The Impact of Nanostructured Silicon and Hybrid Materials on the Thermoelectric Performance of Thermoelectric Devices: Review

Abstract

1. Introduction

2. Characteristic Features of Thermoelectric Devices

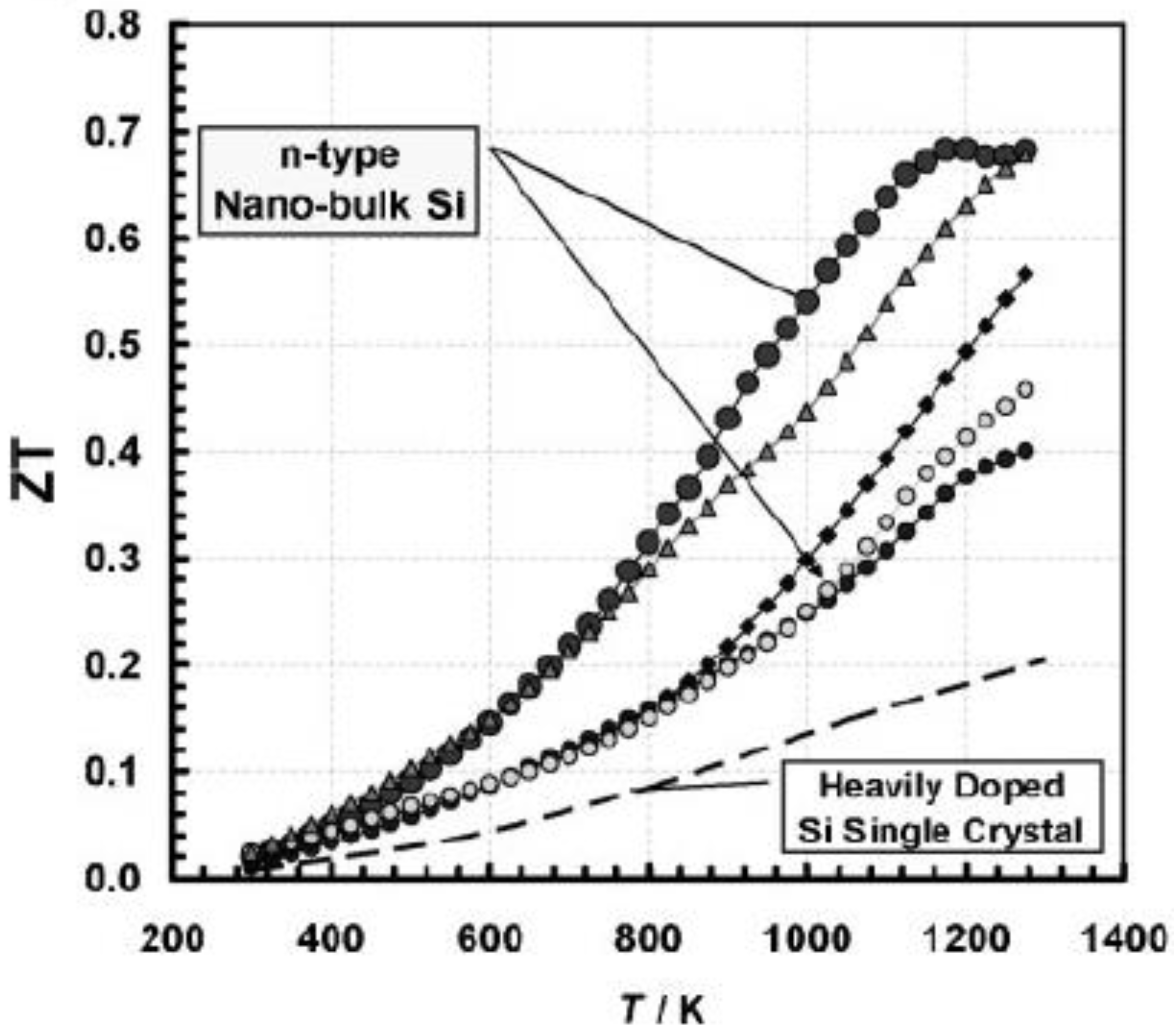

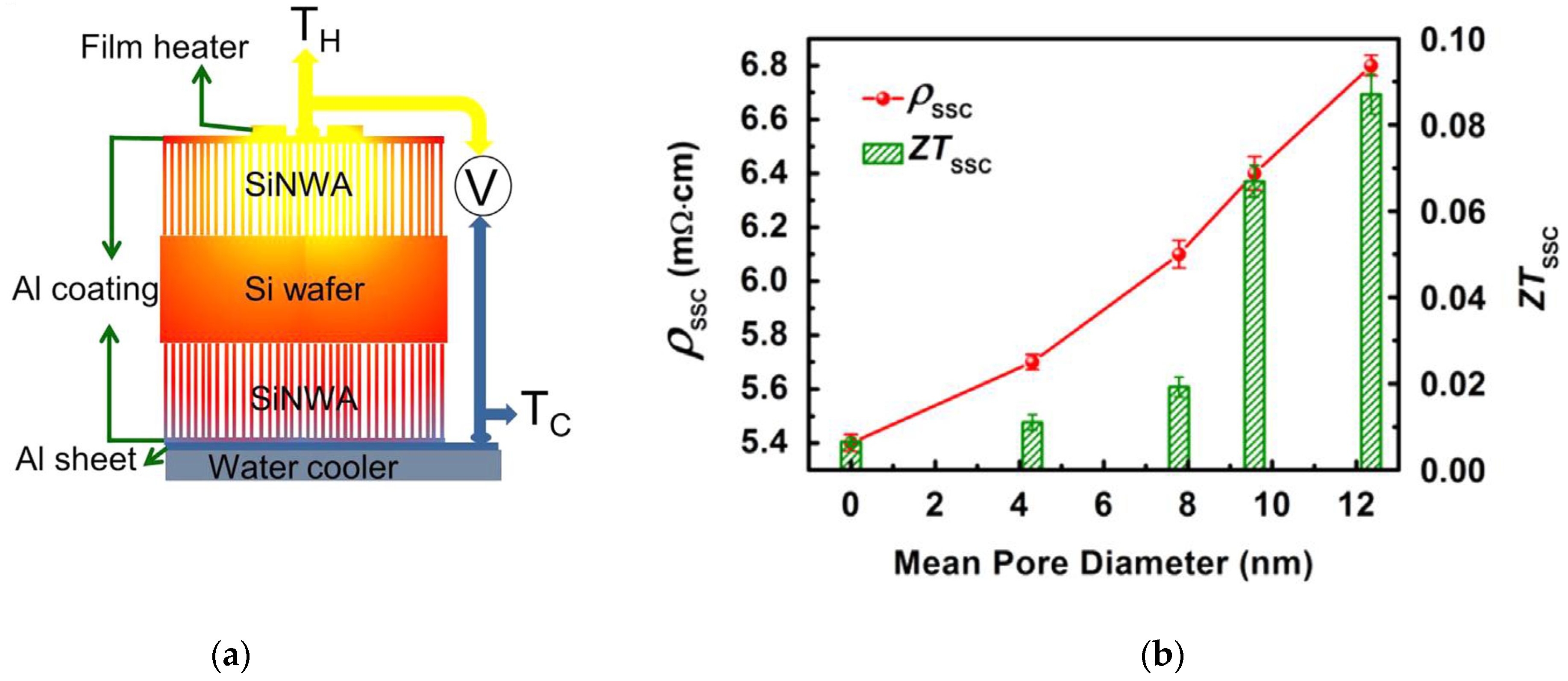

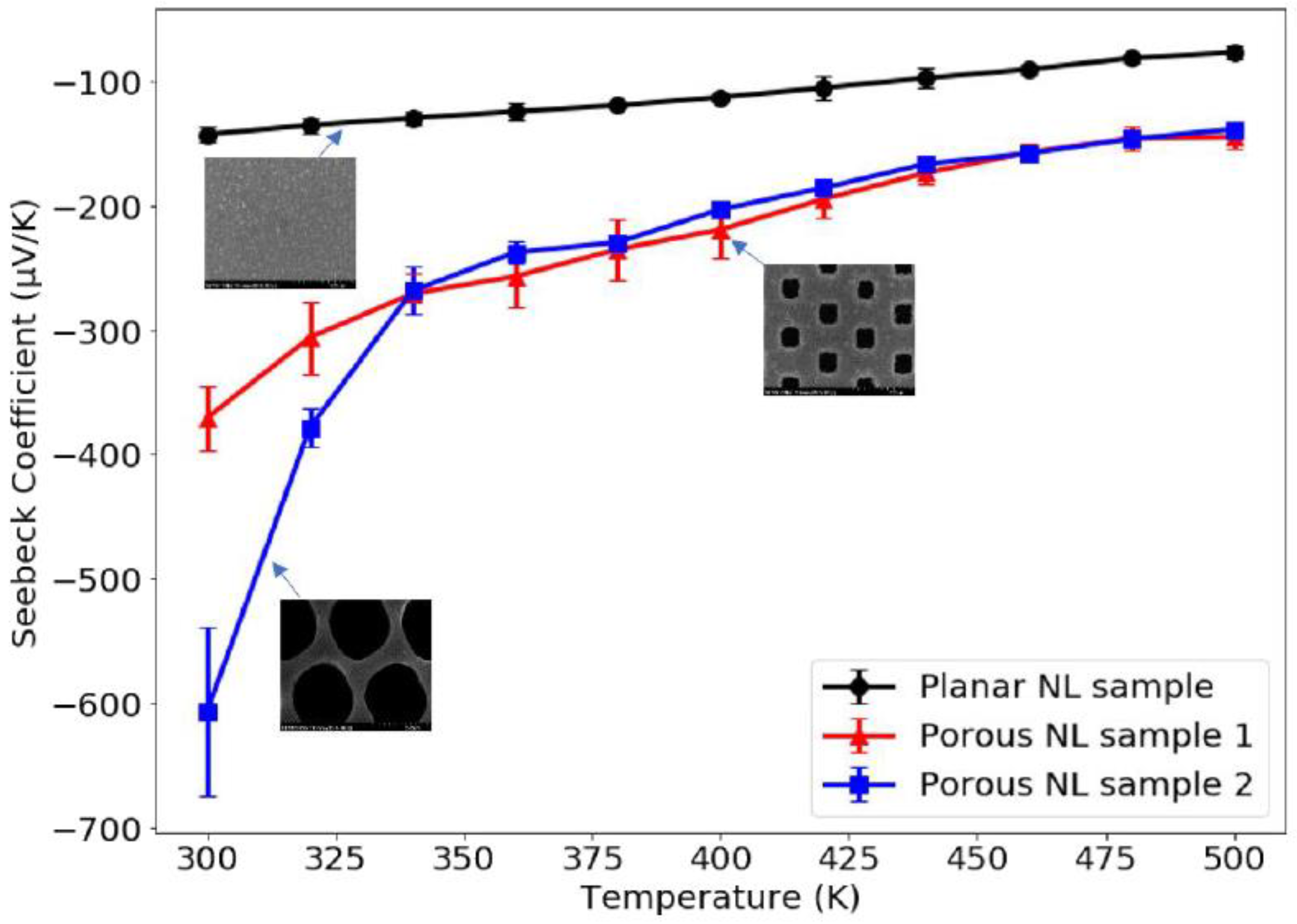

3. Si-Based Thermoelectric Materials

4. Thermoelectric Devices Modified by Nanostructured Silicon

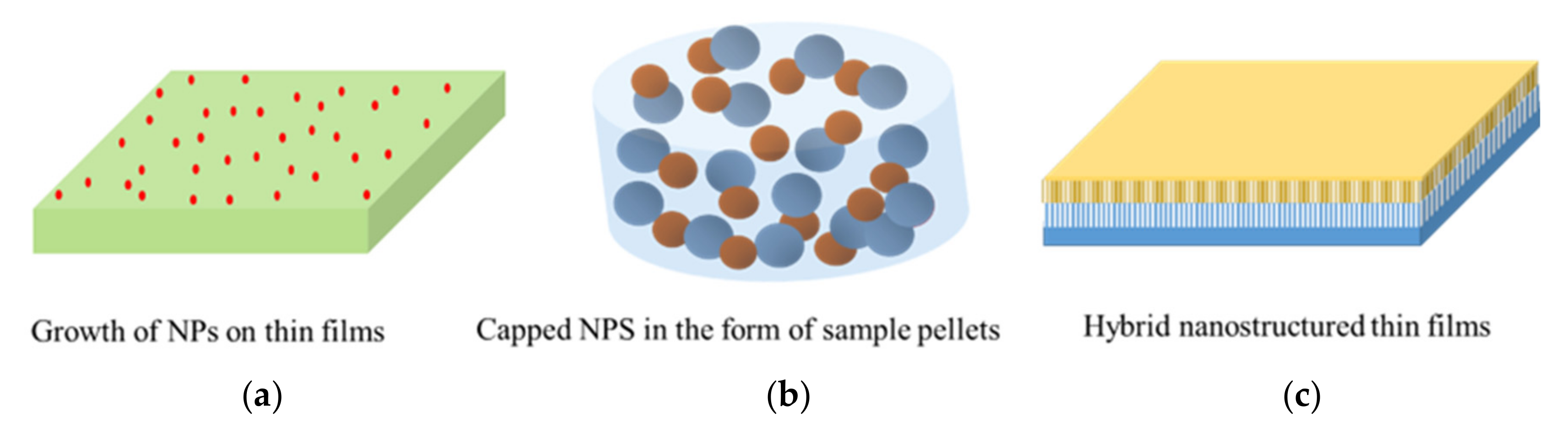

5. Thermoelectric Materials Modified by Hybrid Nanocomposites

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Price, S. The Peltier Effect and Thermoelectric Cooling, WWW-Dokumentti. Available online: http://ffden-2.phys.uaf.edu/212_spring2007.web.dir/sedona_price/phys_212_webproj_peltier.html (accessed on 20 May 2017).

