Improving Thermal Efficiency of Internal Combustion Engines: Recent Progress and Remaining Challenges

Abstract

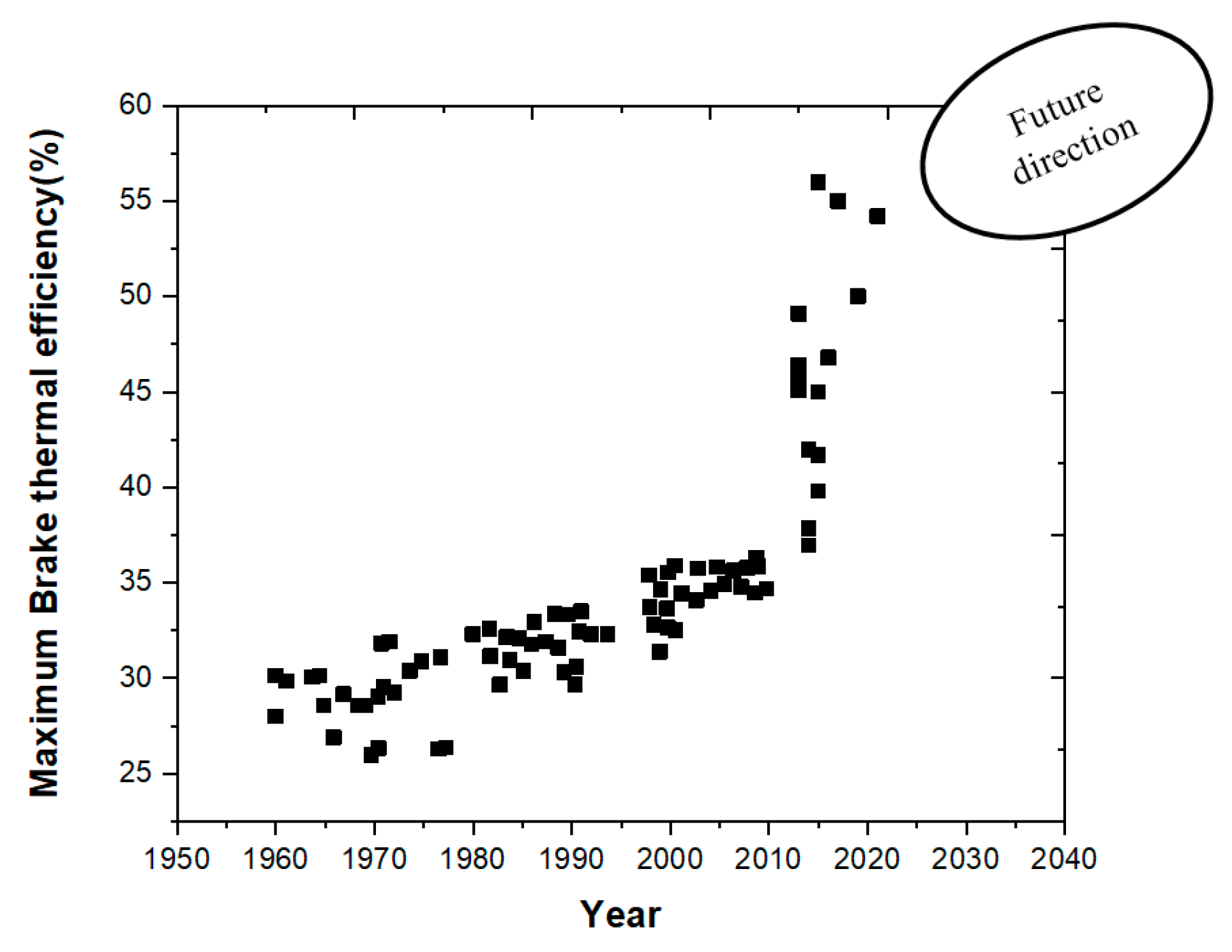

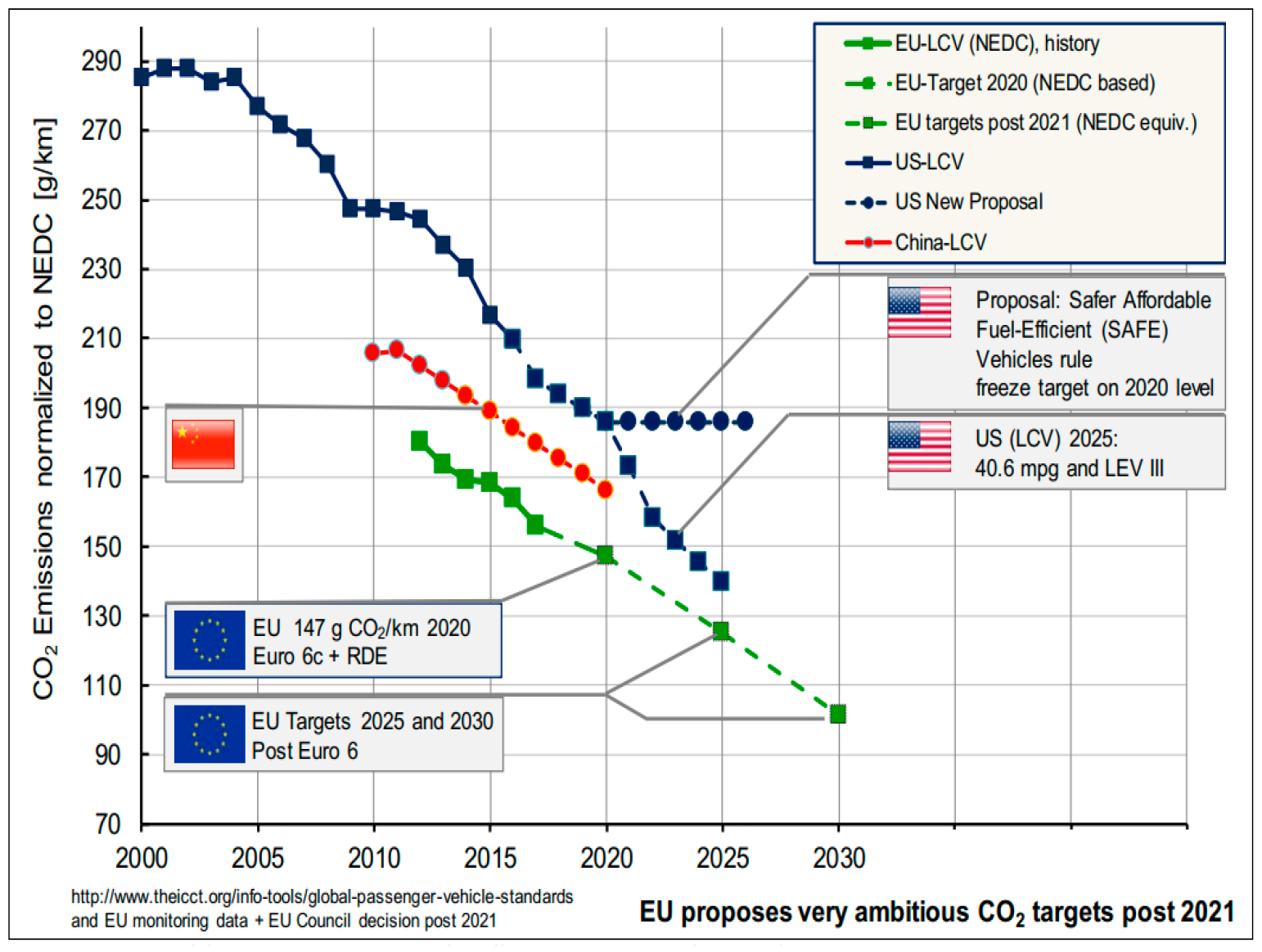

1. Introduction

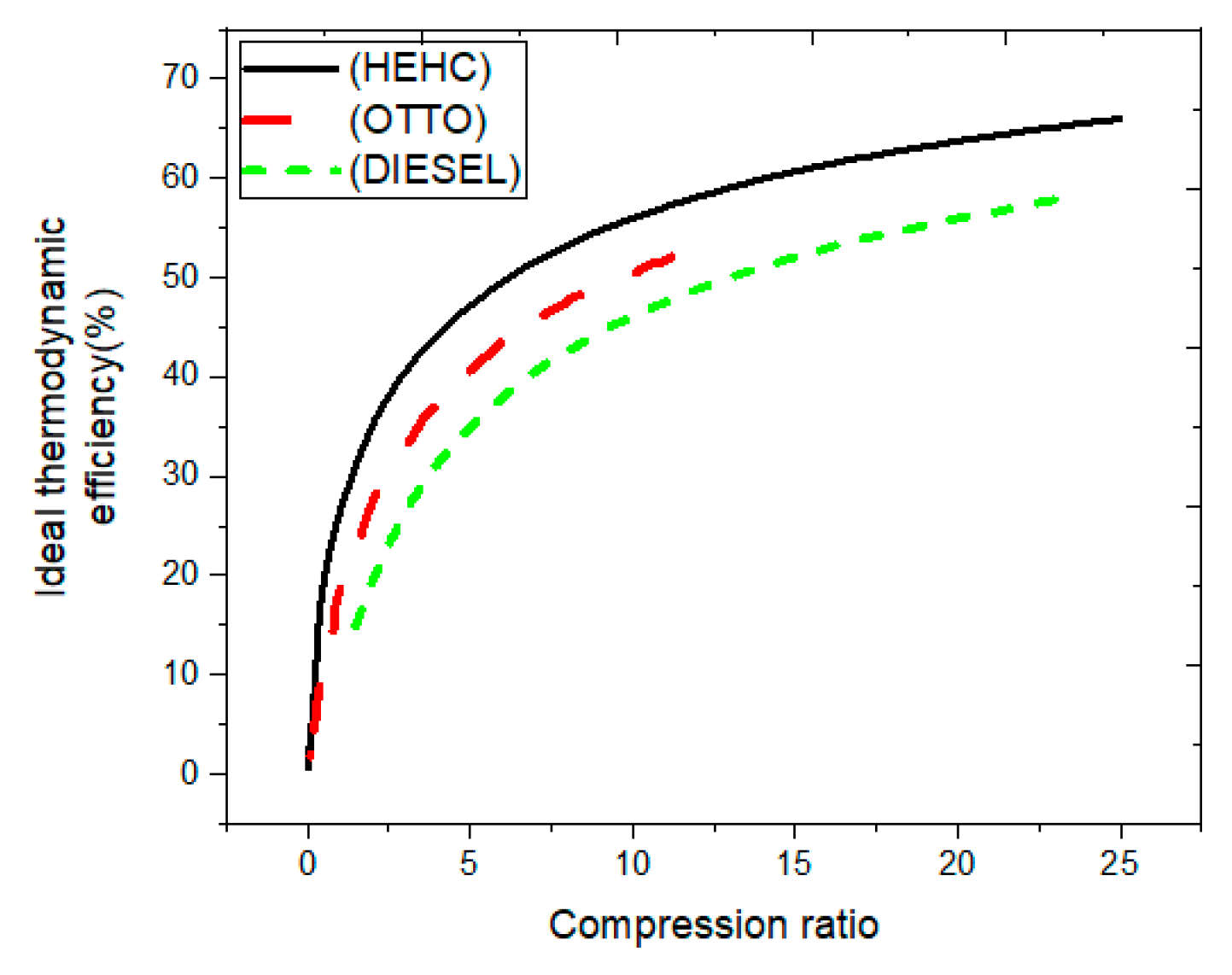

2. The Thermodynamic Cycle of IC Engines

2.1. Otto Cycle

- Lower compression ratio (CR).

- Longer combustion evolution.

- Gas exchange losses by throttle valves.

- Lower specific heat ratio.

2.2. Diesel Cycle

2.3. Hybrid Thermal Cycle

- Air is compressed to high CRs like those in the diesel cycle.

- Constant-volume combustion and isochoric combustion.

- Expansion volume is greater than compression volume.

- Water is added optionally during combustion and/or expansion.

3. Advanced Gas Exchange for Improving Thermal Efficiency

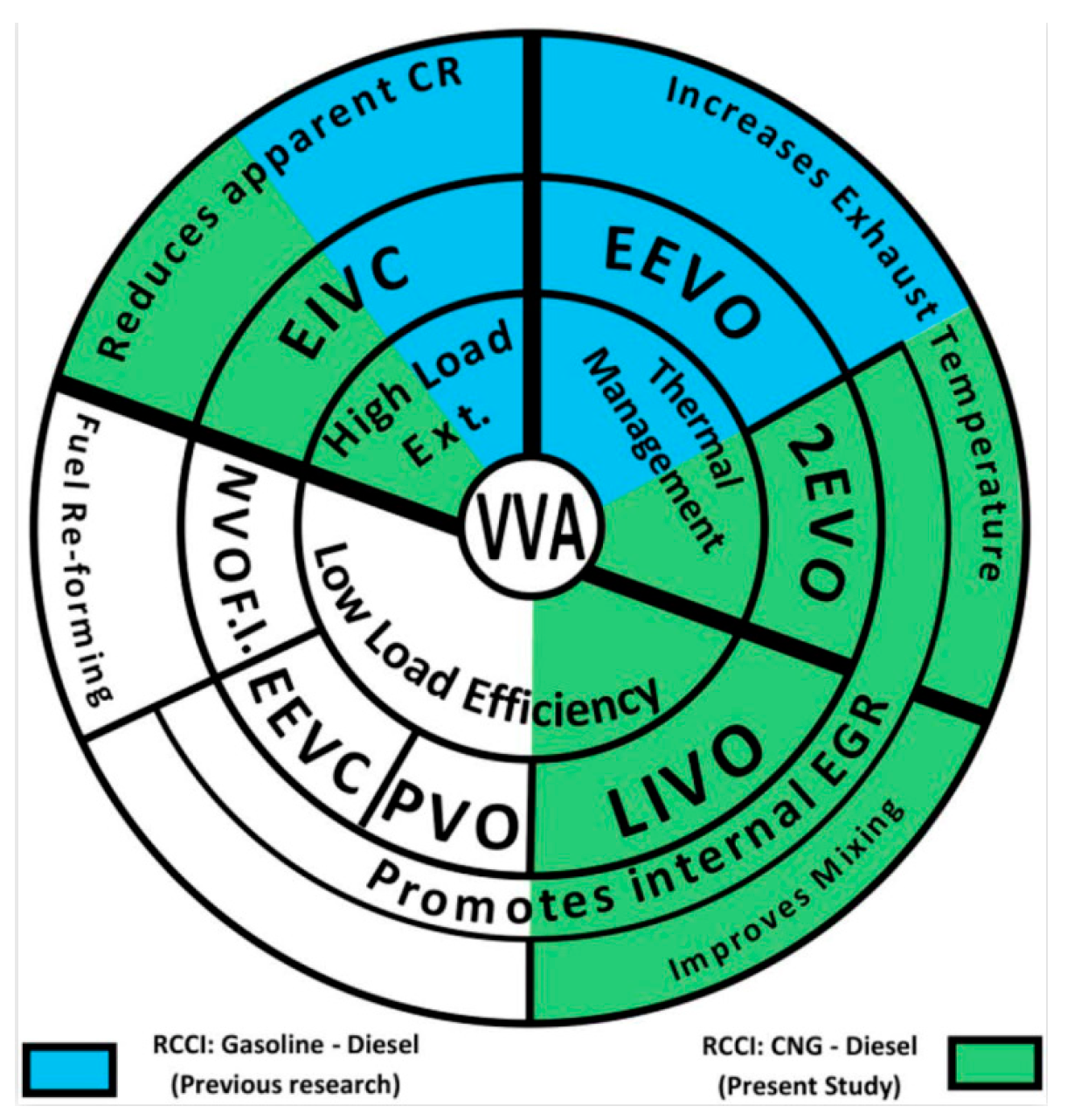

3.1. Variable Valve Systems

- Cam-driven systems: cam lobes are used to actuate the valve lift.

- Cam-less systems: various actuators are used, such as hydraulic, electromagnetic, or pneumatic, to vary valve lift with flexibility in control.

- Variable valve lift (VVL).

- Variable valve timing (VVT).

- Variable valve duration (VVD).

3.1.1. Variable Valve Lift

3.1.2. Variable Valve Timing

- Early exhaust valve opening (EEVO).

- Exhaust valve re-opening (2EVO).

- Intake valve re-opening (2IVO).

- Negative valve overlap (NVO).

- The EIVC and LIVC strategies reduce the mass flow, thereby decreasing pumping work and improving gas exchange efficiency.

- The decline of the trapped mass generates a higher combustion temperature and leads to an increase in the heat losses, offsetting the lowering of the pumping work.

- Since IVC timing has such a poor effect on engine friction, the BTE does not improve significantly or settle constant during tested conditions.

- The uncommon valve lift profiles with EIVC cannot correspond practically with traditional camshafts [58].

- Solenoid-actuated valves and EIVC can achieve the highest efficiency.

- The gas exchange process and engine performance can be optimized by utilizing VVL technology [71].

- It cannot be employed to increase the compression ratio beyond the geometric limit.

