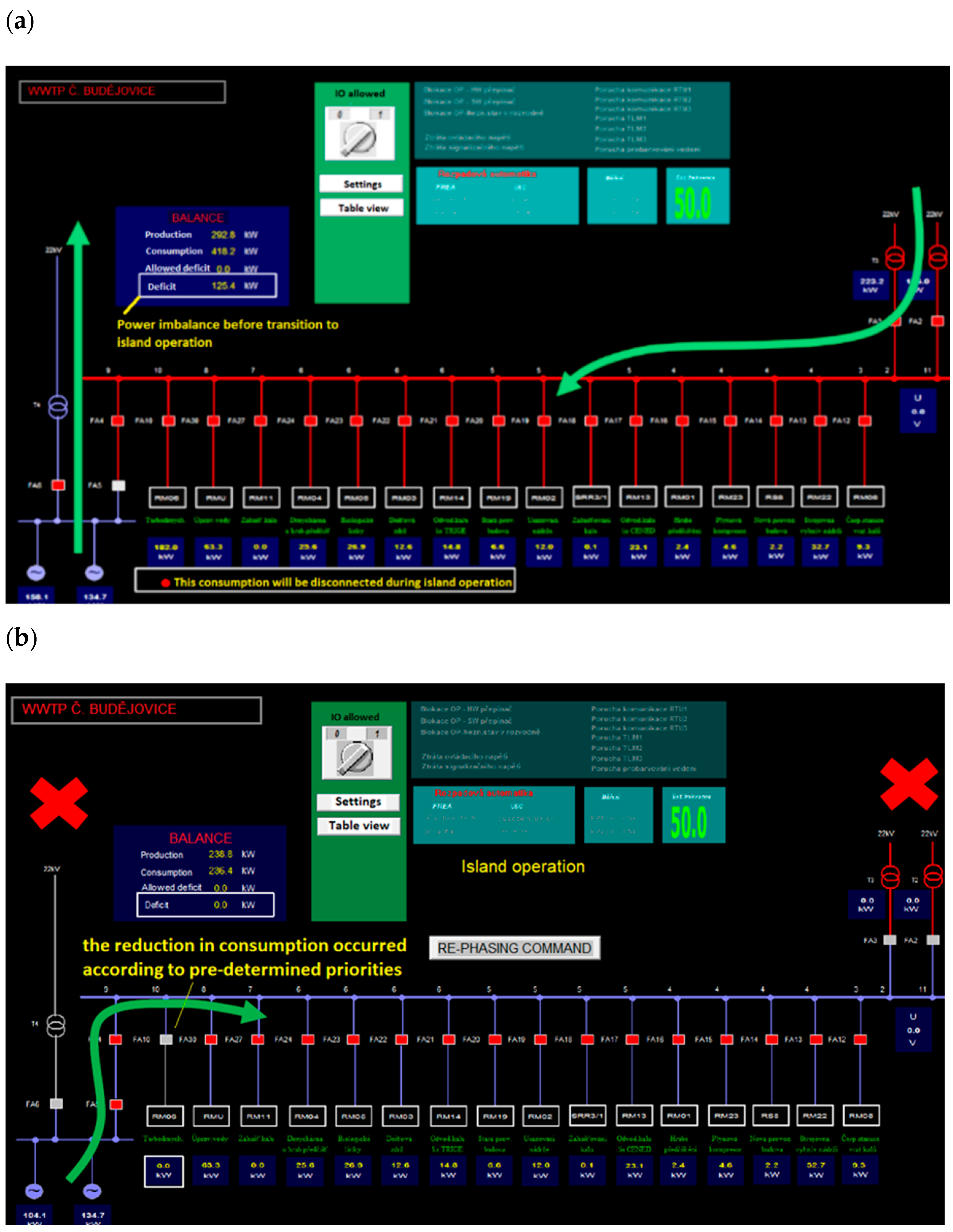

Example of a WWTP with Island Operation during Blackout

A WWTP in České Budějovice, Czechia is an example of a WWTP with CHP that can be operated in island operation during a blackout. This WWTP serves the residential agglomeration of two cities and 15 municipalities with a capacity of 112 thousand inhabitants (375,000 population equivalent). Two biogas CHP units with an output of 512 kW are installed directly in the wastewater treatment plant. This covers about 2/3 of the electricity needed for the WWTP’s own consumption. In its vicinity, there is a new water treatment plant for the emergency supply of drinking water for the city. In the case of a blackout, the CHP units at the WWTP in island operation are able to meet the consumption needs of both the WWTP and the water treatment plant for a limited time after disconnection of the turbochargers. During normal operation, the CHP source works into the distribution network and the consumption of the WWTP is supplied from the distribution network. At the same time, the current consumption of all technological units of the wastewater treatment plant is monitored. The control system calculates the difference between the production of electricity from biogas and the total consumption of technological units, as shown in

Figure 10a.

When a fault occurs in the electrical network, it is necessary to detect and evaluate the fault very quickly, and automatically (in the order of tenths of a second) disconnect the wastewater treatment plant from the network and change the power supply to the local biogas CHP station. Because the CHP station has not enough capacity to cover the entire energy consumption of the wastewater treatment plant (there can be more than 100 kW deficit as shown in

Figure 10a), it is necessary to disconnect some equipment. The turbochargers required for aeration of activation tanks have the highest consumption (see

Figure 10b), and therefore it is necessary to disconnect them [

39].

This will cause the production of secondary sludge needed for biogas production to gradually decrease. However, if the supply of primary sludge to the digestion tanks is maintained, the partial development of biogas will also be maintained and the WWTP should be able to operate in the island mode for at least two days. Biological treatment will also gradually deteriorate.

If we consider a normal rainless day, this will affect the quality of the discharged water after about 36–48 h [

39].

When the network voltage is restored, the island operation is automatically synchronized with the network and normal operation is restored.

8. Conclusions

