Co-Firing of Refuse-Derived Fuel with Ekibastuz Coal in a Bubbling Fluidized Bed Reactor: Analysis of Emissions and Ash Characteristics

Abstract

1. Introduction

2. Materials and Methods

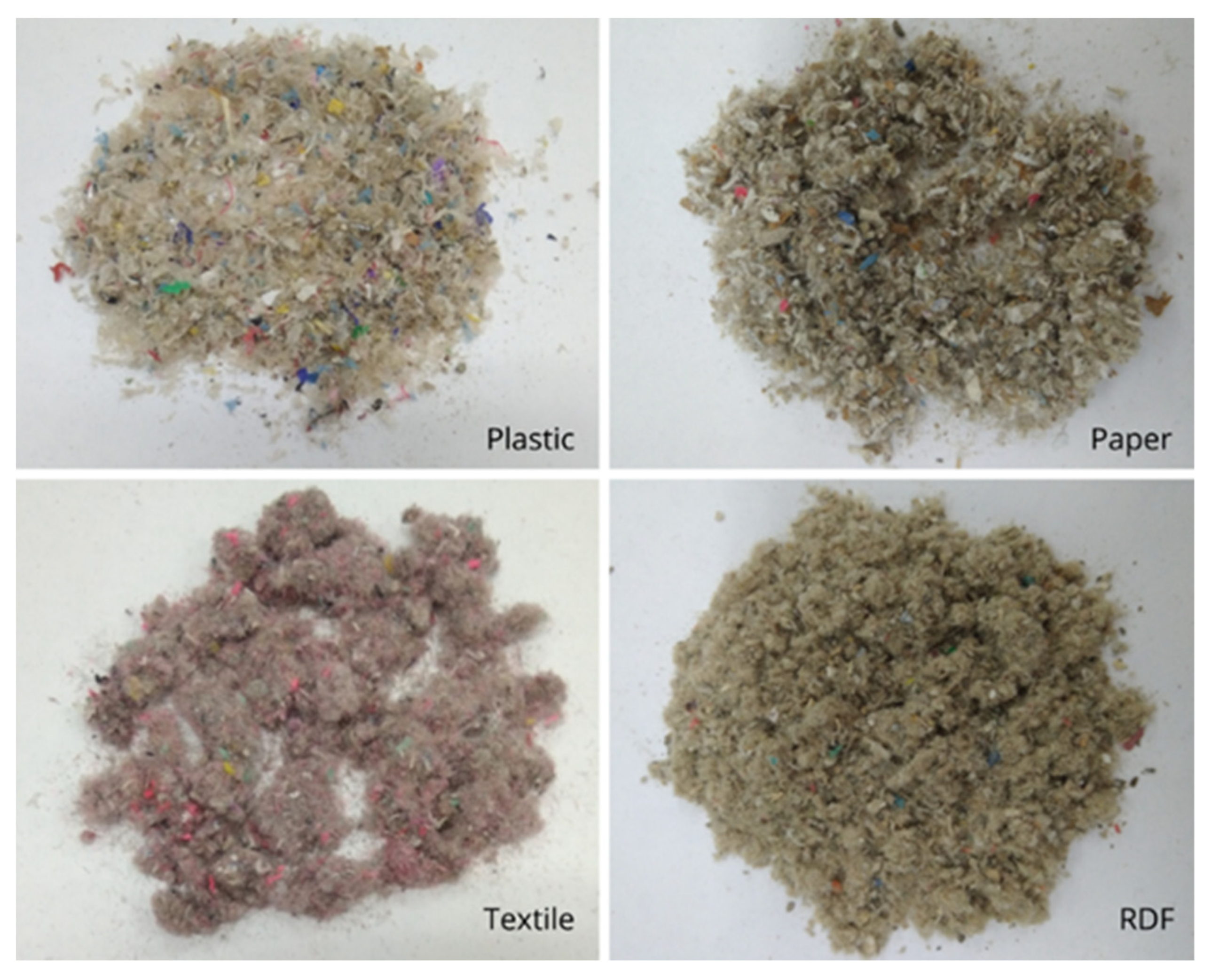

2.1. Fuels Samples and Bed Materials

2.2. Experimental Setup

2.3. Experimental Procedure

3. Results and Discussion

3.1. Exit Gas Measurements

