DC Optimal Power Flow Model to Assess the Irradiance Effect on the Sizing and Profitability of the PV-Battery System

Abstract

:1. Introduction

1.1. Related Works

1.2. Study Problem

1.3. Study Contribution

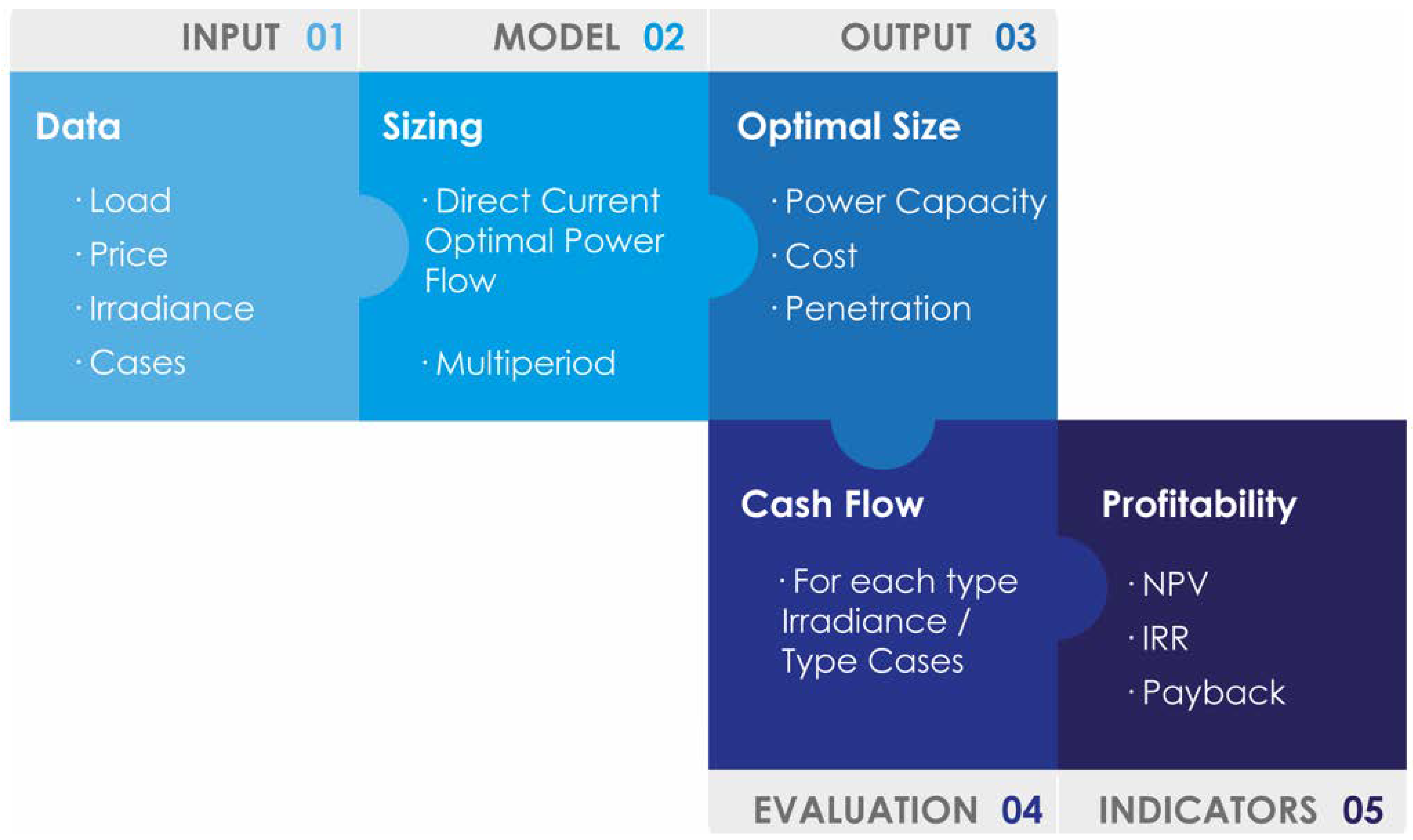

- A mathematical model for integrating and sizing photovoltaic panels and storage devices in a power system based on a multi-period DC optimal power flow is proposed.

