Numerical Simulation of Oil Shale Retorting Optimization under In Situ Microwave Heating Considering Electromagnetics, Heat Transfer, and Chemical Reactions Coupling

Abstract

:1. Introduction

2. Mathematical Model

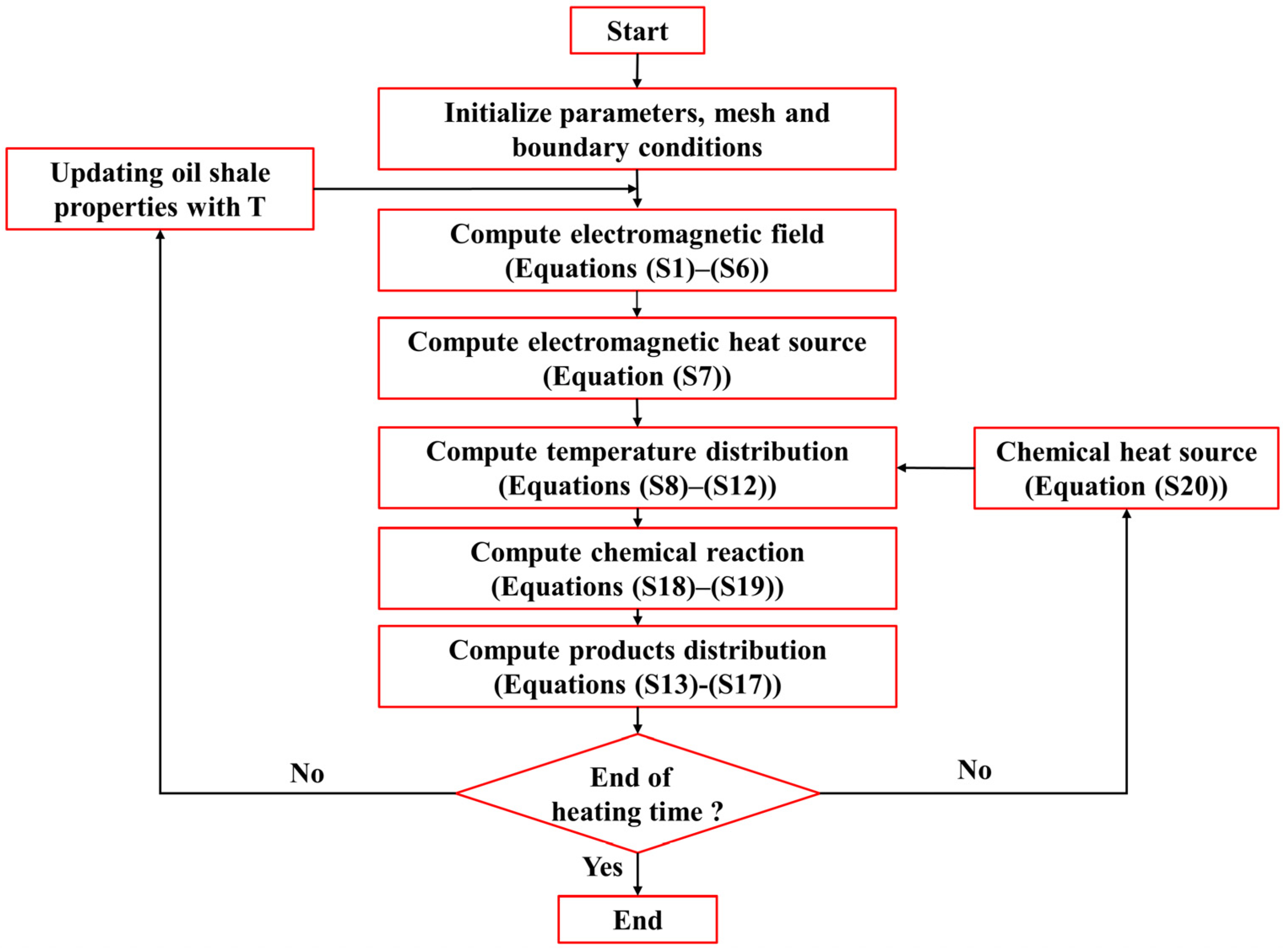

