Marine Exhaust Gas Treatment Systems for Compliance with the IMO 2020 Global Sulfur Cap and Tier III NOx Limits: A Review

Abstract

1. Introduction

1.1. General Concepts

1.2. Literature Review

1.3. Motivation, Methodology and Innovative Aspects of the Present Work

2. Operational Principles and Key Characteristics of Marine Exhaust Gas Treatment Systems

2.1. General Description

- Aqueous—wet exhaust gas treatment and SOx and PM curtailment systems, or wet scrubbers.

- Dry flue gas treatment and SOx mainly reduction systems (dry scrubbers).

- The aqueous SOx and PM mitigation systems are divided into three categories [30]:

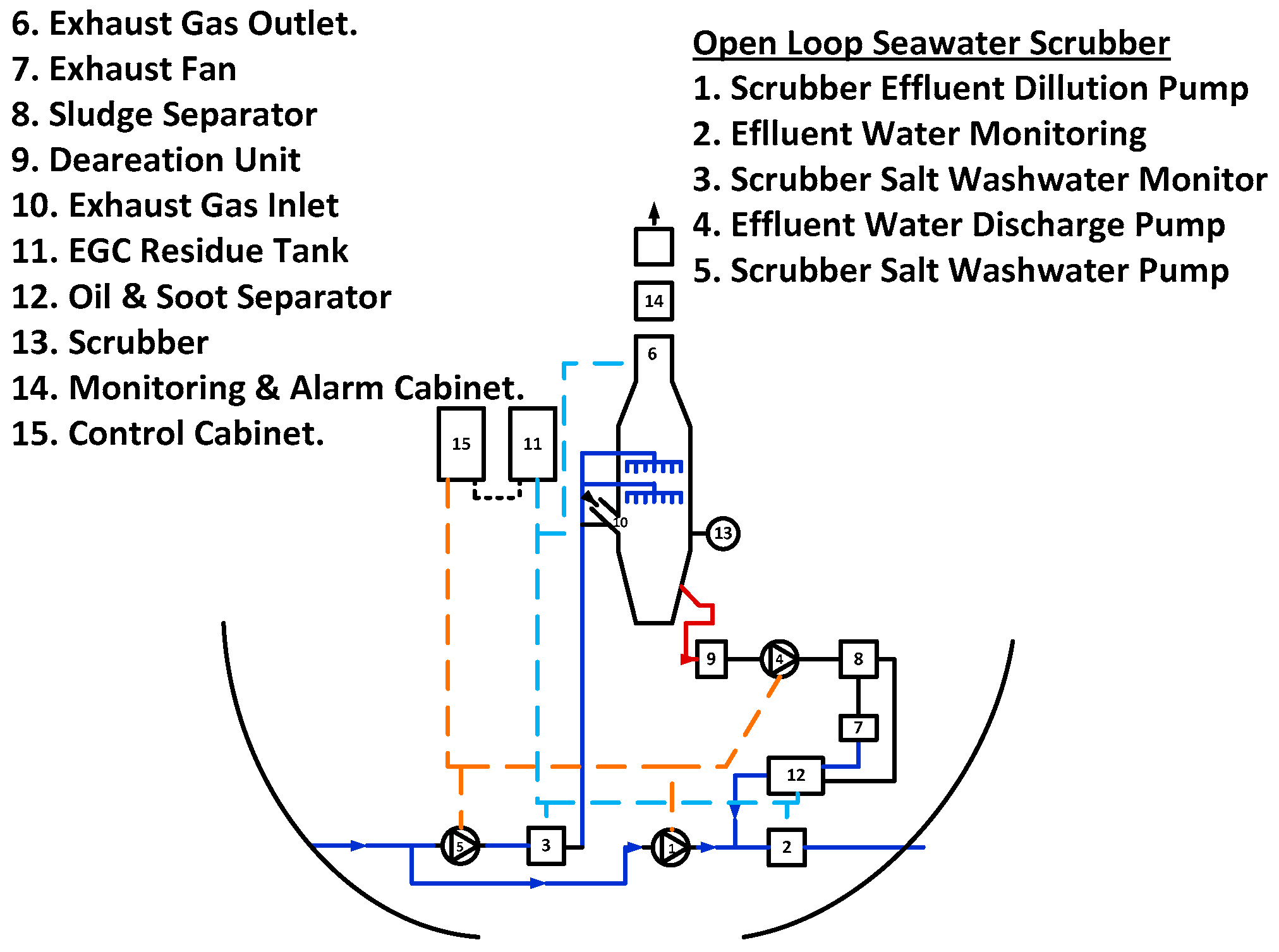

- Open circuit or open-loop aqueous scrubbing systems, usually based on the use of seawater as flue gas scrubbing and SOx and PM mitigating medium in specially designed counterflow heat exchangers that are called scrubbers [31].

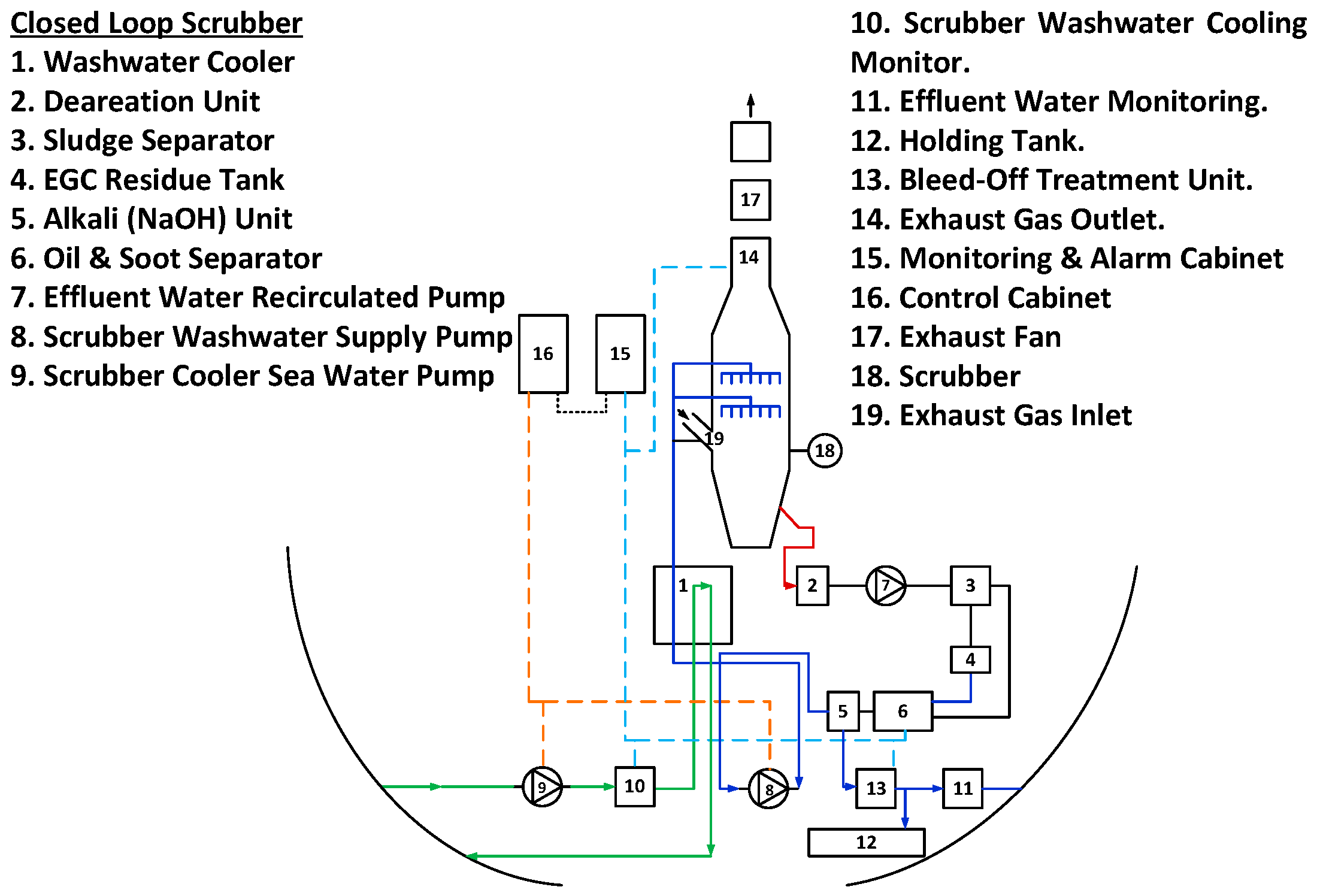

- Closed circuit or closed-loop aqueous scrubbing systems usually based on the use of an aqueous solution of fresh water and alkaline medium (usually sodium hydroxide (caustic soda), NaOH) as exhaust gas scrubbing, and SOx and PM mitigation medium in specially designed counterflow heat exchangers [32].

