1. Introduction

Nowadays, increasing attention is being paid to carbonate reservoirs that are substantially affected by cracks. More than 40% of the world’s oil reserves and about 60% of the world’s oil production are associated with carbonate reservoirs [

1,

2,

3]. The development of fissured carbonate reservoirs is fraught with difficulties and challenges, such as the breakthrough of formation or injection water through interlayers with high permeability or fracture network. Additionally, oil development can also be complicated by underlying water that comes to the bottomhole formation zone and enters the well. It leads to early flooding of the well stream and, as a result, to a sudden decrease in oil recovery.

1.1. Techniques to Determine Causes of Excessive Water Production

To make the process of development more effective, probable causes of uneven and rapid watering need to be determined. There are two groups of methods and techniques that can be used to identify causes of excessive water production: production logging tests (PLT) and analytical methods.

PLT is the most effective way to determine probable causes of well stream watering, but at the same time, it is considered to be the most expensive way [

4]. Among the advantages is a high level of informativity and accuracy of the results. Among the disadvantages are additional costs associated with the performance of work, the use of equipment, specialized software, and losses connected with the well shutdown at the time of the isolation process.

Analytical methods based on analysis and comparison of geological–physical, seismic, and production history data do not require significant capital and operational expenditures and have good prospects of application. However, it is impossible to accurately determine the causes of a well stream watering using only analytical methods. In reality, available information about the subject of the study should be examined in complex, and usually, the combination of several methods should be used for determination of possible causes of watering. Together with well tests and logs, analytical methods can optimize treatments to enhance oil recovery.

The method of analysis of water control diagnostic plots, presented by K.S. Chan, was chosen for this work. It is based on systematic numerical simulation studies on reservoir water coning and channeling [

4,

5]. It was discovered that log-log plots of WOR (Water/Oil Ratio) vs. time show different characteristic trends for different mechanisms [

5]. The transition to bilogarithmic coordinates (log-log plots) is explained by the convenience of interpretation of the information on the dynamics of production.

In his work [

5], K.S. Chan combined the main causes of watering into three groups: water coning, fracturing, and a system of channels with high permeability and wellbore channeling. It is enough to have a production performance (liquid and oil rate) as initial data. The author of the work [

5] noted that the dynamics of WOR and time derivatives of the WOR were found to be capable of differentiating whether the well is experiencing water coning, high-permeability, or near wellbore channeling.

1.2. Overview and Analysis of the Main Water Shut-Off Technologies

Excessive water production is caused by different physical, technological, and geological factors. There are a lot of different water shut-off technologies.

In order to control water inflow in the well, various chemical components are used based on polymers, suspensions, gel-forming, and sludging compositions [

1,

6,

7,

8].

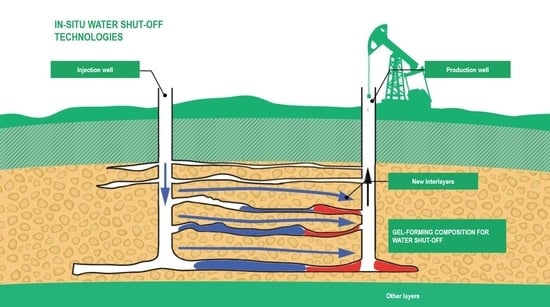

All the in situ water shut-off technologies are divided into two large groups: non-selective and selective. In the next section, each of the methods will be considered in more detail.

1.2.1. Non-Selective Methods

Non-selective methods are based on the use of special reagents, which form sludge after it is injected into the reservoir. This sludge will not dissolve in water or oil and will form an impermeable water insulating barrier.

To carry out such a type of isolation it is required to precisely identify the flooding interval and except the decrease in permeability of the productive oil-saturated part of the formation [

9].

Non-selective water-insulating compositions include cement slurries and synthetic resins.

Cement slurries are the most common reagents because of their low cost and availability of using reagents. Among the disadvantages of using these compositions, low penetration capability is identified and this makes some boundary conditions in the process of isolation of low permeability areas and fractures with a small degree of opening. In addition, the forming stone will have low adhesive properties and, as a result, the water insulating barrier will be destroyed early.

Despite the fact that synthetic resins have a higher penetration capability compared to the previously described composition and rather high strength characteristics, it has a significant disadvantage: there is an absence of a selective effect and it can lead to the unconvertible lowering of filtration characteristics in oil-saturated productive intervals [

3].

1.2.2. Selective Methods

Selective methods are based on the use of selective properties of the insulation reagents, the technology of carrying out the works, and the nature of rock saturation [

2,

10,

11,

12].

Injection of selective materials is made in the entire perforated part of the formation. Filtration resistance increases in the water-saturated part of the reservoir; although the oil-saturated part is not plugged. These facts show that the main advantage of this method is a selective effect and the absence of necessity to precisely identify the water- and oil-saturated interval of the reservoir. In addition, this method of water isolation does not require additional perforation of the borehole. Therefore, selective materials are often preferred for water shut-off.

A large number of selective water-insulating compositions are known.

Silicate-Alkaline Compositions

Materials based on silicates and alkaline metals are used to form water insulating barriers. Gel-like systems, sediments, and gels with high plugging properties are formed after the injection of composition into the formation [

9]. Compositions based on sodium silicate (water glass) are widely used. Among the drawbacks is the difficulty of controlling the building-up process of the gel as a result of the interaction of sodium silicate and alkali. Further, it is quite problematic to control this process because of the absence of an induction period, and it causes the formation of sediment in the bottomhole zone of the reservoir.