For the protection of a sewage treatment plant in case of a long-term power outage, it is necessary to consider not only securing the electricity supply for the WWTP, but also appropriate provisions from alternative sources and ensuring the reliability of their supply. It is very important to determine the priorities of the processes in the treatment technology that should be supported by an alternative source. It is known that using some alternative sources of electricity, there will usually not be the same amount of electricity available as the WWTP normally consumes. The priority is to find out how technologies can work in emergency mode and which processes must always be turned on, even in the event of a critical situation, and what devices can be turned off. Then we can calculate the necessary electrical power to be provided from alternative sources.

Most wastewater treatment plants have the potential to switch to island operation during a blackout. The smaller ones can be supplied by diesel engine-generators. The use of renewable sources appears to be advantageous, especially with the option of using biogas, especially for large WWTPs, which produce biogas in the fermentation process. However, most of these are not able to work in island operation for a long time (more than two days), because the consumption of turbochargers would not be covered and the development of biogas would decrease. This can be solved by a diesel engine-generator that would supply electricity to the turbochargers, or by installing sufficient solar panels with battery storage for the same purpose.

Data from a Czech WWTP, which uses energy from biogas, were used to model individual solutions. Calculations were made for the installation of a number of solar panels that would produce the same amount of energy per year as the WWTP now takes from the grid. The calculations show that it is possible to operate the WWTP independently of the network in the period April to September under Czech conditions. During this period, a blackout would not limit the operation of the WWTP. In the other months, the WWTP would remain in full operation during the blackout for a maximum of several days, and at least for24 h. In areas with high (northern Italy) or very high (Egypt) solar radiation intensities, it is possible to achieve full energy-autonomy. The combination of biogas CHP production, solar power and batteries can provide an affordable solution in these localities. The monetary investment could be returned in a few years.

There are already energy autonomous WWTPs that do not have to be connected to the grid because apart from biogas produced from anaerobic sludge digestion they also use biogas from biowaste and/or nearby landfills. In the future it may be possible to build WWTPs that produce more energy than they consume. In such situations, installation of advanced microsieving and filtration technologies would reduce the required power input for turbochargers.