Study on Morphological Identification of Tight Oil Reservoir Residual Oil after Water Flooding in Secondary Oil Layers Based on Convolution Neural Network

Abstract

:1. Introduction

- Physical simulation method:

- (1)

- Indoor oil displacement experiment. The cores were separately isolated to carry out water flooding. When the content of water reached 98%, with the injected polymer solution, the molecular weight of the polymer, PV number of the solution and the concentration of polymer solution as the control variable, the following water flooding was conducted until the water content reached 98% again.

- (2)

- Nuclear magnetic resonance technology. At present, NMR is an advanced nondestructive, multifunctional and quantitative measurement method. In 1986, the Boldwin magnetic resonance imager was used for the first time to study the oil displacement process of sandstone core. Since then, new MRI technologies have attracted widespread attention in the oil industry. Water and polymer flooding were performed on four different sections of natural cores. For the same core, the part profile and middle longitudinal profile were photographed after the completion of water injection, polymer flooding and subsequent water flooding. The residual oil was determined according to the distribution of remaining oil saturation [3,4,5,6].

- (3)

- Fluorescence analysis of grinding disc. The two cores were subjected to a water flooding test and then placed under sealing conditions for 15 days. The two cores uniformly intercepted the three sections and the fluorescence analysis technology of G was used to make sections of each section. The plate was rinsed to create an abrasive disc. Five lines were selected evenly on each piece; scan imaging was used to generate continuous images and one of them was selected. The distribution of residual oil was studied with several pictures.

- Closed core analysis and Logging interpretation method. This method is an explanation of the distribution law of residual oil in the main reservoir after polymer flooding. This method was used to study the distribution law of residual oil and analyze it in horizontal and vertical directions. In addition, the factors affecting the difference in the residual oil distribution were also analyzed.

- Numerical simulation method and relative permeability characteristic curve method. These methods establish the relative permeability curve equation, through which the relative permeability curve of each grid block is calculated so as to improve the accuracy of reservoir numerical simulation.

