2.1. Method

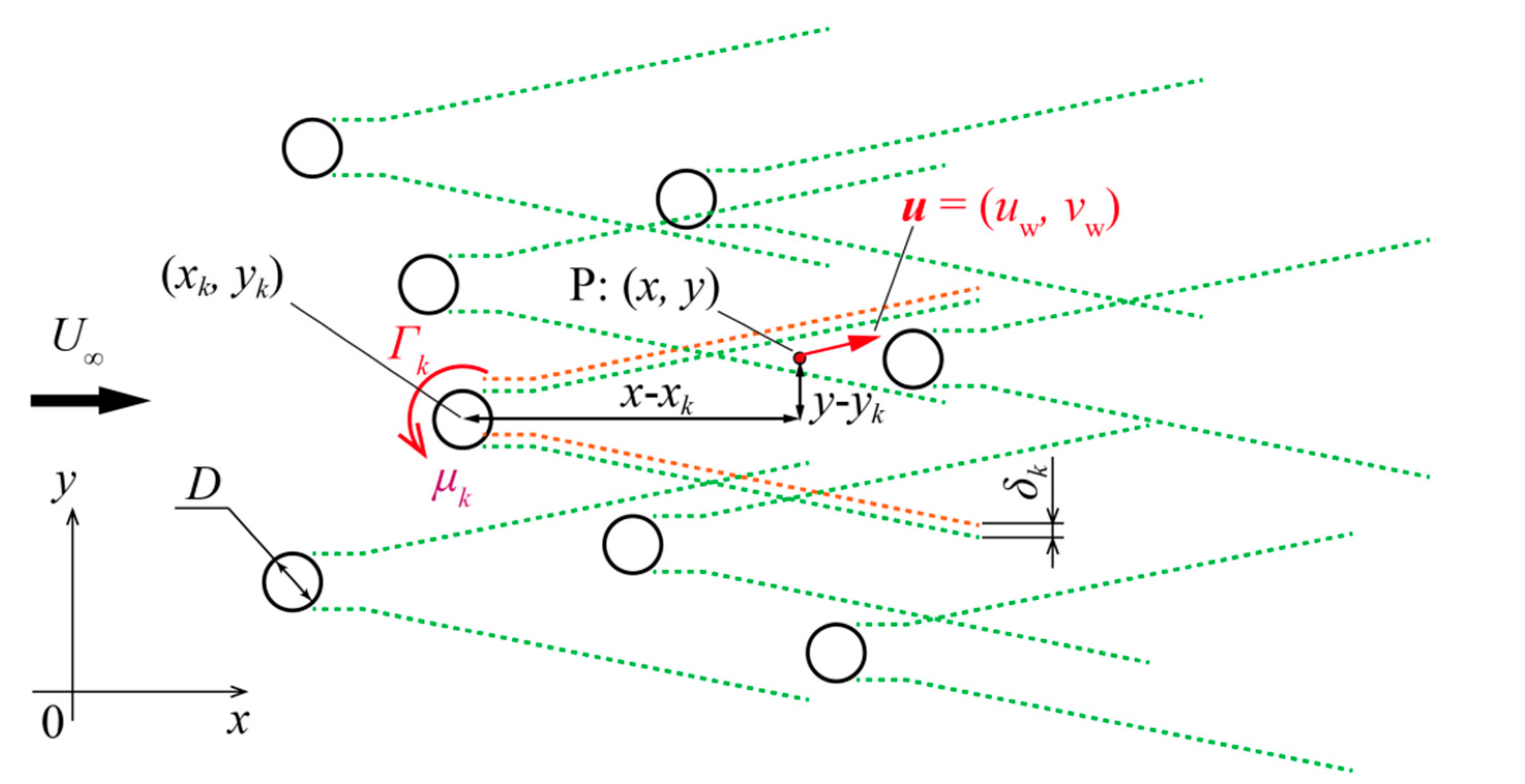

Figure 1 shows a schematic image of a VAWT wind farm, where a VAWT rotor is shown by a circle and our method does not need detailed information on the configuration of a turbine such as the number of blades and the cross-section. In our method, the VAWTs are dealt with as 2D rotors with each having a diameter,

D. Let us assume the wind farm consists of

N VAWTs. In

Figure 1, the coordinate axis

x is defined as parallel to the upstream wind speed

U∞; the coordinate axis

y is perpendicular to the dominant wind direction. The center position (rotational axis) of the

k-th rotor is expressed as (

xk,

yk). Our method assumes that the circulation around an isolated single rotor (

Γ) is given as a linear function of wind speed (

U∞) in advance. Therefore, the blockage effect (dipole

μ), thrust force (

Th), and power output (

P) are given as functions of the circulation, respectively, for each rotor.

If an arbitrary set of the conditions of circulation (

Γk) and blockage effect (

μk) is given for a wind farm, the complex velocity potential

W(

z), where

z =

x +

iy is expressed by Equation (1) [

23].

Using the above potential

W(

z), the potential flow (

up,

vp) at an arbitrary position P:(

x,

y) in the wind farm can be calculated as follows:

However, the potential flow is an ideal flow and cannot express the actual velocity deficit or wake generated by each rotor. Therefore, as Whittlesey et al. introduced [

23], the component in the

x-direction of the potential flow is modified by a wake function

duk showing the velocity deficit of each rotor; the resultant flow

uw(

x,

y) is expressed by Equation (4). The subscript “w” means the flow field obtained by applying the wake function (or wake model) in this study.

In our method, the wake function

duk is given by Equation (5) including the ultra-super-Gaussian function

fUSG_k defined in our previous study [

37]. The function

fUSG_k modifies the super-Gaussian function 𝑓

SG_k proposed by Shapiro et al. [

38] expressing the wake profile transformation from top-hat shape to Gaussian by adding the correction function 𝑓

COR_k expressing the acceleration regions and the deflection

δk of the wake.

μref is a reference value of the blockage effect and

CW_k is a fitting parameter to the prepared flow field of an isolated single rotor.

The present method modifies the wake deflection

δk and the wake width

dW, which are used in the ultra-super-Gaussian function 𝑓

USG_k, by using the induced velocity given by the Biot–Savart law. The details are described in

Appendix A.

The component in the

y-direction of the potential flow is also modified by Equation (6) in our method [

40].

where

dvk shows the difference in

y-component velocity between the potential flow and the prepared flow (by CFD or experiments) around an isolated single rotor, the circulation of which is defined as

ΓSI and depends on

U∞ (see Equation (A17) in

Appendix B). The

dvk is approximated using the sum of four Gaussian-type functions

fG_i and four resonant-type functions

fR_i as shown in Equation (7). The details of functions

fG_i and functions

fR_i are described in

Appendix A.

If an arbitrary set of circulations (Γk) of N rotors is given, a flow field and a set of rotor outputs are calculated by using Equations (2)–(7) and the prepared relation between the circulation and rotor power. However, the result is not always the actual correct condition. Therefore, we have to find out the set of circulations that give the condition satisfying the conservation of momentum expressed by Newton’s law of motion.