- Aqueous hybrid scrubbing systems which can function as either open-loop systems with seawater or closed-loop systems with aqueous solution of NaOH [33].

- The aqueous exhaust gas treatment and scrubbing systems (scrubbers) that operate as sub-systems of exhaust gas recirculation (EGR) installations in marine engines. As known, EGR is used in marine engines for the reduction of the in-cylinder NOx formation rate. Hence, the integrated EGR systems equipped with wet scrubbers are primarily used to mitigate NOx formation inside the cylinders through exhaust gas recirculation, and they employ wet scrubbers to curtail SOx and PM emissions. The employment of the aqueous gas treatment systems of this category, besides SOx and PM mitigation, result in the curtailment of the fouling and corrosion phenomena of the marine diesel due to aqueous exhaust gas cleaning [34,35].

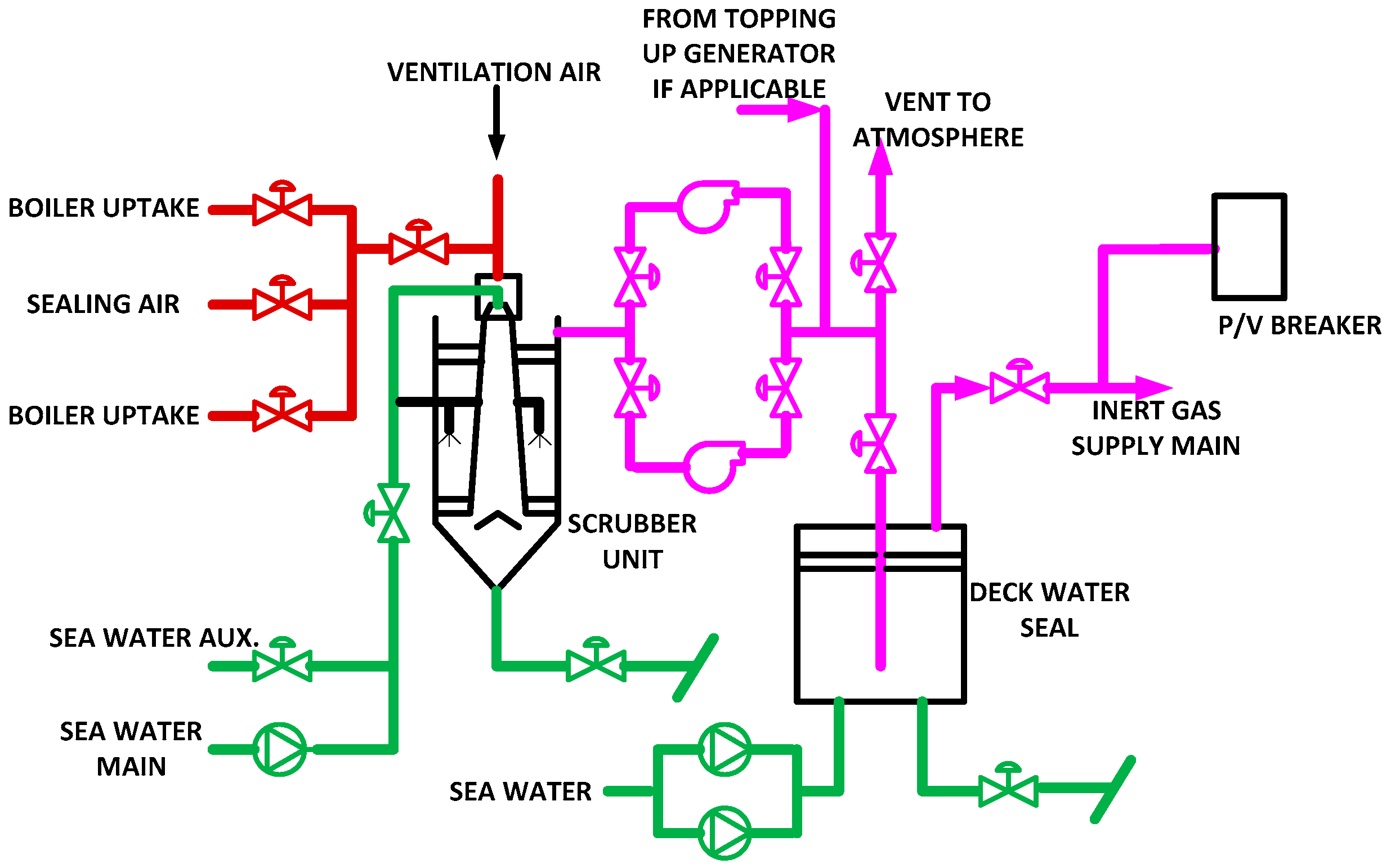

- Inert gas aqueous systems that use small-size aqueous SOx and PM mitigation systems to clean and convert exhaust gas to inert gas can further be used for tanker evacuation [36].

2.2. Wet Exhaust Gas Cleaning and SOx Reduction Systems with Seawater or with Caustic Soda (SOx Scrubbers)

- The preservation of exhaust gas buoyancy phenomenon (i.e., the avoidance of excess temperature reduction of exhaust gases during their scrubbing process by the aqueous medium).

- The simultaneous minimization of the space captured and the weight and the energy consumption by the SOx and PM mitigation aqueous gas treatment system.

- The minimization of the pressure drop of the exhaust gas stream.

- Hot corrosion avoidance of the SOx scrubber constructional elements from exhaust gases that contain sulfur and possibly acid sulfate roots.

- The avoidance of exhaust gas vapor condensation and appearance of water droplets at the SOx and PM scrubber outlet.

- The effluent water from the scrubber which is either ejected to the sea or guided to an on-board wastewater treatment plant.

- The heavy residues that are rejected from the on-board wastewater treatment plant or from the freshwater recirculation process.

- The flue gases that contain the remaining pollutant species which were not captured from the aqueous flue gas treatment process.

- The impure water rejection rate from a SOx scrubber with seawater as the scrubbing medium is 45 m3/MWh.

- The impure water rejection rate from a SOx scrubber with caustic soda varies from 0.1 to 0.3 m3/MWh (The indicative recirculation rate is 20 m3/MWh).

- Exhaust gases that are generated from marine diesel engines (Exhaust gases are produced from the combustion of intake air with fuel. Lubricant oil can also be present in exhaust gases depending on the engine status and the operational conditions).

- Seawater or fresh water with NaOH which are used for scrubbing exhaust gases.

- Impure water which may contain combustion products and chemical additives.

- A total of 2 kg CO2/GJ of fuel heating energy can be produced from the neutralization/inactivation process.

- A total of 1.6 kg CO2/GJ of fuel heating energy can be generated from the flue gases scrubbing process in the aqueous scrubber.

