Abstract

During well drilling in offshore conditions beyond the North of the Arctic Circle, there are often problems associated with deviations in the rheological parameters of the drilling mud as the temperature changes. Mud temperature in the upper part of the well in most cases is in the range up to 20 °C, whereas in the productive formation it is up to 80 °C and more. For such conditions, it is necessary to estimate the influence of temperature on the rheological parameters of drilling fluids, which is done in this paper. Compositions of water-based and hydrocarbon-based muds that may be used in the conditions of the offshore hydrocarbon fields were considered. The paper presents the authors’ formula for a drilling mud that possesses more stable rheological parameters in the temperature conditions of the offshore oil field and is more environmentally friendly. The physical properties of the newly designed drilling mud were measured with laboratory equipment. Rheological investigations were carried out under varying temperatures up to 80 °C. The results of the experiments show the newly designed drilling mud to be more stable than its hydrocarbon-based analogue. Besides, the newly developed composition has a lower content of solid phase, which is also an important parameter for the process of sea wells construction, often characterized by a narrow window of permissible pressure.

1. Introduction

In drilling operations, the correct type and composition of drilling mud is a key element. One of its main functions is to transport cuttings and solids from the borehole bottom to the surface and to keep them suspended in the borehole during circulation shutdown [1].

Drilling muds are generally divided into three main types, namely water-based muds (WBM), hydrocarbon-based muds (HBM) and synthetic-based muds (SBM) [2,3,4]. Offshore drilling involves many wellbore and operation problems. Wellbore stability, rate of penetration (ROP), borehole cleaning and pressure control are some of the key performance parameters that are influenced by the selection of drilling fluids for these wells [5].

Water-based drilling muds are the most widespread type of drilling fluids, which have been widely used in the oil industry for more than 150 years due to its profitability, environmental friendliness, safety, and the highest efficiency compared to other fluids [6,7,8].

Nowadays, there is a trend towards replacement of water-based drilling muds by hydrocarbon or synthetic-based systems. Hydrocarbon-based muds and SBM provide excellent wellbore stability and maximum ROP, especially when combined with PDC bits. Conversely, controlling equivalent circulation density (ECD), pump start-up pressure and fluctuating pressure is more difficult with HBM and SBM because of the thermobaric effect on rheological properties. Failure to effectively control these drilling parameters can lead to lost circulation with negative impacts on operating costs associated with non-productive time (NPT), as well as high specific cost of HBM and SBM [9,10]. Furthermore, the use of HBM and SBM is often associated with serious environmental problems and high operating costs, especially in offshore wells [11]. Therefore, WBM often remain the preferred drilling fluid despite its lower efficiency. Thus, to compensate for the WBM limitations, it is necessary to develop and apply new compositions of these fluids.

Formate brine (sodium, potassium, and caesium formic acid salts) drilling fluids are one of the modern types of drilling muds, which can successfully compete with HBM and SBM [12,13]. Formate systems are solutions with low solid phase content that are more environmentally friendly than other widely used brine systems, and are compatible with formation fluids. This creates prerequisites for increasing ROP and reducing contamination of near-bottomhole zone [14]. Besides, the systems based on carboxylic acids salts in combination with polymer additives have effective inhibiting ability in relation to clay shales, increased thermal stability of polysaccharide reagents, low corrosive activity, and contribute to decrease of friction in drilling fluids [15,16].

Table 1 shows the advantages and disadvantages of HBM, SBM and formate WBM.

Table 1.

Comparison of HBM and SBM with formate WBM.