Moreover, the use of sodium silicate has some boundary conditions due to low structural stability:

Pre-injection of hydrochloric acid could partly minimize the negative effect of using silicate–alkaline compositions.

Polymer-Dispersed Systems

Polymer-dispersed systems increase the filtration resistance of the watered zones of the reservoir.

This composition consists of macro-dispersed particles of gel powder stabilized with ionogenic polymers with flocculating properties, surface-active agents (SAA/surfactants), and emulsifiers.

The polymer modifies the surface of the rock due to adsorption on it. The clay suspension pumped after the polymer reacts with the adsorbed on the pore surface polymer, thereby maintaining the suspended state of the gel powder particles and supporting flocculation processes to form polymer-dispersed conglomerates [

13].

Crosslinked Polymeric Compositions

The technology is based on the use of polymer crosslinked compositions, which slowly crosslink and make through the reservoir over considerable distances. Chromium acetate, chromium potassium sulfate, and potassium bichromate are used as cross-linking agents. When macromolecules of polyacrylamide crosslink with a crosslinking reagent, a gel-like system forms from a viscous solution, which improves the rheological properties of the composition, thermal stability, and the composition becomes more stable against all types of destruction.

The advantage of such polymer gel systems is relatively low cost because the composition includes water in addition to the main component—polymer. Water is in a bound state after crosslinking the polymer.

Viscoelastic systems, «Temposkrin» are used such as polymer gel systems [

15].

Viscoelastic systems are partially solidified gels that are formed by the crosslinking of a polymer, for instance, polyacrylamide, with a crosslinking agent.

The «Temposkrin» gel is a dispersed structure with high mobility and the ability to penetrate fractures and large pores. However, due to the fact that the size of the gel particles is larger than the pores (0, 2–4, 0 mm), this composition does not penetrate low permeability zones, nor into hydrophobic sections of the reservoir, and this fact underlines its selective properties [

13,

14,

16,

17].

It can also be noted that the use of a combination of several materials with selective properties is quite challenging and can help to combine their advantages.

1.3. Object of the Study

The carbonate deposit of the oil field of the Timan–Pechora oil and gas province is taken as an object of investigation. The reservoir type of the deposit is fractured-porous.

Extensive study of the geological structure of reservoirs containing both the matrix and fracture parts in their structure allows us to conclude that the presence of the developed fracture system plays an important role in the process of filtration. At the same time, the features of the geological structure of such deposits complicate the process of development by rapid and uneven watering.

2. Materials and Methods

Technique to determine excessive water production mechanisms based on diagnostic plots, presented by K.S. Chan in his work [

5], was chosen for analysis in this work. Plots using the actual production history data determined the production problem mechanisms. A set of diagnostic plots has been generated by conducting a series of systematic water-control numerical simulation studies using a black oil simulator [

5]. This simulator is capable of modeling the performance of reservoir flow under different drive mechanisms and waterflood schemes.

Log-log plots of WOR vs. time are considered to be more effective in identifying the production trends and problem mechanisms. It was discovered that the derivatives of the WOR vs. time can be used for differentiating whether the excessive water production problem as seen in a well is due to water coning or multilayer channeling. For coning a water–oil contact (WOC) was defined and a bottomwater influx was simulated by constant pressure water injection at the edge and only into the bottomwater layer, only 20% of the oil zone was perforated in the model. For channeling, the bottomwater layer was eliminated, the water injection was modeled with constant pressure water injection into all layers at the edge and all layers were perforated.

Coning is a mechanism that describes the movement of water from lower to higher into the perforations of a producing oil well, which can affect the well productivity.