2.1. Multiphysics Coupling

2.2. Electromagnetics

2.3. Energy Conservation Equation

2.4. Mass Conservation Equation

2.5. Chemical Reactions

2.6. Model Description

2.7. Input Parameters

2.8. Grid Size Sensitivity Test

3. Numerical Simulation

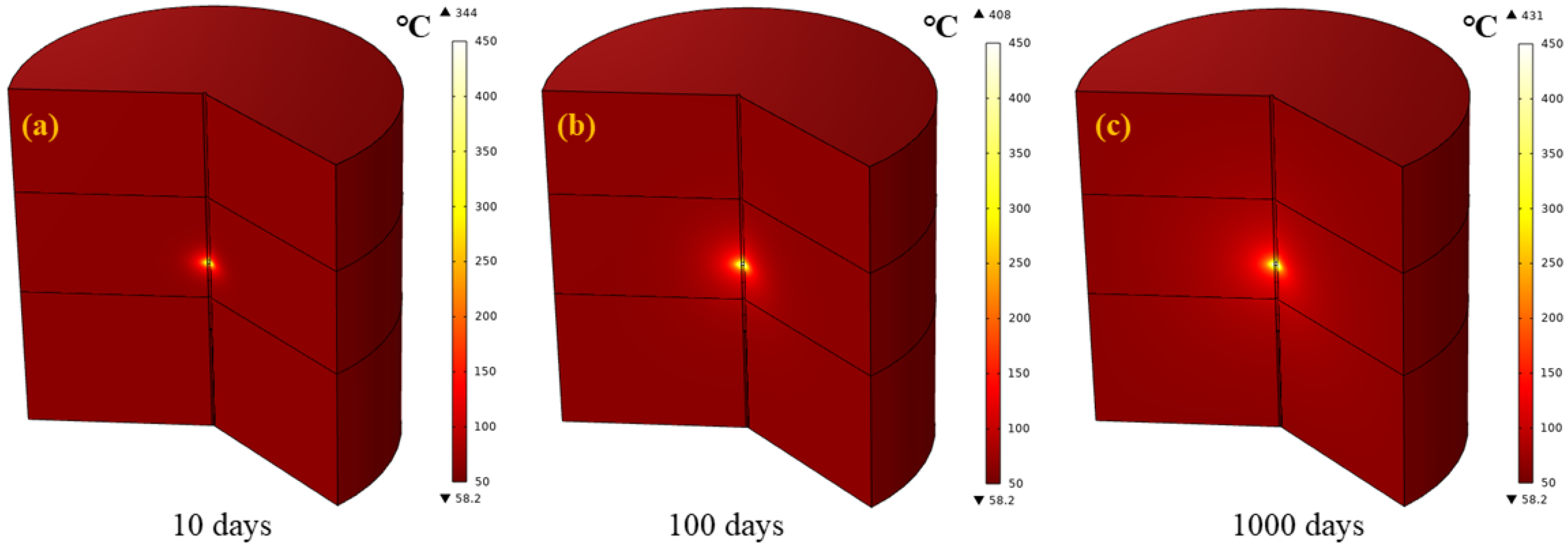

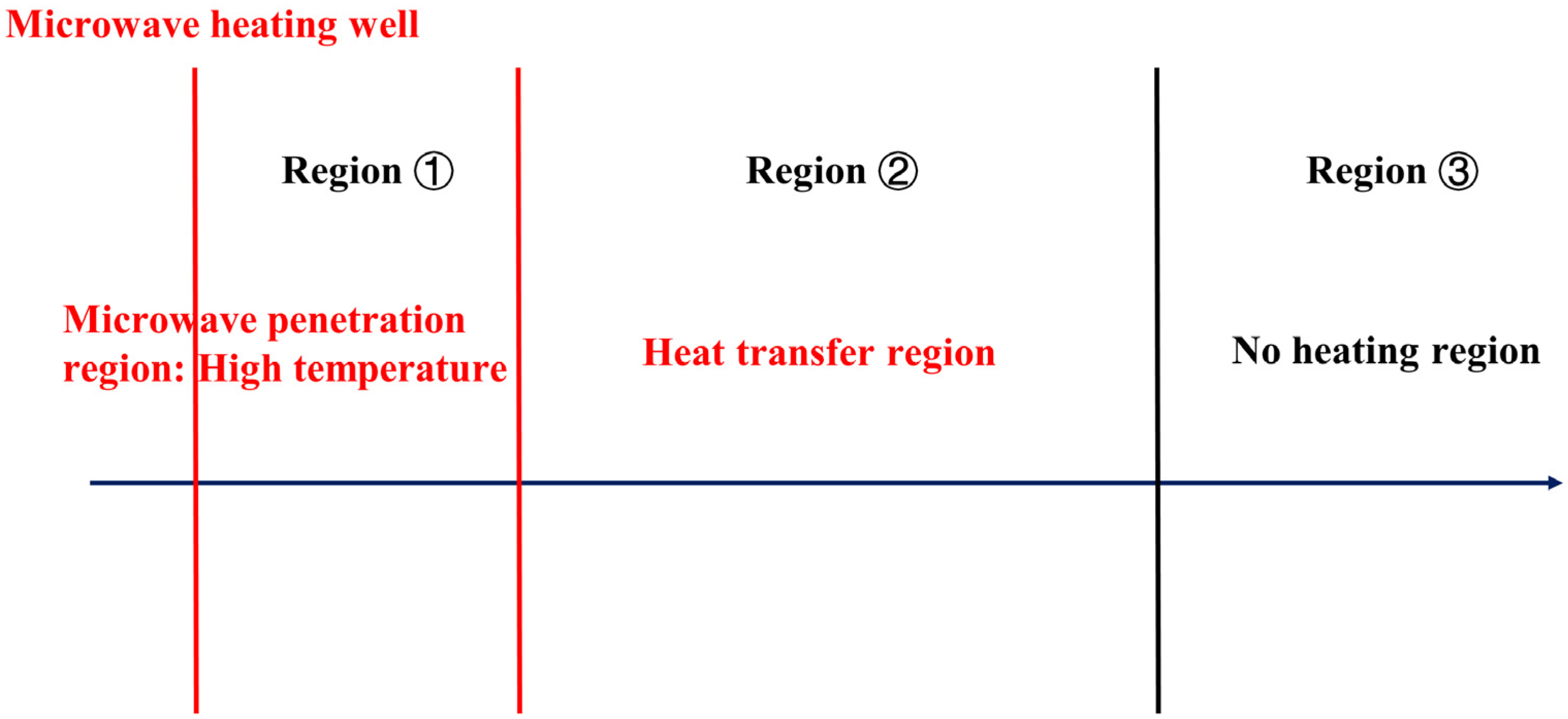

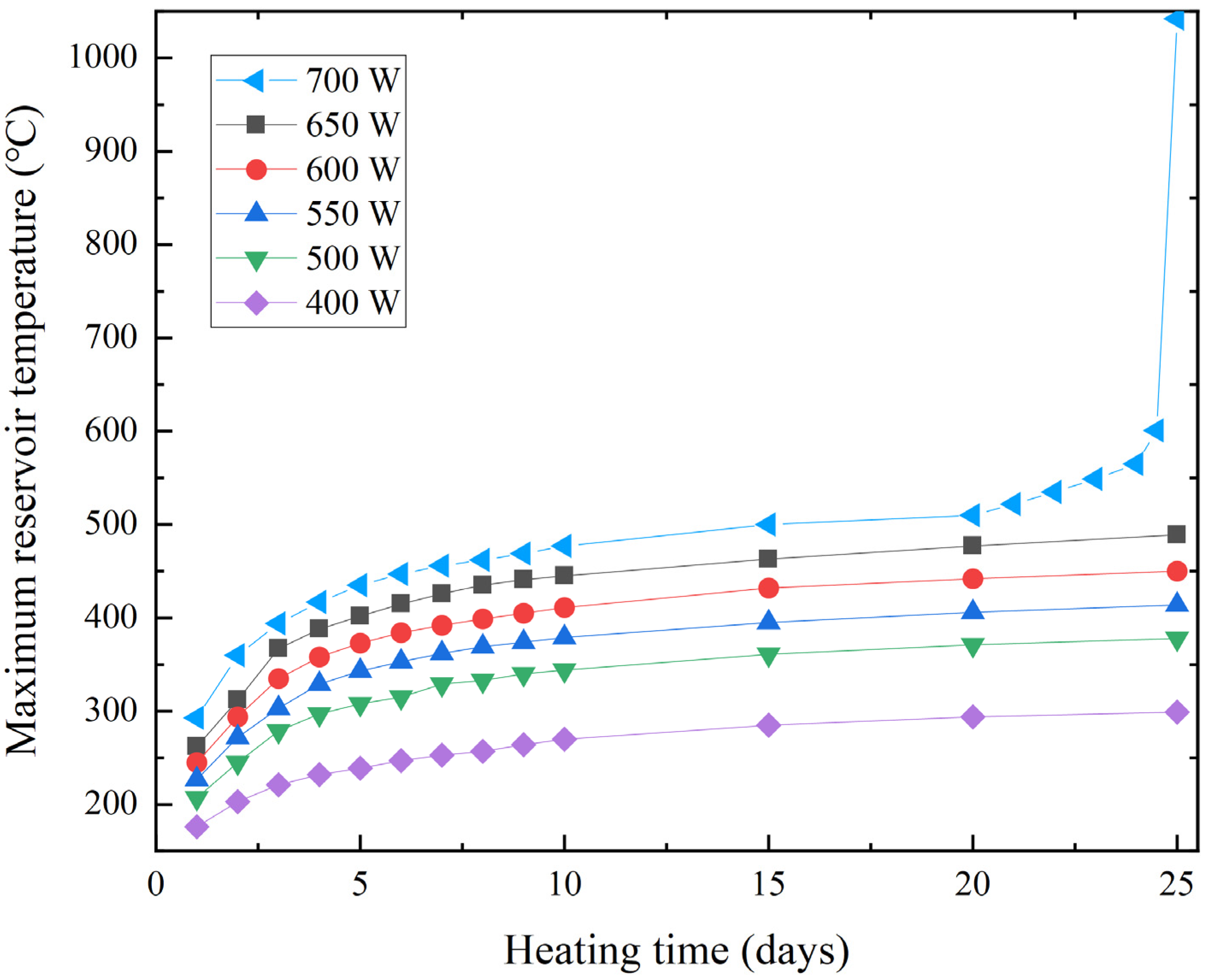

3.1. The Effect of Microwave Power

3.2. The Effect of Antenna Number

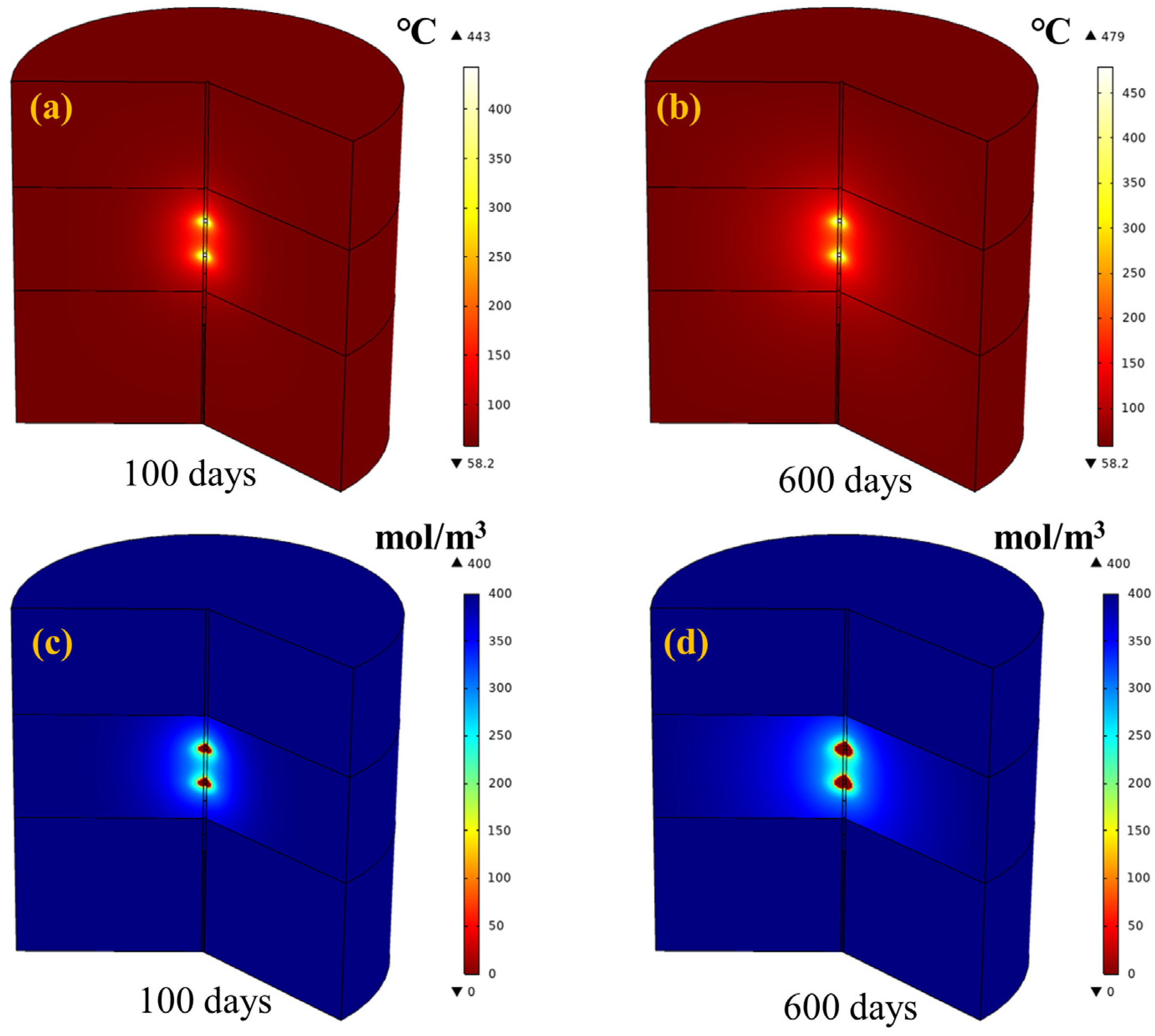

