Energy Consumption Depending on the Durability of Pellets Formed from Sawdust with an Admixture of FFP2 Masks

Abstract

:1. Introduction

2. Materials and Methods

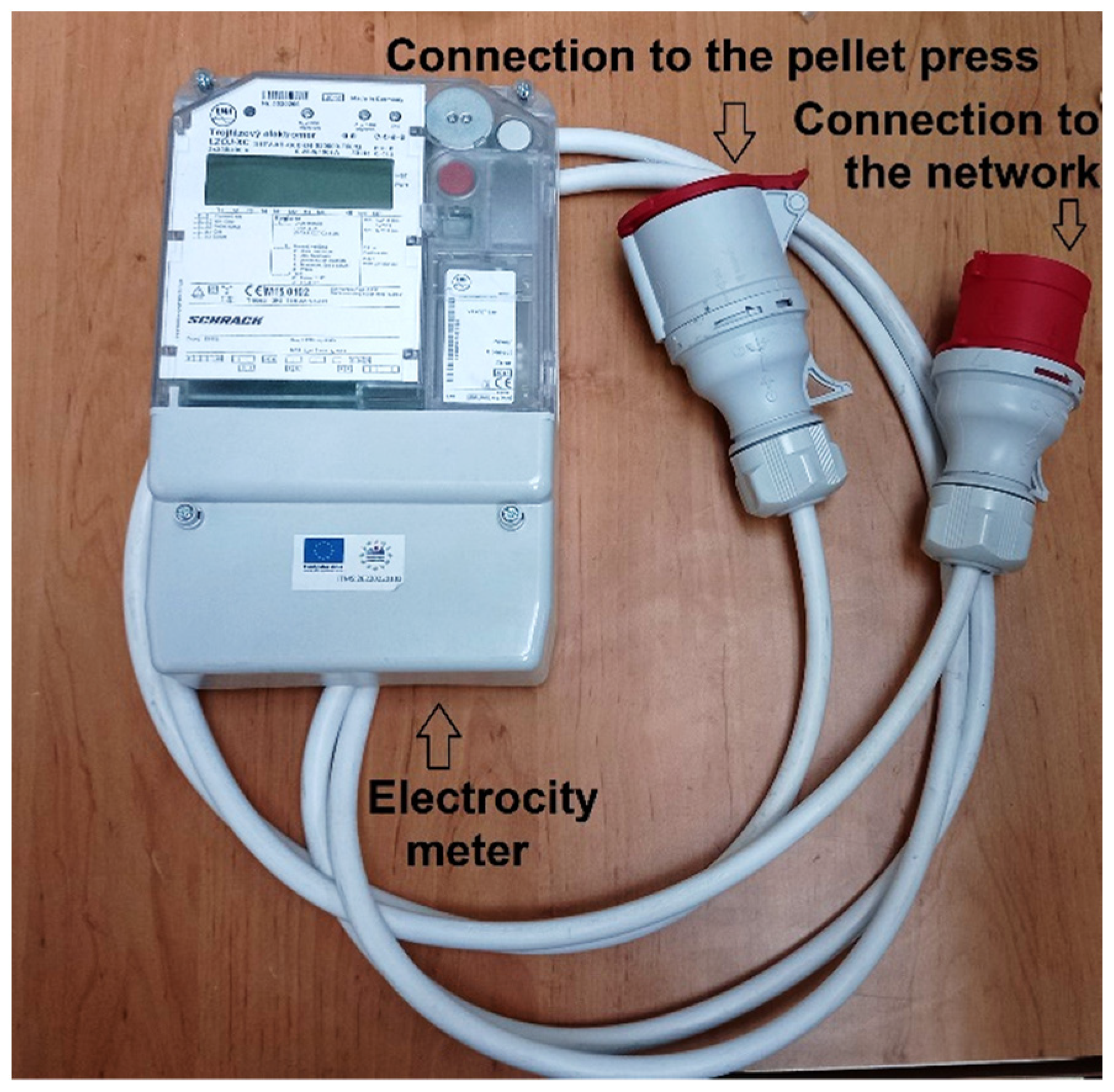

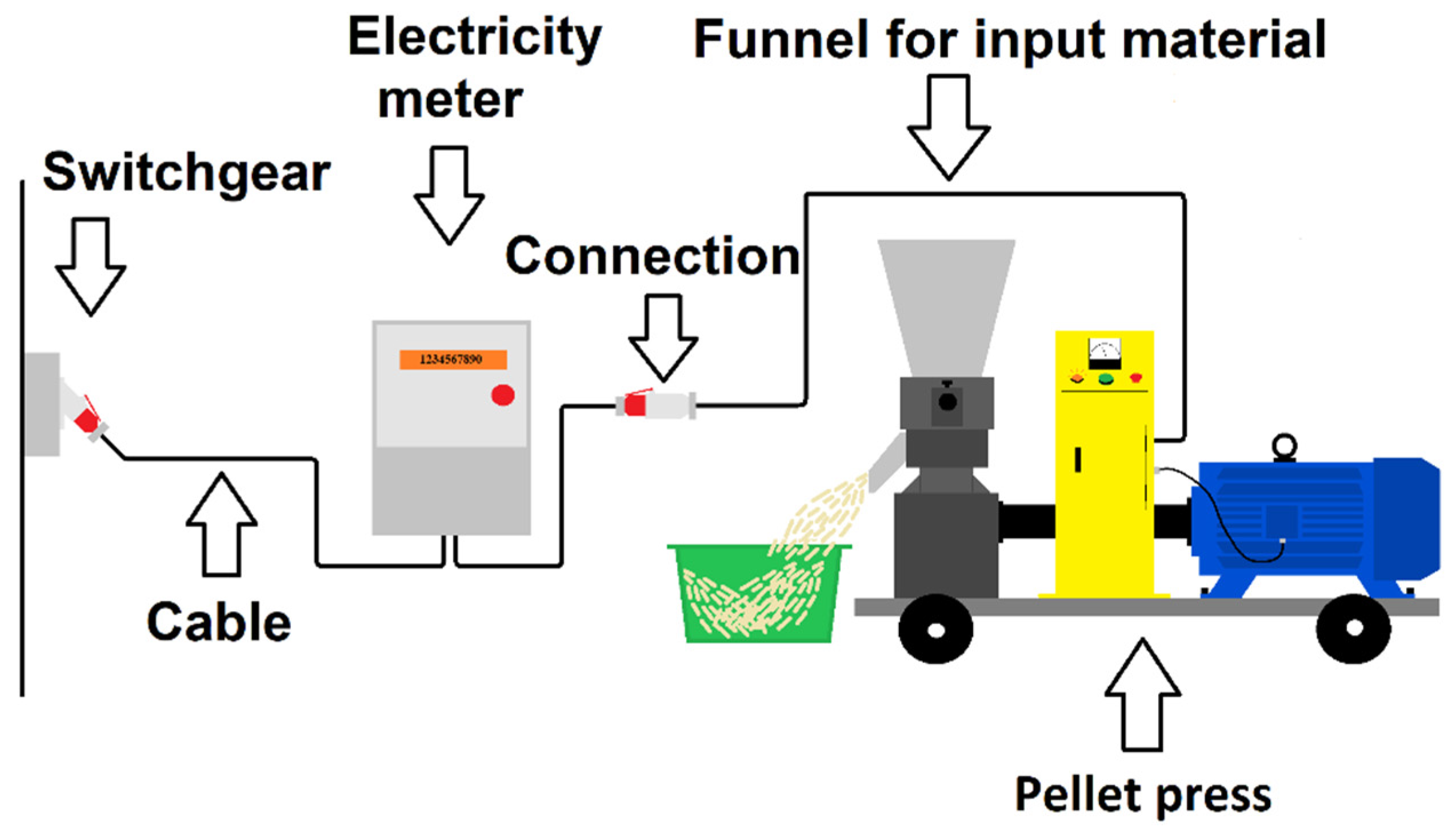

2.1. Energy Consumption

2.2. Mechanical Durability

2.3. Pellet Dimensions

2.4. Sample Standard Deviation

3. Results

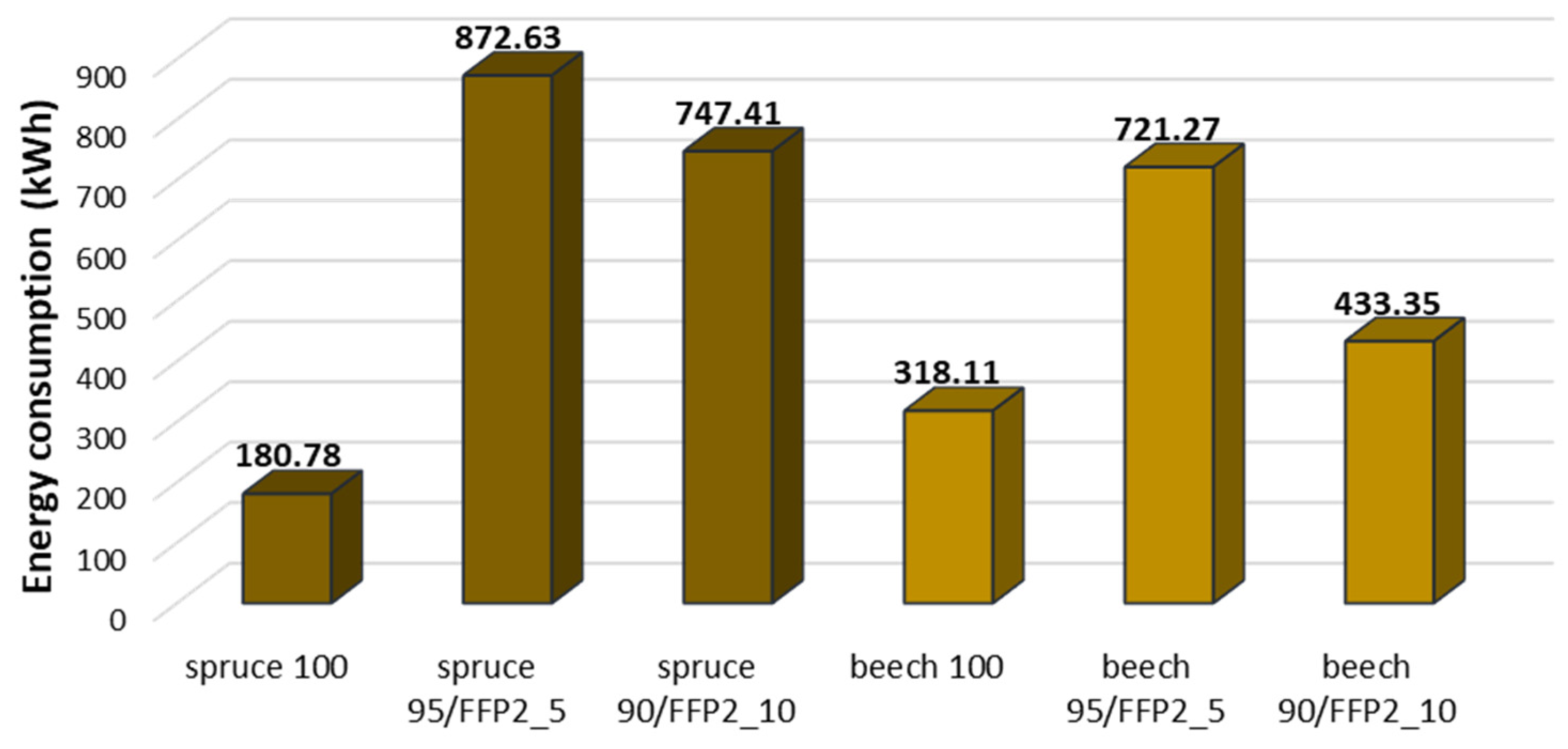

3.1. Energy Consumption

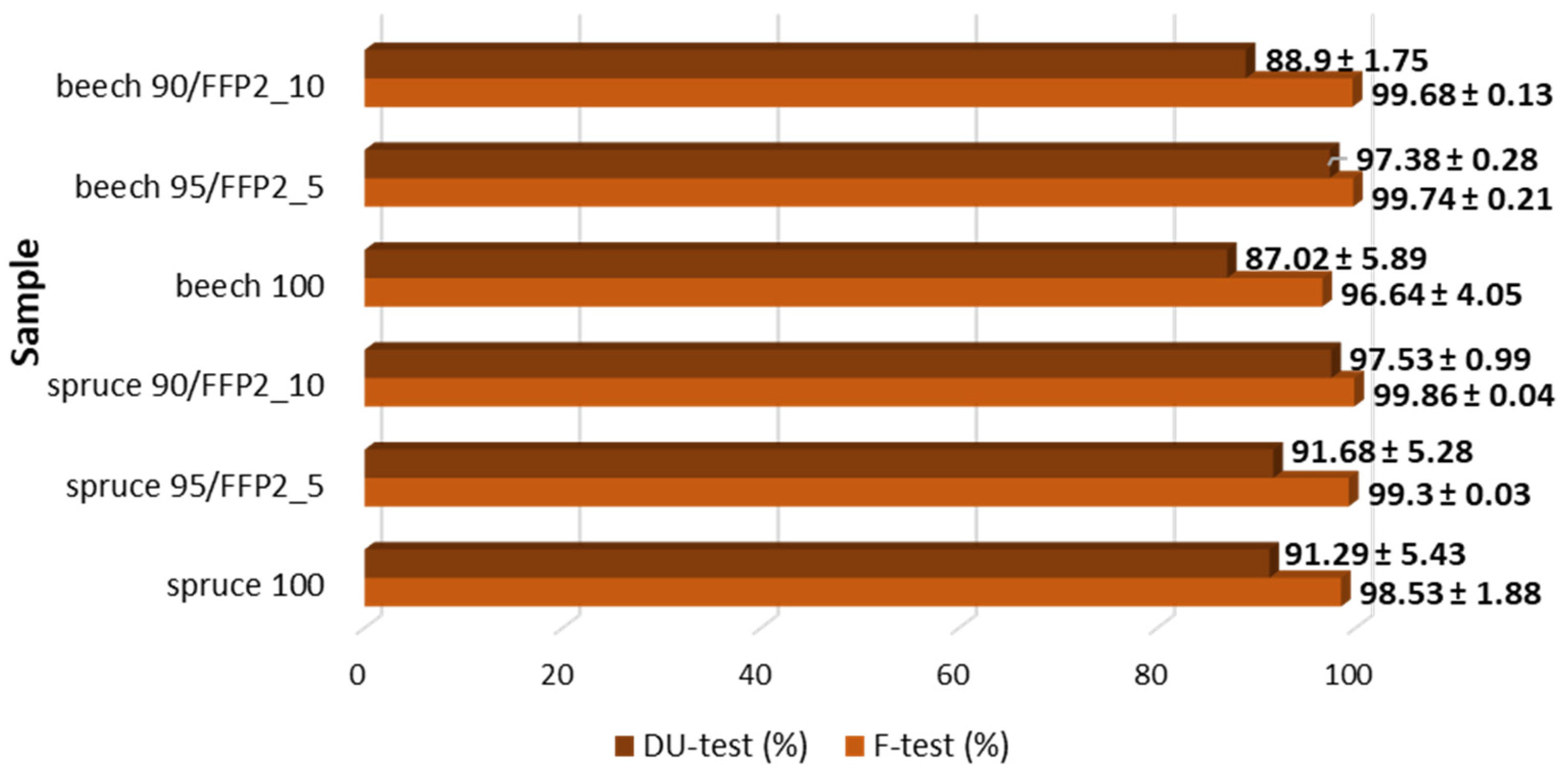

3.2. Mechanical Durability

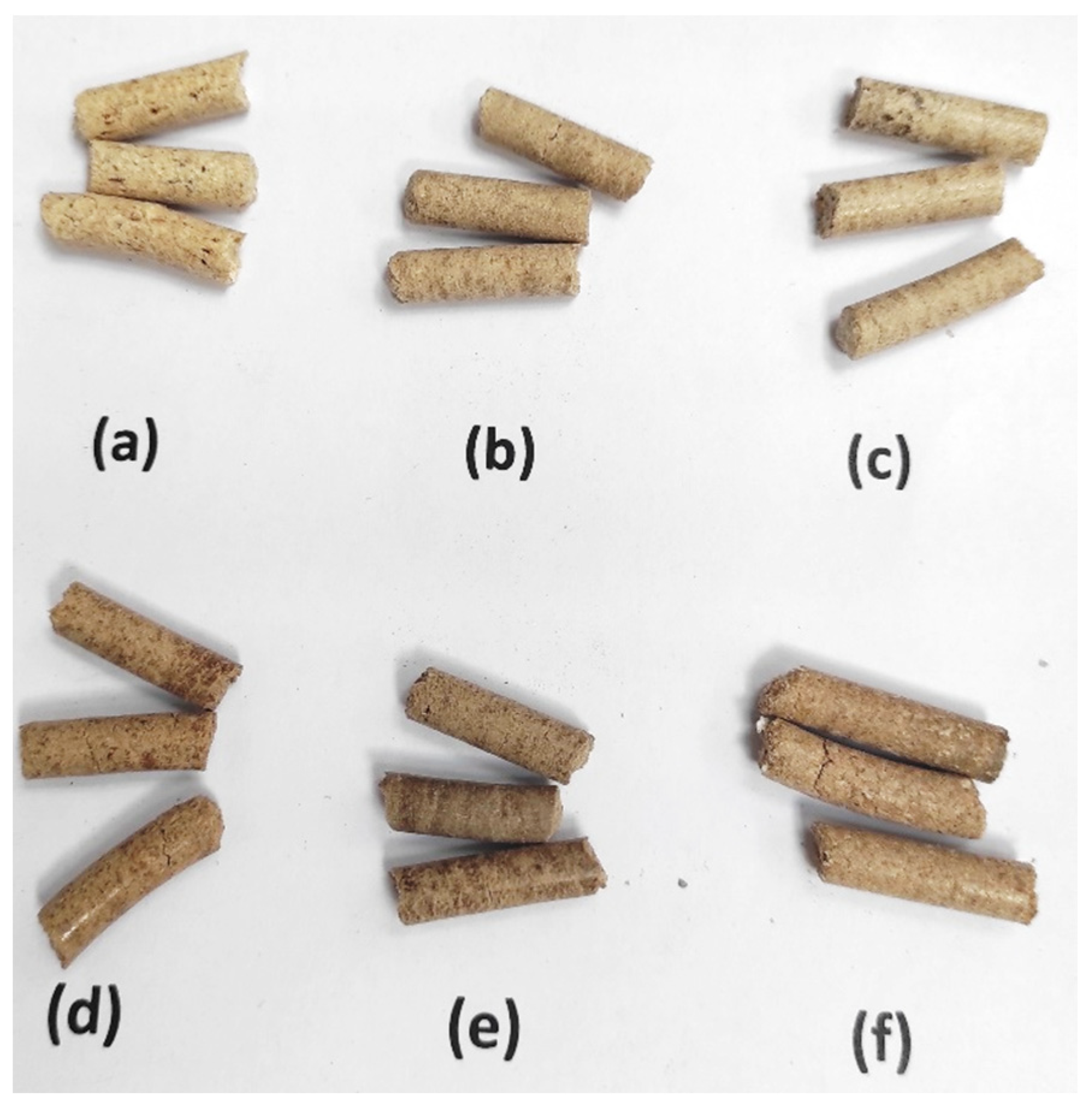