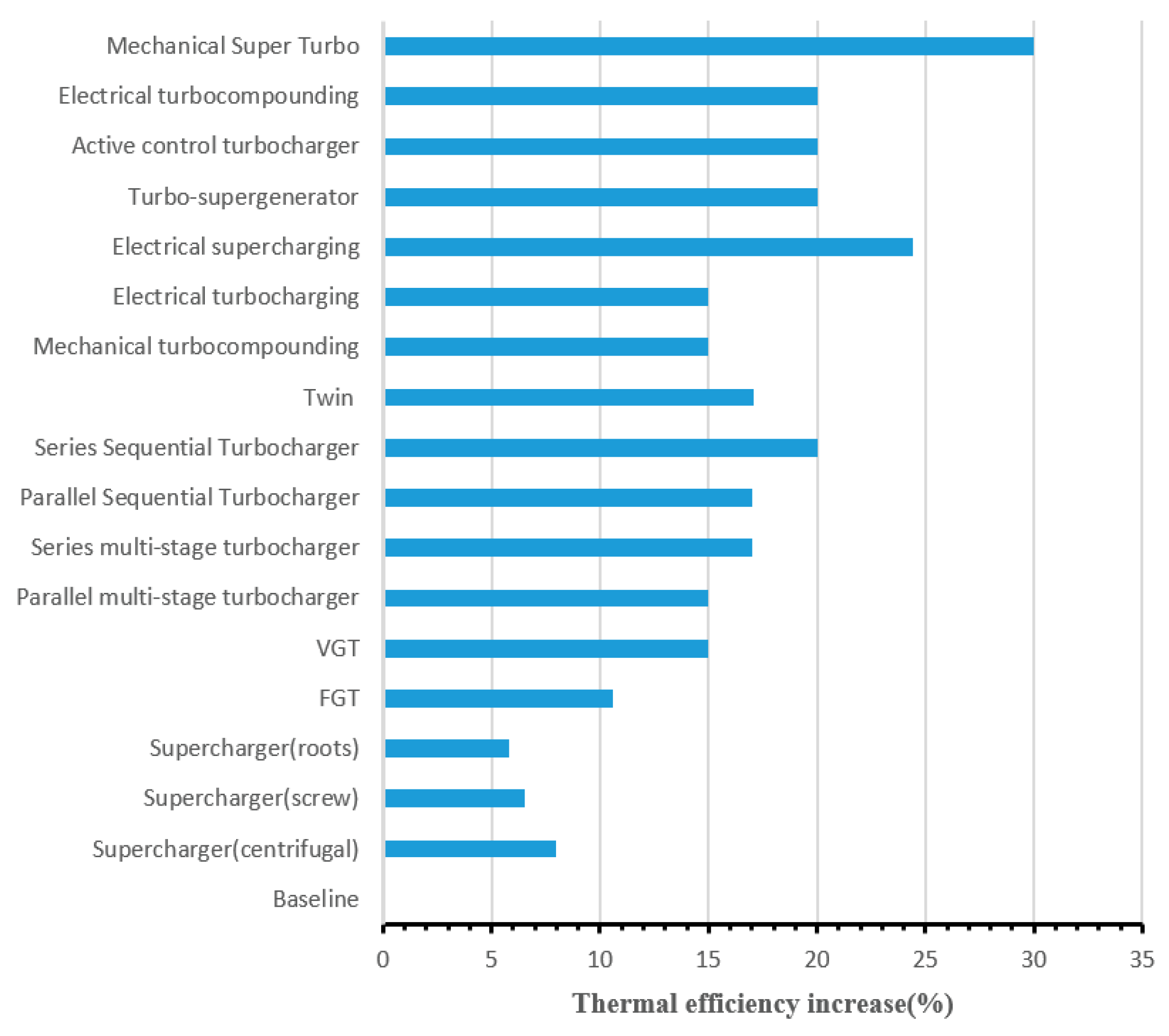

3.2. Exhaust Gas Turbocharging

3.2.1. Variable Geometry Turbocharging

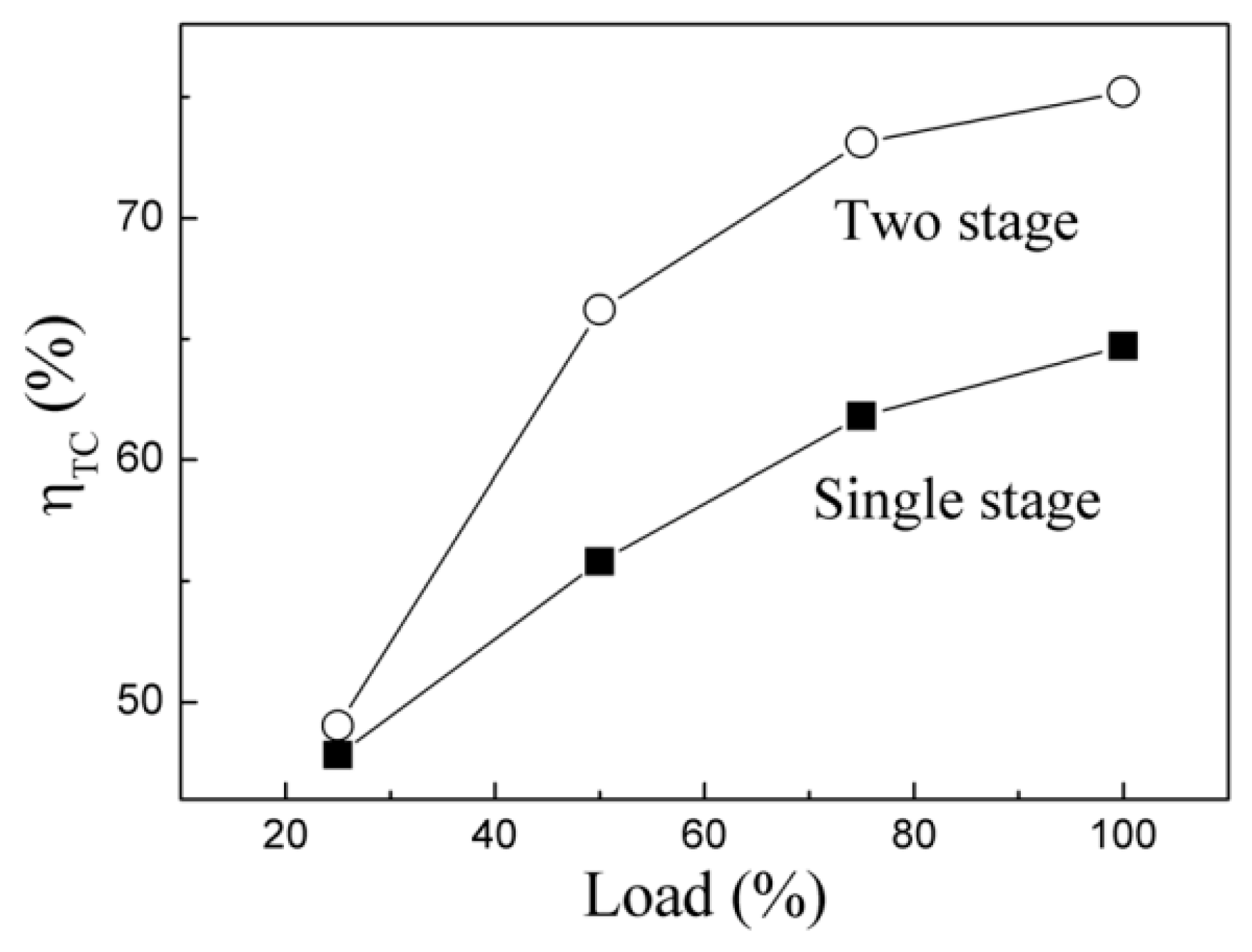

3.2.2. Multi-Stage Turbocharging

3.2.3. Electrically Assisted Turbocharging

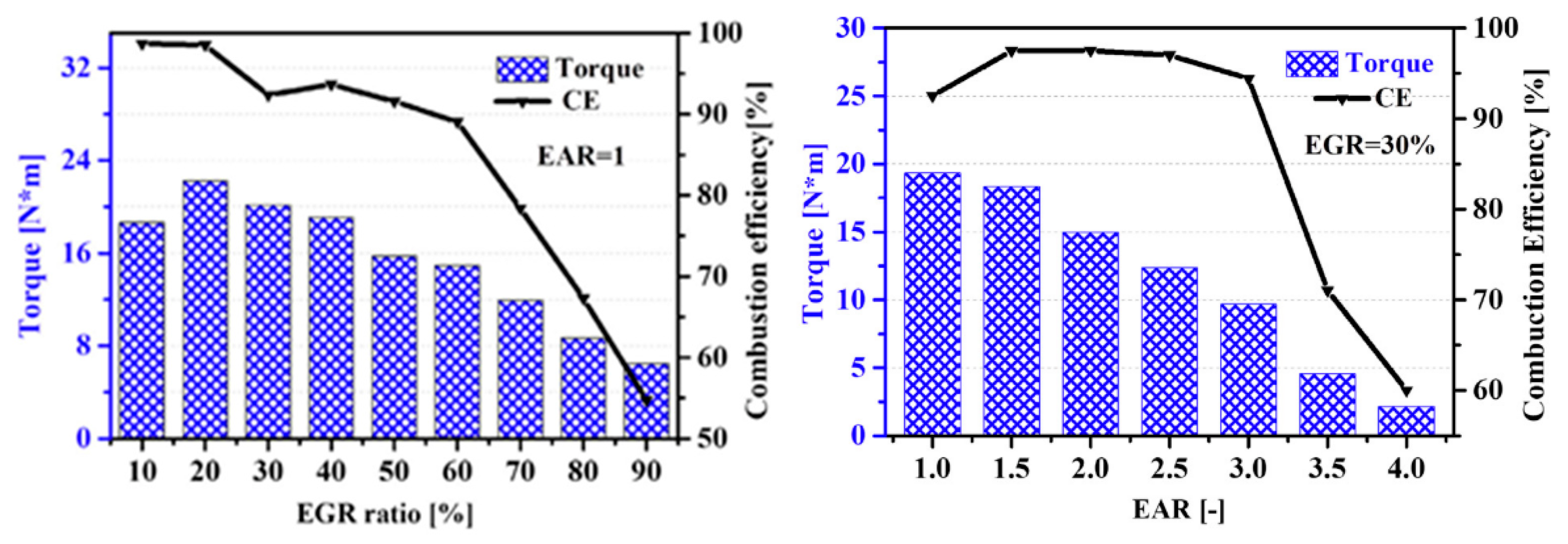

3.3. Exhaust Gas Recycle

- A reforming mode involves injecting a small amount of diesel fuel into the EGR stream and then reforming catalytically in the rich combustor to create gaseous fuels like hydrogen for enhancing engine combustion.

- An oxidation mode in which the products of incomplete combustion are oxidized on a palladium/platinum-based catalyst to reduce the instability caused using EGR.

3.3.1. External Exhaust Gas Recycles

3.3.2. Internal Exhaust Gas Recycles

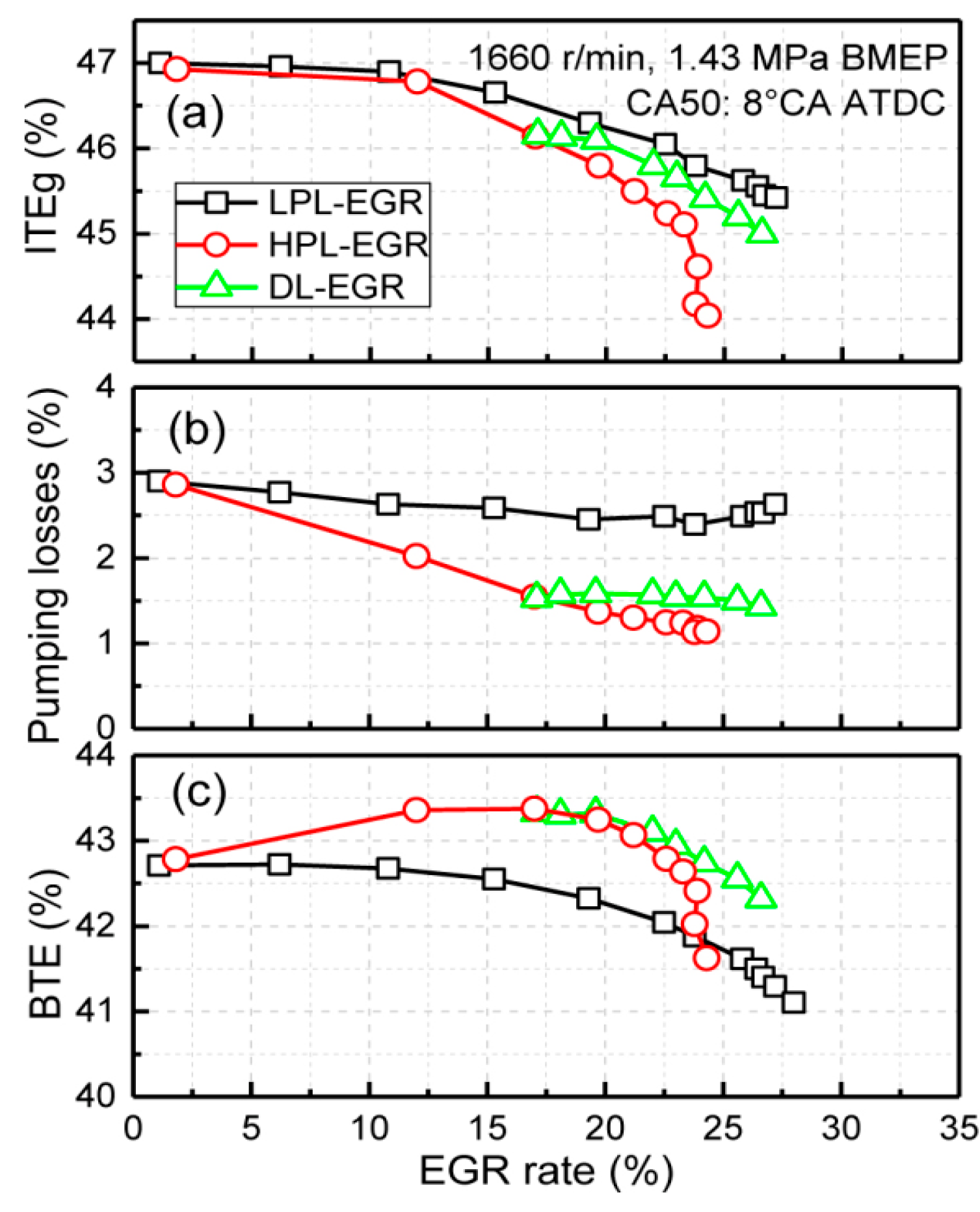

3.3.3. Hybrid Exhaust Gas Recycle

4. Advanced Combustion for Improving Thermal Efficiency

4.1. Low-Temperature Combustion

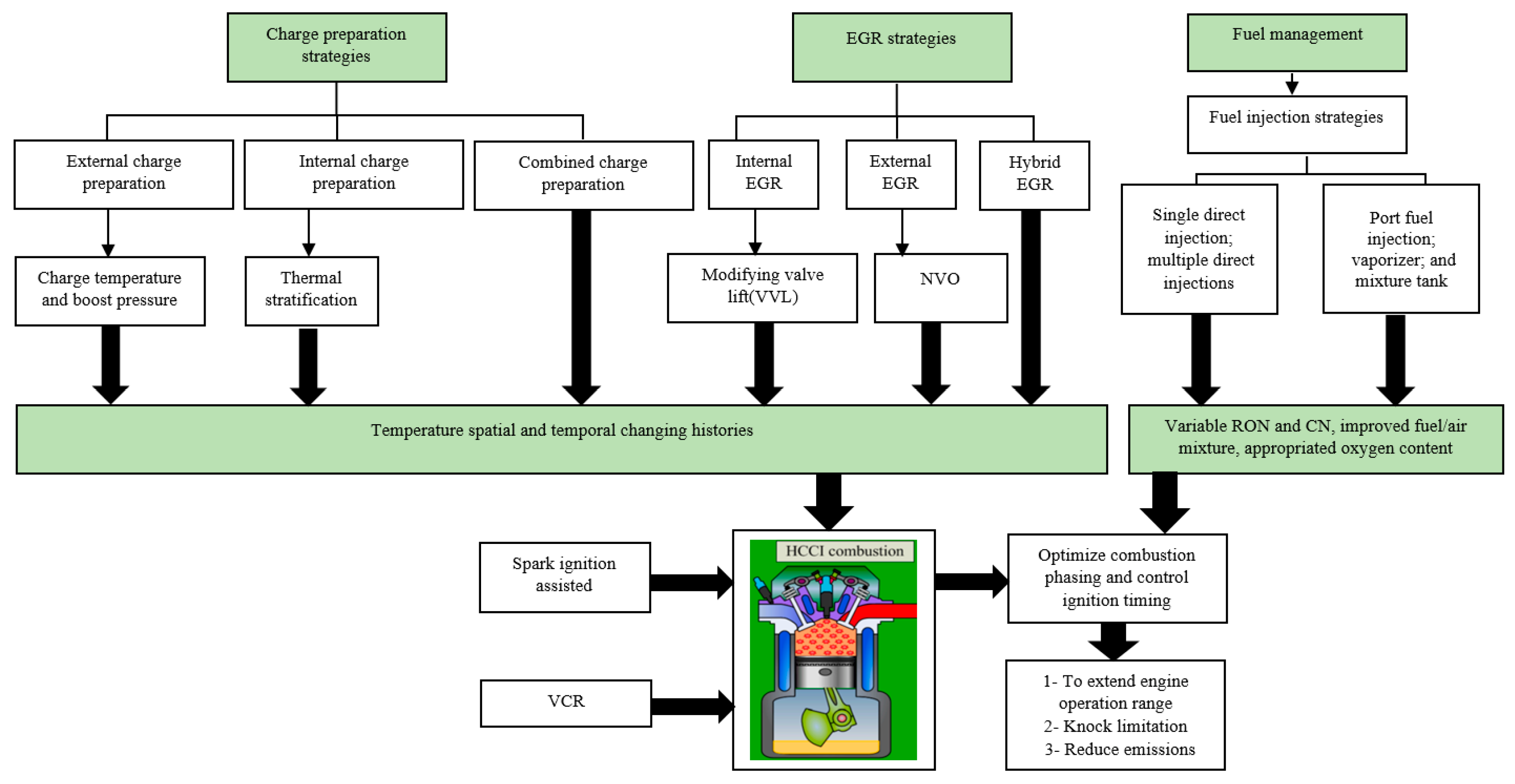

4.1.1. Homogeneous Charge Compression Ignition

- Designing, modifying, and controlling fuel compositions, and employing fuel physical-chemical properties in HCCI engines to improve the combustion phasing and ignition timing and expand operating loads.

- Fuel reactivity stratification may be an attractive method of controlling ignition timing and reducing the excessive PRR.

- Fuel reforming and modification were common techniques for adjusting the chemical components to control combustion phasing and ignition timing.

- As compared to preheated intake temperature, reactive species, and fuel additives have potential advantages in HCCI engines by lowering the intake temperature and making it easier to control the combustion timing.

- In contrast to conventional gasoline and diesel fuels, alternative fuels have remarkable superior advantages in regulating combustion phasing and ignition timing.

- Negative valve overlap is an efficient way of increasing in internal EGR of the HCCI engine, which leads to delay in the auto-ignition for high load, hence retard the combustion phasing.

- Combining external and internal mixture preparation can be considered effective method for controlling ignition timing and combustion phasing.

- The preheating of intake air and boosting the air pressure can shorten ignition timing and extend the load engine to high. Therefore, the combination of the two ways is commonly used in the HCCI engine.

- To stratify the temperature distribution in the cylinder of the unburned mixture before auto-ignition, thermal stratification can be used. It is an efficient technique for governing the HRR and controlling the auto-ignition.

- The combustion phasing and auto-ignition can be controlled using a variable compression ratio instead of preheating the air intake.

