Organic Waste Substrates for Bioenergy Production via Microbial Fuel Cells: A Key Point Review

Abstract

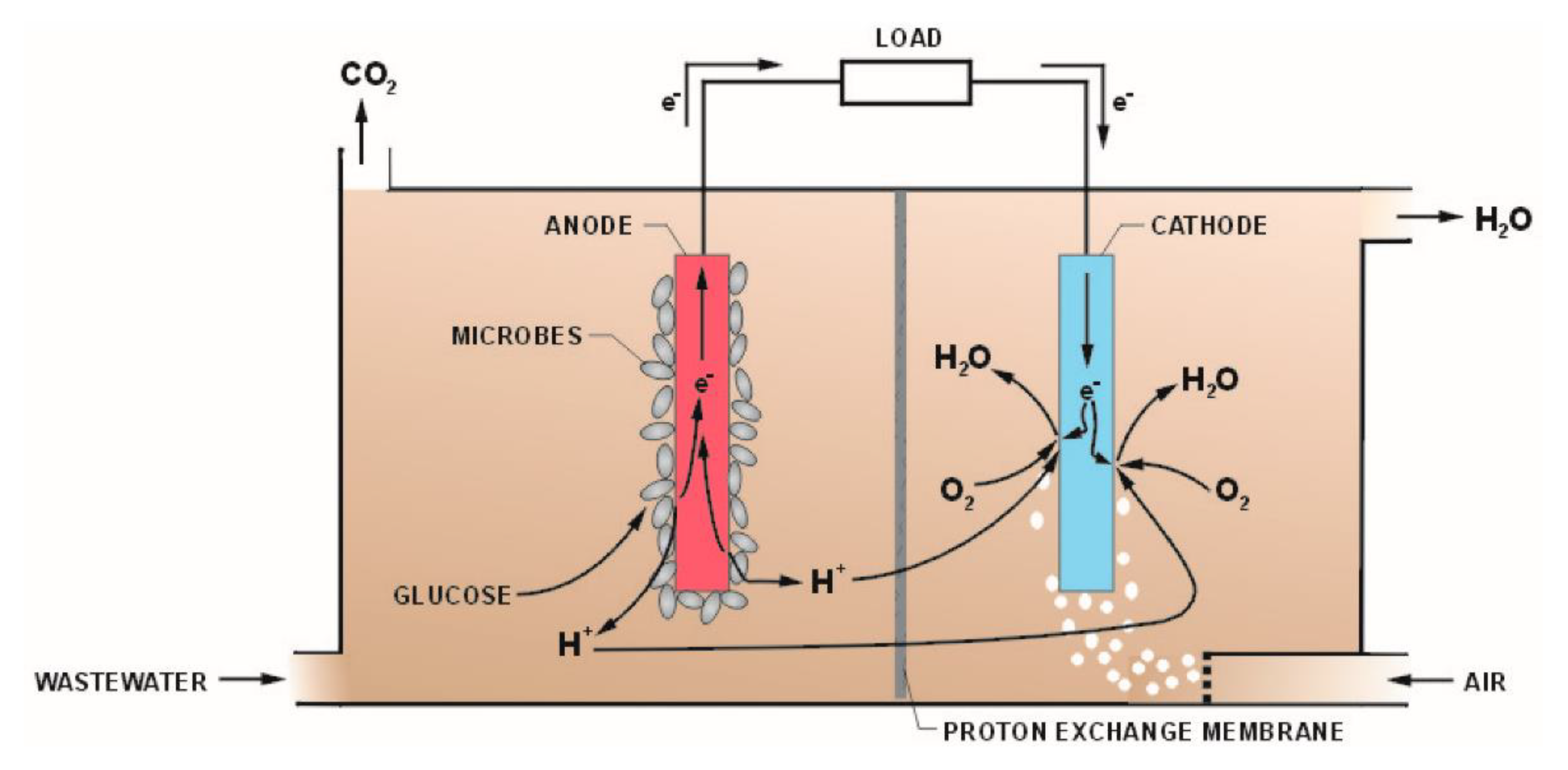

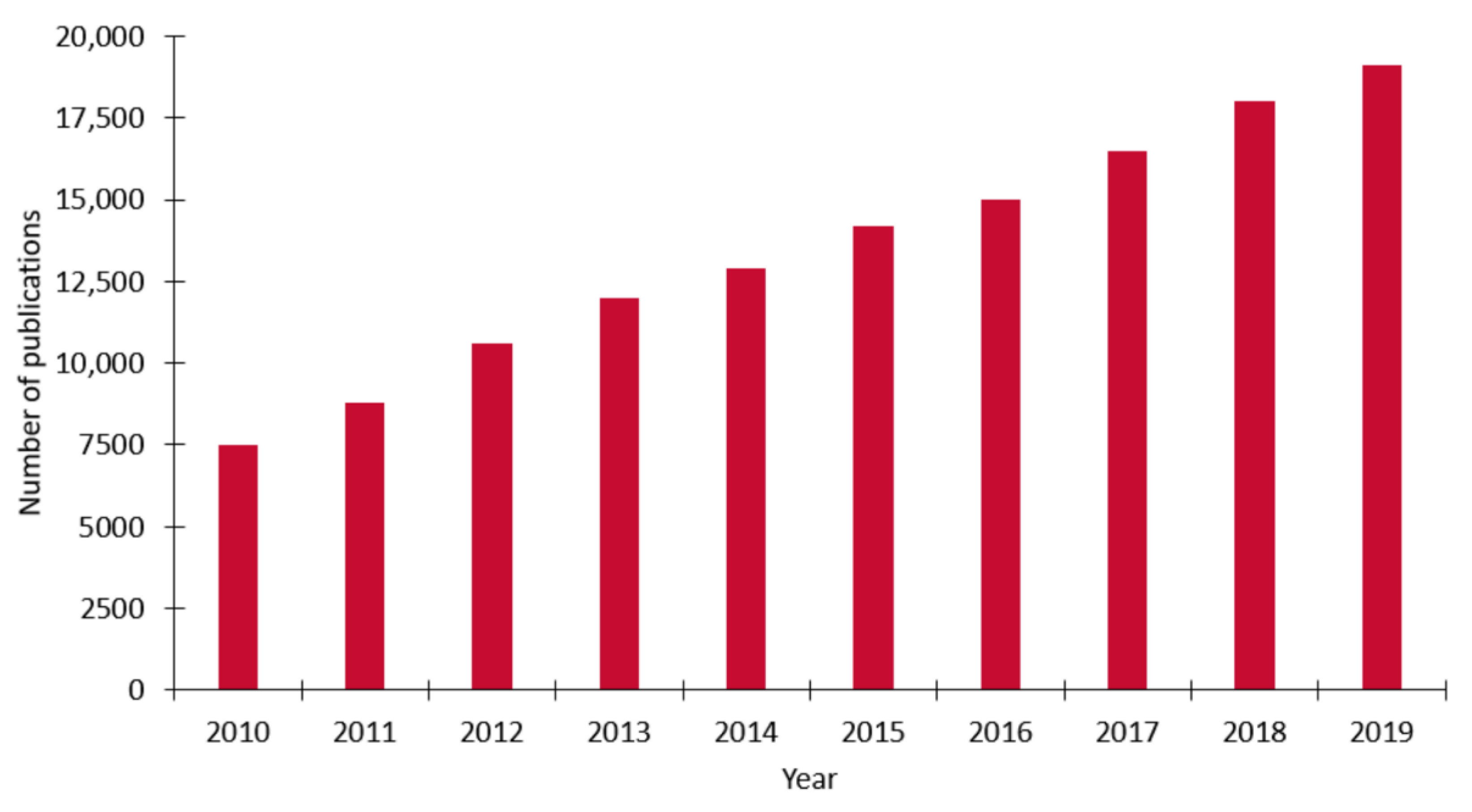

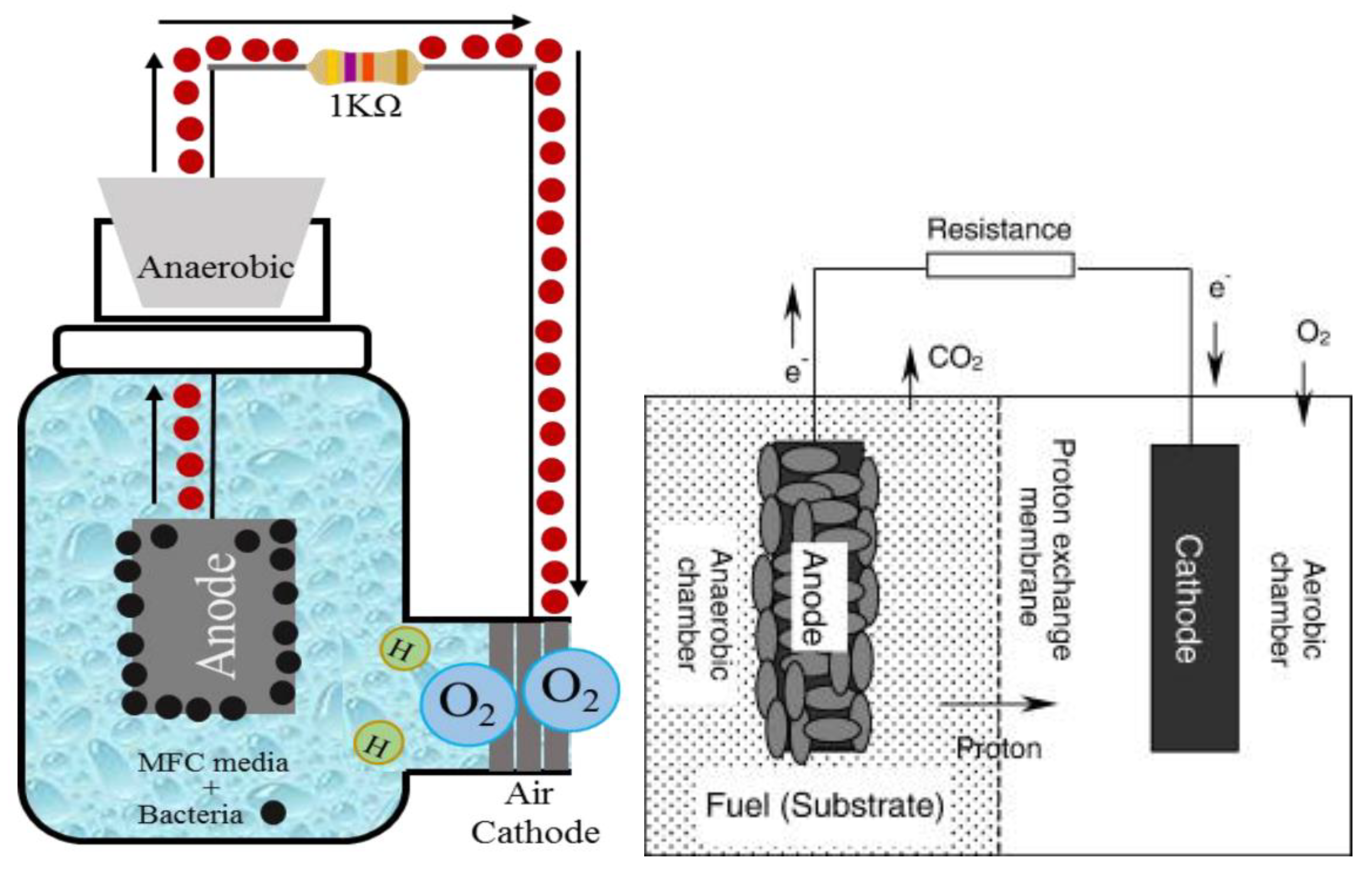

1. Introduction

2. Energy Production Using Waste as MFC Substrate

2.1. Food, Fruit, and Vegetable Waste and Wastewater

2.2. Seafood Industry

2.3. Dairy Industry

2.4. Brewery and Winery Waste

2.5. Oil Industry

2.6. Animals and Meat Industry Waste

2.7. Distillery and Sugar-Based Industries

2.8. Agricultural—Plant Waste

2.9. Sludge, Sewage/Solid Waste

2.10. Soil Waste

2.11. Municipal/Solid Waste—Mixed Waste

3. Future Perspectives and Research Needs

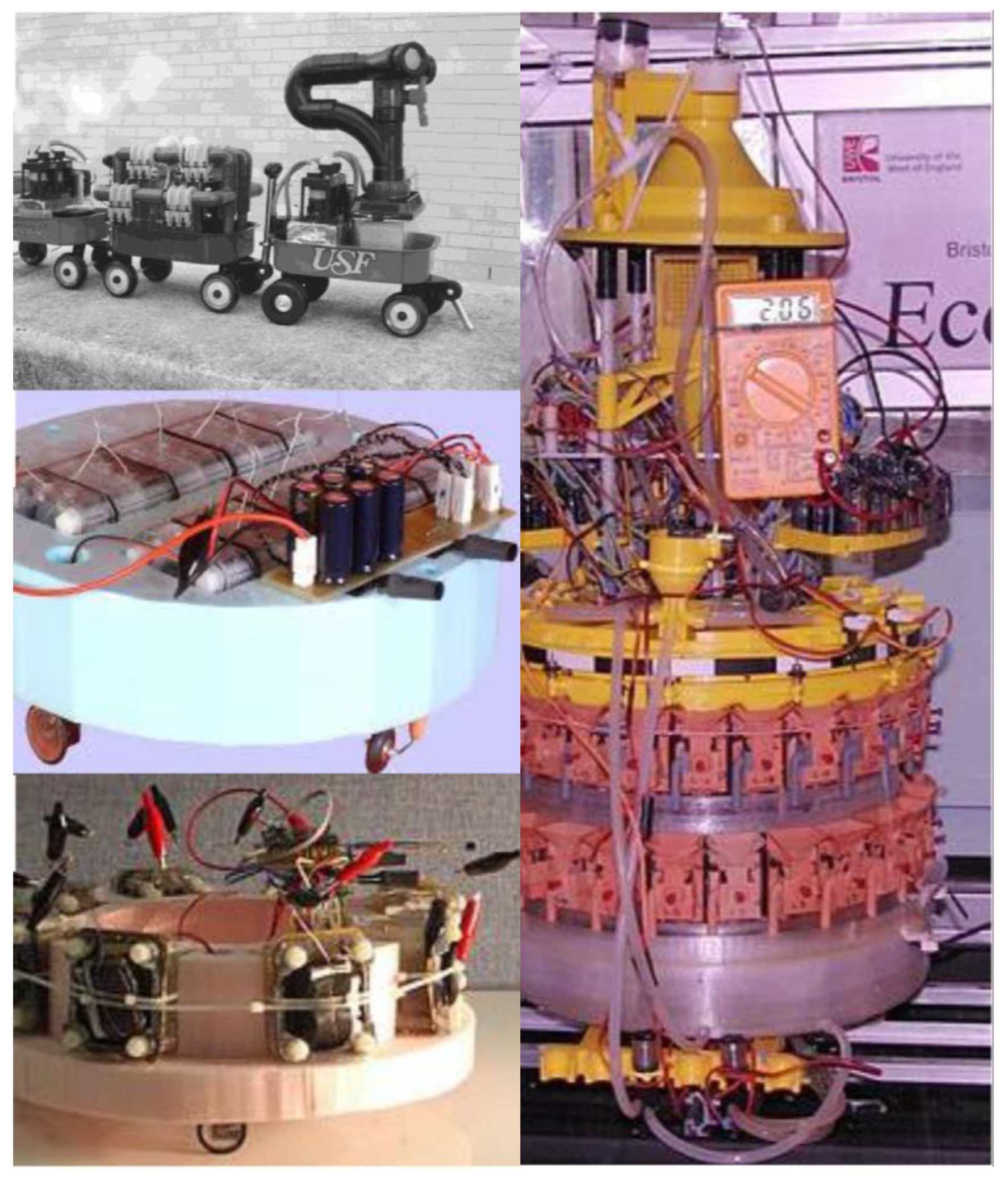

4. Prospects for Upscaling and Technology Readiness Level (TRL) Assessment

- electrode costs.

- biofouling effects on membranes and electrodes.

- inconsistent power generation depending on the type of substrate and operational conditions.

- acquisition methods of the power generated in the system.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Waste Type | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Ref |

|---|---|---|---|---|---|---|---|---|---|

| Food, Fruit, and Vegetable Waste and Wastewater | |||||||||

| potato | single-chamber | 28 | graphite fiber brushes | carbon cloth–Pt–PFTE | 89% | 217 mW/m2 | n/a | 21 | [53] |

| potato pulp | single-chamber | 25 | graphite fiber brushes | carbon cloth–Pt–PFTE | 68.40% | 32,100 mW/m3 | n/a | 56 | [56] |

| potato pulp | two-chamber | 240 | carbon felts | carbon felts | 90% | 1.4–6.8 mW/m2 | n/a | 44 | [57] |

| potato | three-chamber | 800 | graphite | graphite | 80% | n/a | 250–400 μA | n/a | [58] |

| potato–shochu | cassette-electrode | 350 | graphite felt | carbon cloth | 68% | 1.2 W/m3 | n/a | 2 | [59] |

| culled (defective) tomatoes | two-chamber | n/a | graphite felt | graphite felt | n/a | 256 mW/m2 | n/a | n/a | [60] |

| tomato seeds and skin | two-chamber | n/a | graphite felt | graphite felt | n/a | 132 mW/m2 | n/a | n/a | |

| natural vegetable waste | two-chamber | 35 | granular graphite | carbon paper | 87% | 596–1019 mW/m3 | n/a | 33 | [62] |

| composite vegetable waste | single-chamber | 430 | graphite plates | graphite plates | 63% | 57.38–215.71 mW/m3 | n/a | n/a | [61] |

| fermented apple juice | two-chamber | 500 | graphite felt | platinum mesh | n/a | 10.2–78 mW/m2 | 56.9–208 mA/m2 | n/a | [64] |

| yogurt waste | two-chamber | 500 | graphite felt | platinum mesh | n/a | n/a | 250 mA/m2 | n/a | |

| chilled ready-to-eat food | tubular | 1000 | carbon veil | carbon cloth | 84% | 3.34–5.86 W/m3 | n/a | n/a | [65] |

| baker’s yeast | two-chamber | 100 | carbon felts | carbon felts | less than 40% | 9.75–18.41 mW/m2 | n/a | n/a | [67] |

| bakery wastewater | single-chamber | 45 | carbon cloth | carbon paper | 86% | n/a | 10–11 mA/m2 | n/a | [66] |

| vegetable waste | U-shaped | n/a | graphite rod | graphite rod | n/a | 88 W/m2 | 314.4 mA/m2 | n/a | [63] |

| food waste leachate | two-chamber | 1200 | carbon | carbon | 90% | 15,140 mW/m3 | n/a | n/a | [68] |

| food waste leachate | two-chamber | 76 | carbon felt | carbon felt | 85.40% | 1 mW/m3 | n/a | 13 | [69] |

| food waste leachate | air-diffusion | 234 | carbon felt | ELAT gas diffusion electrode | 95% | 1.86 W/m3 | n/a | n/a | [70] |

| soy-based foods | three-chamber | n/a | carbon | carbon | 71.40% | less than 100 mW/m2 | n/a | 18 | [71] |

| food waste | two-chamber | 84 | carbon cloth | carbon paper | n/a | 1007 mW/m3 | 5524 mA/m3 | 12 | [72] |

| food waste | two-chamber | 84 | carbon cloth | carbon paper | n/a | 190.5 mW/m3 | 853 mA/m3 | 8 | |

| food industry waste | two-chamber | 250 | carbon cloth | carbon cloth | 64.20% | n/a | 0.78 mA | n/a | [73] |

| food industry waste | single-chamber | 250 | carbon cloth | carbon cloth | 63% | n/a | 0.72 mA | n/a | |

| food processing waste | two-chamber | 250 | carbon paper | carbon–Pt | 95% | 371 mW/m2 | n/a | n/a | [74] |

| food processing waste | single-chamber | 250 | carbon paper | carbon–Pt | 95% | 81 mW/m2 | n/a | n/a | |

| oranges | n/a | felt disc | felt disc | n/a | n/a | 357 mV | n/a | n/a | [75] |

| food waste | single-air-cathode | n/a | carbon brush | n/a | n/a | 16–27 mW/m2 | n/a | n/a | [76] |

| liquid part of food waste | cylinder-type air-cathode single-chamber | n/a | n/a | n/a | n/a | 125 million KWh | n/a | n/a | [77] |

| canteen waste leachate | single-chamber | 24 | graphite brush | carbon cloth | 85.10% | 1540 mW/m2 | n/a | 89 | [78] |

| canteen waste leachate | single-chamber | 22 | graphite fiber brush | carbon cloth–Pt | 86% | 371–556 mW/m2 | n/a | 27 | [79] |