Offshore drilling in the polar region often encounters problems with variations in the rheological parameters of the drilling fluid as the temperature changes [17,18,19]. Mud temperature in the upper part of the well can be 20 °C or less, whereas in the pay zone, it may be 80 °C or more [20,21,22]. These conditions will affect the process performance of temperature-dependent drilling fluids when flowing back from borehole bottom with higher temperature. Conventional drilling fluids are more viscous due to low temperatures before they enter the formation [23]. As the drilling continues, the temperature increases, thereby causing the viscosity to decrease. Viscosity can drop to the point where the drilling fluid loses its ability to carry out the cuttings and weighting agents, affecting the drilling fluid’s ability to clean the borehole. Under such conditions, a thickener is added to the mud to improve the resulting rheology of the fluid. However, the drilling fluid becomes excessively viscous as it returns to the low-temperature surface, resulting in a high equivalent circulation density (ECD) [24,25]. High ECD should always be avoided during drilling because it increases pumping pressure, which can lead to formation fracturing if the fluid pressure exceeds the rock absorption (or fracturing) pressure. Being free of excess solids, such as barite, high-density formate muds will also tend to exhibit lower plastic viscosity and, therefore, lower ECD and lower bottomhole pressure loss, thereby improving drilling efficiency [26]. Damage to reservoir properties can occur because of clogging of the pore formation by solids from the drilling fluid filtrate or by solids detached from the rock skeleton by the drilling fluid filtrate. To prevent clogging, chalk of different fractional composition is used as a bridging agent when formulating drilling systems for productive formation drilling-in. Its main advantage is the ability to be dissolved by more than 98% in 15% hydrochloric acid (HCl).

Formation pressure is one of the most important factors affecting the technological parameters of the drilling fluid. The designed density of the drilling fluid depends on it. Most often barite is used to increase the density [26,27]. Barite is acid-insoluble and, therefore, it is very difficult to remove it from pores of the pay zone [28,29]. The investigations were carried out considering this and a formate-free drilling mud of high density was designed by the authors [30]. The obtained mud is applicable at anomaly coefficients up to 1.35.

As a continuation of the work [30], it was essential to carry out a study to evaluate the effect of temperature on the rheological parameters of the drilling mud. In addition to WBM, it is necessary to experimentally evaluate the change in rheological parameters of the HBM with the same density.

Thus, the aim of the work was to assess the effect of temperature on the characteristics of the newly developed composition of environmentally friendly water-based drilling mud, containing various additives, which give the mud HBM-like properties. The newly designed mud should provide an effective well construction process, while having no negative impact on the environment, especially in the conditions of offshore fields. The idea of the work was to evaluate the effect of temperature in the range from 20 °C to 80 °C on the rheological parameters of newly designed barite-free drilling mud and the HBM. Correctly chosen solution density, based on expected pressures, and its stable rheological parameters during temperature changes in the well, will preserve the permeability of the pay zone.

The novelty of the work lies in obtaining the dependencies of the rheological characteristics for the newly designed WBM composition on the temperatures that are typical for the offshore fields in the northern seas. Analogous dependencies for HBM of the same density and under same conditions were also obtained.

2. Methodology

The investigated drilling mud is meant to be used during the construction of a horizontal directional well at the Prirazlomnoye field (Arctic shelf of Russia). Drilling operations at this field are complicated by a narrow safe pressure window in terms of mud density and the presence of unstable clay deposits in the geological section, causing problems with wellbore stability. The formation anomaly coefficient is ka = 1.35 and the formation temperature is 65 °C. A temperature up to 80 °C must be considered when designing the drilling program. The newly designed drilling mud is more environmentally safe than the HBM, but the effect of temperature on rheological parameters should be studied in order to assess its efficiency.

2.1. Laboratory Equipment

A lever scale (Model 140, Mud Balance, Fann Instrument Company) was used to measure the density of the drilling mud. To determine the rheological properties of the developed and investigated drilling fluids, a Fann 6-speed rotary viscometer, model 35A, was used in the laboratory of the Saint Petersburg Mining University. The compositions of the investigated formate drilling muds and the HBM were tested by rotating the outer cylinder at 600, 300, 200, 100, 6 and 3 rpm.

Determination of the filtration index was performed on an API filter press. Drilling fluid engineers estimate the filtration index of the drilling mud at ambient temperature under the pressure of 100 lb/in2. The analysis consists of determining the flow rate of the fluid through the filter paper. The result is the volume of filtrate produced (mL) in 30 min [31,32].

The effect of temperature on the rheology of the drilling fluid was analysed with the “Rheotest RN 4.1” rotary viscometer with cylinder measuring system (Figure 1). It automatically generates viscosity curves and dynamic shear stress (DSS) curves over a wide range of stresses and shear rates at different temperatures.