- The investment variation when the energy demand is satisfied by using three different power systems—PV panels and batteries, PV panels with batteries connected to the grid (GD), and PV panels connected to the utility grid— is shown.

- The question of how the irradiance level impacts the investment and optimal capacity of the power system is considered.

- A methodology showing the profitability of integrating renewable energy in the long term, considering technical network constraints, is demonstrated

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PV | Photovoltaic |

| GD | Grid |

| COE | Cost of energy |

| NPV | Net present value |

| IRR | Internal rate of return |

| ACC | Annualized cost of the system |

| O&M | Operation and maintenance |

| PVB | Photovoltaic battery |

| SOC | State-of-charge |

| PSO | Particle swarm optimization |

| TAC | Total annual cost |

| EWR | Energy wastage rate |

| DHW | Domestic hot water |

| TNPC | Total net present cost |

| HRES | Hybrid renewable energy system |

| LPSP | Loss of power supply probability |

| MILP | Mixed integer linear programming |

| LCOE | Levelized cost of energy |

| OPEX | Operational expenditure |

| CAPEX | Capital expenditure |

References

- Khan, F.A.; Pal, N.; Saeed, S.H. Review of solar photovoltaic and wind hybrid energy systems for sizing strategies optimization techniques and cost analysis methodologies. Renew. Sustain. Energy Rev. 2018, 92, 937–947. [Google Scholar] [CrossRef]

- Lowe, R.J.; Drummond, P. Solar, wind and logistic substitution in global energy supply to 2050—Barriers and implications. Renew. Sustain. Energy Rev. 2022, 153, 111720. [Google Scholar] [CrossRef]

- Wei, Z.; Quan, Z.; Wu, J.; Li, Y.; Pou, J.; Zhong, H. Deep deterministic policy gradient-DRL enabled multiphysics-constrained fast charging of Lithium-Ion battery. IEEE Trans. Ind. Electron. 2022, 69, 2588–2598. [Google Scholar] [CrossRef]

- Wu, J.; Wei, Z.; Liu, K.; Quan, Z.; Li, Y. Battery-involved energy management for hybrid electric bus based on expert-assistance deep deterministic policy gradient algorithm. IEEE Trans. Veh. Technol. 2020, 69, 12786–12796. [Google Scholar] [CrossRef]

- Li, H.; Ren, Z.; Fan, M.; Li, W.; Xu, Y.; Jiang, Y.; Xia, W. A review of scenario analysis methods in planning and operation of modern power systems: Methodologies, applications, and challenges. Electr. Power Syst. Res. 2022, 205, 107722. [Google Scholar] [CrossRef]

- Mahesh, A.; Sandhu, K.S. Hybrid wind/photovoltaic energy system developments: Critical review and findings. Renew. Sustain. Energy Rev. 2015, 52, 1135–1147. [Google Scholar] [CrossRef]

- Sabattin, J.; Fuertes, G.; Alfaro, M.; Quezada, L.; Vargas, M. Optimization of large electric power distribution using a parallel genetic algorithm with dandelion strategy. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 1–13. [Google Scholar] [CrossRef]

- Lagos, C.; Carrasco, R.; Fuertes, G.; Gutiérrez, S.; Soto, I.; Vargas, M. Big data on decision making in energetic management of copper mining. Int. J. Comput. Commun. Control 2017, 12, 61–75. [Google Scholar] [CrossRef] [Green Version]

- Lagos, C.; Gutierrez, S.; Cordova, F.; Fuertes, G.; Carrasco, R. Data analysis methods related to energetic consumption in copper mining—A test case in Chile. In Proceedings of the IEEE International Conference on Computers Communications and Control, Oradea, Romania, 10–14 May 2016; pp. 244–249. [Google Scholar]