| canteen waste leachate | single-chamber | 300 | graphite | graphite air-cathode | 72% | 162.4 mW/m2 | n/a | n/a | [80] |

| canteen waste leachate | single-chamber | 430 | graphite plates | graphite plates | 65% | 108 mW/m2 | 390 mA/m2 | n/a | [81] |

| diluted canteen waste | single-chamber | 120 | carbon cloth | carbon cloth | 80.80% | 5.6 mW/m3 | 15.3 mA/m3 | n/a | [333] |

| undilued canteen waste | solid-phase | 500 | graphite plates | graphite plates | 76.00% | 41.8–170.81 mW/m2 | n/a | n/a | [82] |

| canteen waste | three-chamber | 1500 | graphite plates | graphite plates | 99% | 123.8 mW/m2 | 54.3 mA/m2 | n/a | [83] |

| canteen waste | three-chamber | 300 | graphite | copper | 44% | 19151 mW/m3 | n/a | n/a | [84] |

| cafeteria fermented waste | two-chamber | n/a | carbon | carbon | n/a | 15.3 mW/m2 | n/a | n/a | [85] |

| canteen waste food | n/a | n/a | n/a | permaganate | 87% | 422 mW/m2 | n/a | n/a | [86] |

| food waste ethanol fermentation stillage | single-chamber | 120 | graphite | titanium | 70% | 0.29 V | 1.4 mA | n/a | [87] |

| food waste ethanol fermentation stillage | n/a | n/a | n/a | n/a | 62% | 612 mW/m2 | 6.4 W/m3 | n/a | [88] |

| kitchen waste | single-chamber air-cathode | n/a | carbon rod | carbon rod | n/a | 85.58 mW/m2 | n/a | n/a | [89] |

| kitchen waste | H-type dual-chamber | 310 | carbon paper | carbon cloth | n/a | 29.6 mW/m2 | n/a | n/a | [90] |

| kitchen waste | single-chamber | n/a | carbon fiber | carbon fiber | n/a | 620 mV | n/a | n/a | [93] |

| Waste Type Seafood Industry | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| seafood | two-chamber | 98 | graphite rod | graphite rod | 28–80 | 16,200 mW/m3 | n/a | 15 | [95] |

| seafood | single-chamber | 26 | carbon cloth steel mesh | carbon cloth steel mesh | 85 | 358.8 mW/m2 | n/a | 14 | [96] |

| seafood | tubular | 50 | activated carbon fiber felt | activated carbon fiber felt | 83 | 105–22 mW/m2 | n/a | <30% | [97] |

| seafood | two-chamber | 26 | carbon cloth steel mesh | carbon cloth steel mesh | 65 | 291.6 mW/m2 | n/a | 20 | [96] |

| seafood | air-cathode | n/a | n/a | n/a | 90 | 570 mW/m2 | 600 mA/m2 | 52 | [98] |

| seafood | dual-chamber | 3000 | polypropylene | polypropylene | 77 | 2960.704 mW/m2 | 2996.664 mA/m2 | n/a | [99] |

| Waste Type Dairy Industry | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| yogurt waste | three-chamber | 500 | graphite felt | platinum mesh | n/a | 53.8 mW/m2 | n/a | n/a | [64] |

| yogurt waste | three-chamber | 500 | platinum mesh | platinum mesh | 91 | 38 mW/m2 | n/a | n/a | [103] |

| yogurt | single-chamber air-cathode | 28 | stainless steel fiber felt | activated carbon | 87 | 1143 mW/m2 | n/a | n/a | [104] |

| dairy manure | single-chamber | 28 | graphite fiber | graphite cloth | 70 | 189 mW/m2 | n/a | 12 | [53] |

| dairy manure | three-chamber | 617 | graphite fiber brush | graphite fiber brush and granules | n/a | 14000 mW/m3 | n/a | 19 | [105] |

| synthetic dairy wastewater | two-chamber | 480 | carbon | carbon | 63 | 92 mW/m2 | 665 mA/m2 | 24 | [106] |

| activated sludge dairy waste | two-chamber | 600 | graphite sheet | graphite sheet | n/a | 0.715 mW/m3 | n/a | n/a | [107] |

| cheese whey | single-chamber | 28 | graphite fiber brush | graphite fiber cloth | n/a | 22.3 mW/m3 | 10 mA/m3 | 49 | [108] |

| cheese whey | two-chamber | 800 | graphite | graphite | n/a | 324.8 μW | 1.19 mA | n/a | [109] |

| dairy | two-chamber | 2000 | graphite | graphite | n/a | 621.3 mW/m2 | 3.74 mA | 38 | [111] |

| dairy | single-chamber | 480 | graphite plate | graphite plate | 96 | 1.28 mW/m2 | n/a | 14 | [102] |

| dairy | two-chamber | 30 | graphite plates | graphite plates | 91 | 197 mW/m2 | n/a | 17 | [110] |

| dairy | continuos-flow-type two-chamber | n/a | stainless steel | stainless steel | 94 | 38 μW | n/a | n/a | [112] |

| dairy | single-chamber | n/a | n/a | n/a | 95 | 62.27 mW/m2 | 263 mA/m2 | 32 | [113] |

| dairy | three MFCs in a series | 300-300-330 | n/a | n/a | n/a | 1.745 V | n/a | n/a | [114] |

| dairy | two-chamber | n/a | carbon felt | carbon | 83 | less than 450 mW/m2 | n/a | 32 | [71] |

| dairy | two-chamber | 17 | graphite brush | carbon cloth | 76 | 131 mW/m2 | 2.4 W/m3 | n/a | [115] |

| dairy | double-chamber salt-bridged | n/a | n/a | n/a | 86 | 1080 mW/m2 | n/a | n/a | [116] |

| dairy | double-chamber agar–salt-bridged | n/a | graphite plates | graphite plates | 92 | n/a | n/a | n/a | [117] |

| cheese | n/a | n/a | n/a | n/a | 92 | 44.05 mW/m2 | n/a | 2% | [118] |

| yogurt waste | n/a | n/a | n/a | n/a | 86 | n/a | n/a | n/a | |

| dairy | two-chamber | 84 | carbon paper | n/a | n/a | 503 mW/m3 | 1946 mA/m3 | <4% | [72] |

