Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger

Abstract

:1. Introduction

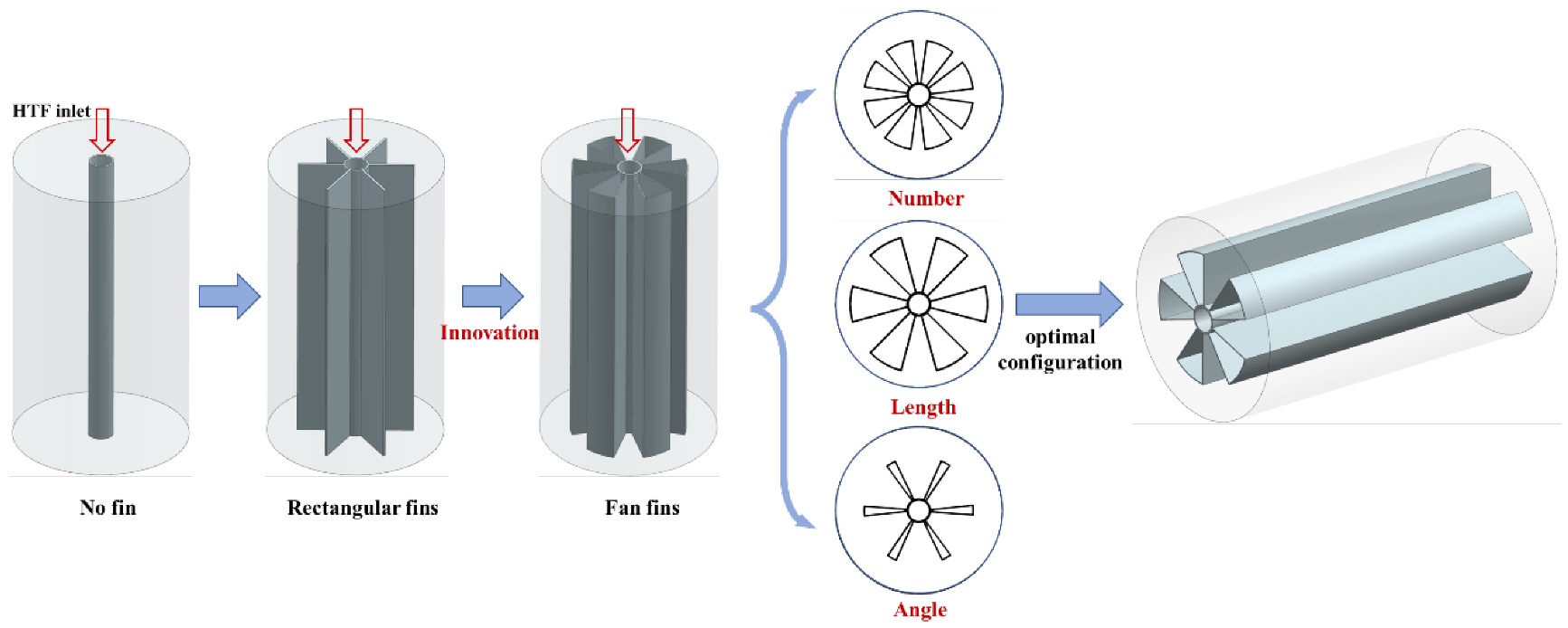

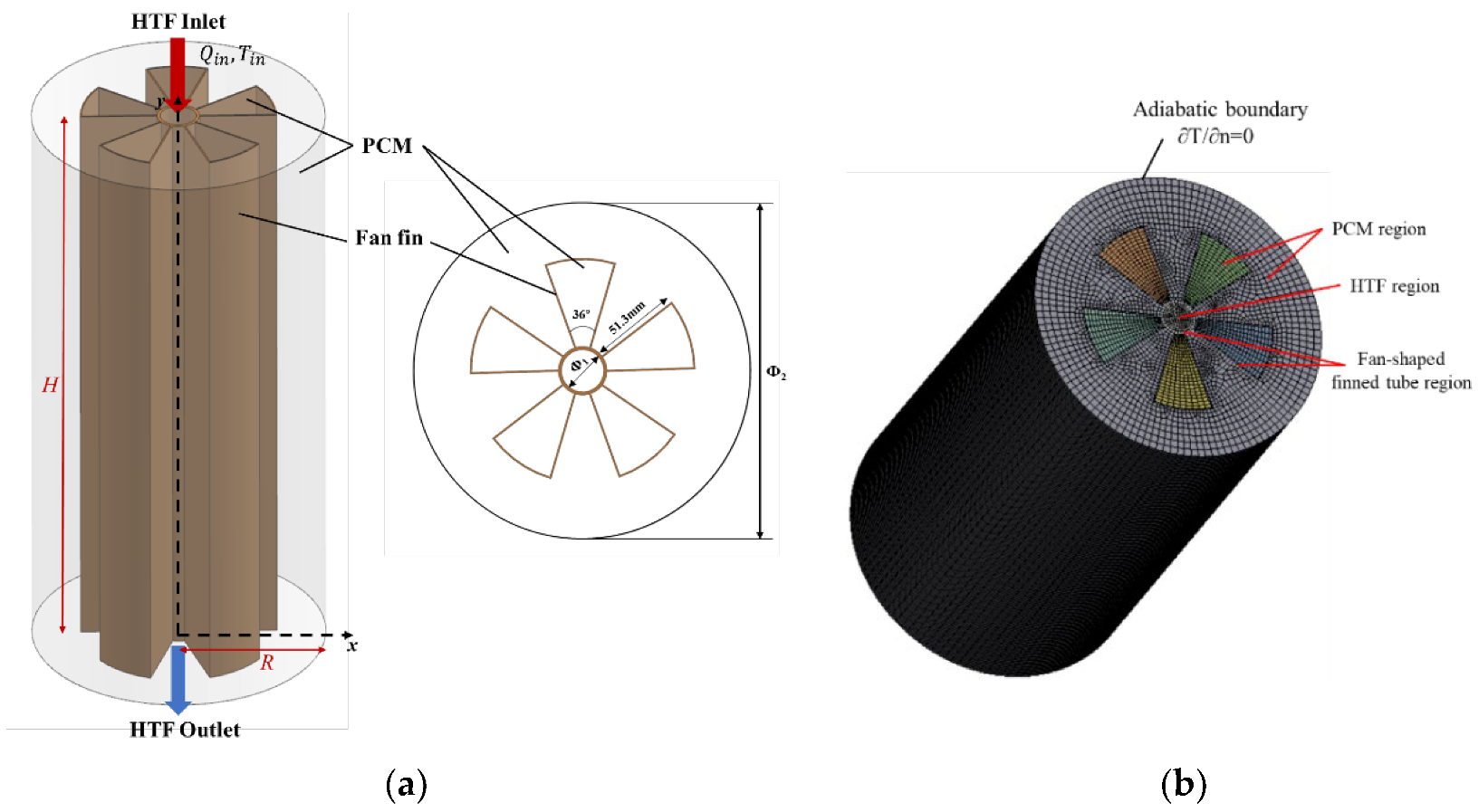

2. Physical Models and Numerical Simulations

2.1. Physical Models and Computational Domains

2.2. Mathematical Model and Governing Equations

- (1)

- The flow of PCMs is considered to be laminar, three-dimensional, and incompressible.