Figure 2 shows a schematic image of a control volume (CV) used for the calculation of the flow field around an isolated single rotor. The prepared data of an isolated single rotor, regardless of CFD data or experimental data, must satisfy Equation (8). The left-hand side of Equation (8) is the total force acting on the fluid in the

x-direction (main flow direction) and the right-hand side shows the variation in the momentum in the

x-direction per unit time. The variation in the momentum

is calculated from the flow velocity at the boundaries of CV by Equation (9), in which the mass flow rate

and

are expressed by

and

, respectively. Here,

is the air density;

dx and

dy are small boundary elements. The total force

is given by Equation (10), in which the pressure forces

Fpin and

Fpout acting on the inlet and outlet boundaries are considered and are calculated by the integration along each boundary. The

Fp in Equation (10) shows the total pressure force in the

x-direction and means the pressure loss. The forces (

) caused by shear stress on the top and bottom boundaries are neglected in this study. From Equations (8) and (10), the relation of Equation (11) is obtained for an isolated single rotor. In our method, the pressure loss

Fp has to be prepared as a function of the upstream speed or the corresponding circulation of a single rotor for an applied CV. Note that the pressure loss

Fp cannot be calculated from the model flow field obtained by using Equations (4) and (6).

To apply the momentum balance given by Equation (11) to a wind farm, an evaluation function

Err is defined by Equation (12).

where

Thk and

Fpk are the thrust force and pressure loss caused by the

k-th rotor under the condition of an isolated single rotor, respectively.

Thk and

Fpk are calculated using the input value of circulation (

Γk) based on the prepared information for an isolated single rotor.

fpk is the correction function introduced to express the interaction between the

k-th rotor and other rotors and is defined by Equation (13), in which

is a function expressing the interaction effects from the

j-th rotor to the

k-th rotor.

