Designing Harvesting and Hauling Cost Models for Energy Cane Production for Biorefineries

Abstract

:1. Introduction

2. Materials and Methods

- HHCi = OCMi + Fueli + Lubrii + Repairi + OLi

- OCMi = capital recovery + TIH

- capital recovery = (total depreciation × capital recovery factor) + (salvage value × interest rate)

- total depreciation = initial costs of machinery − salvage value

- capital recovery factor = 0.13

- salvage value = initial costs of machinery × salvage value factor (0.3)

- TIH = Taxes, Insurance & Housing = 0.01 × purchase price

- Fueli (Average diesel consumption per hour) = diesel consumption factor (0.044) × maximum horsepower

- Lubrii =lubrication factor (0.15) × Average cost for fuel consumption

- Repairi = repair cost factor (0.03) × purchase price

- Labori = labor cost for the harvest unit + labor cost for transportation

3. Results

3.1. Energy Cane Feedstock Requirement

3.2. Harvesting Unit

3.3. Hauling Unit

3.4. Ownership and Operation Costs of Harvesting and Hauling

3.4.1. Machinery Ownership

3.4.2. Accumulated Repair and Maintenance

3.4.3. Operating Labor

3.4.4. Fuel and Lubricants

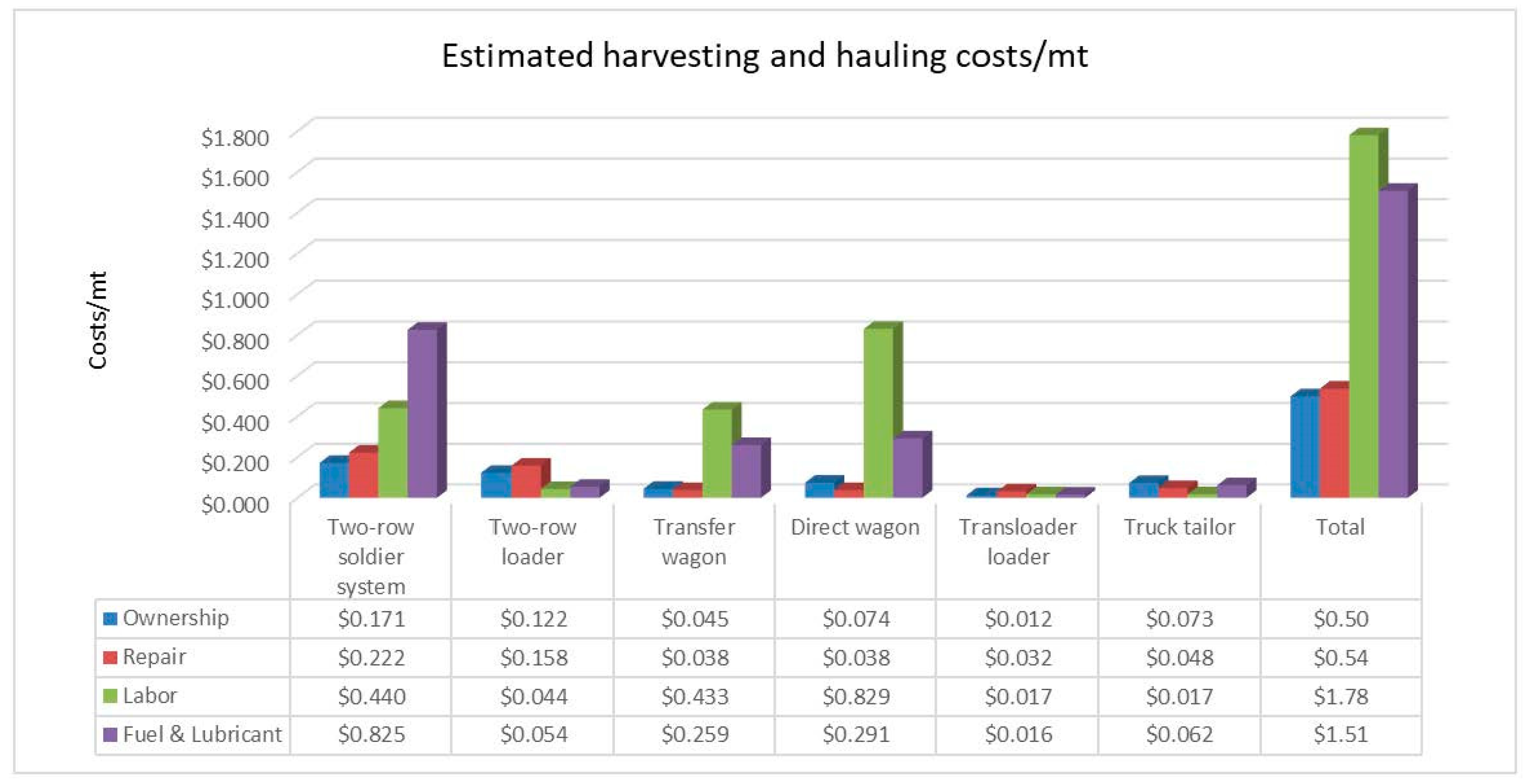

3.5. Distribution of Harvesting and Hauling Costs

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Field, C.B.; Campbell, J.E.; Lobell, D.B. Biomass energy: The scale of the potential resource. Trends Ecol. Evol. 2008, 23, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Abdul Malek, A.B.M.; Hasanuzzaman, M.; Rahim, N.A. Prospects, progress, challenges and policies for clean power generation from biomass resources. Clean Technol. Environ. Policy 2020, 22, 1229–1253. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Bazmi, A.A.; Karim, S.; Abro, R.; Mazari, S.A.; Nizamuddin, S. Promoting sustainability of use of biomass as energy resource: Pakistan’s perspective. Environ. Sci. Pollut. Res. 2019, 26, 29606–29619. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, A.S.; Eras, J.J.C.; Huisingh, D.; Vandecasteele, C.; Hens, L. The current potential of low-carbon economy and biomass-based electricity in Cuba. The case of sugarcane, energy cane and marabu (Dichrostachys cinerea) as biomass sources. J. Clean. Prod. 2018, 172, 2108–2122. [Google Scholar] [CrossRef]

