The Experimental Study of Pangium Edule Biodiesel in a High-Speed Diesel Generator for Biopower Electricity

Abstract

:1. Introduction

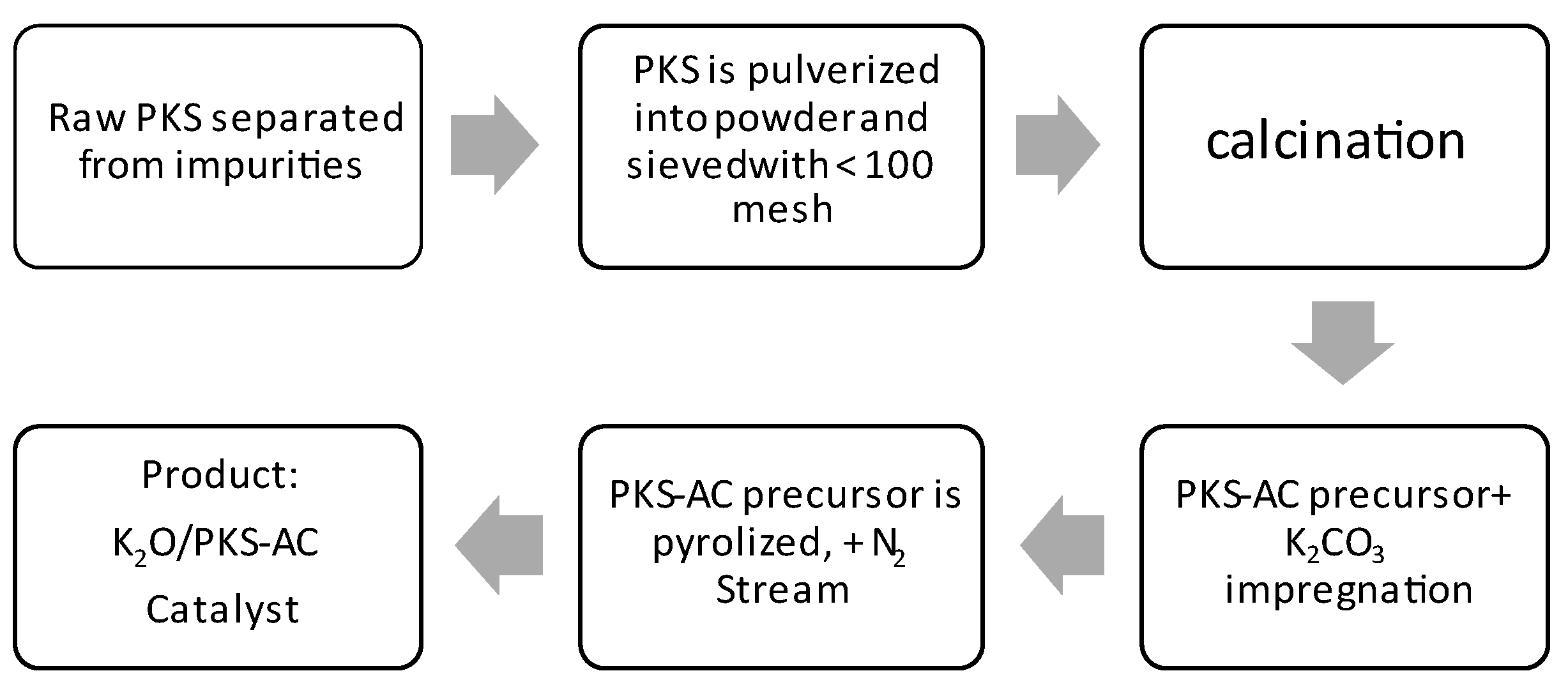

2. Materials and Methods

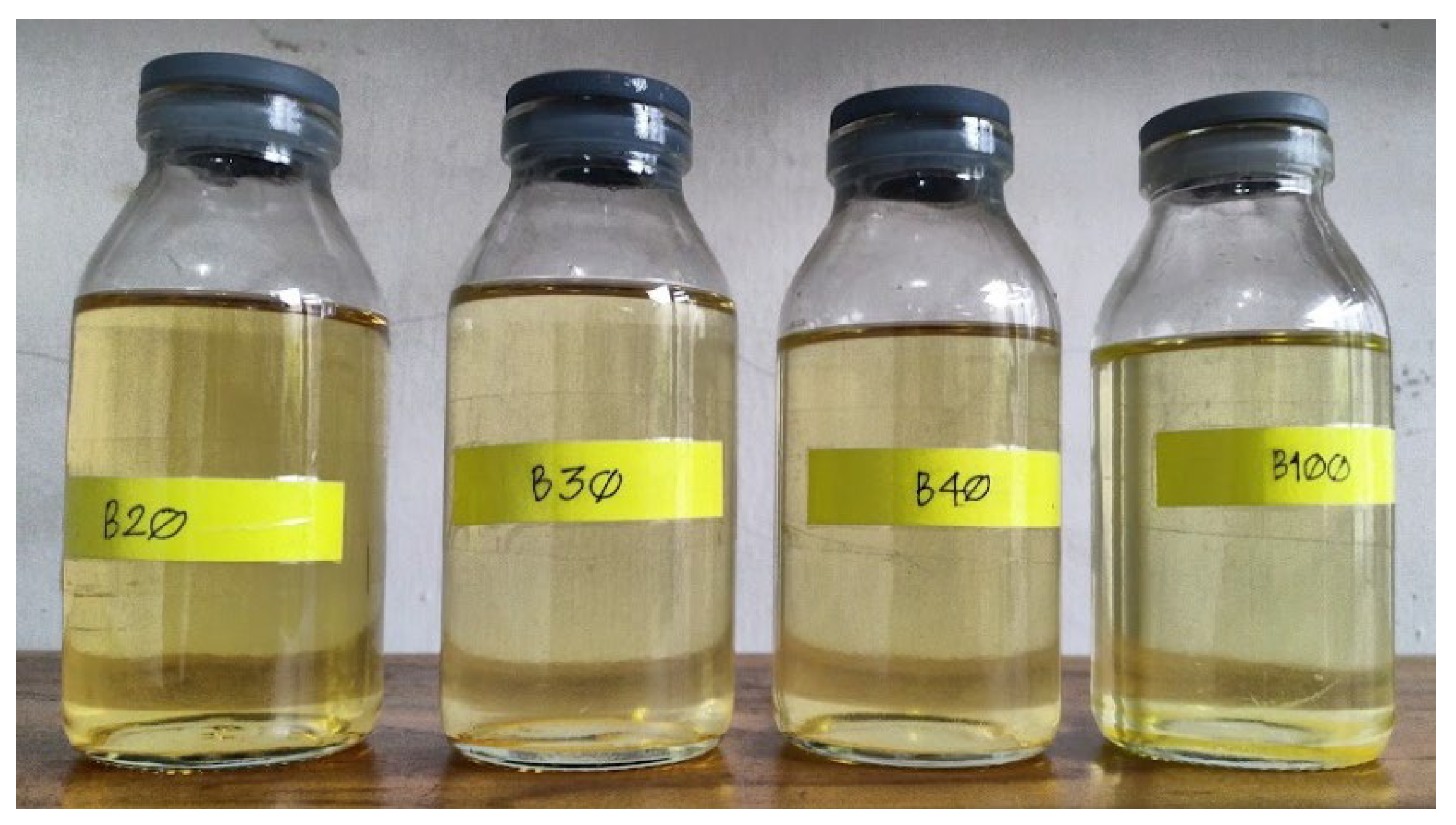

2.1. Biodiesel Blend Preparation

- Splash blending: in this method, biodiesel and diesel fuel are loaded separately into a tank, while the mixing occurs during transport as the fuel is agitated along the road.

- In-tank blending: fuels are loaded separately through a different incoming channel and the fuel rests without additional agitation.

- In-Line blending: the biodiesel is added to a stream of diesel fuel as it travels through a pipeline, and the mixing process occurs during turbulent flow along the pipe.

- Rack blending: the most straightforward mixing approach, where biodiesel is directly poured into the tank prior to use.