| dairy | two-chamber | 84 | carbon paper | n/a | n/a | 38 mW/m3 | 404 mA/m3 | <1% | |

| dairy | single-chamber | 45 | carbon cloth | carbon paper | 82 | n/a | 25 mA/m2 | n/a | [66] |

| Waste Type Brewery and Winery | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| winery | tubular | 170 | carbon felts | carbon felts | 10 | 890 mW/m2 | n/a | 42 | [129] |

| winery | two-chamber | 70 | carbon felts | carbon felts | 17 | 465 mW/m2 | n/a | 15 | [130] |

| wine lees | two-chamber | 500 | graphite felt | platinum mesh | n/a | 0.8 mW/m2 | 6.6 mA/m2 | n/a | [64] |

| brewery | single-chamber | n/a | carbon cloth | carbon cloth | 98 | 205 mW/m2 | n/a | 10 | [124] |

| brewery | single-chamber | 100 | carbon fibers | stainless steel-activated carbon–PTFE | 21 | 669 mW/m2 | n/a | 2 | [131] |

| brewery | single-chamber | 225 | graphite felt | carbon cloth–Pt | n/a | 552 mW/m2 | n/a | 41 | [132] |

| brewery | single-chamber | n/a | carbon cloth | carbon cloth–Pt | 87 | 483 mW/m2 | n/a | 38 | [133] |

| brewery | single-chamber | 4000 | carbon fiber brushses | activated carbon | 75 | 304 mW/m2 | n/a | 2 | [123] |

| brewery | two-chamber | 200 | graphite felt | graphite cloth | 80 | 305 mW/m2 | 745 mA/m2 | n/a | [134] |

| brewery | two-chamber | n/a | carbon paper | carbon paper | n/a | 38.4 mW/m2 | n/a | n/a | [135] |

| brewery | two-chamber | n/a | graphite felt | graphite felt–Pt | 65 | n/a | 0.78 mA/m2 | n/a | [136] |

| brewery | three-chamber | 1200 | graphite plates | graphite plates | 93 | 173 mW/m2 | 370 mA/m2 | n/a | [137] |

| brewery | single-chamber | n/a | n/a | n/a | 93 | less than 300 mW/m3 | 1100 mA/m3 | n/a | [138] |

| brewery | single-chamber | 180 | carbon fiber and graphite rods | stainless steel activated carbon–Pt–PTFE | 43 | 264 mW/m2 | 1.79 mA/m2 | 20 | [139] |

| brewery | single-chamber | 45 | carbon cloth | carbon cloth coated Pt–PTFE | 85 | n/a | 10 mA/m2 | n/a | [66] |

| brewery | two-chamber | 250 | copper mesh | copper mesh | 82 | 80 mW/m2 | n/a | n/a | [140] |

| brewery | serpentine-type | 10,000 | graphite felt | n/a | 85 | 4.1 W/m3 | n/a | 6–8 | [141] |

| brewery | industrial two-chamber | n/a | graphite brush | carbon cloth | 92 | 26.4 KWh | n/a | n/a | [142] |

| brewery | single-chamber | 700 | carbon paper | graphite | 94 | n/a | 10.89 mA | n/a | [143] |

| Waste Type Oil Industry | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| soybean oil | single-chamber | 18 | graphite felt | carbon cloth | 78 | 2240 mW/m2 | 658 mA/m2 | 20 | [146] |

| soybean oil | single-chamber | 2 | graphite felt | stainless steel | 96 | 746 mW/m2 | n/a | 34 | [147] |

| palm | two-chamber | 450 | PACF carbon felt | PACF carbon felt | 70 | 22 mW/m2 | 180 mA/m2 | 24 | [148] |

| vegetable oil | two-chamber | 500 | carbon cloth | carbon cloth | 86 | n/a | n/a | n/a | [149] |

| vegetable oil effluent | dual-chamber | 500 | graphite rod | carbon cloth | 80–90 | 5839 mV | n/a | 37 | [150] |

| petroleum refinery | single-chamber air-cathode membrane-less | 350 | carbon fiber brush | platinum-coated carbon cloth | 48% | 132 mW/m2 | n/a | n/a | [151] |

| petroleum refinery | single-chamber | n/a | n/a | n/a | 85 | 225 W/m2 | n/a | 2 | [152] |

| oil sewage | constructed wetland reactor | 2400 | crushed stone, glass wool, activated carbon | MnO2-modified | 73–75 | 102 mW/m2 | n/a | n/a | [153] |

| oil sewage | simple MFC | 2400 | crushed stone, glass wool, activated carbon | n/a | 73–75 | 80 mW/m2 | n/a | n/a | [153] |

| mineral oil | single-chamber air cathode | n/a | n/a | n/a | 80 | 45 mW/m3 | n/a | n/a | [154] |

| Waste Type Animal and Meat Industry | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| swine | single-chamber | 70 | carbon felt | carbon paper | 91 | 2300 mW/m2 | 6000–7000 mA/m2 | 47 | [157] |

| swine | two-chamber | 450 + 350 | graphite granule and graphite rod | carbon felt | 77 | 3.1–7.9 mW/m3 | 1.7–2.8 mA | n/a | [158] |

| swine | two-chamber | 1000 | carbon | carbon rod | 86 | 88.45 mW/m2 | 0.49 mA | n/a | [159] |

| swine | single-chamber | n/a | graphite brush | 75 | n/a | n/a | n/a | [160] | |

| swine | 2 single-chambers | 100 | graphite fiber brushes | activated carbon–PVDF–carbon black | 65 | 750 mW/m2 | 1400–1600 mA/m2 | n/a | [161] |

| swine | combination of a single- and two-chamber | 250 | carbon paper | carbon–Pt | 92 | 261 mW/m2 | 1400 mA/m2 | 8 | [162] |

| swine | dual-chamber | 350 | carbon fiber brush | carbon fiber brush | 95 | n/a | n/a | n/a | [163] |

| swine | single-chamber air cathode with flocculation | n/a | carbon brush | nickel | 97 | 37.5 W/m3 | n/a | 22 | [10] |

| swine farm waste and wastewater | two-chamber | n/a | carbon fiber brush | carbon cloth–Pt | n/a | 880–1056 mW/m2 | n/a | n/a | [164] |

| swine farm waste and wastewater | single-chamber | 128 | carbon fiber | carbon fiber stainless steel mesh | 72 | 256 mW/m2 | 4400 mA/m2 | 39 | [165] |

| swine manure | single-chamber | 28 | carbon paper | carbon–Pt | 84 | 228 mW/m2 | n/a | n/a | [166] |

| swine manure | two-chamber | 420 | granular graphite and graphite rod | granular graphite and graphite rod | n/a | 20 mW/m2 | n/a | 24 | [167] |

| diluted swine manure | single-chamber | 65 | carbon felt | commercial gas diffusion | 15 | 28 mW/m2 | n/a | 24 | [168] |

| swine manure | two-chamber | 380 | granular graphite | granular graphite | 52 | n/a | 14.9 mA | 70 | [169] |

| swine slurry | two-chamber | 504 | carbon felt | stainless steel mesh | 21 | n/a | 250 mA/m2 | n/a | [170] |

| swine slurry digested | two-chamber | 504 | carbon felt | stainless steel mesh | 12 | n/a | 225 mA/m2 | n/a | |

| swine slurry liquid | two-chamber | 336 | carbon felt mesh | stainless steel mesh | 51 | 46.1 mW/m2 | 146.8 mA/m2 | 7 | [171] |

| swine slurry | two-chamber | 269 | granular graphite and carbon felt | stainless steel mesh | n/a | 5623 mW/m3 | n/a | n/a | [172] |

| cattle manure | H-type | 380 | carbon cloth | carbon cloth | 60 | 1.25 W/m3 | n/a | n/a | [173] |

| cattle manure | cassette-electrode | n/a | carbon felt | n/a | n/a | 16.3 W/m3 | n/a | n/a | [174] |

| cattle dung | two-chamber | 15,000 | carbon brushes | n/a | 74 | 220 W/m3 | n/a | 3 | [175] |

| swine | three single-chamber | 1500 | graphite rod | carbon cloth–Pt | 85 | 1.5 W/m3 | n/a | 15 | [176] |

| swine | three single chamber | 12,000 | graphite rod | carbon cloth | 50 | 4 W/m3 | n/a | 15 | |

| swine | two single-chamber | 100,000 | graphite rod | carbon cloth–Pt | 52 | 2.2 W/m3 | n/a | 10 | |

| swine | 12 MFCs | 110,000 | graphite fiber brush | gas air diffusion | 65 | 42 mW/m2 | 103 mA/m2 | n/a | [177] |

| slaughterhouse waste | two-chamber | n/a | graphite | graphite, zipper, zinc | n/a | 700 mW/m2 | 318 mA/m2 | n/a | [178] |

| slaughterhouse | tubular | n/a | n/a | n/a | 99 | 165 mW/m2 | 472 mA/m2 | n/a | [179] |

| slaughterhouse | MFC aerobic bioreactor | n/a | n/a | n/a | 99 | 162.55 mW/m2 | n/a | 13 | [180] |

| slaughterhouse | H-type | n/a | carbon cloth | platinized titanium mesh | n/a | 578 mW/m2 | n/a | 64 | [181] |

| slaughterhouse | MFC with air-breathing cathode | 250 | graphite rod | platinum Vulcan | n/a | 37 mW/m2 | n/a | 72 | [182] |

| slaughterhouse | two-chamber | n/a | stainless steel | mild steel plate | 80 | 2.1 V | n/a | n/a | [183] |

| protein food industry | two-chamber | 1500 | graphite sheets | graphite sheets | 86 | 230 mW/m2 | 527 mA/m2 | 21 | [184] |

| goat rumen fluid | four two-chamber | 2500 | copper | zinc | n/a | 42,110 mW/m2 | 0.82 mA/m2 | n/a | [185] |

| goat rumen fluid and hay | two-chamber | 2500 | copper | zinc | n/a | 9700 mW/m2 | 0.24 A | n/a | |

| cow urine | two-chamber | 400 | carbon felt | carbon felt | 82 | 5.23 mW/m3 | 14.42 mA/m3 | n/a | [186] |

| manure diluted | two-chamber | 1850 | graphite fiber brush | carbon cloth–Pt | n/a | 93 mW/m2 | 370–780 mA/m2 | 5 | [187] |

| manure wash waste | two-chamber | 1850 | graphite fiber brush | carbon cloth–Pt | n/a | 216 mW/m2 | 1380 mA/m2 | 5 | |

| high-moistrue cow manure | single-chamber air-cathode | n/a | carbon mesh | n/a | n/a | 350 mW/m2 | n/a | n/a | [188] |

| dried, blended farm manure | membrane-less MFC | n/a | carbon cloth | carbon cloth | n/a | 5 mW/m2 | n/a | n/a | [189] |

| high-strength liquid manure | single-chamber air cathode | 150 | carbon cloth | carbon cloth | n/a | 28.2 μW | n/a | 2 | [190] |

| Waste Type Distillery and Sugar-Based Industry | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| molasses | two-chamber | 300 | carbon cloth | carbon cloth | 67 | 2425 mW/m2 | 2600 mA/m2 | n/a | [191] |

| molasses | single-chamber | 900 | carbon felt | air diffusion | 90 | 7.9 mW/m2 | 57.3 mW/m2 | n/a | [192] |

| molasses | two-chamber | 900 | carbon felt | carbon felt | 89 | 7.5 mW/m2 | 56.7 mA/m2 | n/a | |

| molasses | two-chamber | 900 | carbon felt | carbon felt | 50 | 17 mW/m2 | 80.2 mA/m2 | n/a | |

| high strength molasses | up-flow anaerobic sludge blanket reactor–microbial fuel cell–biological aerated filter | n/a | graphite rod | carbon paper | 53 | 1410 mW/m2 | 4947.9 mA/m2 | n/a | [193] |

| sugar mill | two-chamber | 500 | carbon felt | carbon felt | 56 | 140 mW/m2 | 50 mA/m2 | 70 | [194] |

| crude sugarcane effluent with anaerobic sludge | dual-chamber | 100 | mild steel coated with Fe2TiO5 | stainless steel | n/a | 8314 mW/m2 | n/a | n/a | [195] |

| molasses | dual-chamber | n/a | carbon cloth | carbon cloth MnO2 modified | n/a | 6.8–10.33 mW/m2 | n/a | n/a | [196] |

| molasses | dual-chamber | n/a | carbon cloth | carbon felt MnO2-modified | n/a | 3.6–31.37 mW/m2 | n/a | n/a | [196] |

| molasses | dual-chamber | 500 | carbon felt | carbon felt | 67 | 0.21 V | n/a | n/a | [197] |

| molasses | dual-chamber | 500 | carbon cloth | carbon cloth | 29 | 8.4 mV | n/a | n/a | [198] |

| molasses | single-chamber | n/a | carbon cloth | carbon cloth/vertical | 67 | 122 μW | n/a | n/a | [199] |

| molasses | single-chamber | n/a | carbon cloth | carbon cloth/horizontal | n/a | 115 μW | n/a | n/a | |

| sugarcane molasses | H-type dual-chamber | 250 | n/a | n/a | 82 | 188.5 mW/m2 | n/a | 28–60 | [200] |

| molasses | membrane electrode assembly (HEM) with MFC/increased tilt angle | n/a | n/a | n/a | 96 | 16.1 mW/m2 | n/a | n/a | [201] |

| molasses | single-chamber | n/a | n/a | n/a | n/a | 1070–1085 mV | n/a | n/a | [84] |