Figure 1.

Rotary viscometer “Rheotest RN 4.1”.

Non-linearity and consistency indices (K and n) were also evaluated based on the obtained rheological characteristics.

2.2. Object of the Investigation

Temperature and pressure affect the parameters of the drilling mud, as their changes lead to fluctuations in rheological, structural, and mechanical properties of the fluid, but at different scales. It is believed that it is inappropriate to study the dependence of rheological parameters of the fluids on temperature without considering changes in pressure. However, analysis of the scientific literature [33,34] proves that in the case of water-based solutions, the influence of pressure on rheology is negligible and less noticeable than in the case of varying temperatures. Generally, as the pressure increases, the rheological parameters of the system will also increase. Thus, the effect of pressure was not considered in the investigation; the experiments were conducted at the ambient pressure. To investigate the effects of temperature on the rheological properties, two solutions were chosen for analysis—a solution based on formate acid salts treated with partially hydrolysed polyacrylamide (PHPA) and a solution based on hydrocarbons. Compositions and basic parameters of the solutions are presented in Table 2.

Table 2.

Compositions and parameters of the investigated solutions.

3. Results of the Investigation

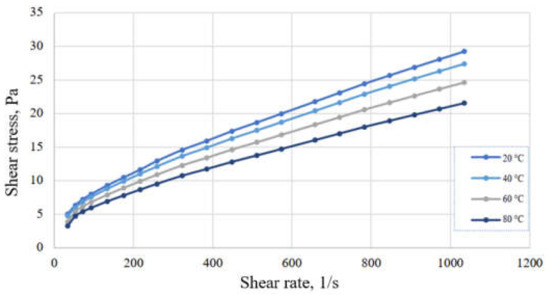

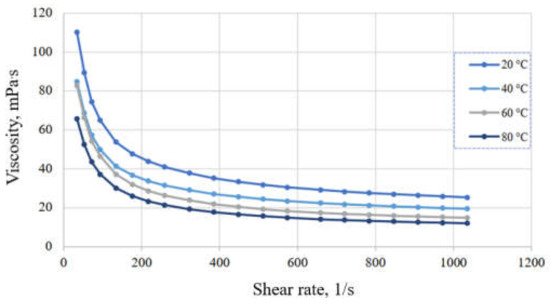

Rheological parameters of the formate-based drilling mud treated with PHPA were investigated at different temperatures (20 °C, 40 °C, 60 °C, 80 °C) with a rotary viscometer “Rheotest RN 4.1”. The rheological behaviour of the studied solution at different temperatures is shown in Figure 2 and Figure 3.

Figure 2.

Dependence of shear stress on the shear rate for the formate-based drilling mud at different temperatures.

Figure 3.

Dependence of viscosity on the shear rate for the formate-based drilling mud at different temperatures.

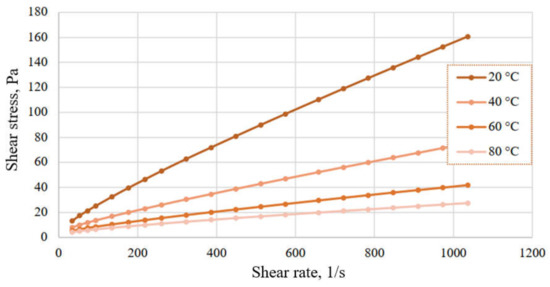

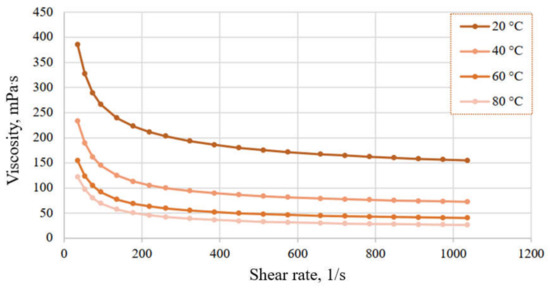

The rheological behaviour of the investigated hydrocarbon-based solution at different temperatures is shown in Figure 4 and Figure 5.

Figure 4.

Dependence of shear stress on the shear rate for the hydrocarbon-based drilling mud at different temperatures.