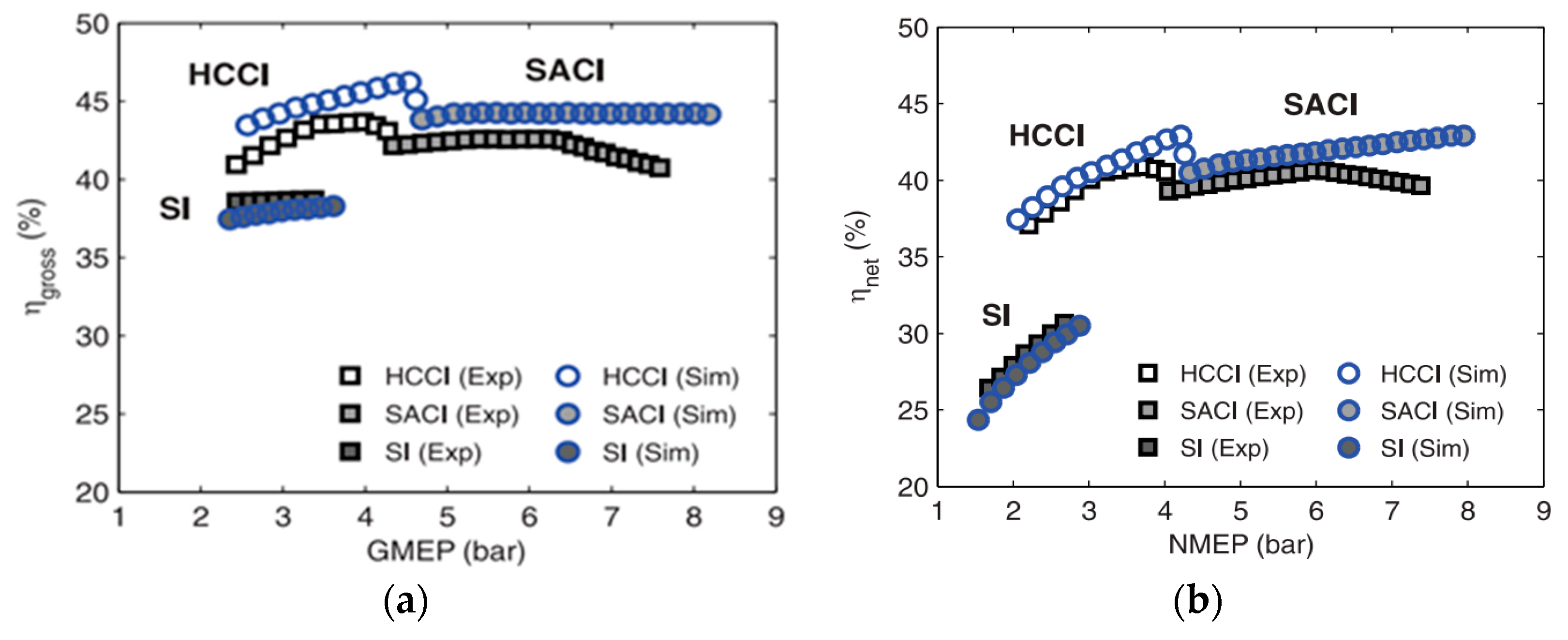

- Applying the SACI mode in the HCCI engine can give an effective approach that operates with lean mixture, controlling combustion phasing, expanding the engine’s load range, and sustaining high thermal efficiency.

4.1.2. Reactivity-Controlled Compression Ignition

- Low emissions such as NOx and soot.

- The losses in heat transfer are lessened.

- Thermodynamic efficiency and fuel efficiency increased.

4.1.3. Partial Premixed Combustion

- Increase thermal exhaust losses with other residual losses.

- Combustion was delayed for 20 bar IMEPg due to hardware limitations.

- Low fuel pressure, extended injection period, and long combustion duration.

4.1.4. Spark-Assisted Compression Ignition

4.1.5. Summary of the LTC Modes

4.2. Highly Dilution Combustion

4.2.1. Advanced Ignition System

- Laser ignition.

- Microwave high-frequency ignition.

- Dual-coil offset/ignition.

- Active and passive jet ignition.

- Multi-charge ignition.

- Laser ignition system (LIS).

- Low-temperature plasma (Corona ignition system (CIS).

- Turbulent jet igniters (TJI).

4.2.2. Laser Ignition System (LIS)

- It is an electrode-less ignition system.

- No electrodes were eroded or quenched effects.

- A laser ignition system’s lifetime will far surpass the spark plug’s lifespan.

- Random position of ignition plasma, capability for the leanest mixture, and precision ignition timing.

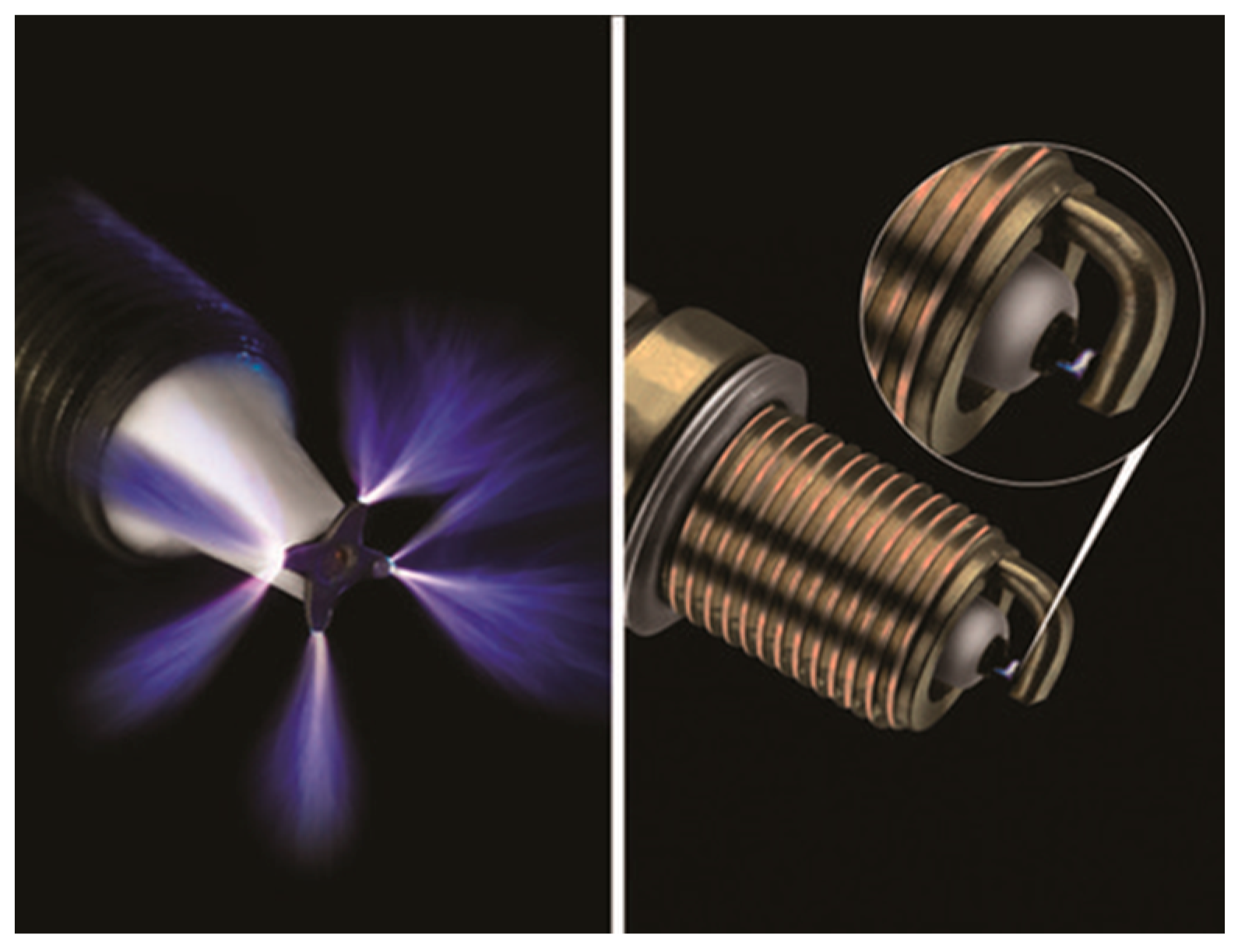

4.2.3. Corona Ignition System (CIS)

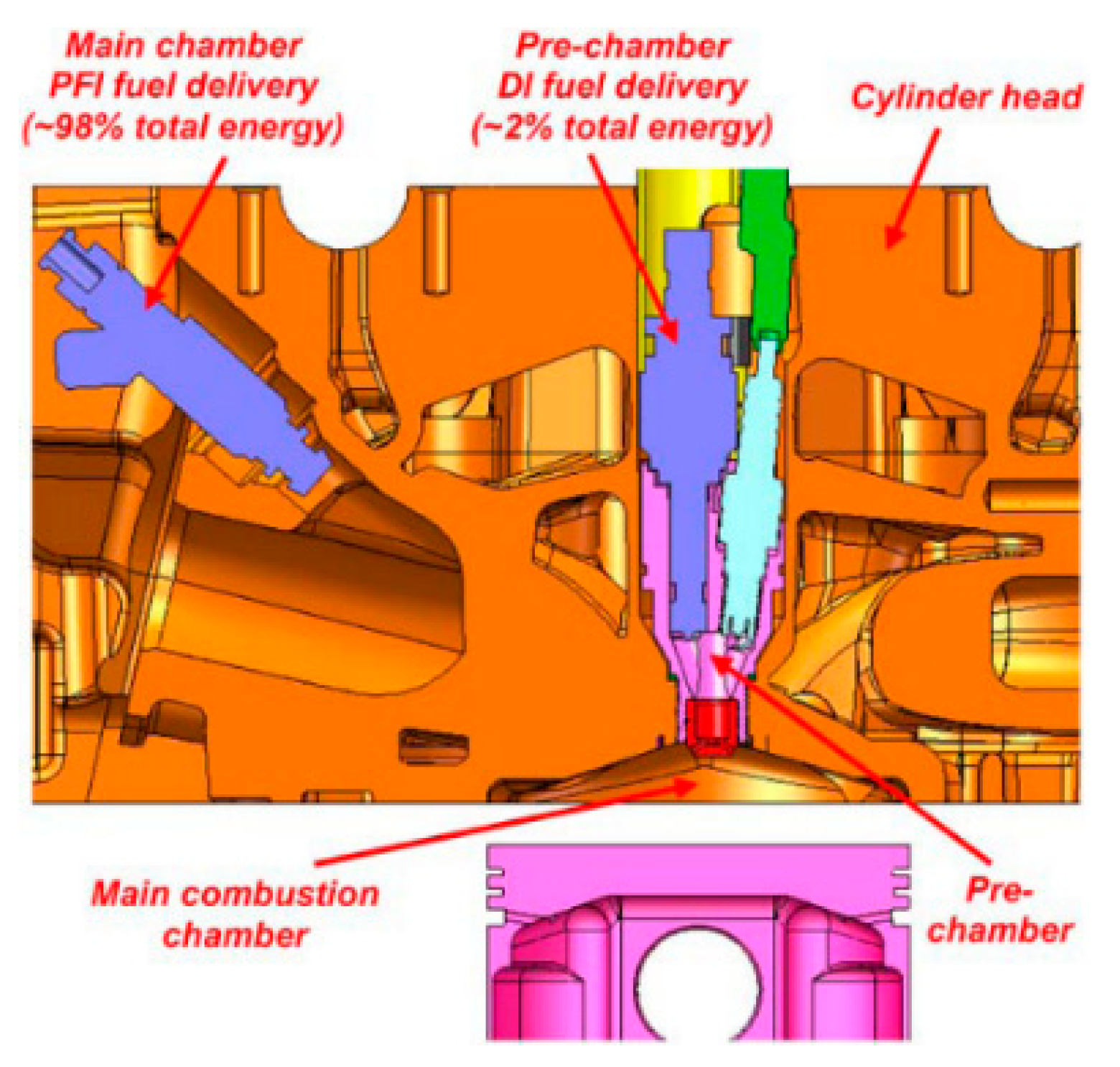

4.2.4. Turbulent Jet Igniters (TJI)

4.2.5. Hydrogen-Enriched Combustion

4.2.6. Thermochemical Recuperation

4.3. Other Advanced Technologies and Strategies

4.3.1. Ultra-High-Pressure Injection

4.3.2. Variable Compression Ratio

4.3.3. Double Compression Expansion Engine

4.3.4. Engine Knock Control

- Heat transfer analysis.

- Temperature analysis.

- Cylinder block vibration analysis.

- In-cylinder pressure analysis.

- Acoustic emissions and light radiation analysis.

- Ion current analysis.

