Abstract

The pore space of autoclaved aerated concretes (ACCs), regardless of their apparent density, is represented by large pores formed as a result of gas formation and fine capillary pores. With the free absorption of liquid moisture, only the capillary pores are filled. Large pores contain vapor-air mixture. Considering such a bimodal pore size distribution, it is proposed to determine the thermal conductivity of moist ACC in two stages. First, an inhomogeneous ternary system that consists of a solid skeleton with a fine porous structure containing gas and liquid moisture should be considered. Then a binary system is taken into account, the first component of which is the mentioned ternary system, and the other component of which consists of isolated gas inclusions in large pores. To determine the thermal conductivity of the ternary system, the dependences constructed using the theory of generalized conductivity were used. The thermal conductivity of the binary system was calculated using well-known formulas. It was found that the results of thermal conductivity calculations based on the proposed two-step method deviate from the experimental data in the range from −7.29 to +5.75%, with an average deviation of −0.71%. With the one-step calculation method (assuming a unimodal pore distribution), the spread of analogous data ranges from −30.72 to −21.98%, with an average deviation of −26%.

1. Introduction

Aerated concretes are commonly used for exterior walls of buildings. In the dry state, they are characterized by a relatively low value of the effective thermal conductivity, however, during the operation of buildings, the moisture content of ACCs can increase significantly. Thus, in the work [1] on the basis of physical and computational experiments, it was shown that the average moisture content of the ACC slab used for exterior wall of a heated building exceeded the standard (normalised) value 4–5 times. This led to an increase in the thermal conductivity of the material and a deterioration in the thermal insulation of the partition.

One of the reasons for the increased dampness of shielding structures is the simultaneous impact of precipitation and wind on the outer surface of the partition, called wind-driven rain [1,2,3,4]. In the course of wind-driven rain the moisture content of the partition outer layer material depends on the intensity and duration of precipitation, as well as on the characteristics of the pore structure of the material and can increase up to the full capillary saturation [4].

The results of measurements of the pore structure of ACC samples [5,6,7] showed that, regardless of the apparent density of the samples, there were always two maxima in the differential pore sizes distribution. The analysis of these data shows that the pore space of the samples under consideration consists mainly of fine capillary pores (≈10−7 m) and large gas pores (≈10−3 m). Large gas pores are formed as a result of using foaming agents or foam for ACC production. Fine pores are incorporated into the solid skeleton surrounding large gas pores. In general, the porosity of ACCs is open. The results of research presented in [8] show that the content of closed pores is only 1.4%, with the total porosity at the level of 62.3%.

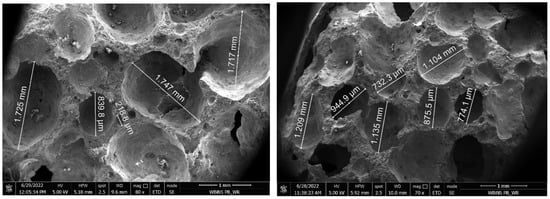

In order to illustrate the bimodal pore structure of ACCs, the photos taken with a scanning electron microscope are shown in Figure 1. Samples of two different apparent densities (450 and 600 kg/m3) were photographed. Regardless of the differences in the apparent density, both samples show large pores with a diameter close to 10−3 m, which are usually enclosed by a microporous skeleton formed by mineral structures. The fine pores of the skeleton, formed together with the solid material, constitute a binary system with a continuous, interpenetrating structure.

Figure 1.

Large gas pores of ACC samples of different apparent density (450 kg/m3 on the left and 600 kg/m3 on the right) enclosed by the microporous skeleton of the material.

With free capillary absorption, liquid moisture fills only fine pores, while large pores are filled with a mixture of vapour and air. According to the authors’ own experimental data, the capillary absorption values of the ACC samples of an apparent density of 447–614 kg/m3 did not exceed half of their porosity. A similar ratio was observed for the ACC samples with the apparent density of 363 and 407 kg/m3 [9]. It seems, therefore, that the determination of the effective thermal conductivity of moist cellular concretes by computation should be carried out in two stages. First the heterogeneous ternary system consisting of a solid skeleton (1) and fine capillary pores containing gas (2) and liquid moisture (3) should be considered. Next, the binary system, whose first component is the above-mentioned ternary system, and whose other component is isolated gas inclusions at large pores, should be taken into account. Until now, such an approach to calculating the effective thermal conductivity of cellular concrete has not been adopted.