- Goldsmid, H.J. Bismuth Telluride and Its Alloys as Materials for Thermoelectric Generation. Materials 2014, 7, 2577–2592. [Google Scholar] [CrossRef] [PubMed]

- Wongprakarn, S.; Pinitsoontorn, S.; Tanusilp, S.-A.; Kurosaki, K. Enhancing thermoelectric properties of p-type SiGe alloy through optimization of carrier concentration and processing parameters. Mater. Sci. Semicond. Process. 2018, 88, 239–249. [Google Scholar] [CrossRef]

- Zhu, G.H.; Lee, H.; Lan, Y.C.; Wang, X.W.; Joshi, G.; Wang, D.Z.; Yang, J.; Vashaee, D.; Guilbert, H.; Pillitteri, A.; et al. Increased Phonon Scattering by Nanograins and Point Defects in Nanostructured Silicon with a Low Concentration of Germanium. Phys. Rev. Lett. 2009, 102, 196803. [Google Scholar] [CrossRef] [PubMed]

- Yi, T.; Chen, S.; Li, S.; Yang, H.; Bux, S.; Bian, Z.; Katcho, N.A.; Shakouri, A.; Mingo, N.; Fleurial, J.-P. Synthesis and characterization of Mg 2 Si/Si nanocomposites prepared from MgH2 and silicon, and their thermoelectric properties. J. Mater. Chem. 2012, 22, 24805–24813. [Google Scholar] [CrossRef]

- Cojocaru, A.; Carstensen, J.; De Boor, J.; Kim, D.S.; Schmidt, V.; Föll, H. Production and Investigation of Porous Si-Ge Structures for Thermoelectric Application. ECS Trans. 2011, 33, 193–202. [Google Scholar] [CrossRef]

- de Boor, J.; Kim, D.S.; Ao, X.; Becker, M.; Hinsche, N.F.; Mertig, I.; Zahn, P.; Schmidt, V. Thermoelectric properties of porous silicon. Appl. Phys. A 2012, 107, 789–794. [Google Scholar] [CrossRef]

- Domínguez-Adame, F.; Martín-González, M.; Sánchez, D.; Cantarero, A. Nanowires: A route to efficient thermoelectric devices. Phys. E Low Dimens. Syst. Nanostructures 2019, 113, 213–225. [Google Scholar] [CrossRef]

- Bux, S.K.; Blair, R.G.; Gogna, P.K.; Lee, H.; Chen, G.; Dresselhaus, M.S.; Kaner, R.B.; Fleurial, J.-P. Nanostructured Bulk Silicon as an Effective Thermoelectric Material. Adv. Funct. Mater. 2009, 19, 2445–2452. [Google Scholar] [CrossRef]

- Martín-Palma, R.; Cabrera, H.; Martín-Adrados, B.; Korte, D.; Pérez-Cappe, E.; Mosqueda, Y.; Frutis, M.; Danguillecourt, E. Thermoelectric properties of nanostructured porous silicon. Mater. Res. Express 2018, 5, 015004. [Google Scholar] [CrossRef]

- Ramadan, R.; Martín-Palma, R.J. Electrical Characterization of MIS Schottky Barrier Diodes Based on Nanostructured Porous Silicon and Silver Nanoparticles with Applications in Solar Cells. Energies 2020, 13, 2165. [Google Scholar] [CrossRef]

- Ramadan, R.; Martín-Palma, R.J. The Infiltration of Silver Nanoparticles into Porous Silicon for Improving the Performance of Photonic Devices. Nanomaterials 2022, 12, 271. [Google Scholar] [CrossRef] [PubMed]