| molasses | anaerobic baffled stacking of four MFCs | n/a | carbon felt | carbon cloth | 50–70 | 115.7 mW/m2 | n/a | 1 | [202] |

| distillery | single-chamber | 28 | carbon cloth | carbon cloth | 57 | 5.46 mW/m3 | 77.7 mA/m2 | n/a | [204] |

| distillery | single-chamber | n/a | graphite rod | graphite rod | 61 | 28.5 mW/m2 | 0.84 mA | n/a | [205] |

| distillery | two-chamber | n/a | graphite rod | graphite rod | 64 | 17.76 mW/m2 | 0.36 mA | n/a | |

| distillery | two-chamber | 500 | graphite rod | graphite rod | 61 | 31490 mW/m3 | n/a | n/a | [118] |

| undigested distillery | single-chamber | 500 | graphite rod | graphite rod | 57 | n/a | n/a | n/a | |

| corn stover powder | single-chamber | n/a | carbon paper | carbon cloth–Pt | n/a | 343 mW/m2 | n/a | n/a | [207] |

| chitin solution | single-chamber | 300 | carbon brush | carbon cloth–Pt | n/a | 272 mW/m2 | n/a | 56 | [208] |

| fermented chitin | two-chamber | 100 | carbon felt | carbon felt | n/a | 8.77 μA/cm2 | n/a | [209] | |

| distillery | two-chamber salt–agar-bridged | 500 | graphite rod | graphite rod | n/a | 349 mW | n/a | n/a | [210] |

| distilled food ethanol fermentation stillage | single-chamber air-cathode | 120 | graphite felt | n/a | 70 | 0.29 V | 1.4 mA | n/a | [87] |

| distillery | dual-chamber | 19 | carbon felt | nickel foam-coated carbon ink | 55–64 | 4.3 W/m3 | n/a | n/a | [211] |

| distillery | n/a | n/a | n/a | n/a | 69 | 2.63 W/m3 | n/a | n/a | [212] |

| distillery | n/a | n/a | n/a | n/a | 85 | 0.625 V | 2.9 mA | 31 | [214] |

| mezcal industry | dual-chamber | 900 | graphite felt | stainless steel plate | 83–92 | 5.83–80.64 W/m3 | n/a | n/a | [214] |

| distillery | single-chamber | n/a | graphite plate | graphite plate | 73 | 325 mV | 400 mA/m2 | n/a | [215] |

| distillery spend | dual-chamber | n/a | graphite rod | graphite rod | 64–84 | 18.35 mW/m2 | 0.27 mA | n/a | [216] |

| distillery | dual-chamber | n/a | graphite rod | graphite rod | 64 | 18.35 mW/m2 | 0.36 mA | n/a | [217] |

| distillery | single-chamber | 2600 | graphite plate | graphite plate | n/a | 25194.8 mW/m2 | 123.5 mA/m2 | 47 | [218] |

| distillery | single-chamber | n/a | n/a | n/a | 80–81 | 29 mW/m | 84 mA/m | n/a | [219] |

| alcohol distillery | anaerobic fluidized bed with MFC | n/a | n/a | n/a | 80–90 | 124.03 mW/m2 | n/a | n/a | [220] |

| alcohol distillery | plate-type thermophilic MFC | 40 | graphite felt | graphite felt | 89 | 1000 mW/m2 | 2.3 A/m2 | 89 | [221] |

| Waste Type Agricultural-Plant Waste | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| cellulose | single-chamber membrane-less | 42 | ammonia gas treated graphite fiber brush | Pt–PTFE gas diffusion | 70 | 1080 mW/m2 | n/a | 25–50 | [223] |

| cellulose | two-chamber | 42 | ammonia gas treated graphite fiber brush | Pt–PTFE gas diffusion | 70 | 880 mW/m2 | n/a | 25–50 | |

| cellulose | three-electrode MFC | n/a | platinum sheet | platinum sheet | n/a | n/a | 130 mA/L | n/a | [224] |

| cellulose | two-chamber | n/a | graphite plates | carbon paper–Pt | 27–38 | 59.2–143 mW/m2 | n/a | 39–47 | [225] |

| cellulose | two-chamber | 800 | graphite plates | graphite plates | n/a | 55 mW/m2 | n/a | n/a | [226] |

| rice straw powder | 3 in a series H-type two-chamber | n/a | carbon paper | carbon paper | n/a | 490 mW/m2 | n/a | 45–54 | [227] |

| cellulose | U-tube two-chamber MFC | 40 | carbon cloth | carbon fiber | n/a | 4.9–5.4 mW/m2 | n/a | n/a | [228] |

| corn stover | air-cathode single-chamber MFC | 28 | carbon paper | carbon cloth | 60–70 | 367–371 mW/m2 | n/a | n/a | [230] |

| corn residue | tubular air-cathode MFC | n/a | grahite rod /graphite granule | carbon cloth | n/a | 230 mW/m2 | n/a | n/a | [231] |

| vocia faba agricultural waste | two-chamber | n/a | carbon | carbon | 78 | 283 mW/m2 | 1255.93 mA/m2 | n/a | [232] |

| orange peel | dual-chamber | n/a | graphite felt | platinum coated graphite cloth | 78 | 358.8 mW/m2 | 847 mA/m2 | n/a | [233] |

| starch wastewater | air-cathode MFC | n/a | carbon paper | carbon paper–Pt | 80–90 | 239.4 mW/m2 | 893.3 mA/m2 | n/a | [234] |

| wheat straw waste | two-chamber | 300 | carbon paper | carbon paper | n/a | 123 mW/m2 | n/a | 16–37 | [229] |

| Waste Type Sludge, Sewage/Solid Waste | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| fermented sewage sludge | single-chamber | 25 | graphite fiber brushes | carbon cloth | 84–94 | 320 W/m2 | n/a | 18–57 | [235] |

| anaerobic mesophilic sludge | single-chamber | 110 | carbon felt | gas diffusion–Pt | 53 | 53 W/m3 | n/a | 28 | [236] |

| sewage sludge | two-chamber | n/a | graphite fiber brush | graphite fiber brush | 47 | 8.5 W/m3 | n/a | n/a | [237] |

| sewage sludge | two-chamber | 2310 | stainless steel mesh | stainless steel mesh | n/a | 15.5–36.72 W/m3 | n/a | n/a | [238] |

| sewage sludge | two-chamber | n/a | graphite fiber brush | graphite fiber brush | 61 | 10.3–12.5 W/m3 | n/a | n/a | [239] |

| sewage sludge | two-chamber | 960 | graphite fiber brush | graphite fiber brush | 66 | 10.2 W/m3 | n/a | n/a | [241] |

| sewage sludge | two-chamber | n/a | graphite fiber brush | graphite fiber brush | n/a | 9.1 W/m3 | n/a | 19 | [240] |

| sewage sludge | two-chamber | n/a | graphite fiber brush | graphite fiber brush | 60 | 12 W/m3 | n/a | n/a | [242] |

| digested sludge | two-chamber | n/a | graphite rod | graphite rod | n/a | 12.67 W/m2 | 29.5–45.68% | n/a | [243] |

| digested sewage sludge | two-chamber | 2500 | carbon felts | carbon felts | n/a | 3.1 μW | n/a | n/a | [244] |

| activated sludge | two-chamber | n/a | carbon cloth | carbon cloth | 55–85 | 42 mW/m2 | n/a | n/a | [245] |

| anaerobic sewage sludge | two-chamber | n/a | n/a | n/a | 60 | 38.1 W/m3 | n/a | n/a | [246] |

| saline domestic sewage sludge | four two-chamber | 75.6 | carbon felt | carbon felt | 59 | 41 W/m3 | n/a | 28 | [247] |

| livestock solid waste | single-chamber | n/a | platinum | platinum | n/a | 36.6 mW/m2 | n/a | n/a | [248] |

| sewage sludge | dual-chamber | n/a | carbon | carbon | n/a | 499 mV | n/a | n/a | [249] |

| sludge waste | dual-chamber | 300 | graphite | graphite | n/a | 312.98 mW/m2 | 39.07 μA/cm2 | n/a | [250] |

| sludge waste | single-chamber | 60 | titanium | titanium | n/a | 97.6 mW/m2 | 17.63 μA/cm2 | n/a | |

| sludge waste | single-chamber | n/a | graphite felt modified with Mn | n/a | n/a | 788 mW/m2 | 1750 mA/m2 | n/a | [251] |

| sludge | single-chamber | n/a | platinum modified with polyanilineco | n/a | n/a | 6000 mW/m2 | n/a | n/a | [255] |

| sewage sludge after pyrolysis | air-cathode single-chamber MFC | n/a | n/a | carbon felt | n/a | 1120 mW/m2 | n/a | n/a | [254] |

| anaerobic sewage sludge from wastetwater treatment plant | two-chamber | n/a | carbon cloth | platinum | n/a | 13.5 mW/cm2 | n/a | 5 | [256] |

| sludge from the sewage of treatment plant | six single-chamber | n/a | carbon | copper | 30 | 1108 mW/cm2 | n/a | n/a | [257] |

| sewage sludge mixed with liquor-suspended solid | air-cathode MFC | n/a | n/a | n/a | n/a | 27.65 W/m3 | 473.5 mA/m3 | n/a | [258] |

| sludge | three-chamber | n/a | graphite granule | graphite brush | 40 | 13.2 W/m3 | n/a | 19 | [259] |

| sludge | submersible MFC | n/a | carbon paper | carbon paper | 78 | 190 mW/m2 | n/a | 3 | [260] |

| sewage sludge | salt-bridged dual-chamber | 2000 | n/a | n/a | n/a | 2.5 V | n/a | n/a | [261] |

| Waste Type Soil Waste | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| urea | coin cell system of a soil-based MFC | n/a | graphite | graphite | n/a | 3.2 mW/m2 | n/a | n/a | [262] |

| soil substrates | 21 air-cathode MFCs | n/a | platinized carbon paper | platinized carbon paper | n/a | 16.4–28.6 mW/m2 | n/a | n/a | [263] |

| soil glucose | single-chamber | n/a | platinum | platinum | n/a | 32 mW/m2 | 100 mA/m2 | n/a | [264] |

| straw-based soil | single-chamber | n/a | platinum | platinum | n/a | 10.6–10.8 mW/m2 | 60–80 mA/m2 | n/a | |

| human urine | soil-based MFC | n/a | carbon | carbon | n/a | 124.16 mW/m2 | n/a | n/a | [265] |

| salt | single-chamber | n/a | carbon | carbon | n/a | 336 mV | n/a | n/a | [266] |

| silt | single-chamber | n/a | carbon | carbon | n/a | 348 mV | n/a | n/a | |

| clay | single-chamber | n/a | carbon | carbon | n/a | 644 mV | n/a | n/a | |

| sand with dried leaves | soil-based MFC | n/a | n/a | n/a | n/a | 29.2 mW/m2 | n/a | n/a | [267] |

| clay with dried leaves | soil-based MFC | n/a | n/a | n/a | n/a | 23.8 mW/m2 | n/a | n/a | |

| soil | portable, plugged-type soil-based MFC | n/a | carbon | carbon | n/a | 7.3 mW/m2 | n/a | n/a | [268] |

| Brinjal-cultivated soil | agar salt-bridged soil-based MFC | n/a | carbon | carbon | n/a | 12.8 mW/m2 | 23.6 mA/m2 | n/a | [269] |

| Waste Type Municipal, Solid, Mixed Waste | MFC Type | Working Volume [mL] | Anode Material | Cathode Material | COD Removal [%] | Power-Density Voltage | Current Density Current | Coulombic Efficiency [%] | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| raw municipal waste | single-chamber submerged into aeration chamber | 144 | graphite felt | graphite felt | n/a | 16.7 W/m3 | n/a | 40 | [270] |

| municipal | single-chamber | n/a | n/a | n/a | n/a | 10 mW/m2 | n/a | n/a | [271] |

| domestic | n/a | 390 | graphite granule | woven grahite mat | n/a | 10 W/m3 | n/a | 22 | [272] |

| municipal | flat plate microbial fuel cell | n/a | carbon paper | carbon cloth | 42–79 | 72 mW/m2 | n/a | 6 | [273] |

| municipal | single-chamber membrane-less MFC | 255,000 | graphite fiber brush | stainless steel | 57 | 78 mW/m2 | n/a | 44 | [274] |

| municipal | 20 air-cathode MFCs | 16,000 | carbon felt | copper | 84 | 1107 mW/m2 | n/a | n/a | [275] |

| municipal | two-chamber | n/a | carbon felt | carbon felt | n/a | 30.47 mW/m2 | n/a | n/a | [276] |

| municipal | two-chamber | n/a | carbon felt | carbon felt | n/a | 1817.88 mW/m2 | n/a | n/a | |

| municipal solid waste landfill leachate with dairy wastewater | two dual-chamber | 1600 | granular grahite | granular graphite | 66–85 | n/a | n/a | 8 | [277] |

| cow dung vs. chicken droppings | single-chamber | n/a | carbon fiber | carbon felt | n/a | 340–450 mV | n/a | n/a | [278] |

| fruit waste vs. food waste | single-chamber | n/a | carbon fiber | carbon felt | n/a | 300–380 mV | n/a | n/a | |

| rice bran vs. leaf waste | single-chamber | n/a | carbon fiber | carbon felt | n/a | 300–320 mV | n/a | n/a | |

| artificial domestic wastewater | cassette-electrode MFC | 1500 | graphite felt | air-cathode | 93 | 140 mW/m2 | n/a | 20 | [279] |