- Burg, V.; Bowman, G.; Erni, M.; Lemm, R.; Thees, O. Analyzing the potential of domestic biomass resources for the energy transition in Switzerland. Biomass Bioenergy 2018, 111, 60–69. [Google Scholar] [CrossRef]

- Rooney, W.L.; Blumenthal, J.; Bean, B.; Mullet, J.E. Designing sorghum as a dedicated bioenergy feedstock. Biofuels Bioprod. Biorefining 2007, 1, 147–157. [Google Scholar] [CrossRef]

- Tew, T.L.; Cobill, R.M.; Richard, E.P. Evaluation of sweet sorghum and sorghum sudan grass hybrids as feedstocks for ethanol production. Bioenergy Res. 2008, 1, 147–152. [Google Scholar] [CrossRef]

- Xie, G.H. Progress and direction of non-food biomass feedstock supply research and development in China. J. Chin. Agr. Univ. 2012, 17, 1–19. [Google Scholar]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first-and second-generation sugar-based feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Salassi, M.E.; Brown, K.; Hilbun, B.M.; Deliberto, M.A.; Gravois, K.A.; Mark, T.B.; Falconer, L.L. Farm-scale cost of producing perennial energy cane as a biofuel feedstock. Bioenergy Res. 2014, 7, 609–619. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Zhang, X.; Tan, T. Ethanol production by solid state fermentation of sweet sorghum using thermotolerant yeast strain. Fuel Process. Technol. 2008, 89, 1056–1059. [Google Scholar] [CrossRef]

- Huang, J.; Khan, M.T.; Perecin, D.; Coelho, S.T.; Zhang, M. Sugarcane for bioethanol production: Potential of bagasse in Chinese perspective. Renew. Sustain. Energy Rev. 2020, 133, 110296. [Google Scholar] [CrossRef]

- Chynoweth, D.P.; Turick, C.E.; Owens, J.M.; Jerger, D.E.; Peck, M.W. Biochemical methane potential of biomass and waste feed- stocks. Biomass Bioenergy 1993, 5, 95–111. [Google Scholar] [CrossRef]