This paper presents a two-step method for calculating the effective thermal conductivity of materials with a bimodal pore size distribution developed by the authors. To determine the thermal conductivity of a heterogeneous ternary system, formulas constructed on the basis of the theory of generalised conductivity in combination with geometric modeling of the structure by transitioning to the unit cell [10] were used. The thermal conductivity of a binary system with insulated gas inclusions was calculated using the known formulas presented in [11]. It was found that the results of the calculations of the thermal conductivity of moist cellular concretes achieved with the proposed method practically agree with experimental values obtained by the authors. Additionally, it was shown that calculation of thermal conductivity of moist cellular concretes using the one-step method presented in [10], which does not take into account the bimodal character of pore distribution of ACCs, gives results much lower than the experimental ones.

2. Geometric Model of a Heterogeneous Ternary System and the Dependence to Determine Its Thermal Conductivity

When constructing a geometric model of a ternary system, it is necessary to know the volumetric concentrations of its components mi. The cellular concrete sample volume V consists of the solid skeleton volume vs. the pores, and the volume of fine Vsp and large Vbp pores. The volume of the ternary system V′ considered in this case is equal to the sum Vs + Vsp. The volume of the solid skeleton vs. the pores can be determined by the pycnometric method, and the volume of fine pores Vsp is assumed to be equal to the volume of the liquid absorbed by a sample of material immersed in water Vsat. The volume of fine pores Vsp = Vsat is filled with water with the volume Vw ≤ Vsp. As a result, the following values of the volumetric concentrations of the considered components are obtained: solid m1 = Vs/V′, liquid m3 = Vw/V′ = ψw (ψw—moisture content of the ternary system) and gas m2 = (Vsp − Vw)/V′ = Psp − ψw, where Psp = Vsp/V′ = Vsat/V′ is the porosity of the ternary system.

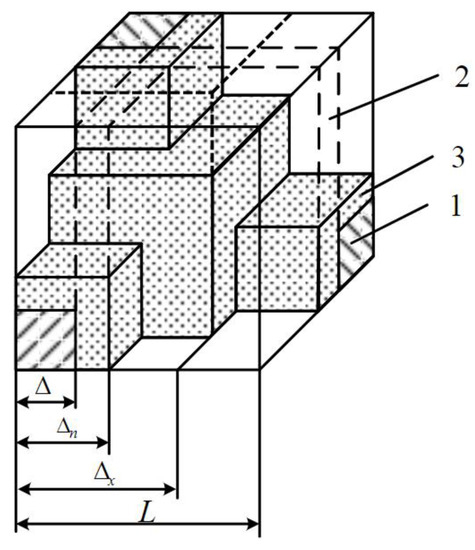

If the volume of the liquid Vw does not exceed a certain limit value Vw′, then the liquid is distributed in the porous space in the form of isolated inclusions. This case is described in detail in [11]. In what follows a ternary system for which Vw > Vw′ will be considered. In a general case, the structure of such an arrangement, according to [11,12], can be represented in the form of the eighth part of the unit cell illustrated in Figure 2. Figure 2 shows that the volume of the liquid Vw covering bars of the solid skeleton with dimension Δ can be conditionally divided into two parts of dimensions Δx and Δn. It is assumed that, when the pore moisture content changes, the value of Δx remains constant. The justification for this assumption is given in [11].

Figure 2.

The eighth part of the unit cell with continuous inclusions of liquid; 1, 2, 3—solid, gas and liquid components, respectively.

