Experimental Characterization of Transitory Functioning Regimes of a Biomass Stirling Micro-CHP

Abstract

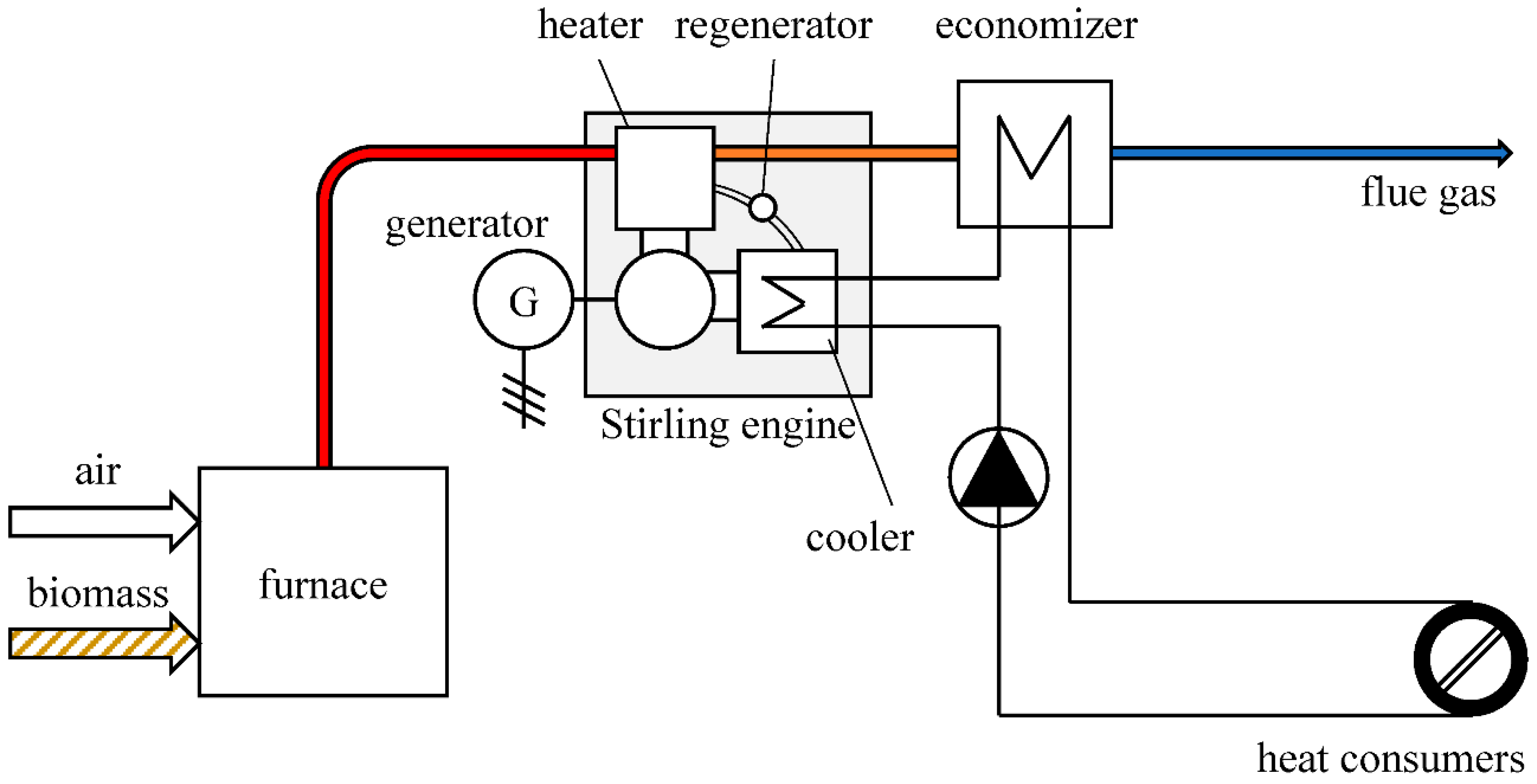

:1. Introduction

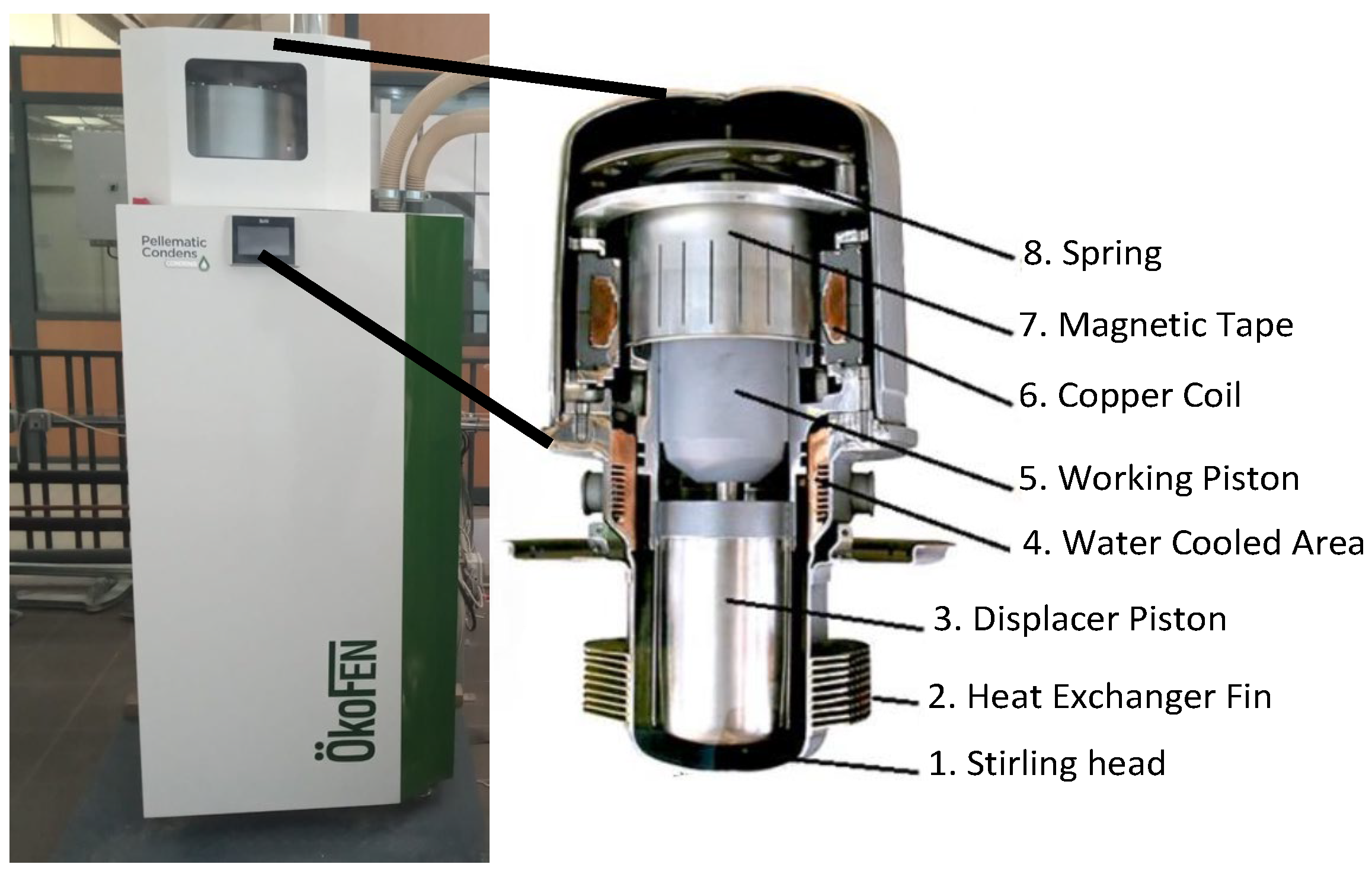

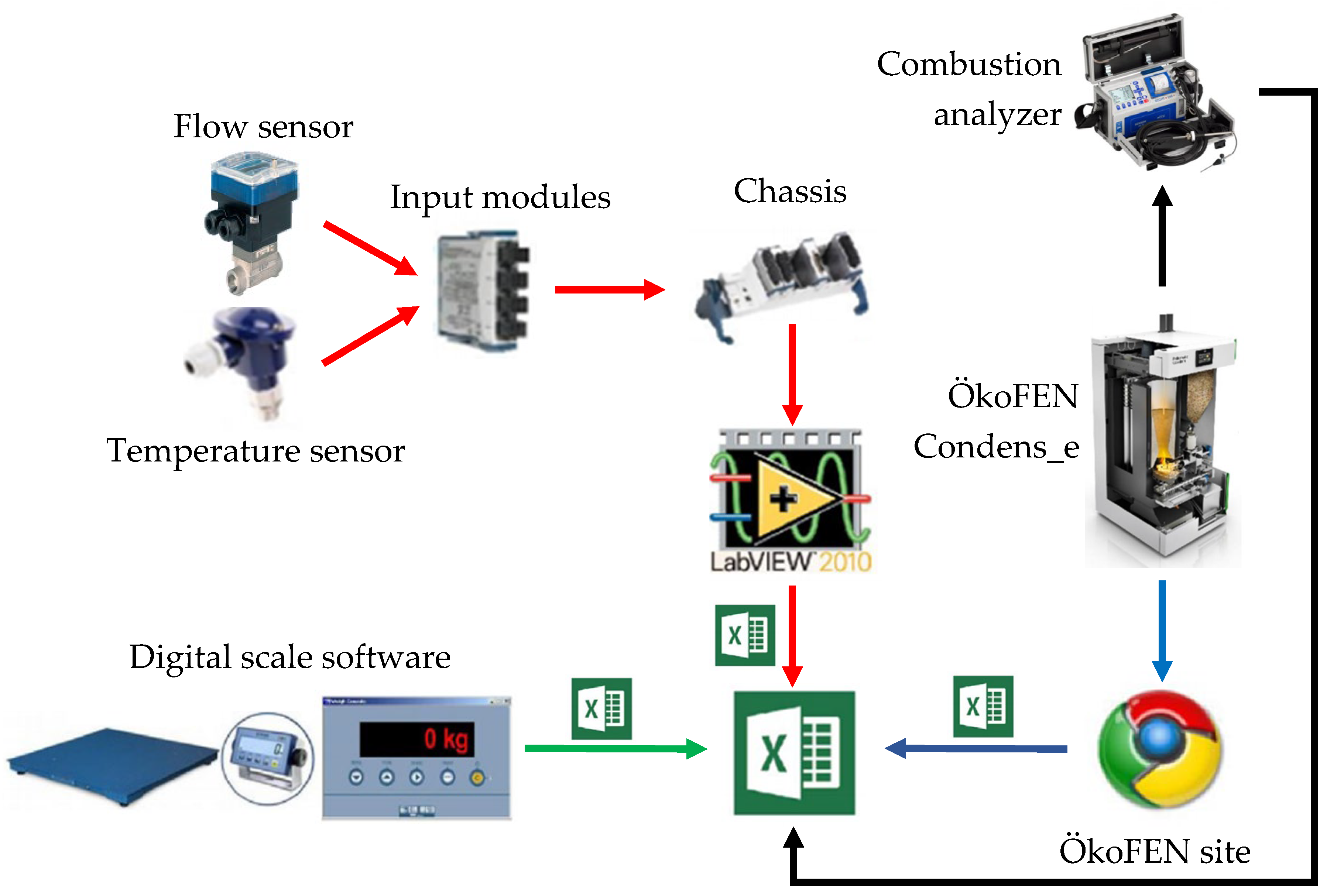

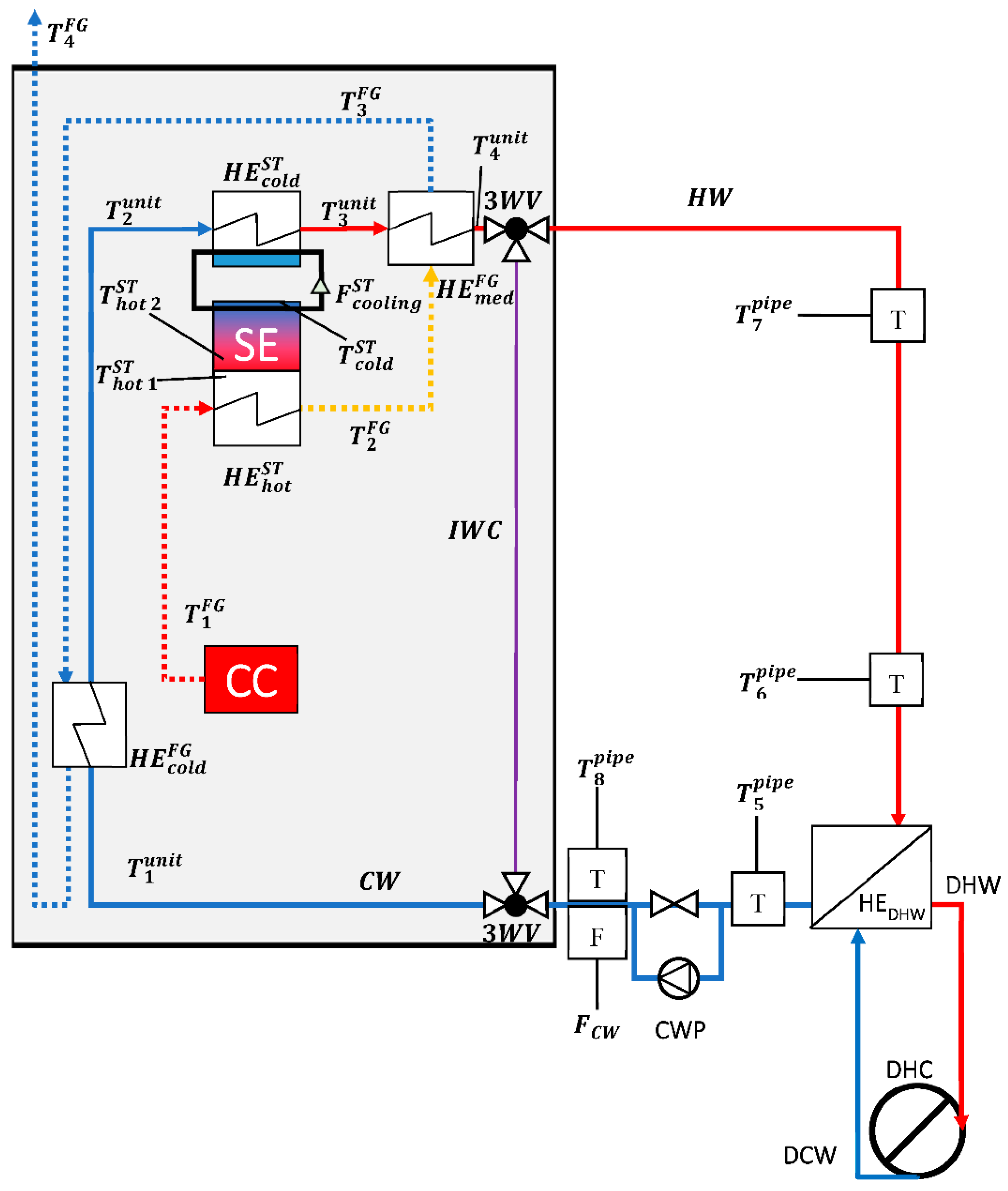

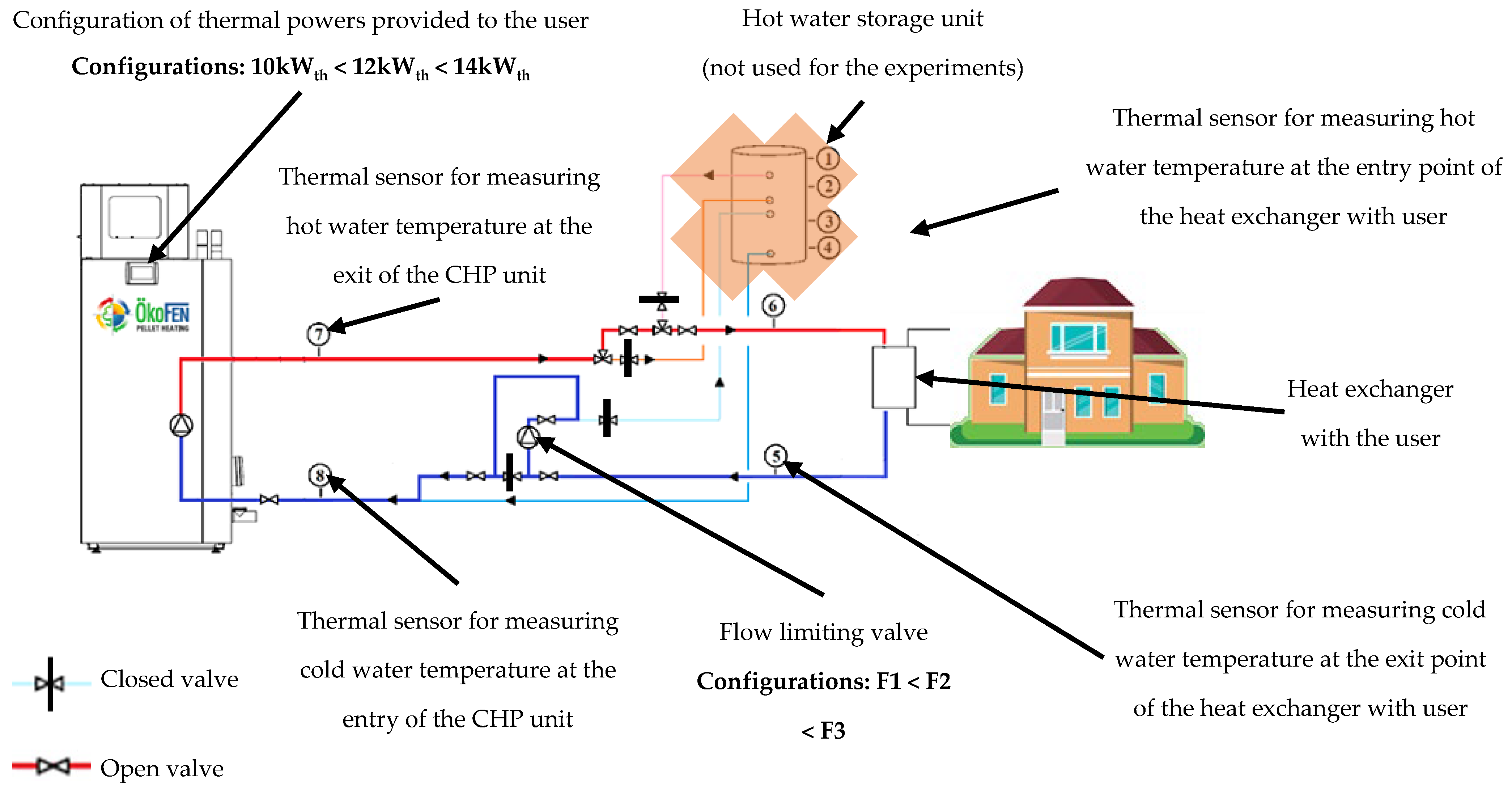

2. Materials and Methods

3. Results

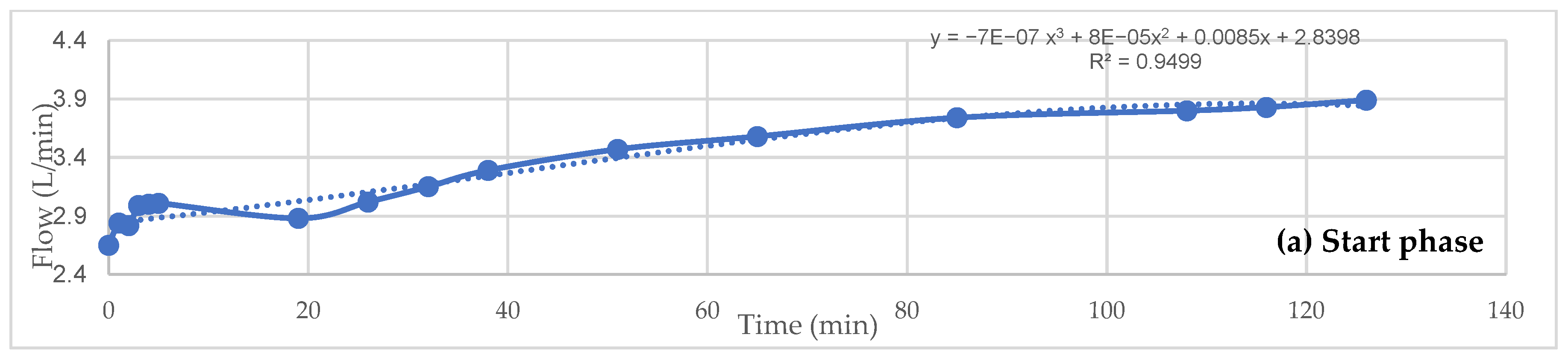

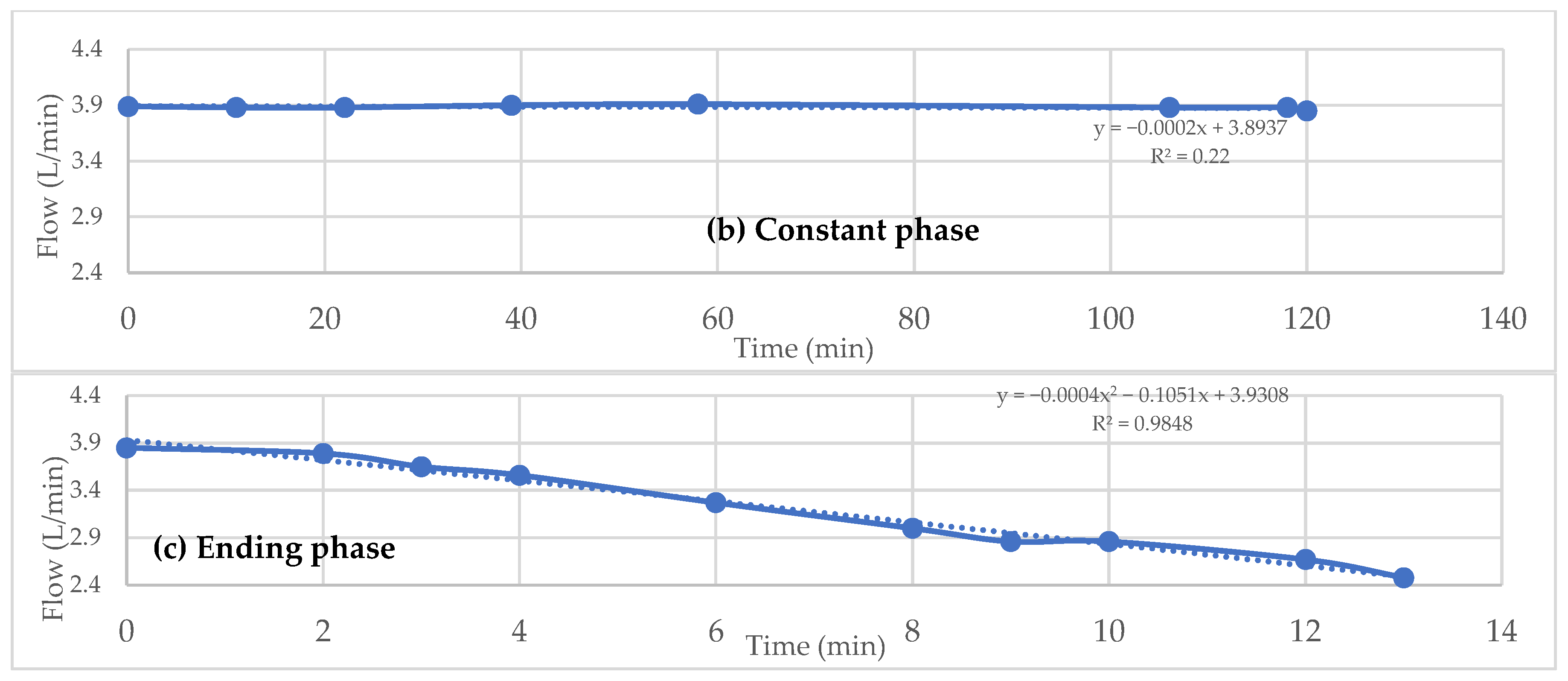

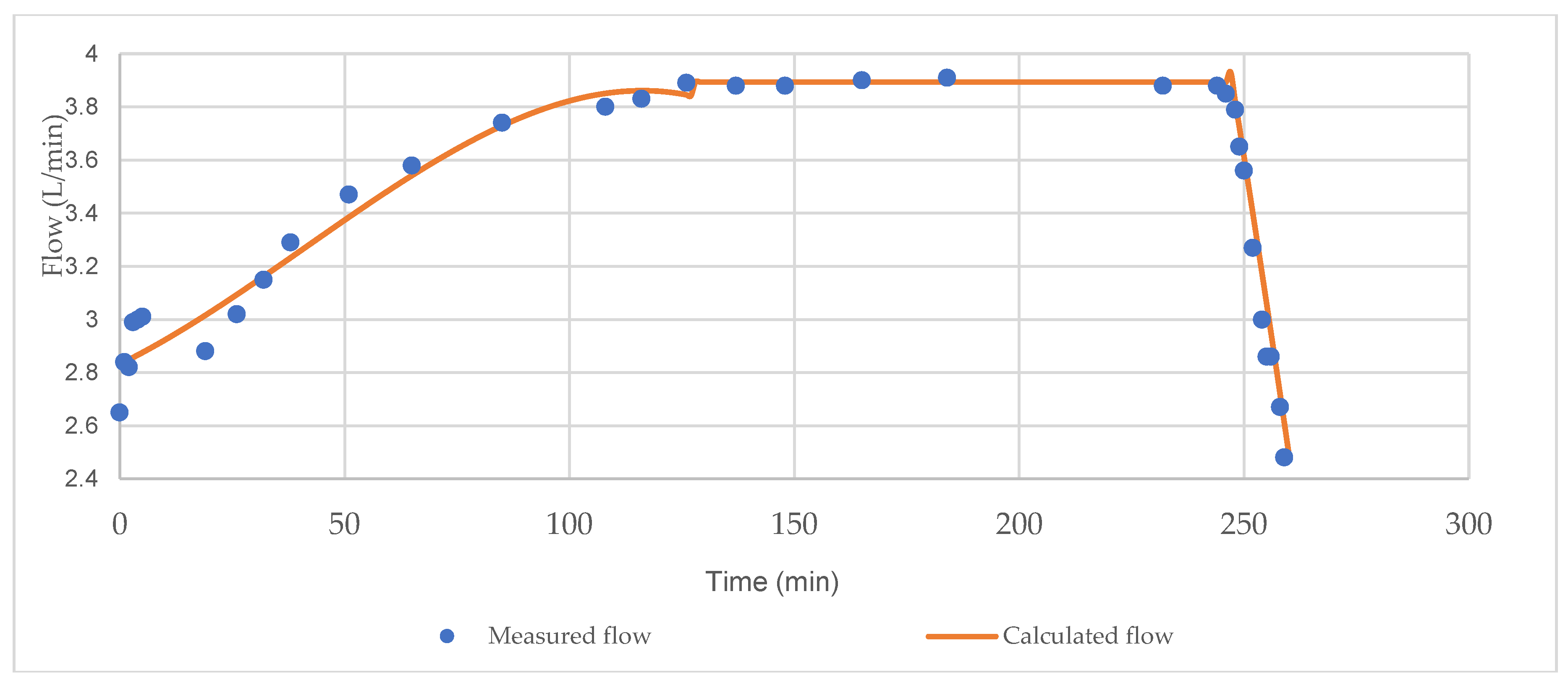

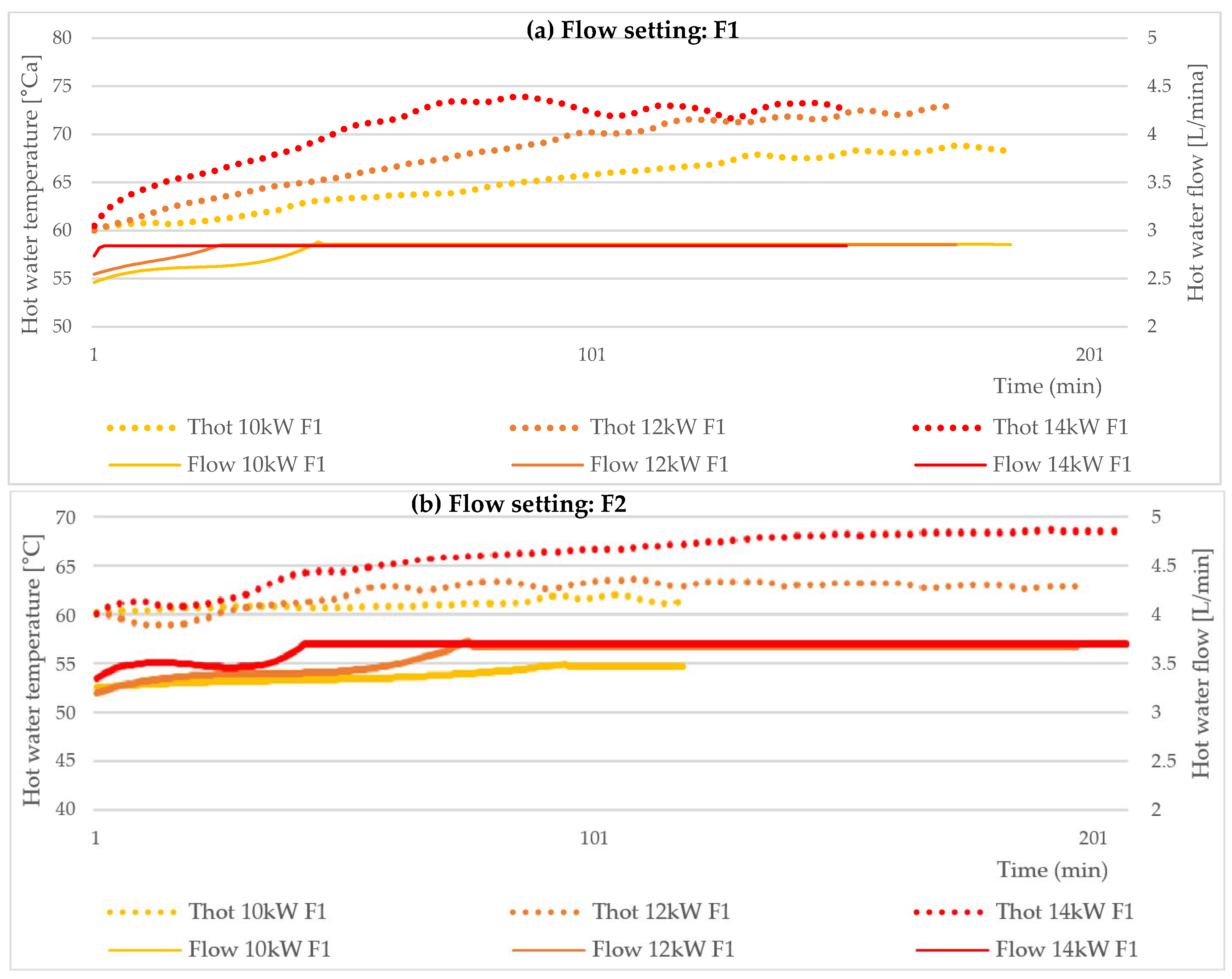

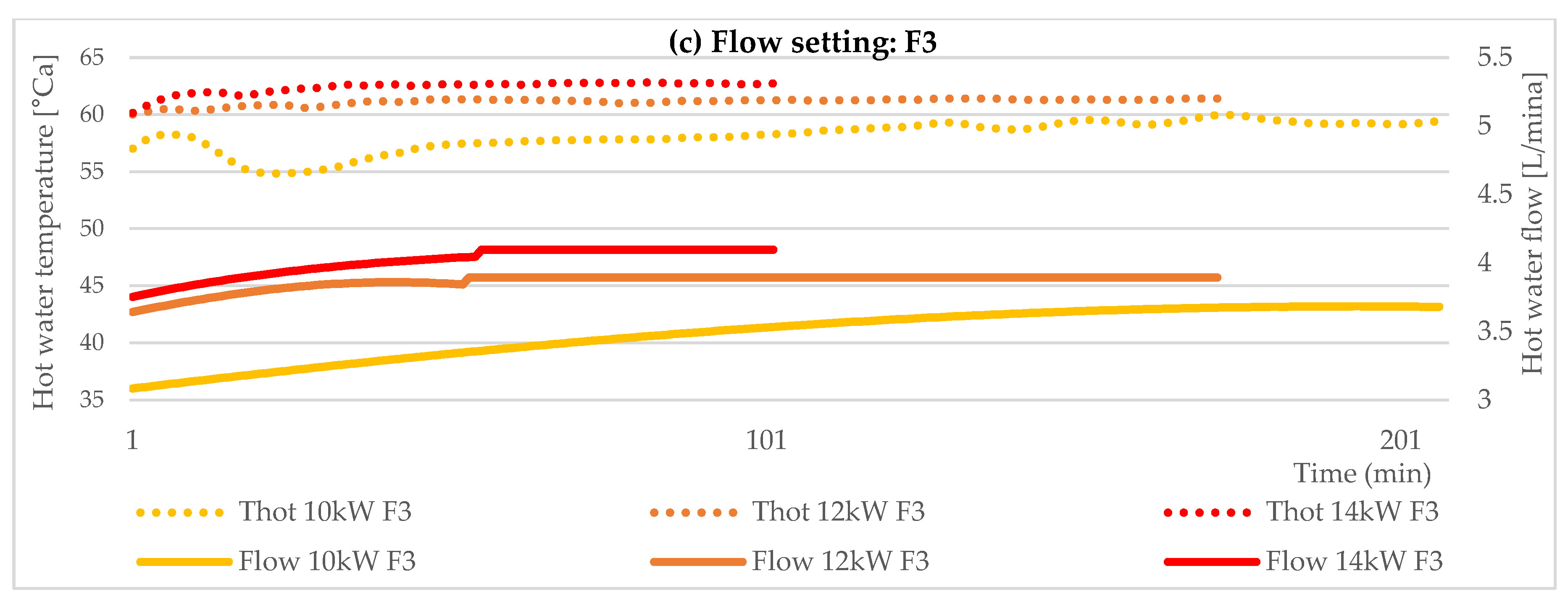