- Grassi, M.C.B.; Pereira, G.A.G. Energy-cane and RenovaBio: Brazilian vectors to boost the development of Biofuels. Ind. Crops Prod. 2019, 129, 201–205. [Google Scholar] [CrossRef]

- Fedenko, J.; Erickson, J.E.; Florida, A. Biomass Production and Composition of Perennial Grasses Grown for Bioenergy in a Subtropical Climate Across Florida, USA. BioEnergy Res. 2013, 6, 1082–1093. [Google Scholar] [CrossRef]

- Leon, R.G.; Gilbert, R.A.; Comstock, J.C. Energycane (Saccharum spp. × Saccharum spontaneum L.) Biomass Production, Reproduction, and Weed Risk Assessment Scoring in the Humid Tropics and Subtropics. Agron. J. 2015, 107, 323–329. [Google Scholar] [CrossRef]

- Langholtz, M.H.; Stokes, B.J.; Eaton, L.M. USDOE 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy; Volume 1: ORNL/TM- 2016/160; Economic availability of feedstock; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016. Available online: https://energy.gov/ (accessed on 16 January 2022).

- Lee, D.K.; Aberle, E.; Anderson, E.K.; Anderson, W.; Baldwin, B.S.; Baltensperger, D.; Owens, V. Biomass production of herbaceous energy crops in the United States: Field trial results and yield potential maps from the multiyear regional feedstock partnership. GCB Bioenergy 2018, 10, 698–716. [Google Scholar] [CrossRef]

- Bischoff, K.P.; Gravois, K.A.; Reagan, T.E.; Hoy, J.W.; Kimbeng, C.A.; LaBorde, C.M.; Hawkins, G.L. Registration of ‘L 79-1002’ sugarcane. J. Plant Regist. 2008, 2, 211–217. [Google Scholar] [CrossRef]

- Knoll, J.E.; Anderson, W.F.; Strickland, T.C.; Hubbard, R.K.; Malik, R. Low-input production of biomass from perennial grasses in the coastal plain of Georgia, USA. Bioenerg. Res. 2012, 5, 206–214. [Google Scholar] [CrossRef] [Green Version]

- Woodard, K.R.; Prine, G.M. Dry matter accumulation of elephant grass, energy cane, and elephant millet in a subtropical climate. Crop. Sci. 1993, 33, 818–824. [Google Scholar] [CrossRef]

- Mitchell, R.B.; Schmer, M.R.; Anderson, W.F.; Jin, V.; Balkcom, K.S.; Kiniry, J.; Coffin, A.; White, P. Dedicated energy crops and crop eesidues for bioenergy feedstocks in the central and eastern USA. Bioenergy Res. 2016, 9, 384–398. [Google Scholar] [CrossRef] [Green Version]

- Perry, A.; Kaplan, J.K. ARS and the Regional Biomass Research Centers. Agric. Res. 2012, 60, 4. [Google Scholar]

- Steiner, J.J.; Buford, M.A. The origin of the USDA regional biomass research centers. Bioenergy Res. 2016, 9, 379–383. [Google Scholar] [CrossRef] [Green Version]

- Proskurina, S.; Junginger, M.; Heinimö, J.; Tekinel, B.; Vakkilainen, E. Global biomass trade for energy—Part 2: Production and trade streams of wood pellets, liquid biofuels, charcoal, industrial roundwood and emerging energy biomass. Biofuels Bioprod. Biorefining 2019, 13, 371–387. [Google Scholar] [CrossRef]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Umar, M.; Ji, X.; Kirikkaleli, D.; Alola, A.A. The imperativeness of environmental quality in the United States transportation sector amidst biomass-fossil energy consumption and growth. J. Clean. Prod. 2021, 285, 124863. [Google Scholar] [CrossRef]

- Junginger, M.; Goh, C.S.; Faaij, A. (Eds.) International bioenergy trade. In History, Status Outlook on Securing Sustainable Bioenergy Supply, Demand and Markets; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Chiang, S. “Cost of Production.” UH Agribusiness Incubator Program. 2013. Available online: http://www.ctahr.hawaii.edu/sustainag/news/articles/V16-Chiang-COP.pdf (accessed on 16 January 2022).