Figure 5.

Dependence of viscosity on the shear rate for the hydrocarbon-based drilling mud at different temperatures.

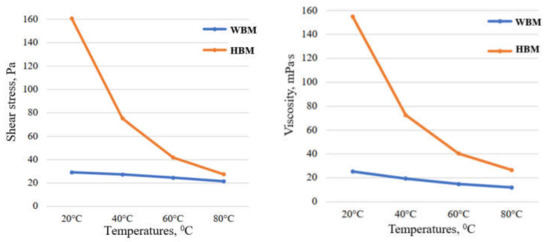

In order to compare the rheological parameters of the formate-based WBM and HBM, it is reasonable to carry out the tests at a constant shear rate (1022 1/s). Data obtained are plotted in Figure 6.

Figure 6.

Comparison of the rheology of the investigated solutions at different temperatures.

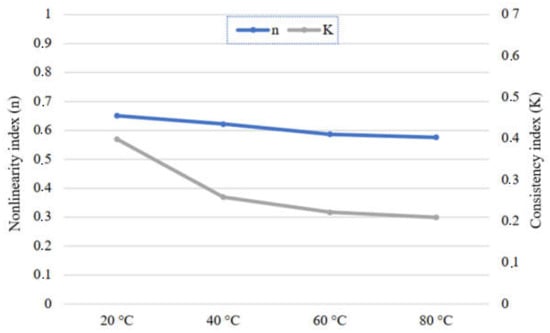

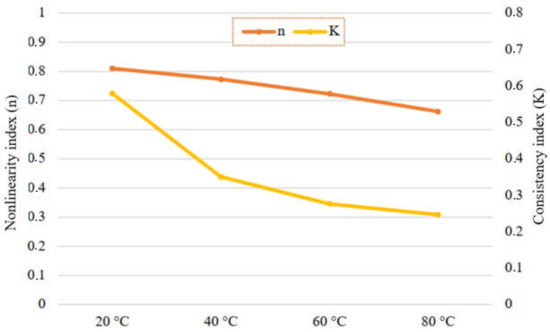

The change in the rheological coefficients of the studied solutions at different temperatures was also considered (Figure 7 and Figure 8).

Figure 7.

Change in the rheological coefficients of the formate-based WBM with PHPA at different temperatures.

Figure 8.

Change in the rheological coefficients of the HBM at different temperatures.

4. Discussion of the Results

The results of the analysis show that the rheological parameters of both studied solutions decreased when heated, but the effect of temperature on the rheology of the HBM was much more significant than on the rheology of formate-based WBM. Under the influence of elevated temperatures, the HBM were prone to liquefaction and were characterized by low thixotropy. Consequently, the use of hydrocarbon systems was accompanied by certain difficulties in terms of controlling their properties. It was important to consider that the use of HBM as flushing fluids is inadvisable when drilling wells at offshore fields due to their negative impact on the environment and fire hazard.

The acquired data show that the decrease in viscosity for WBM with increasing temperature was about 25%, whereas for the HBM the same increase in temperature led to a decrease in viscosity of more than 80%.

The dependence of viscosity on temperature for the HBM was non-linear, and there was also a strong decrease of DSS with increasing temperature, which contributed to a decrease of quality and efficiency of borehole cleaning. When analysing the dependencies received with the “Rheotest RN 4.1”, it should be noted that the investigated formate drilling fluid was relatively stable in the given range of moderate temperatures. Plastic viscosity of the investigated fluid tended to decrease with increase of temperature from 20 °C to 80 °C. This agrees with the well-known theoretical conceptions. At the same time, it was seen that the structural properties of the drilling fluid undergo insignificant change depending on shear stress.

The consistency index of the investigated formate fluid decreased with increasing temperature, which was primarily due to a decrease in the viscosity of the dispersion medium. The non-linearity index, in contrast, was stable at different temperatures—these dependencies were due to the properties of the biopolymer and PHPA used [35,36]. Under the conditions of varying temperature, a slight decrease of the non-linearity index with a simultaneous decrease of the consistency index will result in a reduction of the hydraulic resistance in the circulation system and, consequently, of pressure at the pumps. For the hydrocarbon-based solution, the change in rheological parameters had a similar trend, however, the HBM exhibited less pseudoplastic properties and were a more viscous system compared to the WBM, which can lead to an increase in ECD.