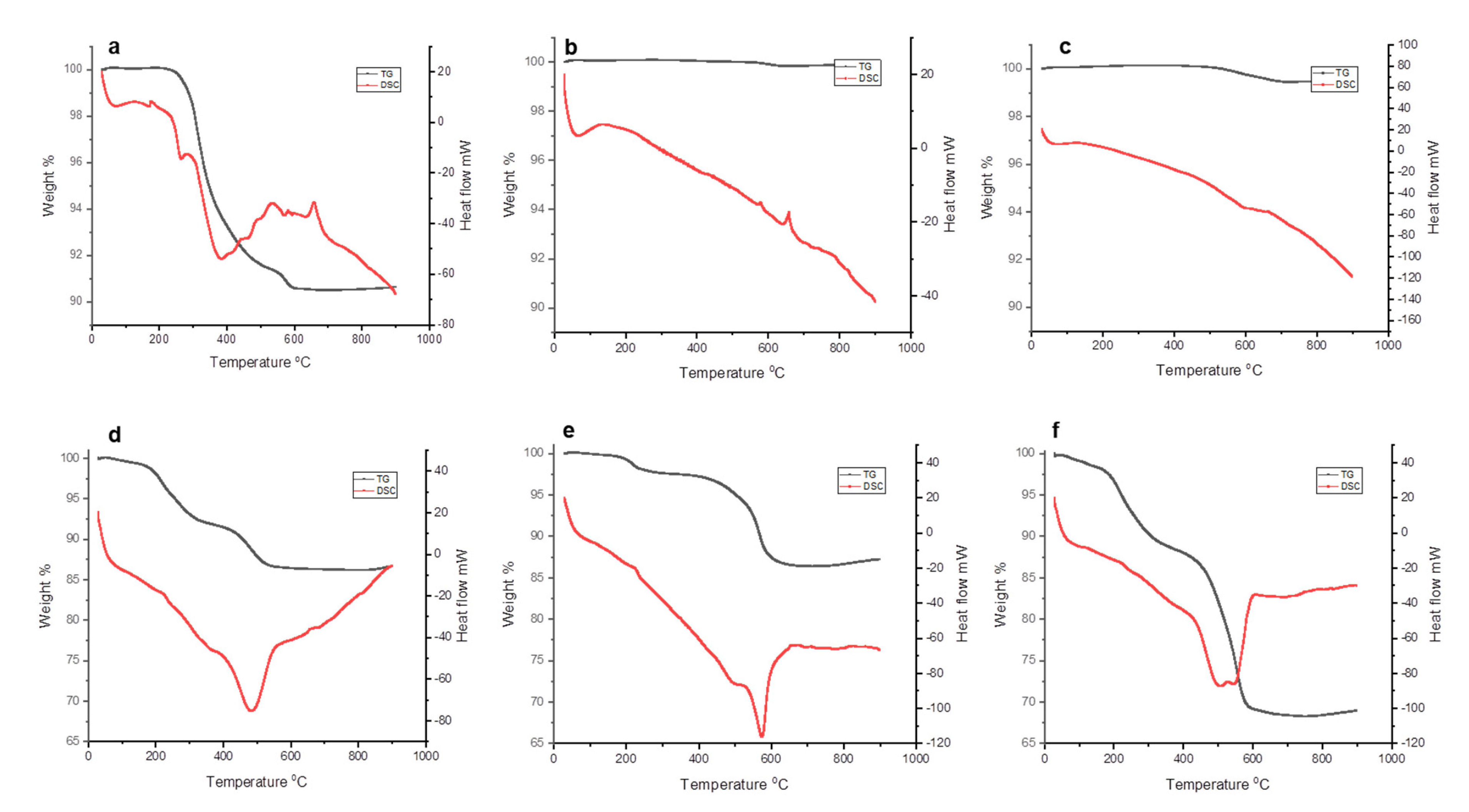

3.2. Ash Analysis with TGA

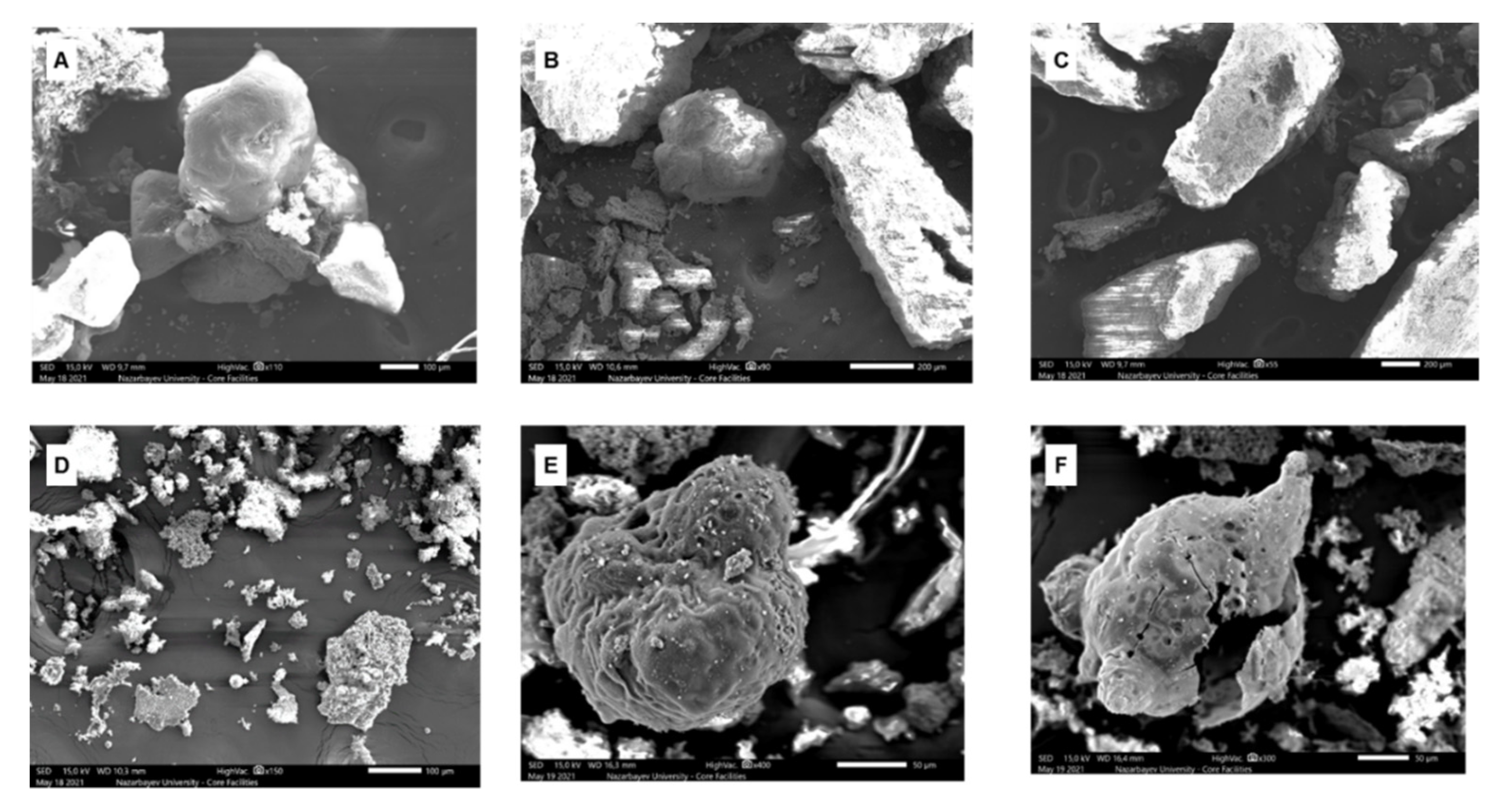

3.3. Characterization of Ashes

4. Conclusions

- (i)

- A higher RDF content decreased SO2 emissions, while it negatively affected NOx release, which could be due to the presence of excess air;

- (ii)

- The concentration of HCl remained constant in our experiments. However, the content of chlorides may vary according to RDF compositions;

- (iii)

- The produced fly ash characteristics have shown the category of class F based on ASTM C618-19 standard, which means that the generated ash products may have pozzolanic activities and can be used in construction industries;

- (iv)

- The chemical composition of ash residues showed the presence of CaO along with aluminosilicates.