2.3. SOx and PM Mitigation Wet Scrubbers Integrated in EGR Systems

2.4. Inert Gas SOx Scrubbers

2.5. Dry Exhaust Gas Treatment and SOx Capture Systems

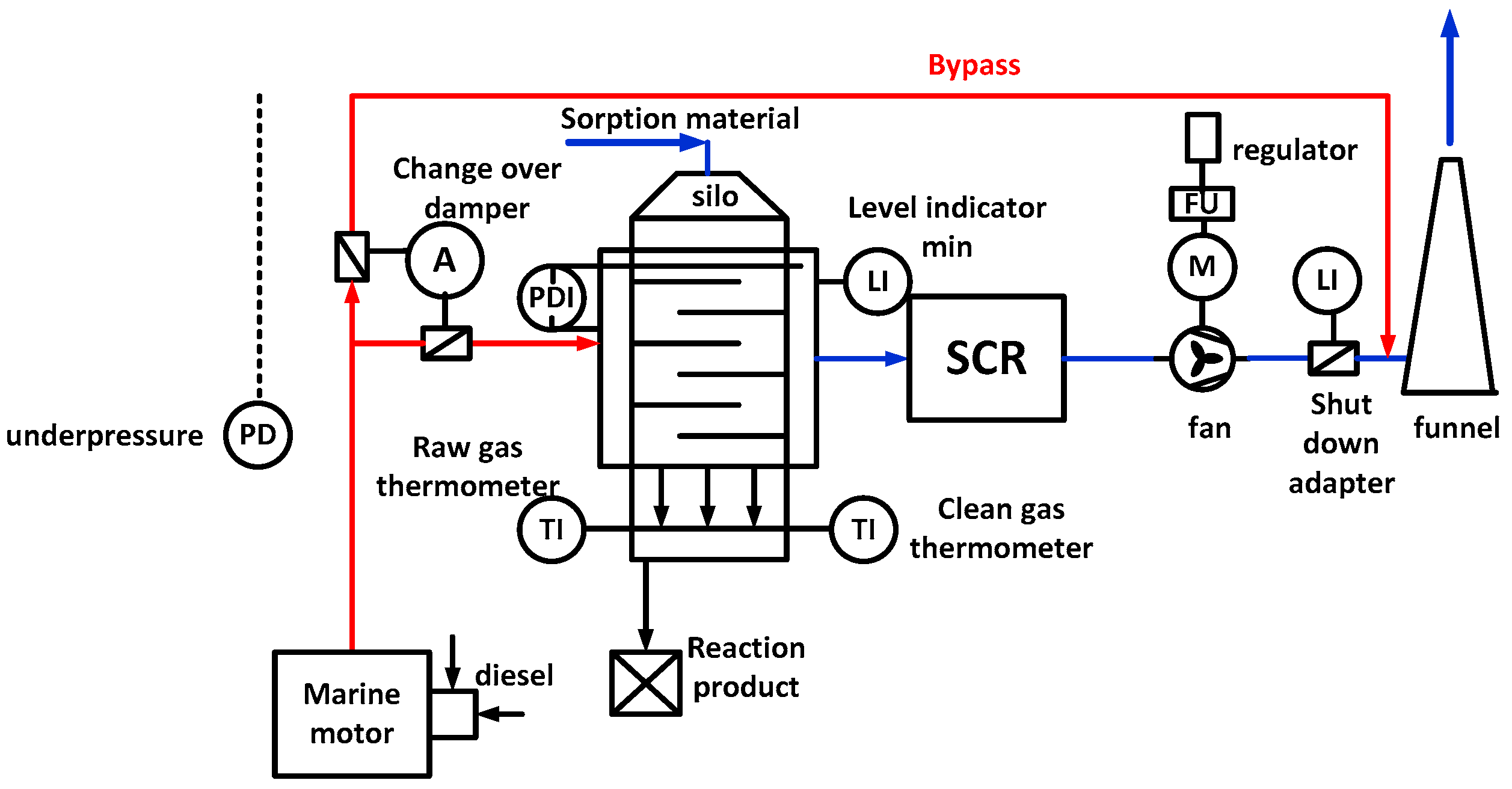

2.6. Marine Selective Catalytic Reduction (SCR) Systems

3. Applications of Marine Exhaust Gas Treatment Systems

3.1. Wet Closed-Loop and Open-Loop SOx Scrubbers

- Quantity of 11 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 2.9% sulfur in fuel oil.

- Quantity of 8 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 2.4% sulfur in fuel oil.

- Quantity of 4 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 1.4% sulfur in fuel oil.

- Quantity of 1 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 0.9% sulfur in fuel oil.