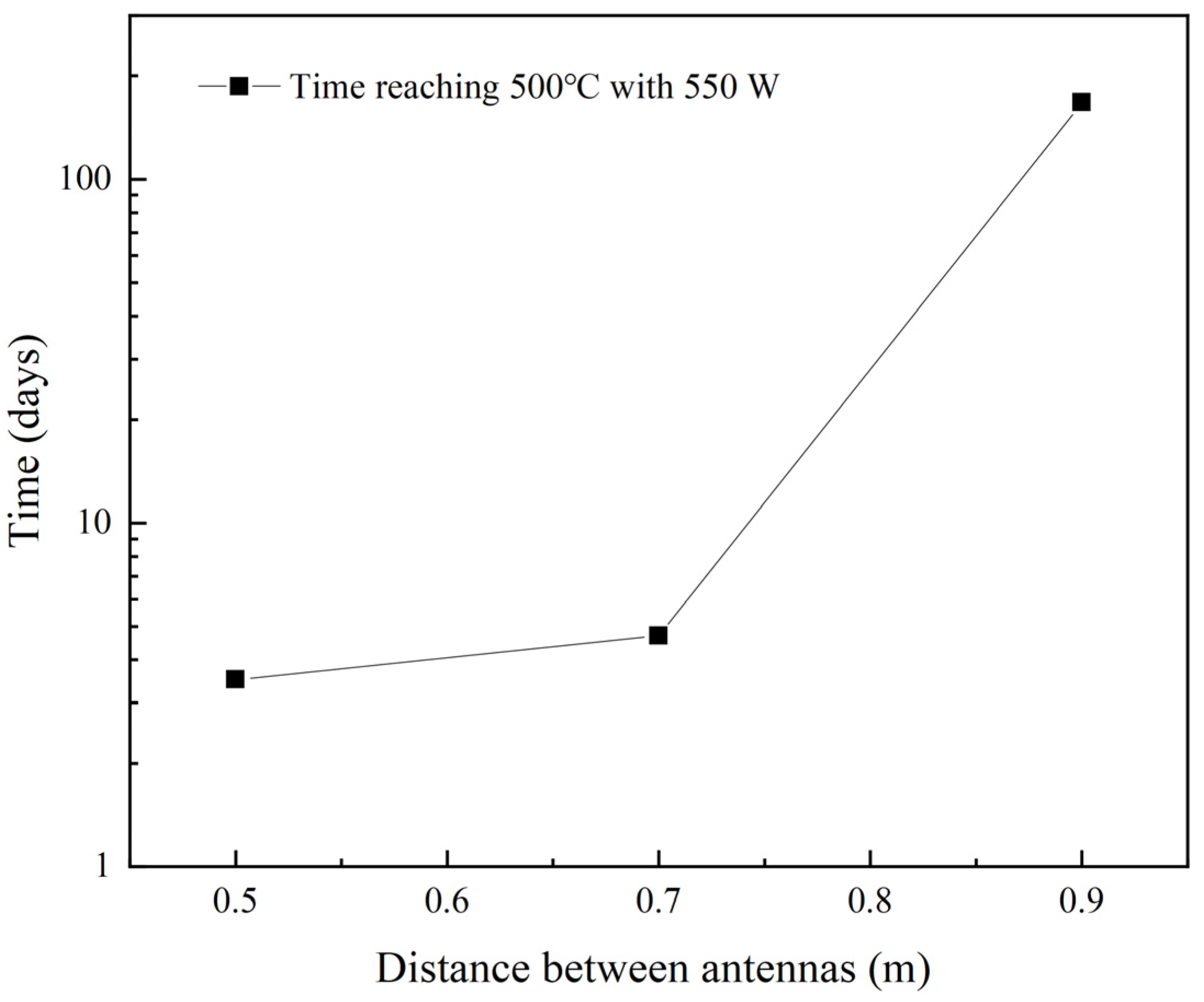

3.3. The Effect of Antenna Position

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| E | Electric field intensity (V/m) | Qc | Chemical reactions heat (W/m3) |

| B | Magnetic flux density (Wb/m2) | keff | Effective thermal conductivity (W/(m·K)) |

| H | Magnetic field intensity (A/m) | ko | Thermal conductivity of matrix (W/(m·K)) |

| D | Electric flux density (A/m2) | kf | Thermal conductivity of fluid (W/(m·K)) |

