Classification and Evaluation of Shale Oil Reservoirs of the Chang 71-2 Sub-Member in the Longdong Area

Abstract

:1. Introduction

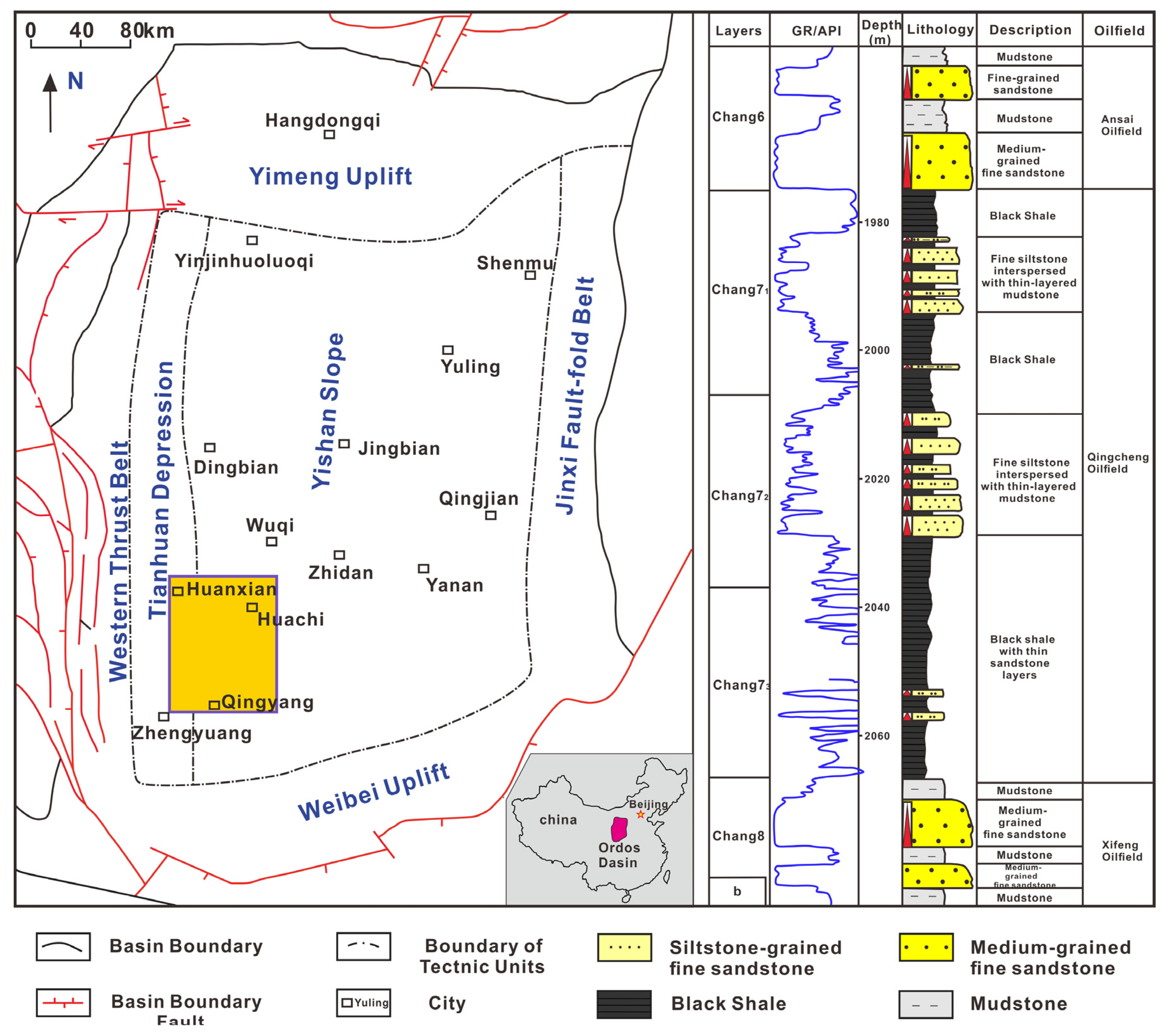

2. Geologic Setting

3. Materials and Methods

3.1. Sample Characteristics

3.2. Experimental Methods

4. Results and Discussion

4.1. Fractal Characteristics of Pore Throats

4.2. Reservoir Classification

4.3. Physical Property and Pore Structure Characteristics of Different Reservoirs

4.3.1. Physical Property Characteristics of Different Reservoirs

4.3.2. Pore Types of Different Types of Reservoirs

4.3.3. Pore Size Distribution of Different Types of Reservoirs

4.4. Relationship of Different Types of Reservoirs with Oil Layers and Productivity

5. Conclusions

- 1.

- According to fractal theory, the pore-throat system is divided into four parts: large pore throats (>0.2 μm), medium pore throats (0.08~0.2 μm), small pore throats (0.03~0.08 μm), and micropore throats (<0.03 μm).

- 2.

- Based on the development degree of different pore throats, the shale samples were statistically clustered and analyzed. The Chang 71-2 shale oil reservoirs are divided into four types: type I reservoirs, type II reservoirs, type III reservoirs, and type IV reservoirs. From type I to IV reservoirs, the physical properties and pore structure gradually deteriorate. Type I, II, III, and IV reservoirs can be named better, good, medium, and poor reservoirs. A classification scheme of reservoirs was established.

- 3.

- The Chang 71 and Chang 72 sub-members mainly develop oil layers, poor oil layers, and dry layers. The intervals where type I and II reservoirs are developed correspond to oil layers, the type III and IV reservoirs correspond to the dry layer. The higher daily oil production from a single well is primarily attributable to type I and II reservoirs.