| artificial industrial wastewater | cassette-electrode MFC | 1500 | graphite felt | air-cathode | 97 | 175 mW/m2 | n/a | 20 | |

| ammonium with municipal wastewater | dual-chamber | n/a | graphite felt | carbon fiber brush | 85 | 230.17 mW/m2 | n/a | n/a | [280] |

| ammonia with municipal wastewater vs. municipal wastewater | bench-scale/45 L MFC | 45,000 | graphite felt brush | platinum-coated carbon cloth | 55–87 | 145 mW/m2 | n/a | n/a | [281] |

| distillery wastewater | two-chamber | 1000 | copper | copper | 70 | n/a | n/a | n/a | [282] |

| municipal or agro or diary wastewater | two-chamber | 1000 | copper | copper | 99 | n/a | n/a | n/a | |

| potato and sludge | eleven two-chamber | 275 | carbon felt | carbon felt | 85 | n/a | 250 mA/m2 | 54–93 | [283] |

| municipal wastewater plants xylan vs. glucose | cell-constructed wetland MFC | n/a | graphite | graphite | n/a | 2.91–6.09 mW/m2 | n/a | n/a | [284] |

| landfill leachate | circular MFC | 934 | graphite plate | waterproof woven carbon cloth | 62 | 24–31 mW/m2 | n/a | n/a | [285] |

| landfill leachate | large, circular MFC | 18,300 | graphite plate | waterproof woven carbon cloth | n/a | 635 mV | n/a | n/a | |

| wood hydrothermal treatment wastewater with municipal wastewater | single-chamber | 28 | carbon fiber brush | carbon paper | 75 | 70–360 mW/m2 | n/a | 40 | [286] |

| artificial wastewater vs. municipal wastewater | 50 stacked MFCs | 1000 | coal GAC | coal GAC | 70–90 | 3.64–7.58 mW/m2 | n/a | n/a | [287] |

| municipal | horizontal plug flow and stackable MFC | 250,000 | carbon brush | carbon mesh | 86 | 116 mV | 0.435 A | n/a | [288] |

| domestic wastewater vs. glucose | cylindrical two-chamber | 805 | carbon fiber | carbon fiber | n/a | 13.6–91 mW/m3 | n/a | n/a | [289] |

| olive oil and molasses | n/a | n/a | n/a | n/a | 53 | 36 mW/m2 | n/a | n/a | [290] |

| distillery spend wash vs. molasses | salt-bridged two-chamber | 500 | graphite | graphite | n/a | 35.42–65.92 mW/m2 | n/a | n/a | [291] |

| molasses | double-chamber mediator-less MFC | 300 | carbon cloth | carbon cloth | 67 | 2.425 W/m2 | n/a | n/a | [191] |

| black liquor from paper pulp | double-chamber mediator-less MFC | 300 | carbon cloth | carbon cloth | 78 | 3.55 W/m2 | n/a | n/a | |

| activated sludge with cattle manure slurry vs. domestic sewage with cattle manure slurry | single-chamber air-cathode | n/a | graphite fiber | activated carbon with PTFE | n/a | 520–577 mV | n/a | 65–70 | [283] |

| onion vs. onions with tomatoes and potatoes | single-chamber | n/a | zinc | copper | n/a | 1.01 mV–10.2 V | n/a | n/a | [284] |

| sewage sludge vs. carbon manure vs. cow manure | salt-bridged two-chamber | n/a | n/a | n/a | n/a | 229–2500 mV/L | n/a | n/a | [285,286] |

| cow manure with slurry | pilot MFC | n/a | n/a | n/a | 98 | 1.6136 mV | n/a | n/a | [287] |

| cow dung vs. distillery wastewater | n/a | n/a | n/a | n/a | n/a | 230–2300 mV/L | n/a | n/a | [288] |

| cow manure with fruit and soil waste | two-chamber | n/a | graphite rod | graphite rod | n/a | 210 mW/m2 | n/a | n/a | [298] |

| vegetable waste with molasses | six U-shaped dual-chamber | n/a | graphite rod | graphite rod | n/a | 44,400–104,400 mW/m2 | n/a | 63–82 | [299] |

| molasses vs. whey, bulgur, olive mill wastewater | single-chamber | n/a | n/a | n/a | n/a | 0.37–0.55 V | n/a | n/a | [300] |

| kitchen waste vs. cow dung vs. palm kernel | single-chamber air-cathode | n/a | n/a | n/a | n/a | 47.9–279.52 mW/m2 | n/a | n/a | [301] |

| cattle manure with or without yogurt | dual-chamber | n/a | graphite, aluminium | graphite, aluminium | n/a | 1.170–1.122 V | n/a | n/a | [302] |

| dumping rubbish | multiple-chamber MFCs | n/a | n/a | n/a | n/a | 5.78 V | 5.03 A | n/a | [303] |

| dairy and distillery wastewater with cow dung | dual-chamber | n/a | graphite rod | air-cathode | 77 | 3.4 W/m2 | n/a | n/a | [304] |

| dairy and distillery wastewater with cow dung | single-chamber | n/a | graphite rod | air-cathode | 85 | 4.6 W/m2 | n/a | n/a | |

| distillery wastewater vs. vermi compost | n/a | n/a | n/a | n/a | 99 | 131–699 mV | n/a | n/a | [305] |

| kitchen garbage vs. bamboo waste | single-chamber | n/a | carbon fiber | carbon fiber | n/a | 540–620 mV | n/a | n/a | [93] |

| sludge vs. urine | single-chamber | n/a | carbon veil | PTFE over carbon veil | n/a | 40.38 mW/m2 | n/a | n/a | [306] |

| garden waste | single-chamber | n/a | graphite fiber brush | carbon cloth | 84 | n/a | n/a | 20 | [307] |

| food waste | single-chamber | n/a | graphite fiber brush | carbon cloth | 69 | n/a | n/a | 25 | |

| paper/cardboard waste | single chamber | n/a | graphite fiber brush | carbon cloth | 76 | n/a | n/a | 21 | |

| garden with food and paper/cardboard waste | single-chamber | n/a | graphite fiber brush | carbon cloth | 78 | n/a | n/a | 24 | |

| sewage sludge and kitchen waste | single-chamber | n/a | zinc plate | copper plate | n/a | 263–918 mV | n/a | n/a | [308] |

References

- Tollefson, J.; Monastersky, R. Awash in carbon. Nature 2012, 491, 654–655. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Mu, W.; Liu, M.; Zhang, X.; Cai, H.; Deng, Y. Solar-induced direct biomass-to-electricity hybrid fuel cell using polyoxometalates as photocatalyst and charge carsrier. Nat. Commun. 2014, 5, 3208. [Google Scholar] [CrossRef] [PubMed]

- Moradian, J.M.; Fang, Z.; Yong, Y.-C. Recent advances on biomass-fueled microbial fuel cell. Bioresour. Bioprocess. 2021, 8, 14. [Google Scholar] [CrossRef]

- O’Mahoney, A.; Thorne, F.; Denny, E. A cost-benefit analysis of generating electricity from biomass. Energy Policy 2013, 57, 347–354. [Google Scholar] [CrossRef]

- Sauer, T.P.; Casaril, L.; Oberziner, A.L.B.; José, H.J.; Moreira, R.d.F.P.M. Advanced oxidation processes applied to tannery wastewater containing direct black 38—Elimination and degradation kinetics. J. Hazard. Mater. 2006, 135, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Pandis, P.K.; Kalogirou, C.; Kanellou, E.; Vaitsis, C.; Savvidou, M.G.; Sourkouni, G.; Zorpas, A.A.; Argirusis, C. Key points of advanced oxidation processes (aops) for wastewater, organic pollutants and pharmaceutical waste treatment: A mini review. Chem Eng. 2022, 6, 8. [Google Scholar] [CrossRef]

- Suthanthararajan, R.; Ravindranath, E.; Chits, K.; Umamaheswari, B.; Ramesh, T.; Rajamam, S. Membrane application for recovery and reuse of water from treated tannery wastewater. Desalination 2004, 164, 151–156. [Google Scholar] [CrossRef]

- Oturan, M.A. Electrochemical advanced oxidation technologies for removal of organic pollutants from water. Environ. Sci. Pollut. Res. 2014, 21, 8333–8335. [Google Scholar] [CrossRef]

- Costa, C.R.; Botta, C.M.R.; Espindola, E.L.G.; Olivi, P. Electrochemical treatment of tannery wastewater using dsa® electrodes. J. Hazard. Mater. 2008, 153, 616–627. [Google Scholar] [CrossRef]

- Ding, W.; Cheng, S.; Yu, L.; Huang, H. Effective swine wastewater treatment by combining microbial fuel cells with flocculation. Chemosphere 2017, 182, 567–573. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dzienis, L.; Dębowski, M.; Zieliński, M. Optimisation of methane fermentation as a valorisation method for food waste products. Biomass Bioenergy 2021, 144, 105913. [Google Scholar] [CrossRef]

- Caruso, M.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent updates on the use of agro-food waste for biogas production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas production from organic wastes: Integrating concepts of circular economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- Nwokolo, N.; Mukumba, P.; Obileke, K.; Enebe, M. Waste to energy: A focus on the impact of substrate type in biogas production. Processes 2020, 8, 1224. [Google Scholar] [CrossRef]

- Singh, H.; Tomar, S.; Qureshi, K.A.; Jaremko, M.; Rai, P.K. Recent advances in biomass pretreatment technologies for biohydrogen production. Energies 2022, 15, 999. [Google Scholar] [CrossRef]

- Lima, R.B.; Raza, R.; Qin, H.; Li, J.; Lindström, M.E.; Zhu, B. Direct lignin fuel cell for power generation. RSC Adv. 2013, 3, 5083–5089. [Google Scholar] [CrossRef]

- Rabaey, K.; Verstraete, W. Microbial fuel cells: Novel biotechnology for energy generation. Trends Biotechnol. 2005, 23, 291–298. [Google Scholar] [CrossRef]

- Mathuriya, A.S.; Yakhmi, J.V. Microbial fuel cells—Applications for generation of electrical power and beyond. Crit. Rev. Microbiol. 2016, 42, 127–143. [Google Scholar] [CrossRef]

- Beegle, J.R.; Borole, A.P. Energy production from waste: Evaluation of anaerobic digestion and bioelectrochemical systems based on energy efficiency and economic factors. Renew. Sustain. Energy Rev. 2018, 96, 343–351. [Google Scholar] [CrossRef]

- Schröder, U. Cover picture: Microbial fuel cells and microbial electrochemistry: Into the next century! (chemsuschem 6/2012). ChemSusChem 2012, 5, 957. [Google Scholar] [CrossRef]

- Tommasi, T.; Salvador, G.P.; Quaglio, M. New insights in microbial fuel cells: Novel solid phase anolyte. Sci. Rep. 2016, 6, 29091. [Google Scholar] [CrossRef] [PubMed]

- Offei, F.; Mensah, M.; Kemausuor, F.; Thygesen, A. A biorefinery approach to bioethanol and bioelectricity co-production from tropical seaweeds. J. Appl. Phycol. 2019, 31, 3899–3913. [Google Scholar] [CrossRef]

- Moradian, J.M.; Xu, Z.A.; Shi, Y.T.; Fang, Z.; Yong, Y.C. Efficient biohydrogen and bioelectricity production from xylose by microbial fuel cell with newly isolated yeast of cystobasidium slooffiae. Int. J. Energy Res. 2019, 44, 325–333. [Google Scholar] [CrossRef]

- Kiely, P.D.; Regan, J.M.; Logan, B.E. The electric picnic: Synergistic requirements for exoelectrogenic microbial communities. Curr. Opin. Biotechnol. 2011, 22, 378–385. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Wang, Y.Z.; Fang, Z.; Shi, Y.T.; Cheng, Q.W.; Chen, Y.X.; Shi, W.; Yong, Y.C. Single cell electron collectors for highly efficient wiring-up electronic abiotic/biotic interfaces. Nat. Commun. 2020, 11, 4087. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Poon, K.; Choi, M.M.; Wang, R. Using live algae at the anode of a microbial fuel cell to generate electricity. Environ. Sci. Pollut. Res. Int. 2015, 22, 15621–15635. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Mangwani, N. Recent developments in microbial fuel cells: A review. J. Sci. Ind. Res. 2010, 69, 727–732. [Google Scholar]

- Rahimnejad, M.; Bakeri, G.; Ghasemi, M.; Zirehpour, A. A review on the role of proton exchange membrane on the performance of microbial fuel cell. Polym. Adv. Technol. 2014, 25, 1426–1432. [Google Scholar] [CrossRef]

- Ziara, R.M.M.; Dvorak, B.I.; Subbiah, J. Sustainable waste-to-energy technologies: Bioelectrochemical systems. In Sustainable Food Waste-To-Energy Systems; Academic Press: Cambridge, MA, USA, 2018; Chapter 7; pp. 111–140. [Google Scholar]

- Chaturvedi, V.; Verma, P. Microbial fuel cell: A green approach for the utilization of waste for the generation of bioelectricity. Bioresour. Bioprocess. 2016, 3, 38. [Google Scholar] [CrossRef]

- Kondaveeti, S.; Mohanakrishna, G.; Pagolu, R.; Kim, I.W.; Kalia, V.C.; Lee, J.K. Bioelectrogenesis from raw algal biomass through microbial fuel cells: Effect of acetate as co-substrate. Indian J. Microbiol. 2019, 59, 22–26. [Google Scholar] [CrossRef]