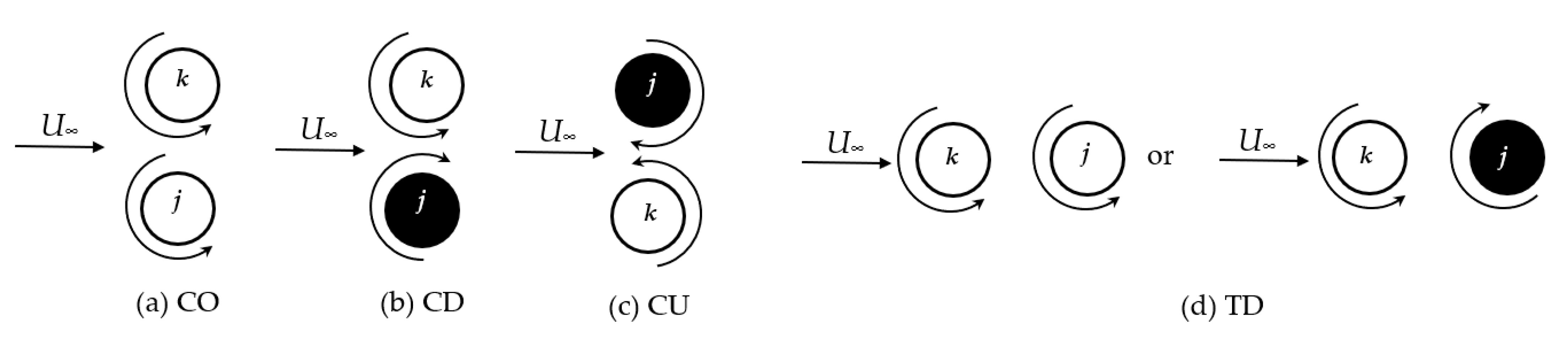

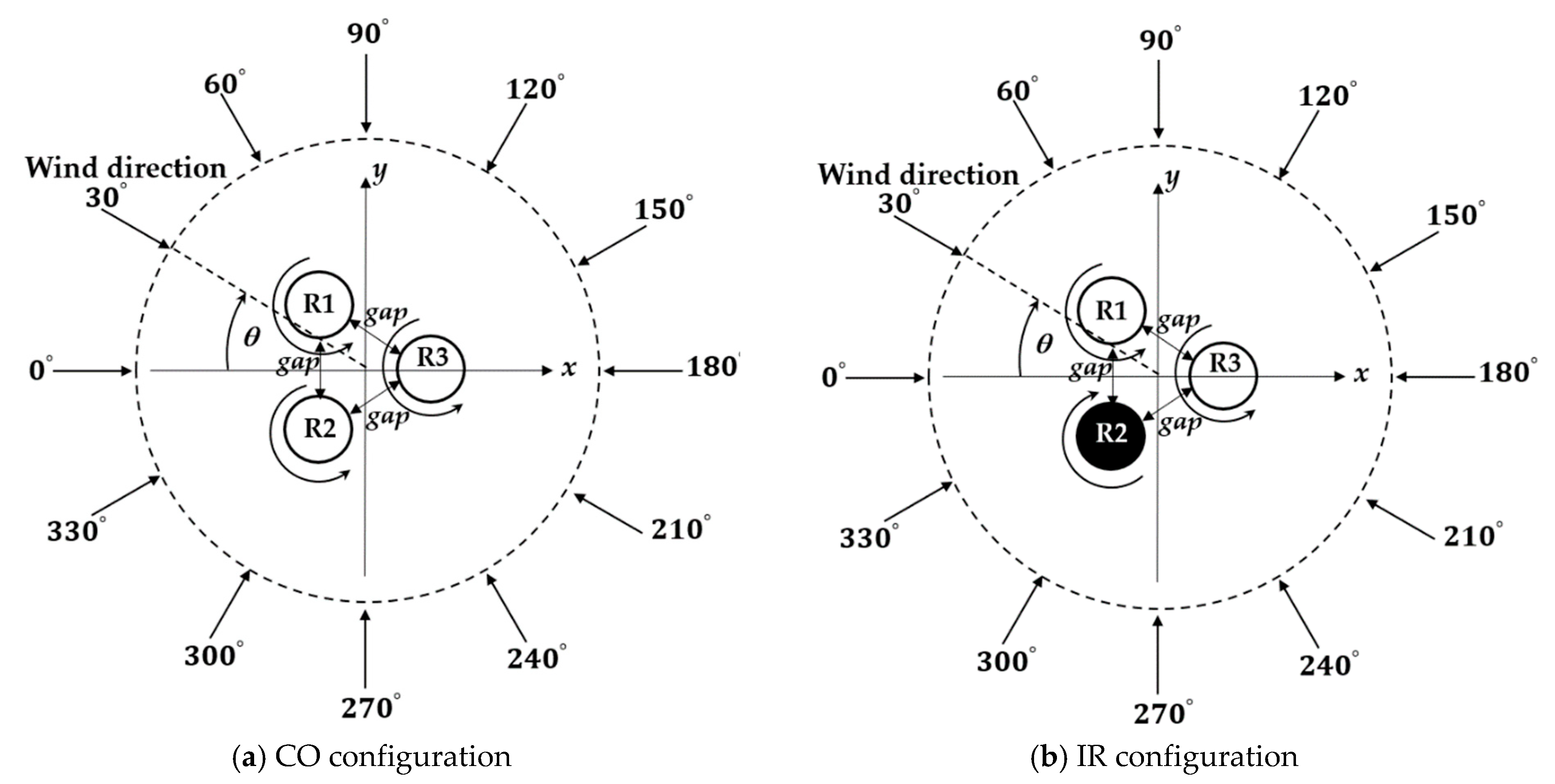

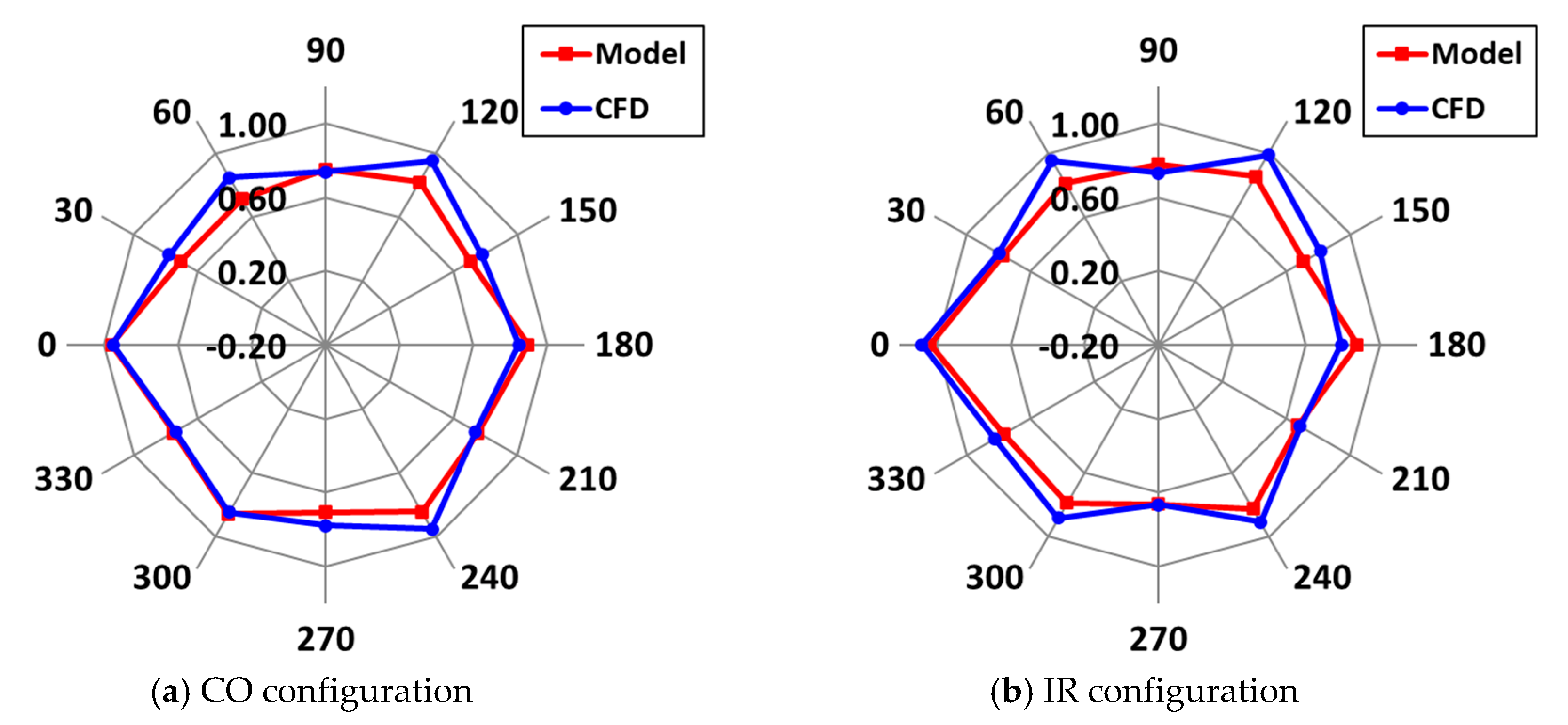

The layouts between selected two 2D-VAWT rotors can be roughly categorized into four kinds according to the relative rotation condition against the main flow

U∞ as shown in

Figure 3; i.e., co-rotating (CO), counter-down (CD), counter-up (CU), and tandem (TD).

In our method, the interaction function

is defined separately for each category of the selected two-rotor layout as shown in Equations (14)–(17).

is defined as the angle between the direction seen from the

k-th rotor to the

j-th rotor and the upwind direction as shown in

Figure 4.

is the distance between the centers of the two rotors. A constant angle

divides the CV into two zones, i.e., the wake zone (in gray) and the out-of-wake zone (in white). If the

j-th rotor (counterpart to the

k-th rotor) exists in the wake zone, Equation (17) is used for the calculation of the interaction function

as the TD-like layout. When the counterpart rotor exists in the out-of-wake zone, the equation used for the calculation of the interaction function

is determined as one of three equations (Equations (14)–(16)) according to the corresponding layout category of the two rotors. The fitting parameters of

,

, and

are introduced so as to obtain a sufficient correspondence between the results of rotor power prediction using the model and the CFD analysis, in the specific four conditions of paired rotors, i.e., CO, CD, CU, and TD layouts.