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Law, B.; Curtis, J. Introduction to unconventional petroleum systems. AAPG Bull. 2002, 86, 1851–1852. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, B.; Yang, Z.; Zhao, P. Pore structure characterization and the controlling factors of the Bakken formation. Energies 2018, 11, 2879. [Google Scholar] [CrossRef] [Green Version]

- Schmoker, J.W. Resource-assessment perspectives for unconventional gas systems. AAPG Bull. 2002, 86, 1993–1999. [Google Scholar] [CrossRef]

- Jia, C.; Zheng, M.; Zhang, Y. Unconventional hydrocarbon resources in China and the prospect of exploration and development. Pet. Explor. Dev. 2012, 39, 139–146. [Google Scholar] [CrossRef]

- Niu, X.; Liu, G. Formation and accumulation mechanism of shale oil in the 7th member of Yanchang Formation, Ordos Basin. Oil Gas Geol. 2020, 41, 719–729. [Google Scholar]

- Reynolds, D.B.; Umekwe, M.P. Shale-oil development prospects: The role of shale-gas in developing shale-oil. Energies 2019, 12, 3331. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Liu, Z.; Zhang, G.; Zheng, Z.; Jia, J.; Gao, X.; Zan, X. Comparison and revelation of tight oil accumulation conditions, distribution characteristics and development status between China and US. Nat. Gas Geosci. 2017, 28, 1126–1138. [Google Scholar]

- EIA. U.S. Crude Oil and Natural Gas Proved Reserves, Year-End 2019; US Energy Information Administration: Washington, DC, USA, 2018.

- Zou, C.; Yang, Z.; Cui, J.; Zhu, R.; Hou, L.; Tao, S.; Yuan, X.; Wu, S.; Lin, S.; Wang, L. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 15–27. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, W.; Liang, C.; Wang, Y.; Liu, H.; Chen, X.J.P.R. Basic characteristics and evaluation of shale oil reservoirs. Pet. Res. 2016, 1, 149–163. [Google Scholar] [CrossRef]

- Jiao, F.; Zou, C.; Yang, Z. Geological theory and exploration & development practice of hydrocarbon accumulation inside continental source kitchens. Pet. Explor. Dev. 2020, 47, 1147–1159. [Google Scholar] [CrossRef]