- (2)

- The viscous dissipation and volume change during phase transition are ignored.

- (3)

- The Boussinesq approximation is used to only consider the PCM density change caused by the temperature change.

- (4)

- The thermophysical properties of the PCM are constant and satisfy the isotropy.

- (5)

- The axial and radial temperature changes of the heat exchange tubes are ignored.

2.3. Initial and Boundary Conditions

2.4. Characteristic Parameters and Evaluation Indicators

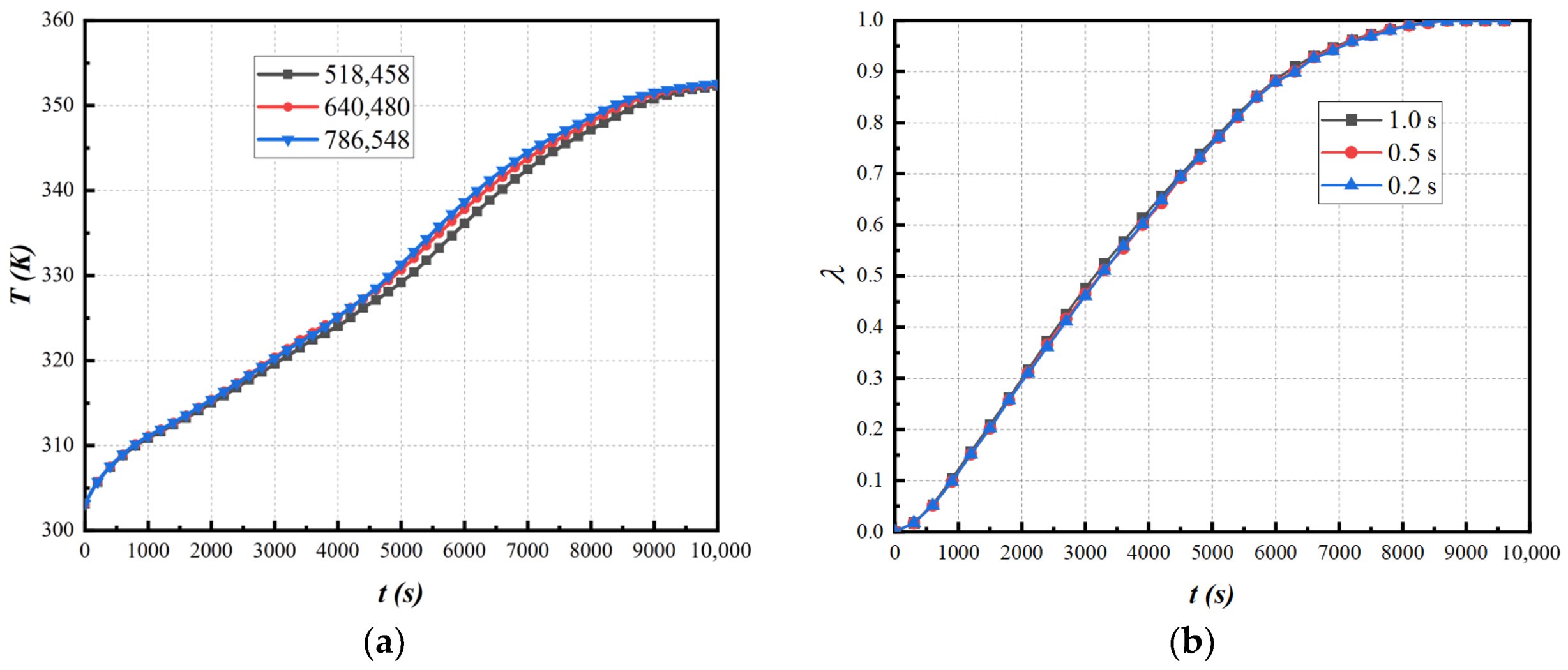

2.5. Numerical Steps

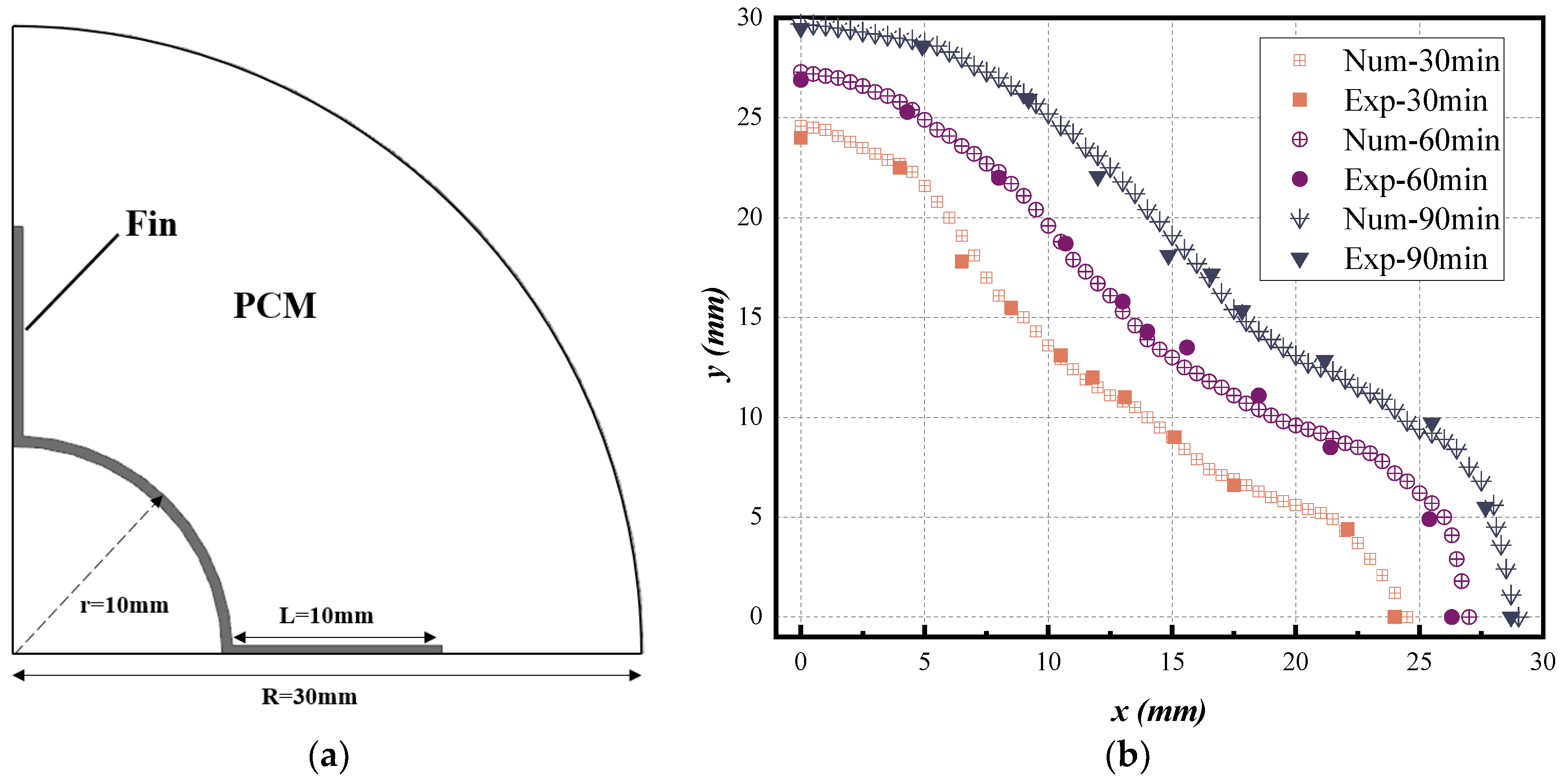

2.6. Model Validation

3. Results and Discussion

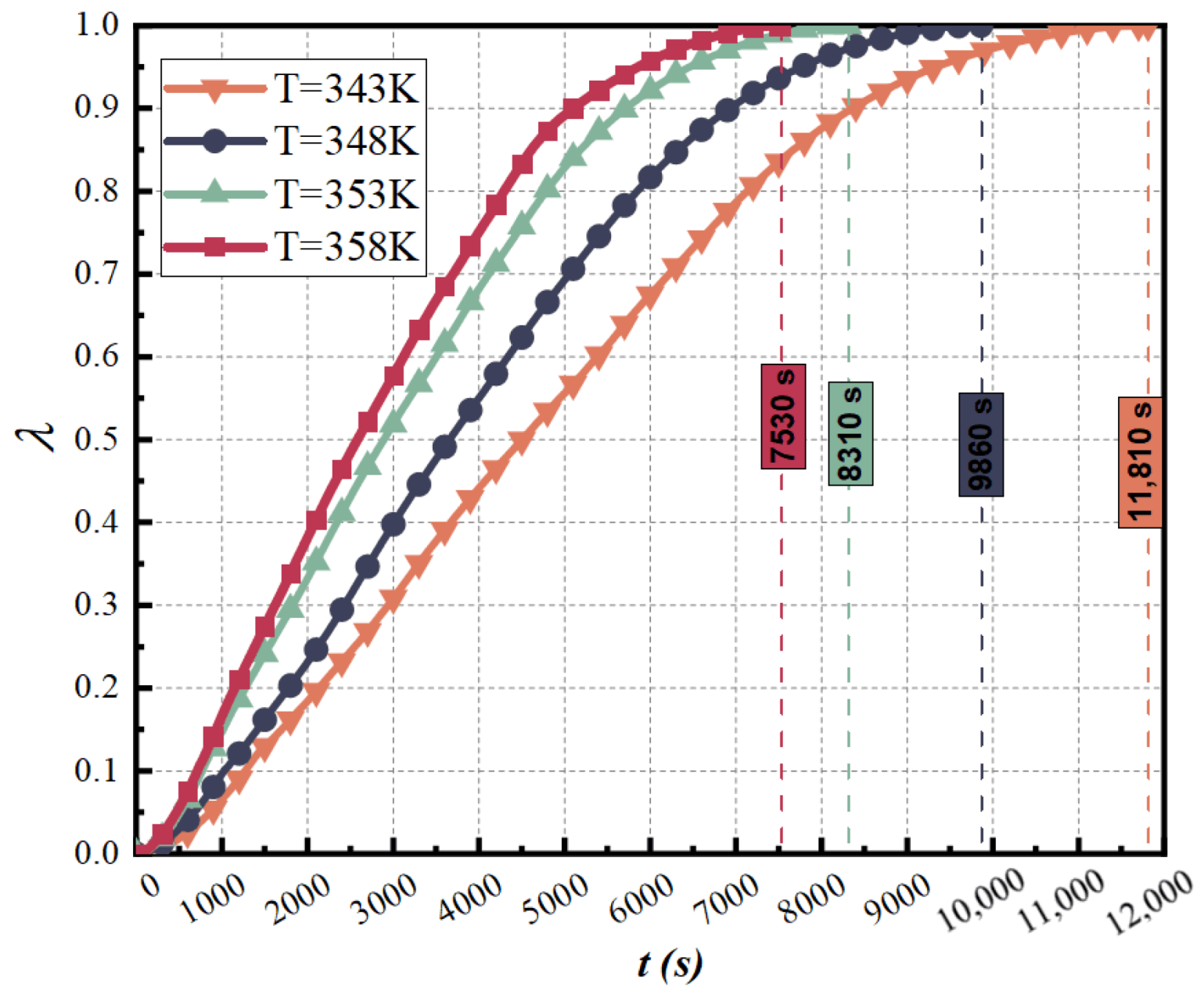

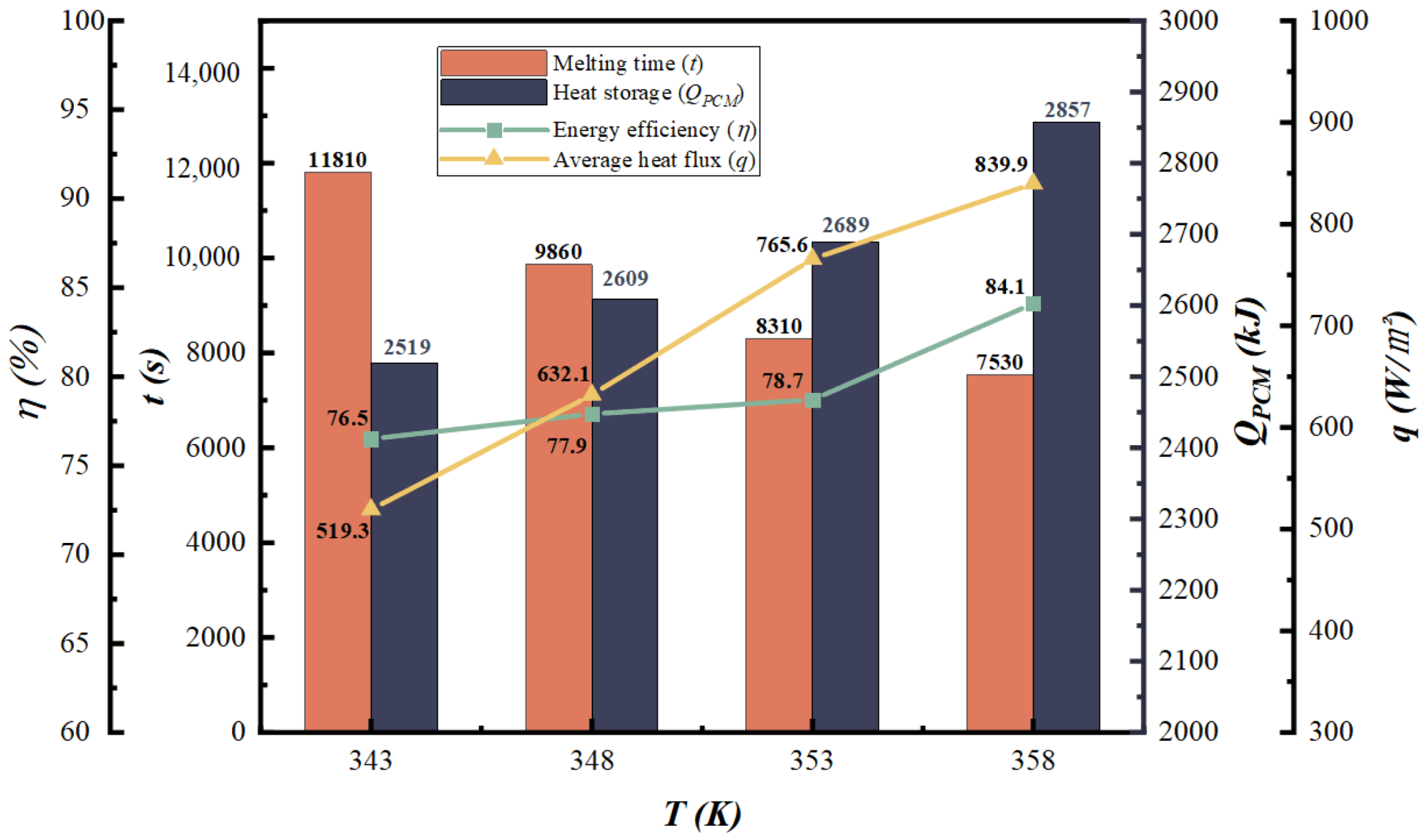

3.1. Influence of Inlet Temperature

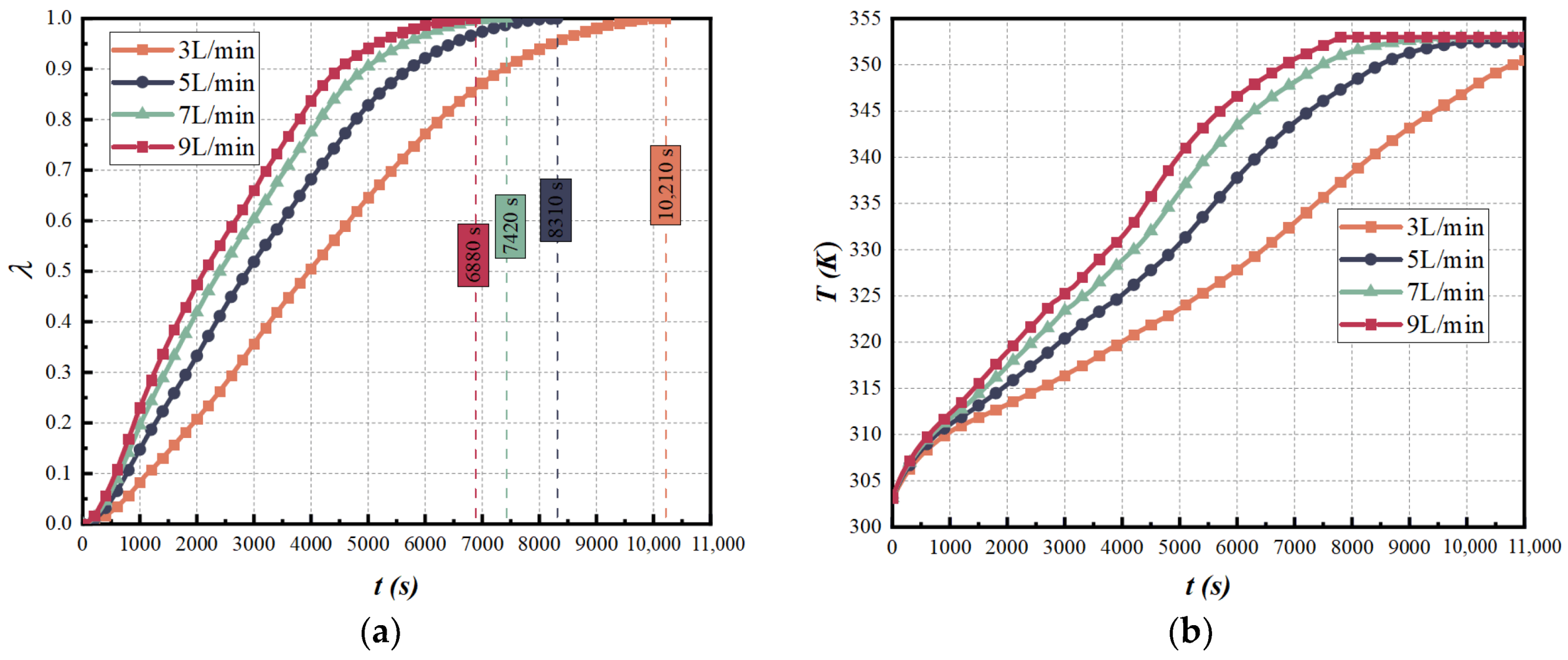