- Lagos, C.; Fuertes, G.; Carrasco, R.; Gutierrez, S.; Vargas, M.; Rodrigues, R. Facing the data analysis complexity for the energetic efficiency management at great copper mining, in Codelco Chuquicamata, Chile. In Proceedings of the IEEE International Conference on Automatica, Curico, Chile, 19–21 October 2016. [Google Scholar]

- Lagos, C.; Carrasco, R.; Soto, I.; Fuertes, G.; Alfaro, M.; Vargas, M. Predictive analysis of energy consumption in minining for making decisions. In Proceedings of the IEEE International Conference on Computers Communications and Control, Oradea, Romania, 8–12 May 2018; pp. 270–275. [Google Scholar]

- Ram, M.; Osorio-Aravena, J.C.; Aghahosseini, A.; Bogdanov, D.; Breyer, C. Job creation during a climate compliant global energy transition across the power, heat, transport, and desalination sectors by 2050. Energy 2022, 238, 121690. [Google Scholar] [CrossRef]

- Ram, M.; Bogdanov, D.; Aghahosseini, A.; Gulagi, A.; Oyewo, A.S.; Odai Mensah, T.N.; Child, M.; Caldera, U.; Sadovskaia, K.; Barbosa, L.D.S.N.S.; et al. Global energy transition to 100% renewables by 2050: Not fiction, but much needed impetus for developing economies to leapfrog into a sustainable future. Energy 2022, 246, 123419. [Google Scholar] [CrossRef]

- Le, H.T.T.; Sanseverino, E.R.; Nguyen, D.Q.; Di Silvestre, M.L.; Favuzza, S.; Pham, M.H. Critical assessment of feed-in tariffs and solar photovoltaic development in Vietnam. Energies 2022, 15, 556. [Google Scholar] [CrossRef]

- Carneiro, T.C.; de Carvalho, P.C.M.; Alves dos Santos, H.; Lima, M.A.F.B.; Braga, A.P.d.S. Review on photovoltaic power and solar resource forecasting: Current status and trends. J. Sol. Energy Eng. 2022, 144, 010801. [Google Scholar] [CrossRef]

- Wu, J.; Wei, Z.; Li, W.; Wang, Y.; Li, Y.; Sauer, D.U. Battery thermal-and health-constrained energy management for hybrid electric bus based on soft actor-critic DRL algorithm. IEEE Trans. Ind. Inform. 2021, 17, 3751–3761. [Google Scholar] [CrossRef]

- Chen, C.; Wei, Z.; Knoll, A.C. Charging optimization for Li-ion battery in electric vehicles: A review. IEEE Trans. Transp. Electrif. 2021, 1–23. [Google Scholar] [CrossRef]

- Ralon, P.; Taylor, M.; Ilas, A.; Diaz-Bone, H.; Kairies, K.-P. Electricity Storage and Renewables: Costs and Markets to 2030; IRENA: Abu Dhabi, United Arab Emirates, 2017; ISBN 9789292600389. [Google Scholar]

- Henao, M.; Espinosa Oviedo, M.; Bidding, J.J.; Henao, M.M.; José, J.; Oviedo, E. Bidding strategy for VPP and economic feasibility study of the optimal sizing of storage systems to face the uncertainty of solar generation modelled with IGDT. Energies 2022, 15, 953. [Google Scholar] [CrossRef]

- Fachrizal, R.; Shepero, M.; Åberg, M.; Munkhammar, J. Optimal PV-EV sizing at solar powered workplace charging stations with smart charging schemes considering self-consumption and self-sufficiency balance. Appl. Energy 2022, 307, 118139. [Google Scholar] [CrossRef]

- Talent, O.; Du, H. Optimal sizing and energy scheduling of photovoltaic-battery systems under different tariff structures. Renew. Energy 2018, 129, 513–526. [Google Scholar] [CrossRef]