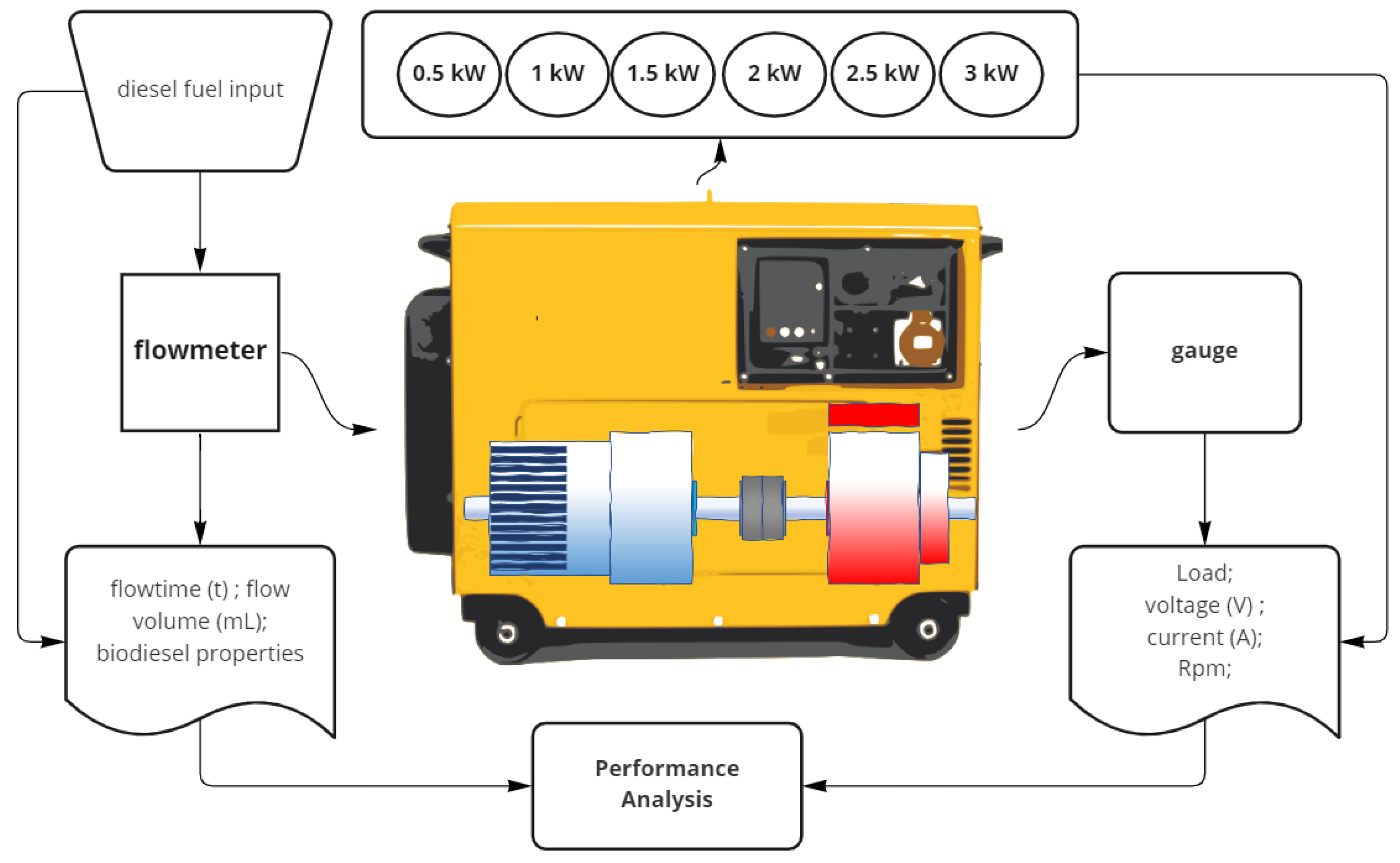

2.2. Experimental Setup and Instrumentation

3. Results

3.1. Fuel Consumption

3.2. Brake Power

3.3. Brake-Specific Fuel Consumption, BSFC

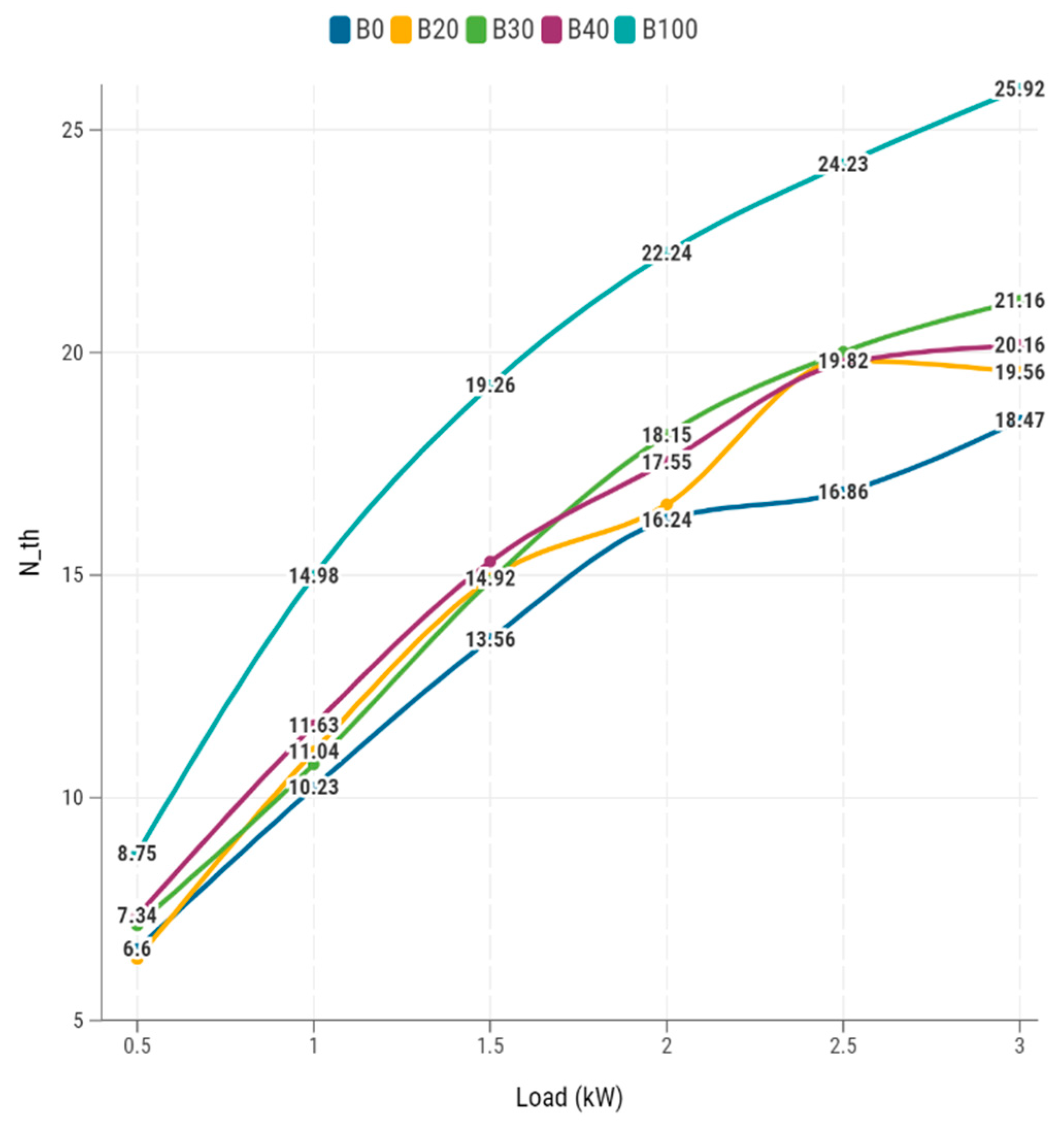

3.4. Brake Thermal Efficiency

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vrabie, C. Electric Vehicles Optimism versus the Energy Market Reality. Sustainability 2022, 14, 5388. [Google Scholar] [CrossRef]

