A Numerical Study on the Application of Stress Cage Technology

Abstract

:1. Introduction

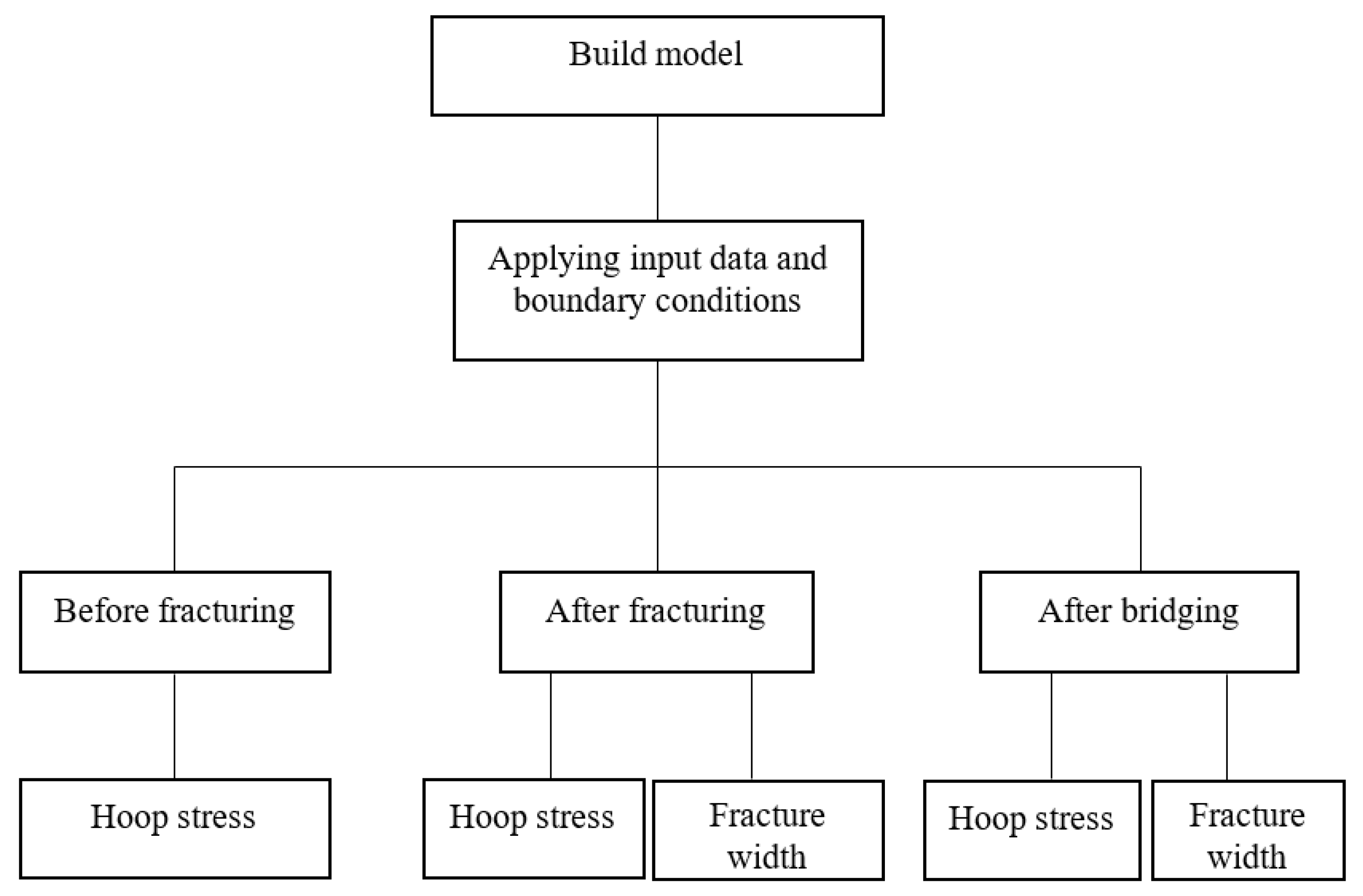