3.3. Pellet Dimensions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fadare, O.O.; Okoffo, E.D. COVID-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef] [PubMed]

- Klemeš, J.J.; Fan, Y.V.; Jiang, P. The energy and environmental footprints of COVID-19 fighting measures e PPE, disinfection, supply chains. Energy 2020, 211, 118701. [Google Scholar] [CrossRef] [PubMed]

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental challenges induced by extensive use of face masks during COVID-19: A review and potential solutions. Environ. Chall. 2021, 3, 100039. [Google Scholar] [CrossRef]

- Taušová, M.; Mihalik, E.; Čulková, K.; Stehlíková, B.; Tauš, P.; Kudelas, D.; Štrba, Ľ.; Domaracká, L. Analysis of municipalwaste development and management in self-governing regions of Slovakia. Sustainability 2020, 12, 5818. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Tan, M.; Luo, L.; Wu, Z.; Huang, Z.; Zhang, J.; Huang, J.; Yang, Y.; Zhang, X.; Li, H. Pelletization of Camellia oleifera Abel. shell after storage: Energy consumption and pellet properties. Fuel Process. Technol. 2020, 201, 106337. [Google Scholar] [CrossRef]

- Xia, X.; Zhang, K.; Xiao, H.; Xiao, S.; Song, Z.; Yang, Z. Effects of additives and hydrothermal pretreatment on the