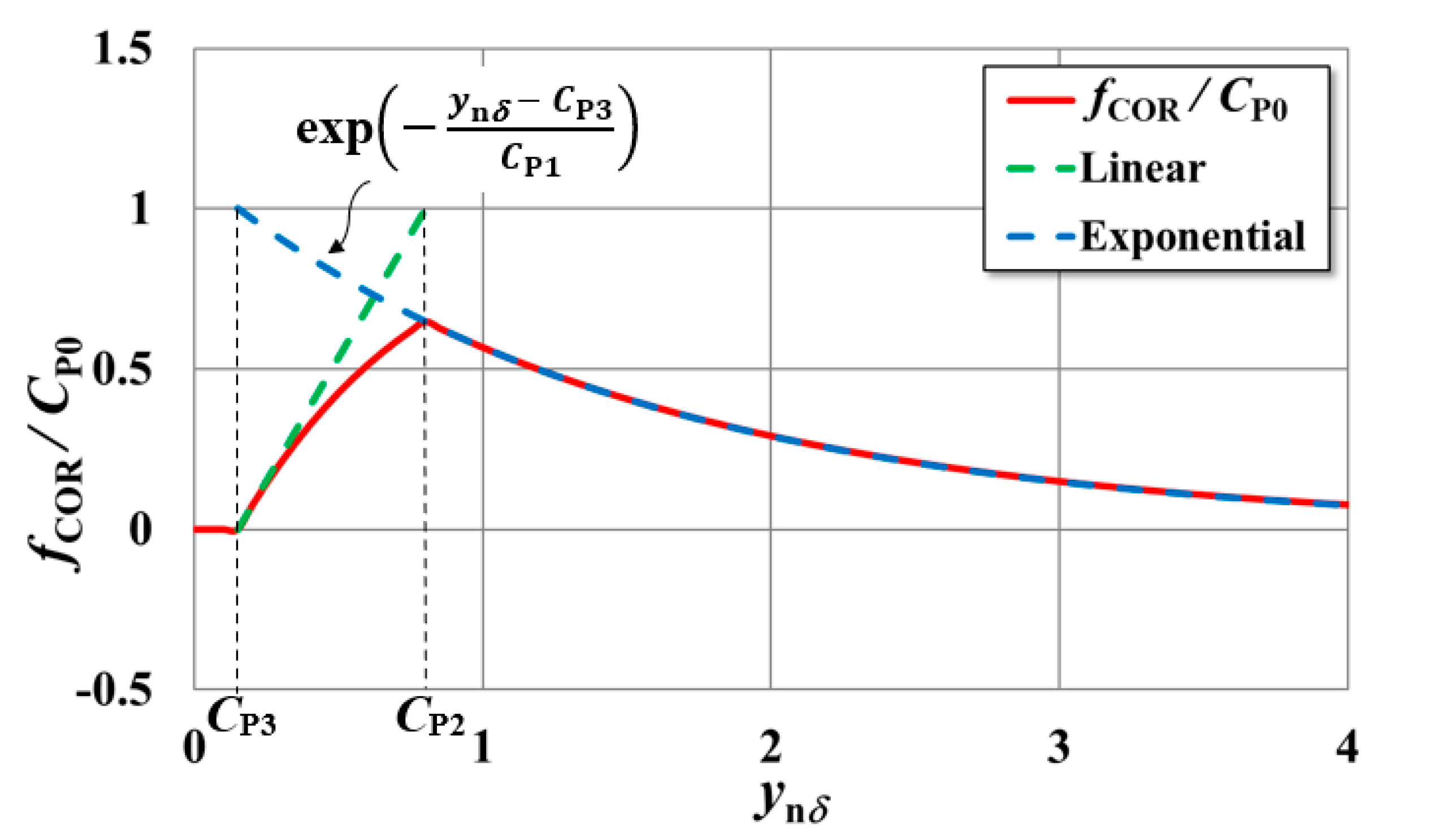

The flow chart of the method is shown in

Figure 5. Before starting the calculation, the relations, such as between the circulation and rotor output, and the fitting parameters must be prepared from the information of an isolated single rotor and four specific conditions of two rotors. The first step of the actual model calculation is to decide the calculation conditions such as the upstream wind speed (

U∞), the positions of the rotors, and the rotational directions. The input parameters are the fitting parameters obtained by comparison of the velocity distribution (

x- and

y-components) of the model with that of the CFD in the case of an isolated single rotor. For example, the fitting parameters include

CN0,

CN1,

CN2,

CN3,

CP0,

CP1,

CP2, and

CP3, which are used to define the correction function

fCOR of the ultra-super-Gaussian function and are defined in Equations (A4)–(A9) in

Appendix A. The fitting parameters must be determined at several positions in the flow field according to the complexity of the local velocity profiles. The present study uses 35 parameters. All the fitting parameters are shown in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5 and

Table A6 of

Appendix A. After the initial condition of the rotors and a set of parameters are input, the process of searching for a reasonable combination of circulations is initiated starting from the lowest value of the circulation in a given searching range for each rotor (determining the searching ranges will be described in

Section 2.2). For a given combination of circulations, the potential flow is calculated first and it is modified by our wake model to include the effects of the velocity deficits. With the flow field (

uw,

vw) obtained, the momentum changes in the

x-direction per unit of time

is calculated from the four boundary conditions. The thrust force

Thk and the (isolated single rotor) pressure loss

Fpk are calculated by Equations (A19) and (A20) in

Appendix B by using the given circulation value for each rotor. Using the interaction function

, the correction function

fpk which expresses the effects of the inter-rotor interaction is obtained for each rotor by Equation (13). Then, the momentum balance

Err is evaluated by Equation (12). The “

error” of momentum balance is defined in Equation (18) in the present study. The denominator in Equation (18) is the momentum per unit time entering into the CV from the inlet boundary.

The above calculation is repeated by changing the combination of circulations with the interval of Δ

Γ throughout all the searching ranges. After the round robin, a combination of circulation

Γk which gives the smallest “

error” is obtained. In the present study, the similar searching process (sub-searching) is repeated twice by narrowing the searching ranges as (

Γk − Δ

Γ)

Γk_i (

Γk + Δ

Γ). Finally, for the smallest “

error” condition, the power output of each rotor can be obtained by using Equation (A21) in

Appendix B.

2.2. Specific Calculation and Searching Range of Circulation

In this section, we consider a specific case assuming small rotors in order to explain the selection of searching range to obtain adequate circulation. The target rotors are the same as those investigated in the previous study [

35] and the rotor configuration is depicted in

Figure A4 in

Appendix B. The necessary relations on the performance of the single rotor are given in Equation (A17)–(A20). The values of

,

, and

were determined as 0.2304, 0.19, −0.2853, and 1.07, respectively, from the preliminary calculations of the specific four layouts of paired rotors. The CV was defined as 20

D × 20

D × 0.868

D. The thickness of the CV given by 0.868

D corresponds to the rotor height of the target rotor; by considering the rotor height, our 2D method can be applied to the prediction of the power output of an actual 3D-VAWT rotor.