- Mussetti, G.; Davin, E.L.; Schwaab, J.; Acero, J.A.; Ivanchev, J.; Singh, V.K.; Jin, L.; Seneviratne, S.I. Do Electric Vehicles Mitigate Urban Heat? The Case of a Tropical City. Front. Environ. Sci. 2022, 10, 42. [Google Scholar] [CrossRef]

- IEA. World Energy Balances: Overview; IEA: Paris, France, 2021. [Google Scholar]

- Sathre, R.; Gustavsson, L. A Lifecycle Comparison of Natural Resource Use and Climate Impact of Biofuel and Electric Cars. Energy 2021, 237, 121546. [Google Scholar] [CrossRef]

- Nuclear Power and Politics. Available online: https://sites.psu.edu/jensci/2014/03/20/nuclear-power-and-politics/ (accessed on 17 June 2022).

- Usman, M.; Jahanger, A.; Radulescu, M.; Balsalobre-Lorente, D. Do Nuclear Energy, Renewable Energy, and Environmental-Related Technologies Asymmetrically Reduce Ecological Footprint? Evidence from Pakistan. Energies 2022, 15, 3448. [Google Scholar] [CrossRef]

- Nuclear Power and the Environment—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/energyexplained/nuclear/nuclear-power-and-the-environment.php (accessed on 17 June 2022).

- Simons, S.; Schmitt, J.; Tom, B.; Bao, H.; Pettinato, B.; Pechulis, M. Advanced Concepts. Therm. Mech. Hybrid Chem. Energy Storage Syst. 2021, 10, 569–596. [Google Scholar] [CrossRef]

- Husin, H.; Mahidin, M.; Zuhra, Z.; Hafita, F. H2 Evolution on Lanthanum and Carbon Co-Doped NaTaO3 Photocatalyst. Bull. Chem. React. Eng. Catal. 2014, 9, 81–86. [Google Scholar] [CrossRef]

- Husin, H.; Pontas, K.; Yunardi; Salamun, A.; Alam, P.N.; Hasfita, F. Photocatalytic Hydrogen Production over Ni/La-NaTaO3 Nanoparticles from NaCl-Water Solution in the Presence of Glucose as Electron Donor. ASEAN J. Chem. Eng. 2018, 17, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Agarwal, S.; Jain, A. Significance of Hydrogen as Economic and Environmentally Friendly Fuel. Energies 2021, 14, 7389. [Google Scholar] [CrossRef]

- Farias, C.B.B.; Barreiros, R.C.S.; da Silva, M.F.; Casazza, A.A.; Converti, A.; Sarubbo, L.A. Use of Hydrogen as Fuel: A Trend of the 21st Century. Energies 2022, 15, 311. [Google Scholar] [CrossRef]

- CEI Lithium-Ion Battery—Clean Energy Institute. Available online: https://www.cei.washington.edu/education/science-of-solar/battery-technology/ (accessed on 17 June 2022).

- Development of a Lithium-Air Battery with an Energy Density over 500 Wh/Kg|NIMS. Available online: https://www.nims.go.jp/eng/news/press/2021/12/202112150.html (accessed on 17 June 2022).

- Matsuda, S.; Ono, M.; Yamaguchi, S.; Uosaki, K. Criteria for Evaluating Lithium-Air Batteries in Academia to Correctly Predict Their Practical Performance in Industry. Mater. Horiz. 2022, 9, 856–863. [Google Scholar] [CrossRef]

- Romare, M.; Dahllöf, L. The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries a Study with Focus on Current Technology and Batteries for Light-Duty Vehicles; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2017. [Google Scholar]

- Davidsson Kurland, S. Energy Use for GWh-Scale Lithium-Ion Battery Production. Environ. Res. Commun. 2019, 2, 012001. [Google Scholar] [CrossRef]

- Kelly, J.C.; Wang, M.; Dai, Q.; Winjobi, O. Energy, Greenhouse Gas, and Water Life Cycle Analysis of Lithium Carbonate and Lithium Hydroxide Monohydrate from Brine and Ore Resources and Their Use in Lithium Ion Battery Cathodes and Lithium Ion Batteries. Resour. Conserv. Recycl. 2021, 174, 105762. [Google Scholar] [CrossRef]

- Nigatu Gebremariam, S.; Mario Marchetti, J. Biodiesel Production Technologies: Review. AIMS Energy 2017, 5, 425–457. [Google Scholar] [CrossRef]

- de Blasio, C. Biodiesel. In Fundamentals of Biofuels Engineering and Technology; de Blasio, C., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 253–265. ISBN 978-3-030-11599-9. [Google Scholar]

- OECD and Food and Agriculture Organization of the United Nations OECD-FAO Agricultural Outlook 2021–2030; OECD-FAO Agricultural Outlook; OECD: Paris, France, 2021; ISBN 9789264436077.