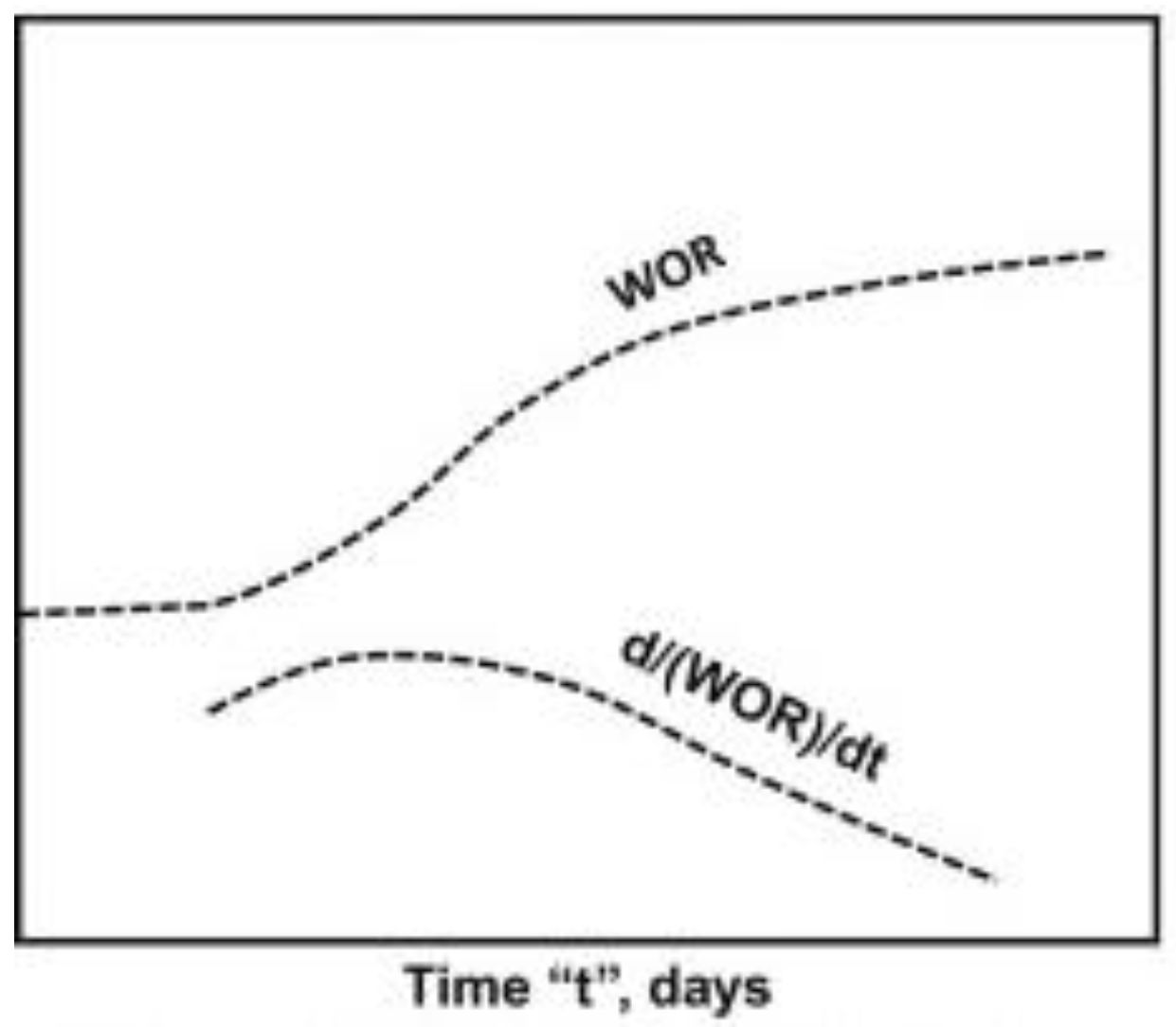

Figure 1 shows a clear distinction between a water coning and a multilayer channeling development with the same conditions and different flow geometry. There are three periods of WOR development. For coning the early time (first) period when WOR is a constant value, it is shorter because the bottomwater cone covers the distance between water oil contact (WOC) and the bottom of the nearest perforation interval more quickly than water at a layer in a multilayer formation comes to perforation interval. The second period shows the WOR increasing with time. For coning the rate of the WOR, the increase is relatively slow and gradually approaches a constant value at the end of the period. The Bottomwater cone expands not only vertically upwards but also expands radially. For channeling, it increases very quickly. The third period for coning shows production mainly of the water.

However, when we have only one plot for the mechanism it is hard to differentiate whether the excessive water production relates to coning or channeling. The WOR’ becomes very helpful to determine it (

Figure 2 and

Figure 3). For WOR’ stands for a simple time derivative of the WOR. For coning, it shows changing negative slope (

Figure 3) and a nearly constant positive slope for channeling (

Figure 2).

3. Results

3.1. Analysis of Main Information about the Object under Investigation

Carbonate deposits in the oil field of the Timan–Pechora oil and gas province are taken as the object of investigation. The deposit is massive and has an anticline trap bounded by oil and water contact (OWC), a complex configuration, and tectonic structures. The Lower Permian carbonate deposit is represented by various reservoir types. However, the porous type with fractured-porous and fractured types prevails.

It is necessary to study all available information in the complex, make correlations between seismic data and the results of the dynamic well tests, and compare this information with the well performance.

Thus, a well interference test was carried out at the site from injection well No. 1006 in three directions: to wells No. 13G, No. 1002, and No. 1001. The interpretation of the results of the interference test towards the producing well No. 13G shows the permeability value 8.06 · 10−2 μm2. Such high permeability in combination with the seismic survey data confirms the presence of a fracture network in this direction.

In addition, the obtained reaction measurements between wells No. 1006 and No. 1001 showed high reservoir connectivity (permeability was 4.37·10−2 μm2). At the same time, the results of the interpretation of the test conducted from the same injection well in the direction of well No. 1002 showed no reaction. These data probably indicate the absence of highly conductive zones in this area.

It is possible to conclude about the sharp discontinuity of reservoir formation based on the well interference test. It can also be mentioned that such conclusions are proved by the behavior of the productive fluid rate of the nearby wells during the drilling phase. They showed a noticeable difference.

According to the above data, it can be assumed with a high degree of probability that the Lower Permian carbon deposit is a system of «matrix and fractures» (fluid is mainly concentrated inside the porous matrix and fractures play the role of connecting channels).