In the HBM case, an exponential increase in plastic viscosity, as the mud cools (e.g., during tripping), will cause a sharp increase in start-up pressures and ECD, which can lead to fracturing, mud loss and absorption, and failure of wellbore wall stability. Therefore, the HBM application for drilling wells in offshore areas is complicated.

5. Conclusions

The paper compares the temperature effect on the rheological properties of drilling muds based on formates to those of the HBM. According to the obtained results it was seen that the plastic viscosity of the studied fluid tended to decrease as the temperature rises. At the same time, the dependence of shear stress on shear rate shows that the structural properties of the drilling mud underwent insignificant change, which creates the preconditions for using these systems under different temperature conditions. It is possible to state, that the investigated newly designed mud was stable in the given range of moderate temperatures (from 20 to 80 °C).

However, it is quite difficult to fully predict the behaviour of a multicomponent mud system (containing not only the structurant and base, but also inhibitors and weighting agents), under varying temperatures throughout the wellbore, due to the large number of factors affecting the rheological properties of drilling fluid. Temperature has a strong influence on the properties of modern drilling systems. Accordingly, changes in temperature must be considered, as improper management of mud properties can lead to complications in the drilling process and reduced quality of drilling-in the productive horizons.

In offshore applications, pseudo-oil (synthetic) muds are appropriate due to their ecological safety and system stability over a wide temperature range. Besides, such drilling fluids are characterized by satisfactory transporting and holding ability. Thus, an actual trend in oil systems’ formulation development is the creation of a “flat” rheological profile by means of rheology modifiers using non-aqueous biodegradable bases (esters of vegetable oils, alphaolefins and polyalphaolefins, acetals, etc.).

In conclusion, it is worth mentioning that the newly developed drilling mud is characterised by a low content of solids and allows to achieve high stability of rheological properties. Furthermore, the more successful rheological profile allows to reduce pressure loss in the well and avoid high values of equivalent circulation density.

Author Contributions

Conceptualization, E.L.; methodology, V.M.; software, E.L.; validation, E.L.; formal analysis, V.M.; investigation, E.L.; data curation, E.L.; writing—original draft, E.L.; writing—review and editing, V.M.; visualization, E.L.; supervision, V.M.; project administration, E.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to its storage in private networks.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| API | American Petroleum Institute |

| DSS | Dynamic Shear Stress |

| ECD | Equivalent Circulation Density |

| HBM | Hydrocarbon-Based Mud |

| NPT | Non-Productive Time |

| PHPA | Partially Hydrolysed Polyacrylamide |

| PDC | Polycrystalline Diamond Composite |

| SBM | Synthetic-Based Mud |

| WBM | Water-Based Mud |

| ROP | Rate of Penetration |

| rpm | revolutions per minute |

References

- Abdo, J.; Haneef, M. Nano-enhanced drilling fluids: Pioneering approach to overcome uncompromising drilling problems. J. Energy Resour. Technol. 2012, 134, 014501. [Google Scholar] [CrossRef]

- Litvinenko, V.S.; Nikolaev, N.I. Development of weighted biopolymer solutions for workover operations. J. Min. Inst. 2012, 199, 375. [Google Scholar]

- Hassani, S.S.; Amrollahi, A.; Rashidi, A.; Soleymani, M.; Rayatdoost, S. The effect of nanoparticles on the heat transfer properties of drilling fluids. J. Pet. Sci. Eng. 2016, 146, 183–190. [Google Scholar] [CrossRef]

- Dvoynikov, M.V.; Kuchin, V.N.; Mintzaev, M.S. Development of viscoelastic systems and technologies for isolating water-bearing horizons with abnormal formation pressures during oil and gas wells drilling. J. Min. Inst. 2021, 247, 57–65. [Google Scholar] [CrossRef]

- Fedorov, G.B.; Dudchenko, O.L.; Kurenkov, D.S. Development of vibroacoustic module for fine filtration of drilling muds. J. Min. Inst. 2018, 234, 647. [Google Scholar] [CrossRef]