3.2. Wet SOx and PM Scrubbers Integrated in Marine EGR Systems

3.3. Inert Gas Wet SOx Scrubbers

3.4. Dry SOx Scrubbers

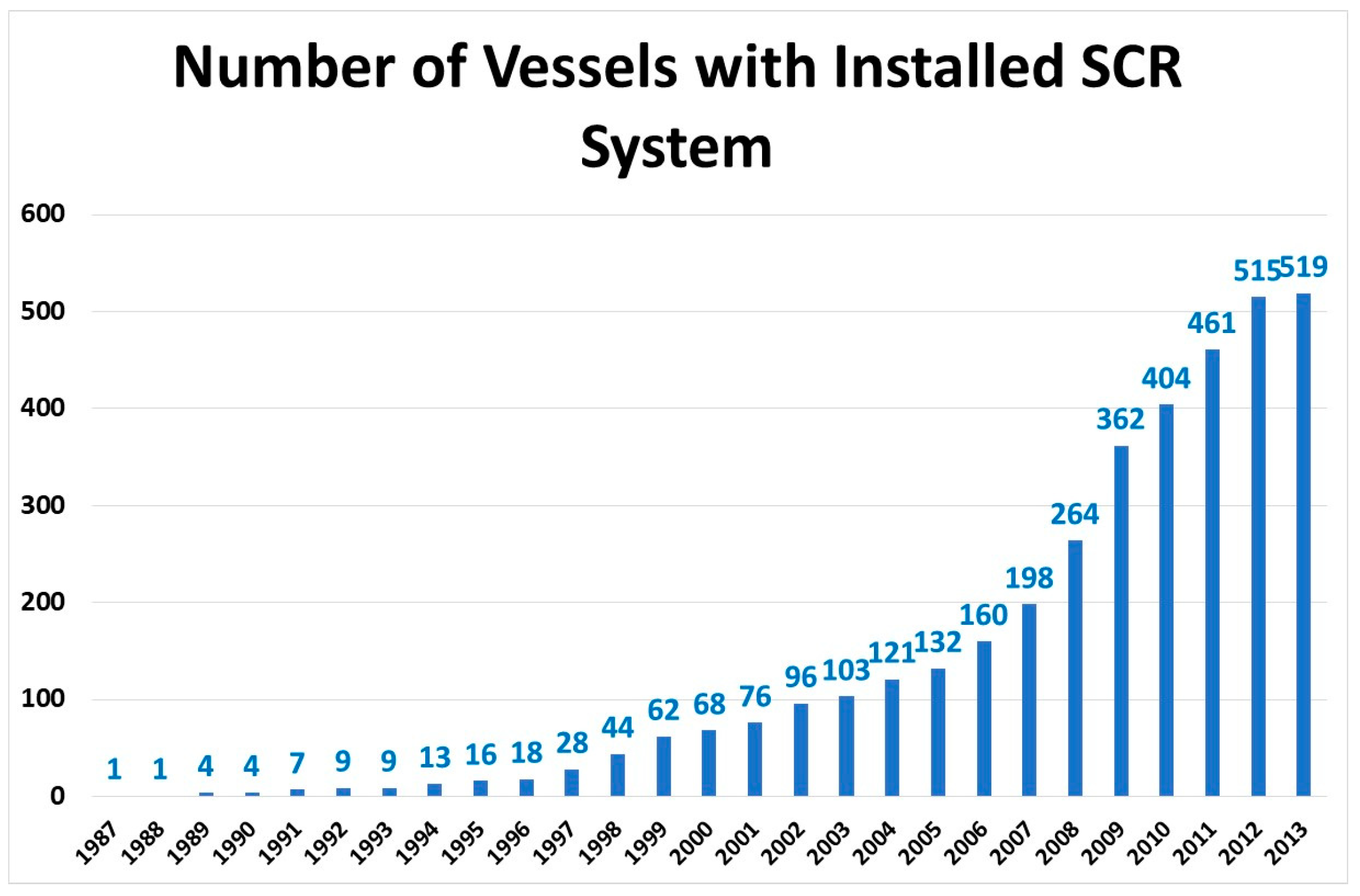

3.5. Marine Selective Catalytic Reduction (SCR) Systems

4. Performance Characteristics of Marine Exhaust Gas Treatment Systems

4.1. Wet Closed-Loop and Open-Loop SOx Scrubbers

- The effectiveness of the aqueous hybrid SOx scrubber is 3% sulfur in fuel without limit. This value is confirmed by three major manufacturers. The effectiveness without limit demands overestimated the liquid cleaning system, the free water flow rate, and the high SOx capturing chemical consumption.

- The effectiveness of the seawater SOx scrubber is 3.5% sulfur in fuel. This value is confirmed by two major manufacturers. Both manufacturers declare 3.5% sulfur in fuel as maximum percentage.

- The effectiveness of the caustic soda SOx scrubber is 3.5% up to 5% sulfur in fuel. This value is confirmed by two major manufacturers.

- Metal oxides and sulfates: These are generated mainly from the fuel type that is used, but also in the quantity of these emissions, which will appear in the effluent water discharge from an aqueous SOx scrubber and can contribute the engine lubricant oil or the engine and scrubber corrosion products. In aqueous scrubbers, the scrubbing water of the exhaust gases can contain specific species that contribute to the production of metal oxides and sulfates. This phenomenon is not considered to be another source of pollution, and the specific subject is generally not expected to be especially important. However, the background values should be taken into consideration when the concentration of dangerous species in the effluent discharged water is monitored.

- Carbon (Soot): Soot and carbon particles are considered as stable species of the exhaust gases. The smaller soot particles (with diameter smaller than 2.5 μm) cause serious respiratory problems in humans. A previous study showed that the carbonaceous soot was comprised mainly of soot particles of intermediate and high diameter which are not easily inhaled by humans. However, more studies are required for the determination of the soot particle size distribution that can be captured from aqueous exhaust gas scrubbers.

- Other organic species: These typically contain polyaromatic hydrocarbons (PAHs) and PAHs products, aldehydes, alkanes, alkenes and a small quantity of unburned fuel or unburned fuel constituents. Many species of the PAHs and of their products, especially the nitric PAHs, has been verified as responsible for genetic mutations and carcinogenesis. Hence, the monitoring of the concentrations of the PAHs and their products in the scrubber-discharged impure water is necessary.

4.2. Wet Scrubbers Integrated in Marine EGR Systems

4.3. Inert Gas Wet Scrubbers

4.4. Dry SOx Scrubbers

4.5. Selective Catalytic Reduction—SCR

5. Economic Evaluation of Marine Exhaust Gas Treatment Systems

5.1. Wet Open-Loop and Closed-Loop Scrubbers

- Use of a seawater SOx scrubber.

- Change from heavy fuel oil with 2.7% sulfur to marine fuel with 1.5% sulfur.

- Change from heavy fuel oil with 2.7% sulfur to marine fuel with 0.5% sulfur.

- Use of a seawater SOx scrubber: 75%.

- Change from heavy fuel oil with 2.7% sulfur to marine fuel with 1.5% sulfur: 44%.

- Change from heavy fuel oil with 2.7% sulfur to marine fuel with 0.5% sulfur: 81%.

- Intrinsic variations of the retrofit cost due to the special characteristics of each vessel.

- The maintenance levels of the mechanical equipment.

- The operating conditions and the loading factors of each vessel.

- Variations in the sulfur contents of all examined fuels.

5.2. Wet SOx Scrubbers Integrated in EGR Systems

5.3. Wet Inert Gas Scrubbers

5.4. Dry SOx Scrubbers

- For 1 MW power engine, the investment cost is USD 0.5 million.

- For 20 MW power engine, the investment cost is USD 4 million.

- For 1 MW power engine, the annual operation cost is USD 43,500.

- For 20 MW power engine, the annual operation cost is USD 477,200.

5.5. SCR Systems

6. Overall Comparative Assessment, Advantages, and Disadvantages

- Seawater scrubbers or open-loop scrubbers: These are heavy and bulky heat, mass, and momentum exchange systems between the exhaust gas stream and the seawater stream. Due to is alkalinity, the seawater stream can capture large quantities of SOx, PM, and heavy metals from the stream of exhaust gases that are generated from the on-board combustion systems. The SOx and PM mitigation efficiency depend heavily on the alkalinity of the local seawater, considering also that seawater alkalinity varies significantly around the world. The on-board installation of seawater scrubbers requires the existence of an impure scrubber-discharged water processing unit for the capture and on-board storage of the heavy residues and of the processed effluent water. Marine seawater scrubbers are bulky installations characterized by high complexity and parasitic losses due to the operation of their auxiliary equipment. Moreover, their operation is associated with significant corrosion to the engines and, in general, to the machinery equipment in case of seawater leakages due to scrubber cracks. Hence, caution is required during their installation and their operation with continuous monitoring of the exhaust gas stream and of the seawater stream to avoid potential operational problems or heavy seawater leakage.

- Freshwater scrubbers or closed-loop scrubbers: These marine exhaust gas treatment systems operate under the same principle as seawater scrubbers. In this case, the variable alkalinity of the seawater is replaced by the almost constant alkalinity of the NaOH aqueous solution that circulates in the installation in a closed-loop. These systems require transport and on-board storage of fresh water and NaOH, and they indicate higher auxiliary requirements and thus parasitic losses compared to the open-loop seawater scrubbers. Closed-loop freshwater scrubbers have lower discharged impure water processing requirements compared to the open-loop systems because the quantity of effluent water discharged from the closed-loop scrubbers is lower compared to seawater scrubbers. Another virtue of a caustic soda scrubber is that the alkalinity of the scrubbing medium can be adjusted through the adjustment of the NaOH dosage unlike the open-loop scrubbers where their efficiency is exposed to the variable seawater alkalinity. Thus, closed-loop scrubbers can achieve higher SOx capture rates compared to open-loop scrubbers, and they can also be highly effective in reducing SOx emissions, even in the case of high sulfur marine fuels. Moreover, open-loop and closed-loop scrubbers require continuous monitoring of the pressure and temperature of the exhaust gas stream and the scrubbing medium stream to ensure reliable operation and to avoid leakage or excessive fouling of the scrubbers, which can create serious back-pressure issues and significant deterioration of the specific fuel oil consumption of the on-board engines.

- Hybrid scrubbers: These systems can operate as either open-loop or closed-loop scrubbers; they are large, heavy, and bulky installations, where the exhaust gas stream exchanges heat, mass, and momentum with the alkaline medium, which depending on the mode of hybrid scrubber operation can be seawater or caustic soda. Owing to their high complexity, high parasitic losses and high investment and operation cost, hybrid scrubbers have more limited application compared to open-loop and to closed-loop scrubbers.

- Aqueous SOx and PM mitigation scrubbers that are integrated in EGR installations: These aqueous scrubbers are mainly used by one major marine engine manufacturer as heat exchangers to reduce the temperature of the recirculated exhaust gases before they are introduced back to the engine intake for curtailing in-cylinder NOx formation rate. These integrated scrubbers cause not only a reduction of recirculated gas temperature but also manage to capture significant quantities of SOx and PM emissions carried in the recirculated gas stream. For this reason, they are proposed by a large marine engine manufacturer as a technology capable of mitigating not only NOx emissions but also SOx and PM emissions. It should be emphasized, however, that the total SOx emissions that are captured with the integrated scrubber, is considerably lower compared to a closed-loop or an open-loop scrubber because in the EGR scrubber the scrubbing medium interacts only with a portion ranging from 20% to 40% of the total exhaust gases generated from a marine engine at each operating point.