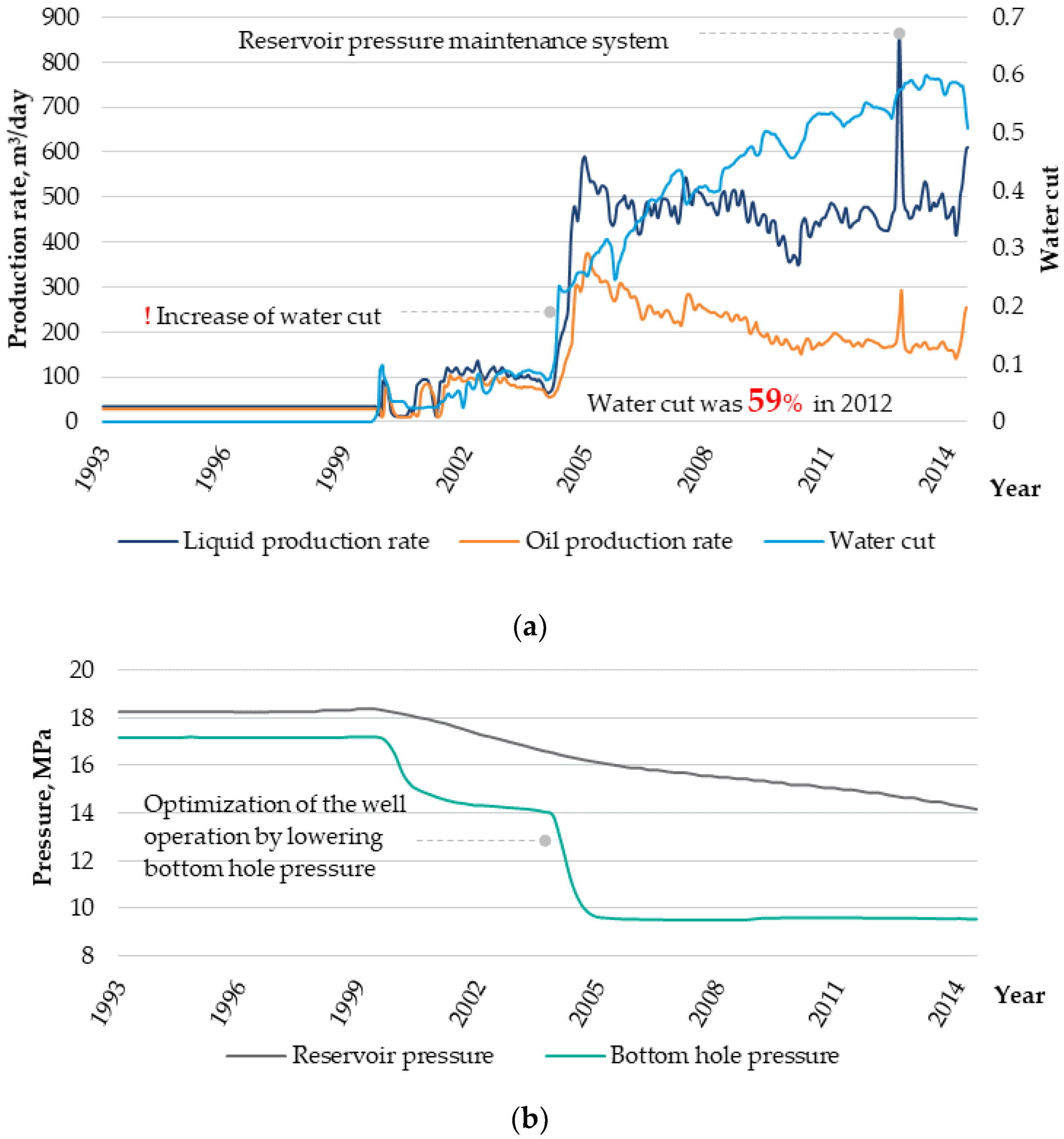

The water content of the field was low at the beginning of the development. However, after the optimization of the development system (conversion from a free-flow production to a mechanical method of production with high differential pressure), there was a significant increase in productivity with a simultaneous increase in the liquid rate and water cut of the produced fluid (

Figure 4a,b).

The nature of watering at the field is different. There are both wells with a long period of production with low values of water cut and rapidly flooded wells, which open zones with extensive coverage of fracture systems according to a complex analysis of the location of fractures in the reservoir. Therefore, it is necessary to perform an analysis of the causes of flooding.

3.2. Analysis for Determination of Possible Causes of Watering

The characteristics of wells located in the area with injection well No. 1006 for probable sources of water flooding were considered. The work provides an example of analysis for horizontal production well No. 13G.

Figure 5 shows the dynamics of the production rate change and water cut in the well.