- Arifin, B.; Putri, K.A.P. Indonesian Government Strategies on Obtaining Crude Palm Oil (CPO) Market Access to European Union Countries Over The EU Parliament Resolution On Palm Oil And Deforestation Of Rainforest. Andalas J. Int. Stud. AJIS 2019, 8, 203–223. [Google Scholar] [CrossRef] [Green Version]

- Purnomo, H.; Okarda, B.; Dermawan, A.; Ilham, Q.P.; Pacheco, P.; Nurfatriani, F.; Suhendang, E. Reconciling Oil Palm Economic Development and Environmental Conservation in Indonesia: A Value Chain Dynamic Approach. For. Policy Econ. 2020, 111, 102089. [Google Scholar] [CrossRef]

- Putri, E.I.K.; Dharmawan, A.H.; Hospes, O.; Yulian, B.E.; Amalia, R.; Mardiyaningsih, D.I.; Kinseng, R.A.; Tonny, F.; Pramudya, E.P.; Rahmadian, F.; et al. The Oil Palm Governance: Challenges of Sustainability Policy in Indonesia. Sustainability 2022, 14, 1820. [Google Scholar] [CrossRef]

- Akram, H.; Levia, D.F.; Herrick, J.E.; Lydiasari, H.; Schütze, N. Water Requirements for Oil Palm Grown on Marginal Lands: A Simulation Approach. Agric. Water Manag. 2022, 260, 107292. [Google Scholar] [CrossRef]

- Safitri, L.; Hermantoro, H.; Purboseno, S.; Kautsar, V.; Saptomo, S.K.; Kurniawan, A. Water Footprint and Crop Water Usage of Oil Palm (Eleasis Guineensis) in Central Kalimantan: Environmental Sustainability Indicators for Different Crop Age and Soil Conditions. Water 2018, 11, 35. [Google Scholar] [CrossRef] [Green Version]

- Atabani, A.E.; Badruddin, I.A.; Masjuki, H.H.; Chong, W.T.; Lee, K.T. Pangium Edule Reinw: A Promising Non-Edible Oil Feedstock for Biodiesel Production. Arab. J. Sci. Eng. 2015, 40, 583–594. [Google Scholar] [CrossRef] [Green Version]

- Premana, Y. Kajian Tumbuhan Pangi (Pangium Edule Reinw) Sebagai Tanaman Konservasi Penghasil Minyak Alternatif Pengganti Kelapa Sawit. [The Study of Pangi Plants (Pangium Edule Reinw) as Conservation Plants to Producing Alternative Oils to Replace Palm Oil]. Master’s Thesis, Universitas Syiah Kuala, Banda Aceh City, Aceh, Indonesia, 2015. [Google Scholar]

- Hamzah, F.H.; Hamzah, N.; Irdoni, H.S. Potency of Picung (Pangium Edule Reinw) Endosperm Utilized as a Raw Material in Producing Frying Oil or Biodiesel. J. Agroindustri 2018, 8, 44–52. [Google Scholar] [CrossRef]

- Taufik, M. Penentuan Kadar Asam Lemak Dan Sianida Serta Kualitas Minyak Dari Daging Buah Picung (Pangium Edule Reinw). [Determination of Fatty Acids and Cyanide Levels as Well as the Quality of Oil from Picung Fruit (Pangium Edule Reinw).]. Master’s Thesis, Universitas Komputer Indonesia, Bandung, Indonesia, 2000. [Google Scholar]

- Norfiarli; Kasim, A.; Nurdin, H. The Biodiesel Characteristic of Kepayang Oil (Pangium Edule Reinw). ARPN J. Agric. Biol. Sci. 2013, 8. [Google Scholar]

- Ricia, A. Kepayang, Potensi Hasil Hutan Bukan Kayu Yang Terabaikan [Neglected Potential of Non-Timber Forest Products]. Available online: https://kmisfip2.menlhk.go.id/news/detail/111 (accessed on 14 July 2022).

- Othman, M.F.; Abdullah, A.A.; Kamal, K.; Asri, S.; Azmi, Z.; Mamat, R. Improvement of Fuel Properties for Palm Oil Methyl Ester (POME) Biodiesel Blends Using Organic Germanium as Additives. IOP Conf. Ser. Mater. Sci. Eng. 2019, 469, 012121. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the Art of Catalysts for Biodiesel Production. Front. Energy Res. 2020, 8. [Google Scholar] [CrossRef]

- Mahandari, C.P.; Wahyuni, R.S.; Fatoni, A. Wiwik Kajian Awal Biji Buah Kepayang Sebagai Bahan Baku Minyak Nabati Kasar [Preliminary Study of Kepayang Fruit Seeds as Raw Material for Crude Vegetable Oil]. In Proceedings of the Seminar Nasional Teknik Industri Universitas Gadjah Mada; Universitas Gadjah Mada: Yogyakarta, Indonesia, 2011; pp. 1–5. [Google Scholar]