- Aui, A.; Wang, Y.; Mba-Wright, M. Evaluating the economic feasibility of cellulosic ethanol: A meta-analysis of techno-economic analysis studies. Renew. Sustain. Energy Rev. 2021, 145, 111098. [Google Scholar] [CrossRef]

- Soha, T.; Papp, L.; Csontos, C.; Munkácsy, B. The importance of high crop residue demand on biogas plant site selection, scaling and feedstock allocation–A regional scale concept in a Hungarian study area. Renew. Sustain. Energy Rev. 2021, 141, 110822. [Google Scholar] [CrossRef]

- Thorsell, S.; Epplin, F.M.; Huhnke, R.L.; Taliaferro, C.M. Economics of a coordinated biorefinery feedstock harvest system: Lignocellulosic biomass harvest cost. Biomass Bioenergy 2004, 27, 327–337. [Google Scholar] [CrossRef]

- Scordia, D.; Cosentino, S.L. Perennial energy grasses: Resilient crops in a changing European agriculture. Agriculture 2019, 9, 169. [Google Scholar] [CrossRef] [Green Version]

- Turhollow, A.; Downing, M.; Butler, J. The Cost of Silage Harvest and Transport Systems for Herbaceous Crops; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1996. Available online: http://bioenergy.ornl.gov/papers/bioen96/turhllw.html (accessed on 5 February 2022).

- Salassi, M.; Champagne, L. A spreadsheet-based cost model for sugarcane harvesting systems. Comput. Electron. Agric. 1998, 20, 215–227. [Google Scholar] [CrossRef]

- Barker, F.G. An Economic Evaluation of Sugarcane Combine Harvester Costs and Optimal Harvest Schedules for Louisiana. Master’s Theses, Louisiana State University, Baton Rouge, LA, USA, 2007; p. 221. Available online: https://digitalcommons.lsu.edu/gradschool_theses/221 (accessed on 5 February 2022).

- Lazarus. Machinery Costs Estimated. University of Minnesota. 2021. Available online: https://wlazarus.cfans.umn.edu/william-f-lazarus-farm-machinery-management (accessed on 16 January 2022).

- Edwards, W. Estimating Farm Machinery Costs. Ag Decision Maker. Iowa State University Extension. 2015. Available online: https://www.extension.iastate.edu/agdm/crops/pdf/a3-29.pdf (accessed on 12 January 2022).

- Schnitkey, G.; Lattz, D. Machinery Costs Estimate summary. University of Illinois at Urbana Champaign. 2021. Available online: https://farmdoc.illinois.edu/wp-content/uploads/2019/08/machinery-cost-estimates_summary.pdf (accessed on 16 January 2022).

- Deliberto, A.; Hilbun, B.M. Projected costs and returns crop enterprise bugets. In Sugarcane Production Costs in Lousiana; Agricultural Economics Information Report Series No. 354; Lousiana State University Agricultural Center: Baton Rouge, LA, USA, 2022; Available online: https://www.lsuagcenter.com/~/media/system/c/3/7/6/c376546954a0ea8e2a04fdac2bfe422f/2022%20sugar%20enterprise%20budgets%20finalpdf.pdf (accessed on 2 March 2022).

| Category | Value |

|---|---|

| Yield (MT/ha) | 66.12 |

| Ethanol yield (imp gal/mt) | 80.00 |

| Ethanol yield (imp gal/mt/year) | 5289.80 |

| Total Ethanol yield per farm (imp gal) | 25,000,000 |

| Plant Capacity (imp gal) | 25,000,000 |

| Days of operation per year | 300 |

| Daily capacity | 83,333 |

| Total cane yield needed (mt) | 312,500 |

| Energycane needed per day (mt) | 1042 |

| Farm size (ha) | 4726 |

| Minimum area needed to harvest (ha/day) | 15.75 |

| Machinery | Capacity (mt/h) | Av.Capacity (mt/h) | Average Farm Yield (mt/ha) | Harvest Capacity (ha/h) | Max. Potential Daily Harvest ha 1 | Actual Daily Harvest Area | Actual Machine Hours Needed per day | Total Daily Harvest (MT) | Total Farm Size (ha) | Total Machine Use h/year 2 | Total Hours for Harvesting per Day | No of Machines Needed per Day 3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Two-row soldier harvester | 90–140 | 81.82 | 66.12 | 1.24 | 9.90 | 15.75 | 12.73 | 1042 | 4726 | 3819 | 12.73 | 2 |