The dimension Δx is related to the volume of the liquid Vk in the node of the skeleton mesh . After determining the difference the dependence is obtained. After the division of the left and right sides of this equality by the volume of the unit cell , the cubic equation combining the volumetric concentration of the liquid in the mesh node with the geometric parameters c = Δ/L and d = x/L = Δx/L − Δ/L = cx − c is obtained:

The value of c depends on the volumetric concentration of the solid skeleton and is determined by the formula [13]

The volumetric concentration of the liquid in the network node ψk is determined by the formula

where is the boundary value of pore moisture at which the transition from isolated liquid inclusions to continuous liquid inclusions (and vice versa) takes place. According to [14,15], the value of ψ′p depends on c and the wetting angle θ. For example, at θ = 45° we have

With the known values of ψk and c a positive, physically justified, root d is determined using formula (1). Then the geometric parameter cx = c + d.

The second part of the liquid volume Vn = Vw − Vk (see Figure 2) is equal to . After dividing both sides of this equation by the volume of the unit cell V = L3, the quadratic equation is obtained

solving which the geometric parameter cn can be found.

In this way, with the known volumetric concentrations of the ternary system components and the assumed wetting angle θ, it is possible to determine the parameters of the structure of the geometric model under consideration (Figure 2). For this model, using the procedure described in [10,15], dependencies were constructed that allow to estimation of the effective thermal conductivity of the ternary system at known values of the thermal conductivity of its components λi (i = 1, 2, 3).

By dividing the unit cell (Figure 2) with adiabatic planes parallel to the heat flux, a formula was obtained that gives the lower estimate of the thermal conductivity of the ternary system λ’a:

where .

By dividing the same unit cell with isothermal planes perpendicular to the heat flux, a formula was obtained determining the upper estimate of the thermal conductivity of the ternary system λ′iz:

As in (6), .

It is easy to establish that Formulas (6) and (7) are transformed from the formula obtained in [15] for isolated inclusions of the liquid. For cn = cx Formulas (6) and (7) are transformed into the form of relationships constructed for the steady distribution of the liquid on the surface of the solid skeleton bars [15]. However, with such a distribution of the liquid, a smooth transition to isolated liquid inclusions is not ensured, and comparative calculations yield significant differences. For example, at the wetting angle θ = 45° and the pore boundary moisture content ψp′ = 0.417, with concentrations of the components of the system m1 = 0.5; m2 = 0.2915; m3 = 0.2085 and their thermal conductivities λ1 = 1.0 W/(m·K), λ2 = 0.03 W/(m·K), λ3 = 0.6 W/(m·K), the effective thermal conductivity of such a system, determined by formulas (6) and (7), is equal to λ = 0.4065 W/(m·K) while, according to formulas from [15], for the steady distribution of the liquid λ = 0.5455 W/(m·K). From a physical point of view, the first result, which is 25.5% lower than the other, gives a more accurate estimate.

If the material is dry (cn = c and cx = c) Formulas (6) and (7) are transformed into known formulas for a system with two interpenetrating components [11] at adiabatic

and isometric division of the unit cell

where .

In order to perform calculations according to Formulas (6) and (7) it is necessary to determine the volumetric concentration of the components mi and their thermal conductivities λi.

The thermal conductivity of the solid component λ1 at the first approximation can be determined by Formulas (8) and (9) in which and are assumed to be equal to the experimental value of the thermal conductivity of dry material λdry, and then the thermal conductivity of the solid component is calculated by an iterative method with adiabatic and isothermal unit division. For further calculations, the average value is adopted.

The thermal conductivity of the vapour-air mixture λ2 (gas component) is the sum of the thermal conductivity of dry air λair and the thermal conductivity of vapour λws caused by the diffusion transfer of vapour in the pore space. The first element of the sum is described by the formula [16]:

where t is the temperature, °C.

The other element is determined by the formula presented in the work [11], based on the Krisher relationship [17],

where:

- D—water vapour diffusion coefficient in stationary air, m2/s;

- Μ—coefficient of resistance of vapour diffusion in the pore space;

- M—molecular weight of water vapour, kg/mol;

- R—universal gas constant, J/(mol·K);

- T—water vapour temperature, K;

- pva—total water vapour and air pressure, Pa;

- pv—partial water vapour pressure, Pa;

- qt—specific heat of evaporation at temperature t, J/kg.

When determining the water vapour diffusion coefficient, the following formula [17] was used

proposed by R. Schirmer in 1938.