- Silalahi, A.; Bahri, S. Yusnimar Perbandingan Biodiesel Hasil Transesterifikasi Minyak Biji Kepayang (Pangium Edule Reinw) Dengan Katalis NaOH Dan H-Zeolit. J. Online Mhs. JOM Bid. Tek. Dan Sains 2016, 3, 1–6. [Google Scholar]

- Ayu, D.F.; Man, Y.C.; Rohman, A. Chemical Properties, Fatty Acid Composition, and Lipid Profiles of Picung (Pangium Edule Reinw ) Kernel Oil from Riau Province. Appl. Sci. Technol. 2017, 1, 41–46. [Google Scholar]

- Yanti, D.; Husin, H.; Yani, F.T.; Maulana, A.; Adisalamun, A.; Husaini, H. Transesterification of Pangium Edule Reinw Oil to Biodiesel Using Durian Rind Ash as Heterogeneous Catalysts. IOP Conf. Ser. Mater. Sci. Eng. 2020, 845, 012031. [Google Scholar] [CrossRef]

- Fitriani, F.; Husin, H.; Marwan, M.; Nasution, F.; Zuhra, Z.; Asnawi, T.M.; Hisbullah, H. Waste Peel of Durian as Solid Cataysts for Biodiesel Production. IOP Conf. Ser. Mater. Sci. Eng. 2020, 845, 012033. [Google Scholar] [CrossRef]

- Bilgin, A.; Gulum, M. Effects of Various Transesterification Parameters on the Some Fuel Properties of Hazelnut Oil Methyl Ester. Energy Procedia 2018, 147, 54–62. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Abdul Aziz, A.R.; Sulaiman, N.M.N. The Effects of Catalysts in Biodiesel Production: A Review. J. Ind. Eng. Chem. 2013, 19, 14–26. [Google Scholar] [CrossRef]

- Bedir, Ö.; Doğan, T.H. Comparison of Catalytic Activities of Ca-Based Catalysts from Waste in Biodiesel Production. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1–18. [Google Scholar] [CrossRef]

- Boggavarapu, P.; Ravikrishna, R.v. A Review on Atomization and Sprays of Biofuels for IC Engine Applications. Int. J. Spray Combust. Dyn. 2013, 5, 85–121. [Google Scholar] [CrossRef] [Green Version]

- Chaudhari, V.D.; Jagdale, V.S.; Chorey, D.; Deshmukh, D. Combustion and Spray Breakup Characteristics of Biodiesel for Cold Start Application. Clean. Eng. Technol. 2021, 5, 100285. [Google Scholar] [CrossRef]

- Ishak, M.H.H.; Ismail, F.; Mat, S.C.; Abdullah, M.Z.; Abdul Aziz, M.S.; Idroas, M.Y. Numerical Analysis of Nozzle Flow and Spray Characteristics from Different Nozzles Using Diesel and Biofuel Blends. Energies 2019, 12, 281. [Google Scholar] [CrossRef] [Green Version]

- Boggavarapu, P.; Ravikrishna, R. V A Comparison of Diesel and Jatropha Methyl Ester (JME) Spray Characteristics: Effect of Nozzle Entry Radius. At. Sprays 2016, 26, 961–982. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Jia, H.; Wen, S.; Li, X.; Yu, J. Theoretical and Experimental Comparison of Internal Flow and Spray Characteristics between Diesel and Biodiesel. Fuel 2017, 208, 20–29. [Google Scholar] [CrossRef]

- Hajra, B.; Kumar, M.; Pathak, A.K.; Guria, C. Surface Tension and Rheological Behavior of Sal Oil Methyl Ester Biodiesel and Its Blend with Petrodiesel Fuel. Fuel 2016, 166, 130–142. [Google Scholar] [CrossRef]

- Ejim, C.E.; Fleck, B.A.; Amirfazli, A. Analytical Study for Atomization of Biodiesels and Their Blends in a Typical Injector: Surface Tension and Viscosity Effects. Fuel 2007, 86, 1534–1544. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. Study on Viscosity and Surface Tension Properties of Biodiesel-Diesel Blends and Their Effects on Spray Parameters for CI Engines. Fuel 2018, 220, 769–779. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (Alcohols and Biodiesel) Applications as Fuels for Internal Combustion Engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Martyr, A.J.; Rogers, D.R. Energy Storage. In Engine Test; Elsevier: Amsterdam, The Netherlands, 2021; pp. 191–215. [Google Scholar] [CrossRef]

- Celik, I.; Aydin, O. Effects of B100 Biodiesel on Injector and Pump Piston. Tribol. Trans. 2011, 54, 424–431. [Google Scholar] [CrossRef]

- Wardani, R.K.; Putri, Y.M.; Nurjanah, D.A.; Susidarti, R.A. Revealing the Potential of Kluwak (Pangium Edule Reinw) as Natural Antioxidants and Senescence Inhibitors. J. Ilmu Kefarmasian Indones. 2021, 19, 189–196. [Google Scholar] [CrossRef]

- Biodiesel Blending Guide for Fuel Blenders—Targray. Available online: https://www.targray.com/biofuels/biodiesel/blending (accessed on 13 July 2022).

- AFDC Alternative Fuels Data Center: Biodiesel Blends. Available online: https://afdc.energy.gov/fuels/biodiesel_blends.html (accessed on 5 June 2022).