| Two-row loader | 75.00 | 68.18 | 66.12 | 1.03 | 8.25 | 15.75 | 15.28 | 1042 | 4726 | 4583 | 15.28 | 2 |

| Transloader loader | 100.00 | 90.91 | 66.12 | 1.37 | 11.00 | 15.75 | 11.46 | 1042 | 4726 | 3437 | 11.46 | 1 |

| Machinery | Waiting Time to Unload (min) | Total Trips | Total Waiting Time | Waiting Time (h) | Overall Waiting Time in the Field and Loading Site | Total Travel Time (h) | Total Time (Q&T): h | Working hour/day | Wagons Needed 1 |

|---|---|---|---|---|---|---|---|---|---|

| Transfer wagon | 8.00 | 95.49 | 763.89 | 12.73 | 20.69 | 4.37 | 25.05 | 8.00 | 3 |

| Direct wagon | 8.00 | 95.49 | 763.89 | 12.73 | 20.69 | 27.28 | 47.97 | 9.00 | 5 |

| Machinery | Queuing Time (min) 1 | No of Trailer Loads | Total Queuing Time (h) 2 | Total Round Trip km 3 | Time per Round Trip (h) 4 | Total Travel Time (h) | Queuing/Unloading at Mill (min) | Total Unloading Time (h) 5 | Total Operation Time (h) 6 | Daily Work Hours | Total Truck Tailor Needed 7 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Truck with tailor | 8.00 | 40.9 | 5.5 | 409.23 | 0.40 | 16.37 | 15.00 | 10.23 | 32.06 | 8.00 | 4 |

| Machinery | HP | Initial Cost | Salvage Value Factor | Salvage Value 1 | Total Depreciation 2 | Capital Recovery Factor | Interest Rate | Capital Recovery 3 | Total Taxes 4 | Total Ownership Costs ($/Year) 5 | Total Ownership Costs/mt |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Two-row soldier system | 350 | $231,000 | 0.3 | $69,300 | $161,700 | 0.13 | 0.05 | $24,486 | $2310 | $53,552 | $0.17 |

| Two-row loader | 220 | $165,000 | 0.3 | $49,500 | $115,500 | 0.13 | 0.05 | $17,490 | $1650 | $38,280 | $0.12 |

| Transfer wagon | 175 | $40,000 | 0.3 | $12,000 | $28,000 | 0.13 | 0.05 | $4240 | $400 | $13,920 | $0.05 |

| Direct wagon | 175 | $40,000 | 0.3 | $12,000 | $28,000 | 0.13 | 0.05 | $4240 | $400 | $23,200 | $0.07 |

| Trans loader loader | 85 | $33,000 | 0.3 | $9900 | $23,100 | 0.13 | 0.05 | $3498 | $330 | $3828 | $0.01 |

| Truck trailer | 160 | $49,500 | 0.3 | $15,345 | $34,155 | 0.13 | 0.05 | $5207 | $495 | $22,810 | $0.07 |

| Machinery | HP | Initial Cost | Annual Use (h) | Age (Year) | Repair Costs Factor | Accumulated Repair Cost 1 | Repair Cost/Year | Repair Costs/h | Repair Costs/mt |

|---|---|---|---|---|---|---|---|---|---|

| Two-row soldier system | 350 | $231,000 | 3819 | 12 | 30% | $69,300 | $5775 | $1.51 | $0.0185 |

| Two-row loader | 220 | $165,000 | 399 | 10 | 30% | $49,500 | $4950 | $12.40 | $0.0158 |