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Tozlu, A.; Özahi, E. Waste to Energy Technologies for Municipal Solid Waste Management in Gaziantep. Renew. Sustain. Energy Rev. 2016, 54, 809–815. [Google Scholar] [CrossRef]

- Hossain, H.M.Z.; Hasna, Q.; Uddin, M.; Ahmed, T. Municipal Solid Waste (MSW) as a Source of Renewable Energy in Bangladesh: Revisited. Renew. Sustain. Energy Rev. 2014, 39, 35–41. [Google Scholar] [CrossRef]

- Zsigraiova, Z.; Tavares, G.; Semiao, V.; de Grac, M. Integrated Waste-to-Energy Conversion and Waste Transportation within Island Communities. Energy 2009, 34, 623–635. [Google Scholar] [CrossRef]

- Tsai, W.; Kuo, K. An Analysis of Power Generation from Municipal Solid Waste (MSW) Incineration Plants in Taiwan. Energy 2010, 35, 4824–4830. [Google Scholar] [CrossRef]

- Wang, L.; Hu, G.; Gong, X.; Bao, L. Emission Reductions Potential for Energy from Municipal Solid Waste Incineration in Chongqing. Renew. Energy 2009, 34, 2074–2079. [Google Scholar] [CrossRef]

- Shehata, N.; Obaideen, K.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; El-Salamony, A.L.H.R.; Mahmoud, H.M.; Olabi, A.G. Role of Refuse-Derived Fuel in Circular Economy and Sustainable Development Goals. Process. Saf. Environ. Prot. 2022, 163, 558–573. [Google Scholar] [CrossRef]

- Neuwahl, F.; Cusano, G.; Benavides, J.G.; Holbrook, S.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Incineration; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Oka, S. Fluidized Bed Combustion; Marcel Dekker, Inc.: New York, NY, USA, 2004. [Google Scholar]

- Robl, T.; Oberlink, A.; Jones, R. Coal Combustion Products (CCPs) 1st Edition Characteristics, Utilization and Beneficiation; Woodhead: Sawston, UK, 2017; ISBN 9780081009451. [Google Scholar]

- Sarbassov, Y.; Sagalova, T.; Tursunov, O.; Venetis, C. Survey on Household Solid Waste Sorting at Source in Developing Economies: A Case Study of Nur-Sultan City in Kazakhstan. Sustainability 2019, 11, 6496. [Google Scholar] [CrossRef]

- Strategy 2050 MSW Utilization: How Situation Has Been Improved over the Past Year. Available online: https://strategy2050.kz/ru/news/utilizatsiya-tbo-naskolko-uluchshilis-pokazateli-za-posledniy-god/ (accessed on 2 July 2022).

- Information on Reduction, Recycle and Utilization of Wastes. Available online: https://egov.kz/cms/ru/articles/ecology/waste_reduction_recycling_and_reuse (accessed on 2 July 2022).

- Abylkhani, B.; Guney, M.; Aiymbetov, B.; Yagofarova, A.; Sarbassov, Y.; Zorpas, A.A.; Venetis, C.; Inglezakis, V. Detailed Municipal Solid Waste Composition Analysis for Nur-Sultan City, Kazakhstan with Implications for Sustainable Waste Management in Central Asia. Environ. Sci. Pollut. Res. 2020, 28, 24406–24418. [Google Scholar] [CrossRef]

- Kuspangaliyeva, B.; Suleimenova, B.; Shah, D.; Sarbassov, Y. Thermogravimetric Study of Refuse Derived Fuel Produced from Municipal Solid Waste of Kazakhstan. Appl. Sci. 2021, 11, 1219. [Google Scholar] [CrossRef]

- Sarbassov, Y.; Venetis, C.; Aiymbetov, B.; Abylkhani, B.; Yagofarova, A.; Tokmurzin, D.; Anthony, E.J.; Inglezakis, V.J. Municipal Solid Waste Management and Greenhouse Gas Emissions at International Airports: A Case Study of Astana International Airport. J. Air Transp. Manag. 2020, 85, 101789. [Google Scholar] [CrossRef]

- Abylkhani, B.; Aiymbetov, B.; Yagofarova, A.; Tokmurzin, D.; Venetis, C.; Poulopoulos, S.; Sarbassov, Y.; Inglezakis, V.J. Seasonal Characterisation of Municipal Solid Waste from Astana City, Kazakhstan: Composition and Thermal Properties of Combustible Fraction. Waste Manag. Res. 2019, 37, 1271–1281. [Google Scholar] [CrossRef]

- Grammelis, P.; Basinas, P.; Malliopoulou, A.; Sakellaropoulos, G. Pyrolysis Kinetics and Combustion Characteristics of Waste Recovered Fuels. Fuel 2009, 88, 195–205. [Google Scholar] [CrossRef]