- Aftab, A.; Ismail, A.; Ibupoto, Z.; Akeiber, H.; Malghani, M. Nanoparticles based drilling muds a solution to drill elevated temperature wells: A review. Renew. Sustain. Energy Rev. 2017, 76, 1301–1313. [Google Scholar] [CrossRef]

- Ahmad, H.M.; Kamal, M.S.; Al-Harthi, M.A. High molecular weight copolymers as rheology modifier and fluid loss additive for water-based drilling fluids. J. Mol. Liq. 2018, 252, 133–143. [Google Scholar] [CrossRef]

- Lin, L.; Luo, P. Effect of polyampholyte-bentonite interactions on the properties of saltwater mud. Appl. Clay Sci. 2018, 163, 10–19. [Google Scholar] [CrossRef]

- Rojas, J.C.; Bern, P.A.; Plutt, L.J.; Romo, L.A.; Greene, B.; Irby, R.D.; Trotter, R.N.; Dye, W.M.; Sharma, N. New Constant-Rheology Synthetic-Based Fluid Reduces Downhole Losses in Deepwater Environments. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar] [CrossRef]

- Byrne, M.; Patey, I.; Liz, G.; Downs, J.; Turner, J. Formate Brines: A Comprehensive Evaluation of Their Formation Damage Control Properties Under Realistic Reservoir Conditions. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 24 February 2002; pp. 1–12. [Google Scholar] [CrossRef]

- Rogachev, M.K.; Nguyen Van, T.; Aleksandrov, A.N. Technology for Preventing the Wax Deposit Formation in Gas-Lift Wells at Offshore Oil and Gas Fields in Vietnam. Energies 2021, 14, 5016. [Google Scholar] [CrossRef]

- Ofei, T.N.; Al Bendary, R.M. Formulating water-based muds for high-temperature wellbores using potassium formate brine and synthetic polymers: A design of experiment approach SPE-180520-MS. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Singapore, 22–24 August 2016. [Google Scholar]

- Palyanitsina, A.; Safiullina, E.; Byazrov, R.; Podoprigora, D.; Alekseenko, A. Environmentally Safe Technology to Increase Efficiency of High-Viscosity Oil Production for the Objects with Advanced Water Cut. Energies 2022, 15, 753. [Google Scholar] [CrossRef]

- Ryabtsev, P.; Khomutov, A.; Korolev, V. The First Experience of Formate Based Drilling Fluids Application in Russia. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 15–17 October 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Howard, S.K.; Downs, J.D. Formate Brines for HPHT Well Control—New Insights into the Role and Importance of the Carbonate/Bicarbonate Additive Package. In The Woodlands; Society of Petroleum Engineers: The Woodlands, TX, USA, 2009; pp. 388–399. [Google Scholar] [CrossRef]

- Howard, S.; Kaminski, L.; Downs, J. Xanthan stability in formate brines—Formulating non- damaging fluids for high temperature applications. In Proceedings of the SPE—European Formation Damage Conference, Proceedings, EFDC 2015, Budapest, Hungary, 3–5 June 2015; pp. 1388–1413. [Google Scholar] [CrossRef]

- Alcázar, L.A.; Cortés, I.R. Drilling fluids for deepwater fields: An overview. In Recent Insights in Petroleum Science and Engineering; Zoveidavianpoor, M., Ed.; IntechOpen: London, UK, 2017; pp. 67–89. [Google Scholar] [CrossRef] [Green Version]

- Samylovskaya, E.; Makhovikov, A.; Lutonin, A.; Medvedev, D.; Kudryavtseva, R.-E. Digital Technologies in Arctic Oil and Gas Resources Extraction: Global Trends and Russian Experience. Resources 2022, 11, 29. [Google Scholar] [CrossRef]

- Berg, P.C.; Pederson, E.S.; Lauritsen, A. Drilling and Completing High-Angle Wells in High-Density, Cesium Formate Brine—The Kvitebjorn Experience. SPE Drill Completion 2009, 24, 15–24. [Google Scholar] [CrossRef]