- Fu, S.; Fu, J.; Niu, X.; Li, S.; Wu, Z.; Zhou, X.; Liu, J. Reservoir formation conditions and key technologies for exploration and development in Qingcheng large oilfield. Pet. Res. 2020, 5, 181–201. [Google Scholar] [CrossRef]

- Yang, H.; Niu, X.; Luo, S.; Feng, Q.; Lv, A. Research of simulated experiment on gravity flow deposits of tight sand bodies of Chang 7 Formation in Longdong area, Ordos Basin. Earth Sci. Front. 2015, 22, 322–332. [Google Scholar] [CrossRef]

- Fu, J.; Liu, X.; Li, S.; Guo, Q.; Zhou, X.; Yang, W. Discovery and resource potential of shale oil of Chang 7 member, Triassic Yanchang Formation, Ordos Basin. China Pet. Explor. 2021, 26, 1–11. [Google Scholar] [CrossRef]

- Fu, S.; Jin, Z.; Fu, J.; Li, S.; Yang, W. Transformation of understanding from tight oil to shale oil in the Member 7 of Yanchang Formation in Ordos Basin and its significance of exploration and development. Acta Pet. Sin. 2021, 42, 561–569. [Google Scholar]

- Wang, X.; Zhang, F.; Li, S.; Dou, L.; Liu, Y.; Ren, X.; Chen, D.; Zhao, W.J.G. The Architectural Surfaces Characteristics of Sandy Braided River Reservoirs, Case Study in Gudong Oil Field, China. Geofluids 2021, 2021, 8821711. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Xu, Y.; Chen, T.; Yan, X.; Sun, L.; Tian, W. Genetic mechanism and grading assessment of the glutenite reservoirs in the Eocene Shahejie Formation, Chezhen Sag, Bohai Bay Basin. J. Pet. Sci. Eng. 2022, 211, 110226. [Google Scholar] [CrossRef]

- Wang, W.; Lu, S.; Tian, W. Liaohe oilfield shale reservoir quality grading with micropore evaluation parameters in Damintun depression. J. China Univ. Pet. 2016, 40, 12–19. [Google Scholar]

- Lu, S.; Li, J.; Zhang, P.; Xue, H.; Wang, G.; Zhang, J.; Liu, H.; Li, Z. Classification of microscopic pore-throats and the grading evaluation on shale oil reservoirs. Pet. Explor. Dev. Online 2018, 45, 452–460. [Google Scholar] [CrossRef]

- Zhou, N.; Lu, S.; Wang, M.; Huang, W.; Xiao, D.; Jiao, C.; Wang, J.; Tian, W.; Zhou, L.; Chen, F.; et al. Limits and grading evaluation criteria of tight oil reservoirs in typical continental basins of China. Pet. Explor. Dev. Online 2021, 48, 1089–1100. [Google Scholar] [CrossRef]

- Yang, W.; Li, J.; Zhao, J.; Huang, Z. Qualitative and quantitative study of micro-pore structures of Longmaxi formation shale in Fuling area, Sichuan Basin. Pet. Geol. Exp. 2018, 40, 97–102. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Xie, Q.; Zhou, J. Micro pore throat structural classification of Chang 7 tight oil reservoir of Jiyuan oilfield in Ordos Basin. China Pet. Explor. 2014, 19, 73. [Google Scholar]

- Zhang, L.; Song, X.; Du, Y.; Lu, S.; Xiao, D.; Jiang, S.; Chen, X.; Zhang, R.; Yu, R. The upper and lower limits and grading evaluation of the Shahezi tight gas reservoirs in the Xujiaweizi Rift, northern Songliao Basin: Implications from microscopic pore structures. J. Pet. Sci. Eng. 2022, 212, 110224. [Google Scholar] [CrossRef]

- Huang, W.; Lu, S.; Osman, S.H. Quality grading system for tight sandstone reservoirs in the Quantou 4 Member, Southern Songliao Basin, Northeast China. Interpretation 2017, 5, T503–T522. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, X.; Li, S.; Zhang, N.; Ji, L.; Lu, H.J.L. Mechanism Study of Hydrocarbon Differential Distribution Controlled by the Activity of Growing Faults in Faulted Basins: Case Study of Paleogene in the Wang Guantun Area, Bohai Bay Basin, China. Lithosphere 2022, 2021, 7115985. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, S.J.F. A coupled Lattice Boltzmann approach to simulate gas flow and transport in shale reservoirs with dynamic sorption. Fuel 2019, 246, 196–203. [Google Scholar] [CrossRef]