The derivative can be determined from reference data or from formula [17]

The dependence of the specific heat of evaporation on the temperature after approximation of the reference data is in the form of:

The water vapour diffusion resistance coefficient μ for the continuous gas component, according to [14,18], can be determined by the formula

where should be calculated by formula (2) in which the concentration of the solid component m1 is replaced by the concentration of the gas component m2. For insulated gas inclusions μ = 1.0 [11].

The thermal conductivity of the liquid component (water) λ3 is determined by the formula obtained after approximation of data from the work [5],

Now, using formulas (6) and (7), it is possible to determine the thermal conductivities λa′ and λiz′ and their mean value λ′ = 0.5(λa′ + λiz′), which is assumed to be the effective thermal conductivity of the ternary system with the volume V′ considered at the first stage of calculation. Then the calculation of the binary system can be performed.

3. Calculation of the Binary System

In the binary system with the volume (Vbp—volume of large pores) the first component is the considered ternary system with the volume V′, thermal conductivity λ1 = λ′ and volumetric concentration , and the other includes closed large pores with the volumetric concentration . The thermal conductivity λ2 of the mixture of vapour and air filling large pores is determined by Formulas (10)–(14) with a vapour diffusion resistance coefficient μ = 1.

When determining the thermal conductivity of a binary system the following formulas from [11] can be used:

when dividing the unit cell by adiabatic planes

when dividing the unit cell by isothermal planes

where .

The average value gives an estimate of the effective thermal conductivity of the moist material with a bimodal distribution of the pore volume by size.

4. Results of the Physical and Computational Experiment

4.1. Results of the Physical Experiment

In order to confirm the accuracy of the proposed method of calculating the thermal conductivity of moist materials with a bimodal pore size distribution, an experiment was carried out using ACC specimens of different apparent density ρ and equal volume V (24 × 24 × 5 cm), which were cut from masonry units (blocks). Four series were considered, each of which consisted of three specimens of a similar apparent density. Using pycnometry, the density of the solid skeleton ρs was determined, at which its volume concentration and porosity of the material were calculated. Water absorption was determined by immersing the specimens in water. The thermal conductivity of dry λdry and moist samples λh was measured by the stationary method. All measurements were carried out at room temperature t ≈ 20 °C. The values of experimental data necessary to calculate the effective thermal conductivity λ of moist materials are given in Table 1.

Table 1.

Experimental mean values of the apparent density ρ, absolute skeleton density ρs, water absorption ψsat, porosity P and thermal conductivity in the dry state λdry of specimens in four series.

4.2. Example of Calculation According to the Two-Step Procedure

The procedure of calculating the thermal conductivity of moist ACCs will be considered based on the data obtained for specimens from the first series with the average apparent density ρ = 447 kg/m3 and the thermal conductivity in the moist state λh = 0.278 W/(m⋅K) at the moisture content , which corresponds to the state of saturation with free capillary water absorption.

At the first stage of the calculation, the ternary system with the volume V′ is considered, which consists of the volume of the solid skeleton (solid phase) vs. and the volume of fine pores Vsp = Vsat. The volumetric concentration of this system is The volumetric concentrations of the components of the ternary system are: solid phase ; liquid and gas . The geometric parameter of the solid skeleton c = 0.4572 is calculated by Formula (2). Before determining the geometrical parameters of the liquid component, the value of the wetting angle should be assumed. Taking into account the data from [14,19], a wetting angle equal to θ = 45° was assumed. In this case, the pore boundary moisture content calculated on the basis of Formula (4) did not exceed the actual moisture content of the pores . This means that the liquid in the pore space is distributed as a continuous component, and that the geometrical parameters cx and cn are determined by Formulas (1), (3) and (5), and the thermal conductivity of the system should be calculated by Formulas (6) and (7). The calculation gave the following values cx = 0.8204 and cn = 0.7844. After performing the iterative procedure described earlier, the thermal conductivity of the solid skeleton λ1 = 0.84 W/(m⋅K) was determined. The thermal conductivity of the gas component was determined by Formulas (10)–(15) and is λ2 = 0.0269 W/(m⋅K). The thermal conductivity of water calculated by Formula (16) is λ3 = 0.597 W/(m⋅K). Formula (6) was employed to determine the thermal conductivity of the system for the adiabatic division of the unit cell λa′ = 0.4845 W/ (m⋅K), whereas Formula (7) was used for the isothermal division of the unit cell λiz′ = 0.6109 W/ (m⋅K). Their average is taken as the estimate of the effective thermal conductivity of the ternary system λ′ = 0.5(0.4845 + 0.6109) = 0.5477 W/(m⋅K).