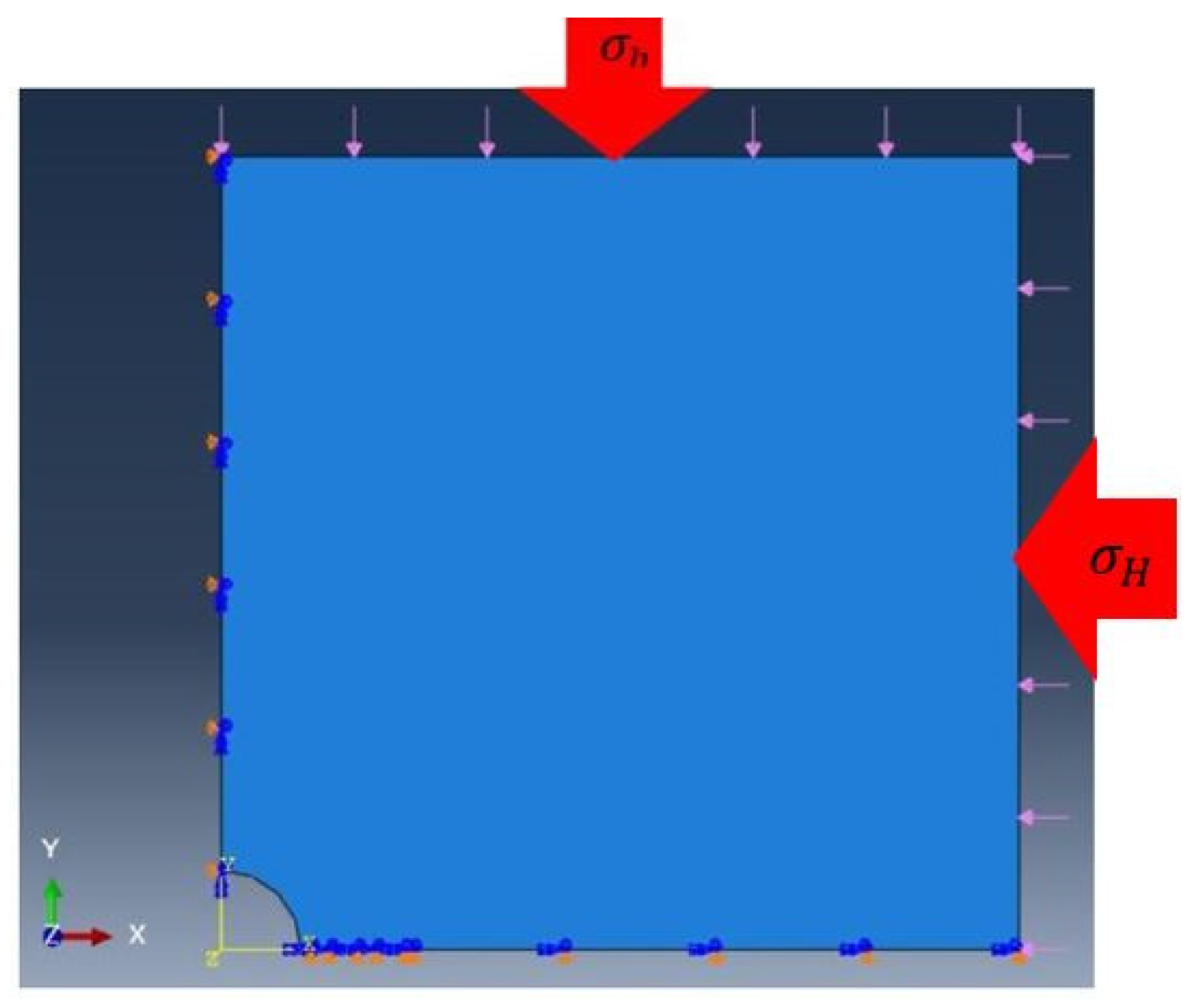

2. Materials and Methods

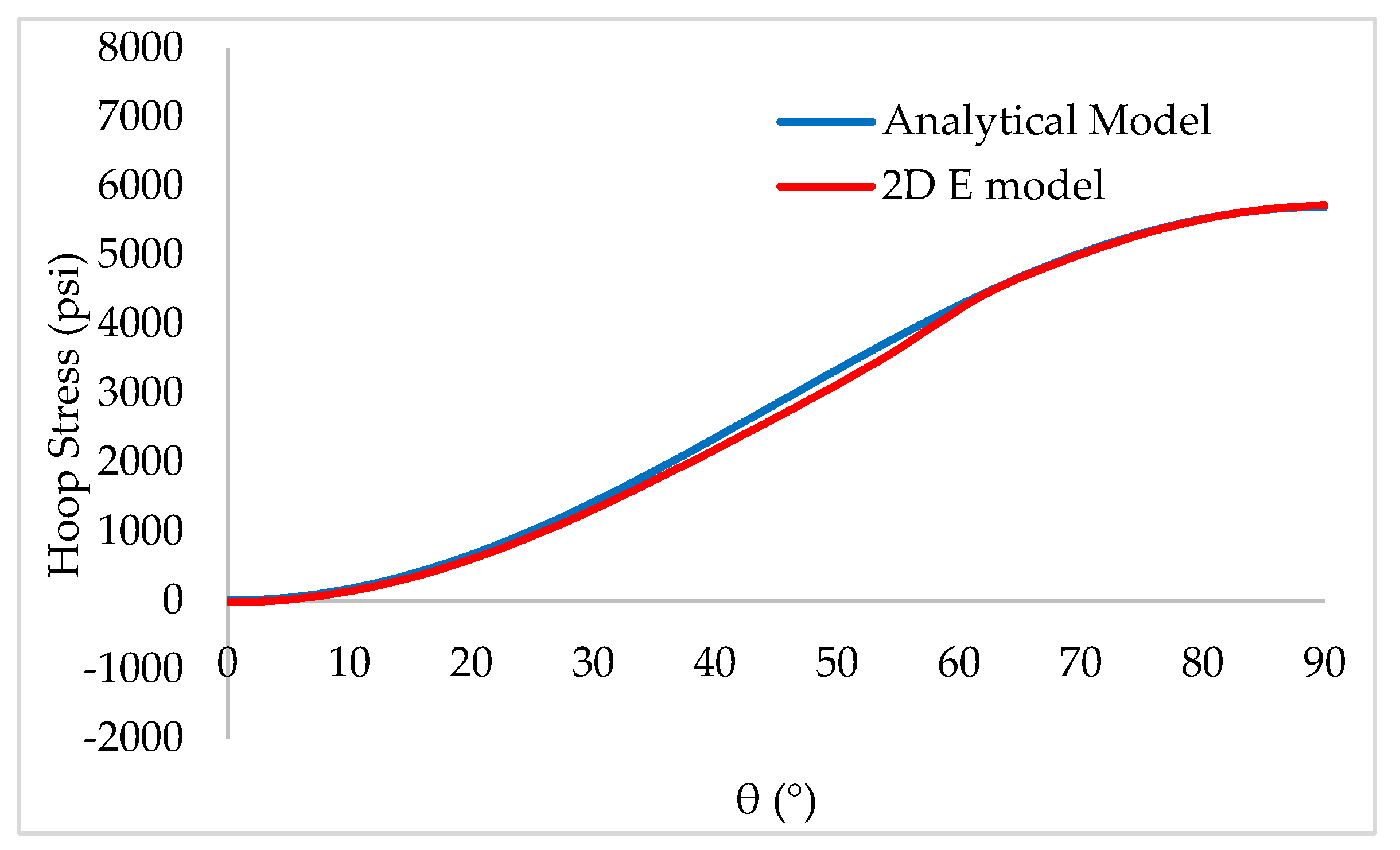

3. Results and Discussions

4. Conclusions