3.1. Flow Results

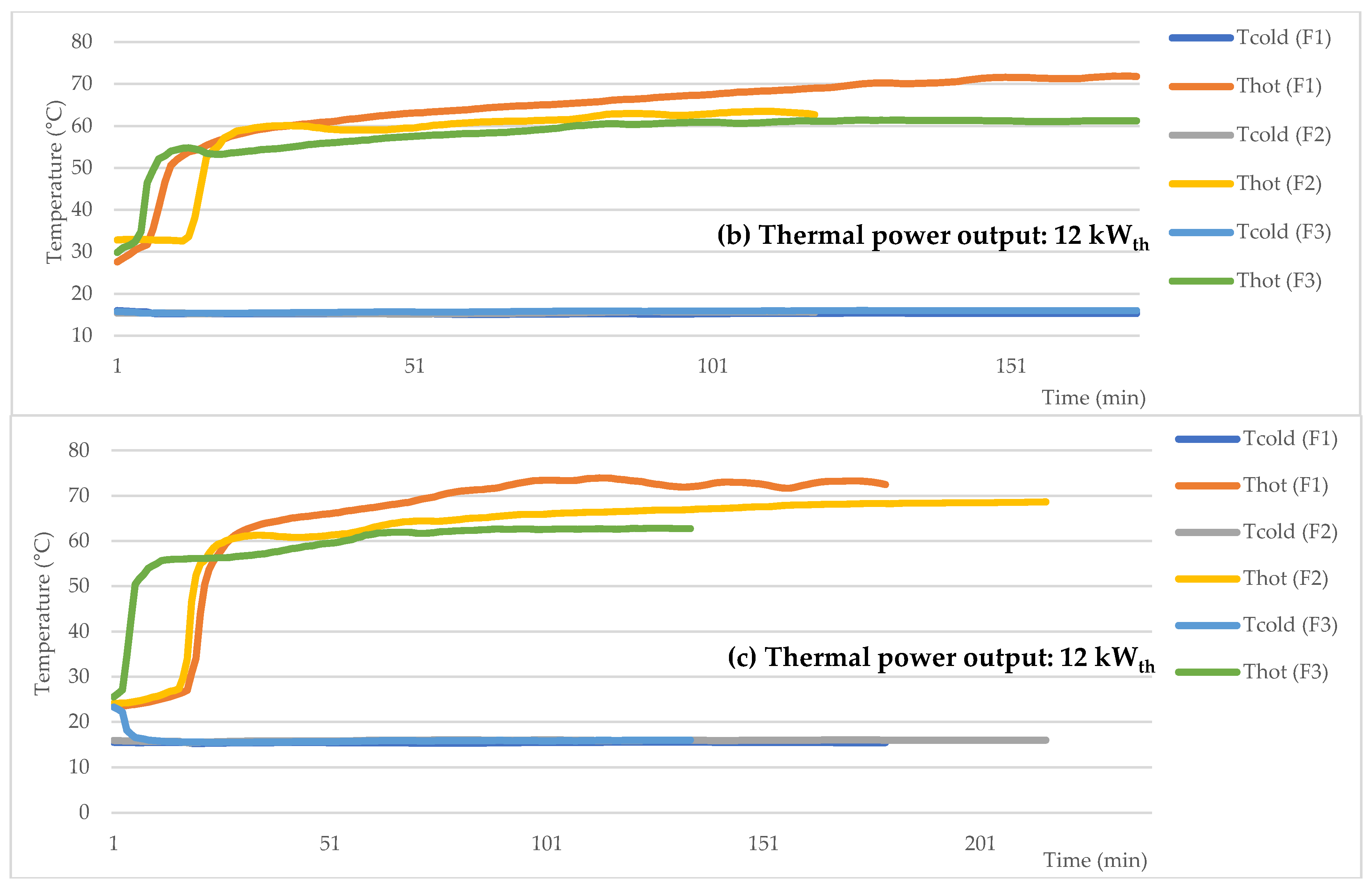

3.2. Heat Transfer Fluid Temperature in Corelation with the Heat Transfer Flow

3.3. Generated Power and Stirling Engine Work Fluid Temperature

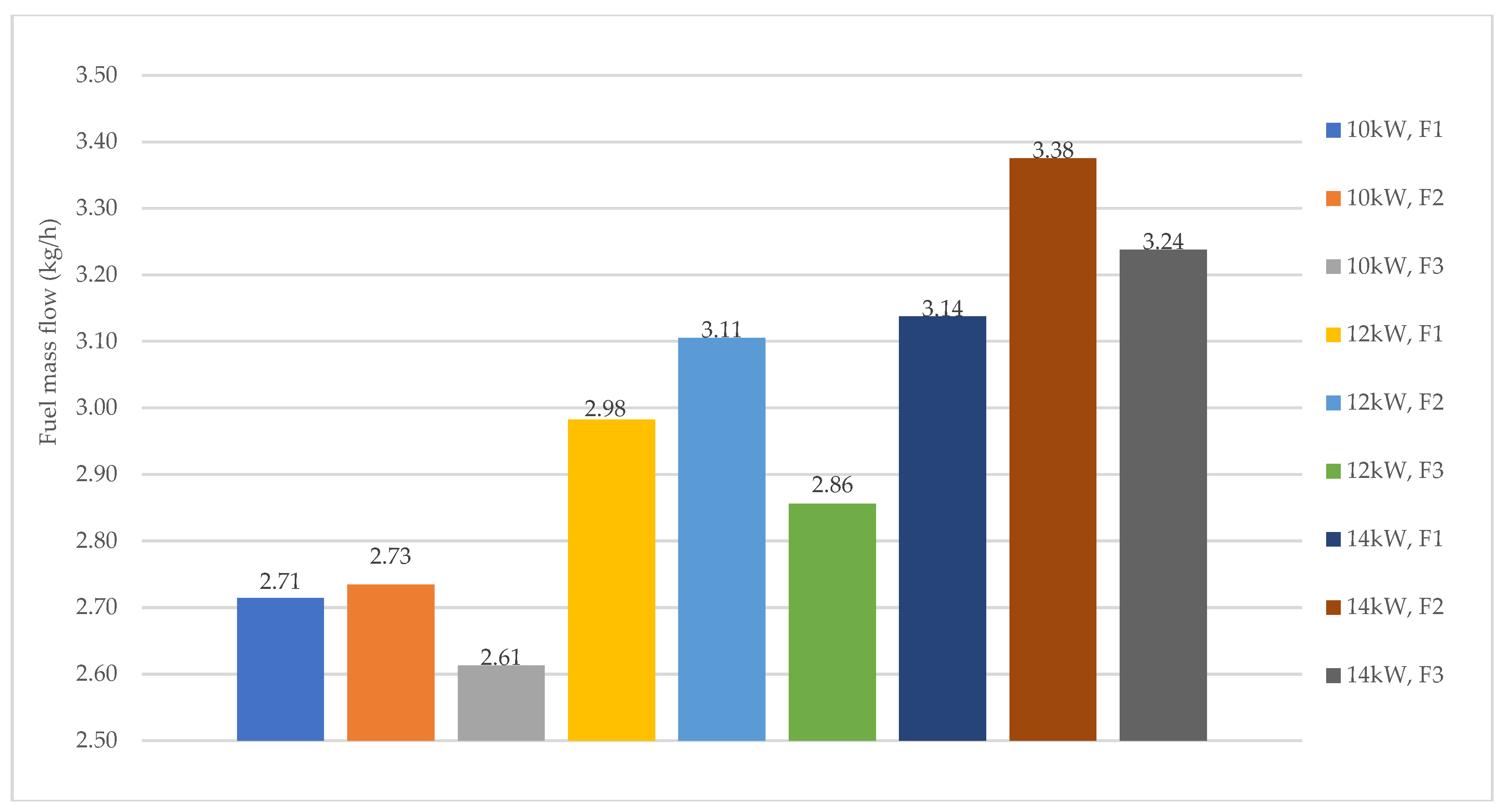

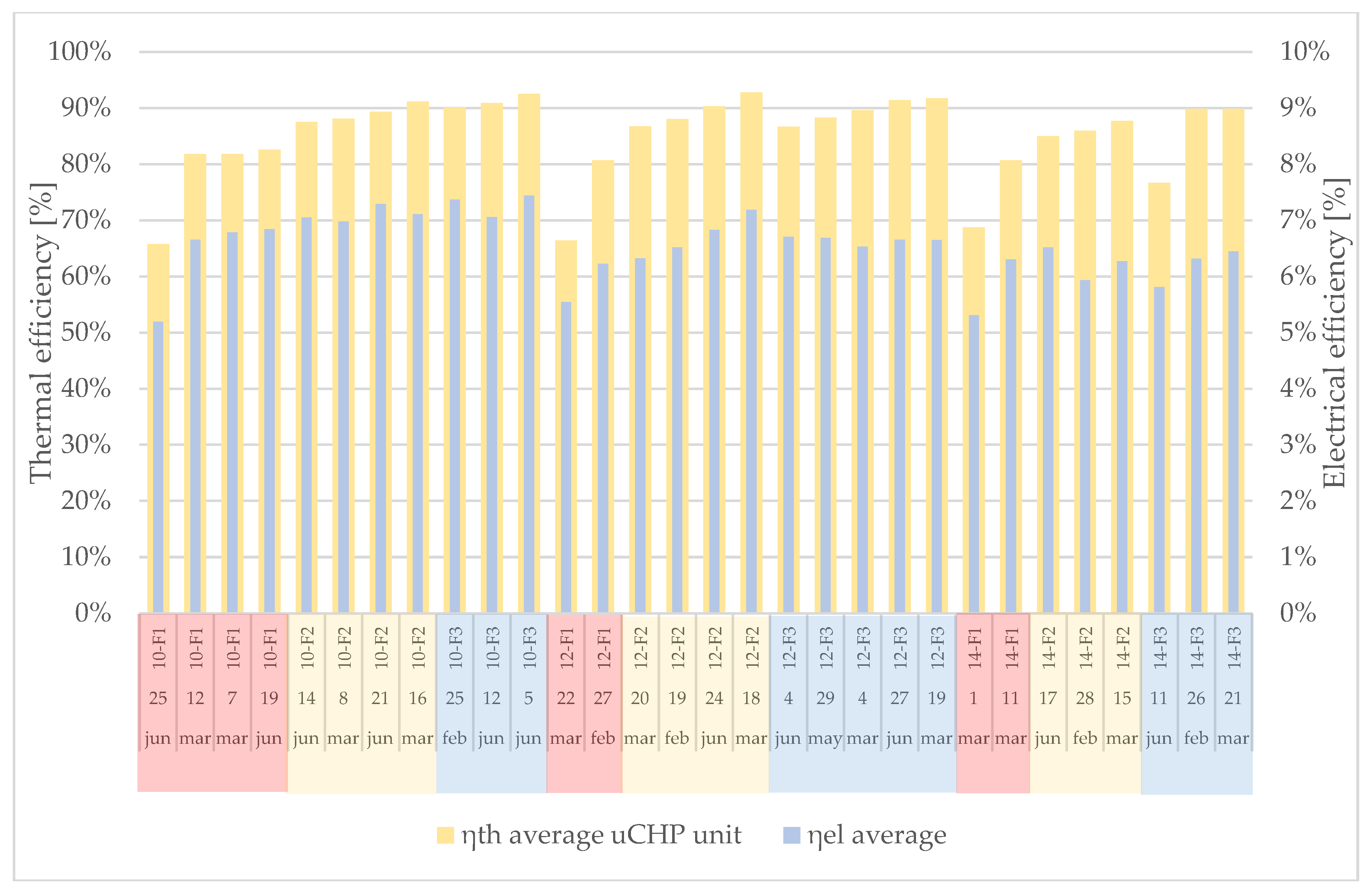

3.4. Fuel Mass Flow Consumption and Efficiencies

4. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Measured Parameter | Equipment Used | Equipment Model | Symbol | Unit |

|---|---|---|---|---|

| Cold water flow | Flow sensor | SE35 | ||

