Advances in Energy Hybridization for Resilient Supply: A Sustainable Approach to the Growing World Demand

Abstract

:1. Introduction

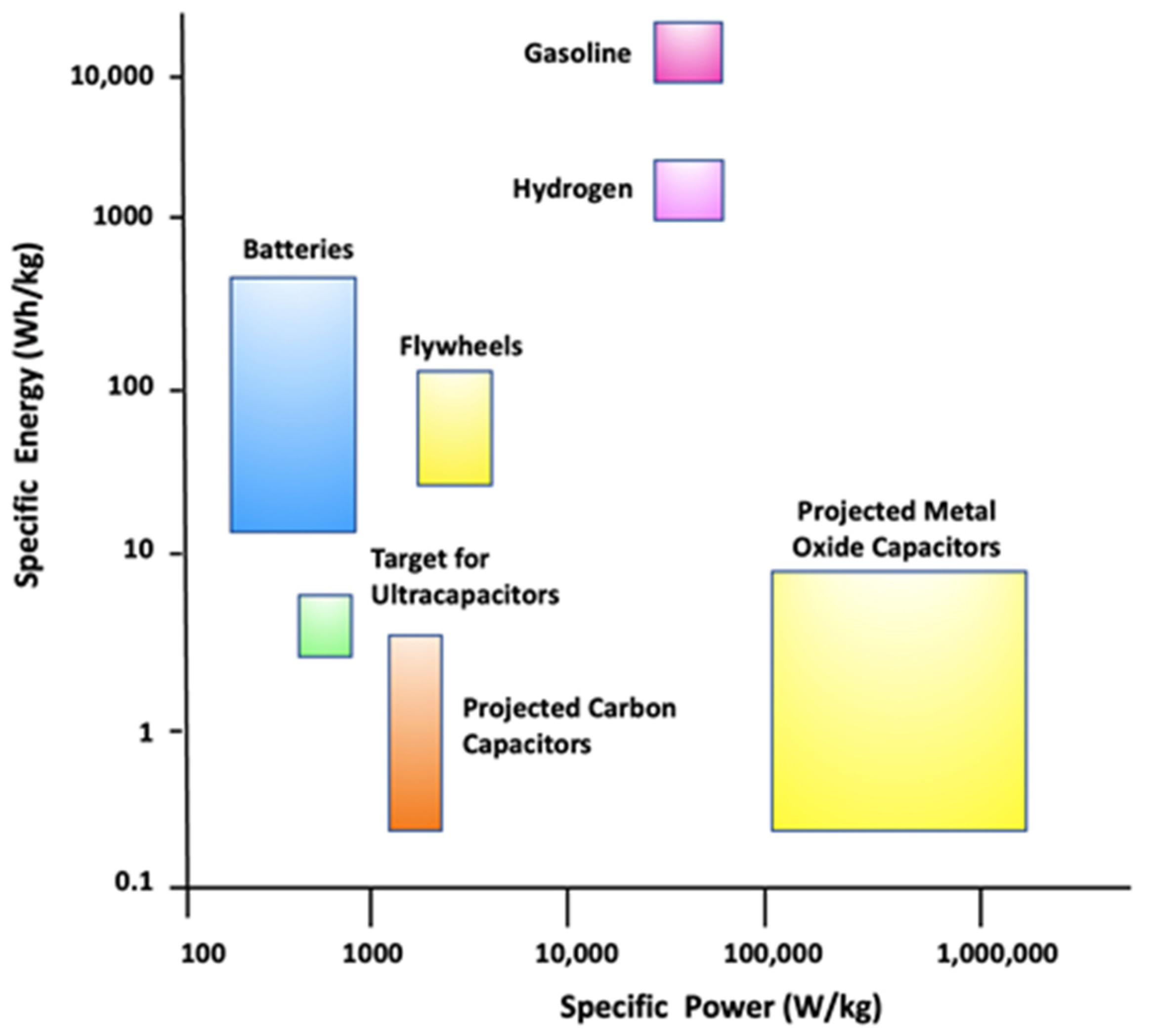

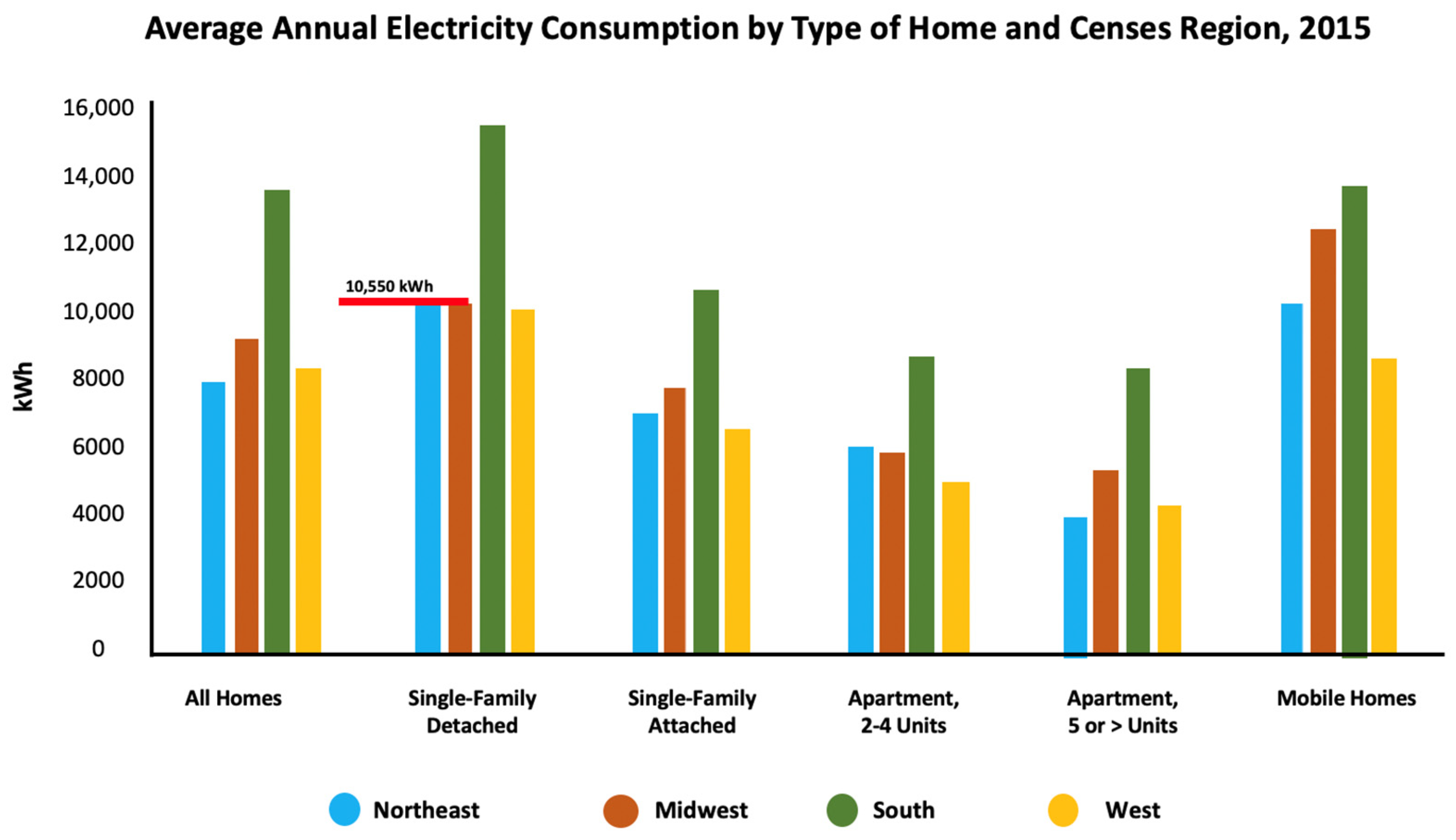

2. Microgrid Energy Storage Cost Analysis