5. Advanced Thermal and Energy Management for Improving Thermal Efficiency

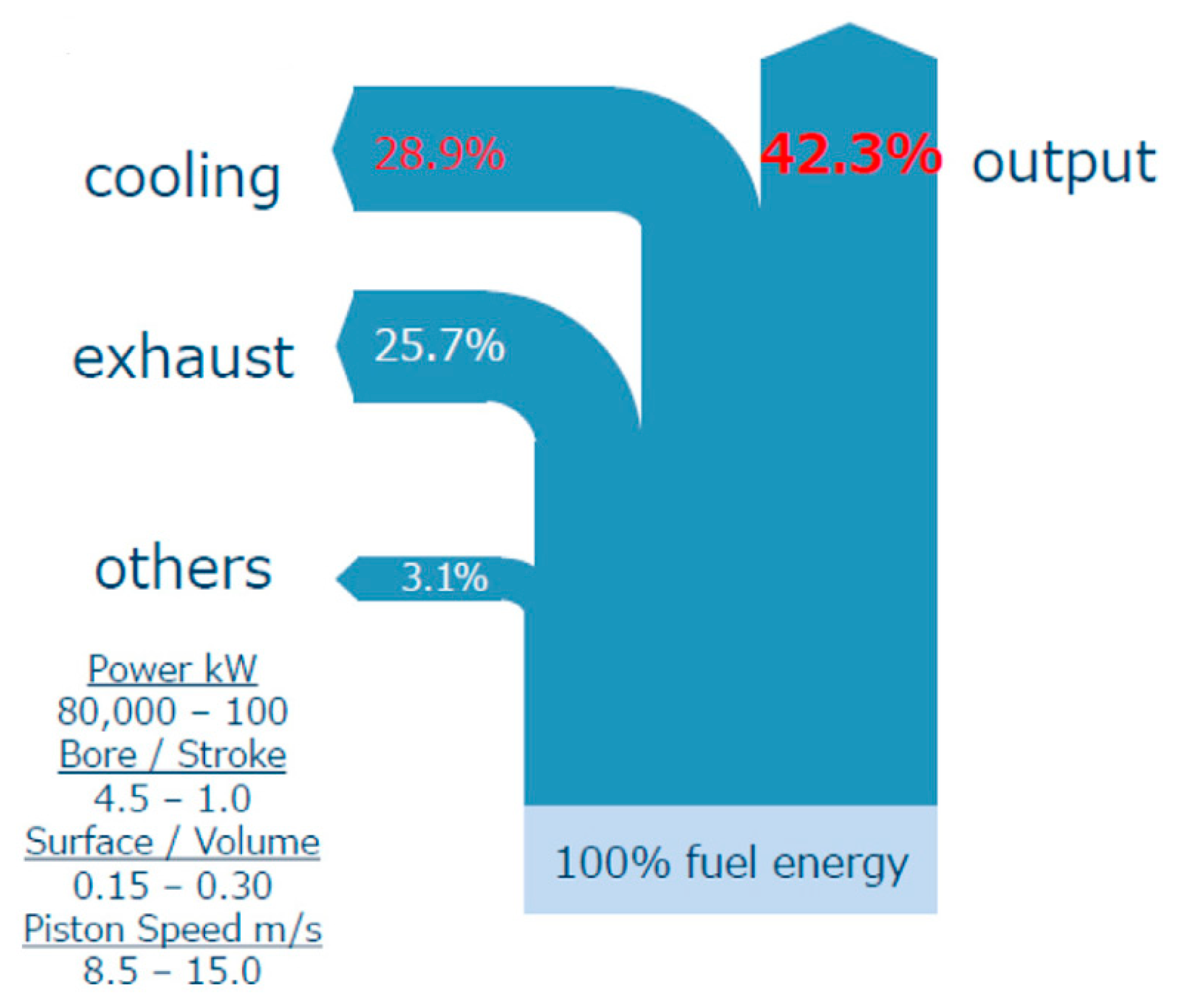

5.1. Exhaust Heat Recovery

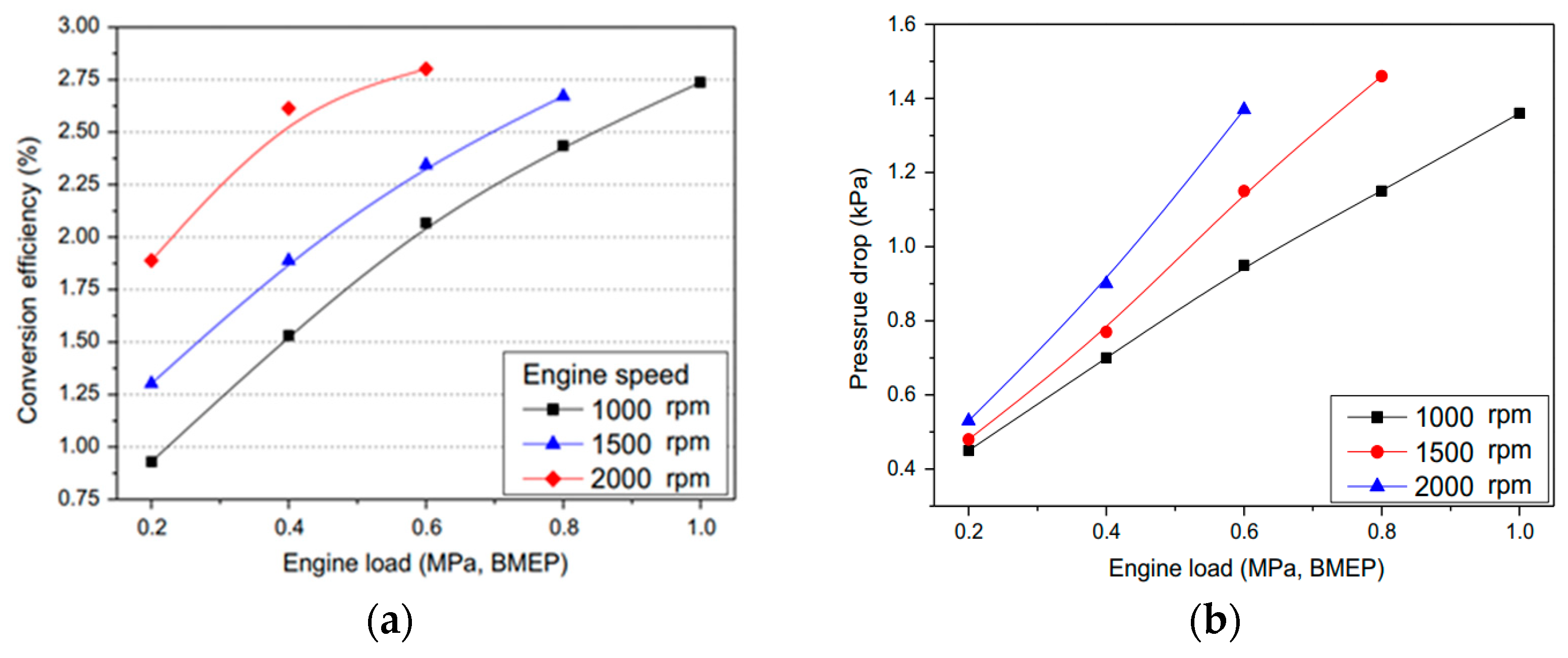

5.1.1. Organic Rankine Cycle

5.1.2. Thermoelectric Generation

5.2. Adiabatic IC Engines

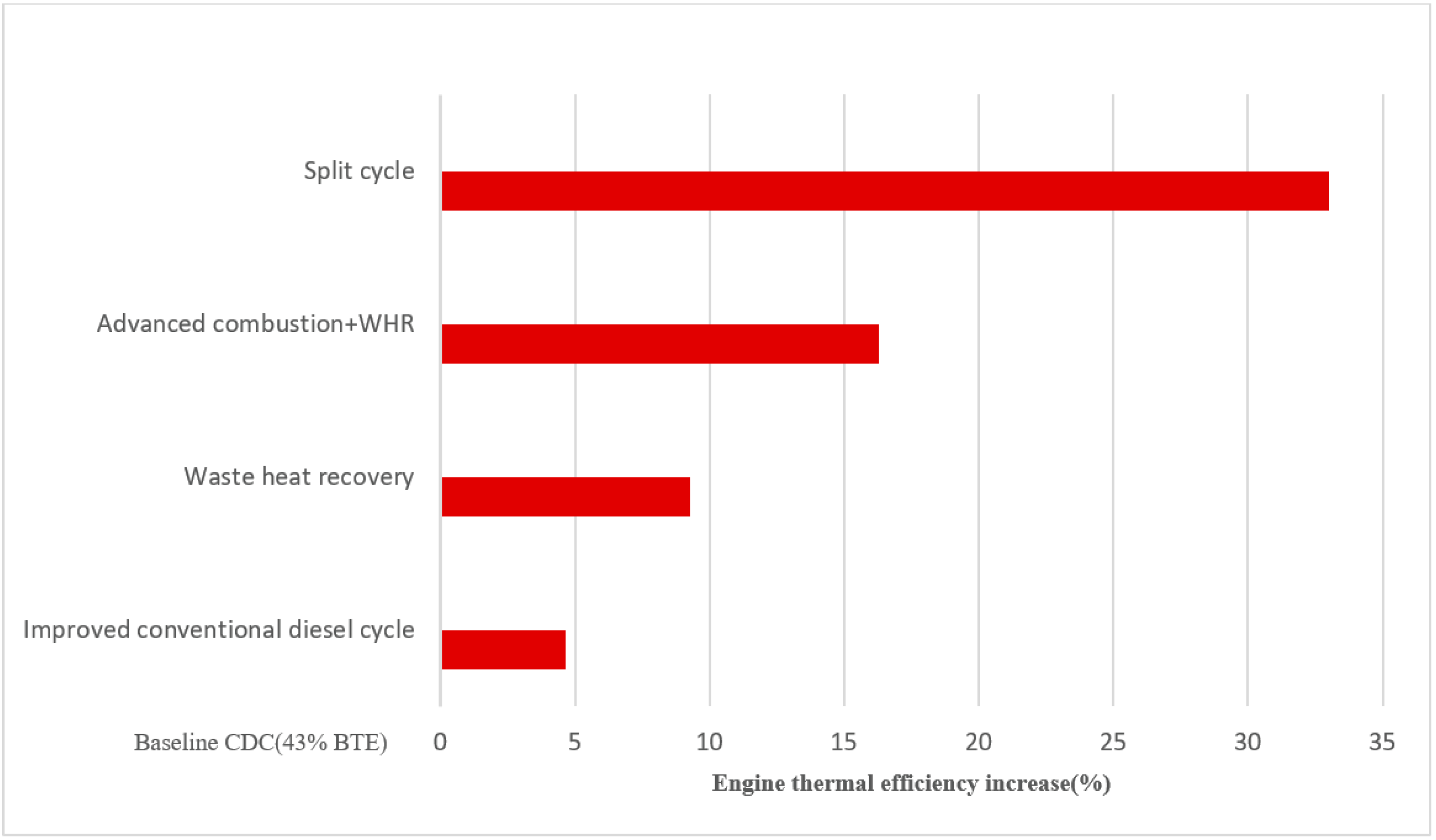

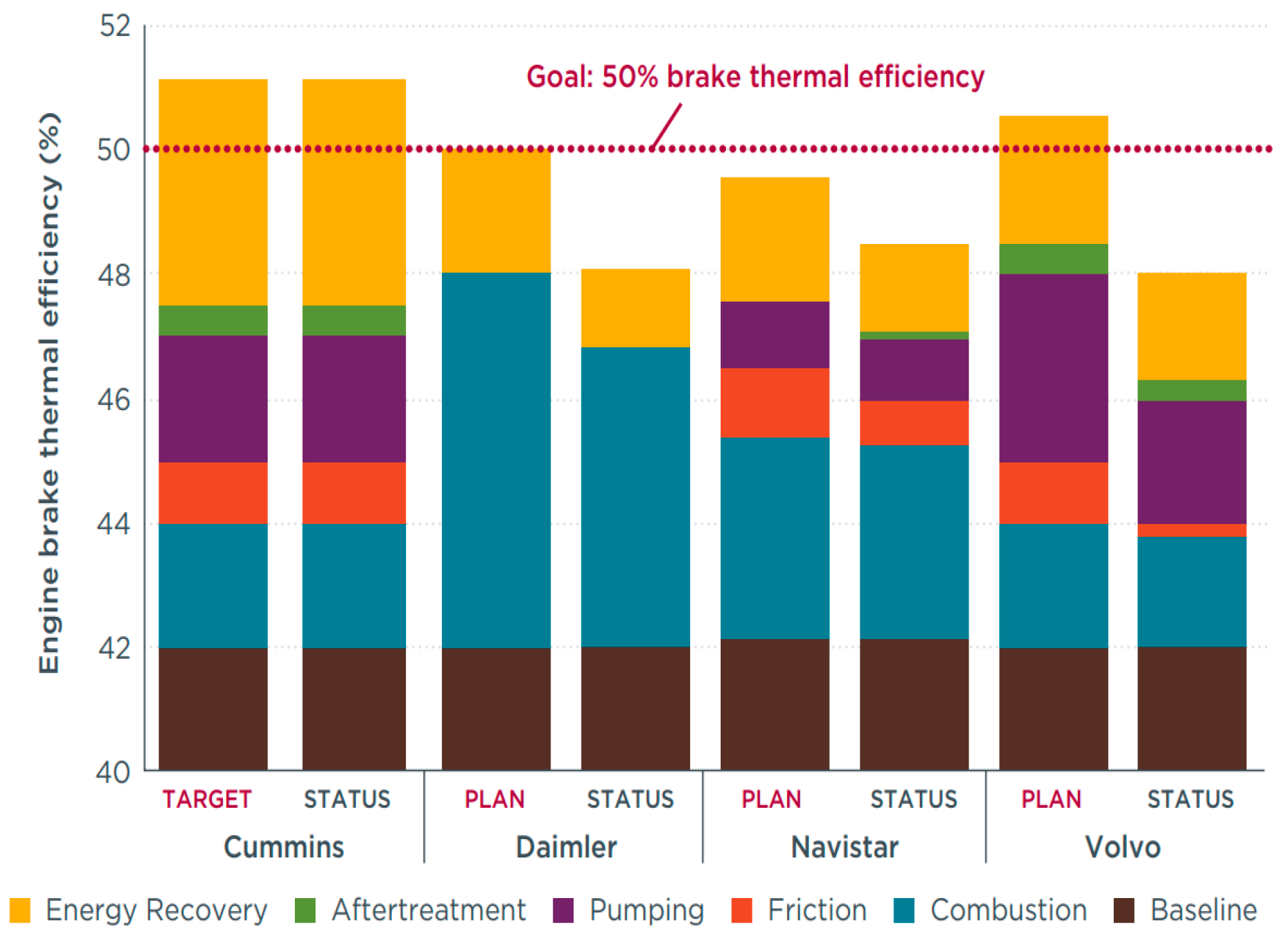

6. Roadmap for Improving Thermal Efficiency

7. Conclusions and Recommendations

- Amongst variable valve actuation (VVA) strategies, early intake valve closing (EIVC) exhibits the ability to extend the load, which requires optimizing combustion phasing. The late intake valve opening (LIVO) has the potential for increasing combustion efficiency at a low load. Due to excellent flexibility and control, the camless system can be considered the best solution for the required profile and quick valve events. It can also be considered an efficient technology for solving the VVA issues and enabling HCCI combustion, thus improving fuel economy (25% better fuel economy) and offering high-efficiency diesel engines.

- Despite the advantages of exhaust gas recirculation (EGR), many restrictions prevent access to the full features, such as fluctuations under transient conditions, misfire, and cycle-to-cycle variations due to high EGR and reduced burning speed. A substantial reduction in the flame speed is considered a significant factor as it affects combustion stability and thermal efficiency related to flame kernel development. As such, combustion initiation periods and burn durations are also increased. The development of the early flame kernel can be completed by using fuels with high flame speed, which makes it faster and less susceptible to cycle-to-cycle variants in turbulence, eventually resulting in greater combustion stability.

- HCCI, PPC, and RCCI have the potential to achieve >50% indicated thermal efficiency. RCCI has been identified as one of the promising technologies, distinguished by its superiority over the other LTC modes in terms of efficiency, emissions reduction, and heat transfer. In comparison, the gross indicated efficiency of RCCI is 16.6% higher than conventional diesel engines. However, this concept is limited by the low combustion efficiency at low loads and high maximum pressure rise rate at high loads. There are various feasible solutions to overcome, including reverse reactivity stratification, control of equivalence ratio, low intake air pressure, adjusting EGR rate, intake temperature, and injection pressure, slowest heat release rate, and the use of direct dual fuel stratification. Apart from the operating parameters and fuel properties, these strategies require further optimization to improve combustion efficiency and reduce the maximum pressure rise rate.

- Most advanced ignition systems can extend the lean limits and improve thermal efficiency. Amongst these ignition systems, laser ignition has an excellent potential to ignite ultra-lean mixtures because of its feasibility of creating multiple ignition points and high-power energy deposition. Compared to conventional spark ignition, multiple ignition points show faster flame propagations, higher lean limits, fast combustion, and improved cycle-to-cycle variations, as well as possess a range of combustion characteristics, such as flammability range and reducing misfire. Consequently, flame quenching has been absent, thus leading to improved engine thermal efficiency. The high cost of this system is a significant challenge in terms of using it as a replacement for conventional spark ignition systems. More efforts are thus needed to overcome this obstacle and achieve further improvements in thermal efficiency by applying this technique. Furthermore, the use of the TJI system is a vital method to improve thermal efficiency and reduce the consumption of fuel and emissions in spark-ignition engines (SIEs) but it is adding small costs to the engine compared to the LIS technique.

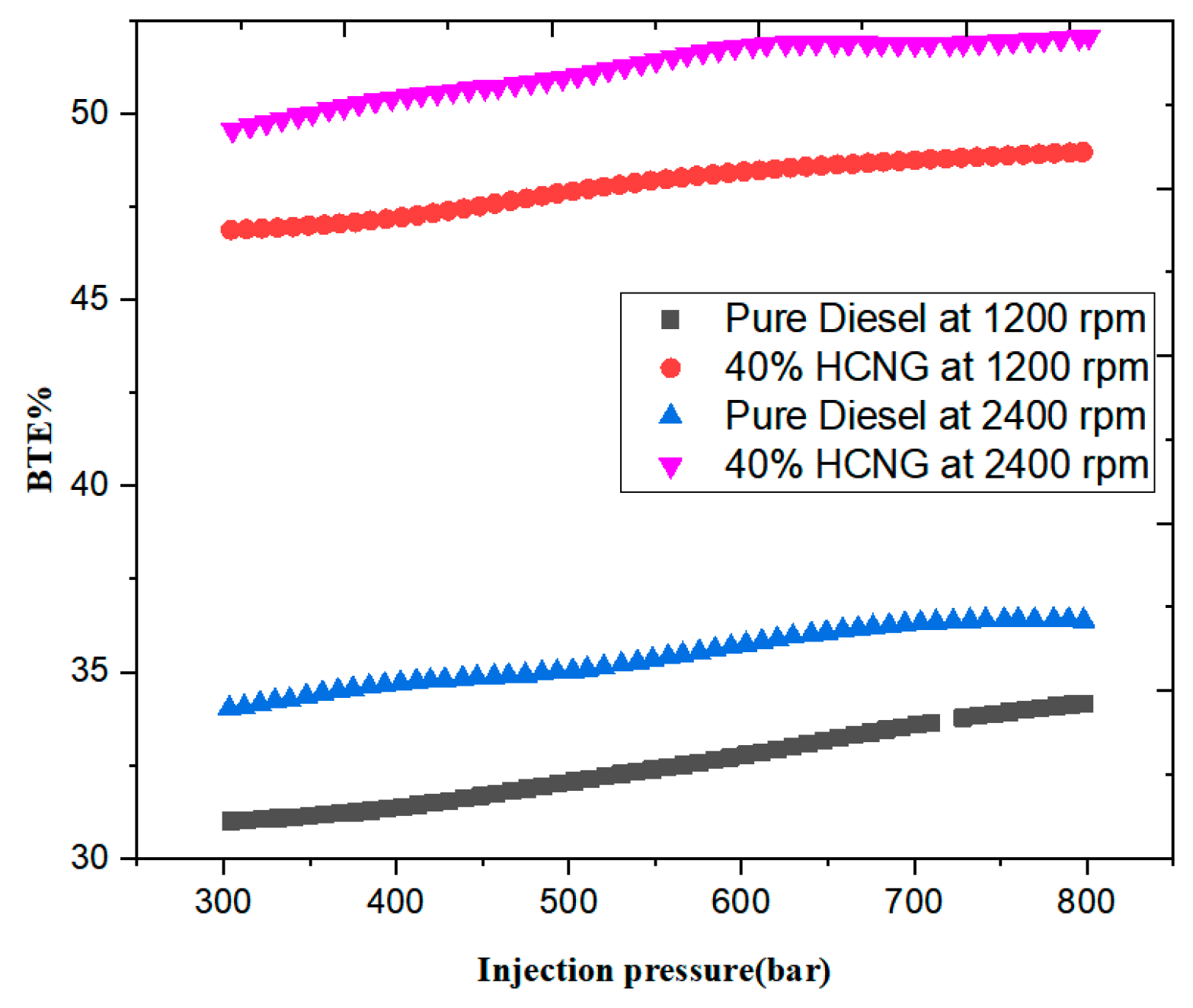

- The addition of hydrogen through intake manifolds can better increase the BTE compared to the direct injection due to a homogeneous mixture. The BTE increases when hydrogen blends into diesel fuel. This can be explained by the fact that hydrogen addition would shorten combustion duration and increase cylinder pressure and heat release resulting from increased flame speed. Following the addition of 40% hydrogen (H2) to compressed natural gas (CNG), a significant improvement in the BTE by 8–14% compared to pure diesel was recorded. Correspondingly, port fuel injection has some limitations that include knocking, pre-ignition, low volumetric efficiency, and backfire, thus limiting engine load and efficiency improvement. Several recommendations are proposed for further consideration, such as the mechanical durability of the engines and safety, further development of an advanced direct injection, as well as the optimization of injection timing and injection duration to sustain engine efficiency at a high value.

- A significant improvement can be obtained in engine efficiency when using an ultra-high injection pressure and micro-hole nozzle (46.3–49.7% BTE). Ultra-high pressures make the flow state in nozzle holes reach a supercritical state due to its thermal effect. Therefore, realizing how fuel flows through nozzle holes at ultra-high pressures remains a crucial challenge. Further experience in designing this technology is needed.

- As the compression ratio increases, the thermal efficiency increases, and specific fuel consumption is reduced. The compression ratio is limited in gasoline engines due to the low resistance to engine knock. On the contrary, the BTE of diesel engines increases significantly, particularly when biodiesel blends with diesel with sacrifices in BSFC. The Miller cycle is suggested to improve thermal efficiency, reduce the knocking issue, and maintain a high expansion ratio by reducing the effective compression ratio. Various methods are used to apply the Miller cycle, amongst which the VVA is the simplest. The Atkinson cycle can also perform the same purpose.