| Transfer wagon | 175 | $40,000 | 2400 | 13 | 30% | $12,000 | $923 | $0.38 | $0.0030 |

| Direct wagon | 175 | $40,000 | 2700 | 10 | 30% | $12,000 | $1200 | $0.44 | $0.0038 |

| Transloader loader | 85 | $33,000 | 299 | 8 | 30% | $9900 | $1237 | $4.13 | $0.0040 |

| Truck trailer | 160 | $49,500 | 625 | 10 | 30% | $14,850 | $1485 | $2.38 | $0.0048 |

| Machinery | No of Machines Needed | Annual Use Hours per Machine 1 | Total Machine Hours | Total Area(ha) | Machine Hours per ha 2 | Labor Cost $/h | Total Labor Costs | Total Energycane Yield (MT) | Cost/Mt |

|---|---|---|---|---|---|---|---|---|---|

| Two-row soldier system | 2 | 3819 | 7639 | 4726 | 1.62 | $18 | $137,500 | 312,483 | $0.44 |

| Two-row loader | 2 | 399 | 762 | 4726 | 0.16 | $18 | $13,719 | 312,483 | $0.04 |

| Transfer wagon | 3 | 2400 | 7516 | 4726 | 1.59 | $18 | $135,290 | 312,483 | $0.43 |

| Direct wagon | 5 | 2700 | 14,391 | 4726 | 3.05 | $18 | $259,040 | 312,483 | $0.83 |

| Transloader loader | 1 | 299 | 299 | 4726 | 0.06 | $18 | $5388 | 312,483 | $0.02 |

| Truck with trailer | 4 | 2400 | 9617 | 4726 | 2.03 | $18 | $173,103 | 312,483 | $0.55 |

| Machinery | Diesel Consumption Factor | Av. Fuel Consumption (imp gal/h) | Diesel Cost/imp gal | Av Fuel Cost per Hour | Fuel Cost/year | Total Lubrication Cost/h 1 | Total Lubrication Cost/year | Total Fuel and Lubrication Cost/year | Fuel and Lubrication Costs/mt |

|---|---|---|---|---|---|---|---|---|---|

| Two-row soldier system | 0.044 | 15.4 | $3.81 | $58.67 | $224,102 | $8.80 | $33,615 | $257,717 | $0.82 |

| Two-row loader | 0.044 | 9.68 | $3.81 | $36.88 | $14,718 | $5.53 | $2207 | $16,926 | $0.05 |

| Transfer wagon | 0.044 | 7.7 | $3.81 | $29.34 | $70,408 | $4.40 | $10,561 | $80,970 | $0.26 |

| Direct wagon | 0.044 | 7.7 | $3.81 | $29.34 | $79,209 | $4.40 | $11,881 | $91,091 | $0.29 |

| Transloader loader | 0.044 | 3.74 | $3.81 | $14.25 | $4265 | $2.14 | $639 | $4905 | $0.02 |

| Truck with trailer | 0.044 | 7.04 | $3.81 | $26.82 | $16,764 | $4.02 | $2515 | $19,279 | $0.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Illukpitiya, P.; Yuldashev, F.; Nasiru, K. Designing Harvesting and Hauling Cost Models for Energy Cane Production for Biorefineries. Energies 2022, 15, 5403. https://doi.org/10.3390/en15155403

Illukpitiya P, Yuldashev F, Nasiru K. Designing Harvesting and Hauling Cost Models for Energy Cane Production for Biorefineries. Energies. 2022; 15(15):5403. https://doi.org/10.3390/en15155403

Chicago/Turabian StyleIllukpitiya, Prabodh, Firuz Yuldashev, and Kabirat Nasiru. 2022. "Designing Harvesting and Hauling Cost Models for Energy Cane Production for Biorefineries" Energies 15, no. 15: 5403. https://doi.org/10.3390/en15155403

APA StyleIllukpitiya, P., Yuldashev, F., & Nasiru, K. (2022). Designing Harvesting and Hauling Cost Models for Energy Cane Production for Biorefineries. Energies, 15(15), 5403. https://doi.org/10.3390/en15155403