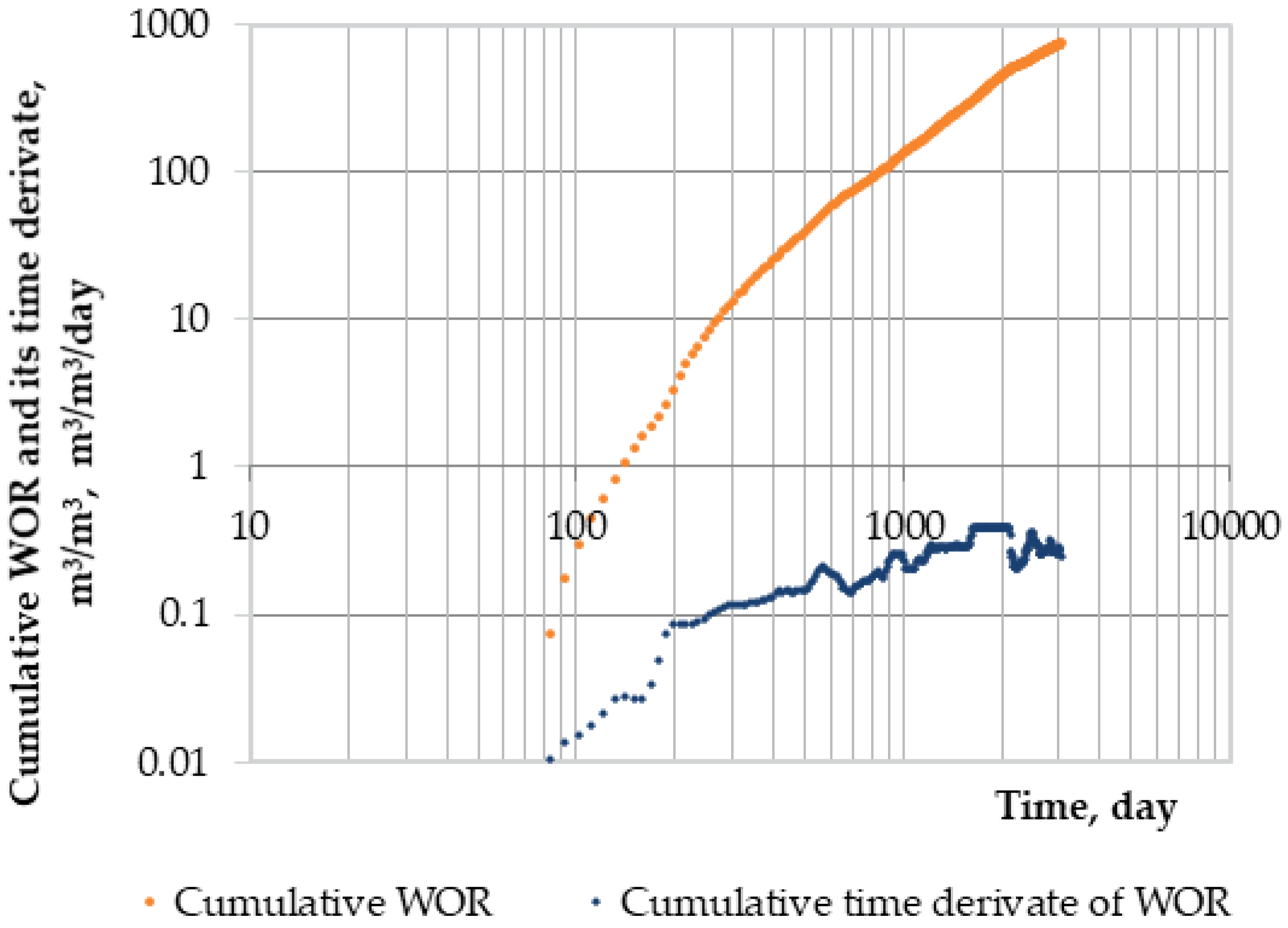

Figure 6 shows log-log plots of WOR. The transition to bilogarithmic coordinates was made due to the convenience and clarity of the visualization of data on the dynamics of oil and water production. Such a scale is useful for displaying a wide range of values of the displayed values.

Plots using the production history data determined the production problem mechanisms. The indicator of a water break can be a simultaneous change in the angle of inclination of the production curves. In the horizontal production well No. 13G, oil production drops, water production grows, and therefore water cut increases. Presumably, water broke through the fractured channel in the direction of the well. the electric submersible pump (ESP) was replaced in 2011. It led to a slight drop in watering and an increase in liquid production due to an increase in oil production.

It also should be noted that the technical reason for watering (seepage in production string) is excluded, since there are results of periodically performed field-geophysical tests, according to which there are no seepages in the production string in this well. It should be noted that the leakage of the production casing was detected only in the well 1001 according to the results of the periodically performed production logging [

17,

18]. In addition, the inflow of additional water from other horizons made up about 12%, and the rest of the water is associated with the formation water of the Lower Permian sediments according to the results of laboratory studies [

17].