2. Method Introduction

3. Data and Methods

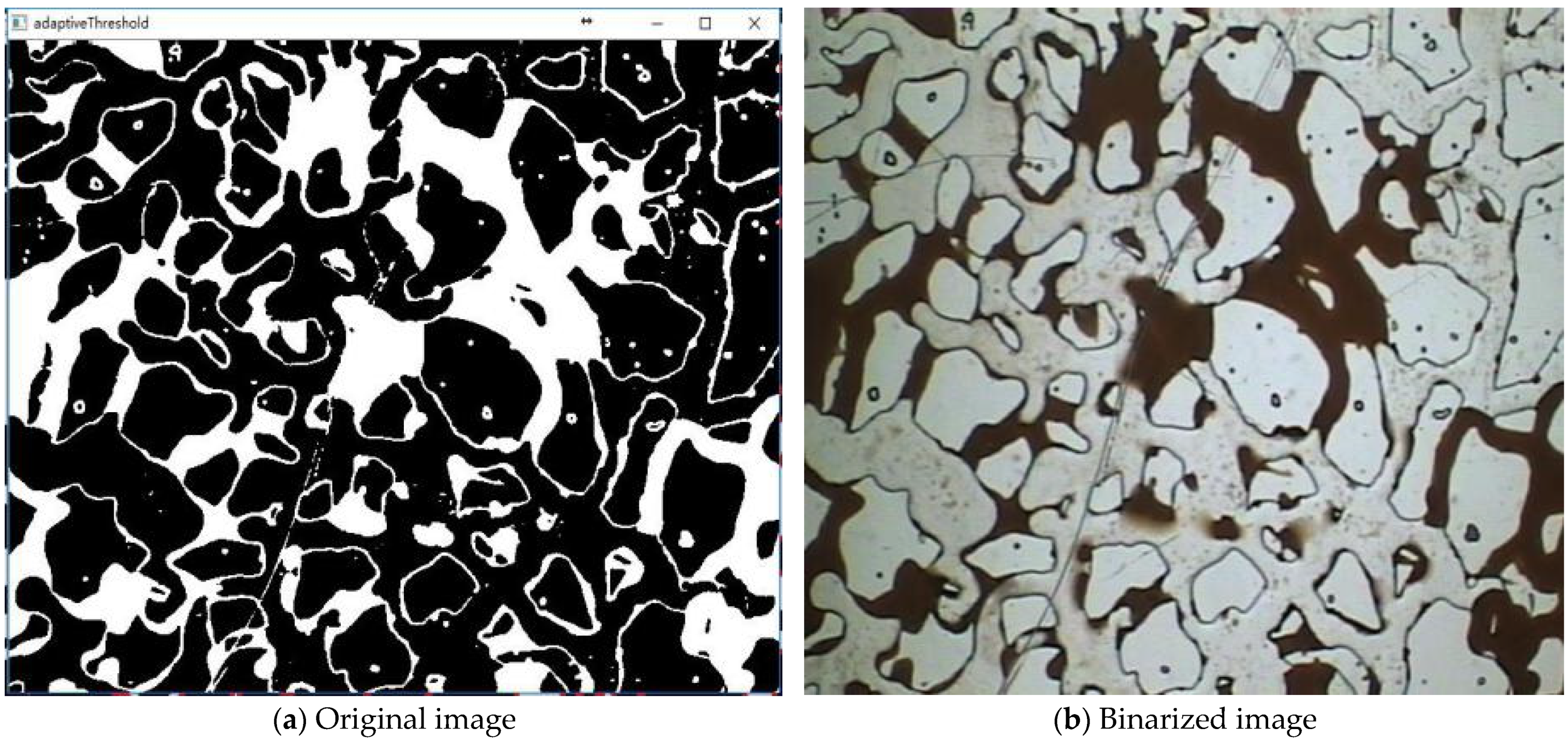

3.1. Binarization Processing

- (1)

- The maximum and minimum values of grayscale images are set to 255 and 0, respectively;

- (2)

- The threshold calculation method based on Gauss is adopted (the Gaussian threshold method is a kind of density estimation method. Its basic principle is to estimate the probability distribution function of the sample set and set a density threshold. When the density of the area where the test sample is located is higher than the threshold, it is judged as normal; otherwise, it is judged as abnormal);

- (3)

- The binvalue graph is reversed (set 255 for pixels less than the threshold and 0 for pixels greater than the threshold);

- (4)

- The calculation threshold block size parameter is set as 401.

3.2. Remove Small Connected Regions

3.3. Contour Extraction and Cropping

3.4. Add the Edge

4. Results and Analysis

4.1. Identification Type of Remaining Oil

4.2. MobileNet Model Training

4.2.1. Dataset Information

- (a)

- randomly rotate an angle less than 20 clockwise or counterclockwise;

- (b)

- scale the picture by multiplying a random number between 0.5 and 1;

- (c)

- translate the image randomly, with the displacement of 0 to 0.1 times the corresponding length and width.

4.2.2. Training Parameter

4.3. Test Dataset

4.4. Test Results

4.4.1. Test Dataset and Results

4.4.2. Ablation Test Dataset and Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cheng, J.; Wu, J.; Hu, J. The key theory and technology of enhanced oil recovery by ASP flooding. Chin. J. Pet. 2014, 02, 310–318. [Google Scholar]

- Cai, Z. Study on the relationship between reservoir pore structure and oil displacement efficiency. Pet. Explor. Dev. 2000, 27, 45–49. [Google Scholar]

- Jamaloei, B.Y.; Kharrat, R.; Asghari, K.; Torabi, F. The influence of pore wettability on the microstructure of residual oil in surfactant-enhanced water flooding in heavy oil reservoirs: Implications for pore-scale flow characterization. J. Pet. Sci. Eng. 2011, 77, 121–134. [Google Scholar] [CrossRef]

- Yang, K. The Simulation Model Study of Microcosmic Remaining Oil; China University of Petroleum: Beijing, China, 2009. [Google Scholar]

- Zhang, W. Distribution of Remaining Oil after Polymer Flooding and Analysis of the Influencing Factors; Daqing Petroleum Institute: Daqing, China, 2010. [Google Scholar]

- Zhou, Z. Research on Object Recognition Based on Shape; National University of Defense Technology: Changsha, China, 2005. [Google Scholar]

- Yang, J. Practical Course in Artificial Neural Network; Zhejiang University Press: Hangzhou, China, 2001. [Google Scholar]