- Wlodarczyk, P.P.; Wlodarczyk, B. Wastewater treatment and electricity production in a microbial fuel cell with cu–b alloy as the cathode catalyst. Catalysts 2019, 9, 572. [Google Scholar] [CrossRef]

- Rajesh, P.P.; Noori, M.T.; Ghangrekar, M.M. Controlling methanogenesis and improving power production of microbial fuel cell by lauric acid dosing. Water Sci. Technol. 2014, 70, 1363–1369. [Google Scholar] [CrossRef] [PubMed]

- Walter, X.A.; Greenman, J.; Ieropoulos, I.A. Intermittent load implementation in microbial fuel cells improves power performance. Bioresour. Technol. 2014, 172, 365–372. [Google Scholar] [CrossRef] [PubMed]

- Winfield, J.; Chambers, L.D.; Rossiter, J.; Greenman, J.; Ieropoulos, I. Towards disposable microbial fuel cells: Natural rubber glove membranes. Int. J. Hydrogen Energy 2014, 39, 21803–21810. [Google Scholar] [CrossRef]

- Winfield, J.; Greenman, J.; HusOn, D.; Ieropoulos, I.A. Comparing terracotta and earthenware for multiple functionalities in microbial fuel cells. Bioprocess Biosyst. Eng. 2013, 36, 1913–1921. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, V.; Mohebbi-Kalhoru, D.; Samini, A. Ceramic-based microbial fuel cells (mfcs): A review. Int. J. Hydrogen Energy 2017, 42, 1672–1690. [Google Scholar] [CrossRef]

- Zhou, L.; Liao, C.; Li, T.; Du, Q.; Wan, L.; Li, N.; Pan, X.; Wang, X. Regeneration of activated carbon air-cathodes by half-wave rectified alternating fields in microbial fuel cells. Appl. Energy 2018, 219, 199–206. [Google Scholar] [CrossRef]

- Chen, S.; Patil, S.A.; Schroder, U. A high-performance rotating graphite fiber brush air-cathode for microbial fuel cells. Appl. Energy 2018, 211, 1089–1094. [Google Scholar] [CrossRef]

- Tremouli, A.; Karydogiannis, I.; Pandis, P.K.; Papadopoulou, K.; Argirousis, C.; Stathopoulos, V.N.; Lyberatos, G. Bioelectricity production from fermentable household waste extract using a single chamber microbial fuel cell. Energy Procedia 2019, 161, 2–9. [Google Scholar] [CrossRef]

- Tremouli, A.; Pandis, P.K.; Kamperidis, T.; Stathopoulos, V.N.; Argirousis, C.; Lyberatos, G. Performance assessment of a four-air cathode membraneless microbial fuel cell stack for wastewater treatment and energy extraction. E3S Web Conf. EDP Sci. 2019, 116, 93. [Google Scholar] [CrossRef]

- Tremouli, A.; Pandis, P.K.; Karydogiannis, I.; Stathopoulos, V.N.; Argirusis, C.; Lyberatos, G. Operation and electro (chemical) characterization of a microbial fuel cell stack fed with fermentable household waste extract. Glob. NEST J. 2019, 21, 253–257. [Google Scholar]

- Tremouli, A.; Kamperidis, T.; Pandis, P.K.; Argirusis, C.; Lyberatos, G. Exploitation of digestate from thermophilic and mesophilic anaerobic digesters fed with fermentable food waste using the mfc technology. Waste Biomass Valorization 2021, 12, 5361–5370. [Google Scholar] [CrossRef]

- Alfonta, L. Genetically engineered microbial fuel cells. Electroanalysis 2010, 22, 822–831. [Google Scholar] [CrossRef]

- Li, F.; An, X.; Wu, D.; Xu, J.; Chen, Y.; Li, W.; Cao, Y.; Guo, X.; Lin, X.; Li, C.; et al. Engineering microbial consortia for high-performance cellulosic hydrolyzates-fed microbial fuel cells. Front. Microbiol. 2019, 10, 409. [Google Scholar] [CrossRef]

- Zhao, J.; Li, F.; Cao, Y.; Zhang, X.; Chen, T.; Song, H.; Wang, Z. Microbial extracellular electron transfer and strategies for engineering electroactive microorganisms. Biotechnol. Adv. 2020, 53, 107682. [Google Scholar] [CrossRef]

- Shanmuganathan, P.; Ramachandra, M.A.; Rajasulochana, A. Factors affecting the performance of microbial fuel cells. Int. J. Mech. Eng. Technol. 2018, 9, 137–148. [Google Scholar]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Dowdy, F.R.; Kawakita, R.; Lange, M.; Simmons, C.W. Meta-analysis of microbial fuel cells using waste substrates. Appl. Biochem. Biotechnol. 2018, 185, 221–232. [Google Scholar] [CrossRef]

- Nosek, D.; Jachimowicz, P.; Cydzik-Kwiatowska, A. Anode modification as an alternative approach to improve electricity generation in microbial fuel cells. Energies 2020, 13, 6596. [Google Scholar] [CrossRef]

- Pant, D.; Van Bogaert, G.; Diels, L.; Vanbroekhoven, K. A review of the substrates used in microbial fuel cells (mfcs) for sustainable energy production. Bioresour. Technol. 2010, 101, 1533–1543. [Google Scholar] [CrossRef]

- Mamma, D. Food wastes: Feedstock for value-added products. Fermentation 2020, 6, 47. [Google Scholar] [CrossRef]

- Kiely, P.D.; Cusick, R.; Call, D.F.; Selembo, P.A.; Regan, J.M.; Logan, B.E. Anode microbial communities produced by changing from microbial fuel cell to microbial electrolysis cell operation using two different wastewaters. Bioresour. Technol. 2011, 102, 388–394. [Google Scholar] [CrossRef]

- Flimban, S.G.A.; Ismail, I.M.I.; Kim, T.; Oh, S.-E. Overview of recent advancements in the microbial fuel cell from fundamentals to applications: Design, major elements, and scalability. Energies 2019, 12, 3390. [Google Scholar] [CrossRef]

- Du, Z.; Li, H.; Gu, T. A state of the art review on microbial fuel cells: A promising technology for wastewater treatment and bioenergy. Biotechnol. Adv. 2007, 25, 464–482. [Google Scholar] [CrossRef]

- Tian, Y.; Mei, X.; Liang, Q.; Wu, D.; Ren, N.; Xing, D. Biological degradation of potato pulp waste and microbial community structure in microbial fuel cells. RSC Adv. 2017, 7, 8376–8380. [Google Scholar] [CrossRef]

- Du, H.; Li, F. Size effects of potato waste on its treatment by microbial fuel cell. Environ. Technol. 2016, 37, 1305–1313. [Google Scholar] [CrossRef]

- Durruty, I.; Bonanni, P.S.; Gonzalez, J.F.; Busalmen, J.P. Evaluation of potato-processing wastewater treatment in a microbial fuel cell. Bioresour. Technol. 2012, 105, 81–87. [Google Scholar] [CrossRef]

- Iigatani, R.; Ito, T.; Watanabe, F.; Nagamine, M.; Suzuki, Y.; Inoue, K. Electricity generation from sweet potato-shochu waste using microbial fuel cells. J. Biosci. Bioeng. 2019, 128, 56–63. [Google Scholar] [CrossRef]

- Shrestha, N.; Fogg, A.; Wilder, J.; Franco, D.; Komisar, S.; Gadhamshetty, V. Electricity generation from defective tomatoes. Bioelectrochemistry 2016, 112, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Mohan, S.V.; Mohanakrishna, G.; Sarma, P.N. Composite vegetable waste as renewable resource for bioelectricity generation through non-catalyzed open-air cathode microbial fuel cell. Bioresour. Technol. 2010, 101, 970–976. [Google Scholar] [CrossRef]

- Tao, K.; Quan, X.; Quan, Y. Composite vegetable degradation and electricity generation in microbial fuel cell with ultrasonic pretreatment. Environ. Eng. Manag. J. 2013, 12, 1423–1427. [Google Scholar]

- Javed, M.M.; Nisar, M.A.; Muneer, B.; Ahmad, M.U. Production of bioelectricity from vegetable waste extract by designing a u-shaped microbial fuel cell. Pak. J. Zool. 2017, 49, 711–716. [Google Scholar] [CrossRef]

- Cercado-Quezada, B.; Delia, M.L.; Bergel, A. Testing various food-industry wastes for electricity production in microbial fuel cell. Bioresour. Technol. 2010, 101, 2748–2754. [Google Scholar] [CrossRef] [PubMed]

- Boghani, H.; Kim, J.R.; Dinsdale, R.M.; Guwy, A.J.; Premier, G.C. Reducing the burden of food processing washdown wastewaters using microbial fuel cells. Biochem. Eng. J. 2017, 117, 210–217. [Google Scholar] [CrossRef]

- Velasquez-Orta, S.B.; Head, I.M.; Curtis, T.P.; Scott, K. Factors affecting current production in microbial fuel cells using different industrial wastewaters. Bioresour. Technol. 2011, 102, 5105–5112. [Google Scholar] [CrossRef] [PubMed]

- Liakos, T.I.; Sotiropoulos, S.; Lazaridis, N.K. Electrochemical and bio-electrochemical treatment of baker’s yeast effluents. J. Environ. Chem. Eng. 2017, 5, 699–708. [Google Scholar] [CrossRef]

- Rikame, S.S.; Mungray, A.A.; Mungray, A.K. Electricity generation from acidogenic food waste leachate using dual chamber mediator less microbial fuel cell. Int. Biodeterior. Biodegrad. 2012, 75, 131–137. [Google Scholar] [CrossRef]

- Li, X.M.; Cheng, K.Y.; Wong, J.W. Bioelectricity production from food waste leachate using microbial fuel cells: Effect of nacl and ph. Bioresour. Technol. 2013, 149, 452–458. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Lim, B.S. Electric power generation from treatment of food waste leachate using microbial fuel cell. Environ. Eng. Res. 2017, 22, 157–161. [Google Scholar] [CrossRef]

- Pant, D.; Van Bogaert, G.; Alvarez-Gallego, Y.; Diels, L.; Vanbroekhoven, K. Evaluation of bioelectrogenic potential of four industrial effluents as substrate for low cost microbial fuel cells operation. Environ. Eng. Manag. J. 2016, 15, 1897–1904. [Google Scholar] [CrossRef]

- Mohamed, H.O.; Obaid, M.; Khalil, K.A.; Barakat, N.A. Power generation from unconditioned industrial wastewaters using commercial membranes-based microbial fuel cells. Int. J. Hydrogen Energy 2016, 41, 4251–4263. [Google Scholar] [CrossRef]

- Zuraidah, R.; Nur, S.; Norilhamiah, Y.; Aida, S.A.; Amelia, M.; Muhammad, F.M. Microbial fuel cell for conversion of chemical energy to electrical energy from food industry wastewater. J. Environ. Sci. Technol. 2016, 9, 481–485. [Google Scholar]

- Oh, S.E.; Logan, B.E. Hydrogen and electricity production from a food processing wastewater using fermentation and microbial fuel cell technologies. Water Res. 2005, 39, 4673–4682. [Google Scholar] [CrossRef]

- Rahman, W.; Yusup, S.; Mohammad, S.N.A.A. Screening of fruit waste as substrate for microbial fuel cell (mfc). In Proceedings of the 4th Internationa Sciences, Technology and Engineering conference (ISTEC), Exploring materials for the future, Brescia, Italy, 8–10 April 2020. [Google Scholar]

- Frattini, D.; Falcuccia, G.; Minutilloa, M.; Feronea, C.; Cioffia, R.; Jannellia, E. On the effect of different configurations in air-cathode mfcs fed by composite food waste for energy harvesting. Chem. Eng. 2016, 49, 85–90. [Google Scholar]

- Xin, X.; Ma, Y.; Liu, Y. Electric energy production from food waste: Microbial fuel cells versus anaerobic digestion. Bioresour. Technol. 2018, 255, 281–287. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Ahn, Y. Enhanced bioelectricity harvesting in microbial fuel cells treating food waste leachate produced from biohydrogen fermentation. Bioresour. Technol. 2015, 183, 53–60. [Google Scholar] [CrossRef]

- Jia, J.; Tang, Y.; Liu, B.; Wu, D.; Ren, N.; Xing, D. Electricity generation from food wastes and microbial community structure in microbial fuel cells. Bioresour. Technol. 2013, 144, 94–99. [Google Scholar] [CrossRef]

- Chandrasekhar, K.; Amulya, K.; Mohan, S.V. Solid phase bio-electrofermentation of food waste to harvest value-added products associated with waste remediation. Waste Manag. 2015, 45, 57–65. [Google Scholar] [CrossRef]

- Goud, R.K.; Babu, P.S.; Mohan, S.V. Canteen based composite food waste as potential anodic fuel for bioelectricity generation in single chambered microbial fuel cell (mfc): Bio-electrochemical evaluation under increasing substrate loading condition. Int. J. Hydrogen Energy 2011, 36, 6210–6218. [Google Scholar] [CrossRef]

- Mohan, S.V.; Chandrasekhar, K. Solid phase microbial fuel cell (smfc) for harnessing bioelectricity from composite food waste fermentation: Influence of electrode assembly and buffering capacity. Bioresour. Technol. 2011, 102, 7077–7085. [Google Scholar] [CrossRef] [PubMed]

- Sangeetha, T.; Muthukumar, M. Catholyte performance as an influencing factor on electricity production in a dual-chambered microbial fuel cell employing food processing wastewater. Energy Sources Part A Recovery Util. Environ. Eff. 2011, 33, 1514–1522. [Google Scholar] [CrossRef]