- Molina Gómez, A.; Morozovska, K.; Laneryd, T.; Hilber, P. Optimal sizing of the wind farm and wind farm transformer using MILP and dynamic transformer rating. Int. J. Electr. Power Energy Syst. 2022, 136, 107645. [Google Scholar] [CrossRef]

- Kayal, P.; Chanda, C.K. Placement of wind and solar based DGs in distribution system for power loss minimization and voltage stability improvement. Int. J. Electr. Power Energy Syst. 2013, 53, 795–809. [Google Scholar] [CrossRef]

- Khosravi, M.; Afsharnia, S.; Farhangi, S. Optimal sizing and technology selection of hybrid energy storage system with novel dispatching power for wind power integration. Int. J. Electr. Power Energy Syst. 2021, 127, 106660. [Google Scholar] [CrossRef]

- Wang, Y.; Rousis, A.O.; Strbac, G. Resilience-driven optimal sizing and pre-positioning of mobile energy storage systems in decentralized networked microgrids. Appl. Energy 2022, 305, 117921. [Google Scholar] [CrossRef]

- Fares, D.; Fathi, M.; Mekhilef, S. Performance evaluation of metaheuristic techniques for optimal sizing of a stand-alone hybrid PV/wind/battery system. Appl. Energy 2022, 305, 117823. [Google Scholar] [CrossRef]

- Emrani, A.; Berrada, A.; Bakhouya, M. Optimal sizing and deployment of gravity energy storage system in hybrid PV-Wind power plant. Renew. Energy 2022, 183, 12–27. [Google Scholar] [CrossRef]

- Cao, Y.; Taslimi, M.S.; Dastjerdi, S.M.; Ahmadi, P.; Ashjaee, M. Design, dynamic simulation, and optimal size selection of a hybrid solar/wind and battery-based system for off-grid energy supply. Renew. Energy 2022, 187, 1082–1099. [Google Scholar] [CrossRef]

- Yadav, A.K.; Malik, H.; Chandel, S.S.; Khan, I.A.; Al Otaibi, S.; Alkhammash, H.I. Novel approach to investigate the influence of optimum tilt angle on minimum cost of energy-based maximum power generation and sizing of PV systems: A case study of diverse climatic zones in India. IEEE Access 2021, 9, 110103–110115. [Google Scholar] [CrossRef]

- Balsalobre-Lorente, D.; Shahzad, U.; Rehman, A.; Radulescu, M.; Dobrowolski, Z.; Drozdowski, G. Does the net present value as a financial metric fit investment in green energy security? Energies 2022, 15, 353. [Google Scholar] [CrossRef]

- Szafranko, E. Assessment of the economic efficiency of energy-saving projects, methodology based on simple and compound methods. Energy Sci. Eng. 2022, 10, 423–438. [Google Scholar] [CrossRef]

- Ould Bilal, B.; Sambou, V.; Ndiaye, P.A.; Kébé, C.M.F.; Ndongo, M. Optimal design of a hybrid solar–wind-battery system using the minimization of the annualized cost system and the minimization of the loss of power supply probability (LPSP). Renew. Energy 2010, 35, 2388–2390. [Google Scholar] [CrossRef]

- Wong, I.L.; Eames, P.C.; Perera, R.S. A review of transparent insulation systems and the evaluation of payback period for building applications. Sol. Energy 2007, 81, 1058–1071. [Google Scholar] [CrossRef]

- Yazdanpanah, M.A. Modeling and sizing optimization of hybrid photovoltaic/wind power generation system. J. Ind. Eng. Int. 2014, 10, 49. [Google Scholar] [CrossRef] [Green Version]

- Adefarati, T.; Bansal, R.C. Reliability and economic assessment of a microgrid power system with the integration of renewable energy resources. Appl. Energy 2017, 206, 911–933. [Google Scholar] [CrossRef]