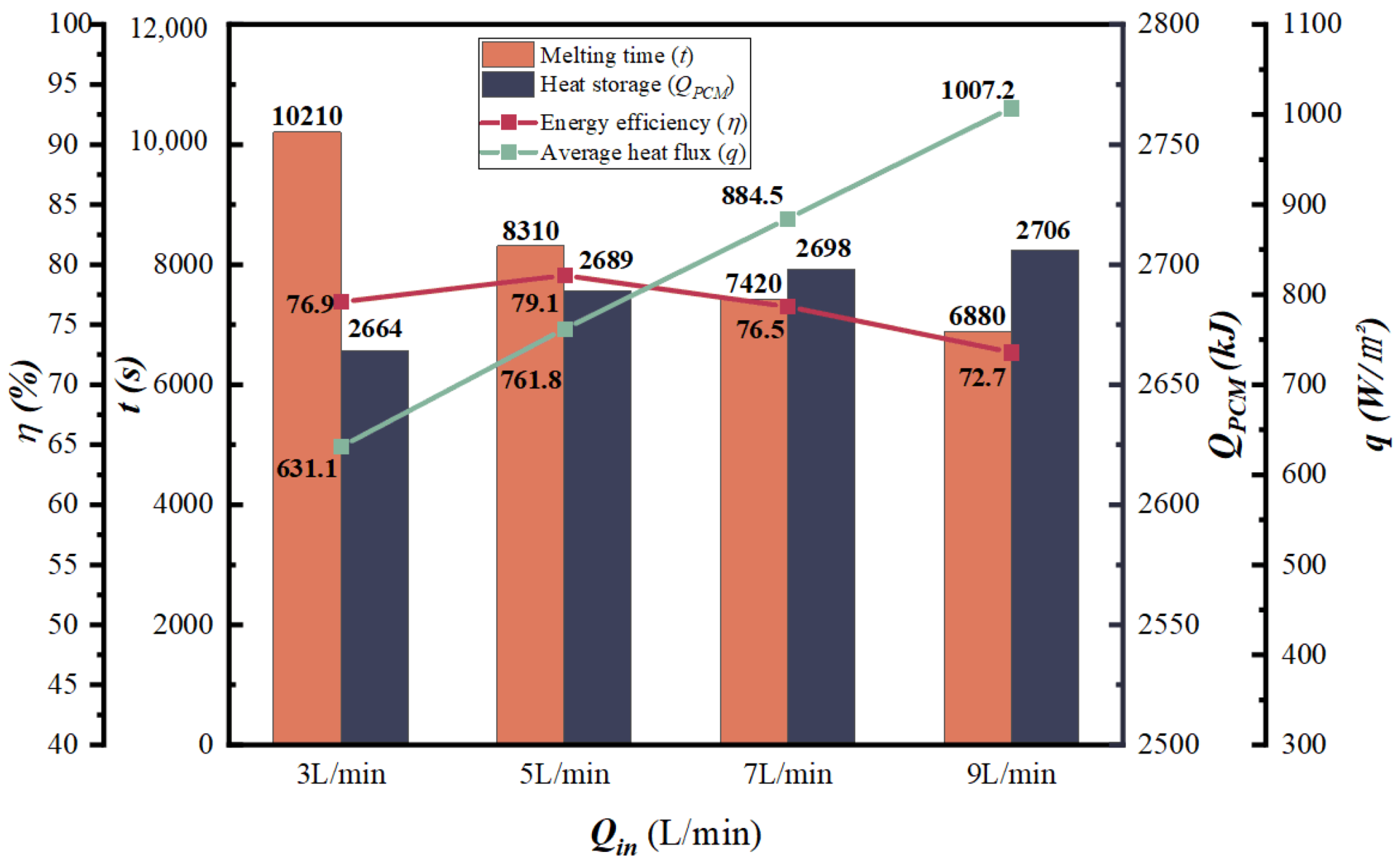

3.2. Influence of Inlet Flow Rate

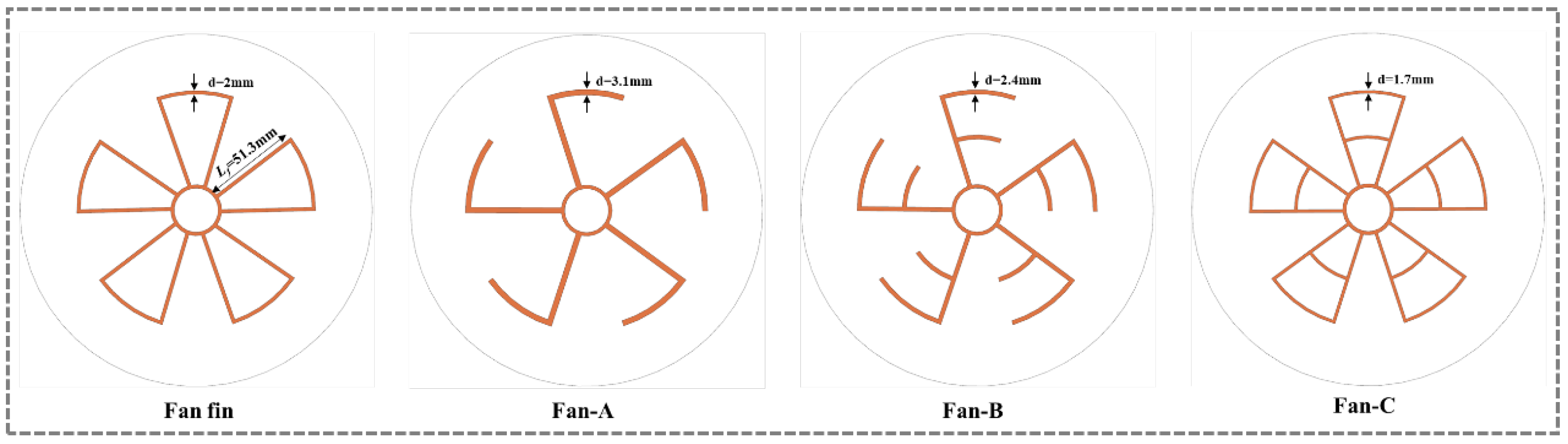

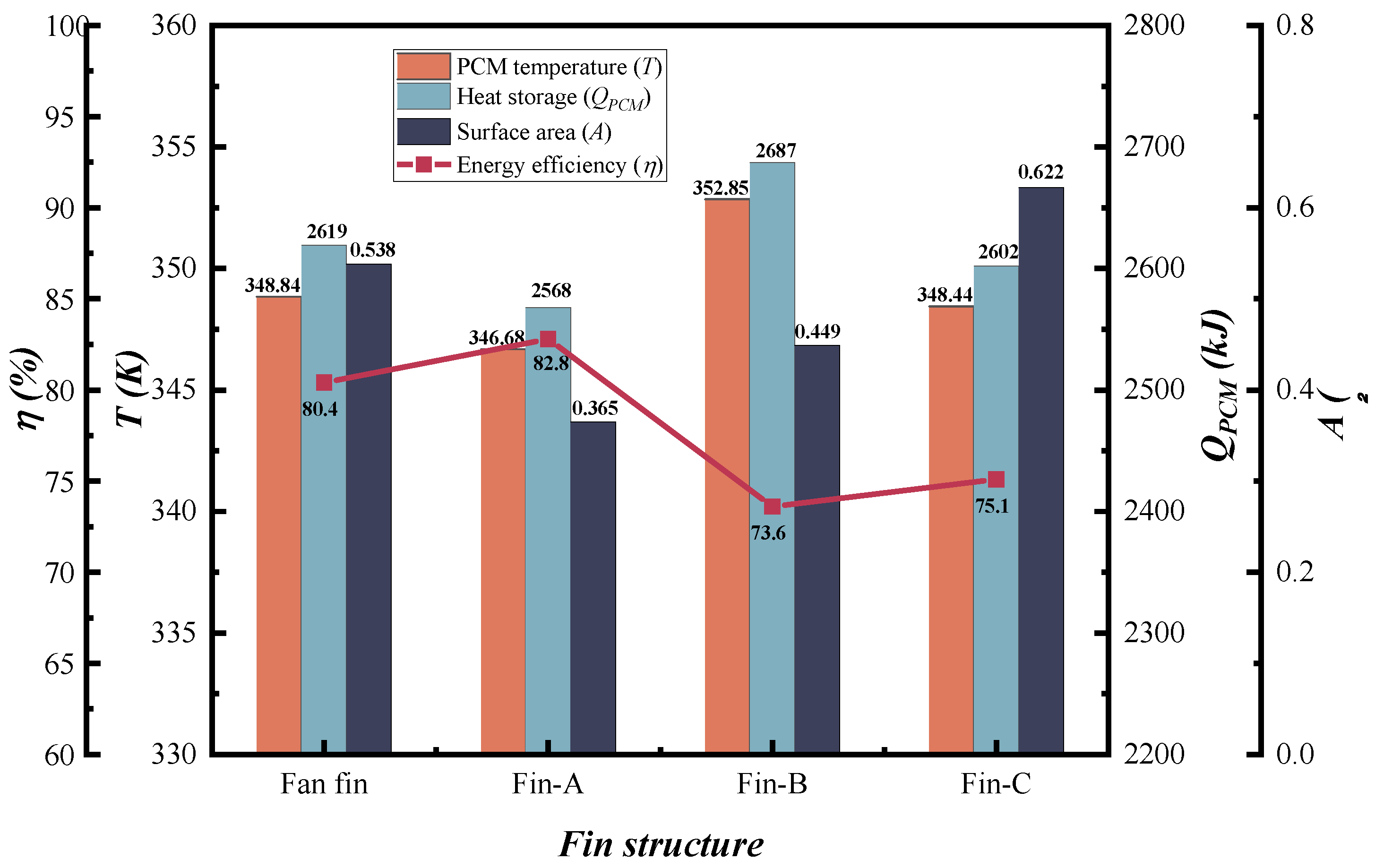

3.3. Optimization of Fin Structure

4. Conclusions

- (1)

- When the inlet temperature increases from 343 K to 348 K, 353 K and 358 K, the heat storage capacity of PCM is increased by 3.5%, 6.7%, and 13.4%, respectively. The melting time of PCM is reduced by 16.5%, 29.6%, and 36.2%, respectively. When the inlet temperature increases from 353 K to 358 K, although the melting time is shortened slightly, the energy efficiency and heat storage show a large increase. This shows that increasing the temperature has a critical value for the optimization of shortening the melting time, but it can still improve the heat storage efficiency of the LHS system.