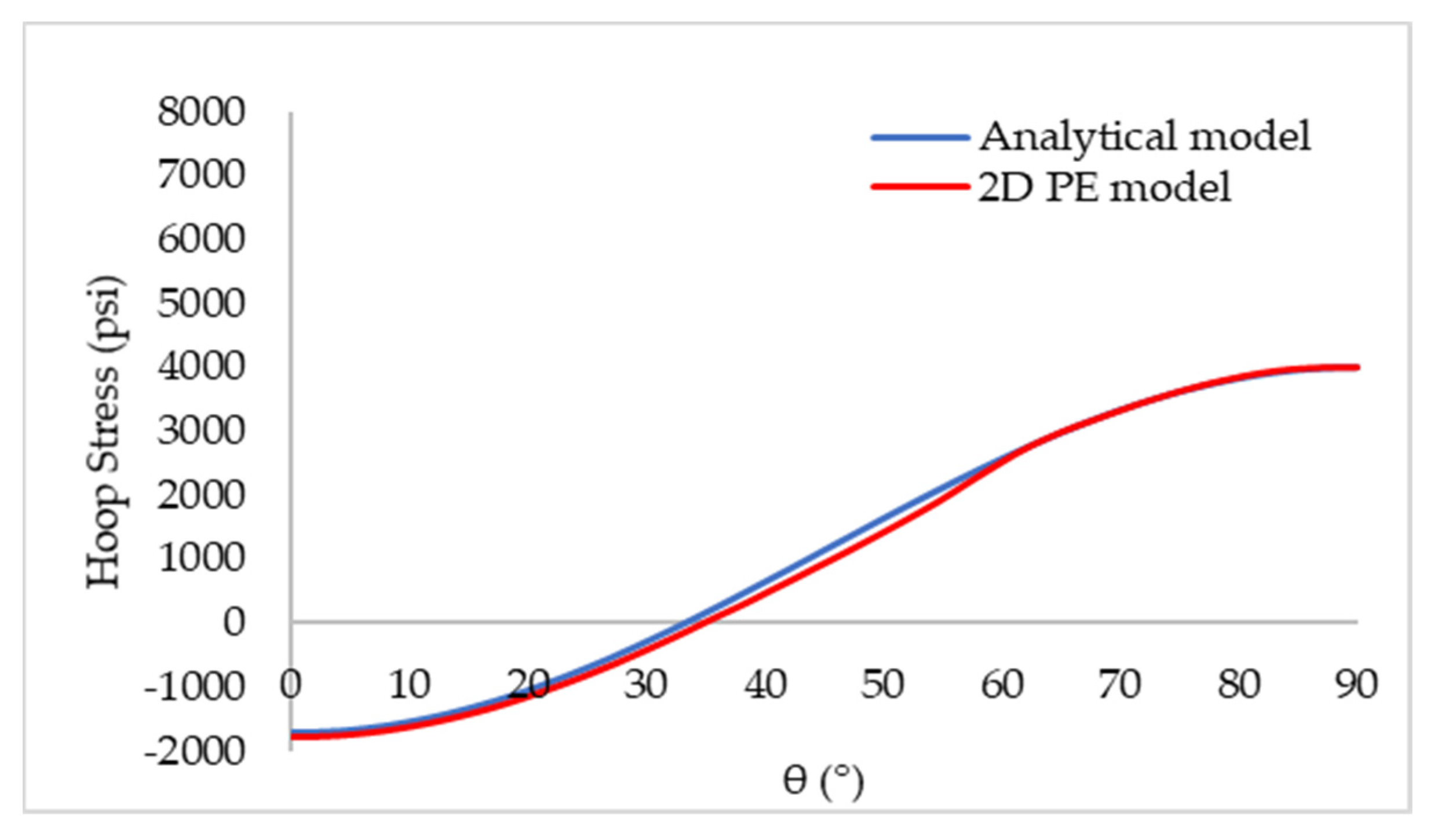

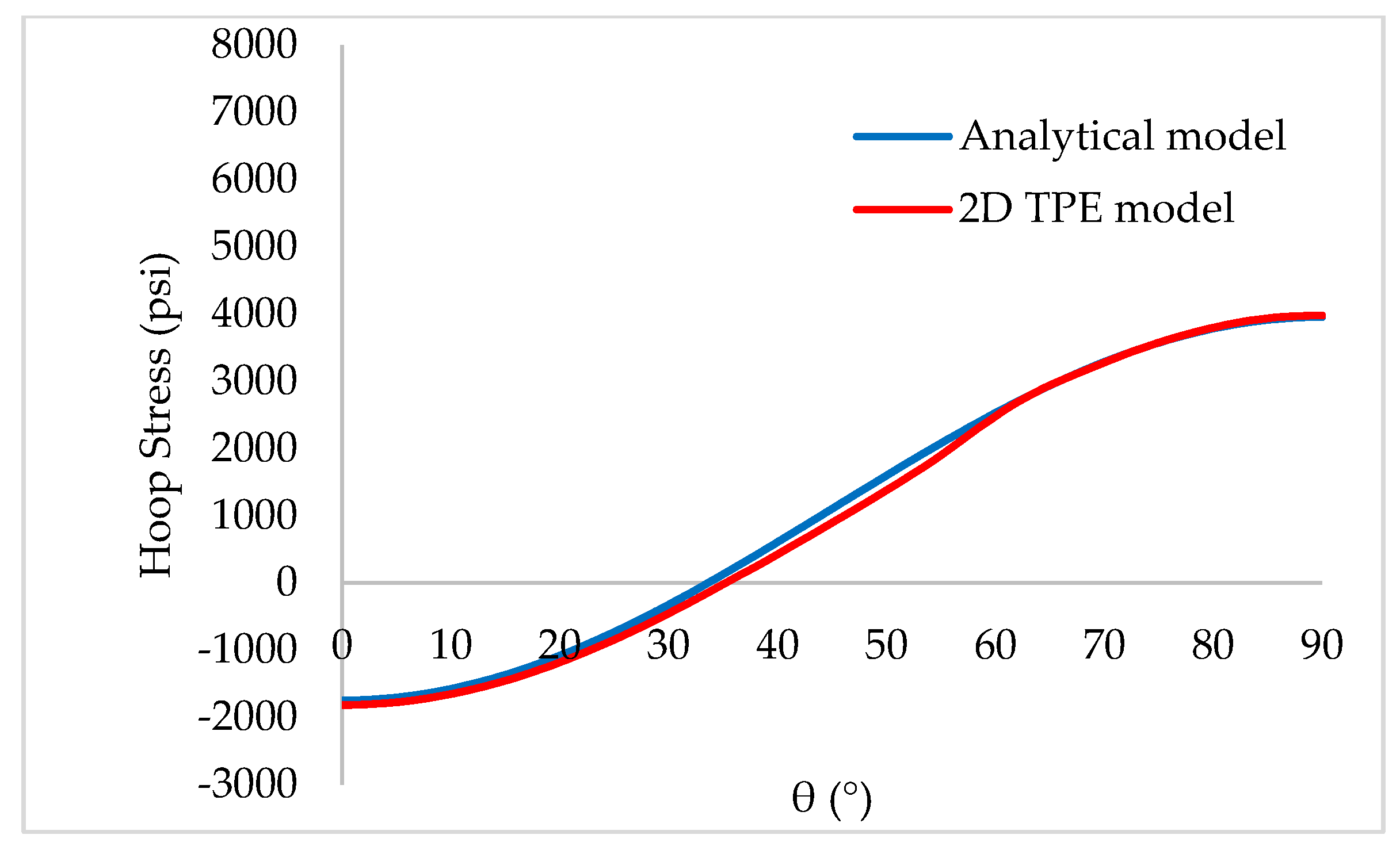

- The built numerical models are in a good agreement with known analytical models;