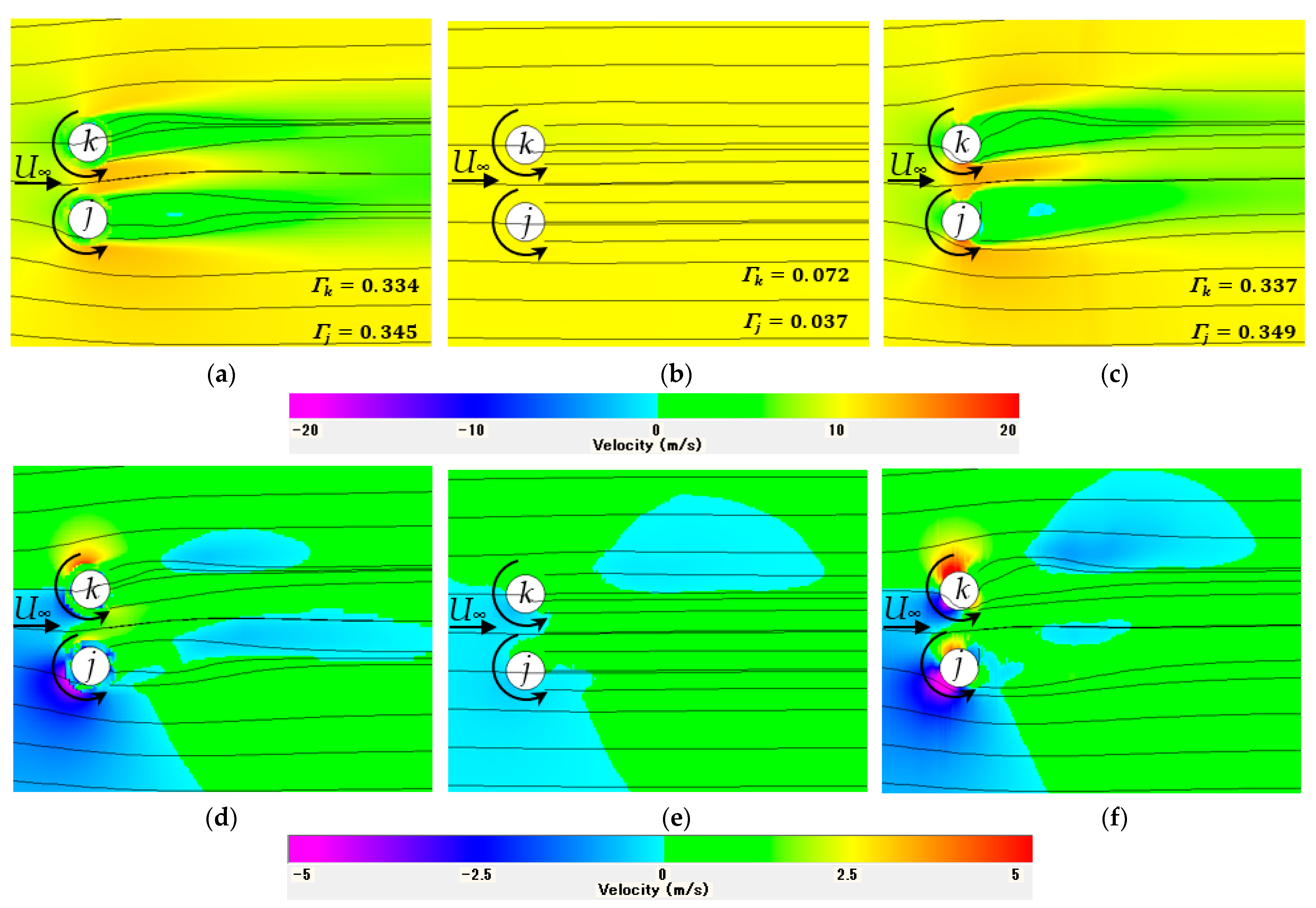

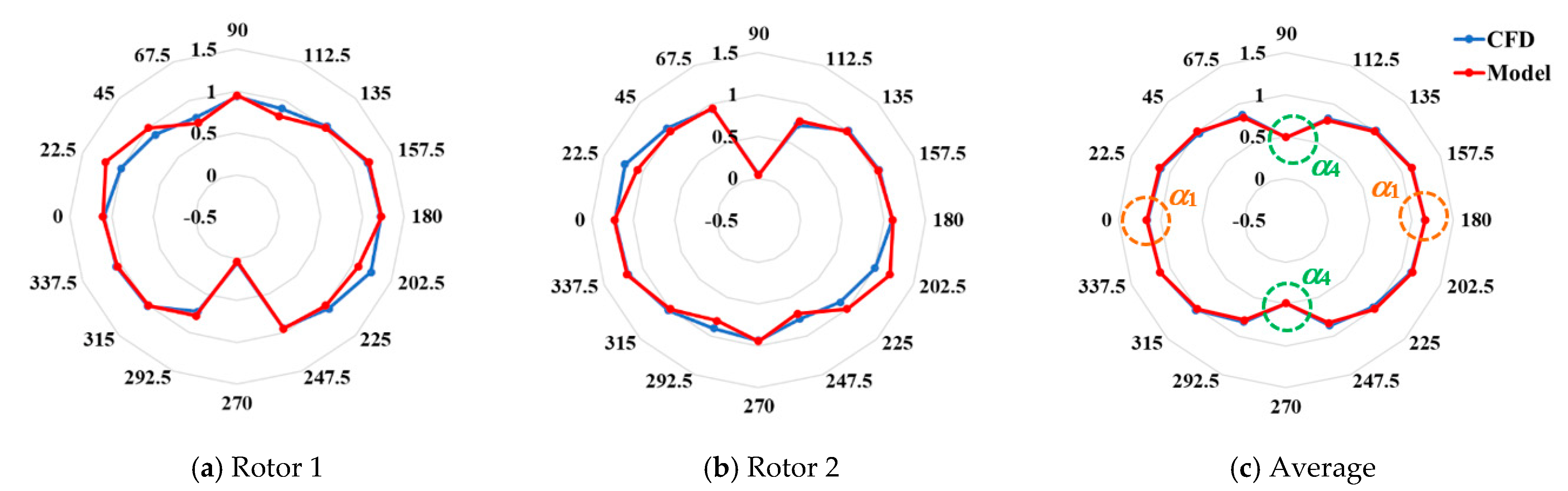

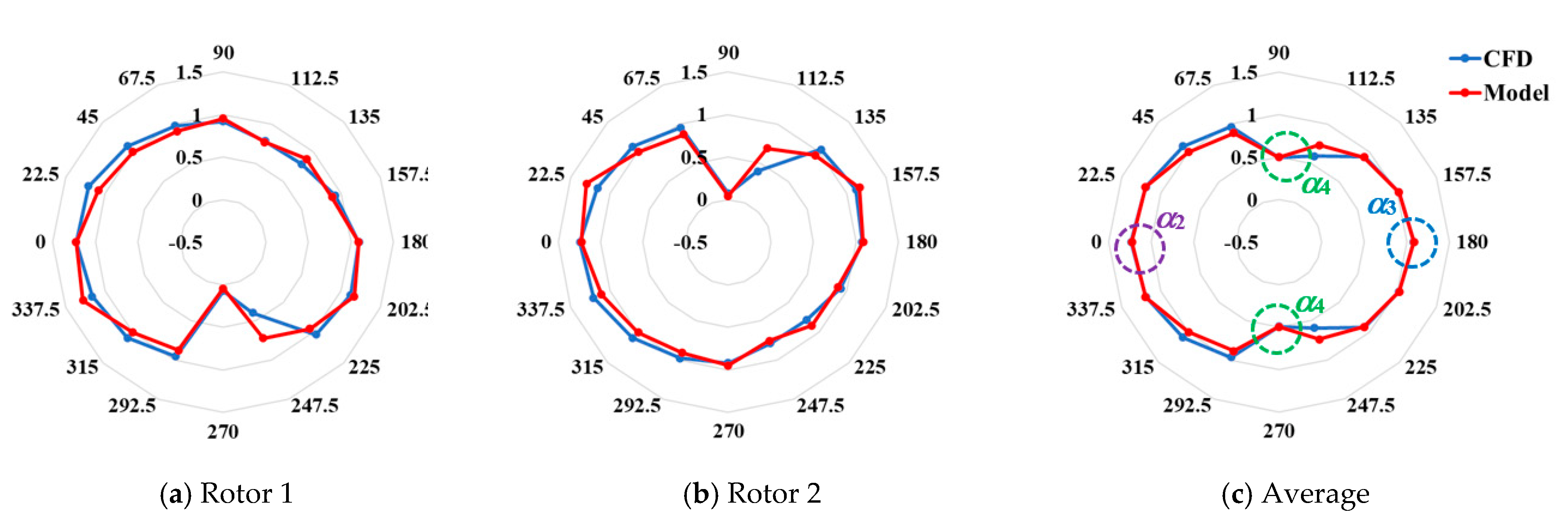

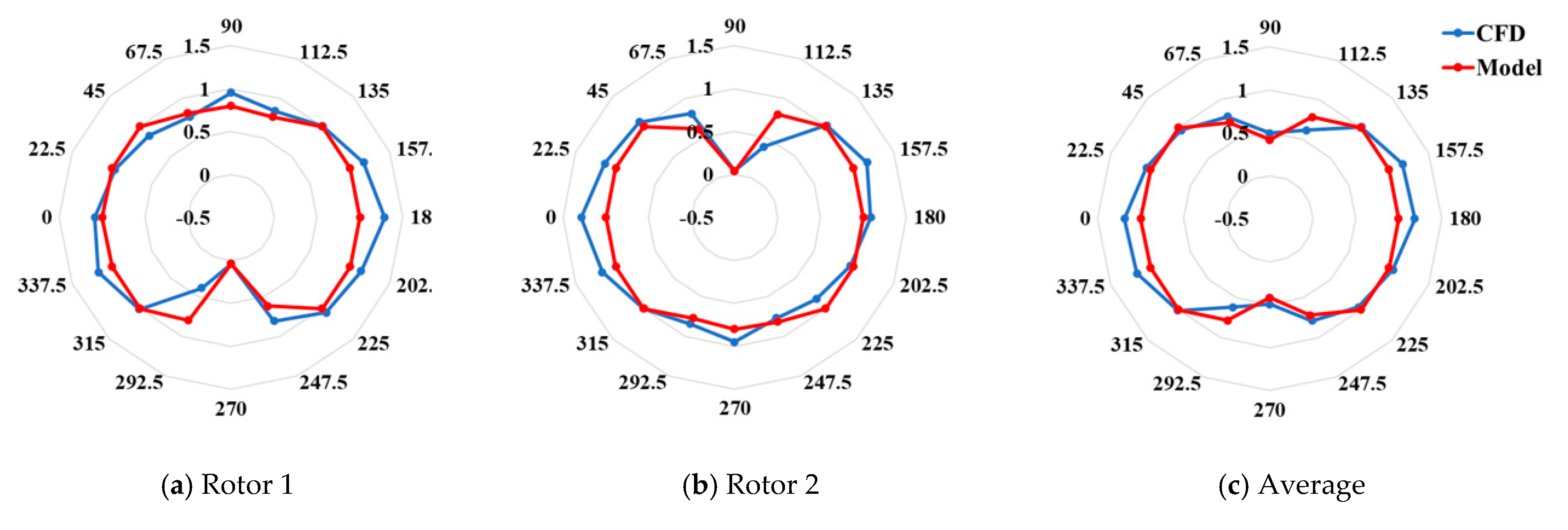

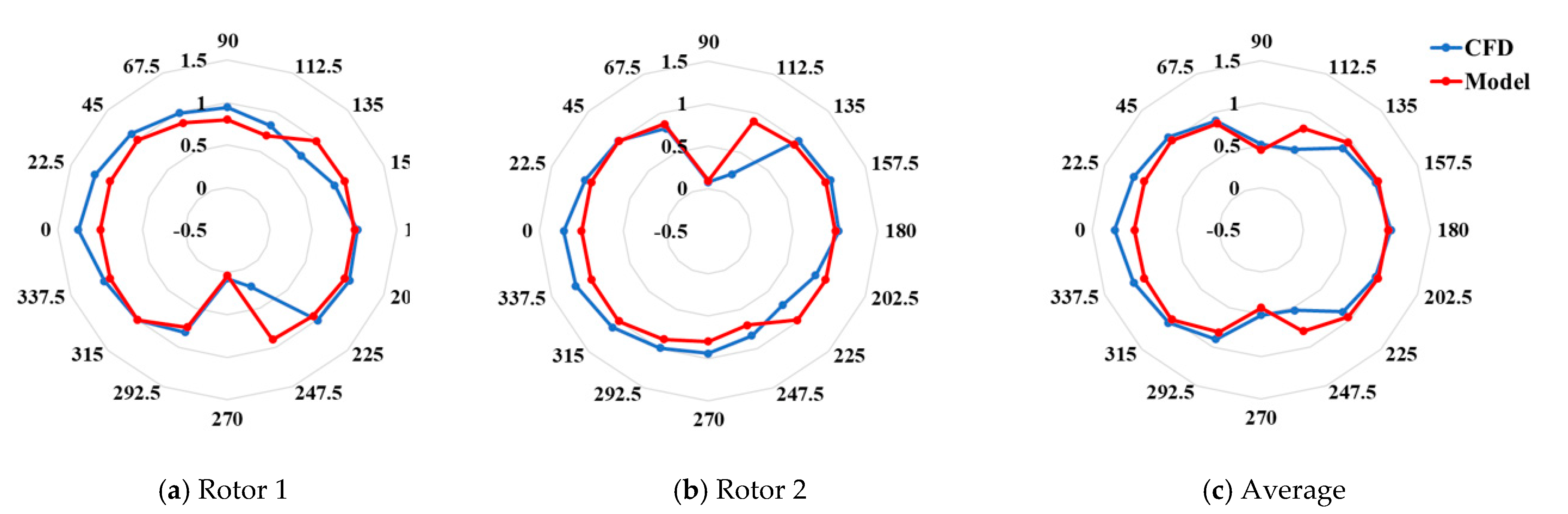

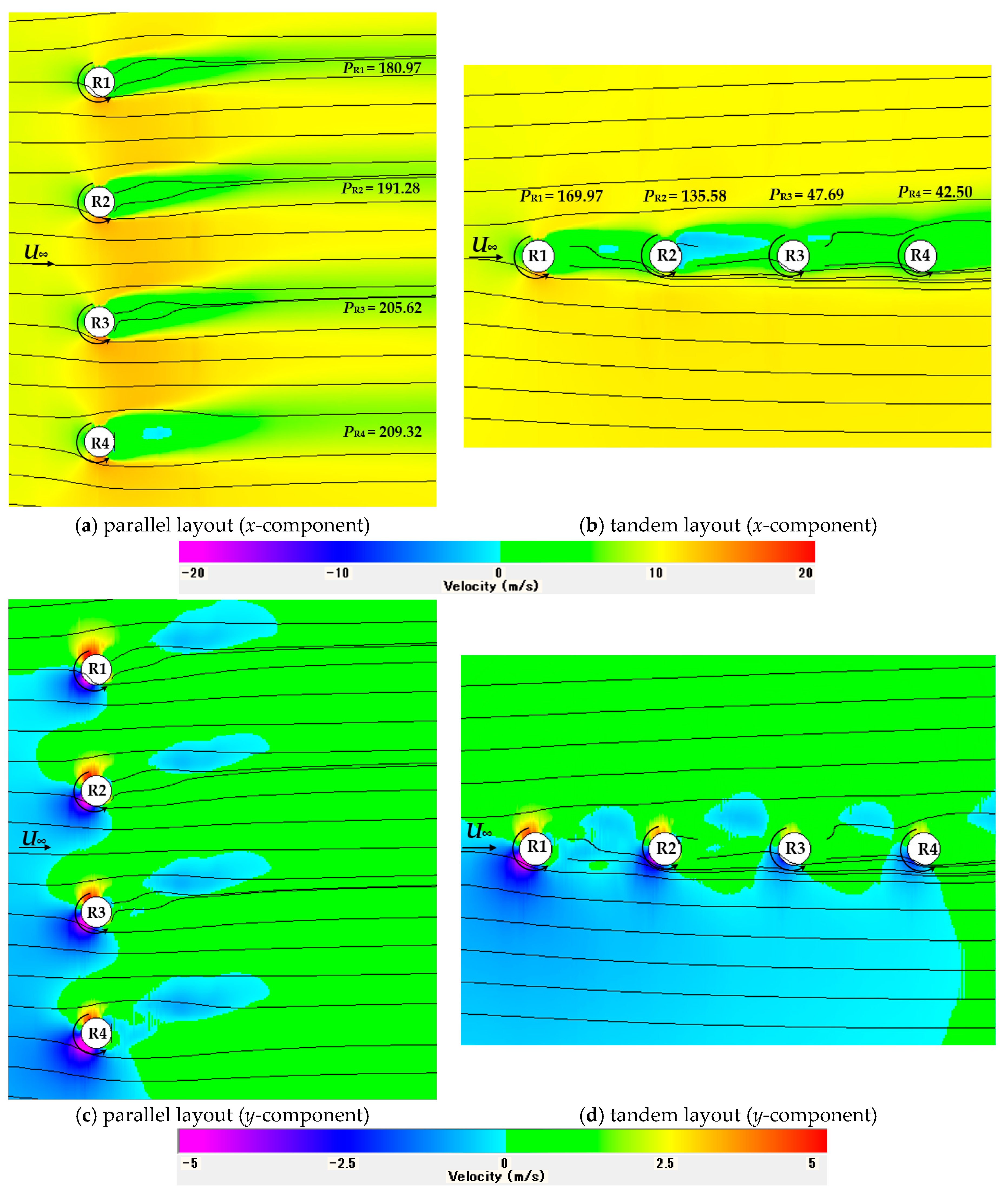

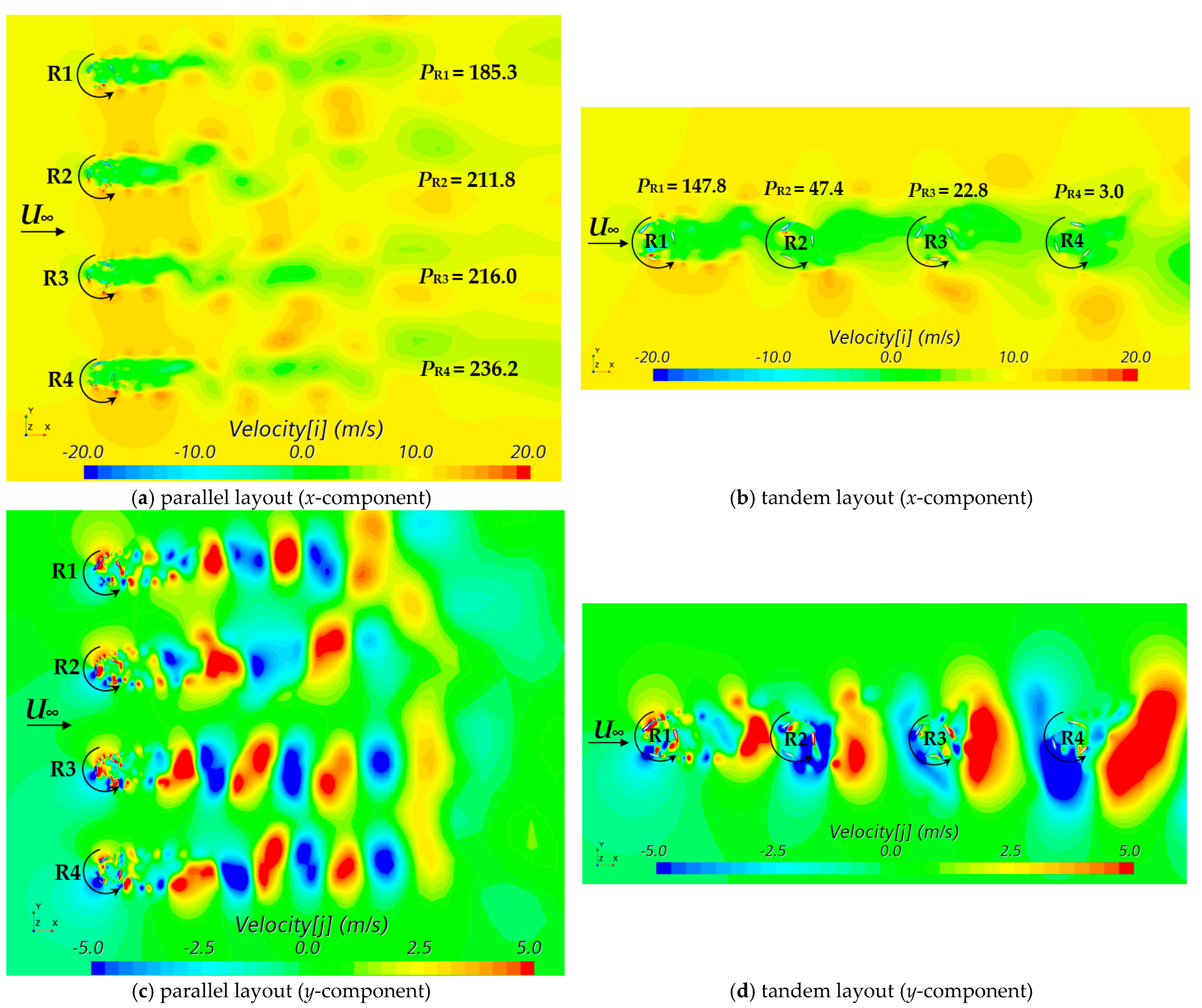

Figure 6a,d show the averaged distributions of the