| J | Current density (A/m2) | θp | Solid volume fraction |

| ρec | Electric charge density (C/m3) | rj | The reaction rate (mol/(m3·s)) |

| µr | Relative permeability | kfj | Forward rate constant (mol/(m3·s)) |

| k0 | Wave number | ci | Concentration of component i (mol/m3) |

| σ | Electrical conductivity (S/m) | vij | Stoichiometric coefficient |

| ω | Angular frequency (rad/s) | Aj | Frequency factor (1/s) |

| εr | Relative permittivity | Ej | Activation energy of reaction j (J/mol) |

| ε0 | Vacuum permittivity (8.854 × 10−12 F/m) | Rg | Gas constant (8.314 J/(mol·K)) |

| Qe | Electromagnetic losses (W/m3) | εp | Porosity |

| ε′ | Relative dielectric constant | Ji | Mass flux (mol/(m2·s)) |

| ε″ | Relative dielectric loss factor | Ri | Mass source (mol/(m3·s)) |

| Cp | Heat capacity (J/(kg·K)) | De,i | Effective diffusion coefficient (m2/s) |

| T | Absolute temperature (K) | DF,i | Single-phase coefficient (m2/s) |

| ρs | Density (kg/m3) | τF,i | Tortuosity |

| q | Conductive heat flux (W/m²) | µ | Fluid’s dynamic viscosity (Pa·s) |

References

- Liu, X.; Pan, H.; Guo, C.; Di, X.; Hu, H. Effect of Double Transition Metal Salt Catalyst on Fushun Oil Shale Pyrolysis. Scanning 2020, 2020, 6685299. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Pan, H.; Di, X.; Liu, X.; Hu, H. Progress in Catalytic Pyrolysis of Oil Shale. Scanning 2021, 2021, 6759176. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Liu, Y.; Zhang, T.; Christopher, D.H.; Bature, N.S.; Fan, T.; Guo, H. Structural and quantitative evolution of organic matters in oil shale during two different retorting processes. AIChE J. 2021, 67, e17278. [Google Scholar] [CrossRef]

- Wang, L.; Yang, D.; Kang, Z. Evolution of permeability and mesostructure of oil shale exposed to high-temperature water vapor. Fuel 2021, 290, 119786. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, Y.; Yang, D. Review of oil shale in-situ conversion technology. Appl. Energy 2020, 269, 115121. [Google Scholar] [CrossRef]

- Yang, L.; Li, P. Evolution of the Oil Shale Permeability under Real-Time High-Temperature Triaxial Stress in the Jimusar Area, Xinjiang. Geofluids 2021, 2021, 7068973. [Google Scholar] [CrossRef]

- Xu, S.; Sun, Y.; Lü, X.; Yang, Q.; Li, Q.; Wang, Z.; Guo, M. Effects of composition and pore evolution on thermophysical properties of Huadian oil shale in retorting and oxidizing pyrolysis. Fuel 2021, 305, 121565. [Google Scholar] [CrossRef]

- Zhu, J.; Yi, L.; Yang, Z.; Li, X. Numerical simulation on the in situ upgrading of oil shale reservoir under microwave heating. Fuel 2021, 287, 119553. [Google Scholar] [CrossRef]

- Yang, D.; Wang, L.; Zhao, Y.; Kang, Z. Investigating pilot test of oil shale pyrolysis and oil and gas upgrading by water vapor injection. J. Pet. Sci. Eng. 2021, 196, 108101. [Google Scholar] [CrossRef]

- Zhao, J.; Kang, Z. Permeability of Oil Shale Under In Situ Conditions: Fushun Oil Shale (China) Experimental Case Study. Nat. Resour. Res. 2021, 30, 753–763. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, Y.; Yang, D.; Tian, L.; Li, X. A pilot investigation of pyrolysis from oil and gas extraction from oil shale by in-situ superheated steam injection. J. Pet. Sci. Eng. 2020, 186, 106785. [Google Scholar] [CrossRef]

- Zhao, S.; Lü, X.; Li, Q.; Sun, Y. Thermal-fluid coupling analysis of oil shale pyrolysis and displacement by heat-carrying supercritical carbon dioxide. Chem. Eng. J. 2020, 394, 125037. [Google Scholar] [CrossRef]

- Wang, Z.; Lü, X.; Li, Q.; Sun, Y.; Wang, Y.; Deng, S.; Guo, W. Downhole electric heater with high heating efficiency for oil shale exploitation based on a double-shell structure. Energy 2020, 211, 118539. [Google Scholar] [CrossRef]

- Kibodeaux, K.R. Evolution of Porosity Permeability, and Fluid Saturations During Thermal Conversion of Oil Shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar] [CrossRef]