- Hou, Q.; Pei, H.; Hu, W.; Jiang, L.; Yu, Z. Mutual facilitations of food waste treatment, microbial fuel cell bioelectricity generation and chlorella vulgaris lipid production. Bioresour. Technol. 2016, 203, 50–55. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.D.; Chang, H.N.; Han, J.I. Performance of microbial fuel cell with volatile fatty acids from food wastes. Biotechnol. Lett. 2011, 33, 705–714. [Google Scholar] [CrossRef] [PubMed]

- Asefi, B.; Li, S.L.; Moreno, H.A.; Sanchez-Torres, V.; Hu, A.; Li, J.; Yu, C.P. Characterization of electricity production and microbial community of food waste-fed microbial fuel cells. Process Saf. Environ. Prot. 2019, 125, 83–91. [Google Scholar] [CrossRef]

- Ma, H.; Peng, C.; Jia, Y.; Wang, Q.; Tu, M.; Gao, M. Effect of fermentation stillage of food waste on bioelectricity production and microbial community structure in microbial fuel cells. R Soc. Open. Sci. 2018, 5, 180457. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Li, H.; Ma, H.; Peng, C.; Wu, W.; Yu, Z.; Wang, Q. Electricity enhancement by mfcs from food waste ethanol fermentation recycle stillage effect of dilution ratio and addition of tween 80. Chem. Sel. 2020, 5, 5701–5705. [Google Scholar] [CrossRef]

- Abedule, A.P.; Aderiye, B.I.; Adebayo, A.A. Improving bioelectricity generation of microbial fuel cell (mfc) with mediators using kitchen waste as substrate. Ann. Appl. Microbiol. Biotechnol. J. 2018, 2, 1008. [Google Scholar]

- Chatzikonstantinou, D.; Tremouli, A.; Papadopoulou, K.; Kanellos, G.; Lampropoulos, I.; Lyberatos, G. Bioelectricity production from fermentable household waste in a dual-chamber microbial fuel cell. Waste Manag. Res. 2018, 36, 1037–1042. [Google Scholar] [CrossRef]

- Kamperidis, T.; Pandis, P.K.; Argirusis, C.; Lyberatos, G.; Tremouli, A. Effect of food waste condensate concentration on the performance of microbial fuel cells with different cathode assemblies. Sustainability 2022, 14, 2625. [Google Scholar] [CrossRef]

- Pandis, P.K.; Kamperidis, T.; Bariamis, K.; Vlachos, I.; Argirusis, C.; Stathopoulos, V.N.; Lyberatos, G.; Tremouli, A. Comparative study of different production methods of activated carbon cathodic electrodes in single chamber mfc treating municipal landfill leachate. Appl. Sci. 2022, 12, 2991. [Google Scholar] [CrossRef]

- Moqsud, M.A.; Omine, K.; Yasufuku, N.; Bushra, Q.S.; Hyodo, M.; Nakata, Y. Bioelectricity from kitchen and bamboo waste in a microbial fuel cell. Waste Manag. Res. 2014, 32, 124–130. [Google Scholar] [CrossRef]

- Kosseva, M.R. Sources, characterization, and composition of food industry wastes. In Food Industry Wastes; Academic Press: Cambridge, MA, USA, 2013; Chapter 3; pp. 37–60. [Google Scholar]

- You, S.-J.; Zhang, J.-N.; Yuan, Y.-X.; Ren, N.-Q.; Wang, X.-H. Development of microbial fuel cell with anoxic/oxic design for treatment of saline seafood wastewater and biological electricity generation. J. Chem. Technol. Biotechnol. 2010, 85, 1077–1083. [Google Scholar] [CrossRef]

- Sun, H.-L. Electricity generation from seafood wastewater in a single- and dual-chamber microbial fuel cell with cotmpp oxygen-reduction electrocatalyst. J. Chem. Technol. Biotechnol. 2012, 87, 1167–1172. [Google Scholar] [CrossRef]

- Jayashree, C.; Tamilarasan, K.; Rajkumar, M.; Arulazhagan, P.; Yogalakshmi, K.N.; Srikanth, M.; Banu, J.R. Treatment of seafood processing wastewater using upflow microbial fuel cell for power generation and identification of bacterial community in anodic biofilm. J. Environ. Manag. 2016, 180, 351–358. [Google Scholar] [CrossRef] [PubMed]

- Jamal, M.T.; Pugazhendi, A.; Jeyakumar, R.B. Application of halophiles in air cathode mfc for seafood industrial wastewater treatment and energy production under high saline condition. Environ. Technol. Innov. 2020, 20, 101119. [Google Scholar] [CrossRef]

- Amrutha, K.M.; Aswathi, M. Bioelectricity production from seafood processing wastewater using microbial fuel cell. Int. Res. J. Eng. Technol. 2019, 6, 376–379. [Google Scholar]

- Dongre, A.; Sogani, M.; Sonu, K.; Syed, Z.; Sharma, G. Treatment of dairy wastewaters: Evaluating microbial fuel cell tools and mechanism. In Environmental Change and Sustainability; IntechOpen: London, UK, 2020. [Google Scholar]

- Demirel, B.; Yenigun, O.; Onay, T.T. Anaerobic treatment of dairy wastewaters: A review. Process Biochem. 2005, 40, 2583–2595. [Google Scholar] [CrossRef]

- Mohan, S.V.; Mohanakrishna, G.; Velvizhi, G.; Babu, V.L.; Sarma, P.N. Bio-catalyzed electrochemical treatment of real field dairy wastewater with simultaneous power generation. Biochem. Eng. J. 2010, 51, 32–39. [Google Scholar] [CrossRef]

- Cercado-Quezada, B.; Delia, M.-L.; Bergel, A. Treatment of dairy wastes with a microbial anode formed from garden compost. J. Appl. Electrochem. 2010, 40, 225–232. [Google Scholar] [CrossRef]

- Luo, H.; Xu, G.; Lu, Y.; Liu, G.; Zhang, R.; Li, X.; Zheng, X.; Yu, M. Electricity generation in a microbial fuel cell using yogurt wastewater under alkaline conditions. RSC Adv. 2017, 7, 32826–32832. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, Q.; Jiao, Y.; Lee, D.J. Long-term operation of manure-microbial fuel cell. Bioresour. Technol. 2015, 180, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Faria, A.; Gonçalves, L.; Peixoto, J.M.; Peixoto, L.; Brito, A.G.; Martins, G. Resources recovery in the dairy industry: Bioelectricity production using a continuous microbial fuel cell. J. Clean. Prod. 2017, 140, 971–976. [Google Scholar] [CrossRef]

- Jayashree, C.; Janshi, G.; Yeom, I.T.; Adish Kumar, S.; Rajesh Banu, R. Effect of low temperature thermo-chemical pretreatment of dairy waste activated sludge on the performance of microbial fuel cell. Int. J. Electrochem. Sci. 2014, 9, 5732–5742. [Google Scholar]

- Rago, L.; Baeza, J.A.; Guisola, A. Bioelectrochemical hydrogen production with cheese whey as sole substrate. J. Chem. Technol. Biotechnol. 2017, 92, 173–179. [Google Scholar] [CrossRef]

- Nasirahmadi, S.; Safekordi, A.A. Whey as a substrate for generation of bioelectricity in microbial fuel cell using E.coli. Int. J. Environ. Sci. Tech. 2011, 8, 823–830. [Google Scholar] [CrossRef]

- Elakkiya, E.; Matheswaran, M. Comparison of anodic metabolisms in bioelectricity production during treatment of dairy wastewater in microbial fuel cell. Bioresour. Technol. 2013, 136, 407–412. [Google Scholar] [CrossRef] [PubMed]

- Mansoorian, H.J.; Mahvi, A.H.; Jafari, A.J.; Khanjani, N. Evaluation of dairy industry wastewater treatment and simultaneous bioelectricity generation in a catalyst-less and mediator-less membrane microbial fuel cell. J. Saudi Chem. Soc. 2016, 20, 88–100. [Google Scholar] [CrossRef]

- Drisya, C.M.; Manjunath, N.T. Dairy wastewater treatment and electricity generation using microbial fuel cell. Int. Res. J. Eng. Technol. 2017, 4, 1293–1296. [Google Scholar]

- Choudhury, P.; Ray, R.N.; Tiwari, O.N.; Bandyopadhyay, T.K.; Muthurai, M.; Bhunia, B. Strategies for improvement of microbial fuel cell performance via stable power generation from real dairy wastewater. Fuel 2021, 288, 119653. [Google Scholar] [CrossRef]

- Choudhury, P.; Bhunia, B.; Bandyopadhyay, T.K.; Ray, R.N. The overall performance improvement of microbial fuel cells connected in series with dairy wastewater treatment. J. Electrochem. Sci. Technol. 2021, 12, 101–111. [Google Scholar] [CrossRef]

- Retnaningrum, E.; Wilopo, W. Performance and bacterial composition of anodic biofilms in microbial fuel cell using dairy wastewater. AIP Conf. Proc. 2016, 1744, 20018. [Google Scholar] [CrossRef]

- Sivakumar, D. Pollution reduction and electricity production from dairy industry wastewater with microbial fuel cell. Glob. J. Environ. Sci. Manag. 2020, 6, 145–164. [Google Scholar]

- Al-saned, A.J.O.; Kitafa, B.A.; Badday, A.S. Microbial fuel cells (mfc) in the treatment of dairy wastewater. In Proceedings of the Materials Science and Engineering, Volume 1067, 4th International Conference on Engineering Sciences (ICES 2020), Kerbala, Iraq, 5–6 December 2020; p. 1067. [Google Scholar]

- Khajeh, R.T.; Aber, S.; Nofouzi, K.; Ebrahimi, S. Treatment of mixed dairy and dye wastewater in anode of microbial fuel cell with simultaneous electricity generation. Environ. Sci. Pollut. Res. 2020, 27, 43711–43723. [Google Scholar] [CrossRef] [PubMed]

- Jaiyeola, A.T.; Bwapwa, J.K. Treatment technology for brewery wastewater in a water-scarce country: A review. South Afr. J. Sci. 2015, 112, 8. [Google Scholar]

- Simate, G.S.; Cluett, J.; Iyuke, S.E.; Musapatika, E.T.; Ndlovu, S.; Walubita, L.F.; Alvarez, A.E. The treatment of brewery wastewater for reuse: State of the art. Desalination 2011, 273, 235–247. [Google Scholar] [CrossRef]

- Amenorfenyo, D.K.; Huang, X.; Zhang, Y.; Zeng, Q.; Zhang, N.; Ren, J.; Huang, Q. Microalgae brewery wastewater treatment: Potentials, benefits and the challenges. Int. J. Environ. Res. Public Health 2019, 16, 1910. [Google Scholar] [CrossRef]

- Ainebyona, P.; Banadda, N.; Kiggundu, N. Extracting economic value from breweries wastewater: A review. MOJ Ecol. Environ. Sci. 2021, 6, 8–13. [Google Scholar] [CrossRef]

- Wang, H.; Qu, Y.; Li, D.; Ambuchi, J.J.; He, W.; Zhou, X.; Liu, J.; Feng, Y. Cascade degradation of organic matters in brewery wastewater using a continuous stirred microbial electrochemical reactor and analysis of microbial communities. Sci. Rep. 2016, 6, 27023. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, X.; Logan, B.E.; Lee, H. Brewery wastewater treatment using air-cathode microbial fuel cells. Appl. Microbiol. Biotechnol. 2008, 78, 873–880. [Google Scholar] [CrossRef]

- Arun, S.; Sinharoy, A.; Pakshirajan, K.; Lens, P.N.L. Algae based microbial fuel cells for wastewater treatment and recovery of value-added products. Renew. Sustain. Energy Rev. 2020, 132, 110041. [Google Scholar] [CrossRef]

- Savvidou, M.G.; Katsabea, A.; Kotidis, P.; Mamma, D.; Lymperopoulou, T.V.; Kekos, D.; Kolisis, F.N. Studies on the catalytic behavior of a membrane-bound lipolytic enzyme from the microalgae Nannochloropsis oceanica CCMP1779. Enzym. Microb. Technol. 2018, 116, 64–71. [Google Scholar] [CrossRef]

- Savvidou, M.G.; Banis, G.; Ferraro, A.; Molino, A.J.; Karatza, D.; Chianese, S.; Musmarra, D.; Kolisis, F.N.; Hristoforou, E. Production of magnetic modified microalgae using iron oxide nanoparticles and electroporation technique. Chem. Eng. Trans. 2019, 73, 13–18. [Google Scholar]

- Savvidou, M.G.; Ferraro, A.; Hristoforou, E.; Mamma, D.; Kekos, D.; Kolisis, F.N. Incorporation of magnetic nanoparticles into protoplasts of microalgae haematococcus pluvialis: A tool for biotechnological applications. Molecules 2020, 25, 5068. [Google Scholar] [CrossRef]

- Penteado, E.D.; Fernandez-Marchante, C.M.; Zaiat, M.; Canizares, P.; Gonzalez, E.R.; Rodrigo, M.A. Influence of sludge age on the performance of mfc treating winery wastewater. Chemosphere 2016, 151, 163–170. [Google Scholar] [CrossRef]

- Penteado, E.D.; Fernandez-Marchante, C.M.; Zaiat, M.; Cañizares, P.; Gonzalez, E.R.; Rodrigo, M.A.R. Energy recovery from winery wastewater using a dual chamber microbial fuel cell. J. Chem. Technol. Biotechnol. 2016, 91, 1802–1808. [Google Scholar] [CrossRef]