- Kara, M. Environmental and Economic Advantages Associated with the Use of RDF in Cement Kilns. Resour. Conserv. Recycl. 2012, 68, 21–28. [Google Scholar] [CrossRef]

- Reza, B.; Soltani, A.; Ruparathna, R.; Sadiq, R.; Hewage, K. Environmental and Economic Aspects of Production and Utilization of RDF as Alternative Fuel in Cement Plants: A Case Study of Metro Vancouver Waste Management. Resour. Conserv. Recycl. 2013, 81, 105–114. [Google Scholar] [CrossRef]

- Sorum, L.; Gronli, M.G.; Hustad, J.E. Pyrolysis Characteristics and Kinetics of Municipal Solid Wastes. Fuel 2001, 80, 1217–1227. [Google Scholar] [CrossRef]

- Wan, H.P.; Chang, Y.H.; Chien, W.C.; Lee, H.T.; Huang, C.C. Emissions during Co-Firing of RDF-5 with Bituminous Coal, Paper Sludge and Waste Tires in a Commercial Circulating Fluidized Bed Co-Generation Boiler. Fuel 2008, 87, 761–767. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Y.; Liu, D.; Sheng, H.; Tian, W.; Xiao, Y. Release of Sulfur and Chlorine during Cofiring RDF and Coal in an Internally Circulating Fluidized Bed. Energy Fuels 2009, 23, 1390–1397. [Google Scholar] [CrossRef][Green Version]

- Isaac, K.; Bada, S.O. The Co-Combustion Performance and Reaction Kinetics of Refuse Derived Fuels with South African High Ash Coal. Heliyon 2020, 6, e03309. [Google Scholar] [CrossRef]

- Zabetta, E.C.; Barisic, V.; Peltola, K.; Hotta, A. Foster Wheeler Experience with Biomass and Waste in CFBs. In Proceedings of the 33rd Clearwater Conference, Clearwater, FL, USA, 1–5 June 2008. [Google Scholar]

- Rigamonti, L.; Grosso, M.; Biganzoli, L. Environmental Assessment of Refuse-Derived Fuel Co-Combustion in a Coal-Fired Power Plant. J. Ind. Ecol. 2012, 16, 748–760. [Google Scholar] [CrossRef]

- Ghani, W.A.; Alias, A.B.; Cliffe, K.R. Co-Combustion of Refuse Derived Fuel with Coal in a Fluidised Bed Combustor. J. Eng. Sci. Technol. 2009, 4, 122–131. [Google Scholar]

- Ryabov, G.A.; Dolgushin, I.A. Use of Circulating Fluidized Bed Technology at Thermal Power Plants with Co-Firing of Biomass and Fossil Fuels. Power Technol. Eng. 2013, 46, 491–495. [Google Scholar] [CrossRef]

- Jiang, D.; Song, W.; Wang, X.; Zhu, Z. Physicochemical Properties of Bottom Ash Obtained from an Industrial CFB Gasifier. J. Energy Inst. 2021, 95, 1–7. [Google Scholar] [CrossRef]

- Wong, G.; Gan, M.; Fan, X.; Ji, Z.; Chen, X.; Wang, Z. Co-Disposal of Municipal Solid Waste Incineration Fly Ash and Bottom Slag: A Novel Method of Low Temperature Melting Treatment. J. Hazard. Mater. 2021, 408, 124438. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Mao, J.; Li, L.; Sun, L.; Xu, K.; Ma, X.; Hu, Y.; Zhao, Z.; Chen, S.; Xu, K. Characterization Comparison of Bottom Ash and Fly Ash during Gasification of Agricultural Residues at an Industrial-Scale Gasification Plant—Experiments and Analysis. Fuel 2021, 285, 119122. [Google Scholar] [CrossRef]

- Maj, I.; Kalisz, S.; Wejkowski, R.; Pronobis, M.; Gołombek, K. High-Temperature Corrosion in a Multifuel Circulating Fluidized Bed (CFB) Boiler Co-Firing Refuse Derived Fuel (RDF) and Hard Coal. Fuel 2022, 324, 124749. [Google Scholar] [CrossRef]

- Sciubidlo, A.; Majchrzak-Kuceba, I.; Niedzielska, M. Comparison of Fly Ash from Co-Combustion of Coal/Solid Recovered Fuel (SRF) and Coal/Refuse Derived Fuel (RDF). J. Phys. Conf. Ser. 2019, 1398, 012015. [Google Scholar] [CrossRef]