- (2)

- When the inlet flow rate increases from 3 L/min to 9 L/min, the melting time of PCM is shortened by 18.6%, 27.3%, and 33.4%, the energy efficiency first increases and then decreases. The energy efficiency reaches the maximum at 5 L/min value. The larger the HTF flow, the larger the Nusselt number in the convective stage, indicating that the convective process is more intense.

- (3)

- The complete melting time of PCM in Fin-A tube is shortened by 5.3%, 14.6%, and 11.6% compared with Fan fin, Fin-B, and Fin-C, respectively. On the whole, under the same fin volume, Fin-A has the highest melting degree. Although the heat storage is slightly decreased, the energy efficiency is 2.98% higher than that of the Fan fin.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | |

| TES | Thermal Energy Storage |

| LHS | Latent Heat Storage |

| PCM | Phase Change Material |

| HTF | Heat Transfer Fluid |

| Symbols | |

| Heat storage unit height (mm) | |

| Shell radius (mm) | |

| Melting temperature (K) | |

| Melting time (s) | |

| Velocity vector (m/s) | |

| Gravity (m/s2) | |

| Specific heat capacity (J/kg·K) | |

| Solid specific heat of paraffin (J/kg·K) | |

| Liquid specific heat of paraffin (J/kg·K) | |

| Specific heat of HTF (J/kg·K) | |

| Pressure (Pa) | |

| Coefficient of thermal conductivity (W/m·K) | |

| Latent heat of PCM (J/kg) | |

| Heat exchange area (m2) | |

| Heat storage capacity (kJ) | |

| Average heat flux (W/m2) | |

| Characteristic length | |

| Greek symbols | |

| Copper tube inner diameter (mm) | |

| shell outer diameter (mm) | |

| Melting fraction | |

| Density (kg/m3) | |

| Dynamic viscosity (kg/m·s) | |

| Coefficient of thermal expansion (1/K) | |

| Energy efficiency (%) | |

| Outer surface of the device housing | |

| Subscript | |

| Initial | |

| Melting | |

| Inlet | |

| Outlet | |

| Liquidus | |

| Solidus | |

| Fluid | |

| Wall | |

| Initial |

References

- He, W.; Tao, L.; Han, L.; Sun, Y.; Campana, P.E.; Yan, J. Optimal analysis of a hybrid renewable power system for a remote island. Renew. Energy 2021, 179, 96–104. [Google Scholar] [CrossRef]

- Mao, Q. Recent developments in geometrical configurations of thermal energy storage for concentrating solar power plant. Renew. Sustain. Energy Rev. 2016, 59, 320–327. [Google Scholar] [CrossRef]