- Pang, X.; Jia, C.; Chen, J.; Li, M.; Wang, W.; Hu, Q.; Guo, Y.; Chen, Z.; Peng, J.; Liu, K.J.G.F. A unified model for the formation and distribution of both conventional and unconventional hydrocarbon reservoirs. Geosci. Front. 2021, 12, 695–711. [Google Scholar] [CrossRef]

- Tian, W.; Lu, S.; Huang, W.; Wang, W.; Li, J.; Gao, Y.; Zhan, Z.; Sun, Y. Quantifying the control of pore types on fluid mobility in low-permeability conglomerates by integrating various experiments. Fuel 2020, 275, 117835. [Google Scholar] [CrossRef]

- Lu, S.; Li, J.; Xiao, D.; Xue, H.; Zhang, P.; Li, J.; Chen, F.; Huang, W.; Wang, M.; Li, W.J.E.; et al. Research Progress of Microscopic Pore–Throat Classification and Grading Evaluation of Shale Reservoirs: A Minireview. Energy Fuels 2022, 36, 4677–4690. [Google Scholar] [CrossRef]

- Zeng, S.; Li, H.; Zhang, N.; Sun, B.; Li, J.; Liu, Y. Full-scale pore size distribution features of uranium-bearing sandstone in the northwest of Xinjiang, China. R. Soc. Open Sci. 2021, 8, 202036. [Google Scholar] [CrossRef]

- Tao, S.; Zhao, X.; Tang, D.; Deng, C.; Meng, Q.; Cui, Y.J.F. A model for characterizing the continuous distribution of gas storing space in low-rank coals. Fuel 2018, 233, 552–557. [Google Scholar] [CrossRef]

- Fu, J.; Li, S.; Niu, X.; Deng, X.; Zhou, X. Geological characteristics and exploration of shale oil in Chang 7 member of Triassic Yanchang Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2020, 47, 931–945. [Google Scholar] [CrossRef]

- Zhong, D.; Zhou, L.; Sun, H.; Yao, J.; Liu, X.; Luo, A.; Deng, X. Petrology of sandstone reservoirs in Longdong area, Ordos Basin. Earth Sci. Front. 2013, 20, 52–60. [Google Scholar]

- Zhang, X.; Feng, S.; Liang, X.; Feng, S.; Mao, Z.; Ren, J.; Chen, S. Sedimentary microfacies identification and inferred evolution of the Chang 7 member of Yanchang Formation in the Longdong area, Ordos Basin. Acta Geol. Sin. 2020, 94, 957–967. [Google Scholar]

- Fu, J.; Li, S.; Guo, Q.; Guo, W.; Zhou, X.; Liu, J. Enrichment condition and favorable area optimization of continental shale oil in Ordos Basin. Acta Pet. Sin. 2022, 1–14. [Google Scholar] [CrossRef]

- Schlueter, E.; Zimmerman, R.; Witherspoon, P.; Cook, N. The fractal dimension of pores in sedimentary rocks and its influence on permeability. Eng. Geol. 1997, 48, 199–215. [Google Scholar] [CrossRef]

- Xie, S.; Cheng, Q.; Ling, Q.; Li, B.; Bao, Z.; Fan, P. Fractal and multifractal analysis of carbonate pore-scale digital images of petroleum reservoirs. Mar. Pet. Geol. 2010, 27, 476–485. [Google Scholar] [CrossRef]

- Anovitz, L.; Cole, D.R.; Rother, G.; Allard, L.F.; Jackson, A.; Littrell, K. Diagenetic changes in macro-to nano-scale porosity in the St. Peter Sandstone: An (ultra) small angle neutron scattering and backscattered electron imaging analysis. Geochim. Cosmochim. Acta 2013, 102, 280–305. [Google Scholar] [CrossRef]