- Lin, Y.; Chen, X. BP neural network learning algorithm and its software implementation. Appl. Mech. Mater. 2014, 513–517, 738–741. [Google Scholar] [CrossRef]

- Chen, C.; Ji, G.; Wang, H.; Huang, H.; Baud, P.; Wu, Q. Geology-engineering integration to improve drilling speed and safety in ultra-deep clastic reservoirs of the Qiulitage structural belt. Adv. Geo-Energy Res. 2022, 6, 347–356. [Google Scholar] [CrossRef]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich Feature Hierarchies for Accurate Object Detection and Semantic Segmentation. In Proceedings of the Computer Vision and Pattern Recognition (CVPR), 2014 IEEE Conference on IEEE, Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar]

- Tang, Y.; Wang, Y.; Cooper, K.M.; Li, L. Owards Big Data Bayesian Network Learning-An Ensemble Learning Based Approach. In Proceedings of the 2014 IEEE International Congress on Big Data, Anchorage, AK, USA, 27 June–2 July 2014; pp. 355–377. [Google Scholar]

- Yan, Y.; Wang, B.; Sheng, Q.Z.; Mahmood, A.; Feng, T.; Xie, P. Modelling the Publishing Process of Big Location Data Using Deep Learning Prediction Methods. Electronics 2020, 9, 420. [Google Scholar] [CrossRef] [Green Version]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the Computer Vision & Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 779–788. [Google Scholar]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the 2015 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). IEEE Computer Society, Boston, MA, USA, 7–12 June 2015; pp. 1–9. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Spatial Pyramid Pooling in Deep Convolutional Networks for Visual Recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 8691, 1904–1916. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Guo, Y.; Qi, Z. The influence of activation function on the performance of BP network and its simulation research. Autom. Technol. Appl. 2002, 21, 15–17. [Google Scholar]

- Uijlings, J.R.; Van De Sande, K.E.; Gevers, T.; Smeulders, A.W. Selective Search for Object Recognition. Int. J. Comput. Vis. 2013, 104, 154–171. [Google Scholar] [CrossRef] [Green Version]

- Zeiler, M.; Fergus, R. Visualizing and Understanding Convolutional Networks. In Computer Vision–ECCV 2014.Springer International Publishing; Springer: Cham, Switzerland, 2014; pp. 818–833. [Google Scholar]

- Wang, L. Research and Discussion on Object Recognition Methods in Machine Vision; Fudan University: Shanghai, China, 2009. [Google Scholar]

- Lowe, D. Distinctive image fearures from scale-invariant keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Xu, F.; Chen, Q.; Ma, M.; Wang, Y.; Yu, F.; Li, J. Displacement mechanism of polymeric surfactant in chemical cold flooding for heavy oil based on microscopic visualization experiments. Adv. Geo-Energy Res. 2020, 4, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Zhou, D. Research on the application of BP neural network sample data preprocessing. World Sci. Technol. Res. Dev. 2012, 34, 27. [Google Scholar]

- Hu, B.; Guan, K. An improved neural network data preprocessing method and its application in construction management. Chin. J. Civ. Eng. 2004, 37, 106–110. [Google Scholar]

- Li, W. Research and Application of Deep Learning in Image Recognition; Wuhan University of Technology: Wuhan, China, 2014. [Google Scholar]

- Liu, J.; Ma, S.; Shen, W.; Zhou, J.; Hong, Y. Image feature recognition and gas permeability prediction of Gaomiaozi bentonite based on digital images and machine learning. Adv. Geo-Energy Res. 2022, 6, 314–323. [Google Scholar] [CrossRef]

- Schölkopf, B.; Platt, J.; Hofmann, T. Efficient sparse coding algorithms. In Advances in Neural Information Processing Systems 19: Proceedings of the 2006 Conference; MIT Press: Cambridge, MA, USA, 2007; pp. 801–808. [Google Scholar]

- David, V.; Sanchez, A. Advanced support vector machines and kernel methods. Neurocomputing 2003, 55, 5–20. [Google Scholar]

- Campbell, C. Kernel methods: A survey of current techniques. Neurocomputing 2002, 48, 63–84. [Google Scholar] [CrossRef]