- Aqueous inert gas scrubbers: These scrubbers can process and capture SOx and PM emissions from inert gases generated from the evacuation of oil tankers or chemical tankers, and for this reason they are suitable only for these limited applications.

- Dry scrubbers: The operation of these systems is based on the processing of the exhaust gas stream from a large dry surface SOx and PM capture medium (usually, limestone). Dry exhaust gas treatment systems are used extensively for the processing of industrial flue gases in land-based installations, but their use in the maritime industry (if any) is very limited due to the problems associated with the supply and on-board storage of the limestone and the packing material.

- SCR systems: The efficiency of SCR systems is based on reaching the proper exhaust gas temperature at the entrance of the SCR reactor because the chemical reactions on the catalyst are optimized for a specific temperature frame. The control of exhaust gas temperature for optimized SCR system operation requires the installation and operation of exhaust gas temperature control devices in case the exhaust gas temperature is not suitable for optimized SCR operation such as in the case of low engine loads of a main marine two-stroke diesel engine. Today, marine SCR systems are highly effective in mitigating NOx emissions, and in many cases, they can practically eliminate NOx emissions, thus providing the opportunity for a vessel to comply with the strictest IMO NOx Tier III limits. The main drawbacks of the marine SCR systems are their relatively high installation and operation cost, which is burdened by the installation of exhaust gas temperature control devices and by the supply and on-board handling cost of the urea.

7. Conclusions

- SOx and PM scrubbers are the only possible current solution for complying with the IMO global sulfur cap in the maritime industry in case conventional high-sulfur fuels continue to be needed for marine combustion systems.

- Contemporary open-loop and closed-loop scrubbers are high effective in reducing SOx and PM emissions, and they can practically eliminate SOx emissions.

- In most vessel applications, open-loop seawater scrubbers are used because they are most cost-effective compared to closed-loop scrubbers, but their effectiveness varies with seawater salinity. On the other hand, closed-loop scrubbers are the most effective systems in reducing SOx emissions mainly due to alkali dosage adjustment, but they have high operational cost compared to seawater scrubbers.

- SCR is the most effective EGTS for practically eliminating NOx emissions generated from marine combustion systems. SCR systems are more effective in reducing NOx emissions compared to all other engine “internal measures”. The operation of modern SCR systems in commercial vessels can lead to marine engines’ operation with output NOx values considerably lower compared to the strictest IMO NOx Tier III limits.

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Heywood, J.B. Internal Combustion Engine Fundamentals, 1st ed.; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Dieselnet. IMO Marine Engine Regulations. 2020. Available online: https://dieselnet.com/standards/inter/imo.php (accessed on 2 April 2022).

- IMO. Sulfur Oxides (SOx) and Particulate Matter (PM)—Regulation 14. Available online: http://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Pages/Sulfur-oxides-(SOx)-%E2%80%93-Regulation-14.aspx (accessed on 2 April 2022).

- European Commission. Report from the Commission to the European Parliament and the Council on Implementation and Compliance with the Sulfur Standards for Marine Fuels Set Out in Directive (EU) 2016/802 Relating to a Reduction in the Sulfur Content of Certain Liquid Fuels, Brussels. 16 April 2018. Available online: https://op.europa.eu/en/publication-detail/-/publication/9050f35b-4155-11e8-b5fe-01aa75ed71a1/language-en/format-PDF (accessed on 2 April 2022).

- IMO. Nitrogen Oxides (NOx)—Regulation 13. Available online: http://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Pages/Nitrogen-oxides-(NOx)-%E2%80%93-Regulation-13.aspx (accessed on 2 April 2022).

- Deniz, C.; Zincir, B. Environmental and economical assessment of alternative marine fuels. J. Clean. Prod. 2016, 113, 438–449. [Google Scholar] [CrossRef]

- Notteboom, T.; Delhaye, E.; Vanherle, K. Analysis of the Consequences of Low Sulfur Fuel Requirements. University of Antwerpen Transport and Mobility. 2010. Available online: https://www.schonescheepvaart.nl/downloads/rapporten/doc_1361790123.pdf (accessed on 2 April 2022).

- Guo, M.; Fu, Z.; Ma, D.; Ji, N.; Song, C.; Liu, Q. A short review of treatment methods of marine diesel engine exhaust gases. Procedia Eng. 2015, 121, 938–943. [Google Scholar] [CrossRef]

- Lu, X.; Geng, P.; Chen, Y. NOx Emission reduction technology for marine engine based on Tier-III: A Review. J. Therm. Sci. 2020, 29, 1242–1268. [Google Scholar] [CrossRef]

- Lion, S.; Vlaskos, I.; Taccani, R. A review of emissions reduction technologies for low and medium speed marine Diesel engines and their potential for waste heat recovery. Energy Convers. Manag. 2020, 207, 112553. [Google Scholar] [CrossRef]

- Ni, P.; Wang, X.; Li, H. A review on regulations, current status, effects and reduction strategies of emissions for marine diesel engines. Fuel 2020, 279, 118477. [Google Scholar] [CrossRef]

- Deng, J.; Wang, X.; Wei, Z.; Wang, L.; Wang, C.; Chen, Z. A review of NOx and SOx emission reduction technologies for marine diesel engines and the potential evaluation of liquefied natural gas fuelled vessels. Sci. Total Environ. 2021, 766, 144319. [Google Scholar] [CrossRef]

- Ushakov, S.; Stenersen, D.; Einang, P.-M.; Ask, T.-O. Meeting future emission regulation at sea by combining low-pressure EGR and seawater scrubbing. J. Mar. Sci. Technol. 2020, 25, 482–497. [Google Scholar] [CrossRef]

- Hämäläinen, E. Estimated impacts of the sulfur directive on the Nordic industry. Eur. Transp. Res. Rev. 2015, 7, 8. [Google Scholar] [CrossRef]

- Lindstad, H.; Sandaas, I.; Strømman, A.H. Assessment of cost as a function of abatement options in maritime emission control areas. Transp. Res. Part D Transp. Environ. 2015, 38, 41–48. [Google Scholar] [CrossRef]

- Panasiuk, I.; Turkina, L. The evaluation of investments efficiency of SOx scrubber installation. Transp. Res. Part D Transp. Environ. 2015, 40, 87–96. [Google Scholar] [CrossRef]

- Hirata, K.; Niki, Y.; Kawada, M.; Iida, M. Development of Marine SCR System and Field Test on Ship. International Symposium on Marine Engineering (ISME) BEXCO, Busan, October 2009. Available online: https://www.nmri.go.jp/oldpages2/power-sys/center/hirata/184_Koichi_Hirata.pdf (accessed on 2 April 2022).