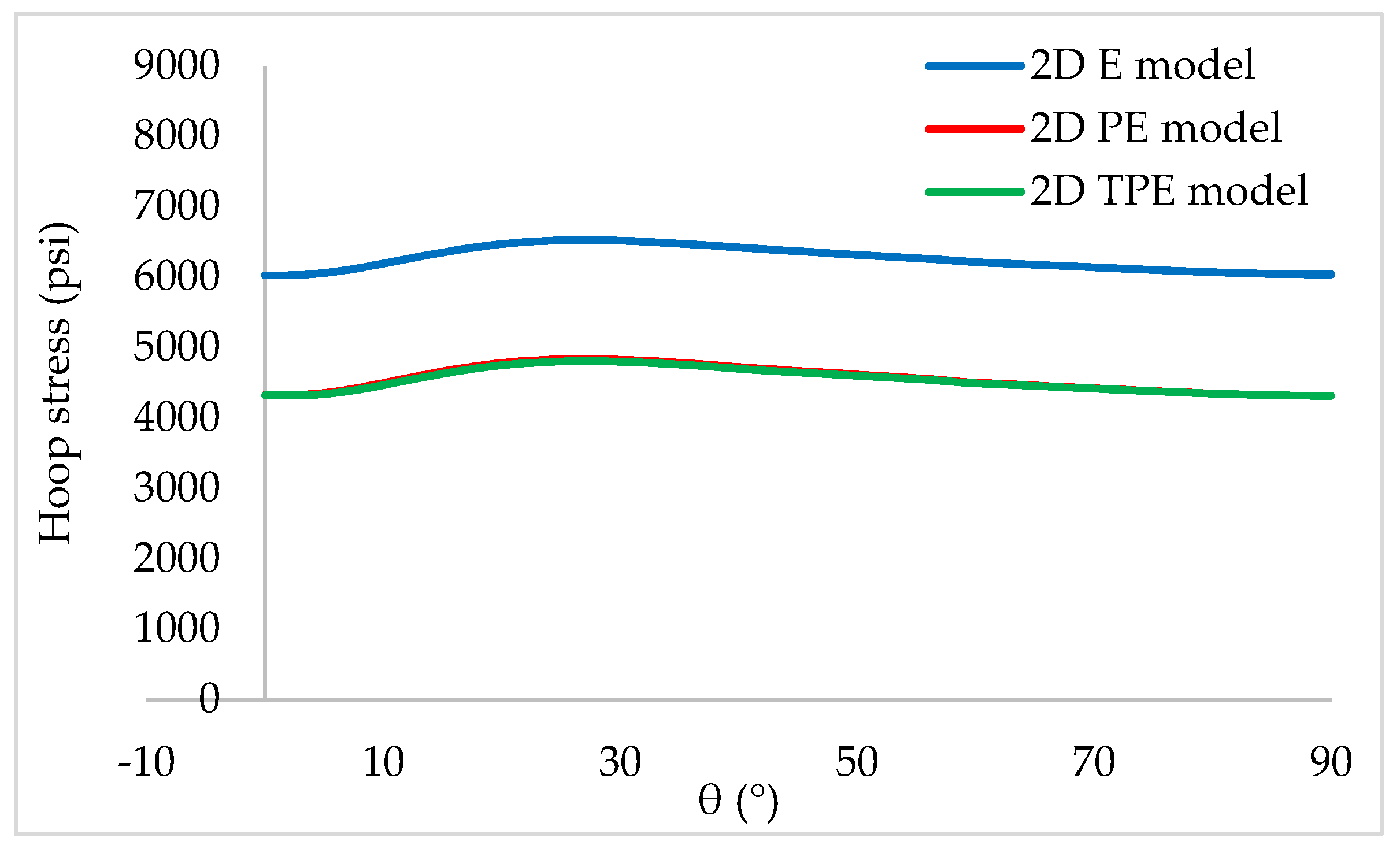

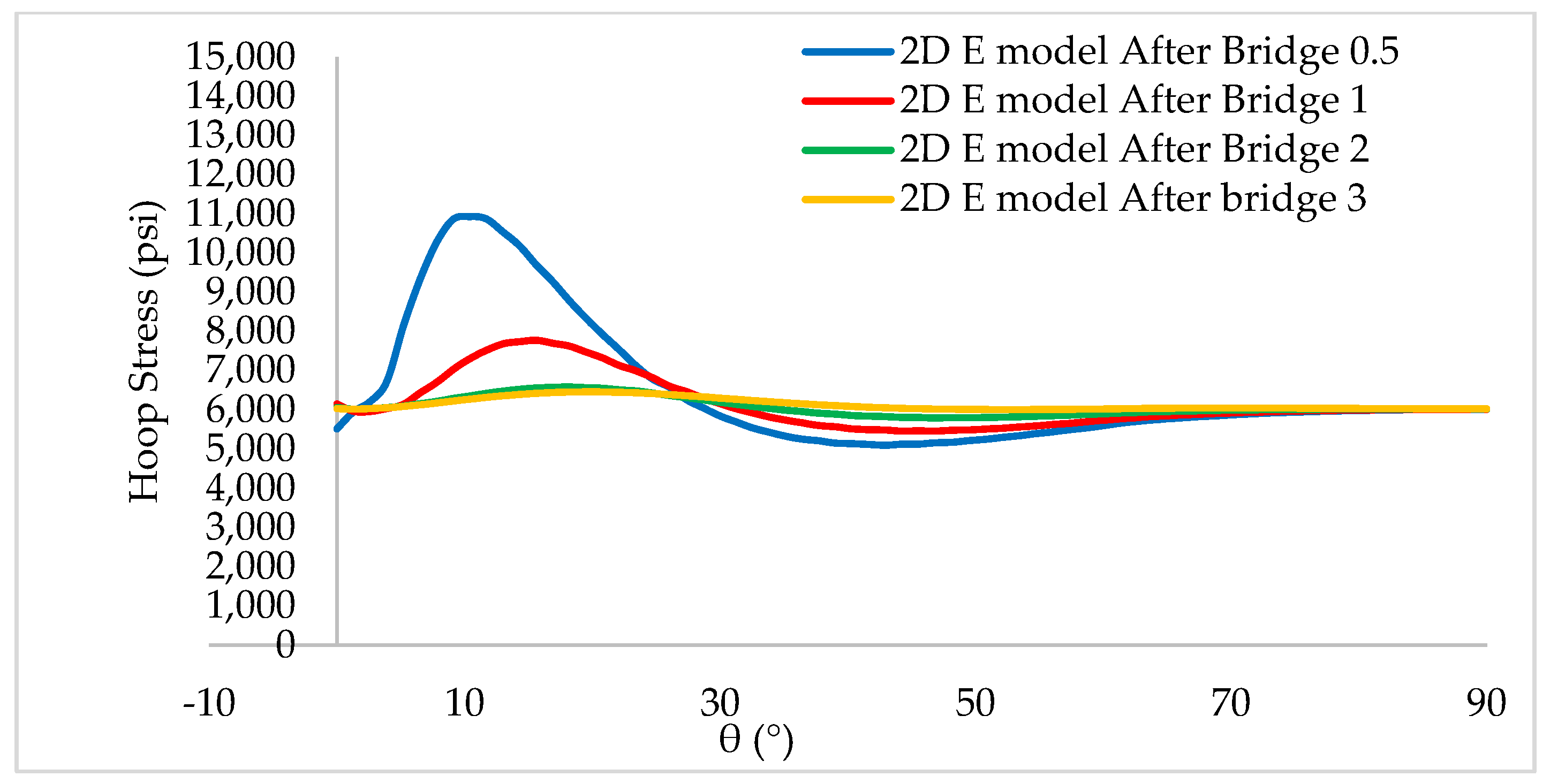

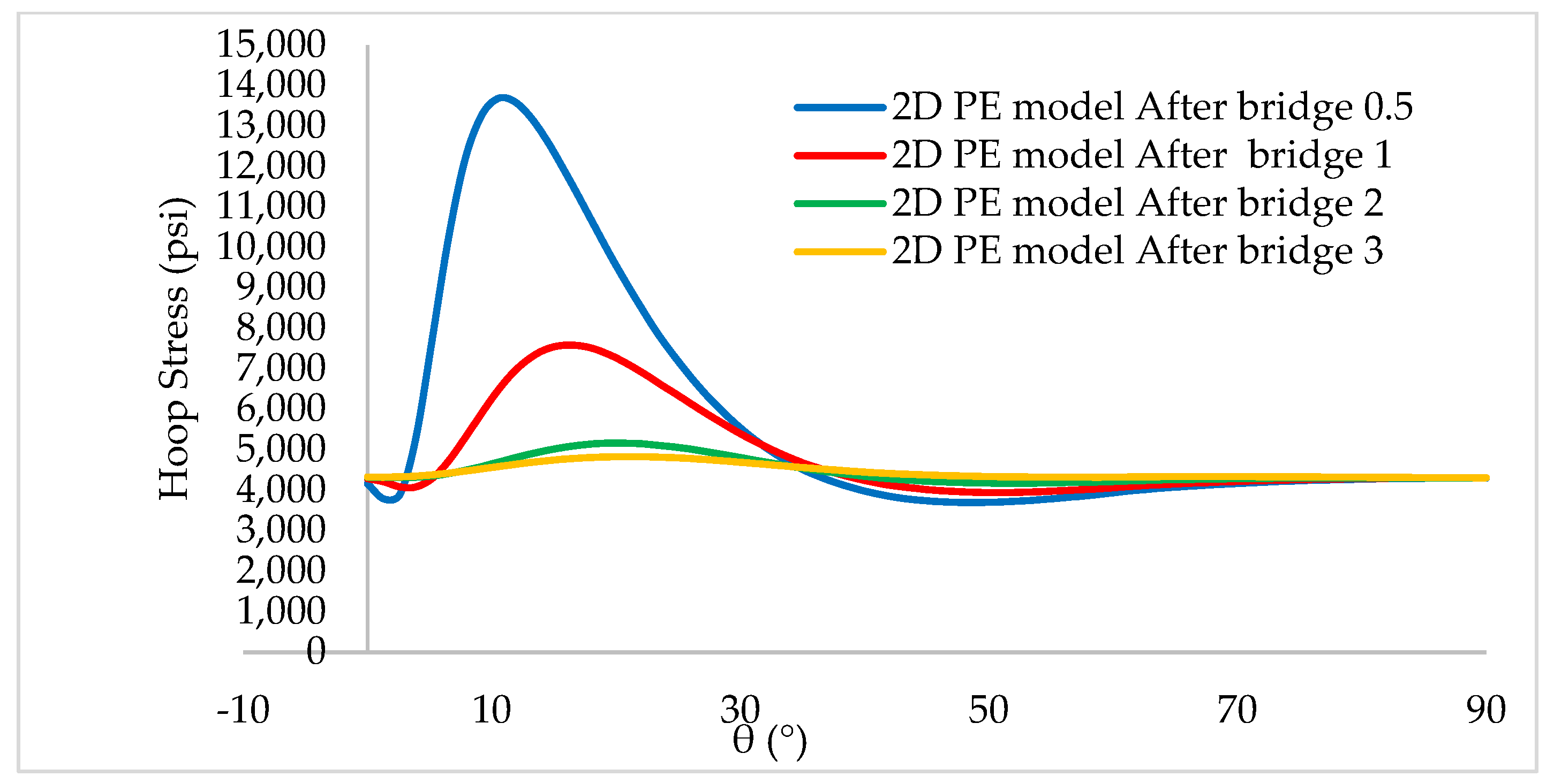

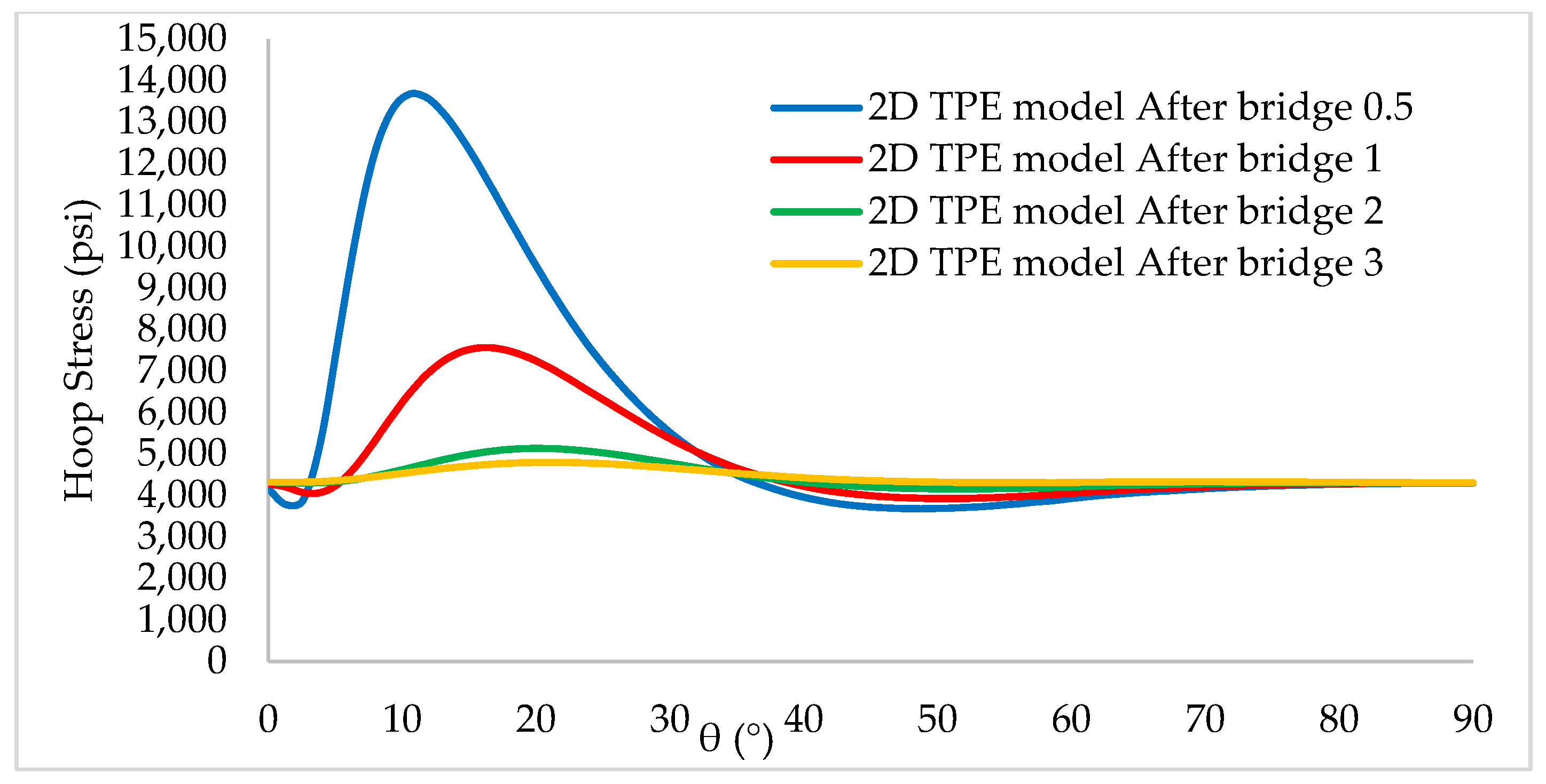

- The maximum hoop stress at three stages (before fracturing, after fracturing, and after bridging) was observed at different circumferential angles. This is due to the change in stress states around the borehole;

- After bridging the fractures, the maximum hoop stress was observed at the bridging location of 0.5 inches, which confirms the results of previous studies;

- All three models showed the hoop stress increase after bridging the fractures, which confirms the applicability of stress cage technology for wellbore strengthening purposes;