It should be noted that, if the actual pore moisture content ψp does not exceed the boundary value ψp′, then the liquid is distributed in the porous material in the form of isolated inclusions. Then the thermal conductivity of the system can be determined by the formulas from [14] or by Formulas (6) and (7), taking cn = c and determining cx from Formula (1), in which the actual moisture should be used instead of the volumetric concentration of the liquid in the node of the network ψk.

In the second stage, calculations are made for a binary system in which the volumetric concentration of the first component is , and the thermal conductivity λ1 = λ′ = 0.5477 W/ (m⋅K). The volumetric concentration of the other component (gas) is 0.4812. The thermal conductivity of the vapour-air mixture in closed large pores λ2 = 0.0962 W/(m⋅K) is calculated by Formulas (10)–(14), assuming that the coefficient of vapour diffusion resistance in closed pores μ = 1. The thermal conductivity of the binary system was determined by Formulas (17) and (18), respectively, when the unit cell is divided by adiabatic planes λa = 0.2833 W/(m⋅K) and isothermal planes λiz = 0.3037 W/(m⋅K). The calculated estimate value of the effective thermal conductivity of the material λ = 0.5(λa + λiz) = 0.2935 W/(m⋅K) exceeds the average experimental value λh = 0.278 W/(m⋅K) by 5.57%.

4.3. Example of Calculation According to The One-Step Procedure

For the purpose of comparison, calculation of the thermal conductivity λ for the same ACC specimens was performed using the one-step procedure proposed in [10], which does not take into account the bimodal pore distribution. In this case, the following values of the volumetric concentrations of the components are obtained: solid phase m1 = ms = 0.2258, liquid m3 = ψ = 0.232 and gas m2 = 1 − m1 − m3 = 0.5422. Thermal conductivity of the solid skeleton λ1 = 0.84 W/(m⋅K) and water λ3 = 0.597 W/(m⋅K) remains the same, and the thermal conductivity and the vapour-air mixture calculated by Formulas (10)–(15) is λ2 = 0.0358 W/(m⋅K). The geometric parameter of the solid skeleton c = 0.3075 is determined by Formula (2) at m1 = 0.2257. The pore boundary moisture content calculated by formula (4) was and exceeded the actual moisture content . From this it follows that the liquid is distributed in the pores of the material in the form of isolated inclusions. In this case, Formulas (6) and (7) or dependencies from [15] constructed specifically for insulated liquid inclusions may be used to calculate the effective thermal conductivity of the material.

Using Formulas (6) and (7) for isolated liquid inclusions cn = c = 0.3075 was adopted, and cx = c + d = 0.7238 were obtained from the solution of cubic Equation (1) at ψk = ψ = 0.232 and d = 0.4163. Next, the thermal conductivity values of the ternary system were determined when dividing the unit cell by adiabatic planes λa = 0.1476 W/(m⋅K) and isothermal planes λiz = 0.2377 W/(m⋅K). Their average value was taken as the estimate of the effective thermal conductivity of the material W/(m⋅K). This value turned out to be 30.7% lower than the experimental value λh = 0.278 W/(m⋅K).

4.4. Results and Discussion

Similarly to the above examples, calculations were performed for all four series of ACC specimens using both procedures, the results of which, together with the experimental data, are presented in Table 2. The analysis of this table shows that the results of the calculation of the thermal conductivity λ using the two-step procedure quite accurately predict experimental values λh. The deviations of computational and experimental values Δ, determined by the ratio , ranged from −7.29 to + 5.75% with the average The mean square deviation of the measured values of the thermal conductivity λh is s = 0.011 W/(m·K) at 16 degrees of freedom. The deviation of the calculated values does not exceed two mean square deviations of experimental ones. The calculated values of λ are within the confidence interval for the measured values with the probability of 0.94. Statistical analysis proves that the proposed two-step method, taking into account the bimodal pore size distribution, can predict the thermal conductivity of moist ACCs with high accuracy.