pelleting process of rice straw: Energy consumption and pellets quality. Ind. Crops Prod. 2019, 133, 178–184. [Google Scholar] [CrossRef]

- Uasuf, A.; Becker, G. Wood pellets production costs and energy consumption under different framework conditions in Northeast Argentina. Biomass Bioenergy 2011, 35, 1357–1366. [Google Scholar] [CrossRef]

- Larsson, S.H.; Samuelsson, R. Prediction of ISO 17831-1:2015mechanical biofuel pellet durability from single pellet characterization. Fuel Process. Technol. 2017, 163, 8–15. [Google Scholar] [CrossRef]

- Kuranc, A.; Stoma, M.; Rydzak, L.; Pilipiuk, M. Durability Assessment of wooden pellets in relation with vibrations occurring in a logistic process of the final product. Energies 2020, 13, 5890. [Google Scholar] [CrossRef]

- Matúš, M.; Križan, P.; Šooš, Ľ.; Beniak, J. The effect of papermaking sludge as an additive to biomass pellets on the final quality of the fuel. Fuel 2018, 219, 196–204. [Google Scholar] [CrossRef]

- Rezaei, H.; Panah, F.Y.; Lim, C.J.; Sokhansanj, S. Pelletization of refuse-derived fuel with varying compositions of plastic, paper, organic and wood. Sustainability 2020, 12, 4645. [Google Scholar] [CrossRef]

- Jandačka, J.; Holubčík, M.; Malcho, M.; Nosek, R. Modification of wood pellets parameters by using of concentrate of organic compounds from defibration. Acta Fac. Xylologiae Zvolen 2013, 55, 105–115. [Google Scholar]

- Holubčík, M.; Jachniak, E.; Smatanová, H. Differences between pellets from biomass made in manufactory and in domestic conditions. AIP Conf. Proc. 2014, 48, 1608. [Google Scholar] [CrossRef]

- ISO 15210; 1 Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO 17225; 2 Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets. International Organization for Standardization: Geneva, Switzerland, 2021.