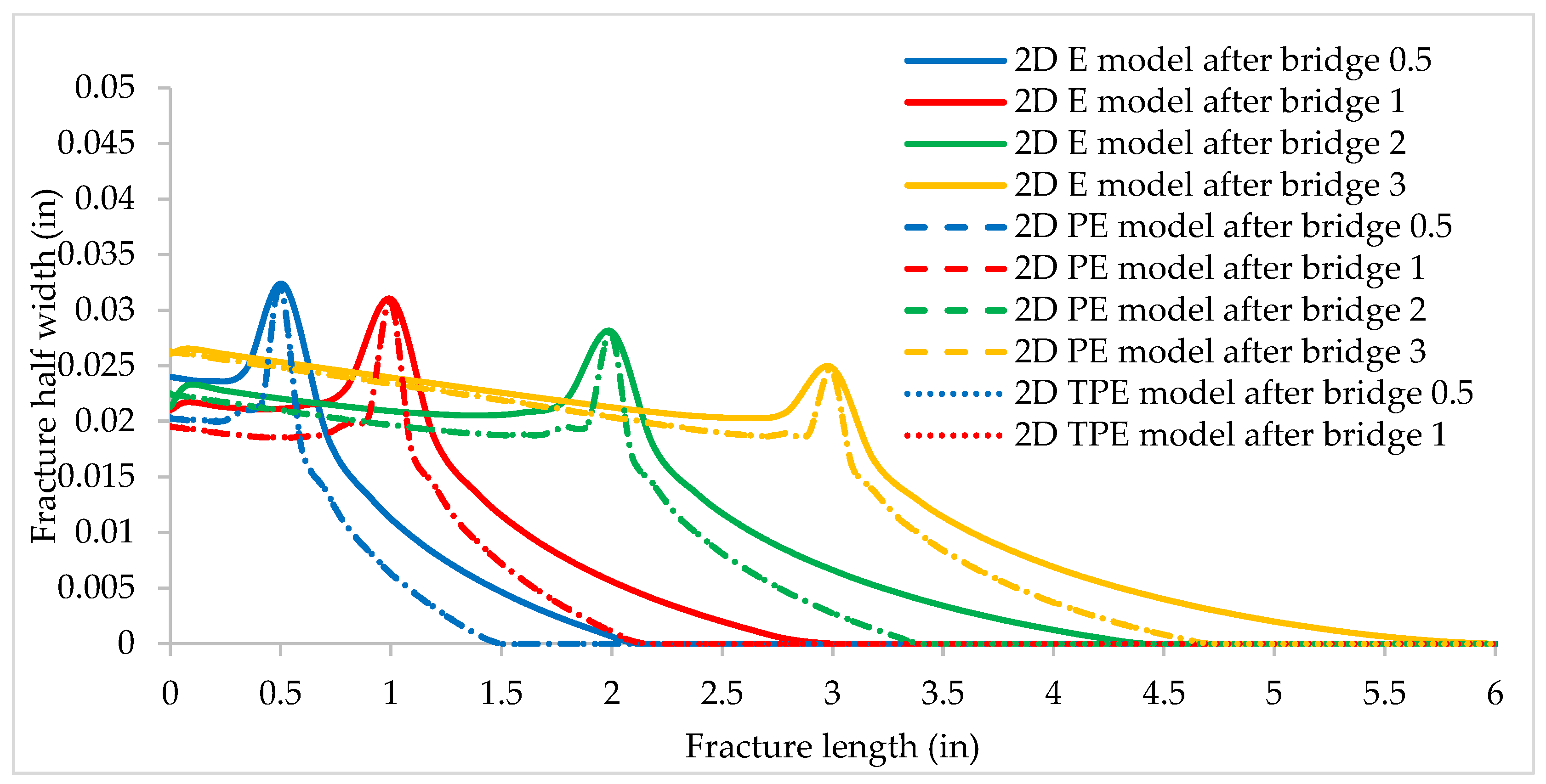

- The maximum area under the fracture was observed for bridging location of 3 inches from the aperture;

- The difference between the elastic, poro-elastic and thermo-poro-elastic models is slightly visible. However, at high-temperature conditions, i.e., when a significant temperature difference between mud and formation is anticipated, the effect of thermal stresses should be investigated.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yili, K.A.; Chengyuan, X.U.; Long, T.A.; Song, L.I.; Daqi, L.I. Constructing a tough shield around the wellbore: Theory and method for lost-circulation control. Pet. Explor. Dev. 2014, 41, 520–527. [Google Scholar]

- Berkay, H. Finite Element Analysis of Wellbore Strengthening. Ph.D. Thesis, University of Texas, Austin, TX, USA, 2011. [Google Scholar]

- Salehi, S.; Nygaard, R. Numerical study of fracture initiation, propagation, sealing to enhance wellbore fracture gradient. In Proceedings of the 45th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 26 June 2011. [Google Scholar]

- Hussain, R. Well Engineering & Construction; Entrac Consulting Limited: London, UK, 2002. [Google Scholar]

- Feng, Y.; Gray, K. Review of fundamental studies on lost circulation and wellbore strengthening. J. Pet. Sci. Eng. 2017, 152, 511–522. [Google Scholar] [CrossRef]