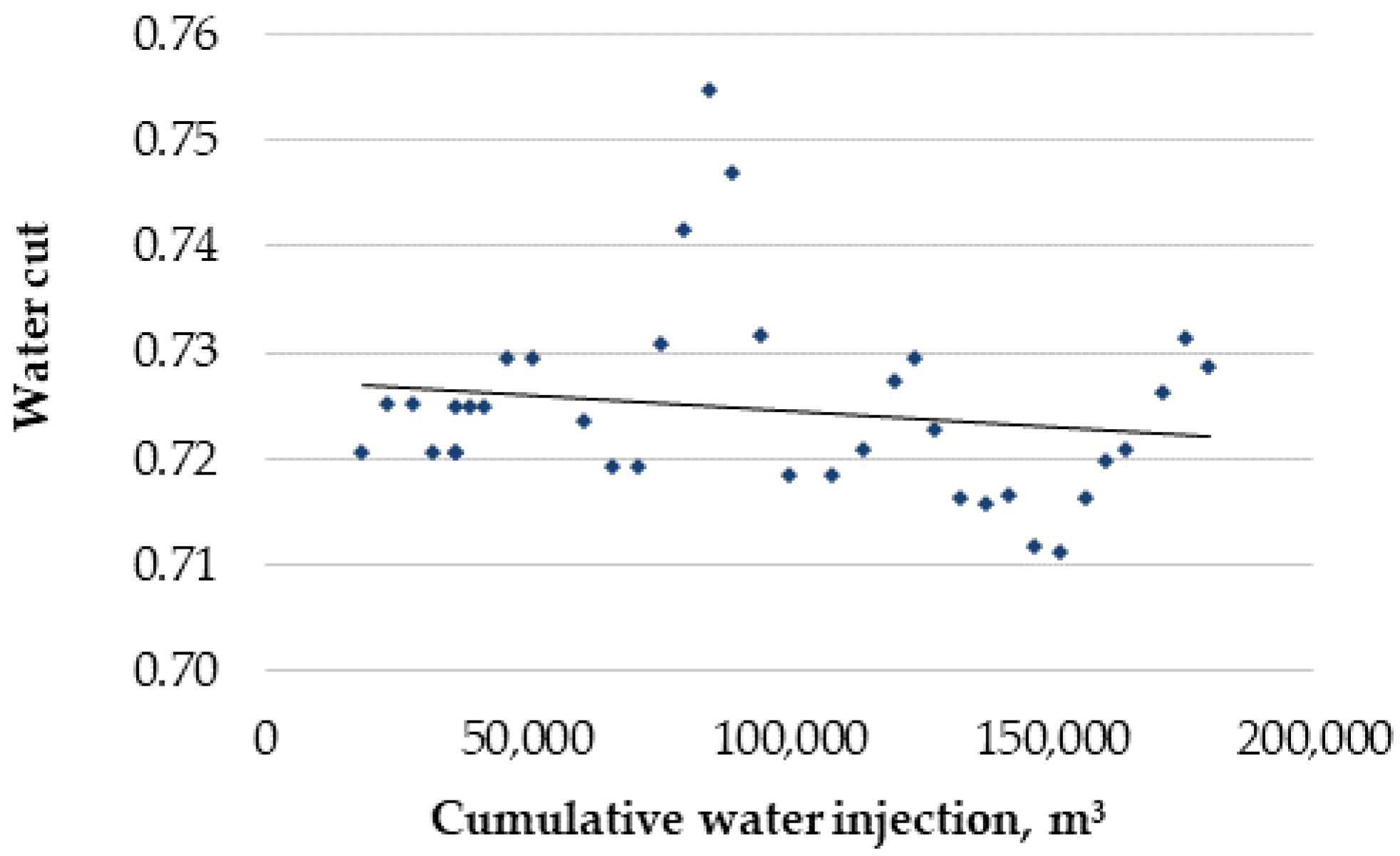

Figure 7 shows the dependence of the water cut of horizontal well No. 13G on the volume of injected water through injection well No. 1006. Water cut varies slightly during injection of the water, that is why the watering occurs, not so much due to the injected water, but due to breaks in the formation waters, and also because of the water coning. The remote location of this well from the injection (2600 m) is another probable cause.

Figure 8 shows diagnostic plots of WOR and its time derivative. According to the plots, a gradual increase in the derivative of accumulated WOR with subsequent stabilization can indicate a breakthrough of water through high-permeability crack channels based on the work of Chan [

5]. Location near this well of the system of fractures and channels is confirmed on the basis of a comparison of data on seismic attributes and results of interference test.

Therefore, analyzing all the above, it should be noted that well No. 13G was put into operation immediately with a watering of 7.4%. In this well, there is a drop in oil production due to the presence of fracturing in the bottom hole zone. Water flooding is mainly due to reservoirs rather than injection water.

All in all, the main reason for the watering of well production is the breakthrough of the formation and injection water through a system of highly permeable natural fractures and channels.

There is provided an application of in situ water shut-off technologies to minimize water flooding of the wells of the object under investigation [

2,

5,

10,

19,

20,

21,

22,

23,

24,

25].

3.3. Composition for Water Shut-Off

As a result of the literature–patent overview of the material about in situ water shut-off technologies, it was concluded that using the gel-forming selective methods will be the most practical and effective for such type of reservoir (carbonate fractured-porous reservoir) because of the high selectivity of the composition (

Table 1).

It is also necessary to select the base of the polymer gelling composition and the components included in it. The technology is based on the use of cross-linking polymer-crosslinking compositions, which penetrate the formation over long distances [

25,

26,

27,

28,

29].

Compositions have different bases:

Polyacrylamide with various structures, molecular weights, and degrees of hydrolysis. Among polyacrylamide-based compositions are viscoelastic compositions, crosslinked polymer systems [

26], gel-forming compositions [

30], and polymer gel systems;

Carboxymethyl cellulose [

3,

17,

30];

Hydrolyzed polyacrylonitrile (HYPAN) [

13];

Water-swelling polymers: polymeric compositions «Ritin», «Temposkrin» [

15].

During the literature–patent overview, a matrix of applicability of different polymer gel-forming compositions for water shut-off was made (

Table 2).

A composition based on carboxymethyl cellulose was selected in accordance with the selected geological and physical conditions of the components’ application (

Table 2).

The formation temperature of the object under consideration is 37 °C, which is a relatively low value. In addition, the high mineralization of the produced water is an important boundary condition of this reservoir. Therefore, carboxyl polymer compositions can be used under these conditions because they are capable of maintaining their properties under conditions of high mineralization [

3].

The gel is formed from a viscous solution during the crosslinking of polymer macromolecules by means of a crosslinking agent. The gel-like composition has improved rheological properties and higher temperature resistance, as a result of which, the composition is less susceptible to various types of destruction. Chromium (III) acetate Cr(CH3COO)3 is offered as a crosslinking agent. Chromium acetate is a popular crosslinking agent. The advantage of this reagent includes its low cost as well as less impact on the environment.

In addition, copper sulfate is recommended as a catalyst agent for gelling to increase reliability and to prevent destruction in course of time [

3].

Sodium hydroxide solution is suggested as a destructor to regenerate permeability of oil-saturated part.

As a result of using the in situ water shut-off proposed in the article, it is possible to increase the oil recovery factor by increasing sweep efficiency. Isolation of water inflows is achieved by the regulation of filtration flows in the formation by making hydraulic insulating shields and barriers to water filtration due to the injection of various water shut-off compositions in the reservoir.