x- and

y-component velocities calculated by the CFD analysis around two VAWT rotors rotating CCW direction in the CO-like layout. The commercial code STAR-CCM+ was utilized for the CFD simulation. The circulation of the upper rotor (rotor-

k) is 0.334 m

2/s, which was obtained by the integration of the flow field along a circular path at

r/

D = 0.75. The circulation of the lower rotor (rotor-

j) is 0.345 m

2/s. The details of the rotor shape are not shown but are replaced by circles in white in

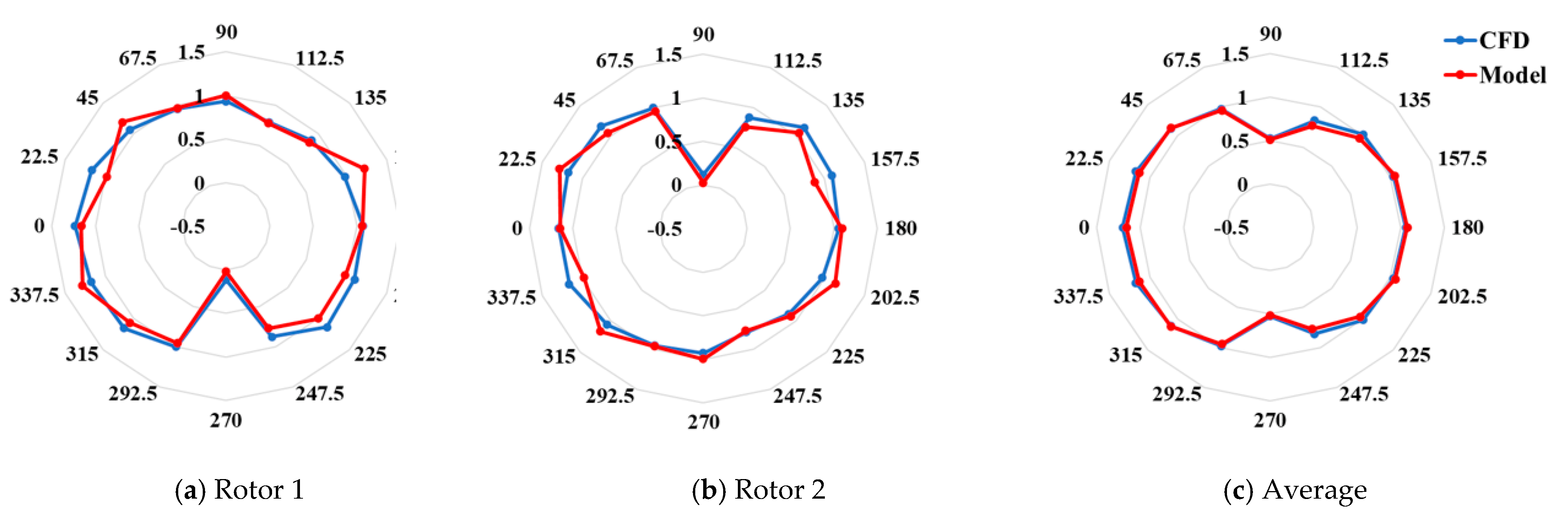

Figure 6a. The black solid lines around the rotors are path lines.