- Khairil; Riayatsyah, T.M.I.; Bahri, S.; Sofyan, S.E.; Jalaluddin, J.; Kusumo, F.; Silitonga, A.S.; Padli, Y.; Jihad, M.; Shamsuddin, A.H. Experimental Study on the Performance of an SI Engine Fueled by Waste Plastic Pyrolysis Oil–Gasoline Blends. Energies 2020, 13, 4196. [Google Scholar] [CrossRef]

- SDM Pertamina Spesifikasi Produk BBM, BBN & LPG [Product Specification for Fuel, Biofuel & LPG]. Available online: https://onesolution.pertamina.com/Product/Download?filename=20201201035120atc_spesifikasi.pdf (accessed on 20 June 2022).

- KIPOR Diesel Generators|Silent Diesel Generator|Kipor Generator Parts- UK. Available online: https://www.kiporuk.co.uk/diesel-generator/kde-6700ta-400-64-67.php (accessed on 25 May 2022).

- Marthur, S.; Sharma, R. A Course in Internal Combustion Engine; Kapur, J., Ed.; Dhanpat Rai & Son: New Delhi, India, 1980. [Google Scholar]

- Maleev, V.L. Diesel Engine Operation and Maintenance; the Construction, Operation, Maintenance, and Repair of Modern Diesel Engines; Glencoe/McGraw-Hill School Publishing Company: Peoria, IL, USA, 1954; p. 504. [Google Scholar]

- Khairil; Thalib, S. Turmizi Fundamental Study of Diesel Engine Performance by Implementing Oil from Tropical Kepayang Seeds (Pangium Edule). Adv. Mater. Res. 2015, 1115, 480–483. [Google Scholar] [CrossRef]

- Nina, K.S.; Suntoro, D.; Irsyad, M.I.; Zulkarnain; Widhiatmaka; Srikandi, G.P.; Khaldun, T.; Fauzi; Anggarani, R. Faridha Performance and Emission Effects of Biodiesel 30% (B30) Usage in Oil-Fired Power Plants and Gas Engine Power Plants. IOP Conf. Ser. Earth Environ. Sci. 2021, 749, 012056. [Google Scholar] [CrossRef]

- Sanjid, A.; Masjuki, H.H.; Kalam, M.A.; Rahman, S.M.A.; Abedin, M.J. Experimental Investigation of Palm-Jatropha Combined Blend Properties, Performance, Exhaust Emission and Noise in an Unmodified Diesel Engine. Procedia Eng. 2014, 90, 397–402. [Google Scholar] [CrossRef]

- El-Araby, R.; Amin, A.; el Morsi, A.K.; El-Ibiari, N.N.; El-Diwani, G.I. Study on the Characteristics of Palm Oil–Biodiesel–Diesel Fuel Blend. Egypt. J. Pet. 2018, 27, 187–194. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K. Eco Friendly Biofuels for CI Engine Applications. Adv. Eco-Fuels A Sustain. Environ. 2019, 407–440. [Google Scholar] [CrossRef]

- Nedayali, A.; Shirneshan, A. Experimental Study of the Effects of Biodiesel on the Performance of a Diesel Power Generator. Energy Environ. 2016, 27, 553–565. [Google Scholar] [CrossRef]

- Suryanto; Rahman, A. Pengaruh Penggunaan Bahan Bakar Biodiesel Pada Sistim Injector Mesin Diesel [Effect of Biodiesel Blend on Fuel Injector System]. In Proceedings of the Prosiding 5th Seminar Nasional Penelitian & Pengabdian kepada Masyarakat 2021, Ujung Pandang, Indonesia, 14 November 2021; pp. 1–6. [Google Scholar]

- UN Goal 7|Department of Economic and Social Affairs. Available online: https://sdgs.un.org/goals/goal7 (accessed on 18 July 2022).

- Economics of Biofuels|US EPA. Available online: https://www.epa.gov/environmental-economics/economics-biofuels (accessed on 29 June 2022).