- Hu, Q.; Ewing, R.P.; Dultz, S. Low pore connectivity in natural rock. J. Contam. Hydrol. 2012, 133, 76–83. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, Y.; Lu, S.; Jin, K.; Zhao, W. Influence of coalification on the pore characteristics of middle–high rank coal. Energy Fuels 2014, 28, 5729–5736. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 2002, 60, 309–319. [Google Scholar] [CrossRef]

- Avnir, D.; Jaroniec, M. An isotherm equation for adsorption on fractal surfaces of heterogeneous porous materials. Langmuir 1989, 5, 1431–1433. [Google Scholar] [CrossRef]

- Jaroniec, M. Evaluation of the fractal dimension from a single adsorption isotherm. Langmuir 1995, 11, 2316–2317. [Google Scholar] [CrossRef]

- Li, K.; Zeng, F.; Cai, J.; Sheng, G.; Xia, P.; Zhang, K. Fractal characteristics of pores in Taiyuan formation shale from Hedong coal field, China. Fractals 2018, 26, 1840006. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Ning, Z.; Liu, H. Fractal characteristics of shales from a shale gas reservoir in the Sichuan Basin, China. Fuel 2014, 115, 378–384. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore throat structure and fractal characteristics of tight oil sandstone: A case study in the Ordos Basin, China. J. Pet. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Gao, Z.; Yang, X.; Hu, C.; Wei, L.; Jiang, Z.; Yang, S.; Fan, Y.; Xue, Z.; Yu, H. Characterizing the pore structure of low permeability Eocene Liushagang Formation reservoir rocks from Beibuwan Basin in Northern South China Sea. Mar. Pet. Geol. 2019, 99, 107–121. [Google Scholar] [CrossRef]

- Cai, J.; Yu, B.; Zou, M.; Mei, M. Fractal analysis of invasion depth of extraneous fluids in porous media. Chem. Eng. Sci. 2010, 65, 5178–5186. [Google Scholar] [CrossRef]

- Huang, W.; Lu, S.; Hersi, O.S.; Wang, M.; Deng, S.; Lu, R. Reservoir spaces in tight sandstones: Classification, fractal characters, and heterogeneity. J. Nat. Gas Sci. Eng. 2017, 46, 80–92. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Passoja, D.; Paullay, A.J. Fractal character of fracture surfaces of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Kettenring, J.R. The practice of cluster analysis. J. Classif. 2006, 23, 3–30. [Google Scholar] [CrossRef]

- Yang, Z.; Li, H.; Yang, K.; Liu, L. Cluster analysis of residents’ consumption levels in provinces and cities based on systematic clustering algorithm and elbow criterion. China Sci. Technol. Inf. 2021, 121–122. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, T.; Xu, Z.; Sun, N.; Temam, O. DianNao family: Energy-efficient hardware accelerators for machine learning. Commun. ACM 2016, 59, 105–112. [Google Scholar] [CrossRef]

- Kabir, M.E.; Wang, H.; Bertino, E.; Chi, Y. Systematic Clustering Method for L-Diversity Model. In Proceedings of the Conferences in Research and Practice in Information Technology (CRPIT), Brisbane, Australia, 18–22 January 2010; Australian Computer Society Inc.: Sydney, Australia, 2010; Volume 104, pp. 93–102. [Google Scholar]