| μCHP unit inner water temperature 1 | Condens_e temperature sensor | N/A | ||

| μCHP unit inner water temperature 2 | Condens_e temperature sensor | N/A | ||

| μCHP unit inner water temperature 3 | Condens_e temperature sensor | N/A | ||

| μCHP unit inner water temperature 4 | Condens_e temperature sensor | N/A | ||

| Cold water exiting the DHW HE temperature 5 | Temperature sensor | JUMO PT100 | ||

| Hot water entering the DHW HE temperature 6 | Temperature sensor | JUMO PT100 | ||

| Hot water exiting the μCHP unit temperature 7 | Temperature sensor | JUMO PT100 | ||

| Cold water exiting the μCHP unit temperature 8 | Temperature sensor | JUMO PT100 | ||

| Flue gas final temperature | Combustion analyzer | ECOM EN2 | ||

| Stirling hot head outer temperature 1 | Condens_e temperature sensor | N/A | ||

| Stirling hot head inner temperature 2 | Condens_e temperature sensor | N/A | ||

| Stirling cold head temperature | Condens_e temperature sensor | N/A | ||

| Power output | Condens_e power sensor | N/A | ||

| Fuel mass | Weight scale | WALL-E Floor Scale | ||

| Room air temperature | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas O2 content | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas CO content | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas NO content | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas NOx content | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas SO2 content | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas CO2 content | Combustion analyzer | ECOM EN2 | ||

| Exiting flue gas air excess | Combustion analyzer | ECOM EN2 |

| Constant | Value | Symbol | Unit |

|---|---|---|---|

| Water density | 997 | kg/m3 | |

| Water specific heat at constant pressure | 4.18 | ||

| Flue gas—water heat exchanger efficiency | 0.98 | - |

| Calculated Parameter | Symbol | Unit |

|---|---|---|

| Thermal power output of the μCHP unit | ||

| Flue gas temperature exiting the combustion chamber CC | ||

| Carnot efficiency | - |

References

- Bouvenot, J.-B.; Andlauer, B.; Stabat, P.; Marchio, D.; Flament, B.; Latour, B.; Siroux, M. Gas Stirling engine μCHP boiler experimental data driven model for building energy simulation. Energy Build. 2014, 84, 113–117. [Google Scholar] [CrossRef]