3. Microgrid Analysis

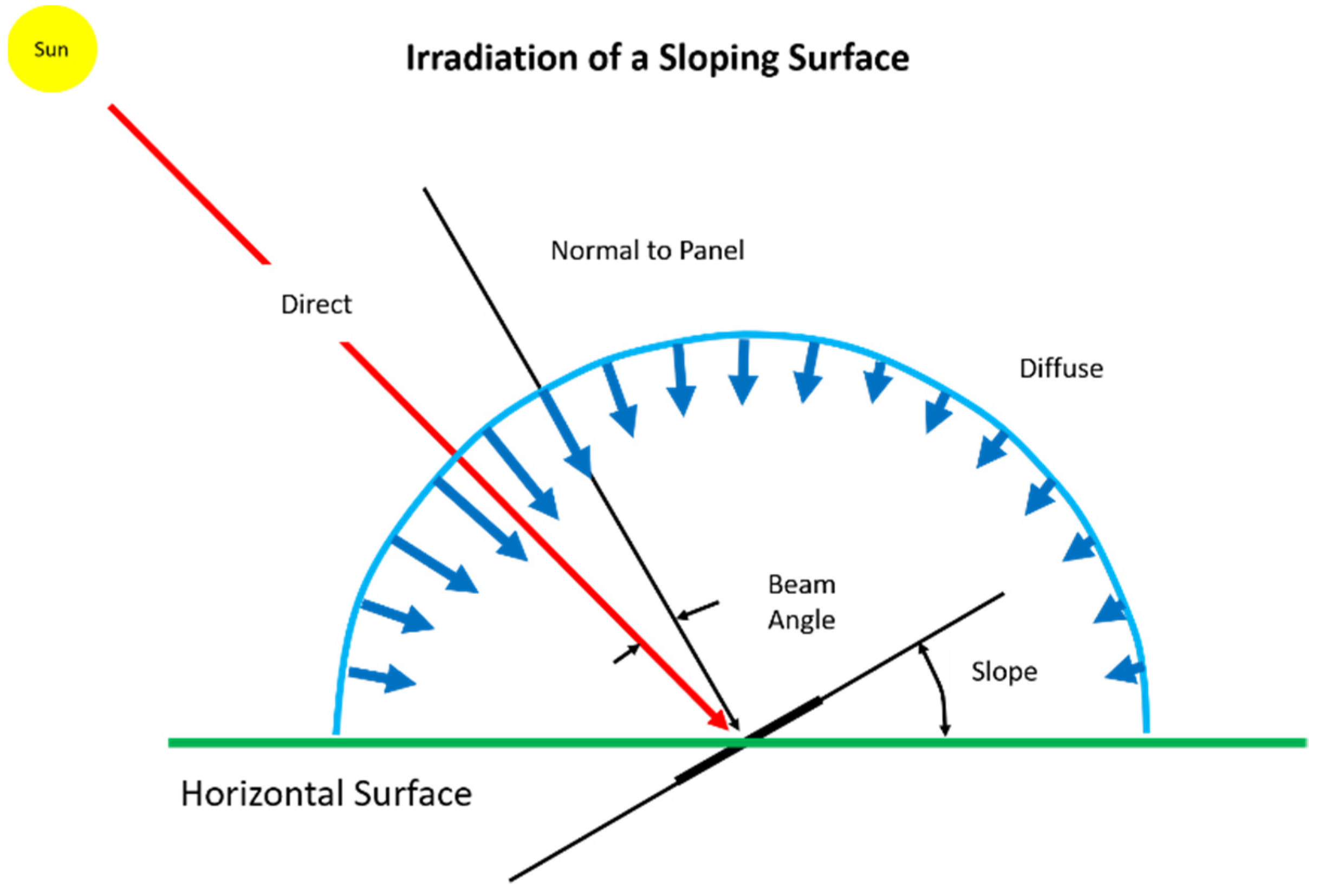

4. Solar PV Energy

5. Wind Energy

6. Microgrid Design Analysis

7. Cost Analysis

8. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tanaka, N.; Kjorven, O.; Yumkella, K.K. Energy Poverty; How to Make Modern Energy Access Universal? Special Early Excerpt of the World Energy Outlook 2010 for the UN General Assembly on the Millennium Development Goals; International Energy Agency: Paris, France, 2010. [Google Scholar]