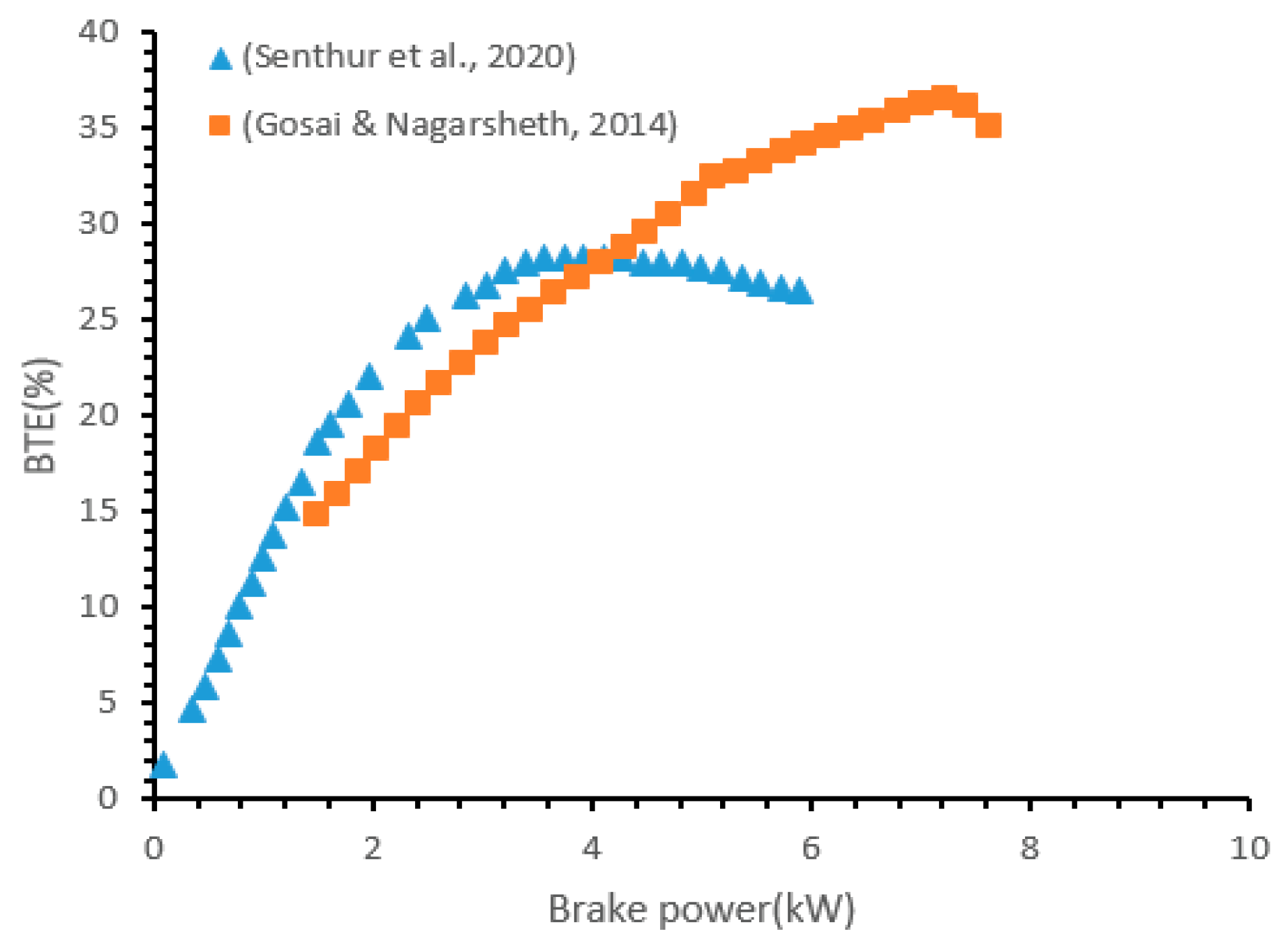

- Most techniques for recovering waste heat have good benefits in terms of the BSFC. Amongst these, Organic Rankine Cycle (ORC) is considered a promising technique in terms of the BSFC (enables ~10% in fuel economy) and thermal efficiency (4.4–8.3% increase in BTE) due to its lower temperature applications, quiet operation, smaller expanders, and no interaction with an engine. In vehicle applications, the ORC is not an appropriate option due to weight and space restrictions. Additionally, it has drawbacks that restrict its commercial application, including safety issues, complexity, cost, working fluid toxicity, flammability, and thermal management issues.

- The key strength of the low heat rejection (LHR) engine is the high exhaust gas temperature resulting from reducing the heat transfer. In turn, this provides more potential benefits for energy recovery by employing turbochargers, superchargers, or electric generators, among others, thus increasing engine efficiency and performance. In contrast, using the LHR engines reduces volumetric efficiency due to high cylinder temperature; however, this can be recovered by utilizing supercharging and turbocharging. The thermal barrier coating (TBC) assists in preserving the heat content of the engine. However, the knocking issues remain a challenge due to the higher wall temperatures caused by TBC. Notwithstanding this limitation, developing an innovative and higher-precision technique for TBC research is suggested to obtain more reliable physical barrier coating models, which can improve combustion characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United States Environmental Protection Agency. Regulations for Emissions from Vehicles and Engines—Cleaner Trucks Initiative. 2020. Available online: https://www.epa.gov/regulations-emissions-vehicles-and-engines/clean-trucks-plan (accessed on 5 August 2021).

- Goyal, H.; Nyrenstedt, G.; Moreno Cabezas, K.; Panthi, N.; Im, H.; Andersson, A.; Johansson, B. A Simulation Study to Understand the Efficiency Analysis of Multiple Injectors for the Double Compression Expansion Engine (DCEE) Concept; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2021; pp. 1–18. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- European Union. Worldwide Emission Standards and Related Regulations—Passenger Cars/Light and Medium Duty Vehicles. Available online: https://www.delphi.com/sites/default/files/inline-files/delphi-worldwide-emissions-standards-passenger-cars-light-duty-2016-7.pdf (accessed on 1 July 2016).

- Boretti, A.A. Energy recovery in passenger cars. J. Energy Resour. Technol. Trans. ASME 2012, 134, 022203. [Google Scholar] [CrossRef]

- Xin, Q.; Pinzon, C.F. Improving the Environmental Performance of Heavy-Duty Vehicles and Engines: Key Issues and System Design Approaches; Woodhead Publishing: Sawston, UK, 2014; pp. 225–278. ISBN 9780857095220. [Google Scholar]

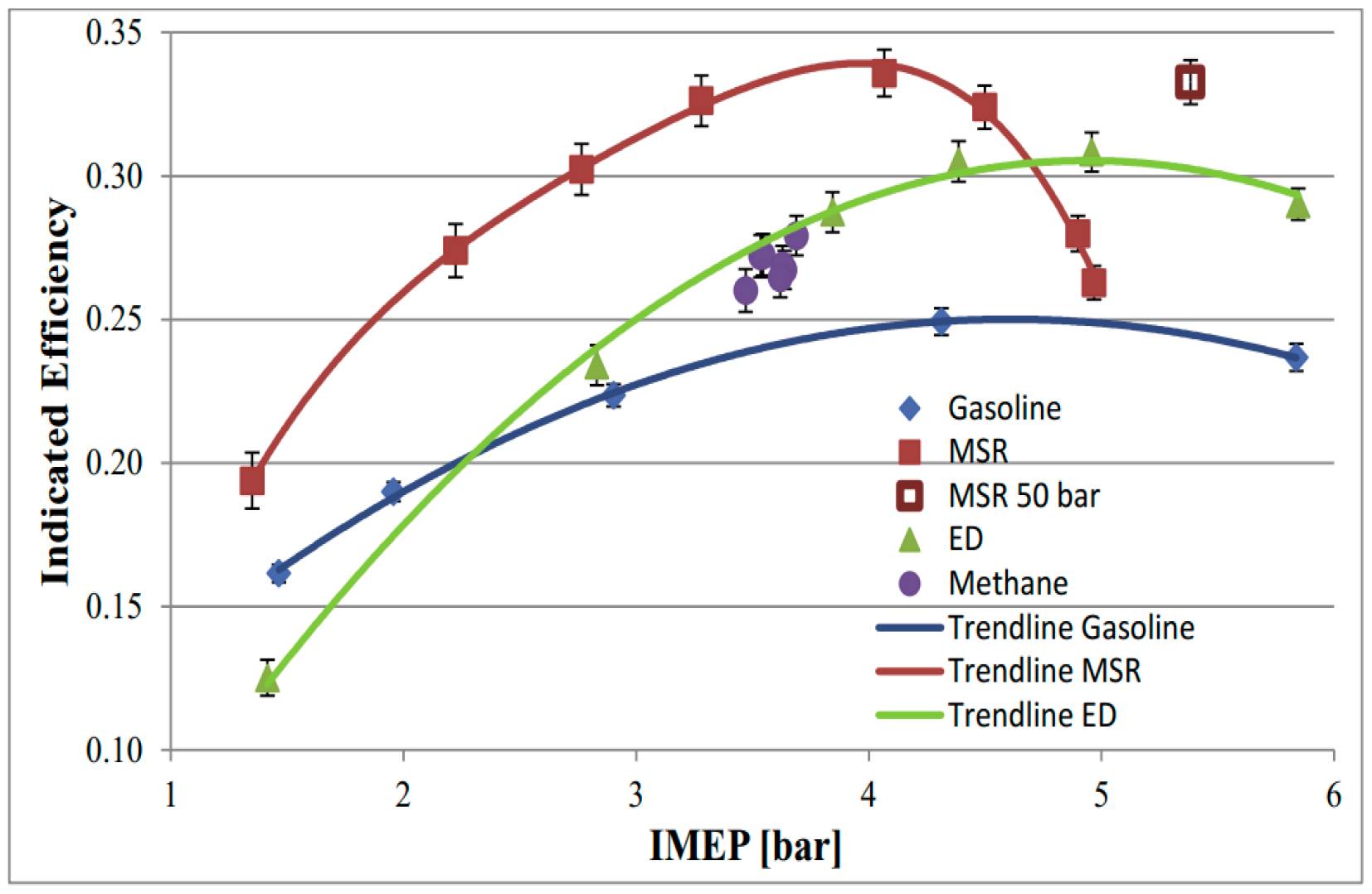

- Morgan, R.E.; Jackson, N.; Atkins, A.; Dong, G.; Heikal, M.; Lenartowicz, C. The Recuperated Split Cycle—Experimental Combustion Data from a Single Cylinder Test Rig. SAE Int. J. Engines 2017, 10, 2596–2605. [Google Scholar] [CrossRef]

- Takahashi, D.; Nakata, K.; Yoshihara, Y.; Ohta, Y.; Nishiura, H. Combustion Development to Achieve Engine Thermal Efficiency of 40% for Hybrid Vehicles; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015; Volume 2015. [Google Scholar] [CrossRef]

- Nakata, K.; Nogawa, S.; Takahashi, D.; Yoshihara, Y.; Kumagai, A.; Suzuki, T. Engine Technologies for Achieving 45% Thermal Efficiency of S.I. Engine. SAE Int. J. Engines 2015, 9, 179–192. [Google Scholar] [CrossRef]

- Alagumalai, A. Internal combustion engines: Progress and prospects. Renew. Sustain. Energy Rev. 2014, 38, 561–571. [Google Scholar] [CrossRef]

- Krishnamoorthi, M.; Malayalamurthi, R.; He, Z.; Kandasamy, S. A review on low temperature combustion engines: Performance, combustion and emission characteristics. Renew. Sustain. Energy Rev. 2019, 116, 109404. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Deng, S. A review of modified Organic Rankine cycles (ORCs) for internal combustion engine waste heat recovery (ICE-WHR). Renew. Sustain. Energy Rev. 2018, 92, 95–110. [Google Scholar] [CrossRef]

- Lion, S.; Michos, C.N.; Vlaskos, I.; Rouaud, C.; Taccani, R. A review of waste heat recovery and Organic Rankine Cycles (ORC) in on-off highway vehicle Heavy Duty Diesel Engine applications. Renew. Sustain. Energy Rev. 2017, 79, 691–708. [Google Scholar] [CrossRef]

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The scope for improving the efficiency and environmental impact of internal combustion engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

- Splitter, D.; Wissink, M.; Delvescovo, D.; Reitz, R. RCCI Engine Operation towards 60% Thermal Efficiency; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2013; Volume 2. [Google Scholar] [CrossRef]

- Abani, N.; Nagar, N.; Zermeno, R.; Chiang, M.; Thomas, I. Developing a 55% BTE Commercial Heavy-Duty Opposed-Piston Engine without a Waste Heat Recovery System; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017; Volume 2017. [Google Scholar] [CrossRef]

- Yu, H.; Su, W. Numerical study on the approach for super-high thermal efficiency in a gasoline homogeneous charge compression ignition lean-burn engine. Int. J. Engine Res. 2021, 22, 1329–1341. [Google Scholar] [CrossRef]

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.K.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Dong, G.; Morgan, R.; Heikal, M. A novel split cycle internal combustion engine with integral waste heat recovery. Appl. Energy 2015, 157, 744–753. [Google Scholar] [CrossRef]

- Szybist, J.P.; Busch, S.; McCormick, R.L.; Pihl, J.A.; Splitter, D.A.; Ratcliff, M.A.; Kolodziej, C.P.; Storey, J.E.; Moses-Debusk, M.; Vuilleumier, D.; et al. What Fuel Properties Enable Higher Thermal Efficiency in Spark-Ignited Engines? Prog. Energy Combust. Sci. 2021, 82, 100876. [Google Scholar] [CrossRef]

- Hayashi, N.; Sugiura, A.; Abe, Y.; Suzuki, K. Development of Ignition Technology for Dilute Combustion Engines. SAE Int. J. Engines 2017, 10, 984–994. [Google Scholar] [CrossRef]

- Johnson, T.V. Review of Diesel Emissions and Control; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010; Volume 3, pp. 16–29. [Google Scholar] [CrossRef]

- Lam, N.; Tuner, M.; Tunestal, P.; Andersson, A.; Lundgren, S.; Johansson, B. Double Compression Expansion Engine Concepts: A Path to High Efficiency. SAE Int. J. Engines 2015, 8, 1562–1578. [Google Scholar] [CrossRef]

- Haseli, Y. Entropy Analysis in Thermal Engineering Systems; Academic Press: Cambridge, MA, USA, 2019; pp. 55–66. [Google Scholar] [CrossRef]

- Nabours, S.; Shkolnik, N.; Nelms, R.; Gnanam, G.; Shkolnik, A. High Efficiency Hybrid Cycle Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Nakata, K.; Sasaki, N.; Ota, A.; Kawatake, K. The effect of fuel properties on thermal efficiency of advanced spark-ignition engines. Int. J. Engine Res. 2011, 12, 274–281. [Google Scholar]

- Dec, J.E. A conceptual model of DL diesel combustion based on laser-sheet imaging. SAE Trans. 1997, 106, 1319–1348. [Google Scholar]

- Kim, T.Y.; Lee, S.H. Combustion and Emission Characteristics of Wood Pyrolysis Oil-Butanol Blended Fuels in a Di Diesel Engine. Int. J. Automot. Technol. 2015, 16, 903–912. [Google Scholar] [CrossRef]

- Haylock, J.C.; Addeo, A.; Hogan, A.J. Thermoplastic Olefins for Automotive Soft Interior Trim; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1990. [Google Scholar]

- Johansson, B. Förbränningsmotorer; Eckerle: Lund, Sweden, 2006. [Google Scholar]

- Eckerle, W. Innovative Approaches to Improving Engine Efficiency. Presented at the 2007 Diesel Engine-Efficiency & Emissions Research Conference (DEER 2007), Detroit, MI, USA, 13–16 August 2007. [Google Scholar]

- Maurya, R.K. Characteristics and Control of Low Temperature Combustion Engines: Employing Gasoline, Ethanol and Methanol; Springer: Cham, Switzerland, 2018; ISBN 3319685082. [Google Scholar]

- Shkolnik, N.; Shkolnik, A.C. High efficiency hybrid cycle engine. In Proceedings of the ASME 2006 Internal Combustion Engine Division Spring Technical Conference, Aachen, Germany, 7–10 May 2006; pp. 823–833. [Google Scholar] [CrossRef]

- Vehicles, M.; Sad, N. Realisation and analysis of a new thermodynamic by. Therm. Sci. 2011, 15, 961–974. [Google Scholar] [CrossRef]

- Diskin, D.; Tartakovsky, L. Finite-time energy conversion in a hybrid cycle combining electrochemical, combustion and thermochemical recuperation processes. Energy Convers. Manag. 2022, 262, 115673. [Google Scholar] [CrossRef]

- Lou, Z.; Zhu, G. Review of advancement in variable valve actuation of internal combustion engines. Appl. Sci. 2020, 10, 1216. [Google Scholar] [CrossRef]

- Tang, H.; Pennycott, A.; Akehurst, S.; Brace, C.J. A review of the application of variable geometry turbines to the downsized gasoline engine. Int. J. Engine Res. 2015, 16, 810–825. [Google Scholar] [CrossRef]

- Lee, W.; Schubert, E.; Li, Y.; Li, S.; Bobba, D.; Sarlioglu, B. Overview of Electric Turbocharger and Supercharger for Downsized Internal Combustion Engines. IEEE Trans. Transp. Electrif. 2017, 3, 36–47. [Google Scholar] [CrossRef]

- Ricardo, M.B.; Apostolos, P.; Yang, M.Y. Overview of boosting options for future downsized engines. Sci. China Technol. Sci. 2011, 54, 318–331. [Google Scholar] [CrossRef]

- Xin, Q. Diesel engine air system design. In Diesel Engine System Design; Elsevier: Amsterdam, The Netherlands, 2011; pp. 860–908. [Google Scholar] [CrossRef]

- Asad, U. Advanced Diagnostics, Control and Testing of Diesel Low Temperature Combustion. Ph.D. Thesis, University of Windsor, Windsor, ON, Canada, 2009. [Google Scholar]

- Kokjohn, S.L.; Hanson, R.M.; Splitter, D.A.; Reitz, R.D. Fuel reactivity controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion. Int. J. Engine Res. 2011, 12, 209–226. [Google Scholar] [CrossRef]

- Hara, S.; Suga, S.; Watanabe, S.; Nakamura, M. Variable valve actuation systems for environmentally friendly engines. Hitachi Rev. 2009, 58, 319–324. [Google Scholar]

- Hyundai Motor Company Hyundai’s Breakthrough Engine that Answers a 133-year Challenge. 2019, pp. 1–12. Available online: https://tech.hyundaimotorgroup.com/article/hyundai-announces-breakthrough-engine-that-answers-a-133-year-challenge/ (accessed on 29 October 2019).