- Litvinenko, V.; Dvoinikov, M. Methodology for determining the parameters of drilling mode for directional straight sections of well using screw downhole motors. J. Min. Inst. 2020, 241, 105–112. [Google Scholar] [CrossRef]

- Dvoynikov, M.V.; Sidorkin, D.I.; Kunshin, A.A.; Kovalev, D.A. Development of Hydraulic Turbodrills for Deep Well Drilling. Appl. Sci. 2021, 11, 7517. [Google Scholar] [CrossRef]

- Cook, J.; Growcock, F.; Guo, Q.; Hodder, M.; van Oort, E. Stabilizing the wellbore to prevent lost circulation. Oilfield Rev. 2011, 23, 26–35. [Google Scholar]

- Wang, H.; Soliman, M.Y.; Towler, B.F. Investigation of Factors for Strengthening a Wellbore by Propping Fractures. SPE Drill. Completion 2008, 24, 441–451. [Google Scholar] [CrossRef]

- Yao, Z.; Alberty, M. Thermal Effect on Fracture Width for Wellbore Strengthening Applications. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Galveston, TX, USA, 25 February 2020. [Google Scholar] [CrossRef]

- Fan, G.; Li, M.; Chen, X.; Palyanitsina, A.; Timoshin, A. Polymer-Nanosilica-assisted to evaluate oil recovery performances in sandstone reservoirs. Energy Rep. 2021, 7, 2588–2593. [Google Scholar] [CrossRef]

- Rogachev, M.K.; Van, T.N.; Aleksandrov, A.N. Technology for Preventing the Wax Deposit Formation in Gas-Lift Wells at Offshore Oil and Gas Fields in Vietnam. Energies 2021, 14, 5016. [Google Scholar] [CrossRef]

- Aston, M.S.; Alberty, M.W.; McLean, M.R.; De Jong, H.J.; Armagost, K. Drilling fluids for wellbore strengthening. In Proceedings of the IADC/SPE Drilling Conference, Dallas, TX, USA, 2 March 2004. [Google Scholar]

- Alberty, M.W.; McLean, M.R. A physical model for stress cages. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26 September 2004. [Google Scholar]

- Mirabbasi, S.M.; Ameri, M.J.; Biglari, F.R.; Shirzadi, A. Thermo-poroelastic wellbore strengthening modeling: An analytical ap-proach based on fracture mechanics. J. Pet. Sci. Eng. 2020, 195, 107492. [Google Scholar] [CrossRef]

- Islamov, S.; Grigoriev, A.; Beloglazov, I.; Savchenkov, S.; Gudmestad, O. Research Risk Factors in Monitoring Well Drilling—A Case Study Using Machine Learning Methods. Symmetry 2021, 13, 1293. [Google Scholar] [CrossRef]

- Liagov, I.; Liagov, A.; Liagova, A. Optimization of the Configuration of the Power Sections of Special Small-Sized Positive Displacement Motors for Deep-Penetrating Perforation Using the Technical System “Perfobore”. Appl. Sci. 2021, 11, 4977. [Google Scholar] [CrossRef]

- Petrakov, D.G.; Penkov, G.M.; Zolotukhin, A.B. Experimental study on the effect of rock pressure on sandstone permeability. J. Min. Inst. 2022, 254, 1–8. [Google Scholar] [CrossRef]

- Blinov, P.A. Saint Petersburg Mining University determining the stability of the borehole walls at drilling intervals of loosely coupled rocks considering zenith angle. J. Min. Inst. 2019, 236, 172–179. [Google Scholar] [CrossRef] [Green Version]

- Grigoriev, B.S.; Peter the Great St. Petersburg Polytechnic University; Eliseev, A.A.; Pogarskaya, T.A.; Toropov, E.E.; Rubin, J.C.M. Mathematical modeling of rock crushing and multiphase flow of drilling fluid in well drilling. J. Min. Inst. 2019, 235, 16–23. [Google Scholar] [CrossRef]

- Gil, I.; Roegiers, J.C. New wellbore strengthening method for low permeability formations. In Proceedings of the Golden Rocks 2006, The 41st US Symposium on Rock Mechanics (USRMS), Golden, CO, USA, 17 June 2006. [Google Scholar]

- Wang, H.; Towler, B.F.; Soliman, M.Y. Near wellbore stress analysis and wellbore strengthening for drilling depleted formations. In Proceedings of the Rocky Mountain Oil & Gas Technology Symposium, Denver, CO, USA, 16 April 2007. [Google Scholar]

- Wang, H.; Towler, B.F.; Soliman, M.Y.; Shan, Z. Wellbore strengthening without propping fractures: Analysis for strengthening a wellbore by sealing fractures alone. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 3 December 2008. [Google Scholar]

- Salehi, S.; Nygaard, R. Finite-element analysis of deliberately increasing the wellbore fracture gradient. In Proceedings of the 44th US Rock Mechanics Symposium and 5th US-Canada Rock Mechanics Symposium, Salt Lake City, UT, USA, 27 June 2010. [Google Scholar]

- Shahri, M.P.P.; Oar, T.T.; Safari, R.; Karimi, M.; Mutlu, O. Advanced Semianalytical Geomechanical Model for Wellbore-Strengthening Applications. SPE J. 2015, 20, 1276–1286. [Google Scholar] [CrossRef]

- Arlanoglu, C.; Feng, Y.; Podnos, E.; Becker, E.; Gray, K.E. Finite element studies of wellbore strengthening. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Fort Worth, TX, USA, 4 March 2014. [Google Scholar]

- Zhong, R.; Miska, S.; Yu, M. Parametric study of controllable parameters in fracture-based wellbore strengthening. J. Nat. Gas Sci. Eng. 2017, 43, 13–21. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, P.; Ma, T.S.; Wu, B.S.; Zhang, X.; Wu, B.L. A transient pressure analysis for wellbore strengthening. In Proceedings of the ARMA-CUPB Geothermal International Conference, Beijing, China, 5 August 2019. [Google Scholar]

- Li, J.; Qiu, Z.; Zhong, H.; Zhao, X.; Huang, W.; Yang, Y. Parametric study on near-wellbore fracture geometry for wellbore strengthening in anisotropic formation. J. Pet. Sci. Eng. 2019, 184, 106549. [Google Scholar] [CrossRef]

- Tabatabaee Moradi, S.S.; Nikolaev, N.I. Uncertainty assessment of wellbore stability analysis in horizontal sections. SN Appl. Sci. 2020, 2, 437. [Google Scholar] [CrossRef] [Green Version]

- Aslannezhad, M.; Manshad, A.K.; Jalalifar, H. Determination of a safe mud window and analysis of wellbore stability to minimize drilling challenges and non-productive time. J. Pet. Explor. Prod. Technol. 2015, 6, 493–503. [Google Scholar] [CrossRef] [Green Version]