- Sens, L.; Neuling, U.; Kaltschmitt, M. Capital expenditure and levelized cost of electricity of photovoltaic plants and wind turbines—Development by 2050. Renew. Energy 2022, 185, 525–537. [Google Scholar] [CrossRef]

- Rady, M.; Georges, J.P.; Lepage, F. Can energy optimization lead to economic and environmental waste in LPWAN architectures? ETRI J. 2021, 43, 173–183. [Google Scholar] [CrossRef]

- Rediske, G.; Michels, L.; Siluk, J.C.M.; Rigo, P.D.; Rosa, C.B.; Bortolini, R.J.F. Management of operation and maintenance practices in photovoltaic plants: Key performance indicators. Int. J. Energy Res. 2022, 46, 7118–7136. [Google Scholar] [CrossRef]

- Semaoui, S.; Hadj Arab, A.; Bacha, S.; Azoui, B. The new strategy of energy management for a photovoltaic system without extra intended for remote-housing. Sol. Energy 2013, 94, 71–85. [Google Scholar] [CrossRef]

- Sadeghi, D.; Amiri, N.; Marzband, M.; Abusorrah, A.; Sedraoui, K. Optimal sizing of hybrid renewable energy systems by considering power sharing and electric vehicles. Int. J. Energy Res. 2022, 46, 8288–8312. [Google Scholar] [CrossRef]

- Serageldin, A.A.; Abdeen, A.; Ahmed, M.M.S.; Radwan, A.; Shmroukh, A.N.; Ookawara, S. Solar chimney combined with earth to-air heat exchanger for passive cooling of residential buildings in hot areas. Sol. Energy 2020, 206, 145–162. [Google Scholar] [CrossRef]

- Schopfer, S.; Tiefenbeck, V.; Staake, T. Economic assessment of photovoltaic battery systems based on household load profiles. Appl. Energy 2018, 223, 229–248. [Google Scholar] [CrossRef]

- Ramli, M.A.M.; Bouchekara, H.R.E.H.; Alghamdi, A.S. Optimal sizing of PV/wind/diesel hybrid microgrid system using multi-objective self-adaptive differential evolution algorithm. Renew. Energy 2018, 121, 400–411. [Google Scholar] [CrossRef]

- Lima, D.A.; Feijão, V.R. Stochastic approach for economic viability of photovoltaic systems with battery storage for big electricity consumers in the regulated marketin Brazil. Electr. Power Syst. Res. 2022, 205, 107744. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Keshavarz, A. CCHP evaluation criteria. Comb. Cool. Heat. Power 2015, 93–102. [Google Scholar] [CrossRef]

- Han, X.; Garrison, J.; Hug, G. Techno-economic analysis of PV-battery systems in Switzerland. Renew. Sustain. Energy Rev. 2022, 158, 112028. [Google Scholar] [CrossRef]

- Arbab, N.; Grabosky, J.; Leopold, R. Economic assessment of urban ash tree management options in New Jersey. Sustainability 2022, 14, 2172. [Google Scholar] [CrossRef]

- Liu, K.; Sun, B.; Gao, X.; Zhang, Y.; Sun, W.; Feng, Q.; Yang, W. Optimal sizing of the stand-alone photovoltaic system for a solar-powered translational sprinkler irrigation machine considering the loss of power supply probability. Math. Probl. Eng. 2022, 2022, 6133969. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Chen, Y.; Wang, D.; Li, Y.; Yuan, X. Design optimization of the solar heating system for office buildings based on life cycle cost in Qinghai-Tibet plateau of China. Energy 2022, 246, 123288. [Google Scholar] [CrossRef]

- Qiu, T.; Wang, L.; Lu, Y.; Zhang, M.; Qin, W.; Wang, S.; Wang, L. Potential assessment of photovoltaic power generation in China. Renew. Sustain. Energy Rev. 2022, 154, 111900. [Google Scholar] [CrossRef]