- Hascakir, B.; Akin, S. Recovery of Turkish Oil Shales by Electromagnetic Heating and Determination of the Dielectric Properties of Oil Shales by an Analytical Method. Energy Fuels 2010, 24, 503–509. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, J.; Li, X.; Luo, D.; Qi, S.; Jia, M. Experimental Investigation of the Transformation of Oil Shale with Fracturing Fluids under Microwave Heating in the Presence of Nanoparticles. Energy Fuels 2017, 31, 10348–10357. [Google Scholar] [CrossRef]

- El harfi, K.; Mokhlisse, A.; Chanâa, M.B.; Outzourhit, A. Pyrolysis of the Moroccan (Tarfaya) oil shales under microwave irradiation. Fuel 2000, 79, 733–742. [Google Scholar] [CrossRef]

- Neto, A.; Thomas, S.; Bond, G.; Thibault-Starzyk, F.; Ribeiro, F.; Henriques, C. The Oil Shale Transformation in the Presence of an Acidic BEA Zeolite under Microwave Irradiation. Energy Fuels 2014, 28, 2365–2377. [Google Scholar] [CrossRef] [Green Version]

- He, L.; Ma, Y.; Yue, C.; Li, S.; Tang, X. The heating performance and kinetic behaviour of oil shale during microwave pyrolysis. Energy 2022, 244, 123021. [Google Scholar] [CrossRef]

- Lee, K.; Moridis, G.J.; Ehlig-Economides, C.A. A Comprehensive Simulation Model of Kerogen Pyrolysis for the In-situ Upgrading of Oil Shales. SPE J. 2016, 21, 1612–1630. [Google Scholar] [CrossRef] [Green Version]

- Brandt, A.R. Converting Oil Shale to Liquid Fuels: Energy Inputs and Greenhouse Gas Emissions of the Shell in Situ Conversion Process. Environ. Sci. Technol. 2008, 42, 7489–7495. [Google Scholar] [CrossRef]

- Symington, W.A.; Olgaard, D.L.; Otten, G.A.; Phillips, T.C.; Thomas, M.M.; Yeakel, J.D. ExxonMobil’s Electrofrac Process for In Situ Oil Shale Conversion. In Proceedings of the 26th Oil Shale Symposium, Golden, CO, USA, 16–18 October 2006; Available online: https://www.searchanddiscovery.com/pdfz/documents/2008/08131symington/ndx_symington.pdf.html (accessed on 7 July 2022).

- Peng, M.; Li, W.-q.; Tan, H.-f.; Lin, L. Simulation Study on Microwave Heating Mechanism of Shale Oil in Situ. In Proceedings of the International Petroleum and Petrochemical Technology Conference 2020, Shanghai, China, 26–28 August 2020; Springer: Singapore, 2021; pp. 439–455. [Google Scholar] [CrossRef]

- Song, X.; Zhang, C.; Shi, Y.; Li, G. Production performance of oil shale in-situ conversion with multilateral wells. Energy 2019, 189, 116145. [Google Scholar] [CrossRef]

- Xu, T.; Yuan, Y.; Heap, M.J.; Zhou, G.-L.; Perera, M.S.A.; Ranjith, P.G. Microwave-assisted damage and fracturing of hard rocks and its implications for effective mineral resources recovery. Miner. Eng. 2021, 160, 106663. [Google Scholar] [CrossRef]

- Youtsos, M.S.K.; Mastorakos, E.; Cant, R.S. Numerical simulation of thermal and reaction fronts for oil shale upgrading. Chem. Eng. Sci. 2013, 94, 200–213. [Google Scholar] [CrossRef]

- Al-Harahsheh, M.; Kingman, S.; Saeid, A.; Robinson, J.; Dimitrakis, G.; Alnawafleh, H. Dielectric properties of Jordanian oil shales. Fuel Processing Technol. 2009, 90, 1259–1264. [Google Scholar] [CrossRef]

- Fianu, J.; Gholinezhad, J.; Hassan, M. Thermal simulation of shale gas recovery involving the use of microwave heating. J. Pet. Sci. Eng. 2020, 186, 106768. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Leung, C.; Gao, F. A Fully Coupled Numerical Model for Microwave Heating Enhanced Shale Gas Recovery. Energies 2018, 11, 1608. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Tang, X.; Yue, G.; Kang, B.; Xie, C.; Li, X. Physical simulation of temperature influence on methane sorption and kinetics in coal: Benefits of temperature under 273.15K. Fuel 2015, 158, 207–216. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.; Chu, Y.; Li, X.; Yuan, J. A novel algorithm approach for rapid simulated microwave heating of food moving on a conveyor belt. J. Food Eng. 2020, 282, 110029. [Google Scholar] [CrossRef]