- Magnusson, M.; Fridell, E.; Ingelsten, H.H. The influence of sulfur dioxide and water on the performance of a marine SCR catalyst. Appl. Catal. B Environ. 2012, 111, 20–26. [Google Scholar] [CrossRef]

- Cimino, S.; Lisi, L.; Tortorelli, M. Low temperature SCR on supported MnOx catalysts for marine exhaust gas cleaning: Effect of KCl poisoning. Chem. Eng. J. 2016, 283, 223–230. [Google Scholar] [CrossRef]

- Fridell, E.; Salo, K. Measurements of abatement of particles and exhaust gases in a marine gas scrubber. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230, 154–162. [Google Scholar] [CrossRef]

- Brynolf, S.; Magnusson, M.; Fridell, E.; Andersson, K. Compliance possibilities for the future ECA regulations through the use of abatement technologies or change of fuels. Transp. Res. Part D Transp. Environ. 2014, 28, 6–18. [Google Scholar] [CrossRef]

- Ammar, N.R.; Seddiek, I.S. Eco-environmental analysis of ship emission control methods: Case study RO-RO cargo vessel. Ocean. Eng. 2017, 137, 166–173. [Google Scholar] [CrossRef]

- Seddiek, I.S.; Elgohary, M.M. Eco-friendly selection of ship emissions reduction strategies with emphasis on SOx and NOx emissions. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 737–748. [Google Scholar] [CrossRef]

- Viana, M.; Hammingh, P.; Colette, A.; Querol, X.; Degraeuwe, B.; de Vlieger, I.; van Aardenne, J. Impact of maritime transport emissions on coastal air quality in Europe. Atmos. Environ. 2014, 90, 96–105. [Google Scholar] [CrossRef]

- Nikopoulou, Z. Incremental costs for reduction of air pollution from ships: A case study on North European emission control area. Marit. Policy Manag. 2017, 44, 1056–1077. [Google Scholar] [CrossRef]

- Boscarato, I.; Hickey, N.; Kašpar, J.; Prati, M.-V.; Mariani, A. Green shipping: Marine engine pollution abatement using a combined catalyst/seawater scrubber system. 1. Effect of catalyst. J. Catal. 2015, 328, 248–257. [Google Scholar] [CrossRef]

- Lindstad, H.; Eskeland, G.S.; Psaraftis, H.; Sandaas, I.; Strømman, A.H. Maritime shipping and emissions: A three-layered, damage-based approach. Ocean. Eng. 2015, 110, 94–101. [Google Scholar] [CrossRef]

- Dulebenets, M.A. Green vessel scheduling in liner shipping: Modeling carbon dioxide emission costs in sea and at ports of call. Int. J. Transp. Sci. Tech. 2018, 7, 26–44. [Google Scholar] [CrossRef]

- ABS. Exhaust Gas Scrubber Systems: Status and Guidance. 2013. Available online: https://ww2.eagle.org/content/dam/eagle/publications/2013/Scrubber_Advisory.pdf (accessed on 2 April 2022).

- EGC Handbook 2012. A Practical Guide to Exhaust Gas Cleaning Systems for the Maritime Industry. 2012. Available online: https://www.egcsa.com/wp-content/uploads/EGCSA-Handbook-2012-A5-size-.pdf (accessed on 2 April 2022).

- Macdonald, F.; Rojon, I. (Eds.) Fathom Maritime Intelligence. Marine Scrubbers: The Guide 2015. 2015. Available online: http://www.fathommaritimeintelligence.com/uploads/2/5/3/9/25399626/scrubber_guide_sample_pages.pdf (accessed on 2 April 2022).

- Gregory, D.; West, M. EGCSA Handbook; Exhaust Gas Cleaning Systems Association: London, UK, 2010. [Google Scholar]

- Watanabe, Y.; Koyanagi, S. Development and installation of marine-use hybrid SOx scrubber system that complies with IMO SOx emission regulations. Mitsubishi Heavy Ind. Tech. Rev. 2016, 53, 48. [Google Scholar]

- MAN Diesel & Turbo. Tier III NOx Technologies—Comparison of EGR with SCR, Presentation; MAN Diesel & Turbo: Augsburg, Germany, 2013. [Google Scholar]

- MAN Diesel & Turbo. Marine Engine IMO Tier II and Tier III Programme 2015; Report. May 2022. Available online: https://mandieselturbo.com/docs/default-source/sales-force-package/marine_engine_programme_2015.pdf?sfvrsn (accessed on 2 April 2022).

- Kjølholt, J.; Aakre, S.; Jürgensen, C.; Lauridsen, J. Assessment of Possible Impacts of Scrubber Water Discharges on the Marine Environment. Environmental Project No. 1431, Danish Ministry of Environment, Environmental Protection Agency. 2012. Available online: https://www2.mst.dk/Udgiv/publications/2012/06/978-87-92903-30-3.pdf (accessed on 2 April 2022).

- Krystallon, H. Sea Water Scrubbing—Does It Contribute to Increased Global CO2 Emission? Danish Ministry of the Environment: Littlehampton, UK, 2007. [Google Scholar]

- Hamworthy. Moss Flue Gas System, Inert Gas Systems; Hamworthy: Moss, Norway, 2007. [Google Scholar]

- Henriksson, T. SOx scrubbing of marine exhaust gases. Wartsila Tech. J. 2007, 55–58. [Google Scholar]

- Høy-Petersen, N. Answers to Specific Questions and General Information from Clean Marine, Oslo, Norway 2011. Available online: www.cleanmarine.com (accessed on 2 April 2022).

- Hufnagl, M.; Liebezeit, G.; Behrends, B. Effects of Sea Water Scrubbing; Final Report; BP Marine: Navi Mumbai, India, 2005. [Google Scholar]

- Kircher, D.; Stotz, T. Holland America Line Sea water scrubber demonstration project. In Proceedings of the Faster Freight, Cleaner Air Northwest Conference, Seattle, WA, USA, 17 September 2008. [Google Scholar]

- Kullas-Nyman, B.-M. Exhaust gas scrubbing systems: Technical and economic aspects. In Proceedings of the Wärtsilä Presentation, Maritime Stakeholder Event, Brussels, Belgium, 1 June 2011. [Google Scholar]

- Lloyd’s Register. Understanding Exhaust Gas Treatment Systems: Guidance for Shipowners and Operators. June 2012. Available online: https://www.rtu.lv/writable/public_files/RTU_understanding_exhaust_gas_treatment_systems.pdf (accessed on 2 April 2022).

- Oikawa, K.; Yongsiri, C.; Takeda, K.; Harimoto, T. Seawater flue gas desulfurization: Its technical implications and performance results. Environ. Prog. 2004, 22, 67–73. [Google Scholar] [CrossRef]

- Reynolds, K. Exhaust gas cleaning systems selection guide. In Ship Operations Cooperative Program; U.S. Department of Transportation: Elliot City, MD, USA, 2011. [Google Scholar]

- Ritchie, A.; de Jonge, E.; Hugi, C.; Cooper, D. Service Contract on Ship Emissions: Assignment, Abatement and Market-Based Instruments, Task 2c-SO2 Abatement; European Commission Directorate General Environment: Brussels, Belgium, 2005. [Google Scholar]

- Scala, F.; Lancia, A.; Nigro, R.; Volpicelli, G. Spray-dry desulfurization of flue gas from heavy oil combustion. J. Air Waste Manag. Assoc. 2005, 55, 20–29. [Google Scholar] [CrossRef]

- Wärtsilä. Wärtsilä Low-Speed Engines NOx—Emission—Tier III Solutions. INTERTANKO Annual Event, Technical Workshop—Air Emissions NOx Tier III; Wärtsilä: Athens, Greece, 2015. [Google Scholar]

- Wärtsilä. Wärtsilä Environmental Technologies, Wartsila Environmental Product Guide; Wärtsilä: Athens, Greece, 2015. [Google Scholar]

- Sun, X.; Meng, F.; Yang, F. Application of seawater to enhance SO2 removal from simulated flue gas through hollow fiber membrane contactor. J. Membr. Sci. 2008, 312, 6–14. [Google Scholar] [CrossRef]

- Tasin, A. Introduction to Scrubber Technologies; Wärtsilä Presentation: Newark, NJ, USA, 2015. [Google Scholar]

- Kouremenos, D.A.; Hountalas, D.T.; Binder, K.B.; Raab, A.; Schnabel, M.H. Using advanced injection timing and EGR to improve DI diesel engine efficiency at acceptable NO and soot levels. SAE Trans. 2001, 110, 55–68. [Google Scholar] [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 1: Effect of reducing inlet charge oxygen. SAE Trans. 1996. [Google Scholar] [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 2: Effects of carbon dioxide. SAE Trans. 1996. [Google Scholar] [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 3: Effects of water vapour. SAE Trans. 1997. [Google Scholar] [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 4: Effects of carbon dioxide and water vapour. SAE Trans. 1997, 106, 1844–1862. [Google Scholar] [CrossRef]

- Ladommatos, N.; Balian, R.; Horrocks, R.; Cooper, L. The effect of exhaust gas recirculation on soot formation in a high-speed direct-injection diesel engine. SAE Trans. 1996. [Google Scholar] [CrossRef]

- Couple Systems. The Very New Exhaust Gas Cleaning System; Couple Systems: Bardowick, Germany, 2010. [Google Scholar]

- Azzara, A.; Rutherford, D.; Wang, H. Feasibility of IMO Annex VI Tier III Implementation Using Selective Catalytic Reduction. The International Council on Clean Transportation (ICCT) 2014, Working Paper 2014-4. Available online: https://theicct.org/sites/default/files/publications/ICCT_MarineSCR_Mar2014.pdf (accessed on 2 April 2022).