- Chiu, C.-C.; Tsai, C.-Y. A K-Anonymity Clustering Method for Effective Data Privacy Preservation. In Proceedings of the International Conference on Advanced Data Mining and Applications, Harbin, China, 6–8 August 2007; Springer: Berlin/Heidelberg, Germany, 2007; pp. 89–99. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Hou, J.; Li, S.; Kang, Q.; Sun, S.; Ji, L.; Sun, J.; Ma, R.J.I. The relationship between synsedimentary fault activity and reservoir quality—A case study of the Ek1 formation in the Wang Guantun area, China. Interpration 2020, 8, SM15–SM24. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R.; Saeedi, A.; Al Hinai, A. Evaluation of pore size spectrum of gas shale reservoirs using low pressure nitrogen adsorption, gas expansion and mercury porosimetry: A case study from the Perth and Canning Basins, Western Australia. J. Pet. Sci. Eng. 2013, 112, 7–16. [Google Scholar] [CrossRef]

| Parameter | Type I | Type II | Type III | Type IV |

|---|---|---|---|---|

| Porosity/% | >10 | 8~10 | 5~8 | <5 |

| Permeability/mD | >0.1 | 0.05~0.1 | 0.02~0.05 | <0.02 |

| Displacement pressure/MPa | <2 | 2~4.2 | 4.2~8 | >8 |

| Pore size | large-sized pores | large-sized pores(main) + small-sized pores | small-sized pores(main) + large-sized pores | small-sized pores |

| Pore-throats Type | large pore-throats, medium pore-throats | mesoporous throats | small pore-throats, micropore throats | micropore throats |

| Pore Type | dissolved pores, intergranular pores | dissolved pores (main) + intercrystalline pores | intercrystalline pores (main) + dissolved pores | intergranular pores |

| Reservoir evaluation | better | good | medium | poor |

| Well | Main Reservoir Types | Oil Testing Layers | Daily Production (t/d) |

|---|---|---|---|

| Zhuang143 | I | Chang71 | 30.60 |

| Li348 | I, II | Chang72 | 22.44 |

| Li239 | I, II | Chang71-2 | 21.42 |

| Li99 | I | Chang72 | 21.34 |

| Li17 | I, II, III | Chang72 | 21.08 |

| Cheng98 | I, II, III, IV | Chang71 | 12.24 |

| Yue36 | I, II | Chang71 | 11.82 |

| Bai128 | II | Chang72 | 11.10 |

| Zhuang38 | I, II | Chang71 | 11.05 |

| Li190 | I, II | Chang71 | 10.97 |

| Xi268 | I, II | Chang71 | 10.03 |

| Cheng75 | I, II | Chang71 | 7.74 |

| Ban7 | I, II | Chang71 | 7.60 |

| Cheng95 | II, III | Chang71 | 6.90 |

| Zhuang89 | I, II, III, IV | Chang71-2 | 6.69 |

| Shan160 | II, III | Chang71 | 5.52 |

| Bai456 | I, II | Chang72 | 5.30 |

| Le23 | II, III | Chang71 | 4.70 |

| Ning156 | II, III | Chang72 | 4.48 |

| Zhen120 | III, IV | Chang72 | 2.64 |

| Ta37 | III, IV | Chang71 | 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Zhou, X.; Wen, Z.; Guo, W.; Tian, W.; Li, S.; Fan, Y.; Luo, Y. Classification and Evaluation of Shale Oil Reservoirs of the Chang 71-2 Sub-Member in the Longdong Area. Energies 2022, 15, 5364. https://doi.org/10.3390/en15155364

Gao H, Zhou X, Wen Z, Guo W, Tian W, Li S, Fan Y, Luo Y. Classification and Evaluation of Shale Oil Reservoirs of the Chang 71-2 Sub-Member in the Longdong Area. Energies. 2022; 15(15):5364. https://doi.org/10.3390/en15155364

Chicago/Turabian StyleGao, Heting, Xinping Zhou, Zhigang Wen, Wen Guo, Weichao Tian, Shixiang Li, Yunpeng Fan, and Yushu Luo. 2022. "Classification and Evaluation of Shale Oil Reservoirs of the Chang 71-2 Sub-Member in the Longdong Area" Energies 15, no. 15: 5364. https://doi.org/10.3390/en15155364

APA StyleGao, H., Zhou, X., Wen, Z., Guo, W., Tian, W., Li, S., Fan, Y., & Luo, Y. (2022). Classification and Evaluation of Shale Oil Reservoirs of the Chang 71-2 Sub-Member in the Longdong Area. Energies, 15(15), 5364. https://doi.org/10.3390/en15155364