- Mao, Q.; Zhang, Y. Thermal energy storage performance of a three-PCM cascade tank in a high-temperature packed bed system. Renew. Energy 2020, 152, 110–119. [Google Scholar] [CrossRef]

- Wang, L.; Guo, L.; Ren, J.; Kong, X. Using of heat thermal storage of PCM and solar energy for distributed clean building heating: A multi-level scale-up research. Appl. Energy 2022, 321, 119345. [Google Scholar] [CrossRef]

- Kim, S.H.; Heu, C.S.; Mok, J.Y.; Kang, S.-W.; Kim, D.R. Enhanced thermal performance of phase change material-integrated fin-type heat sinks for high power electronics cooling. Int. J. Heat Mass Transf. 2022, 184, 122257. [Google Scholar] [CrossRef]

- Wen, X.; Ji, J.; Li, Z.; Song, Z. Performance analysis of a concentrated system with series photovoltaic/thermal module and solar thermal collector integrated with PCM and TEG. Energy 2022, 249, 123777. [Google Scholar] [CrossRef]

- De Falco, M.; Capocelli, M.; Giannattasio, A. Performance analysis of an innovative PCM-based device for cold storage in the civil air conditioning. Energy Build. 2016, 122, 1–10. [Google Scholar] [CrossRef]

- Malik, F.K.; Khan, M.M.; Ahmed, H.F.; Irfan, M.; Ahad, I.U. Performance characteristics of PCM based thermal energy storage system for fluctuating waste heat sources. Case Stud. Therm. Eng. 2022, 34, 102012. [Google Scholar] [CrossRef]

- Wan, X.; Wang, F. Udayraj Numerical analysis of cooling effect of hybrid cooling clothing incorporated with phase change material (PCM) packs and air ventilation fans. Int. J. Heat Mass Transf. 2018, 126, 636–648. [Google Scholar] [CrossRef]

- Parsazadeh, M.; Duan, X. Numerical Study of a Hybrid Thermal Insulation with Phase Change Material for Subsea Pipelines. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar] [CrossRef]

- Yang, X.; Lu, T.; Kim, T. Temperature effects on the effective thermal conductivity of phase change materials with two distinctive phases. Int. Commun. Heat Mass Transf. 2011, 38, 1344–1348. [Google Scholar] [CrossRef]

- Sun, B.; Liu, Z.; Ji, X.; Gao, L.; Che, D. Thermal energy storage characteristics of packed bed encapsulating spherical capsules with composite phase change materials. Appl. Therm. Eng. 2022, 201, 117659. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A.; Biwole, P.H. Heat transfer study of phase change materials with graphene nanoparticle for thermal energy storage. Sol. Energy 2017, 146, 453–463. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, C.Y.; Xu, Z.G.; Xu, H.J. Modeling metal foam enhanced phase change heat transfer in thermal energy storage by using phase field method. Int. J. Heat Mass Transf. 2016, 99, 170–181. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, S.; Wang, C.; Zhu, Q. Effect of EG particle size on the thermal properties of NaNO3–NaCl/EG shaped composite phase change materials. Energy 2022, 239, 122062. [Google Scholar] [CrossRef]

- Mao, Q.; Li, Y.; Li, G.; Badiei, A. Study on the influence of tank structure and fin configuration on heat transfer performance of phase change thermal storage system. Energy 2021, 235, 121382. [Google Scholar] [CrossRef]

- Kirincic, M.; Trp, A.; Lenic, K. Influence of natural convection during melting and solidification of paraffin in a longitudinally finned shell-and-tube latent thermal energy storage on the applicability of developed numerical models. Renew. Energy 2021, 179, 1329–1344. [Google Scholar] [CrossRef]

- Pássaro, J.; Rebola, A.; Coelho, L.; Conde, J.; Evangelakis, G.; Prouskas, C.; Papageorgiou, D.; Zisopoulou, A.; Lagaris, I. Effect of fins and nanoparticles in the discharge performance of PCM thermal storage system with a multi pass finned tube heat exchange. Appl. Therm. Eng. 2022, 212, 118569. [Google Scholar] [CrossRef]

- Alizadeh, M.; Shahavi, M.H.; Ganji, D.D. Performance enhancement of nano PCM solidification in a hexagonal storage unit with innovative fin shapes dealing with time-dependent boundary conditions. Energy Rep. 2022, 8, 8200–8214. [Google Scholar] [CrossRef]

- Kirincic, M.; Trp, A.; Lenic, K. Numerical evaluation of the latent heat thermal energy storage performance enhancement by installing longitudinal fins. J. Energy Storage 2021, 42, 103085. [Google Scholar] [CrossRef]

- Medrano, M.; Yilmaz, M.O.; Nogués, M.; Martorell, I.; Roca, J.; Cabeza, L.F. Experimental evaluation of commercial heat exchangers for use as PCM thermal storage systems. Appl. Energy 2009, 86, 2047–2055. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, R.; Zheng, N. Thermal management of a simulated battery with the compound use of phase change material and fins: Experimental and numerical investigations. Int. J. Therm. Sci. 2021, 165, 106945. [Google Scholar] [CrossRef]

- Mekrisuh, K.U.; Giri, S.; Udayraj; Singh, D.; Rakshit, D. Optimal design of the phase change material based thermal energy storage systems: Efficacy of fins and/or nanoparticles for performance enhancement. J. Energy Storage 2021, 33, 102126. [Google Scholar] [CrossRef]

- Tay, N.H.S.; Bruno, F.; Belusko, M. Comparison of pinned and finned tubes in a phase change thermal energy storage system using CFD. Appl. Energy 2013, 104, 79–86. [Google Scholar] [CrossRef]

- Yang, X.; Lu, Z.; Bai, Q.; Zhang, Q.; Jin, L.; Yan, J. Thermal performance of a shell-and-tube latent heat thermal energy storage unit: Role of annular fins. Appl. Energy 2017, 202, 558–570. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Z.; Yang, B.; Yang, X.; Yan, J. Melting assessment on the angled fin design for a novel latent heat thermal energy storage tube. Renew. Energy 2022, 183, 406–422. [Google Scholar] [CrossRef]

- Darzi, A.A.R.; Jourabian, M.; Farhadi, M. Melting and solidification of PCM enhanced by radial conductive fins and nanoparticles in cylindrical annulus. Energy Convers. Manag. 2016, 118, 253–263. [Google Scholar] [CrossRef]