- Mlonka-Medrala, A.; Dziok, T.; Magdziarz, A.; Nowak, W. Composition and Properties of Fly Ash Collected from a Multifuel Fluidized Bed Boiler Co-Firing Refuse Derived Fuel (RDF) and Hard Coal. Energy 2021, 234, 121229. [Google Scholar] [CrossRef]

- Williams, A.; Pourkashanian, M.; Jones, J.M.; Skorupska, N. Combustion and Gasification of Coal; Taylor & Francis: New York, NY, USA, 2000. [Google Scholar]

- Sharonova, O.M. Composition and Morphology of Char Particles of Fly Ashes from Industrial Burning of High-Ash Coals with Different Reactivity. Fuel 2008, 87, 1989–1997. [Google Scholar] [CrossRef]

| Proximate (wt%, as Received) | RDF | Plastic | Paper | Textile | Coal |

|---|---|---|---|---|---|

| Moisture | 1.5 | 0.8 | 2.6 | 1.2 | 2.1 |

| Volatile matter | 86.7 | 87.3 | 85.7 | 86.7 | 19.9 |

| Ash | 8.2 | 8.7 | 8.5 | 4.0 | 38.5 |

| Fixed carbon | 3.6 | 3.2 | 3.2 | 8.1 | 39.3 |

| Ultimate (wt%, and dry ash-free) | |||||

| Carbon | 66.5 | 83.5 | 46.8 | 47.8 | 61.2 |

| Hydrogen | 9.9 | 13.0 | 6.4 | 6.1 | 3.5 |

| Nitrogen | 0.6 | 0.5 | 0.6 | 1.3 | 2.1 |

| Sulfur | 0.2 | 0.3 | 0.1 | 0.2 | 0.7 |

| Oxygen * | 22.8 | 2.7 | 46.1 | 44.6 | 32.4 |

| Gross Calorific value (MJ/kg) ** | 23.4 | 32.6 | 16.4 | 20.1 | 19.37 |

| Parameters | RDF | RDF/Coal Blend I | RDF/Coal Blend II | Coal |

|---|---|---|---|---|

| Particle size (mm) | 1–2.5 | 1–2.5/0.4–0.8 | 1–2.5/0.4–0.8 | 0.4–0.8 |

| Temperature fluctuation during feeding (°C) | 7–12 | 6–10 | 6–10 | 3–5 |

| Pressure drop (kPa) | 1.5 | 1.2 | 1.2 | 1.0 |

| RDF/coal blend ratio | - | 1:1 (50%) | 1:9 (10%) | - |

| Weight of sample (g) | 1–1.5 | |||

| Furnace temperature (°C) | 850 | |||

| Minimum fluidizing velocity (m/s) | 0.0645 | |||

| Primary air flow rate (L/min) | 3.5 | |||

| Secondary air flow rate (L/min) | 3.0 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suleimenova, B.; Aimbetov, B.; Zhakupov, D.; Shah, D.; Sarbassov, Y. Co-Firing of Refuse-Derived Fuel with Ekibastuz Coal in a Bubbling Fluidized Bed Reactor: Analysis of Emissions and Ash Characteristics. Energies 2022, 15, 5785. https://doi.org/10.3390/en15165785

Suleimenova B, Aimbetov B, Zhakupov D, Shah D, Sarbassov Y. Co-Firing of Refuse-Derived Fuel with Ekibastuz Coal in a Bubbling Fluidized Bed Reactor: Analysis of Emissions and Ash Characteristics. Energies. 2022; 15(16):5785. https://doi.org/10.3390/en15165785

Chicago/Turabian StyleSuleimenova, Botakoz, Berik Aimbetov, Daulet Zhakupov, Dhawal Shah, and Yerbol Sarbassov. 2022. "Co-Firing of Refuse-Derived Fuel with Ekibastuz Coal in a Bubbling Fluidized Bed Reactor: Analysis of Emissions and Ash Characteristics" Energies 15, no. 16: 5785. https://doi.org/10.3390/en15165785

APA StyleSuleimenova, B., Aimbetov, B., Zhakupov, D., Shah, D., & Sarbassov, Y. (2022). Co-Firing of Refuse-Derived Fuel with Ekibastuz Coal in a Bubbling Fluidized Bed Reactor: Analysis of Emissions and Ash Characteristics. Energies, 15(16), 5785. https://doi.org/10.3390/en15165785