- De Ojeda, W. Effect of Variable Valve Timing on Diesel Combustion Characteristics; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Gonca, G.; Sahin, B.; Parlak, A.; Ust, Y.; Ayhan, V.; Cesur, İ.; Boru, B. Theoretical and experimental investigation of the Miller cycle diesel engine in terms of performance and emission parameters. Appl. Energy 2015, 138, 11–20. [Google Scholar] [CrossRef]

- Kovacs, D.; Eilts, P. Potentials of Miller Cycle on HD Diesel Engines Using a 2-Stage Turbocharging System; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Guan, W.; Pedrozo, V.B.; Zhao, H.; Ban, Z.; Lin, T. Variable valve actuation–based combustion control strategies for efficiency improvement and emissions control in a heavy-duty diesel engine. Int. J. Engine Res. 2020, 21, 578–591. [Google Scholar] [CrossRef]

- Milovanovic, N.; Chen, R.; Turner, J. Influence of the Variable Valve Timing Strategy on the Control of a Homogeneous Charge Compression (HCCI) Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Badami, M.; Marzano, M.R.; Nuccio, P. Influence of Late Intake-Valve Opening on the SI Engine-Performance in Idle Condition; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Hunicz, J.; Kordos, P. An experimental study of fuel injection strategies in CAI gasoline engine. Exp. Therm. Fluid Sci. 2011, 35, 243–252. [Google Scholar] [CrossRef]

- Urushihara, T.; Hiraya, K.; Kakuhou, A.; Itoh, T. Expansion of HCCI operating region by the combination of direct fuel injection, negative valve overlap and internal fuel reformation. SAE Trans. 2003, 112, 1092–1100. [Google Scholar]

- Xie, H.; Li, L.; Chen, T.; Yu, W.; Wang, X.; Zhao, H. Study on spark assisted compression ignition (SACI) combustion with positive valve overlap at medium–high load. Appl. Energy 2013, 101, 622–633. [Google Scholar] [CrossRef]

- Koopmans, L.; Ström, H.; Lundgren, S.; Backlund, O.; Denbratt, I. Demonstrating a SI-HCCI-SI Mode Change on a Volvo 5-Cylinder Electronic Valve Control Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Fuerhapter, A.; Piock, W.F.; Fraidl, G.K. CSI-Controlled Auto Ignition—the Best Solution for the Fuel Consumption—Versus Emission Trade-Off? SAE Trans. 2003, 112, 1142–1151. [Google Scholar]

- Assanis, D.N.; Polishak, M. Valve event optimization in a spark-ignition engine. J. Eng. Gas Turbines Power 1990, 112, 341–347. [Google Scholar] [CrossRef]

- Martins, M.E.S.; Lanzanova, T.D.M. Full-load Miller cycle with ethanol and EGR: Potential benefits and challenges. Appl. Therm. Eng. 2015, 90, 274–285. [Google Scholar] [CrossRef]

- Flierl, R.; Gollasch, D.; Knecht, A.; Hannibal, W. Improvements to a Four Cylinder Gasoline Engine through the Fully Variable Valve Lift and Timing System UniValve®; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Li, Q.; Liu, J.; Fu, J.; Zhou, X.; Liao, C. Comparative study on the pumping losses between continuous variable valve lift (CVVL) engine and variable valve timing (VVT) engine. Appl. Therm. Eng. 2018, 137, 710–720. [Google Scholar] [CrossRef]

- Xin, Q. Advanced diesel valvetrain system design. Diesel Engine Syst. Des. 2013, 529–650. [Google Scholar] [CrossRef]

- Kodama, Y.; Nishizawa, I.; Sugihara, T.; Sato, N.; Iijima, T.; Yoshida, T. Full-Load HCCI Operation with Variable Valve Actuation System in a Heavy-Duty Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007; Volume 2007. [Google Scholar] [CrossRef]

- Pedrozo, V.B.; May, I.; Lanzanova, T.D.M.; Zhao, H. Potential of internal EGR and throttled operation for low load extension of ethanol-diesel dual-fuel reactivity controlled compression ignition combustion on a heavy-duty engine. Fuel 2016, 179, 391–405. [Google Scholar] [CrossRef]

- Sugimoto, C.; Sakai, H.; Umemoto, A.; Shimizu, Y.; Ozawa, H. Study on Variable Valve Timing System Using Electromagnetic Mechanism; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Xu, G.; Jia, M.; Li, Y.; Chang, Y.; Liu, H.; Wang, T. Evaluation of variable compression ratio (VCR)and variable valve timing (VVT)strategies in a heavy-duty diesel engine with reactivity controlled compression ignition (RCCI)combustion under a wide load range. Fuel 2019, 253, 114–128. [Google Scholar] [CrossRef]

- Fallahzadeh, F.; Subrahamanyam, J.P.; Sharma, V.; Babu, M.K.G. Simulation and Evaluation of a Variable Valve Timing Single Cylinder Spark Ignition Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Fontana, G.; Galloni, E.; Palmaccio, R.; Torella, E. The Influence of Variable Valve Timing on the Combustion Process of a Small Spark-Ignition Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006; Volume 2006. [Google Scholar] [CrossRef]

- Nanjundaswamy, H.; Tatur, M.; Tomazic, D.; Dahodwala, M.; Eping, T.; Virnich, L.; Xin, Q.H.; Gorczowski, W.; Read, M. Development and Calibration of On-Board-Diagnostic Strategies Using a Micro-HiL Approach; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Wu, B.; Yu, H.; Pak, P.; Pei, Y.; Su, W. Effects of Late Intake Valve Closing Timing on Thermal Efficiency and Emissions Based on a Two-stage Turbocharger Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2013; Volume 2013. [Google Scholar] [CrossRef]

- Ickes, A.; Hanson, R.; Wallner, T. Impact of Effective Compression Ratio on Gasoline-Diesel Dual-Fuel Combustion in a Heavy-Duty Engine Using Variable Valve Actuation; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015; Volume 2015. [Google Scholar] [CrossRef]

- Maurya, R.K. Reciprocating Engine Combustion Diagnostics; Springer: Cham, Switzerland, 2019; ISBN 9783030119539. [Google Scholar]

- Mikulski, M.; Balakrishnan, P.R.; Doosje, E.; Bekdemir, C. Variable Valve Actuation Strategies for Better Efficiency Load Range and Thermal Management in an RCCI Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2018; Volume 2018, pp. 1–14. [Google Scholar] [CrossRef]

- Council, N.R. Cost, Effectiveness, and Deployment of Fuel Economy Technologies for Light-Duty Vehicles; National Academies Press: Washington, DC, USA, 2015; ISBN 0309373913. [Google Scholar]

- Kelly Blue Book. 2014 Chevy Impala Gets Variable Valve Lift on Ecotec 4-Cylinder; Kelly Blue Book: Irvine, CA, USA, 17 September 2012. [Google Scholar]

- Izadi Najafabadi, M.; Abdul Aziz, N. Homogeneous charge compression ignition combustion: Challenges and proposed solutions. J. Combust. 2013, 2013, 783789. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Review of Some Methods for Improving Transient Response in Automotive Diesel Engines through Various Turbocharging Configurations. Front. Mech. Eng. 2016, 2, 4. [Google Scholar] [CrossRef]

- Filipi, Z.; Wang, Y.; Assanis, D. Effect of Variable Geometry Turbine (VGT) on Diesel Engine and Vehicle System Transient Response; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Lee, B.; Filipi, Z.; Assanis, D.; Jung, D. Simulation-based assessment of various dual-stage boosting systems in terms of performance and fuel economy improvements. SAE Int. J. Engines 2009, 2, 1335–1346. [Google Scholar] [CrossRef]

- Zheng, Z.; Feng, H.; Mao, B.; Liu, H.; Yao, M. A theoretical and experimental study on the effects of parameters of two-stage turbocharging system on performance of a heavy-duty diesel engine. Appl. Therm. Eng. 2018, 129, 822–832. [Google Scholar] [CrossRef]

- Romagnoli, A.; Martinez-Botas, R.F.; Rajoo, S. Steady state performance evaluation of variable geometry twin-entry turbine. Int. J. Heat Fluid Flow 2011, 32, 477–489. [Google Scholar] [CrossRef]

- Wu, B.; Zhan, Q.; Yu, X.; Lv, G.; Nie, X.; Liu, S. Effects of Miller cycle and variable geometry turbocharger on combustion and emissions in steady and transient cold process. Appl. Therm. Eng. 2017, 118, 621–629. [Google Scholar] [CrossRef]

- Keidel, S.; Wetzel, P.; Biller, B.; Bevan, K.; Birckett, A. Diesel engine fuel economy improvement enabled by supercharging and downspeeding. SAE Int. J. Commer. Veh. 2012, 5, 483–493. [Google Scholar] [CrossRef]

- Franke, M.; Bhide, S.; Liang, J.; Neitz, M.; Hamm, T. Development trends for commercial and industrial engines. SAE Int. J. Engines 2014, 7, 1629–1636. [Google Scholar] [CrossRef]

- Martin, S.; Beidl, C.; Mueller, R. Responsiveness of a 30 Bar BMEP 3-Cylinder Engine: Opportunities and Limits of Turbocharged Downsizing; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Kirwan, J.E.; Shost, M.; Roth, G.; Zizelman, J. 3-cylinder turbocharged gasoline direct injection: A high value solution for low CO2 and NOx emissions. SAE Int. J. Engines 2010, 3, 355–371. [Google Scholar] [CrossRef]

- Watson, N.; Janota, M. Turbocharging the Internal Combustion Engine; Macmillan International Higher Education: London, UK, 1982; ISBN 134904024X. [Google Scholar]

- Winkler, N.; Ångström, H.-E. Simulations and Measurements of a Two-Stage Turbocharged Heavy-Duty Diesel Engine including Egr in Transient Operation; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Chadwell, C.; Alger, T.; Roberts, C.; Arnold, S. Boosting Simulation of High Efficiency Alternative Combustion Mode Engines. SAE Int. J. Engines 2011, 4, 375–393. [Google Scholar] [CrossRef]

- Manente, V.; Zander, C.-G.; Johansson, B.; Tunestal, P.; Cannella, W. An Advanced Internal Combustion Engine Concept for Low Emissions and High Efficiency from Idle to Max Load Using Gasoline Partially Premixed Combustion; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Manente, V.; Johansson, B.; Cannella, W. Gasoline partially premixed combustion, the future of internal combustion engines? Int. J. Engine Res. 2011, 12, 194–208. [Google Scholar] [CrossRef]

- Joo, S.M.; Alger, T.; Chadwell, C.; De Ojeda, W.; Zuehl, J.; Gukelberger, R. A high efficiency, dilute gasoline engine for the heavy-duty market. SAE Int. J. Engines 2012, 5, 1768–1789. [Google Scholar] [CrossRef]

- Sellnau, M.C.; Sinnamon, J.; Hoyer, K.; Husted, H. Full-time gasoline direct-injection compression ignition (GDCI) for high efficiency and low NOx and PM. SAE Int. J. Engines 2012, 5, 300–314. [Google Scholar] [CrossRef]

- Tran, H.H.; Richard, B.; Gray, K.; Hall, J.M. Developing a Performance Specification for an Electric Supercharger to Satisfy a Range of Downsized Gasoline Engine Applications; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Tang, Q.; Fu, J.; Liu, J.; Boulet, B.; Tan, L.; Zhao, Z. Comparison and analysis of the effects of various improved turbocharging approaches on gasoline engine transient performances. Appl. Therm. Eng. 2016, 93, 797–812. [Google Scholar] [CrossRef]

- Cui, Y.; Hu, Z.; Deng, K.; Wang, Q. Miller-Cycle regulatable, two-stage turbocharging system design for marine diesel engines. J. Eng. Gas Turbines Power 2014, 136, 022201. [Google Scholar] [CrossRef]

- Yoo, H.; Park, B.Y.; Cho, H.; Park, J. Performance optimization of a diesel engine with a two-stage turbocharging system and dual-loop EGR using multi-objective Pareto optimization based on diesel cycle simulation. Energies 2019, 12, 4223. [Google Scholar] [CrossRef]

- Wu, B.; Han, Z.; Yu, X.; Zhang, S.; Nie, X.; Su, W. A method for matching two-stage turbocharger system and its influence on engine performance. J. Eng. Gas Turbines Power 2019, 141, 054502. [Google Scholar] [CrossRef]

- Zhao, D.; Winward, E.; Yang, Z.; Stobart, R.; Steffen, T. Characterisation, control, and energy management of electrified turbocharged diesel engines. Energy Convers. Manag. 2017, 135, 416–433. [Google Scholar] [CrossRef]

- Terdich, N.; Martinez-Botas, R. Experimental Efficiency Characterization of an Electrically Assisted Turbocharger; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2013; Volume 6. [Google Scholar] [CrossRef]

- Terdich, N.; Martinez-Botas, R.F.; Romagnoli, A.; Pesiridis, A. Mild hybridization via electrification of the air system: Electrically assisted and variable geometry turbocharging impact on an off-road diesel engine. J. Eng. Gas Turbines Power 2014, 136, 031703. [Google Scholar] [CrossRef]

- Millo, F.; Mallamo, F.; Pautasso, E.; Mego, G.G. The Potential of Electric Exhaust Gas Turbocharging for HD Diesel Engines; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Katsanos, C.O.; Hountalas, D.T.; Zannis, T.C. Simulation of a heavy-duty diesel engine with electrical turbocompounding system using operating charts for turbocharger components and power turbine. Energy Convers. Manag. 2013, 76, 712–724. [Google Scholar] [CrossRef]

- Panting, J.; Pullen, K.R.; Martinez-Botas, R.F. Turbocharger motor-generator for improvement of transient performance in an internal combustion engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2001, 215, 369–383. [Google Scholar] [CrossRef]

- Xue, X.; Rutledge, J. Potentials of Electrical Assist and Variable Geometry Turbocharging System for Heavy-Duty Diesel Engine Downsizing; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017; Volume 2017. [Google Scholar] [CrossRef]

- Alshammari, M.; Alshammari, F.; Pesyridis, A. Electric boosting and energy recovery systems for engine downsizing. Energies 2019, 12, 4636. [Google Scholar] [CrossRef]

- Maiboom, A.; Tauzia, X.; Hétet, J.-F. Experimental study of various effects of exhaust gas recirculation (EGR) on combustion and emissions of an automotive direct injection diesel engine. Energy 2008, 33, 22–34. [Google Scholar] [CrossRef]

- Jacobs, T.; Assanis, D.N.; Filipi, Z. The Impact of Exhaust Gas Recirculation on Performance and Emissions of a Heavy-Duty Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Ladommatos, N.; Abdelhalim, S.M.; Zhao, H.; Hu, Z. The Dilution, Chemical, and Thermal Effects of Exhaust Gas Recirculation on Disesel Engine Emissions—Part 4: Effects of Carbon Dioxide and Water Vapour; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1997. [Google Scholar] [CrossRef]

- Wei, H.; Zhu, T.; Shu, G.; Tan, L.; Wang, Y. Gasoline engine exhaust gas recirculation—A review. Appl. Energy 2012, 99, 534–544. [Google Scholar] [CrossRef]

- Inagaki, K.; Fuyuto, T.; Nishikawa, K.; Nakakita, K.; Sakata, I. Dual-Fuel PCI Combustion Controlled by in-Cylinder Stratification of Ignitability; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006; Volume 2006. [Google Scholar] [CrossRef]

- Dimitriou, P.; Burke, R.; Copeland, C.D.; Akehurst, S. Study on the Effects of EGR Supply Configuration on Cylinder-to-Cylinder Dispersion and Engine Performance Using 1D-3D Co-Simulation; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015; Volume 2015. [Google Scholar]

- Selim, M.Y.E. Effect of exhaust gas recirculation on some combustion characteristics of dual fuel engine. Energy Convers. Manag. 2003, 44, 707–721. [Google Scholar] [CrossRef]

- Duchaussoy, Y.; Lefebvre, A.; Bonetto, R. Dilution Interest on Turbocharged SI Engine Combustion; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Hoepke, B.; Jannsen, S.; Kasseris, E.; Cheng, W.K. EGR Effects on Boosted SI Engine Operation and Knock Integral Correlation. SAE Int. J. Engines 2012, 5, 547–559. [Google Scholar] [CrossRef]

- Li, T.; Wu, D.; Xu, M. Thermodynamic analysis of EGR effects on the first and second law efficiencies of a boosted spark-ignited direct-injection gasoline engine. Energy Convers. Manag. 2013, 70, 130–138. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Wang, X.; Yao, M. Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2,5-dimethylfuran and biodiesel/ethanol. Energy 2018, 148, 824–838. [Google Scholar] [CrossRef]

- Liu, H.; Ma, G.; Ma, N.; Zheng, Z.; Huang, H.; Yao, M. Effects of charge concentration and reactivity stratification on combustion and emission characteristics of a PFI-DI dual injection engine under low load condition. Fuel 2018, 231, 26–36. [Google Scholar] [CrossRef]

- Jung, D.; Iida, N. Closed-loop control of HCCI combustion for DME using external EGR and rebreathed EGR to reduce pressure-rise rate with combustion-phasing retard. Appl. Energy 2015, 138, 315–330. [Google Scholar] [CrossRef]

- Baratta, M.; Finesso, R.; Misul, D.; Spessa, E. Comparison between internal and external EGR performance on a heavy duty diesel engine by means of a refined 1D fluid-dynamic engine model. SAE Int. J. Engines 2015, 8, 1977–1992. [Google Scholar] [CrossRef]

- Shimada, T.; Yoshida, Y.; Rin, C.; Yamada, M.; Ito, N.; Iijima, A.; Yoshida, K.; Shoji, H. Influence of Internal EGR on Knocking in an HCCI Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Cho, I.; Lee, Y.; Lee, J. Investigation on the effects of internal EGR by variable exhaust valve actuation with post injection on auto-ignited combustion and emission performance. Appl. Sci. 2018, 8, 597. [Google Scholar] [CrossRef]

- Pan, M.; Qian, W.; Wei, H.; Feng, D.; Pan, J. Effects on performance and emissions of gasoline compression ignition engine over a wide range of internal exhaust gas recirculation rates under lean conditions. Fuel 2020, 265, 116881. [Google Scholar] [CrossRef]

- Mueller, V.; Christmann, R.; Muenz, S.; Gheorghiu, V. System Structure and Controller Concept for an Advanced Turbocharger/EGR System for a Turbocharged Passenger Car Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Kobayashi, M.; Aoyagi, Y.; Adachi, T.; Murayama, T.; Hashimoto, M.; Goto, Y.; Suzuki, H. Effective BSFC and NOx Reduction on Super Clean Diesel of Heavy Duty Diesel Engine by High Boosting and High EGR Rate; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Vítek, O.; Macek, J.; Polášek, M.; Schmerbeck, S.; Kammerdiener, T. Comparison of Different EGR Solutions; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Van Aken, M.; Willems, F.; de Jong, D.-J. Appliance of High EGR Rates with a Short and Long Route EGR System on a Heavy Duty Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Park, Y.; Bae, C. Experimental study on the effects of high/low pressure EGR proportion in a passenger car diesel engine. Appl. Energy 2014, 133, 308–316. [Google Scholar] [CrossRef]

- Mao, B.; Yao, M.; Zheng, Z.; Liu, H. Effects of Dual Loop EGR and Variable Geometry Turbocharger on Performance and Emissions of a Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2016; Volume 2016. [Google Scholar] [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Hybrid EGR and turbocharging systems control for low NOX and fuel consumption in an automotive diesel engine. Appl. Energy 2016, 165, 839–848. [Google Scholar] [CrossRef]