Figure 6b,e show the resultant flow field obtained by the proposed method using an in-house code, in which the circulation of each rotor was changed step by step in a round robin over a wide searching range from 0.1

to 1.1

. Here,

is the circulation of an isolated single rotor obtained from the CFD analysis and the value is 0.326 m

2/s in the case of

U∞ = 10 m/s. The obtained circulations of two rotors in

Figure 6b are

Γk = 0.072 m

2/s and

Γj = 0.037 m

2/s, respectively, and they are different from the CFD results in

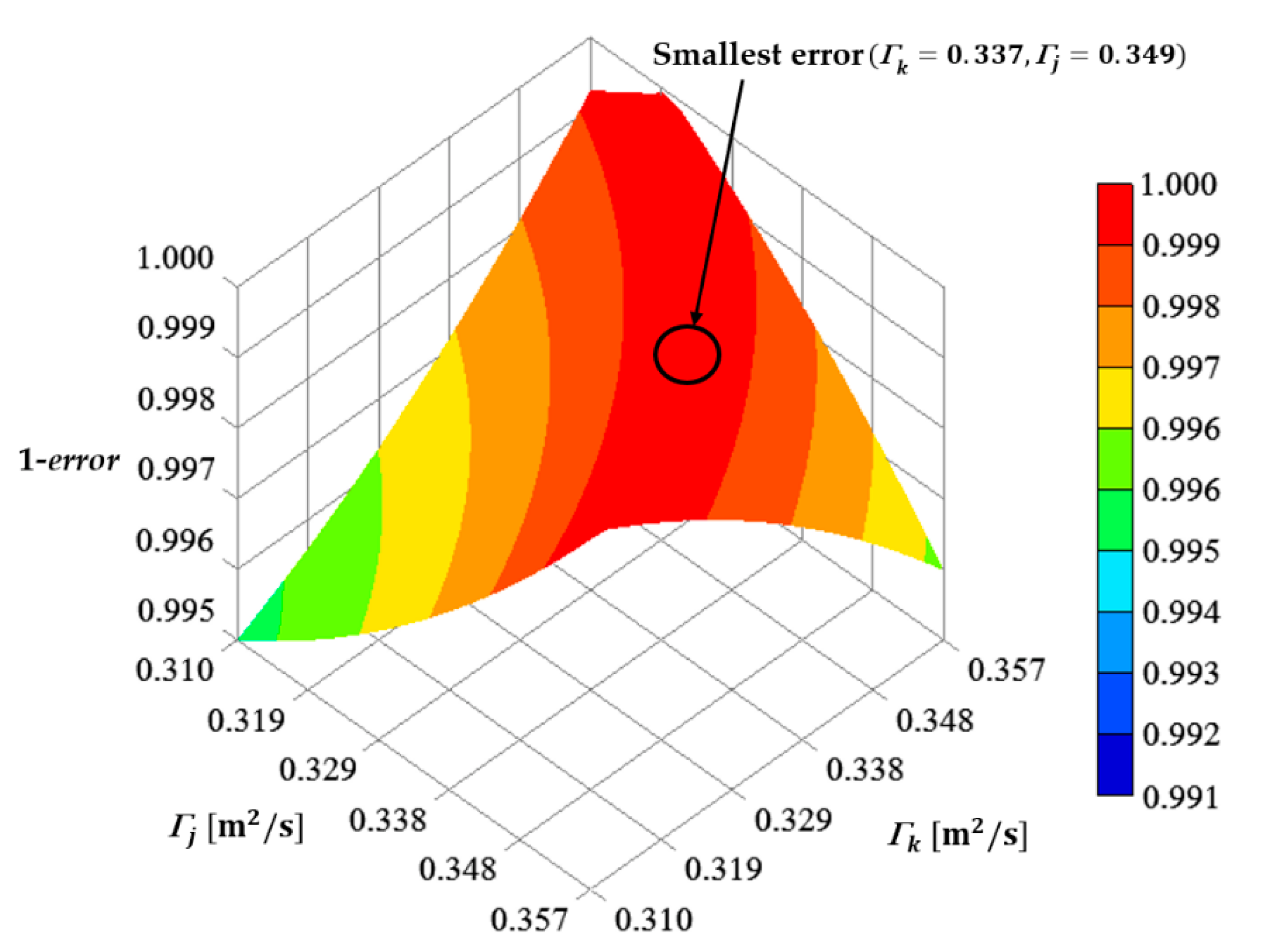

Figure 6a. To demonstrate the variation in the error of momentum balance graphically, we define a new indicator (1 −

error) that approaches 1 when the error becomes small. The distribution of the values of (1 −

error) obtained in the searching process of the smallest error in the case of

Figure 6b is shown in

Figure 7, which includes 625 results corresponding to the combinations of circulation values (

Γj,

Γk) with the interval of (1.1 − 0.1)

/25.

Figure 7 shows that there are a lot of combinations of circulation which might give a small error.

In the parallel layouts, it is expected that two rotors have large circulations close to the value of

. Therefore, the search range can be narrowed.

Figure 6c,f are is the flow field obtained using a searching range limited from 0.95

to 1.1

for each rotor in the CO layout. The circulation combination giving the smallest error, shown in

Figure 6c, is

Γk = 0.337 m

2/s and

Γj = 0.349 m

2/s, respectively.

Figure 8 is the distribution of the 625 values of (1 −

error) obtained in the searching process with a limited range from 0.95

to 1.1

for each rotor. The results of our method with appropriately limited searching ranges can approach the CFD results.

Incorrect results are also obtained when the rotor at issue exists in the wake of other rotors if the wide searching range of circulation is applied. In our method, we propose a procedure to search for the appropriate result close to the CFD result, in which the searching range of circulation of each rotor in a VAWT wind farm is limited in the manner described below.

Let us define a circular region of the radius Rint around a rotor (k) at issue, and assume there are Nint rotors in the region. We consider that only the rotors (j) included in the interaction region defined by Rint are used to decide the searching range of circulation of the rotor (k).

First of all, the angle

defined in

Figure 4 is checked for all rotors in the interaction region. If the absolute value of one of the angles is less than a constant angle

, the searching range expressed by Equation (19) is applied. Note that the angle

is different from the angle

, and

is less than

. The interaction region is determined to be a circle of

Rint = 10

D in this specific calculation; therefore, the maximum of the inter-rotor distance (between rotor centers)

rjk is 10

D in Equation (19) in this study.

In the second step of the procedure, the average of the distance

dj between the center of the

j-th rotor and the stream-wise center line through the

k-th rotor at issue is calculated with all the counterpart rotors of the

k-th rotor in the interaction region using Equation (20).

In the third step of the procedure, the searching range of the circulation

Γk of the

k-th rotor is determined as one of Equations (21)–(23) according to the averaged lateral distance

.

Figure 9 schematically shows the definition of the angle

and three zones determining the searching range of circulation of the

k-th rotor. The delimiting lateral distances are determined as

d1 = 0.9

D and

d2 = 1.5

D in this study.