Table 2.

Thermal conductivity values of moist cellular concrete samples determined experimentally λh and computationally according to the two-step method λ and one-step method , apparent density ρ and moisture content ψ of the samples in four series.

In contrast, the previously proposed one-step method, which does not take into account the bimodal pore size distribution, gives individual deviations in the range from −30.72 to −21.98% with an average . This means that the thermal conductivity values calculated by the method proposed previously are much lower than the experimental data λh.

The above results therefore indicate that the currently proposed two-step method should be used to determine the thermal conductivity of moist cellular concretes, up to the state of water saturation with free capillary absorption.

5. Conclusions

A method for calculating the effective thermal conductivity of cellular concretes with a bimodal pore size distribution has been proposed. The calculation should be carried out in two stages to take into account this property of the pore structure. First, the ternary system is considered, consisting of the solid skeleton and gas and liquid contained at fine (capillary) pores. The volumetric concentration of the fine pores is determined on the basis of the water absorption of samples previously immersed in water. Then, the binary system is taken into account, consisting of the mentioned ternary system, the effective thermal conductivity of which is determined by the formula constructed using the theory of generalised conductivity and large gas pores. The thermal conductivity of the binary system is calculated using well-known formulas.

The thermal conductivity of samples of cellular concretes was measured under laboratory conditions, the moisture content of which was increased until free capillary saturation. On the basis of experimental data, the thermal conductivity of the samples was calculated using the currently proposed and previous methods. It was found that the results of the calculation of the thermal conductivity using the currently proposed method practically agree with the experimental values, whereas the previous method of calculation yielded much lower results compared to the experimental values.

Author Contributions

Conceptualisation, B.B.-B. and V.I.N.; methodology B.B.-B., V.I.N. and A.A.; software, S.K.N.; validation, A.A., and B.B.-B.; formal analysis, A.A.; investigation, B.B.-B. and W.R.; resources, A.A. and B.B.-B.; data curation, B.B.-B.; writing—original draft preparation, V.I.N.; writing—review and editing, B.B.-B.; visualisation, S.K.N.; supervision, A.A.; project administration, B.B.-B.; funding acquisition, A.A. and B.B.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Education and Science in Poland (grant number WZ-WB-IIL/3/2020, Bialystok University of Technology) and Ministry of Education in Belarus (grant number 811.12.218, Brest State Technical University).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Many thanks to Tomasz Żukowski and Grzegorz Orzepowski (Bialystok University of Technology) for technical support in testing of the ACC thermal conductivity and density.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alsabry, A.; Nikitsin, V.I.; Kotanov, V.A.; Backiel-Brzozowska, B. Evaluation of the influence of wind-driven rain in moisture in cellular concrete wall boards. Int. J. Appl. Mech. Eng. 2017, 22, 509–519. [Google Scholar] [CrossRef]

- Blocken, B.J.; Carmeliet, J.E. A review of wind-driven rain research in building science. J. Wind. Eng. Ind. Aerodyn. 2004, 92, 1079–1130. [Google Scholar] [CrossRef]

- Blocken, B.J.; Carmeliet, J.E. On the validity of the cosine projection in wind-driven rain calculations on buildings. Build Env. 2006, 41, 1182–1189. [Google Scholar] [CrossRef]

- Nikitsin, V.I.; Backiel-Brzozowska, B. On Taking Wind-Driven Rain and Capillary Characteristics of Materials into Account While Calculating Dampness of Shielding Structures for Buildings in Modern Materials, Installations and Construction Technologies; Fic, S., Ed.; Wyd. PSW JP II.: Biala Podlaska, Poland, 2013; pp. 36–46. [Google Scholar]

- Gawin, D. Modelowanie Sprzężonych Zjawisk Cieplno-Wilgotnościowych w Materiałach i Elementach Budowlanych/Modeling of Coupled Hygrothermal Phenomena in Building Materials and Elements; Publishing House of the Lodz University of Technology: Lodz, Poland, 2000; p. 69. [Google Scholar]