- International Association for Catalytic Control of Ship Emissions to Air (IACCSEA). 2020. Available online: https://www.iaccsea.com/wp-content/uploads/2018/12/IACCSEA-Marine-SCR-Technical-and-operational-capabilities-2013.pdf (accessed on 2 April 2022).

- Kang, X.; Ma, X.; Yin, J.; Gao, X. A study on simultaneous removal of NO and SO2 by using sodium persulfate aqueous scrubbing. Chin. J. Chem. Eng. 2018, 26, 1536–1544. [Google Scholar] [CrossRef]

- ABS, Global Sulfur Cap—2020. Available online: https://ww2.eagle.org/content/dam/eagle/advisories-and-debriefs/ABS_Debrief_Global_Sulfur_Cap_16385.pdf (accessed on 2 April 2022).

- Caiazzo, G.; Langella, G.; Miccio, F.; Scala, F. An experimental investigation on seawater SO2 scrubbing for marine application. Environ. Progress Sustain. Energy 2013, 32, 1179–1186. [Google Scholar] [CrossRef]

- Chevron, Marine Lubricants White Paper, The 2020 Global Sulfur Cap and the Role of Cylinder Oil Lubricants. Available online: https://www.chevronmarineproducts.com/content/dam/chevron-marine/white-papers/2020%20Global%20Cap%20Whitepaper%20DESKTOP.pdf (accessed on 2 April 2022).

- Ülpre, H.; Eames, I. Environmental policy constraints for acidic exhaust gas scrubber discharges from ships. Mar. Pollut. Bull. 2014, 88, 292–301. [Google Scholar] [CrossRef]

- Flagiello, D.; Erto, A.; Lancia, A.; Di Natale, F. Experimental and modelling analysis of seawater scrubbers for sulfur dioxide removal from flue-gas. Fuel 2018, 214, 254–263. [Google Scholar] [CrossRef]

- Abadie, L.-M.; Goicoechea, N.; Galarraga, I. Adapting the shipping sector to stricter emissions regulations: Fuel switching or installing a scrubber? Transp. Res. Part D Transp. Environ. 2017, 57, 237–250. [Google Scholar] [CrossRef]

- International Chamber of Shipping. Guidance to Shipping Companies and Crews on Preparing for Compliance with the 2020 ‘Global Sulfur Cap’ for Ships’ Fuel Oil in Accordance with MARPOL Annex VI, 1 July 2019. Available online: https://www.ics-shipping.org/docs/default-source/resources/guidance-for-compliance-with-the-2020-global-sulfur-cap-july-2019.pdf?sfvrsn=24 (accessed on 2 April 2022).

- Rass, K.; Affolter, S.; Mader, R.; Rozmyslowicz, B.; Stark, M.; Weber, M.F. Impact of Sulfur Cap 2020 on Two-Stroke Engine Tribology Aspects. 19th CIMAC Congress, Paper 437, Vancouver, Canada, 10–14 June 2019. Available online: https://www.wingd.com/en/documents/general/papers/impact-of-sulfur-cap-2020-on-2-stroke-engine-tribology-cimac2019-paper-437-k-rass/ (accessed on 2 April 2022).

- Marocco, L. Modeling of the fluid dynamics and SO2 absorption in a gas–liquid reactor. Chem. Eng. J. 2010, 162, 217–226. [Google Scholar] [CrossRef]

- Brown, K.; Kalata, W.; Schick, R. Optimization of SO2 Scrubber using CFD Modeling. Procedia Eng. 2014, 83, 170–180. [Google Scholar] [CrossRef]

- Tang, X.-J.; Li, T.; Yu, H.; Zhu, Y.-M. Prediction model for desulfurization efficiency of on-board magnesium-base seawater scrubber. Ocean Eng. 2014, 76, 98–104. [Google Scholar] [CrossRef]

- Kim, A.-R.; Seo, Y.-J. The reduction of SOx emissions in the shipping industry: The case of Korean companies. Mar. Policy 2019, 100, 98–106. [Google Scholar] [CrossRef]

- Gu, Y.; Wallace, S.W. Scrubber: A potentially overestimated compliance method for the Emission Control Areas. The importance of involving a ship’s sailing pattern in the evaluation. Transp. Res. Part D Transp. Environ. 2017, 55, 51–66. [Google Scholar] [CrossRef]

- Makkonen, T.; Inkinen, T. Sectoral and technological systems of environmental innovation: The case of marine scrubber systems. J. Clean. Prod. 2018, 200, 110–121. [Google Scholar] [CrossRef]

- Schinas, O.; Stefanakos, C.N. Selecting technologies towards compliance with MARPOL Annex VI: The perspective of operators. Transp. Res. Part D Transp. Environ. 2014, 28, 28–40. [Google Scholar] [CrossRef]

- Darake, S.; Hatamipour, M.S.; Rahimi, A.; Hamzeloui, P. SO2 removal by seawater in a spray tower: Experimental study and mathematical modeling. Chem. Eng. Res. Des. 2016, 109, 180–189. [Google Scholar] [CrossRef]

- Jiang, L.; Kronbak, J.; Christensen, L.-P. The costs and benefits of sulfur reduction measures: Sulfur scrubbers versus marine gas oil. Transp. Res. Part D Transp. Environ. 2014, 28, 19–27. [Google Scholar] [CrossRef]

- Lindstad, H.E.; Rehn, C.-F.; Eskeland, G.S. Sulfur abatement globally in maritime shipping. Transp. Res. Part D Transp. Environ. 2017, 57, 303–313. [Google Scholar] [CrossRef]

- Endres, S.; Maes, F.; Hopkins, F.; Houghton, K.; Mårtensson, E.M.; Oeffner, J.; Quack, B.; Singh, P.; Turner, D. A new perspective at the ship-air-sea-interface: The environmental impacts of exhaust gas scrubber discharge. Front. Mar. Sci. 2018, 5, 139. [Google Scholar] [CrossRef]

- Turkina, L.; Panasiuk, I. Optimization of production of ship hull parts. In Proceedings of the 15th International Conference Transport Means 2011, Kaunas, Lithuania, 20–21 October 2011. [Google Scholar]

- Turner, D.R.; Edman, M.; Gallego-Urrea, J.-A.; Claremar, B.; Hassellov, I.-M.; Omstedt, A.; Rutgersson, A. The potential future contribution of shipping to acidification of the Baltic Sea. Ambio 2018, 47, 368–378. [Google Scholar] [CrossRef]

- Ma, H.; Steernberg, K.; Riera-Palou, X.; Tait, N. Well-to-wake energy and greenhouse gas analysis of SOx abatement options for the marine industry. Transp. Res. Part D Transp. Environ. 2012, 17, 301–308. [Google Scholar] [CrossRef]

- Kackur, J. Wartsila, Shipping in the 2020 Era—Selection of Fuel and Propulsion Machinery, Business White Paper. Available online: https://www.motorship.com/__data/assets/pdf_file/0036/986319/White-Paper_Shipping-in-the-2020-era_Pre-final.pdf (accessed on 2 April 2022).