- Modi, N.; Wang, X.; Negnevitsky, M.; Cao, F. Melting characteristics of a longitudinally finned-tube horizontal latent heat thermal energy storage system. Sol. Energy 2021, 230, 333–344. [Google Scholar] [CrossRef]

- Qin, Z.; Low, Z.H.; Ji, C.; Duan, F. Efficacy of angled metallic fins for enhancing phase change material melting. Int. Commun. Heat Mass Transf. 2022, 132, 105921. [Google Scholar] [CrossRef]

- Ranjbar, A.M.; Pouransari, Z.; Siavashi, M. Improved design of heat sink including porous pin fins with different arrangements: A numerical turbulent flow and heat transfer study. Appl. Therm. Eng. 2021, 198, 117519. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Lohrasbi, S.; Nsofor, E.C. Hybrid heat transfer enhancement for latent-heat thermal energy storage systems: A review. Int. J. Heat Mass Transf. 2019, 137, 630–649. [Google Scholar] [CrossRef]

- Akhilesh, R.; Narasimhan, A.; Balaji, C. Method to improve geometry for heat transfer enhancement in PCM composite heat sinks. Int. J. Heat Mass Transf. 2005, 48, 2759–2770. [Google Scholar] [CrossRef]

- Wang, P.; Yao, H.; Lan, Z.; Peng, Z.; Huang, Y.; Ding, Y. Numerical investigation of PCM melting process in sleeve tube with internal fins. Energy Convers. Manag. 2016, 110, 428–435. [Google Scholar] [CrossRef]

- Shahsavar, A.; Goodarzi, A.; Mohammed, H.I.; Shirneshan, A.; Talebizadehsardari, P. Thermal performance evaluation of non-uniform fin array in a finned double-pipe latent heat storage system. Energy 2020, 193, 116800. [Google Scholar] [CrossRef]

- Yagci, O.K.; Avci, M.; Aydin, O. Melting and solidification of PCM in a tube-in-shell unit: Effect of fin edge lengths’ ratio. J. Energy Storage 2019, 24, 100802. [Google Scholar] [CrossRef]

- Abdulateef, A.M.; Mat, S.; Sopian, K.; Abdulateef, J.; Gitan, A.A. Experimental and computational study of melting phase-change material in a triplex tube heat exchanger with longitudinal/triangular fins. Sol. Energy 2017, 155, 142–153. [Google Scholar] [CrossRef]

- Calamas, D.; Baker, J. Tree-like branching fins: Performance and natural convective heat transfer behavior. Int. J. Heat Mass Transf. 2013, 62, 350–361. [Google Scholar] [CrossRef]

- Konan, H.; Cetkin, E. Snowflake shaped high-conductivity inserts for heat transfer enhancement. Int. J. Heat Mass Transf. 2018, 127, 473–482. [Google Scholar] [CrossRef]

- Alizadeh, M.; Hosseinzadeh, K.; Shahavi, M.; Ganji, D. Solidification acceleration in a triplex-tube latent heat thermal energy storage system using V-shaped fin and nano-enhanced phase change material. Appl. Therm. Eng. 2019, 163, 114436. [Google Scholar] [CrossRef]

- Pizzolato, A.; Sharma, A.; Maute, K.; Sciacovelli, A.; Verda, V. Design of effective fins for fast PCM melting and solidification in shell-and-tube latent heat thermal energy storage through topology optimization. Appl. Energy 2017, 208, 210–227. [Google Scholar] [CrossRef]

- Al-Mudhafar, A.H.; Nowakowski, A.F.; Nicolleau, F.C. Enhancing the thermal performance of PCM in a shell and tube latent heat energy storage system by utilizing innovative fins. Energy Rep. 2021, 7, 120–126. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Guo, J.; Wang, F.; Yang, X.; Yan, J. Innovative ladder-shaped fin design on a latent heat storage device for waste heat recovery. Appl. Energy 2022, 321, 119300. [Google Scholar] [CrossRef]

- Ma, J.; Xu, H.; Liu, S.; Peng, H.; Ling, X. Numerical study on solidification behavior and exergy analysis of a latent heat storage unit with innovative circular superimposed longitudinal fins. Int. J. Heat Mass Transf. 2021, 169, 120949. [Google Scholar] [CrossRef]

- Mao, Q.; Hu, X.; Li, T. Study on heat storage performance of a novel vertical shell and multi-finned tube tank. Renew. Energy 2022, 193, 76–88. [Google Scholar] [CrossRef]

- Huang, Y.; Cao, D.; Sun, D.; Liu, X. Experimental and numerical studies on the heat transfer improvement of a latent heat storage unit using gradient tree-shaped fins. Int. J. Heat Mass Transf. 2022, 182, 121920. [Google Scholar] [CrossRef]

- Younsi, Z.; Naji, H. A numerical investigation of melting phase change process via the enthalpy-porosity approach: Application to hydrated salts. Int. Commun. Heat Mass Transf. 2017, 86, 12–24. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Alves, C.L.F.; Modesto, M.S. Numerical and experimental study on the solidification of PCM around a vertical axially finned isothermal cylinder. Appl. Therm. Eng. 2001, 21, 53–77. [Google Scholar] [CrossRef]

- Safari, V.; Abolghasemi, H.; Kamkari, B. Experimental and numerical investigations of thermal performance enhancement in a latent heat storage heat exchanger using bifurcated and straight fins. Renew. Energy 2021, 174, 102–121. [Google Scholar] [CrossRef]

| Materials | PCM (Paraffin) | Fin (Cooper) |

|---|---|---|

| Density (kg/m3) | 885 | 8978 |

| Thermal conductivity (W/m·K) | 0.279 | 387.6 |

| Specific heat capacity (J/kg·K) | 3085 (s) 2106 (L) | 381 |

| Latent heat (J/kg) | 172,620 | - |

| Melting range (K) | 321–323 | - |

| Viscosity (kg/m·s) | 1.72 × 10−5 | - |

| Thermal expansion coefficient (1/K) | 0.0006 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Q.; Hu, X.; Zhu, Y. Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger. Energies 2022, 15, 5682. https://doi.org/10.3390/en15155682

Mao Q, Hu X, Zhu Y. Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger. Energies. 2022; 15(15):5682. https://doi.org/10.3390/en15155682

Chicago/Turabian StyleMao, Qianjun, Xinlei Hu, and Yuanyuan Zhu. 2022. "Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger" Energies 15, no. 15: 5682. https://doi.org/10.3390/en15155682

APA StyleMao, Q., Hu, X., & Zhu, Y. (2022). Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger. Energies, 15(15), 5682. https://doi.org/10.3390/en15155682