- Chowdhury, S.; Chowdhury, S.P.; Crossley, P. Microgrids and Active Distribution Networks; Renewable Energy Series 6; The Institution of Engineering and Technology: London, UK, 2009. [Google Scholar]

- Del Rio, P.; Burguillo, M. An empirical analysis of the impact of renewable energy deployment on local sustainability. Renew. Sustain. Energy Rev. 2009, 13, 1314–1325. [Google Scholar] [CrossRef]

- Mahapatra, S.; Dasappa, S. Rural electrification: Optimising the choice between decentralised renewable energy sources and grid extension. Energy Sustain. Dev. 2012, 16, 146–154. [Google Scholar] [CrossRef]

- Chaurey, A.; Kandpal, T.C. Assessment and evaluation of PV based decentralized rural electrification: An overview. Renew. Sustain. Energy Rev. 2010, 14, 2266–2278. [Google Scholar] [CrossRef]

- Cook, P. Infrastructure, rural electrification and development. Energy Sustain. Dev. 2011, 15, 304–313. [Google Scholar] [CrossRef]

- Lasseter, R.; Akhil, A.; Marnay, C.; Stephens, J.; Dagle, J.; Guttromsom, R.; A Sakis, M.; Robert, Y.; Eto, J. Integration of Distributed Energy Resources. The CERTS Microgrid Concept; (No. LBNL-50829); Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2002.

- Hatziargyriou, N.; Asano, H.; Iravani, R.; Marnay, C. Microgrids. IEEE Power Energy Mag. 2007, 5, 78–94. [Google Scholar] [CrossRef]

- Infield, D.; Li, F. Integrating micro-generation into distribution systems—A review of recent research. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; pp. 1–4. [Google Scholar]

- Lasseter, R.H.; Paigi, P. Microgrid: A conceptual solution. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No. 04CH37551), Aachen, Germany, 20–25 June 2004; Volume 6, pp. 4285–4290. [Google Scholar]

- IEEE Std 1547.4-2011; IEEE Guide for Design, Operation, and Integration of Distributed Resource Island Systems with Electric Power Systems. IEEE: New York, NY, USA, 2011.

- Melton, R.; Jones, E. Pacific Northwest Smart Grid Demonstration Project Technology Performance Report Volume 1: Technology Performance; PNW-SGDP-TPR-Vol. 1-Rev.1.0, PNWD-4438; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2015; Volume 1.

- Nagapurkar, P.; Smith, J. Techno-economic optimization and social costs assessment of microgrid-conventional grid integration using genetic algorithm and Artificial Neural Networks: A case study for two US cities. J. Clean. Prod. 2019, 229, 552–569. [Google Scholar] [CrossRef]