- Wen, Q.; Wu, Y.; Zhao, L.; Sun, Q. Production of electricity from the treatment of continuous brewery wastewater using a microbial fuel cell. Fuel 2010, 89, 1381–1385. [Google Scholar] [CrossRef]

- Yu, J.; Park, Y.; Kim, B.; Lee, T. Power densities and microbial communities of brewery wastewater-fed microbial fuel cells according to the initial substrates. Bioprocess Biosyst. Eng. 2015, 38, 85–92. [Google Scholar] [CrossRef]

- Wang, X.; Feng, Y.J.; Lee, H. Electricity production from beer brewery wastewater using single chamber microbial fuel cell. Water Sci. Technol. 2008, 57, 1117–1121. [Google Scholar] [CrossRef]

- Miran, W.; Nawaz, M.; Kadam, A.; Shin, S.; Heo, J.; Jang, J.; Lee, D.S. Microbial community structure in a dual chamber microbial fuel cell fed with brewery waste for azo dye degradation and electricity generation. Environ. Sci. Pollut. Res. Int. 2015, 22, 13477–13485. [Google Scholar] [CrossRef]

- Mshoperi, E.; Fogel, R.; Limson, J. Application of carbon black and iron phthalocyanine composites in bioelectricity production at a brewery wastewater fed microbial fuel cell. Acta 2014, 128, 311–317. [Google Scholar] [CrossRef]

- Pisutpaisal, N.; Sirisukpoca, U. Bioelectricity Generation from Wastewaters in Microbial Fuel Cells. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2012; Volume 512, pp. 1456–1460. [Google Scholar]

- Zhang, X.; Zhu, F.; Chen, L.; Zhao, Q.; Tao, G. Removal of ammonia nitrogen from wastewater using an aerobic cathode microbial fuel cell. Bioresour. Technol. 2013, 146, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Angosto, J.M.; Fernandez-Lopez, J.A.; Godinez, C. Brewery and liquid manure wastewaters as potential feedstocks for microbial fuel cells: A performance study. Environ. Technol. 2015, 36, 68–78. [Google Scholar] [CrossRef] [PubMed]

- Wen, Q.; Wu, Y.; Cao, D.; Zhao, L.; Sun, Q. Electricity generation and modeling of microbial fuel cell from continuous beer brewery wastewater. Bioresour. Technol. 2009, 100, 4171–4175. [Google Scholar] [CrossRef] [PubMed]

- Çetinkaya, A.Y.; Köroğlu, E.O.; Demir, N.M.; Baysoy, D.Y.; Özkaya, B.; Çakmakçı, M. Electricity production by a microbial fuel cell fueled by brewery wastewater and the factors in its membrane deterioration. Chin. J. Catal. 2015, 36, 1068–1076. [Google Scholar] [CrossRef]

- Zhuang, L.; Yuan, Y.; Wang, Y.; Zhou, S. Long-term evaluation of a 10-L serpentine-type microbial fuel cell stack treating brewery wastewater. Bioresour. Technol. 2012, 123, 406–412. [Google Scholar] [CrossRef]

- Dannys, E.; Green, T.; Wettlaufer, A.; Madhurnathakam, C.M.R.; Elkamel, A. Wastewater treatment with microbial fuel cells: A design and feasibility study for scale-up in microbreweries. J. Bioprocess. Biotech. 2016, 6, 1–6. [Google Scholar]

- Mathuriya, A.S.; Sharma, V.N. Treatment of brewery wastewater and production of electricity through microbial fuel cell technology. Int. J. Biotechnol. Biochem. 2010, 6, 71–78. [Google Scholar]

- Hung, Y.T.; Salman, H.; Awad, A. Olive Oil Waste Treatment. In Waste Treatment in the Food Processing Industry; CRC Press: Boca Raton, FL, USA, 2005; pp. 119–192. [Google Scholar]

- Guo, H.; Tang, S.; Xie, S.; Wang, P.; Huang, C.; Geng, X.; Jia, X.; Huo, H.; Li, X.; Zhang, J.; et al. The oil removal and the characteristics of changes in the composition of bacteria based on the oily sludge bioelectrochemical system. Sci. Rep. 2020, 10, 15474. [Google Scholar] [CrossRef]

- Hamamoto, K.; Miyahara, M.; Kouzuma, A.; Matsumoto, A.; Yoda, M.; Ishiguro, T.; Watanabe, K. Evaluation of microbial fuel cells for electricity generation from oil-contaminated wastewater. J. Biosci. Bioeng. 2016, 122, 589–593. [Google Scholar] [CrossRef]

- Yu, N.; Xing, D.; Li, W.; Yang, Y.; Li, Z.; Li, Y.; Ren, N. Electricity and methane production from soybean edible oil refinery wastewater using microbial electrochemical systems. Int. J. Hydrogen Energy 2017, 42, 96–102. [Google Scholar] [CrossRef]

- Baranitharan, E.; Khan, M.R.; Prasad, D.M.; Teo, W.F.; Tan, G.Y.; Jose, R. Effect of biofilm formation on the performance of microbial fuel cell for the treatment of palm oil mill effluent. Bioprocess Biosyst. Eng. 2015, 38, 15–24. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, U.; Jin, W.; Pervez, A.; Bhatti, Z.A.; Tariq, M.; Shaheen, S.; Iqbal, A.; Mahmood, Q. Anaerobic microbial fuel cell treating combined industrial wastewater: Correlation of electricity generation with pollutants. Bioresour. Technol. 2016, 200, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Firdous, S.; Jin, W.; Shahid, N.; Bhatti, Z.A.; Iqbal, A.; Abbasi, U.; Mahmood, Q.; Ali, A. The performance of microbial fuel cells treating vegetable oil industrial wastewater. Environ. Technol. Innov. 2018, 10, 143–151. [Google Scholar] [CrossRef]

- Mohanakrishna, G.; Abu-Reesh, I.M.; Kondaveeti, S.; Al-Raoush, R.I.; He, Z. Enhanced treatment of petroleum refinery wastewater by short-term applied voltage in single chamber microbial fuel cell. Bioresour. Technol. 2018, 253, 16–21. [Google Scholar] [CrossRef] [PubMed]

- Srikanth, S.; Kumar, M.; Singh, D.; Singh, M.P.; Das, B.P. Electro-biocatalytic treatment of petroleum refinery wastewater using microbial fuel cell (mfc) in continuous mode operation. Bioresour. Technol. 2016, 221, 70–77. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, Z.; Liu, L.; Zhang, F.; Liang, S. Treatment of oil wastewater and electricity generation by integrating constructed wetland with microbial fuel cell. Materials 2016, 9, 885. [Google Scholar] [CrossRef]

- Addi, H.; Mateo-Ramírez, F.; Ortiz-Martínez, V.M.; Salar-García, M.J.; Hernández-Fernández, F.J.; Pérez de los Ríos, A.; Godinez, C.; Lofti, L.M.; El Mahhi, M.; Blanco, L.J.L. Treatment of mineral oil refinery wastewater in microbial fuel cells using ionic liquid based separators. Appl. Sci. 2018, 8, 438. [Google Scholar] [CrossRef]

- Caro, D.; Davis, S.J.; Bastianoni, S.; Caldeira, K. Greenhouse Gas Emissions due to Meat Production in the Last Fifty Years. In Quantification of Climate Variability, Adaptation and Mitigation for Agricultural Sustainability; Springer: Berlin/Heidelberg, Germany, 2017; pp. 27–37. [Google Scholar]

- Banks, C.J.; Wang, Z. Treatment of Meat Wastes. In Handbook of Industrial and Hazardous Wastes Treatment; CRC Press: Boca Raton, FL, USA, 2004; pp. 750–787. [Google Scholar]

- Ichihashi, O.; Hirooka, K. Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour. Technol. 2012, 114, 303–307. [Google Scholar] [CrossRef]

- Xu, N.; Zhou, S.; Yuan, Y.; Qin, H.; Zheng, Y.; Shu, C. Coupling of anodic biooxidation and cathodic bioelectro-fenton for enhanced swine wastewater treatment. Bioresour. Technol. 2011, 102, 7777–7783. [Google Scholar] [CrossRef]

- Egbadon, E.; Akujobi, C.O.; Nweke, C.O.; Braide, W.; Akaluka, C.K.; Adeleye, S.A. Simultaneous generation of bioelectricity and treatment of swine wastewater in a microbial fuel cell. Int. Lett. Nat. Sci. 2016, 54, 100–107. [Google Scholar] [CrossRef]

- Wagner, R.C.; Regan, J.M.; Oh, S.E.; Zuo, Y.; Logan, B.E. Hydrogen and methane production from swine wastewater using microbial electrolysis cells. Water Res. 2009, 43, 1480–1488. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.Y.; Yang, W.; Evans, P.J.; Logan, B.E. Continuous treatment of high strength wastewaters using air-cathode microbial fuel cells. Bioresour. Technol. 2016, 221, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Min, B.; Kim, J.; Oh, S.; Regan, J.M.; Logan, B.E. Electricity generation from swine wastewater using microbial fuel cells. Water Res. 2005, 39, 4961–4968. [Google Scholar] [CrossRef] [PubMed]

- Cheng, D.; Ngo, H.H.; Guo, W.; Lee, D.; Nghiem, D.L.; Zhang, J.; Liang, S.; Varjani, S.; Wang, J. Performance of microbial fuel cell for treating swine wastewater containing sulfonamide antibiotics. Bioresour. Technol. 2020, 311, 123588. [Google Scholar] [CrossRef]

- Ma, J.; Ni, H.; Su, D.; Meng, X. Bioelectricity generation from pig farm wastewater in microbial fuel cell using carbon brush as electrode. Int. J. Hydrogen Energy 2016, 41, 16191–16195. [Google Scholar] [CrossRef]

- Estrada-Arriaga, E.B.; García-Sánchez, L.; Garzón-Zuñiga, M.A.; González-Rodríguez, J.G. Utilization of microbial fuel cells for the treatment of wastewater from a pig farm. Fresenius Environ. Bull. 2015, 24, 2512–2518. [Google Scholar]

- Kim, J.R.; Dec, J.; Bruns, M.A.; Logan, B.E. Removal of odors from swine wastewater by using microbial fuel cells. Appl. Environ. Microbiol. 2008, 74, 2540–2543. [Google Scholar] [CrossRef]

- Vilajeliu-Pons, A.; Puig, S.; Pous, N.; Salcedo-Davila, I.; Baneras, L.; Balaguer, M.D.; Colprim, J. Microbiome characterization of mfcs used for the treatment of swine manure. J. Hazard Mater. 2015, 288, 60–68. [Google Scholar] [CrossRef]

- Vogl, A.; Bischof, F.; Wichern, M. Single chamber microbial fuel cells for high strength wastewater and blackwater treatment—A comparison of idealized wastewater, synthetic human blackwater, and diluted pig manure. Biochem. Eng. J. 2016, 115, 64–71. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Molognoni, D.; Puig, S.; Balaguer, M.D.; Colprim, J. Role of operating conditions on energetic pathways in a microbial fuel cell. Energy Procedia 2015, 74, 728–735. [Google Scholar] [CrossRef]

- Cerrillo, M.; Oliveras, J.; Vinas, M.; Bonmati, A. Comparative assessment of raw and digested pig slurry treatment in bioelectrochemical systems. Bioelectrochemistry 2016, 110, 69–78. [Google Scholar] [CrossRef] [PubMed]

- Sotres, A.; Cerrillo, M.; Vinas, M.; Bonmati, A. Nitrogen recovery from pig slurry in a two-chambered bioelectrochemical system. Bioresour. Technol. 2015, 194, 373–382. [Google Scholar] [CrossRef] [PubMed]

- Sotres, A.; Tey, L.; Bonmati, A.; Vinas, M. Microbial community dynamics in continuous microbial fuel cells fed with synthetic wastewater and pig slurry. Bioelectrochemistry 2016, 111, 70–82. [Google Scholar] [CrossRef] [PubMed]

- Najafpour, G.D.; Sahne, F. Power Generation and Cattle Manure Leachate Treatment in Continuous Operation of Microbial Fuel Cell; Biotechnology Research Lab., Noshirvani University of Technology: Babol, Iran, 2017. [Google Scholar]

- Inoue, K.; Ito, T.; Kawano, Y.; Iguchi, A.; Miyahara, M.; Suzuki, Y.; Watanabe, K. Electricity generation from cattle manure slurry by cassette-electrode microbial fuel cells. J. Biosci. Bioeng. 2013, 116, 610–615. [Google Scholar] [CrossRef]

- Zhao, G.; Ma, F.; Wei, L.; Chua, H.; Chang, C.C.; Zhang, X.J. Electricity generation from cattle dung using microbial fuel cell technology during anaerobic acidogenesis and the development of microbial populations. Waste Manag. 2012, 32, 1651–1658. [Google Scholar] [CrossRef] [PubMed]

- Goto, Y.; Yoshida, N. Scaling up microbial fuel cells for treating swine wastewater. Water 2019, 11, 1803. [Google Scholar] [CrossRef]

- Babanova, S.; Jones, J.; Phadke, S.; Lu, M.; Angulo, C.; Garcia, J.; Carpenter, K.; Cortese, R.; Chen, S.; Phan, T.; et al. Continuous flow, large-scale, microbial fuel cell system for the sustained treatment of swine waste. Water Environ. Res. 2020, 92, 60–72. [Google Scholar] [CrossRef] [PubMed]