- Małolepszy, J.; Pichór, W. Possibility of Producing Autoclaved Aerated Concrete Verety 300 (Możliwości Wytwarzania Autoklawizowanego Betonu Komórkowego Odmiany 300), Scientific Conf. “Technological, Organizational and Economic Aspects of Construction Development”; Edycja: Olsztyn, Poland, 2002; pp. 297–305. [Google Scholar]

- Schober, G. Porosity in Autoclaved Aerated Concrete (AAC): A Review on Pore Structure, Types of Porosity, Measurement Methods and Effects of Porosity on Properties; Cement Wapno Beaton: Kraków, Poland, 2011; pp. 39–43. [Google Scholar]

- Liu, J.; Ren, Y.; Chen, R.; Wu, Y.; Lei, W. The Effect of Pore Structure on Impact Behavior of Concrete Hollow Brick, Autoclaved Aerated Concrete and Foamed Concrete. Materials 2022, 15, 4075. [Google Scholar] [CrossRef] [PubMed]

- Jerman, M.; Keppert, M.; Vyborný, J.; Černý, R. Moisture and Heat Transport and Storage Characteristics of Two Commercial Autoclaved Aerated Concretes; Cement Wapno Beton: Kraków, Poland, 2011; pp. 18–29. [Google Scholar]

- Alsabry, A.; Backiel-Brzozowska, B.; Nikitsin, V.I.; Nikitsin, S.K. Equations for Calculating the Thermal Conductivity of Capillary-Porous Materials with over Sorption Moisture Content. Sustainability 2022, 14, 5796. [Google Scholar] [CrossRef]

- Dul’nev, G.N.; Novikov, V.V. Protsessy Perenosa v Neodnorodnyh Sredah/Transport Processes in Heterogeneous Media; Energoatomizdat: Petersburg, Russia, 1991; pp. 129–135. [Google Scholar]

- Dul’nev, G.N.; Volkov, D.P.; Malarev, V.I. Thermal conductivity of moist porous materials. J. Eng. Phys. 1989, 56, 198–206. [Google Scholar] [CrossRef]

- Nikitsin, V.I.; Backiel-Brzozowska, B. Determination of capillary tortuosity coefficient in calculations of moisture transfer in building materials. Int. J. Heat Mass Transf. 2013, 56, 30–34. [Google Scholar] [CrossRef]

- Nikitsin, V.I.; Alsabry, A.; Kofanov, V.A.; Backiel-Brzozowska, B.; Truszkiewicz, P. A Model of Moist Polymer Foam and a Scheme for the Calculation of It’s Thermal Conductivity. Energies 2020, 13, 520. [Google Scholar] [CrossRef]

- Alsabry, A.; Backiel-Brzozowska, B.; Nikitsin, V.I. Dependencies for Determining the Thermal Conductivity of Moist Capillary-Porous Materials. Energies 2020, 13, 3211. [Google Scholar] [CrossRef]

- Gur’yev, V.V.; Zholudov, V.S.; Petrov-Denisov, V.G. Teplovaya Izolyatsiya v Promyshlennosti: Teoriya i raschet/Thermal Insulation in Industry. Theory and Calculation; Stroyizdat: Moscow, Russia, 2003; pp. 215–243. [Google Scholar]

- Ochs, F.; Heidemann, W.; Müller-Steinhagen, H. Effective thermal conductivity of moisture isolation as a function of temperature. Int. J. Heat Mass Transf. 2008, 51, 539–552. [Google Scholar] [CrossRef]

- Epstein, N. On tortuosity and tortuosity factor in flow and diffusion through porous media. Chem. Eng. Sci. 1989, 44, 777–779. [Google Scholar] [CrossRef]

- Janz, M. Methods of Measuring the Moisture Diffusivity of High Moisture Levels; Report TVBM-3076; Lund Institute of Technology: Lund, Sweden, 1997; pp. 38–47. Available online: https://lucris.lub.lu.se/ws/files/4798472/759003.pdf (accessed on 30 May 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).