- Bientinesi, M.; Petarca, L.; Cerutti, A.; Bandinelli, M.; De Simoni, M.; Manotti, M.; Maddinelli, G. A radiofrequency/microwave heating method for thermal heavy oil recovery based on a novel tight-shell conceptual design. J. Pet. Sci. Eng. 2013, 107, 18–30. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D.; Diao, B.; Tan, L.; Zhang, W.; Liu, K. Comparative performance of electric heater vs. RF heating for heavy oil recovery. Appl. Therm. Eng. 2019, 160, 114105. [Google Scholar] [CrossRef]

- Eskandari, S.; Jalalalhosseini, S.M.; Mortezazadeh, E. Microwave Heating as an Enhanced Oil Recovery Method—Potentials and Effective Parameters. Energy Sources Part A Recovery Util. Environ. Eff. 2015, 37, 742–749. [Google Scholar] [CrossRef]

- Fia, A.Z.; Amorim, J. Heating of biomass in microwave household oven—A numerical study. Energy 2021, 218, 119472. [Google Scholar] [CrossRef]

- Lan, W.; Wang, H.; Liu, Q.; Zhang, X.; Chen, J.; Li, Z.; Feng, K.; Chen, S. Investigation on the microwave heating technology for coalbed methane recovery. Energy 2021, 237, 121450. [Google Scholar] [CrossRef]

| Decomposition Reaction | Frequency Factor (1/s) | Activation Energy (kJ/mol) | Enthalpy (J/mol) |

|---|---|---|---|

| Kerogen (oil shale) → 0.279 Heavy Oil + 0.143 Light Oil + 0.018 Gas + 0.005 Methane + 0.555 Coke1 | 3.0 × 1013 | 225.9 | −335,000 |

| Heavy Oil → 0.037 Light Oil + 0.156 Gas + 0.03 Methane + 0.441 Coke2 | 5.0 × 1011 | 225.9 | −46,500 |

| Light Oil → 0.595 Gas + 0.115 Methane + 0.29 Coke3 | 1.0 × 1013 | 213.4 | −46,500 |

| Coke1 → 0.031 Gas + 0.033 Methane + 0.936 Coke2 | 1.0 × 1013 | 225.9 | −46,500 |

| Coke2 → 0.003 Gas + 0.033 Methane + 0.964 Coke3 | 5.0 × 1011 | 225.9 | −46,500 |

| Parameter | Symbol | Value | Source |

|---|---|---|---|

| Initial temperature | T0 | 323.15 K | Given |

| Initial pressure | P0 | 8 MPa | Given |

| Well diameter | dwell | 0.1 m | Given |

| Microwave frequency | f | 2.45 GHz | Given |

| Microwave power | P | 400 W | Given |

| Kerogen concentration | cker | 400 mol/m3 | Ref. [26] |

| Gas diffusion coefficient | Dgas | 1 × 10−9 m2/s | Ref. [30] |

| Methane diffusion coefficient | Dch | 2 × 10−9 m2/s | Ref. [30] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Su, J.; Zhu, J.; Yang, Z.; Meng, X.; Li, X.; Zhou, J.; Yi, L. Numerical Simulation of Oil Shale Retorting Optimization under In Situ Microwave Heating Considering Electromagnetics, Heat Transfer, and Chemical Reactions Coupling. Energies 2022, 15, 5788. https://doi.org/10.3390/en15165788

Wang H, Su J, Zhu J, Yang Z, Meng X, Li X, Zhou J, Yi L. Numerical Simulation of Oil Shale Retorting Optimization under In Situ Microwave Heating Considering Electromagnetics, Heat Transfer, and Chemical Reactions Coupling. Energies. 2022; 15(16):5788. https://doi.org/10.3390/en15165788

Chicago/Turabian StyleWang, Hao, Jianzheng Su, Jingyi Zhu, Zhaozhong Yang, Xianglong Meng, Xiaogang Li, Jie Zhou, and Liangping Yi. 2022. "Numerical Simulation of Oil Shale Retorting Optimization under In Situ Microwave Heating Considering Electromagnetics, Heat Transfer, and Chemical Reactions Coupling" Energies 15, no. 16: 5788. https://doi.org/10.3390/en15165788

APA StyleWang, H., Su, J., Zhu, J., Yang, Z., Meng, X., Li, X., Zhou, J., & Yi, L. (2022). Numerical Simulation of Oil Shale Retorting Optimization under In Situ Microwave Heating Considering Electromagnetics, Heat Transfer, and Chemical Reactions Coupling. Energies, 15(16), 5788. https://doi.org/10.3390/en15165788