- Leusheva, E.; Morenov, V.; Tabatabaee Moradi, S. Effect of Carbonate Additives on Dynamic Filtration Index of Drilling Mud. Int. J. Eng. 2020, 33, 934–939. [Google Scholar] [CrossRef]

- Bozorgi, M.J.; Parham, M.; Rahmani, O.; Piroozian, A.; Gebretsadik, H.T.; Ibad, S.M. A Three-Dimensional Finite-Element Model in ABAQUS to Analyze Wellbore Instability and Determine Mud Weight Window. Energies 2022, 15, 3449. [Google Scholar] [CrossRef]

- Zhang, J.J. Applied Petroleum Geomechanics; Gulf Professional Publishing: Houston, TX, USA, 2019. [Google Scholar] [CrossRef]

- Aadnøy, B.; Looyeh, R. Wellbore instability analysis. In Petroleum Rock Mechanics; Gulf Professional Publishing: Houston, TX, USA, 2019. [Google Scholar]

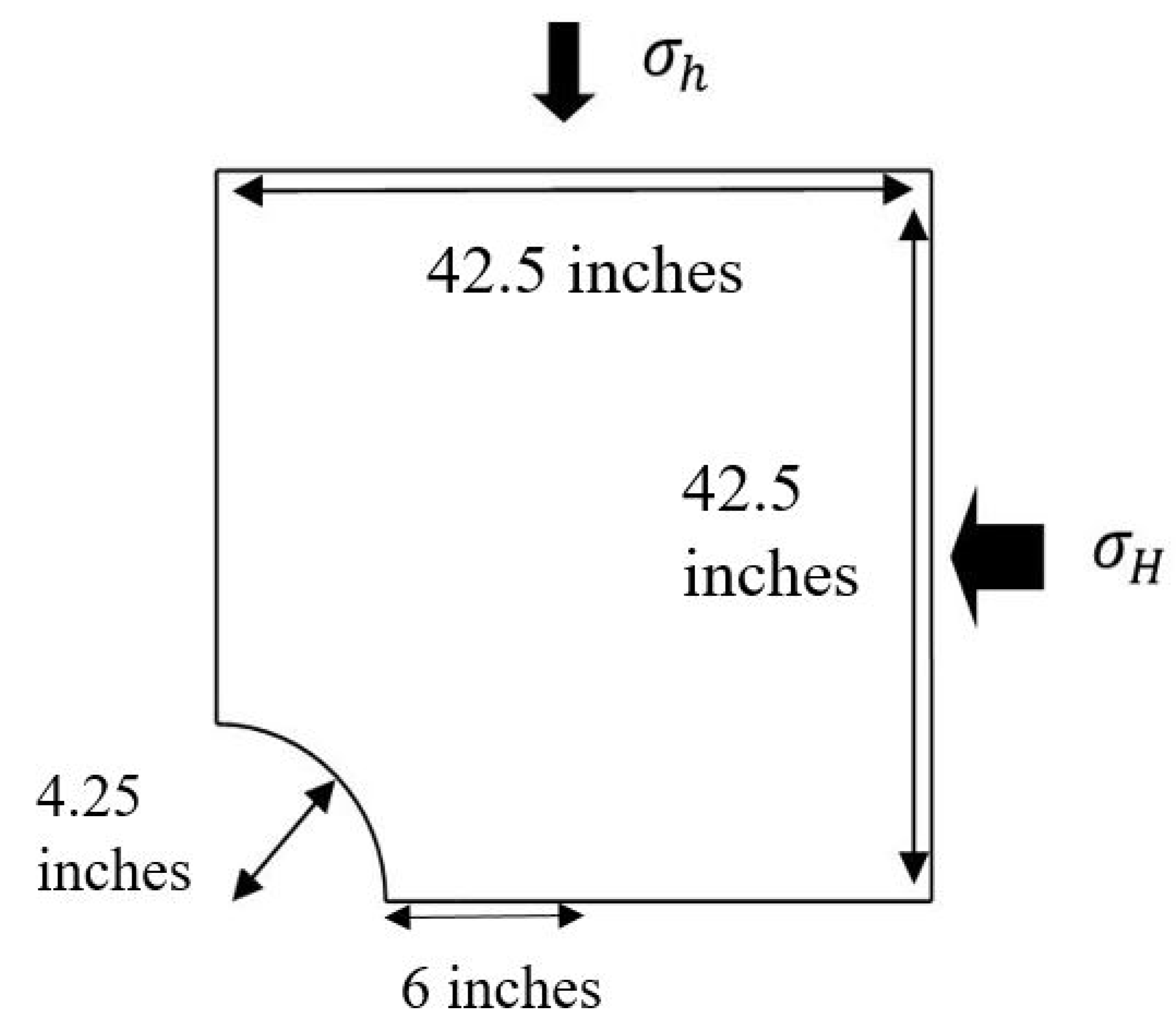

| Parameter | Values | Units |

|---|---|---|

| Model length | 42.5 | in |

| Model width | 42.5 | in |

| Wellbore radius | 4.25 | in |

| Fracture length | 6 | in |

| Young’s modulus | 1,500,000 | psi |

| Poisson’s ratio | 0.25 | - |

| Maximum horizontal stress | 5000 | psi |

| Minimum horizontal stress | 3575 | psi |

| Overburden stress | 6000 | psi |

| Wellbore pressure | 5725, 6025 | psi |

| Formation breakdown pressure | 5725 | psi |

| Pore pressure | 1700 | psi |

| Void ratio | 0.3 | - |

| Permeability | 100 | md |

| Rock thermal expansion coefficient | 1.1 × 10−6 | 1/°F |

| Specific heat | 1000 | J/(kg·K) |

| Conductivity | 4.5 | W/(m·K) |

| Bulk formation density | 2 | g/cm3 |

| Formation temperature | 120 | °F |

| Drilling fluid temperature | 100 | °F |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdollahpour, P.; Tabatabaee Moradi, S.S.; Leusheva, E.; Morenov, V. A Numerical Study on the Application of Stress Cage Technology. Energies 2022, 15, 5439. https://doi.org/10.3390/en15155439

Abdollahpour P, Tabatabaee Moradi SS, Leusheva E, Morenov V. A Numerical Study on the Application of Stress Cage Technology. Energies. 2022; 15(15):5439. https://doi.org/10.3390/en15155439

Chicago/Turabian StyleAbdollahpour, Pouya, Seyyed Shahab Tabatabaee Moradi, Ekaterina Leusheva, and Valentin Morenov. 2022. "A Numerical Study on the Application of Stress Cage Technology" Energies 15, no. 15: 5439. https://doi.org/10.3390/en15155439

APA StyleAbdollahpour, P., Tabatabaee Moradi, S. S., Leusheva, E., & Morenov, V. (2022). A Numerical Study on the Application of Stress Cage Technology. Energies, 15(15), 5439. https://doi.org/10.3390/en15155439