| Country | Rank | Production Rating (%) | Main Raw Materials |

|---|---|---|---|

| European Union | 1 | 32.3 | rapeseed oil/palm oil/used cooking oil |

| United States | 2 | 18.1 | soybean oil/used cooking oil |

| Indonesia | 3 | 15 | palm oil |

| Brazil | 4 | 12.2 | soybean oil |

| Canada | 14 | 0.7 | canola oil/used cooking oil/soybean oil |

| Paraguay | 19 | 0.03 | castor oil (Jatropha) |

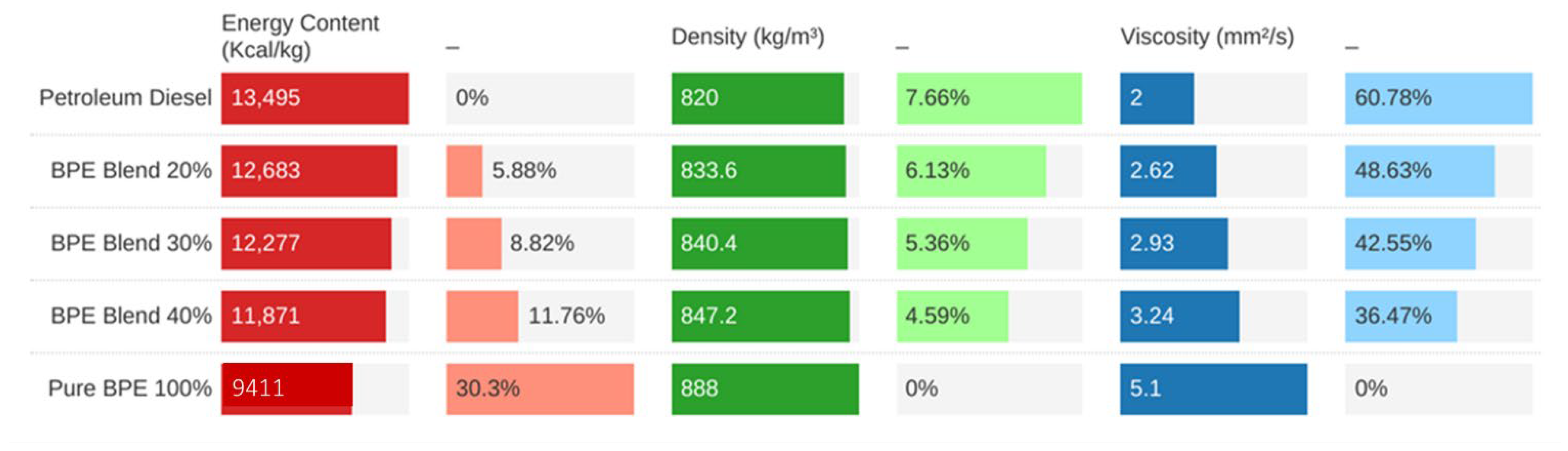

| Fuel Parameters | Unit | B0 [58] | B20 * | B30 * | B40 * | B100 |

|---|---|---|---|---|---|---|

| Kinematic Viscosity | mm2/s (cSt) | 2.0–4.5 | 2.62 | 2.93 | 3.24 | 4.4–5.1 |

| Density | kg/m3 | 820–860 | 845.9 | 848.85 | 851.8 | 851–888 |

| Calorific Value | kcal/kg | 13,495 | 12,683 | 12,277 | 11,871 | 9411 |

| Diesel Engine | Alternator | ||

|---|---|---|---|

| Parameter | Description | Parameter | Description |

| Engine Model | KM186FAGET | Model | KDE6700T |

| Engine Type | Single cylinder, vertical, four-stroke, direct injection | Rated frequency (Hz) | 50–60 |

| Cylinder Number | 1 | Rated output (kVA) | 4.5–5.0 |

| Bore (mm) | 86 | Max. output (kVA) | 5.0–5.5 |

| Stroke (mm) | 72 | Rated Voltage (V) | 115/230–120/240 |

| Compression ratio | 19:1 | Rated current (A) | 39.2/19.6–4 1.7/20.8 |

| Rated rotation speed (r/min) | 3000–3600 | Rated rotation speed (r/min) | 3000–3600 |

| Combustion system | Direct injection | Phase NO. | Single phase |

| Cooling system | Air-cooled | Power factor (Cos Φ) | 1.0 |

| Continuous running time (hr.) | 6 | ||

| Performance | Load (kW) | Requirement | 1st Selection | 2nd Selection | ||

|---|---|---|---|---|---|---|

| FMC, (kg/h) | Low | Lowest rate | B40 | 0.783 | B0 | 0.797 |

| High | B30 | 1.33 | B100 | 1.418 | ||

| P, (kW) | Low | Highest rate | B30 | 0.845 | B0 | 0.837 |

| High | B0 | 4.219 | B20 | 4.174 | ||

| BSFC, (kg/kW.h) | Low | Lowest rate | B0 | 0.71 | B30 | 0.72 |

| High | B30 | 0.243 | B0 | 0.254 | ||

| BTE, (%) | Low | Highest rate | B100 | 8.75 | B40 | 7.34 |

| High | B100 | 25.92 | B30 | 21.16 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizal, T.A.; Khairil; Mahidin; Husin, H.; Ahmadi; Nasution, F.; Umar, H. The Experimental Study of Pangium Edule Biodiesel in a High-Speed Diesel Generator for Biopower Electricity. Energies 2022, 15, 5405. https://doi.org/10.3390/en15155405

Rizal TA, Khairil, Mahidin, Husin H, Ahmadi, Nasution F, Umar H. The Experimental Study of Pangium Edule Biodiesel in a High-Speed Diesel Generator for Biopower Electricity. Energies. 2022; 15(15):5405. https://doi.org/10.3390/en15155405

Chicago/Turabian StyleRizal, Teuku Azuar, Khairil, Mahidin, Husni Husin, Ahmadi, Fahrizal Nasution, and Hamdani Umar. 2022. "The Experimental Study of Pangium Edule Biodiesel in a High-Speed Diesel Generator for Biopower Electricity" Energies 15, no. 15: 5405. https://doi.org/10.3390/en15155405

APA StyleRizal, T. A., Khairil, Mahidin, Husin, H., Ahmadi, Nasution, F., & Umar, H. (2022). The Experimental Study of Pangium Edule Biodiesel in a High-Speed Diesel Generator for Biopower Electricity. Energies, 15(15), 5405. https://doi.org/10.3390/en15155405