- Rezaei, O.; Moghaddam, H.A.; Papari, B. A fast sliding-mode-based estimation of state-of-charge for Lithium-ion batteries for electric vehicle applications. J. Energy Storage 2022, 45, 103484. [Google Scholar] [CrossRef]

- Sun, H.; Ebadi, A.G.; Toughani, M.; Nowdeh, S.A.; Naderipour, A.; Abdullah, A. Designing framework of hybrid photovoltaic-biowaste energy system with hydrogen storage considering economic and technical indices using whale optimization algorithm. Energy 2022, 238, 121555. [Google Scholar] [CrossRef]

- Al-Masri, H.M.K.; Al-Sharqi, A.A.; Magableh, S.K.; Al-Shetwi, A.Q.; Abdolrasol, M.G.M.; Ustun, T.S. Optimal allocation of a hybrid photovoltaic biogas energy system using multi-objective feasibility enhanced particle swarm algorithm. Sustainability 2022, 14, 685. [Google Scholar] [CrossRef]

- Medani, K.b.o.; Sayah, S.; Bekrar, A. Whale optimization algorithm based optimal reactive power dispatch: A case study of the Algerian power system. Electr. Power Syst. Res. 2018, 163, 696–705. [Google Scholar] [CrossRef]

- Zhang, S.; Bristow, N.; Wyn David, T.; Elliott, F.; O’Mahony, J.; Kettle, J. Development of an organic photovoltaic energy harvesting system for wireless sensor networks; application to autonomous building information management systems and optimisation of OPV module sizes for future applications. Sol. Energy Mater. Sol. Cells 2022, 236, 111550. [Google Scholar] [CrossRef]

- Farh, H.M.H.; Al-Shamma’a, A.A.; Al-Shaalan, A.M.; Alkuhayli, A.; Noman, A.M.; Kandil, T. Technical and economic evaluation for off-grid hybrid renewable energy system using novel bonobo optimizer. Sustainability 2022, 14, 1533. [Google Scholar] [CrossRef]

- Dong, J.; Dou, Z.; Si, S.; Wang, Z.; Liu, L. Optimization of capacity configuration of wind–solar–diesel–storage using improved sparrow search algorithm. J. Electr. Eng. Technol. 2021, 17, 1–14. [Google Scholar] [CrossRef]

- Yuan, X.; Yang, F.; Xu, J.; Liu, H. Configuration optimization of wind-solar-storage system considering demand response. In Proceedings of the IEEE International Conference on Electric Power and Energy Conversion Systems, Kitakyushu, Japan, 23–25 April 2018; pp. 3224–3229. [Google Scholar]

- Torres-Madroñero, J.L.; Nieto-Londoño, C.; Sierra-Pérez, J. Hybrid energy systems sizing for the Colombian context: A genetic algorithm and particle swarm optimization Approach. Energies 2020, 13, 5648. [Google Scholar] [CrossRef]

- Mahmoudi, S.M.; Maleki, A.; Rezaei Ochbelagh, D. A novel method based on fuzzy logic to evaluate the storage and backup systems in determining the optimal size of a hybrid renewable energy system. J. Energy Storage 2022, 49, 104015. [Google Scholar] [CrossRef]

- Sanyal, A.; Kumar Goswami, A.; Kumar Tiwari, P. Risk and cost benchmarking of solar energy technology based on celestial phenomenon for a power market integration. Sustain. Energy Technol. Assess. 2022, 49, 101650. [Google Scholar] [CrossRef]

- Poonia, S.; Jat, N.K.; Santra, P.; Singh, A.K.; Jain, D.; Meena, H.M. Techno-economic evaluation of different agri-voltaic designs for the hot arid ecosystem India. Renew. Energy 2022, 184, 149–163. [Google Scholar] [CrossRef]

- Xiao, X.; Sun, J.; Yang, J. Operation and maintenance(O&M) for data center: An intelligent anomaly detection approach. Comput. Commun. 2021, 178, 141–152. [Google Scholar] [CrossRef]