- Bianchi, M.; De Pascale, A.; Melino, F. Performance analysis of an integrated CHP system with thermal and Electric Energy Storage for residential application. Appl. Energy 2013, 112, 928–938. [Google Scholar] [CrossRef]

- Mameri, F. Caractérisation Multi-Physique et Multi-Échelle d’une Installation de Conversion d’Énergie: Application À une Unité de Cogénération Biomasse. Ph.D. Thesis, Université Polytehnique Hauts de France, Valenciennes, France, 2018. [Google Scholar]

- Martinez, S. Etudes Expérimentales et Numériques d’un Micro-Cogénérateur Solaire—Intégration à un BÂtiment Résidentiel. Ph.D. Thesis, Université de la Rochelle, La Rochelle, France, 2018. [Google Scholar]

- ÖkoFEN Pellematic Condens_e Technical Data. 2017. Available online: http://www.ÖkoFEN-e.com/en/pellematic_smart_e/ (accessed on 20 August 2021).

- Gliński, M.; Bojesen, C.; Rybiński, W.; Bykuć, S. Modelling of the biomass µCHP unit for power peak shaving in the local electrical grid. Energies 2019, 12, 458. [Google Scholar] [CrossRef] [Green Version]

- Jones, S.R.; Beardmore, J.; Gillott, M.; Boukhanouf, R.; Walker, G. A control methodology for building energy management systems (BEMS) in heat networks with distributed generation. Energy Procedia 2018, 153, 295–302. [Google Scholar] [CrossRef]

- Cardozo, E.; Malmquist, A. Performance comparison between the use of wood and sugarcane bagasse pellets in a Stirling engine micro-CHP system. Appl. Therm. Eng. 2019, 159, 113945. [Google Scholar] [CrossRef]

- Schneider, T.; Müller, D.; Karl, J. A review of thermochemical biomass conversion combined with Stirling engines for the small-scale cogeneration of heat and power. Renew. Sustain. Energy Rev. 2020, 134, 110288. [Google Scholar] [CrossRef]

- Żołądek, M.; Figaj, R.; Sornek, K. Energy analysis of a micro-scale biomass cogeneration system. Energy Convers. Manag. 2021, 236, 114079. [Google Scholar] [CrossRef]

- Rosato, A.; Sibilio, S.; Ciampi, G. Energy, environmental and economic dynamic performance assessment of different micro-cogeneration systems in a residential application. Appl. Therm. Eng. 2013, 59, 599–617. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Nunes, M.L.; Teixeira, J.C.; Martins, L.A.; Teixeira, S.F. Thermodynamic and economic optimization of a solar-powered Stirling engine for micro-cogeneration purposes. Energy 2016, 111, 1–17. [Google Scholar] [CrossRef]

- Bartela, Ł.; Kotowicz, J.; Dubiel-Jurgaś, K. Investment risk for biomass integrated gasification combined heat and power unit with an internal combustion engine and a Stirling engine. Energy 2018, 150, 601–616. [Google Scholar] [CrossRef]

- Valenti, G.; Silva, P.; Fergnani, N.; Di Marcoberardino, G.; Campanari, S.; Macchi, E. Experimental and numerical study of a micro-cogeneration Stirling engine for residential applications. Energy Procedia 2014, 45, 1235–1244. [Google Scholar] [CrossRef] [Green Version]

- Bartela, Ł.; Kotowicz, J.; Remiorz, L.; Skorek-Osikowska, A.; Dubiel, K. Assessment of the economic appropriateness of the use of Stirling engine as additional part of a cogeneration system based on biomass gasification. Renew. Energy 2017, 112, 425–443. [Google Scholar] [CrossRef]

- Cardozo, E.; Erlich, C.; Malmquist, A.; Alejo, L. Integration of a wood pellet burner and a Stirling engine to produce residential heat and power. Appl. Therm. Eng. 2014, 73, 671–680. [Google Scholar] [CrossRef]

- Damirchi, H.; Najafi, G.; Alizadehnia, S.; Mamat, R.; Nor Azwadi, C.S.; Azmi, W.H.; Noor, M.M. Micro combined heat and power to provide heat and electrical power using biomass and gamma-type Stirling engine. Appl. Therm. Eng. 2016, 103, 1460–1469. [Google Scholar] [CrossRef] [Green Version]

- Qiu, S.; Gao, Y.; Rinker, G.; Yanaga, K. Development of an advanced free-piston Stirling engine for micro combined heating and power application. Appl. Energy 2019, 235, 987–1000. [Google Scholar] [CrossRef]

- Park, B.-S.; Usman, M.; Imran, M.; Pesyridis, A. review of organic Rankine cycle experimental data trends. Energy Convers. Manag. 2018, 173, 679–691. [Google Scholar] [CrossRef]

- Urciuolo, M.; Chirone, R.; Saverio Marra, F.; Solimene, R. Power generation by Stirling engine during fluidized bed combustion of wood pellets. Combust. Sci. Technol. 2018, 191, 263–274. [Google Scholar] [CrossRef]

- Katona, B.; Laza, T. The technical applicability of Stirling engines in a Hungarian village. Chem. Pap. 2018, 72, 3093–3103. [Google Scholar] [CrossRef]

- Biedermann, F.; Carlsen, H.; Obernberger, I.; Schöch, M. Small-scale CHP Plant based on a 75 kWel hermetic eight cylinder Stirling engine for biomass fuels—Development, technology and operating experiences. In Proceedings of the 2nd World Conference and Exhibition on Biomass for Energy, Industry and Climate Protection, Rome, Italy, 10–14 May 2004. [Google Scholar]

- Ulloa, C.; Míguez, J.L.; Porteiro, J.; Eguía, P.; Cacabelos, A. Development of a transient model of a Stirling-based CHP system. Energies 2013, 6, 3115–3133. [Google Scholar] [CrossRef] [Green Version]

- van Loo, S.; Koppejean, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008; p. 195. Available online: https://boilersinfo.com/ (accessed on 5 September 2019).

- Engineering Toolbox Website. Available online: https://www.engineeringtoolbox.com/ (accessed on 20 August 2021).

- Bouvenot, J.B.; Latour, B.; Siroux, M.; Flament, B.; Stabat, P.; Marchio, D. Dynamic model based on experimental investigations of a wood pellet steam engine micro CHP for building energy simulation. Appl. Therm. Eng. 2014, 73, 1041–1054. [Google Scholar] [CrossRef]

- Kallio, S.; Siroux, M. Exergy and Exergo-economic analysis of a hybrid renewable energy system under different climate conditions. Renew. Energy 2022, 194, 396–414. [Google Scholar] [CrossRef]

- Barbu, M.; Darie, G.; Siroux, M. Analysis of a residential photovoltaic-thermal (PVT) system in two similar climate conditions. Energies 2019, 12, 3595. [Google Scholar] [CrossRef] [Green Version]

| Source | Stirling Type | Working Fluid | Thermal Power [kWth] | Power [kWel] | TStirling [°C] | Fuel Use | Fuel Type | ηth | ηel |

|---|---|---|---|---|---|---|---|---|---|

| [8] | N/A | Nitrogen | 20 | 1 | 549 | Combustion | Pellets | 81% | 9% |

| [13] | N/A | N/A | N/A | N/A | N/A | Gasification | Biomass | 46% | 23% |

| [14] | N/A | Nitrogen | 8 | 1 | 823 | Combustion | Natural gas | 90% | 9% |

| [15] | Alpha | N/A | N/A | N/A | 600 | N/A | N/A | N/A | N/A |

| [16] | Gamma | Nitrogen | 20 | 1 | 500–660 | N/A | Biomass | N/A | N/A |

| [17] | Gamma | Helium | N/A | 1 | 370–410 | Combustion | Agricultural waste | N/A | N/A |