- Stelte, W.; Holm, J.; Sanadi, A.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef] [Green Version]

- Sonawane, Y.B.; Shindikar, M.R.; Khaladkar, M.Y. High calorific value fuel from household plastic waste by catalytic pyrolysis. Nat. Environ. Pollut. Technol. 2017, 16, 879–882. [Google Scholar]

- Nosek, R.; Holubčík, M. Energy properties of air dry firewood. Acta Fac. Xylologiae Zvolen 2016, 58, 105–112. [Google Scholar] [CrossRef]

| Sample | Weight Proportion Sawdust (%) | Weight Proportion Face Masks FFP2 (%) |

|---|---|---|

| Spruce 100 | 100 | 0 |

| Spruce 95/face masks FFP2_5 | 95 | 5 |

| Spruce 90/face masks FFP2_10 | 90 | 10 |

| Beech 100 | 100 | 0 |

| Beech 95/face masks FFP2_5 | 95 | 5 |

| Beech 90/face masks FFP2_10 | 90 | 10 |

| Sample | Weight Proportion (%) | Household Prices (€/1 ton) | Factories Prices (€/1 ton) |

|---|---|---|---|

| Spruce | 100 | 34.56 | 17.23 |

| Spruce/face masks FFP2 | 95/5 | 166.84 | 83.16 |

| Spruce/face masks FFP2 | 90/10 | 142.90 | 71.22 |

| Beech | 100 | 60.82 | 30.31 |

| Beech/face masks FFP2 | 95/5 | 137.90 | 68.73 |

| Beech/face masks FFP2 | 90/10 | 82.85 | 41.29 |

| Sample | Weight Proportion (%) | Diameter (mm) | Length (mm) | Volume (mm3) | Density (kg·m−3) |

|---|---|---|---|---|---|

| Spruce | 100 | 5.96 ± 0.02 | 20.03 ± 0.93 | 558.52 | 1186.53 |

| Spruce/face masks FFP2 | 95/5 | 5.73 ± 0.09 | 22.14 ± 0.73 | 571.10 | 1132.32 |

| Spruce/face masks FFP2 | 90/10 | 5.88 ± 0.15 | 22.04 ± 0.33 | 598.73 | 1129.16 |

| Beech | 100 | 5.91 ± 0.03 | 22.15 ± 0.81 | 607.11 | 1199.62 |

| Beech/face masks FFP2 | 95/5 | 5.99 ± 0.05 | 21.07 ± 1.33 | 594.41 | 1078.38 |

| Beech/face masks FFP2 | 90/10 | 5.97 ± 0.03 | 21.47 ± 2.19 | 600.84 | 1163.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Čajová Kantová, N.; Belány, P.; Holubčík, M.; Čaja, A. Energy Consumption Depending on the Durability of Pellets Formed from Sawdust with an Admixture of FFP2 Masks. Energies 2022, 15, 4813. https://doi.org/10.3390/en15134813

Čajová Kantová N, Belány P, Holubčík M, Čaja A. Energy Consumption Depending on the Durability of Pellets Formed from Sawdust with an Admixture of FFP2 Masks. Energies. 2022; 15(13):4813. https://doi.org/10.3390/en15134813

Chicago/Turabian StyleČajová Kantová, Nikola, Pavol Belány, Michal Holubčík, and Alexander Čaja. 2022. "Energy Consumption Depending on the Durability of Pellets Formed from Sawdust with an Admixture of FFP2 Masks" Energies 15, no. 13: 4813. https://doi.org/10.3390/en15134813

APA StyleČajová Kantová, N., Belány, P., Holubčík, M., & Čaja, A. (2022). Energy Consumption Depending on the Durability of Pellets Formed from Sawdust with an Admixture of FFP2 Masks. Energies, 15(13), 4813. https://doi.org/10.3390/en15134813