- Jun, J.H.; Song, S.H.; Chun, K.M.; Lee, K.S. Comparison of NOx Level and BSFC for HPL EGR and LPL EGR System of Heavy-Duty Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Lujan, J.M. Effect of Low Pressure EGR on gas exchange processes and turbocharging of a HSDI engine. In Proceedings of the THIESEL 2008 Conference on Thermo-and Fluid Dynamic Processes in Diesel Engines, Valencia, Spain, 9–12 September 2008; pp. 429–442. [Google Scholar]

- Maiboom, A.; Tauzia, X.; Shah, S.R.; Hétet, J.-F. Experimental Study of an LP EGR System on an Automotive Diesel Engine, compared to HP EGR with respect to PM and NOx Emissions and Specific Fuel Consumption. SAE Int. J. Engines 2010, 2, 597–610. [Google Scholar] [CrossRef]

- Cho, K.; Han, M.; Wagner, R.M.; Sluder, C.S. Mixed-source EGR for enabling high efficiency clean combustion modes in a light-duty diesel engine. SAE Int. J. Engines 2009, 1, 457–465. [Google Scholar] [CrossRef]

- Pachiannan, T.; Zhong, W.; Rajkumar, S.; He, Z.; Leng, X.; Wang, Q. A literature review of fuel effects on performance and emission characteristics of low-temperature combustion strategies. Appl. Energy 2019, 251, 113380. [Google Scholar] [CrossRef]

- Duan, X.; Lai, M.C.; Jansons, M.; Guo, G.; Liu, J. A review of controlling strategies of the ignition timing and combustion phase in homogeneous charge compression ignition (HCCI) engine. Fuel 2021, 285, 119142. [Google Scholar] [CrossRef]

- Paykani, A.; Kakaee, A.H.; Rahnama, P.; Reitz, R.D. Progress and recent trends in reactivity-controlled compression ignition engines. Int. J. Engine Res. 2016, 17, 481–524. [Google Scholar] [CrossRef]

- Chiodi, M.; Kaechele, A.; Bargende, M.; Wichelhaus, D.; Poetsch, C. Development of an Innovative Combustion Process: Spark-Assisted Compression Ignition. SAE Int. J. Engines 2017, 10, 247–256. [Google Scholar] [CrossRef]

- Yu, S.; Zheng, M. Future gasoline engine ignition: A review on advanced concepts. Int. J. Engine Res. 2021, 22, 1743–1775. [Google Scholar] [CrossRef]

- Dale, J.D.; Checkel, M.D.; Smy, P.R. Application of high energy ignition systems to engines. Prog. Energy Combust. Sci. 1997, 23, 379–398. [Google Scholar] [CrossRef]

- Patane, P.; Nandgaonkar, M. Review: Multipoint laser ignition system and its applications to IC engines. Opt. Laser Technol. 2020, 130, 106305. [Google Scholar] [CrossRef]

- Morsy, M.H. Review and recent developments of laser ignition for internal combustion engines applications. Renew. Sustain. Energy Rev. 2012, 16, 4849–4875. [Google Scholar] [CrossRef]

- Toulson, E.; Schock, H.J.; Attard, W.P. A Review of Pre-Chamber Initiated Jet Ignition Combustion Systems; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Alvarez, C.E.C.; Couto, G.E.; Roso, V.R.; Thiriet, A.B.; Valle, R.M. A review of prechamber ignition systems as lean combustion technology for SI engines. Appl. Therm. Eng. 2018, 128, 107–120. [Google Scholar] [CrossRef]

- Deheri, C.; Acharya, S.K.; Thatoi, D.N.; Mohanty, A.P. A review on performance of biogas and hydrogen on diesel engine in dual fuel mode. Fuel 2020, 260, 116337. [Google Scholar] [CrossRef]

- Alrazen, H.A.; Abu Talib, A.R.; Adnan, R.; Ahmad, K.A. A review of the effect of hydrogen addition on the performance and emissions of the compression—Ignition engine. Renew. Sustain. Energy Rev. 2016, 54, 785–796. [Google Scholar] [CrossRef]

- Shaik, A.; Moorthi, N.S.V.; Rudramoorthy, R. Variable compression ratio engine: A future power plant for automobiles—An overview. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2007, 221, 1159–1168. [Google Scholar] [CrossRef]

- Suresh, M.; Jawahar, C.P.; Richard, A. A review on biodiesel production, combustion, performance, and emission characteristics of non-edible oils in variable compression ratio diesel engine using biodiesel and its blends. Renew. Sustain. Energy Rev. 2018, 92, 38–49. [Google Scholar] [CrossRef]

- Finneran, J.; Garner, C.P.; Bassett, M.; Hall, J. A review of split-cycle engines. Int. J. Engine Res. 2020, 21, 897–914. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y.; Xu, S.; Zhu, Y.; Tao, C.; Xu, T.; Song, M. The engine knock analysis—An overview. Appl. Energy 2012, 92, 628–636. [Google Scholar] [CrossRef]

- Polat, S.; Yücesu, H.S.; Uyumaz, A.; Kannan, K.; Shahbakhti, M. An experimental investigation on combustion and performance characteristics of supercharged HCCI operation in low compression ratio engine setting. Appl. Therm. Eng. 2020, 180, 115858. [Google Scholar] [CrossRef]

- Maurya, R.K.; Agarwal, A.K. Experimental study of combustion and emission characteristics of ethanol fuelled port injected homogeneous charge compression ignition (HCCI) combustion engine. Appl. Energy 2011, 88, 1169–1180. [Google Scholar] [CrossRef]

- Zheng, M.; Han, X.; Asad, U.; Wang, J. Investigation of butanol-fuelled HCCI combustion on a high efficiency diesel engine. Energy Convers. Manag. 2015, 98, 215–224. [Google Scholar] [CrossRef]

- Ganesh, D.; Nagarajan, G.; Ganesan, S. Experimental investigation of homogeneous charge compression ignition combustion of biodiesel fuel with external mixture formation in a CI engine. Environ. Sci. Technol. 2014, 48, 3039–3046. [Google Scholar] [CrossRef]

- Lu, X.; Qian, Y.; Yang, Z.; Han, D.; Ji, J.; Zhou, X.; Huang, Z. Experimental study on compound HCCI (homogenous charge compression ignition) combustion fueled with gasoline and diesel blends. Energy 2014, 64, 707–718. [Google Scholar] [CrossRef]

- Lü, X.; Hou, Y.; Zu, L.; Huang, Z. Experimental study on the auto-ignition and combustion characteristics in the homogeneous charge compression ignition (HCCI) combustion operation with ethanol/n-heptane blend fuels by port injection. Fuel 2006, 85, 2622–2631. [Google Scholar] [CrossRef]

- Nagarajan, G.; MillerJothi, N.K.; Renganarayanan, S. A New Approach for Utilisation of Lpg-Dee in Homogeneous Charge Compression Ignition (Hcci) Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Wang, S. Limitations of Partially Premixed Combustion. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2017. [Google Scholar]

- Mathivanan, K.; Mallikarjuna, J.M.; Ramesh, A. Influence of multiple fuel injection strategies on performance and combustion characteristics of a diesel fuelled HCCI engine—An experimental investigation. Exp. Therm. Fluid Sci. 2016, 77, 337–346. [Google Scholar] [CrossRef]

- Çelebi, S.; Haşimoğlu, C.; Uyumaz, A.; Halis, S.; Calam, A.; Solmaz, H.; Yılmaz, E. Operating range, combustion, performance and emissions of an HCCI engine fueled with naphtha. Fuel 2021, 283, 118828. [Google Scholar] [CrossRef]

- Ganesh, D.; Nagarajan, G. Homogeneous charge compression ignition (HCCI) combustion of diesel fuel with external mixture formation. Energy 2010, 35, 148–157. [Google Scholar] [CrossRef]

- Qiu, L.; Cheng, X.; Liu, B.; Dong, S.; Bao, Z. Partially premixed combustion based on different injection strategies in a light-duty diesel engine. Energy 2016, 96, 155–165. [Google Scholar] [CrossRef]

- Liu, J.; Shang, H.; Wang, H.; Zheng, Z.; Wang, Q.; Xue, Z.; Yao, M. Investigation on partially premixed combustion fueled with gasoline and PODE blends in a multi-cylinder heavy-duty diesel engine. Fuel 2017, 193, 101–111. [Google Scholar] [CrossRef]

- Lu, X.; Han, D.; Huang, Z. Fuel design and management for the control of advanced compression-ignition combustion modes. Prog. Energy Combust. Sci. 2011, 37, 741–783. [Google Scholar] [CrossRef]

- Urushihara, T.; Yamaguchi, K.; Yoshizawa, K.; Itoh, T. A Study of a Gasoline-fueled Compression Ignition Engine~ Expansion of HCCI Operation Range Using SI Combustion as a Trigger of Compression Ignition~. SAE Trans. 2005, 114, 419–425. [Google Scholar]

- Haraldsson, G.; Tunestål, P.; Johansson, B.; Hyvönen, J. HCCI Combustion Phasing with Closed-Loop Combustion Control Using Variable Compression Ratio in a Multi Cylinder Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Aroonsrisopon, T.; Werner, P.; Waldman, J.O.; Sohm, V.; Foster, D.E.; Morikawa, T.; Iida, M. Expanding the HCCI operation with the charge stratification. SAE Trans. 2004, 113, 1130–1145. [Google Scholar]

- Milovanovic, N.; Blundell, D.; Pearson, R.; Turner, J.; Chen, R. Enlarging the Operational Range of a Gasoline HCCI Engine by Controlling the Coolant Temperature; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Calam, A.; Aydoğan, B.; Halis, S. The comparison of combustion, engine performance and emission characteristics of ethanol, methanol, fusel oil, butanol, isopropanol and naphtha with n-heptane blends on HCCI engine. Fuel 2020, 266, 117071. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Roso, V.R.; Martins, M.E.S. Evaluating the emissions and performance of two dual-mode RCCI combustion strategies under the World Harmonized Vehicle Cycle (WHVC). Energy Convers. Manag. 2017, 149, 263–274. [Google Scholar] [CrossRef]

- Fang, W.; Kittelson, D.B.; Northrop, W.F. Optimization of reactivity-controlled compression ignition combustion fueled with diesel and hydrous ethanol using response surface methodology. Fuel 2015, 160, 446–457. [Google Scholar] [CrossRef]

- Kokjohn, S.L.; Hanson, R.M.; Splitter, D.A.; Reitz, R.D. Experiments and modeling of dual-fuel HCCI and PCCI combustion using in-cylinder fuel blending. SAE Int. J. Engines 2010, 2, 24–39. [Google Scholar] [CrossRef]

- Kokjohn, S.L.; Reitz, R.D. Reactivity controlled compression ignition and conventional diesel combustion: A comparison of methods to meet light-duty NOx and fuel economy targets. Int. J. Engine Res. 2013, 14, 452–468. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.M.; An, H.; Zhou, D.Z.; Yu, W.B.; Wang, J.X.; Li, L. Numerical investigation on the effect of reactivity gradient in an RCCI engine fueled with gasoline and diesel. Energy Convers. Manag. 2015, 92, 342–352. [Google Scholar] [CrossRef]

- Kakaee, A.-H.; Rahnama, P.; Paykani, A. Influence of fuel composition on combustion and emissions characteristics of natural gas/diesel RCCI engine. J. Nat. Gas Sci. Eng. 2015, 25, 58–65. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.; Zhou, D. Review on the management of RCCI engines. Renew. Sustain. Energy Rev. 2017, 69, 65–79. [Google Scholar] [CrossRef]

- Benajes, J.; Molina, S.; García, A.; Belarte, E.; Vanvolsem, M. An investigation on RCCI combustion in a heavy duty diesel engine using in-cylinder blending of diesel and gasoline fuels. Appl. Therm. Eng. 2014, 63, 66–76. [Google Scholar] [CrossRef]

- Han, X.; Zheng, M.; Tjong, J.S.; Li, T. Suitability Study of n-Butanol for Enabling PCCI and HCCI and RCCI Combustion on a High Compression-Ratio Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Dempsey, A.B.; Walker, N.R.; Gingrich, E.; Reitz, R.D. Comparison of low temperature combustion strategies for advanced compression ignition engines with a focus on controllability. Combust. Sci. Technol. 2014, 186, 210–241. [Google Scholar] [CrossRef]

- Curran, S.; Prikhodko, V.; Cho, K.; Sluder, C.S.; Parks, J.; Wagner, R.; Kokjohn, S.; Reitz, R.D. In-Cylinder Fuel Blending of Gasoline/Diesel for Improved Efficiency and Lowest Possible Emissions on a Multi-Cylinder Light-Duty Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Heuser, B.; Ahling, S.; Kremer, F.; Pischinger, S.; Rohs, H.; Holderbaum, B.; Körfer, T. Experimental Investigation of a RCCI Combustion Concept with In-Cylinder Blending of Gasoline and Diesel in a Light Duty Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Leermakers, C.A.J.; Van den Berge, B.; Luijten, C.C.M.; Somers, L.M.T.; de Goey, L.P.H.; Albrecht, B.A. Gasoline-Diesel Dual Fuel: Effect of Injection Timing And Fuel Balance; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Ickes, A.; Wallner, T.; Zhang, Y.; De Ojeda, W. Impact of cetane number on combustion of a gasoline-diesel dual-fuel heavy-duty multi-cylinder engine. SAE Int. J. Engines 2014, 7, 860–872. [Google Scholar] [CrossRef]

- Splitter, D.; Hanson, R.; Kokjohn, S.; Reitz, R.D. Reactivity Controlled Compression Ignition (RCCI) Heavy-Duty Engine Operation at Mid- and High-Loads with Conventional and Alternative Fuels; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Soloiu, V.; Gaubert, R.; Moncada, J.; Wiley, J.; Williams, J.; Harp, S.; Ilie, M.; Molina, G.; Mothershed, D. Reactivity controlled compression ignition and low temperature combustion of Fischer-Tropsch Fuel Blended with n-butanol. Renew. Energy 2019, 134, 1173–1189. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Lago Sari, R. Fuel consumption and engine-out emissions estimations of a light-duty engine running in dual-mode RCCI/CDC with different fuels and driving cycles. Energy 2018, 157, 19–30. [Google Scholar] [CrossRef]

- Pan, S.; Li, X.; Han, W.; Huang, Y. An experimental investigation on multi-cylinder RCCI engine fueled with 2-butanol/diesel. Energy Convers. Manag. 2017, 154, 92–101. [Google Scholar] [CrossRef]

- Gross, C.W.; Reitz, R. Investigation of Steady-State RCCI Operation in a Light-Duty Multi-Cylinder Engine Using “Dieseline”; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017; Volume 2017. [Google Scholar] [CrossRef]

- Charitha, V.; Thirumalini, S.; Prasad, M.; Srihari, S. Investigation on performance and emissions of RCCI dual fuel combustion on diesel—bio diesel in a light duty engine. Renew. Energy 2019, 134, 1081–1088. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Najafi, M.; Jazayeri, S.A.; Mohammadzadeh, A.R. A detail simulation of reactivity controlled compression ignition combustion strategy in a heavy-duty diesel engine run on natural gas/diesel fuel. Int. J. Engine Res. 2018, 19, 774–789. [Google Scholar] [CrossRef]

- Han, J.; Somers, B. Effects of Butanol Isomers on the Combustion and Emission Characteristics of a Heavy-Duty Engine in RCCI Mode; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Pan, S.; Han, W.; Liu, X.; Cai, K.; Li, X.; Li, B. Experimental study on combustion and emission characteristics of iso-butanol/diesel and gasoline/diesel RCCI in a heavy-duty engine under low loads. Fuel 2020, 261, 116434. [Google Scholar] [CrossRef]

- Eyal, A.; Thawko, A.; Baibikov, V.; Tartakovsky, L. Performance and pollutant emission of the reforming-controlled compression ignition engine—Experimental study. Energy Convers. Manag. 2021, 237, 114126. [Google Scholar] [CrossRef]

- Rahnama, P.; Paykani, A.; Reitz, R.D. A numerical study of the effects of using hydrogen, reformer gas and nitrogen on combustion, emissions and load limits of a heavy duty natural gas/diesel RCCI engine. Appl. Energy 2017, 193, 182–198. [Google Scholar] [CrossRef]

- Molina, S.; García, A.; Pastor, J.M.; Belarte, E.; Balloul, I. Operating range extension of RCCI combustion concept from low to full load in a heavy-duty engine. Appl. Energy 2015, 143, 211–227. [Google Scholar] [CrossRef]

- Jia, M.; Dempsey, A.B.; Wang, H.; Li, Y.; Reitz, R.D. Numerical simulation of cyclic variability in reactivity-controlled compression ignition combustion with a focus on the initial temperature at intake valve closing. Int. J. Engine Res. 2015, 16, 441–460. [Google Scholar] [CrossRef]

- Noehre, C.; Andersson, M.; Johansson, B.; Hultqvist, A. Characterization of Partially Premixed Combustion; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Shankar, V. Double Compression Expansion Engine: Evaluation of Thermodynamic Cycle and Combustion Concepts. Ph.D. Thesis, King Abdullah University of Science and Technology, Thuwal, Saudi Arabia, 2019. [Google Scholar]

- Tuner, M.; Johansson, B.; Keller, P.; Becker, M. Loss Analysis of a HD-PPC Engine with Two-Stage Turbocharging Operating in the European Stationary Cycle; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Kalghatgi, G.T.; Hildingsson, L.; Harrison, A.J.; Johansson, B. Autoignition quality of gasoline fuels in partially premixed combustion in diesel engines. Proc. Combust. Inst. 2011, 33, 3015–3021. [Google Scholar] [CrossRef]

- Kalghatgi, G.T.; Risberg, P.; Ångström, H.-E. Partially Pre-Mixed Auto-Ignition of Gasoline to Attain Low Smoke and Low NOx at High Load in a Compression Ignition Engine and Comparison with a Diesel Fuel; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- An, Y.; Jaasim, M.; Raman, V.; Im, H.G.; Johansson, B. In-cylinder combustion and soot evolution in the transition from conventional compression ignition (CI) mode to partially premixed combustion (PPC) mode. Energy Fuels 2018, 32, 2306–2320. [Google Scholar] [CrossRef]

- Ilango, T.; Natarajan, S. Effect of compression ratio on partially premixed charge compression ignition engine fuelled with methanol diesel blends-an experimental investigation. Int. J. Mech. Prod. Eng. 2014, 2, 41–45. [Google Scholar]