- Na’Imi, S.; Shadizadeh, S.; Riahi, M.; Mirzakhanian, M. Estimation of reservoir porosity and water saturation based on seismic attributes using support vector regression approach. J. Appl. Geo-Phys. 2014, 107, 93–101. [Google Scholar] [CrossRef]

- Alanazi, A.; Gates, I. Support vector regression to predict porosity and permeability: Effect of sample size. Comput. Geosci. 2012, 39, 64–76. [Google Scholar] [CrossRef]

- Kong, D.; Gao, J.; Lian, P.; Zheng, R.; Zhu, W.; Xu, Y. Characteristics of gas-oil contact and mobilization limit during gas-assisted gravity drainage process. Adv. Geo-Energy Res. 2022, 6, 169–176. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Processing Syst. 2012, 25, 50–52. [Google Scholar] [CrossRef]

- Deng, L.; Li, J.; Huang, J.-T.; Yao, K.; Yu, D.; Seide, F.; Seltzer, M.; Zweig, G.; He, X.; Williams, J.; et al. Recent advances in deep learning for speech research at Microsoft. In Proceedings of the IEEE International Conference on Acoustics, Vancouver, BC, Canada, 26–31 May 2013; pp. 8604–8608. [Google Scholar]

- Li, F. Convolutional Neural Network and Its Applications; Dalian University of Technology: Dalian, China, 2014. [Google Scholar]

- Glorot, X.; Bengio, Y. Understanding the difficulty of training deep feedforward neural networks. J. Mach. Learn. Res. 2010, 9, 249–256. [Google Scholar]

- Yang, P.; Guo, H.; Yang, D. Determination of Residual Oil Distribution during Waterflooding in Tight Oil Formations with NMR Relaxometry Measurements. Energy Fuels 2013, 27, 5750–5756. [Google Scholar] [CrossRef]

- Zhou, Z.; Slaný, M.; Kuzielová, E.; Zhang, W.; Ma, L.; Dong, S.; Zhang, J.; Chen, G. Influence of reservoir minerals and ethanol on catalytic aquathermolysis of heavy oil. Fuel 2022, 307, 121871. [Google Scholar] [CrossRef]

| Oil Droplet | Columnar | Tufted | Blind End | Membranous | |

|---|---|---|---|---|---|

| Oil droplet | 58 | 3 | 4 | 2 | 3 |

| Columnar | 2 | 73 | 6 | 1 | 3 |

| Tufted | 2 | 3 | 62 | 4 | 4 |

| Blind end | 2 | 5 | 1 | 58 | 3 |

| Membranous | 1 | 3 | 2 | 2 | 38 |

| Recall Rate | Accuracy Rate | |

|---|---|---|

| Oil droplet | 60% | 80% |

| Columnar | 70% | 84% |

| Tufted | 67% | 83% |

| Blind end | 67% | 82.4% |

| Membranous | 64% | 84% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Sun, X.; Liu, F.; Wang, P.; Chang, L. Study on Morphological Identification of Tight Oil Reservoir Residual Oil after Water Flooding in Secondary Oil Layers Based on Convolution Neural Network. Energies 2022, 15, 5367. https://doi.org/10.3390/en15155367

Zhao L, Sun X, Liu F, Wang P, Chang L. Study on Morphological Identification of Tight Oil Reservoir Residual Oil after Water Flooding in Secondary Oil Layers Based on Convolution Neural Network. Energies. 2022; 15(15):5367. https://doi.org/10.3390/en15155367

Chicago/Turabian StyleZhao, Ling, Xianda Sun, Fang Liu, Pengzhen Wang, and Lijuan Chang. 2022. "Study on Morphological Identification of Tight Oil Reservoir Residual Oil after Water Flooding in Secondary Oil Layers Based on Convolution Neural Network" Energies 15, no. 15: 5367. https://doi.org/10.3390/en15155367

APA StyleZhao, L., Sun, X., Liu, F., Wang, P., & Chang, L. (2022). Study on Morphological Identification of Tight Oil Reservoir Residual Oil after Water Flooding in Secondary Oil Layers Based on Convolution Neural Network. Energies, 15(15), 5367. https://doi.org/10.3390/en15155367