4. Conclusions

The article is devoted to one of the main problems of the development of such reservoirs—high levels of watering. Analysis of water shut-off technologies and methods in carbonate reservoirs is performed. The main materials for water shut-off are presented in this work. Finally, it can be concluded that using selective reagents is the most practical and effective.

The main features of the geological structure of the oil field in the Timan–Pechora oil and gas province are considered in this article. Conclusions about the main causes of rapid watering were made based on the analysis of the state of development of the deposit, specifically information about the water invasion of the wells, and on the analysis of water control diagnostic plots according to the methodology of K.S. Chan. Water flooding from the underlying lower aquifer, as well as watering through a system of highly permeable natural fractures are among the main causes of high water cut. Differences in filtration characteristics associated with the presence of the fracture system are a negative feature of the structure of this reservoir, which complicates the development of the deposit.

As a result of the literature–patent overview of the material about in situ water shut-off technologies, a matrix of applicability of the technology was created. It is concluded that using the selective methods for such types of reservoirs has good prospects. Based on the matrix of applicability, the polymer gelling composition is selected due to its high selectivity.

Selective composition includes carboxymethylcellulose as the water-soluble polymer, chromium acetate as a crosslinking agent, copper sulfate as a catalyst agent for gelling, and sodium hydroxide solution as a destructor.

The composition for water shut-off has a lot of requirements. Compositions based on carboxymethylcellulose are suitable for the effective removal of the causes of water flooding. A distinctive feature of carboxymethylcellulose is the resistance to reservoir waters with high mineralization. It is the main factor in selecting this composition for consideration in this work field.

Application of the considered technology of in situ water shut-off will make it possible to achieve an increase in oil recovery due to an increase in sweep efficiency, a drop in permeability of fractures and channels, and additional production due to involvement in the development of undeveloped areas not covered by flooding, as well as a reduction in the operating costs associated with extracted water.

Author Contributions

Conceptualization, A.S. and S.Y.; methodology, A.S. and S.Y.; software, A.S. and S.Y.; validation, A.S. and S.Y.; formal analysis, S.Y.; investigation, S.Y.; resources, S.Y.; data curation, S.Y.; writing—original draft preparation, S.Y.; writing—review and editing, A.S.; visualization, S.Y.; supervision, A.S.; project administration, A.S.; funding acquisition, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Apasov, G.T. Development and Research of Complex Technology of Intensification of Oil Production and Limitation of Water Inflows. Ph.D. Dissertation, IUT, Tyumen, Russia, 2014; 152p. (In Russian). [Google Scholar]

- Sintsov, I.A. Diagnosis of the causes of horizontal well watering. In Geology, Geophysics and Development of Oil and Gas Fields; Sintsov, I.A., Ostapchuk, D.A., Eds.; IUT: Tyumen, Russia, 2014; pp. 30–33. (In Russian) [Google Scholar]

- Sukhodanova, S.S. Creating a 3D Model of a Deposit with Carbonate Fractured Collectors Based on the Integration of Hydrodynamic, Geophysical, Seismic and Field Data (on the Example of Lower Permian Deposits of the Varandeisky Deposit. Ph.D. Dissertation, IPNG RAS, Moscow, Russia, 2016; 157p. (In Russian). [Google Scholar]

- Raupov, I.R. Technology of Intraflast Water Insulation of Terrigenous Collectors Using Polymer Compositions and Optical Method of Process Control. Ph.D. Dissertation, St. Petersburg Mining University, St. Petersburg, Russia, 2016; 143p. (In Russian). [Google Scholar]

- Chan, K.S. Water Control Diagnostic Plots. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 2015. Paper SPE 30775. [Google Scholar]

- Kaushansky, D.A.; Demyanovsky, V.V. Creation and industrial implementation of the technology of physicochemical impact on the productive formations of oil fields of the Temposkrin polymer-gel system—A new generation technology. Neftepromysol Bus. 2006, 28–37. (In Russian) [Google Scholar]

- Penkov, G.M.; Karmansky, D.A.; Petrakov, D.G. Simulation of a fluid influx in complex reservoirs of Western Siberia. In Topical Issues of Rational Use of Natural Resources, Proceedings of the International Forum-Contest of Young Researchers, St. Petersburg, Russia, 18–20 April 2018; CRC Press: Leiden, The Netherlands, 2019; pp. 119–124. [Google Scholar]

- Pevneva, A.G.; Penkov, G.M.; Bakiev, M.D. On designing a computational experiment system for various engineering interpretations of a global optimization problem. ARPN J. Eng. Appl. Sci. 2017, 12, 1219–1225. [Google Scholar]

- Ibragimov, L.K.; Mishchenko, I.T.; Cheloyants, D.K.-M. Intensification of Oil Production; Science: Moscow, Russia, 2000; 414p. (In Russian) [Google Scholar]

- Mardashov, D.V. Development of blocking compositions with a bridging agent for oil well killing in conditions of abnormally low formation pressure and carbonate reservoir rocks. J. Min. Inst. 2021, 251, 617–626. [Google Scholar] [CrossRef]

- Pavlov, A.V.; Tokareva, G.N. Thermotropic Gel-Forming Composition. Patent 2014115367/05, 17 April 2014. [Google Scholar]

- Popov, S.G.; Garshin, O.V.; Chugaev, O.A.; Okromelidze, G.V.; Lebedev, K.P.; Permyakov, A.Y. Selective Emulsion Composition for Water Insulation and Leveling of the Flow Profile of Production Wells. Patent 2019124396, 29 July 2019. [Google Scholar]