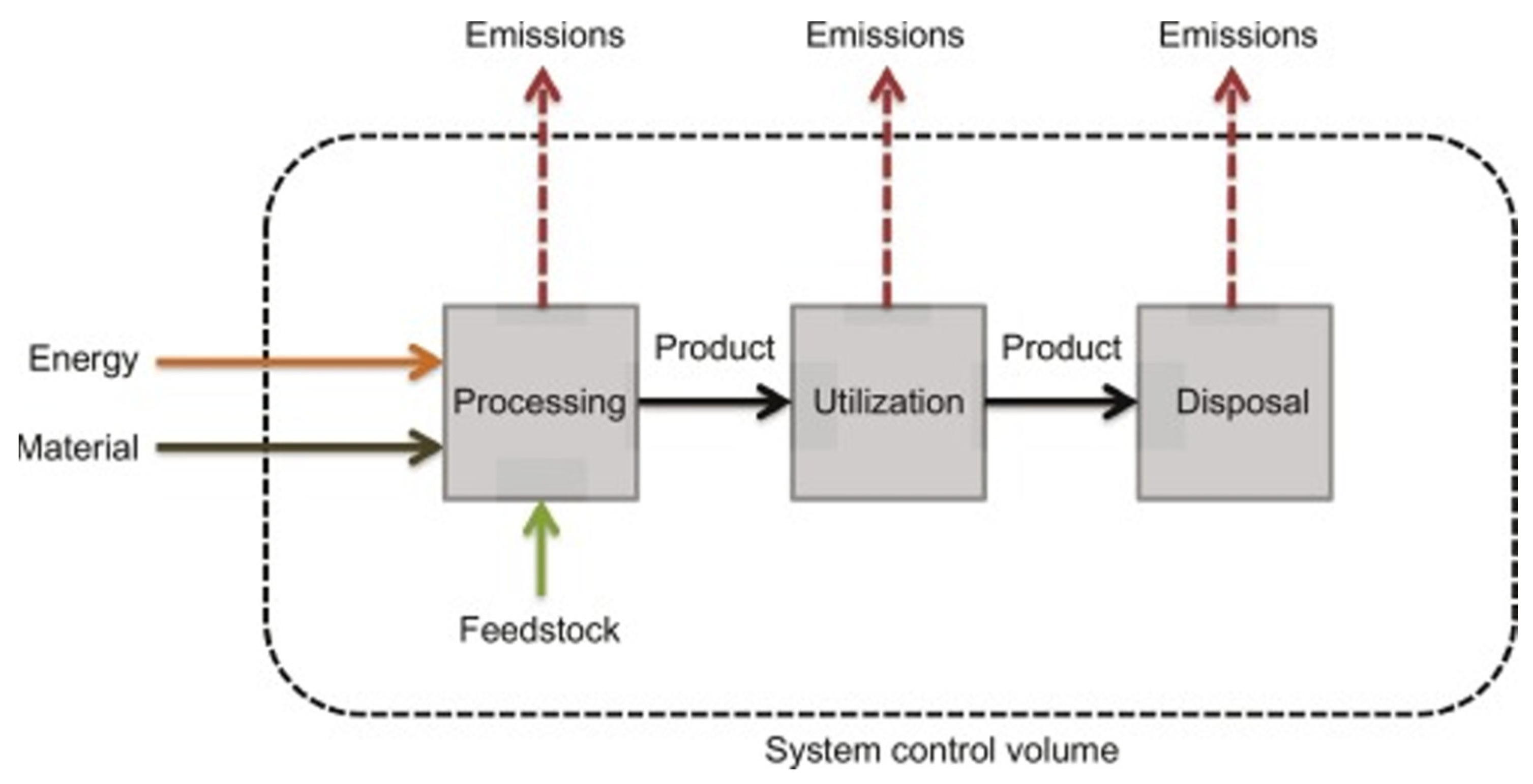

- Nagapurkar, P.; Smith, J. Techno-economic optimization and environmental Life Cycle Assessment (LCA) of microgrids located in the US using genetic algorithm. Energy Convers. Manag. 2019, 181, 272–291. [Google Scholar] [CrossRef]

- Lee, U.; Benavides, T.P.; Wang, M. Life Cycle Analysis of Waste-to-Energy Pathways; Figure 8.1, Chapter 8. In Life Cycle Assessment—An Overview; Academic Press: Cambridge, MA, USA, 2020; pp. 213–233. [Google Scholar] [CrossRef]

- Wu, M.; Wang, M.; Liu, J.; Huo, H. Assessment of potential life cycle energy and gas emission effects from using corn based butanol as a transportation fuel. Biotechnol. Prog. 2008, 24, 1204–1219. [Google Scholar] [CrossRef]