- García-Muñoz, F.; Díaz-González, F.; Corchero, C. A novel algorithm based on the combination of AC-OPF and GA for the optimal sizing and location of DERs into distribution networks. Sustain. Energy Grids Netw. 2021, 27, 100497. [Google Scholar] [CrossRef]

- García-Muñoz, F.; Díaz-González, F.; Corchero, C. A two-stage stochastic programming model for the sizing and location of DERs considering electric vehicles and demand response. Sustain. Energy Grids Netw. 2022, 30, 100624. [Google Scholar] [CrossRef]

- Hung, D.Q.; Mithulananthan, N.; Lee, K.Y. Determining PV penetration for distribution systems with time-varying load models. IEEE Trans. Power Syst. 2014, 29, 3048–3057. [Google Scholar] [CrossRef]

- Atwa, Y.M.; El-Saadany, E.F.; Salama, M.M.A.; Seethapathy, R. Optimal renewable resources mix for distribution system energy loss minimization. IEEE Trans. Power Syst. 2010, 25, 360–370. [Google Scholar] [CrossRef]

- NREL National Renewable Energy Laboratory. Available online: https://www.nrel.gov/ (accessed on 24 February 2022).

- OMIE Energy Iberian Market Operator, Anual Spot Market Prices. Available online: https://www.omie.es/ (accessed on 26 May 2022).

- Ren, Z.; Grozev, G.; Higgins, A. Modelling impact of PV battery systems on energy consumption and bill savings of Australian houses under alternative tariff structures. Renew. Energy 2016, 89, 317–330. [Google Scholar] [CrossRef]

- Weniger, J.; Tjaden, T.; Quaschning, V. Sizing of residential PV battery systems. Energy Procedia 2014, 46, 78–87. [Google Scholar] [CrossRef] [Green Version]