| [18] | Free piston | N/A | 1.1 | 1 | N/A | N/A | Biomass | 38% | 42% |

| [19] | Free piston | N/A | N/A | 1 | 525 | Combustion | Natural gas | N/A | 23% |

| [20] | Gamma | N/A | 15–40 | 0.3 | 625 | N/A | Pellets | N/A | N/A |

| [21] | N/A | N/A | N/A | N/A | N/A | N/A | Wood residue | N/A | N/A |

| [22] | N/A | Helium | 475 | 75 | N/A | N/A | Chopped wood | 74% | 12% |

| [23] | Alpha | Nitrogen | 6 | 0.92 | 460–480 | Combustion | Diesel | N/A | N/A |

| Type | Metrologic Means | Measurement Range | Uncertainty |

|---|---|---|---|

| Water temperature | JUMO PT--100 | −20 °C to +150 °C | 0.1 °C |

| Water flow rate | Flowmeter Burkert 8035 | 0.5 L/min to 1000 L/min | 1% |

| Fuel mass | WALL-E Floor Scale | 0 kg to 600 kg | 0.03% |

| Exhaust gas | Combustion analyzer ECOM EN2 | NO (0–5000 ppm) CO (0–4000 ppm) |

| Power, Flow 1 | Power, Flow 2 | Power, Flow 3 |

|---|---|---|

| 10 kWth, F1 | 10 kWth, F2 | 10 kWth, F3 |

| 12 kWth, F1 | 12 kWth, F2 | 12 kWth, F3 |

| 14 kWth, F1 | 14 kWth, F2 | 14 kWth, F3 |

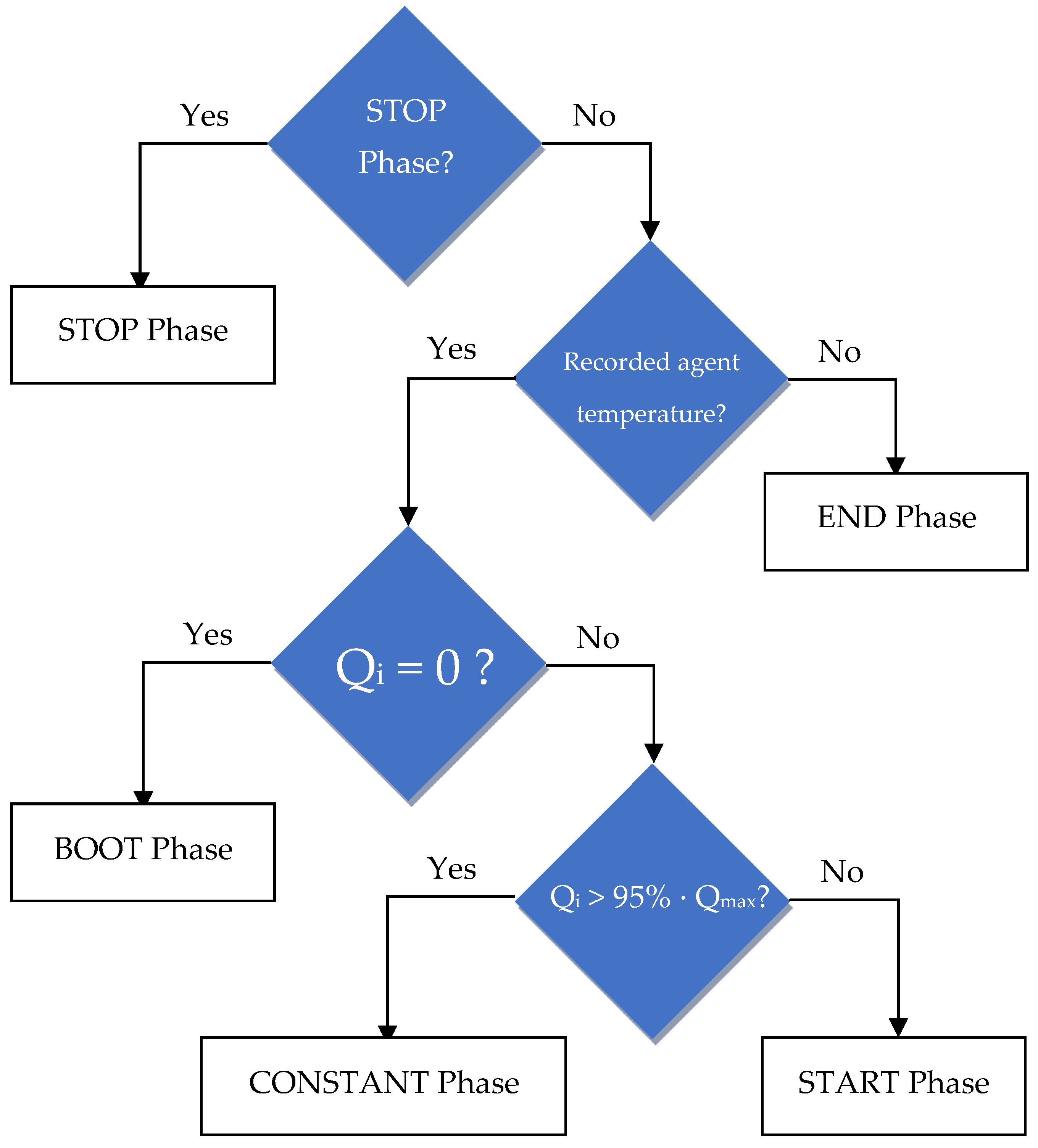

| Stage | Description |

|---|---|

| Boot | combustion process has started |

| Start | thermal power evacuation process has started |

| Constant | thermal power production is constant |

| Stop | thermal power production is stopping |

| End | thermal power production ended |

| Coefficient | Microsoft Excel Function |

|---|---|

| x3 | |

| x2 | |

| x1 | |

| x0 |

| Coefficient | Microsoft Excel Function |

|---|---|

| x1 | |

| x0 |

| Coefficient | Excel Function |

|---|---|

| x2 | |

| x1 | |

| x0 |

| Configuration | Stable Temperature [°C] | Time to Reach Stable Temperature [min] | Automatic Switch to Partial Load Functioning |

|---|---|---|---|

| 10 kWth, F1 | 69 | 160 | YES |

| 10 kWth, F2 | 60 | 75 | NO |

| 10 kWth, F3 | 58 | 75 | NO |

| 12 kWth, F1 | 71 | 150 | YES |

| 12 kWth, F2 | 61 | 80 | YES |

| 12 kWth, F3 | 59 | 80 | NO |

| 14 kWth, F1 | 74 | 120 | YES |

| 14 kWth, F2 | 69 | 100 | YES |

| 14 kWth, F3 | 62 | 60 | NO |

| Configuration | Time to Reach 60 °C [min] | Time to Reach 0.8 kWel [min] |

|---|---|---|

| 10 kW, F1 | 25 | 110 |

| 10 kW, F2 | 70 | 110 |

| 10 kW, F3 | 150 | 110 |

| 12 kW, F1 | 20 | 80 |

| 12 kW, F2 | 20 | 70 |

| 12 kW, F3 | 80 | 60 |

| 14 kW, F1 | 20 | 40 |

| 14 kW, F2 | 25 | 50 |

| 14 kW, F3 | 55 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voronca, Ș.-D.; Siroux, M.; Darie, G. Experimental Characterization of Transitory Functioning Regimes of a Biomass Stirling Micro-CHP. Energies 2022, 15, 5547. https://doi.org/10.3390/en15155547

Voronca Ș-D, Siroux M, Darie G. Experimental Characterization of Transitory Functioning Regimes of a Biomass Stirling Micro-CHP. Energies. 2022; 15(15):5547. https://doi.org/10.3390/en15155547

Chicago/Turabian StyleVoronca, Ștefan-Dominic, Monica Siroux, and George Darie. 2022. "Experimental Characterization of Transitory Functioning Regimes of a Biomass Stirling Micro-CHP" Energies 15, no. 15: 5547. https://doi.org/10.3390/en15155547

APA StyleVoronca, Ș.-D., Siroux, M., & Darie, G. (2022). Experimental Characterization of Transitory Functioning Regimes of a Biomass Stirling Micro-CHP. Energies, 15(15), 5547. https://doi.org/10.3390/en15155547