- Wang, M.; Han, J.; Haq, Z.; Tyner, W.E.; Wu, M.; Elgowainy, A. Energy and Greenhouse Gas Emission Effects of Corn and Cellulosic Ethanol with Technology Improvements and Land Use Changes. Biomass Bioenergy 2011, 35, 1885–1896. [Google Scholar] [CrossRef]

- Fikru, M.G.; Gelles, G.; Ichim, A.; Kimball, J.; Smith, J.; Zawodniok, M.J. An Economic Model for Residential Energy Consumption, Generation and Reliance on Cleaner Energy in Missouri Energy Consumption, Generation and Reliance on Cleaner Energy in Missouri. Renew. Energy 2018, 119, 429–438. [Google Scholar] [CrossRef]

- Mosher, T. Economic Valuation of Energy Storage Coupled with Photovoltaics: Current Technologies and Future Projections. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Hadjipaschalis, I.; Poullikkas, A.; Efthimiou, V. Overview of current and future energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2010, 13, 1513–1522. [Google Scholar] [CrossRef]

- Schoenung, S.M. Energy Storage Systems Cost Update: A Study for the DOE Energy Storage Systems Program; No. SAND2011-2730; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2011.

- Chatzivasileiadi, A. Electrical energy storage technologies and the Built Environment. In Proceedings of the International Renewable Energy Storage Conference, Berlin, Germany, 12–14 November 2012. [Google Scholar]

- Yang, H.; Lu, L.; Zhou, W. A novel optimization sizing model for hybrid solar-wind power generation system. Solar Energy 2007, 81, 76–84. [Google Scholar] [CrossRef]

- Bradbury, K. Energy Storage Technology Review; Duke University: Durham, NC, USA, 2010; pp. 1–34. [Google Scholar]

- Eyer, J.M. Benefits from Flywheel Energy Storage for Area Regulation in California-Demonstration Results: A Study for the DOE Energy Storage Systems Program; No. SAND2009-6457; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2009.

- Wilcox, S.M. National Solar Radiation Database 1991–2010 Update: User’s Manual; No. NREL/TP-5500-54824; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2012.

- Yenen, M.; Ercan, F.; Fahrioglu, M. Solar Energy Technology for Northern Cyprus: Assessment, Statistical Analysis, and Feasibility Study. Energies 2020, 13, 940. [Google Scholar] [CrossRef]

- Stapleton, G.; Neill, S. Grid-Connected Solar Electric Systems—The Earthscan Expert Handbook for Planning, Design and Installation; Routledge: New York, NY, USA, 2021. [Google Scholar]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic degradation rates—An analytical review. Prog. Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- Anjum, L. Wind resource estimation techniques-an overview. Int. J. Wind Renew. Energy 2014, 3, 26–38. [Google Scholar]

- Dolan, S.L.; Heath, G.A. Life cycle greenhouse gas emissions of utility-scale wind power: Systematic review and harmonization. J. Ind. Ecol. 2012, 16, S136–S154. [Google Scholar] [CrossRef]

- Elsied, M.; Oukaour, A.; Gualous, H.; Brutto, O.A.L. Optimal economic and environment operation of micro-grid power systems. Energy Convers. Manag. 2016, 122, 182–194. [Google Scholar] [CrossRef]

| Pb-A | Pb-C | Li-Ion | S-S | V-Redox | Zn-Br | Flywheel | |

|---|---|---|---|---|---|---|---|

| Roundtrip Efficiency (%) | 80 | 75 | 85 | 75 | 65 | 70 | 85 |

| Cycle life | 1000 | 3000 | 4000 | 4000 | 5000 | 2000 | 25,000 |

| Calendar Life (yr) | 6 | 6 * | 9 | 14 | 12 | 11 | 20 |

| Self-Discharge (%/yr) | 108 | 52 | 108 | 7300 | 108 | 365 | 36,500 |

| Pb-A | Pb-C | Li-Ion | S-S | V-Redox | Zn-Br | Flywheel | |

|---|---|---|---|---|---|---|---|

| Energy Cost ($/kWh) | 330.00 | 330.00 | 600.00 | 350.00 | 600.00 | 400.00 | 1600.00 |