- Novara, R.; Rafati, R.; Haddad, A.S. Rheological and filtration property evaluations of the nano-based muds for drilling applications in low temperature environments. Colloids Surf. A Physicochem. Eng. Asp. 2021, 622, 126632. [Google Scholar] [CrossRef]

- Litvinenko, V.S.; Dvoynikov, M.V.; Trushko, V.L. Elaboration of a conceptual solution for the development of the Arctic shelf from seasonally flooded coastal areas. Int. J. Min. Sci. Technol. 2022, 32, 113–119. [Google Scholar] [CrossRef]

- Saychenko, L.; Tananykhin, D.; Ashena, R. Prevention of scale in the downhole equipment and productive reservoir during the oil well operation. J. Appl. Eng. Sci. 2021, 19, 363–368. [Google Scholar] [CrossRef]

- Mahto, V.; Sharma, V.P. Rheological study of a water based oil well drilling fluid. J. Pet. Ence Eng. 2004, 45, 123–128. [Google Scholar] [CrossRef]

- Hilfiger, M.G.; Thaemlitz, C.J.; Moellendick, E. Investigating the chemical nature of flat rheology. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 14–15 September 2016. [Google Scholar] [CrossRef]

- Islamov, S.; Grigoriev, A.; Beloglazov, I.; Savchenkov, S.; Gudmestad, O.T. Research Risk Factors in Monitoring Well Drilling—A Case Study Using Machine Learning Methods. Symmetry 2021, 13, 1293. [Google Scholar] [CrossRef]

- Abdou, M.I.; Al-Sabagh, A.M.; Ahmed, H.E.S.; Fadl, A.M. Impact of barite and ilmenite mixture on enhancing the drilling mud weight. Egypt. J. Pet. 2018, 27, 955–967. [Google Scholar] [CrossRef]

- Champeau, M.; Wei, X.; Jackson, P.; Sui, C.; Zhang, J.; Okhrimenko, A. Alternative High Density Brines. In Proceedings of the SPE Offshore Europe Conference and Exhibition, Aberdeen, UK, 4 September 2019; pp. 544–554. [Google Scholar] [CrossRef]

- Mohamed, A.; Al-afnan, S.; Elkatatny, S.; Hussein, I. Prevention of barite sag in water-based drilling fluids by a urea-based additive for drilling deep formations. Sustainability 2020, 12, 2719. [Google Scholar] [CrossRef] [Green Version]

- Davarpanah, A.; Mirshekari, B. Effect of formate fluids on the shale stabilization of shale layers. Energy Rep. 2019, 5, 987–992. [Google Scholar] [CrossRef]

- Leusheva, E.; Brovkina, N.; Morenov, V. Investigation of Non-Linear Rheological Characteristics of Barite-Free Drilling Fluids. Fluids 2021, 6, 327. [Google Scholar] [CrossRef]

- API RP 13B-1-2019; Recommended Practice for Field Testing Water-based Drilling Fluids/Note: Second Edition. API Publishing Services: Washington, DC, USA, 2019; p. 132.

- API RP 13D; Rheology and Hydraulics of Oil-well Drilling Fluids. Norm of American Petroleum Institute: Washington, DC, USA, 2006; p. 98.

- Sharafutdinova, R.Z. Rheology of water-based drilling fluids. Constr. Oil Gas Wells Onshore Offshore 2006, 8, 41–47. [Google Scholar]

- Mardashov, D.; Duryagin, V.; Islamov, S. Technology for Improving the Efficiency of Fractured Reservoir Development Using Gel-Forming Compositions. Energies 2021, 14, 8254. [Google Scholar] [CrossRef]

- Neverov, A.L.; Rozhkov, V.P.; Batalina, L.S.; Mineev, A.V. Effect of simple salts on rheological properties of polymer solutions for drilling with CCK systems in clay sediments. Proc. Tomsk. Polytech. Univ. 2013, 323, 196–200. [Google Scholar]

- Dvoynikov, M.V.; Budovskaya, M.E. Development of a hydrocarbon completion system for wells with low bottomhole temperatures for conditions of oil and gas fields in Eastern Siberia. J. Min. Inst. 2022, 253, 12–22. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).