- Gumerova, A.S. Improving the Technology of Intraflast Insulation with Silicate-Polymer Compositions in Conditions of Heterogeneous Compositions. Ph.D. Dissertation, USPTU, Ufa, Russia, 2020; 151p. (In Russian). [Google Scholar]

- Demakhin, S.A. Selective Methods of Isolation of Water Inflow to Oil Wells: Textbook; Demakhin, S.A., Demakhin, A.G., Eds.; GosUNC College: Saratov, Russia, 2003; 167p. (In Russian) [Google Scholar]

- Islamov, S.R.; Bondarenko, A.V.; Gabibov, A.F.; Mardashov, D.V. Polymer compositions for well killing operation in fractured reservoirs. In Advances in Raw Material Industries for Sustainable Development Goals; Taylor & Francis: London, UK, 2021; pp. 343–351. [Google Scholar] [CrossRef]

- Uvarov, S.G.; Ganeev, Z.M.; Abrosimova, N.N.; Rizvanov, R.Z.; Yakhina, O.A. Gelling Composition for Isolation of Water Inflow into the Well. Patent RF2004136413/03, 14 December 2004. [Google Scholar]

- Shagiakhmetov, A.; Tananykhin, D.; Terleev, A. Development of water-shutoff composition on the basis of carboxymethyl cellulose for fractured and fractured-porous oil and gas reservoirs. Acta Tech. CSAV 2018, 63, 475–480. [Google Scholar]

- Strizhnev, K.V. Repair and Insulation Work in Wells; Strizhnev, K.V., Ed.; Nedra: St. Petersburg, Russia, 2010; 560p. (In Russian) [Google Scholar]

- Grigorev, M.B.; Tananykhin, D.S.; Poroshin, M.A. Sand management approach for a field with high viscosity oil. J. Appl. Eng. Sci. 2020, 18, 64–69. [Google Scholar] [CrossRef][Green Version]

- Duryagin, V.N. Rationale for the Technology of Limiting Water Inflow for Oil Fields with a Fractured-Pore Type of Reservoir. Ph.D. Dissertation, St. Petersburg Mining University, St. Petersburg, Russia, 2015; 132p. (In Russian). [Google Scholar]

- Ketova, Y.A.; Bai, B.; Khizhnyak, G.P.; Gladkikh, Y.A.; Galkin, S.V. Testing of preformed particles polymer gel technology on core filtration models to limit water inflows. J. Min. Inst. 2020, 241, 91. [Google Scholar] [CrossRef]

- Mardashov, D.V.; Bondarenko, A.V.; Raupov, I.R. Technique for calculating technological parameters of non-Newtonian liquids injection into oil well during workover. J. Min. Inst. 2022. [Google Scholar] [CrossRef]

- Mardashov, D.; Duryagin, V.; Islamov, S. Technology for improving the efficiency of fractured reservoir development using gel-forming compositions. Energies 2021, 14, 8254. [Google Scholar] [CrossRef]

- Tananykhin, D.; Korolev, M.; Stecyuk, I.; Grigorev, M. An investigation into current sand control methodologies taking into account geomechanical, field and laboratory data analysis. Resources 2021, 10, 125. [Google Scholar] [CrossRef]

- Rogachev, M.K.; Kondrashev, A.O. Experiments of fluid diversion ability of a new waterproofing polymer solution. Oil Ind. 2015, 42, 507–551. [Google Scholar] [CrossRef]

- Shagiakhmetov, A.M. Substantiation of the Technology of Intraflast Water Insulation in Carbonate Collectors Using a Polymer Composition. Ph.D. Dissertation, St. Petersburg Mining University, St. Petersburg, Russia, 2016; 103p. (In Russian). [Google Scholar]

- Kunakova, A.M.; Duryagin, V.N.; Strizhnev, K.V.; Mardashov, D.V.; Duryagina, A.M. Inorganic gel-forming composition for water shut-off in carbonate reservoir of fractured-porous type. Oil Ind. 2015, 11, 114–116. [Google Scholar]

- Rogachev, M.K.; Kondrashev, A.O.; Kondrashev, O.F. Water-shut-off polymeric composition for low-permeable reservoirs. Oil Ind. 2014, 4, 63–65. [Google Scholar]

- Rogachev, M.K.; Kondrashev, A.O. Substaniation of intrastratal water shut-off technology in low-permeability reservoirs. J. Min. Inst. 2016, 217, 5082. [Google Scholar]

- Raupov, I.R.; Shagiakhmetov, A.M. The results of the complex rheological studies of the cross-linked polymer composition and the grounding of its injection volume. Int. J. Civ. Eng. Technol. 2019, 10, 493–509. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

—The parameter of the deposit under review corresponds to the geological–physical conditions of the application of the technology.

—The parameter of the deposit under review corresponds to the geological–physical conditions of the application of the technology.  —The parameter of the deposit under review does not correspond to the geological–physical conditions of the application of the technology.

—The parameter of the deposit under review does not correspond to the geological–physical conditions of the application of the technology. —The parameter of the deposit under review corresponds to the geological–physical conditions of the application of the technology.

—The parameter of the deposit under review corresponds to the geological–physical conditions of the application of the technology.  —The parameter of the deposit under review does not correspond to the geological–physical conditions of the application of the technology.

—The parameter of the deposit under review does not correspond to the geological–physical conditions of the application of the technology.