- Saxena, N.; Čorić, M.; Greppmair, A.; Wernecke, J.; Pflüger, M.; Krumrey, M.; Brandt, M.S.; Herzig, E.M.; Müller-Buschbaum, P. Morphology-Function Relationship of Thermoelectric Nanocomposite Films from PEDOT:PSS with Silicon Nanoparticles. Adv. Electron. Mater. 2017, 3, 1700181. [Google Scholar] [CrossRef]

- Kolhatkar, G.; Boucherif, A.; Boucherif, A.R.; Dupuy, A.; Fréchette, L.G.; Arès, R.; Ruediger, A. Extreme temperature stability of thermally insulating graphene-mesoporous-silicon nanocomposite. Nanotechnology 2018, 29, 145701. [Google Scholar] [CrossRef] [PubMed]

- Ashby, S.P.; García-Cañadas, J.; Min, G.; Chao, Y. Measurement of thermoelectric properties of phenylacetylene-capped silicon nanoparticles and their potential in fabrication of thermoelectric materials. J. Electron. Mater. 2013, 42, 1495–1498. [Google Scholar] [CrossRef]

- Fahrizal, F.N.; Ahmad, M.K.; Ramli, N.M.; Ahmad, N.; Fakhriah, R.; Mohamad, F.; Nafarizal, N.; Soon, C.F.; Ameruddin, A.S.; Faridah, A.B.; et al. Fabrication of TiO2 nanostructures on porous silicon for thermoelectric application. AIP Conf. Proc. 2017, 1883, 020031. [Google Scholar]

- Chen, X.; Lin, P.; Zhang, K.; Baumgart, H.; Geist, B.; Kochergin, V. Seebeck Coefficient Enhancement of ALD PbTe/PbSe Nanolaminate Structures Deposited inside Porous Silicon Templates. ECS J. Solid State Sci. Technol. 2016, 5, P503–P508. [Google Scholar] [CrossRef][Green Version]

- Zhang, T.; Wu, S.; Xu, J.; Zheng, R.; Cheng, G. High thermoelectric figure-of-merits from large-area porous silicon nanowire arrays. Nano Energy 2015, 13, 433–441. [Google Scholar] [CrossRef]

- Martín-Palma, R.J.; McAtee, P.D.; Ramadan, R.; Lakhtakia, A. Hybrid Nanostructured Porous Silicon-Silver Layers for Wideband Optical Absorption. Sci. Rep. 2019, 9, 7291. [Google Scholar] [CrossRef] [PubMed]

- Rowe, D. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Joshi, G.; Lee, H.; Lan, Y.; Wang, X.; Zhu, G.; Wang, D.; Gould, R.W.; Cuff, D.C.; Tang, M.Y.; Dresselhaus, M.S.; et al. Enhanced Thermoelectric Figure-of-Merit in Nanostructured p-type Silicon Germanium Bulk Alloys. Nano Lett. 2008, 8, 4670–4674. [Google Scholar] [CrossRef] [PubMed]

- Zamanipour, Z.; Shi, X.; Dehkordi, A.M.; Krasinski, J.S.; Vashaee, D. The effect of synthesis parameters on transport properties of nanostructured bulk thermoelectric p-type silicon germanium alloy. Phys. Status Solidi a 2012, 209, 2049–2058. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan, R.; Martín-Palma, R.J. The Impact of Nanostructured Silicon and Hybrid Materials on the Thermoelectric Performance of Thermoelectric Devices: Review. Energies 2022, 15, 5363. https://doi.org/10.3390/en15155363

Ramadan R, Martín-Palma RJ. The Impact of Nanostructured Silicon and Hybrid Materials on the Thermoelectric Performance of Thermoelectric Devices: Review. Energies. 2022; 15(15):5363. https://doi.org/10.3390/en15155363

Chicago/Turabian StyleRamadan, Rehab, and Raúl J. Martín-Palma. 2022. "The Impact of Nanostructured Silicon and Hybrid Materials on the Thermoelectric Performance of Thermoelectric Devices: Review" Energies 15, no. 15: 5363. https://doi.org/10.3390/en15155363

APA StyleRamadan, R., & Martín-Palma, R. J. (2022). The Impact of Nanostructured Silicon and Hybrid Materials on the Thermoelectric Performance of Thermoelectric Devices: Review. Energies, 15(15), 5363. https://doi.org/10.3390/en15155363