- Najafabadi, M.I.; Dam, N.; Somers, B.; Johansson, B. Ignition Sensitivity Study of Partially Premixed Combustion by Using Shadowgraphy and OH* Chemiluminescence Methods; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- An, Y.; Vallinayagam, R.; Vedharaj, S.; Masurier, J.-B.; Dawood, A.; Najafabadi, M.I.; Somers, B.; Johansson, B. Analysis of Transition from HCCI to CI via PPC with Low Octane Gasoline Fuels Using Optical Diagnostics and Soot Particle Analysis; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Vedharaj, S.; Vallinayagam, R.; An, Y.; Dawood, A.; Najafabadi, M.I.; Somers, B.; Chang, J.; Johansson, B. Fuel Effect on Combustion Stratification in Partially Premixed Combustion; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Manente, V.; Tunestal, P.; Johansson, B.; Cannella, W.J. Effects of Ethanol and Different Type of Gasoline Fuels on Partially Premixed Combustion from Low to High Load; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Han, X.; Yang, Z.; Wang, M.; Tjong, J.; Zheng, M. Clean combustion of n-butanol as a next generation biofuel for diesel engines. Appl. Energy 2017, 198, 347–359. [Google Scholar] [CrossRef]

- Zincir, B.; Shukla, P.; Shamun, S.; Tuner, M.; Deniz, C.; Johansson, B. Investigation of effects of intake temperature on low load limitations of methanol partially premixed combustion. Energy Fuels 2019, 33, 5695–5709. [Google Scholar] [CrossRef]

- Yin, L.; Turesson, G.; Tunestål, P.; Johansson, R. Evaluation and transient control of an advanced multi-cylinder engine based on partially premixed combustion. Appl. Energy 2019, 233–234, 1015–1026. [Google Scholar] [CrossRef]

- Leermakers, C.A.J. Efficient Fuels for Future Engines; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2014; ISBN 9789038635545. [Google Scholar]

- Liu, B.; Cheng, X.; Liu, J.; Pu, H. Investigation into particle emission characteristics of partially premixed combustion fueled with high n-butanol-diesel ratio blends. Fuel 2018, 223, 1–11. [Google Scholar] [CrossRef]

- Valentino, G.; Corcione, F.E.; Iannuzzi, S.; Serra, S. An Experimental Analysis on Diesel/n-Butanol Blends Operating in Partial Premixed Combustion in a Light Duty Diesel Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Cheng, X.; Shuai, L.I.; Yang, J.; Dong, S.; Bao, Z. Effect of N-Butanol-Diesel Blends on Partially Premixed Combustion and Emission Characteristics in a Light-Duty Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Zhang, M.; Derafshzan, S.; Richter, M.; Lundgren, M. Effects of different injection strategies on ignition and combustion characteristics in an optical PPC engine. Energy 2020, 203, 117901. [Google Scholar] [CrossRef]

- Mao, B.; Chen, P.; Liu, H.; Zheng, Z.; Yao, M. Gasoline compression ignition operation on a multi-cylinder heavy duty diesel engine. Fuel 2018, 215, 339–351. [Google Scholar] [CrossRef]

- Aziz, A.; Garcia, A.; Dos Santos, C.P.; Tuner, M. Impact of Multiple Injection Strategies on Performance and Emissions of Methanol PPC under Low Load Operation; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Dimitrakopoulos, N.; Tuner, M. Investigation of the Effect of Glow Plugs on Low Load Gasoline PPC; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Manofsky, L.; Vavra, J.; Assanis, D.N.; Babajimopoulos, A. Bridging the Gap between HCCI and SI: Spark-Assisted Compression Ignition; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Olesky, L.M.; Martz, J.B.; Lavoie, G.A.; Vavra, J.; Assanis, D.N.; Babajimopoulos, A. The effects of spark timing, unburned gas temperature, and negative valve overlap on the rates of stoichiometric spark assisted compression ignition combustion. Appl. Energy 2013, 105, 407–417. [Google Scholar] [CrossRef]

- Cupo, F. Virtual Fuel Design for SACI Operation Strategy. In Modeling of Real Fuels and Knock Occurrence for an Effective 3D-CFD Virtual Engine Development; Springer: Berlin/Heidelberg, Germany, 2021; pp. 97–110. [Google Scholar]

- Kalian, N.; Standing, R.; Zhao, H. Effects of Ignition Timing on CAI Combustion in a Multi-Cylinder DI Gasoline Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Wang, Z.; Wang, J.; Shuai, S.; He, X.; Xu, F.; Yang, D.; Ma, X. Research on Spark Induced Compression Ignition (SICI); SAE Technical Papers; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Szybist, J.P.; Nafziger, E.; Weall, A. Load expansion of stoichiometric HCCI using spark assist and hydraulic valve actuation. SAE Int. J. Engines 2010, 3, 244–258. [Google Scholar] [CrossRef]

- Weall, A.J.; Szybist, J.P. The effects of fuel characteristics on stoichiometric spark-assisted HCCI. In Proceedings of the ASME 2011 Internal Combustion Engine Division Fall Technical Conference, Morgantown, WV, USA, 2–5 October 2011; pp. 243–259. [Google Scholar] [CrossRef]

- Ortiz-Soto, E.A.; Lavoie, G.A.; Wooldridge, M.S.; Assanis, D.N. Thermodynamic efficiency assessment of gasoline spark ignition and compression ignition operating strategies using a new multi-mode combustion model for engine system simulations. Int. J. Engine Res. 2019, 20, 304–326. [Google Scholar] [CrossRef]

- Yun, H.; Wermuth, N.; Najt, P. Extending the High Load Operating Limit of a Naturally-Aspirated Gasoline HCCI Combustion Engine. SAE Int. J. Engines 2010, 3, 681–699. [Google Scholar] [CrossRef]

- Verma, G.; Sharma, H.; Thipse, S.S.; Agarwal, A.K. Spark assisted premixed charge compression ignition engine prototype development. Fuel Process. Technol. 2016, 152, 413–420. [Google Scholar] [CrossRef]

- Zhou, L.; Dong, K.; Hua, J.; Wei, H.; Chen, R.; Han, Y. Effects of applying EGR with split injection strategy on combustion performance and knock resistance in a spark assisted compression ignition (SACI) engine. Appl. Therm. Eng. 2018, 145, 98–109. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, R.; Pan, J.; Wei, H. Effects of partitioned fuel distribution on auto-ignition and knocking under spark assisted compression ignition conditions. Appl. Energy 2020, 260, 114269. [Google Scholar] [CrossRef]

- Hunicz, J.; Mikulski, M.; Koszałka, G.; Ignaciuk, P. Detailed analysis of combustion stability in a spark-assisted compression ignition engine under nearly stoichiometric and heavy EGR conditions. Appl. Energy 2020, 280, 115955. [Google Scholar] [CrossRef]

- Biswas, S.; Ekoto, I. Spark Assisted Compression Ignition Engine with Stratified Charge Combustion and Ozone Addition. SAE Int. J. Adv. Curr. Pract. Mobil. 2019, 2, 385–400. [Google Scholar]

- Robertson, D.; Prucka, R. A Review of Spark-Assisted Compression Ignition (SACI) Research in the Context of Realizing Production Control Strategies; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Li, Z.L.; Qian, Y.; Huang, G.; Zhao, W.B.; Zhang, Y.Y.; Lu, X.C. Gasoline-diesel dual fuel intelligent charge compression ignition (ICCI) combustion: Conceptual model and comparison with other advanced combustion modes. Sci. China Technol. Sci. 2021, 64, 719–728. [Google Scholar] [CrossRef]

- Caton, J.A. On the importance of specific heats as regards efficiency increases for highly dilute IC engines. Energy Convers. Manag. 2014, 79, 146–160. [Google Scholar] [CrossRef]

- Yun, H.; Idicheria, C.; Najt, P. The effect of advanced ignition system on gasoline low temperature combustion. Int. J. Engine Res. 2019, 22, 417–429. [Google Scholar] [CrossRef]

- Dale, J.D.; Smy, P.R.; Clements, R.M. Laser ignited internal combustion engine—An experimental study. SAE Trans. 1978, 87, 1539–1548. [Google Scholar]

- McIntyre, D.L. A Laser Spark Plug Ignition System for a Stationary Lean-Burn Natural Gas Reciprocating Engine; National Energy Technology Lab. (NETL): Morgantown, WV, USA; West Virginia University: Morgantown, WV, USA, 2007.

- McMillian, M.H.; Woodruff, S.D.; Richardson, S.W.; McIntyre, D.L. Laser spark ignition: Laser development and engine testing. In Proceedings of the ICEF04 2004 Fall Technical Conference of the ASME Internal Combustion Engine Division, Long Beach, CA, USA, 24–27 October 2004. [Google Scholar]

- Weinrotter, M.; Kopecek, H.; Tesch, M.; Wintner, E.; Lackner, M.; Winter, F. Laser ignition of ultra-lean methane/hydrogen/air mixtures at high temperature and pressure. Exp. Therm. Fluid Sci. 2005, 29, 569–577. [Google Scholar] [CrossRef]

- Ryu, S.K.; Won, S.H.; Chung, S.H. Laser-induced multi-point ignition with single-shot laser using conical cavities and prechamber with jet holes. Proc. Combust. Inst. 2009, 32, 3189–3196. [Google Scholar] [CrossRef]

- Phuoc, T.X. Single-point versus multi-point laser ignition: Experimental measurements of combustion times and pressures. Combust. Flame 2000, 122, 508–510. [Google Scholar] [CrossRef]

- Nakaya, S.; Iseki, S.; Gu, X.; Kobayashi, Y.; Tsue, M. Flame kernel formation behaviors in close dual-point laser breakdown spark ignition for lean methane/air mixtures. Proc. Combust. Inst. 2017, 36, 3441–3449. [Google Scholar] [CrossRef]

- Lyon, E.; Kuang, Z.; Cheng, H.; Page, V.; Shenton, T.; Dearden, G. Multi-point laser spark generation for internal combustion engines using a spatial light modulator. J. Phys. D Appl. Phys. 2014, 47, 475501. [Google Scholar] [CrossRef]

- Saito, T.; Suzuta, Y.; Takahashi, E.; Furutani, H. Performance of internal combustion engine using multi-point laser ignition under nitrogen dilution conditions. In Proceedings of the 4th Laser Ignition Conference, Yokohama, Japan, 17–15 May 2016; p. LIC6-5. [Google Scholar]

- Grzeszik, R. Impact of Turbulent In-Cylinder Air Motion and Local Mixture Formation on Inflammation in Lean Engine Operation: Is Multiple Point Ignition a Solution? In Proceedings of the Laser Ignition Conference 2017, Bucharest, Romania, 20–23 June 2017; p. LFA3-1. [Google Scholar]

- Kuang, Z.; Lyon, E.; Cheng, H.; Page, V.; Shenton, T.; Dearden, G. Multi-location laser ignition using a spatial light modulator towards improving automotive gasoline engine performance. Opt. Lasers Eng. 2017, 90, 275–283. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Takahashi, E.; Furutani, H.; Kojima, H.; Inami, S.; Miyata, J.; Kashiwazaki, T.; Nishioka, M. Two-point laser ignition for stable lean burn operation of gas engine. In Proceedings of the 2nd Laser Ignition Conference 2014, Yokohama, Japan, 22–24 April 2014. [Google Scholar]

- Bihari, B.; Gupta, S.B.; Sekar, R.R.; Gingrich, J.; Smith, J. Development of advanced laser ignition system for stationary natural gas reciprocating engines. In Proceedings of the ASME 2005 Internal Combustion Engine Division Fall Technical Conference, Ottawa, ON, Canada, 11–14 September 2005; Volume 47365, pp. 601–608. [Google Scholar]

- Pal, A.; Agarwal, A.K. Comparative study of laser ignition and conventional electrical spark ignition systems in a hydrogen fuelled engine. Int. J. Hydrogen Energy 2015, 40, 2386–2395. [Google Scholar] [CrossRef]

- Prasad, R.K.; Mustafi, N.; Agarwal, A.K. Effect of spark timing on laser ignition and spark ignition modes in a hydrogen enriched compressed natural gas fuelled engine. Fuel 2020, 276, 118071. [Google Scholar] [CrossRef]

- Gunther, M.; Sens, M. Ignition Systems for Gasoline Engines. In Proceedings of the 3rd International Conference, Berlin, Germany, 3–4 November 2016; Springer: Cham, Switzerland, 2017. ISBN 3319455036. [Google Scholar]

- Cimarello, A.; Cruccolini, V.; Discepoli, G.; Battistoni, M.; Mariani, F.; Grimaldi, C.; Dal Re, M. Combustion Behavior of an RF Corona Ignition System with Different Control Strategies; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2018; Volume 2018, pp. 1–19. [Google Scholar] [CrossRef]

- Burrows, J.; Mixell, K.; Reinicke, P.B.; Riess, M.; Sens, M. Corona ignition-assessment of physical effects by pressure chamber, rapid compression machine, and single cylinder engine testing. In Proceedings of the 2nd International Conference on Ignition Systems for Gasoline Engines, Berlin, Germany, 24–25 November 2014. [Google Scholar]

- Cimarello, A.; Grimaldi, C.N.; Mariani, F.; Battistoni, M.; Dal Re, M. Analysis of RF Corona Ignition in Lean Operating Conditions Using an Optical Access Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017; Volume 2017. [Google Scholar] [CrossRef]

- Cruccolini, V.; Discepoli, G.; Cimarello, A.; Battistoni, M.; Mariani, F.; Grimaldi, C.N.; Dal Re, M. Lean combustion analysis using a corona discharge igniter in an optical engine fueled with methane and a hydrogen-methane blend. Fuel 2020, 259, 116290. [Google Scholar] [CrossRef]

- Agneray, A.; Jaffrezic, X.; Mispreuve, L. Radio Frequency Ignition System, Breakthrough Technology for the Future Spark Ignition Engine; SAI: Strasbourg, France, 2009. [Google Scholar]

- Mariani, A.; Foucher, F. Radio frequency spark plug: An ignition system for modern internal combustion engines. Appl. Energy 2014, 122, 151–161. [Google Scholar] [CrossRef]

- Hampe, C.; Bertsch, M.; Beck, K.W.; Spicher, U.; Bohne, S.; Rixecker, G. Influence of High Frequency Ignition on the Combustion and Emission Behaviour of Small Two-Stroke Spark Ignition Engines; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Ricci, F.; Petrucci, L.; Cruccolini, V.; Discepoli, G.; Grimaldi, C.N.; Papi, S. Investigation of the Lean Stable Limit of a Barrier Discharge Igniter and of a Streamer-Type Corona Igniter at Different Engine Loads in a Single-Cylinder Research Engine. Multidiscip. Digit. Publ. Inst. Proc. 2020, 58, 11. [Google Scholar]

- Hua, J.; Zhou, L.; Gao, Q.; Feng, Z.; Wei, H. Influence of pre-chamber structure and injection parameters on engine performance and combustion characteristics in a turbulent jet ignition (TJI) engine. Fuel 2021, 283, 119236. [Google Scholar] [CrossRef]

- Attard, W.P.; Fraser, N.; Parsons, P.; Toulson, E. A Turbulent Jet Ignition Pre-Chamber Combustion System for Large Fuel Economy Improvements in a Modern Vehicle Powertrain; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2010; Volume 3, pp. 20–37. [Google Scholar] [CrossRef]

- Bianco, A.; Millo, F.; Piano, A. Modelling of combustion and knock onset risk in a high-performance turbulent jet ignition engine. Transp. Eng. 2020, 2, 100037. [Google Scholar] [CrossRef]

- Ghorbani, A.; Steinhilber, G.; Markus, D.; Maas, U. Ignition by transient hot turbulent jets: An investigation of ignition mechanisms by means of a PDF/REDIM method. Proc. Combust. Inst. 2015, 35, 2191–2198. [Google Scholar] [CrossRef]

- Gholamisheeri, M.; Wichman, I.S.; Toulson, E. A study of the turbulent jet flow field in a methane fueled turbulent jet ignition (TJI) system. Combust. Flame 2017, 183, 194–206. [Google Scholar] [CrossRef]

- Biswas, S.; Qiao, L. Ignition of ultra-lean premixed hydrogen/air by an impinging hot jet. Appl. Energy 2018, 228, 954–964. [Google Scholar] [CrossRef]

- Attard, W.P.; Parsons, P. A normally aspirated spark initiated combustion system capable of high load, high efficiency and near zero NOx emissions in a modern vehicle powertrain. SAE Int. J. Engines 2010, 3, 269–287. [Google Scholar] [CrossRef]

- Bueschke, W.; Szwajca, F.; Wislocki, K. Experimental Study on Ignitability of Lean CNG/Air Mixture in the Multi-Stage Cascade Engine Combustion System; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Hua, J.; Zhou, L.; Gao, Q.; Feng, Z.; Wei, H. Effects on Cycle-to-Cycle Variations and Knocking Combustion of Turbulent Jet Ignition (TJI) with a Small Volume Pre-Chamber; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Distaso, E.; Amirante, R.; Cassone, E.; De Palma, P.; Sementa, P.; Tamburrano, P.; Vaglieco, B.M. Analysis of the combustion process in a lean-burning turbulent jet ignition engine fueled with methane. Energy Convers. Manag. 2020, 223, 113257. [Google Scholar] [CrossRef]

- Zwitserlood, J.G.; Hofman, T.; Erickson, P.A. Hydrogen Enrichment of an Internal Combustion Engine via Closed Loop Thermochemical Recuperation; Eindhoven University of Technology: Eindhoven, The Netherlands, 2013. [Google Scholar]

- Bari, S.; Mohammad Esmaeil, M. Effect of H2/O2 addition in increasing the thermal efficiency of a diesel engine. Fuel 2010, 89, 378–383. [Google Scholar] [CrossRef]

- Akansu, S.O.; Kahraman, N.; Çeper, B. Experimental study on a spark ignition engine fuelled by methane–hydrogen mixtures. Int. J. Hydrogen Energy 2007, 32, 4279–4284. [Google Scholar] [CrossRef]

- Kahraman, N.; Ceper, B.; Akansu, S.O.; Aydin, K. Investigation of combustion characteristics and emissions in a spark-ignition engine fuelled with natural gas–hydrogen blends. Int. J. Hydrogen Energy 2009, 34, 1026–1034. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G.; Dhanasekaran, C.; Kalaiselvan, K.M. Experimental investigation of hydrogen port fuel injection in DI diesel engine. Int. J. Hydrogen Energy 2007, 32, 4071–4080. [Google Scholar] [CrossRef]

- Karim, G.A.; Wierzba, I.; Al-Alousi, Y. Methane-hydrogen mixtures as fuels. Int. J. Hydrogen Energy 1996, 21, 625–631. [Google Scholar] [CrossRef]