| Power Cost ($/kW) | 400.00 | 400.00 | 400.00 | 350.00 | 400.00 | 400.00 | 600.00 |

| Fixed O&M Cost ($/kW-year) * | 1.55 | 1.55 | 0.00 | 9.00 | 4.00 | 0.00 | 11.60 |

| Variable O&M Cost ($/kW) | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Pb-A | Pb-C | Li-Ion | S-S | V-Redox | Zn-Br | Flywheel | |

|---|---|---|---|---|---|---|---|

| Energy Storage Size (kWh) | 4688.00 | 4920.00 | 4329.00 | 25,808.00 | 5847.00 | 6391.00 | 9884.00 |

| Average State of Charge (%) | 97.32 | 97.41 | 97.20 | 82.76 | 97.51 | 97.45 | 72.74 |

| Replacement lifetime (year) | 4.00 | 3.00 | 2.00 | 2.00 | 1.00 | 2.00 | 1.00 |

| Net Present Value ($1000) | 1580.00 | 1652.00 | 2623.00 | 9057.00 | 3534.00 | 2582.00 | 15,859.00 |

| Electricity Cost ($/kW) | 0.46 | 0.48 | 0.76 | 2.63 | 1.03 | 0.75 | 4.61 |

| # | Assumption |

|---|---|

| 1 | Hourly data is sufficient to estimate the dynamic behavior of the microgrid performance |

| 2 | Load profile remains constant throughout system lifetime |

| 3 | O&M costs for microgrid are negligible |

| 4 | Sufficient space exists for both wind turbines and solar arrays to effectively operate (do not interfere with each other) and solar arrays receive full sun during day light hours |

| 5 | Lead acid batteries have 5 year replacement lifetime |

| 6 | Bad year for solar and wind generation is 90% of 2010 National Renewable Energy Laboratory (NREL) dataset (energy generation multiplied by 0.9 to account for reduced generation in this scenario) |

| 7 | Demand data excludes natural gas use for environmental heating and hot water |

| 8 | Transmission and supplemental electrical equipment costs are negligible |

| 9 | Wind turbines and solar arrays have 20-year replacement lifetime |

| 10 | Lead acid battery OPEX and O&M costs constant over the entire time considered |

| 11 | European Union (EU) Emission Trading System price used to estimate cost of carbon credits |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Rubaye, H.; Smith, J.D.; Zangana, M.H.S.; Nagapurkar, P.; Zhou, Y.; Gelles, G. Advances in Energy Hybridization for Resilient Supply: A Sustainable Approach to the Growing World Demand. Energies 2022, 15, 5903. https://doi.org/10.3390/en15165903

Al-Rubaye H, Smith JD, Zangana MHS, Nagapurkar P, Zhou Y, Gelles G. Advances in Energy Hybridization for Resilient Supply: A Sustainable Approach to the Growing World Demand. Energies. 2022; 15(16):5903. https://doi.org/10.3390/en15165903

Chicago/Turabian StyleAl-Rubaye, Haider, Joseph D. Smith, Mohammed H. S. Zangana, Prashant Nagapurkar, Yishu Zhou, and Greg Gelles. 2022. "Advances in Energy Hybridization for Resilient Supply: A Sustainable Approach to the Growing World Demand" Energies 15, no. 16: 5903. https://doi.org/10.3390/en15165903

APA StyleAl-Rubaye, H., Smith, J. D., Zangana, M. H. S., Nagapurkar, P., Zhou, Y., & Gelles, G. (2022). Advances in Energy Hybridization for Resilient Supply: A Sustainable Approach to the Growing World Demand. Energies, 15(16), 5903. https://doi.org/10.3390/en15165903