| Sets: | |

|---|---|

| : Set of buses. | |

| : Set of time periods. | |

| : Set of lines, such that | |

| Parameters: | |

| : Minimum active power output of bus at time [%]. | |

| : Maximum active power output of bus at time [%]. | |

| : Active load of bus at time [MW]. | |

| : Allowed maximum line power between buses and [MVA]. | |

| : Minimum state of battery charge [%]. | |

| : Maximum state of battery charge [%]. | |

| : Rated generator power [MW]. | |

| : Rated battery power [MW]. | |

| φ | : Battery efficiency [%]. |

| M | : Maximum charge/discharge for the battery during a period [MWh]. |

| : Operational and maintenance cost for the generation of bus [€k/MW/yr]. | |

| : Operational and maintenance cost for the battery of bus [€k/MWh]. | |

| : Fixed installation cost of storage [€k]. | |

| : Variable installation cost of storage in bus [€k/MWh]. | |

| : Fixed installation cost of the generator [€k]. | |

| : Variable installation cost of the generator in bus [€k/MW]. | |

| : Operational cost of the storage units [€k]. | |

| : Operational cost of generation sources [€k]. | |

| : Energy price from the grid [€k]. | |

| : Number of panels. | |

| : Fill factor. | |

| : Cell temperature [°C]. | |

| : Ambient temperature [°C]. | |

| : Current temperature coefficient [A/°C]. | |

| : Voltage temperature coefficient [V/°C]. | |

| : Nominal operating temperature [°C]. | |

| : Irradiance [MW/ ]. | |

| : Open-circuit voltage [V]. | |

| : Short-circuit current [A]. | |

| : Voltage maximum power point [V]. | |

| : Current maximum power point [A]. | |

| Variables: | |

| : Active generator power of bus at period [MW]. | |

| : Active power provided by the grid of bus at period [MW]. | |

| : Active line power between buses and at period [MW]. | |

| : Power absorbed for the storage of bus at period [MW]. | |

| : Power injected for the storage of bus at period [MW]. | |

| : State of battery charge in bus at period [MWh]. | |

| : Active power capacity of the generator in bus [MW]. | |

| : Storage power capacity of the battery in bus [MWh]. | |

| : Binary variable: if the storage charge is at period ; otherwise. |

| Case 1: PV + BT | |||||

|---|---|---|---|---|---|

| Place | System [%] | Total Cost [k€] | |||

| 1 | 6.08 | 47.04 | 20.5 | 100% | 18,130.6 |

| 2 | 5.97 | 52.58 | 39.91 | 100% | 23,619.1 |

| 3 | 5.49 | 103.28 | 28.99 | 100% | 24,032.0 |

| 4 | 3.86 | 254.89 | 41.46 | 100% | 37,171.0 |

| 5 | 3.22 | 234.38 | 68.68 | 100% | 43,024.1 |

| Case 2: PV + BT + GD | |||||

|---|---|---|---|---|---|

| Place | System [%] | Total Cost [k€] | |||

| 1 | 6.08 | 22.23 | 15.19 | 99% | 15,868.6 |

| 2 | 5.97 | 43.26 | 17.69 | 97% | 18,840.7 |

| 3 | 5.49 | 51.07 | 18.72 | 97% | 19,549.6 |

| 4 | 3.86 | 90.74 | 19.12 | 93% | 24,979.3 |

| 5 | 3.22 | 120.97 | 17.7 | 89% | 28,788.7 |

| Case 3: PV + GD | |||||

|---|---|---|---|---|---|

| Place | System [%] | Total Cost [k€] | |||

| 1 | 6.08 | 18.63 | 0 | 50% | 62,259.7 |

| 2 | 5.97 | 38.92 | 0 | 50% | 65,369.9 |

| 3 | 5.49 | 42.52 | 0 | 49% | 68,136.3 |

| 4 | 3.86 | 72.59 | 0 | 48% | 70,777.2 |

| 5 | 3.22 | 76.28 | 0 | 45% | 71,708.5 |

| Place 1 | |||

|---|---|---|---|

| Indicator | PV + GD | PV + BT | PV + BT + GD |

| ΔNPV | 234,160.9 | 506,607.6 | 528,437.8 |

| Savings | 39% | 85% | 89% |

| IRR | 146% | 138% | 250% |

| Payback period | 0.69 | 0.74 | 0.4 |

| Place 5 | |||

|---|---|---|---|

| Indicator | PV + GD | PV + BT | PV + BT + GD |

| ΔNPV | 141,075.0 | 307,224.0 | 392,745.8 |

| Savings | 24% | 52% | 66% |

| IRR | 38% | 31% | 56% |

| Payback period | 2.69 | 3.29 | 1.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Muñoz, F.; Alfaro, M.; Fuertes, G.; Vargas, M. DC Optimal Power Flow Model to Assess the Irradiance Effect on the Sizing and Profitability of the PV-Battery System. Energies 2022, 15, 4408. https://doi.org/10.3390/en15124408

García-Muñoz F, Alfaro M, Fuertes G, Vargas M. DC Optimal Power Flow Model to Assess the Irradiance Effect on the Sizing and Profitability of the PV-Battery System. Energies. 2022; 15(12):4408. https://doi.org/10.3390/en15124408

Chicago/Turabian StyleGarcía-Muñoz, Fernando, Miguel Alfaro, Guillermo Fuertes, and Manuel Vargas. 2022. "DC Optimal Power Flow Model to Assess the Irradiance Effect on the Sizing and Profitability of the PV-Battery System" Energies 15, no. 12: 4408. https://doi.org/10.3390/en15124408

APA StyleGarcía-Muñoz, F., Alfaro, M., Fuertes, G., & Vargas, M. (2022). DC Optimal Power Flow Model to Assess the Irradiance Effect on the Sizing and Profitability of the PV-Battery System. Energies, 15(12), 4408. https://doi.org/10.3390/en15124408