- An, S.; Nishida, O. New application of seawater and electrolyzed seawater in air pollution control of marine diesel engine. JSME Int. J. Ser. B Fluids Therm. Eng. 2003, 46, 206–213. [Google Scholar] [CrossRef][Green Version]

- Andreasen, A.; Mayer, S. Use of seawater scrubbing for SO2 removal from marine engine exhaust gas. Energy Fuels 2007, 21, 3274–3279. [Google Scholar] [CrossRef]

- Caiazzo, G.; Di Nardo, A.; Langella, G.; Scala, F. Seawater scrubbing desulfurization: A model for SO2 absorption in fall-down droplets. Environ. Prog. Sustain. Energy 2012, 31, 277–287. [Google Scholar] [CrossRef]

- Caiazzo, G.; Miccio, F.; Scala, F. Modeling Heat and Mass Transfer in a Seawater Scrubber for Marine Application: Some Improvements Based on a CFD Simulation. XXXVI Meeting of the Italian Section of the Combustion Institute. 2013. Available online: http://www.combustion-institute.it/proceedings/XXXVI-ASICI/papers/36proci2013.VI1.pdf (accessed on 2 April 2022).

- Rakopoulos, C.D.; Giakoumis, E.G.; Hountalas, D.T.; Rakopoulos, D.C. The Effect of Various Dynamic, Thermodynamic and Design Parameters on the Performance of a Turbocharged Diesel Engine Operating under Transient Load Conditions; SAE Technical Paper 2004-01-0926; SAE International: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Kosmadakis, G.M.; Rakopoulos, D.C.; Rakopoulos, C.D. Methane/hydrogen fueling a spark-ignition engine for studying NO, CO and HC emissions with a research CFD code. Fuel 2016, 185, 903–915. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Kosmadakis, G.M. Numerical and experimental study by quasi-dimensional modeling of combustion and emissions in variable compression ratio high-speed spark-ignition engine. ASCE J. Energy Eng. 2021, 147, 04021032. [Google Scholar] [CrossRef]

- Papagiannakis, R.G.; Hountalas, D.T.; Rakopoulos, C.D.; Rakopoulos, D.C. Combustion and Performance characteristics of a Di Diesel Engine Operating from Low to High Natural Gas Supplement Ratios at Various Operating Conditions; SAE Technical Paper No. 2008-01-1392; SAE International: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Papagiannakis, R.G.; Krishnan, S.R.; Rakopoulos, D.C.; Srinivasan, K.K.; Rakopoulos, C.D. A combined experimental and theoretical study of diesel fuel injection timing and gaseous fuel/diesel mass ratio effects on the performance and emissions of natural gas–diesel HDDI engine operating at various loads. Fuel 2017, 202, 675–687. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Papagiannakis, R.G. Evaluating oxygenated fuel’s influence on combustion and emissions in diesel engines using a two-zone combustion model. ASCE J. Energy Eng. 2018, 144, 04018046. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kosmadakis, G.M.; Papagiannakis, R.G. Experimental comparative assessment of butanol or ethanol diesel-fuel extenders impact on combustion features, cyclic irregularity, and regulated emissions balance in heavy-duty diesel engine. Energy 2019, 174, 1145–1157. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Mavropoulos, G.C.; Kosmadakis, G.M. Investigating the EGR rate and temperature impact on diesel engine combustion and emissions under various injection timings and loads by comprehensive two-zone modeling. Energy 2018, 157, 990–1014. [Google Scholar] [CrossRef]

- Rakopoulos, D.C. Effects of exhaust gas recirculation under fueling rate or air/fuel ratio–controlled strategies on diesel engine performance and emissions by two-zone combustion modeling. ASCE J. Energy Eng. 2021, 147, 04020079. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Kosmadakis, G.M.; Giakoumis, E.G. Exergy assessment of combustion and EGR and load effects in DI diesel engine using comprehensive two-zone modeling. Energy 2020, 202, 117685. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Development of cumulative and availability rate balances in a multi-cylinder turbocharged indirect injection diesel engine. Energy Convers. Manag. 1997, 38, 347–369. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Combustion noise radiation during dynamic diesel engine operation including effects of various biofuels blends: A review. Renew. Sust. Energy Rev. 2016, 54, 1099–1113. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Mavropoulos, G.C. Experimental instantaneous heat fluxes in the cylinder head and exhaust manifold of an air-cooled diesel engine. Energy Convers. Manag. 2000, 41, 1265–1281. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kyritsis, D.C.; Andritsakis, E.C.; Mavropoulos, G.C. Exergy evaluation of equivalence ratio, compression ratio and residual gas effects in variable compression ratio spark-ignition engine using quasi-dimensional combustion modelling. Energy 2022, 244, 123080. [Google Scholar] [CrossRef]

- Tingas, E.A.; Im, H.G.; Kyritsis, D.C.; Goussis, D.A. The use of CO2 as an additive for ignition delay and pollutant control in CH4/Air autoignition. Fuel 2018, 211, 898–905. [Google Scholar] [CrossRef]

- Tingas, E.-A.; Kyritsis, D.C.; Goussis, D.A. H2/Air autoignition dynamics around the third explosion limit. ASCE J. Energy Eng. 2019, 145, 04018139. [Google Scholar] [CrossRef]

- Konstandopoulos, A.G.; Zarvalis, D.; Chasapidis, L.; Deloglou, D.; Vlachos, N.; Kotrba, A.; Anderson, G. Investigation of SCR catalysts for marine diesel applications. SAE Int. J. Engines 2017, 10, 1653–1666. [Google Scholar] [CrossRef]

- Liang, X.; Xiao, J.; Xu, Y.; Liu, S.; Men, X. CFD simulations to research the control rules with gate leaves in SCR-DeNOx facility for marine diesel engines. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015. [Google Scholar]

- Chen, Y.; Lv, L. Design and evaluation of an integrated SCR and exhaust muffler from marine diesels. J. Mar. Sci. Technol. 2015, 20, 505–519. [Google Scholar] [CrossRef]

- Zhu, Y.; Xia, C.; Shreka, M.; Wang, Z.; Yuan, L.; Zhou, S.; Feng, Y.; Hou, Q.; Abdu Ahmed, S. Combustion and emission characteristics for a marine low-speed diesel engine with high-pressure SCR system. Environ. Sci. Pollut. Res. 2020, 27. [Google Scholar] [CrossRef]

- Park, T.; Sung, Y.; Kim, T.; Lee, I.; Choi, G.; Kim, D. Effect of static mixer geometry on flow mixing and pressure drop in marine SCR applications. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 27–38. [Google Scholar] [CrossRef]

- Guo, Y.; Deng, Y.; Zhang, J.; Shen, Y.; Wilson, C. Experimental and numerical analysis of NOx reduction in marine urea-SCR system. In Proceedings of the 4th International Conference on Information, Cybernetics and Computational Social Systems (ICCSS), Dalian, China, 24–26 July 2017; pp. 450–455. [Google Scholar]

- Ayre, L.S.; Johnson, D.R.; Clark, N.N.; England, J.A.; Atkinson, R.J.; McKain, D.L., Jr.; Ralston, B.A.; Thomas, H.; Balon, T.H., Jr.; Moynihan, P.J. Novel NOx emission reduction technology for diesel marine engines. In Proceedings of the ASME 2011 Internal Combustion Engine Division Fall Technical Conference, ICEF2011, Morgantown, WV, USA, 2–5 October 2011. ICEF2011-60182. [Google Scholar]

- Xiao, Y.; Zhao, H.; Tian, X.; Tan, W. Investigation on the control strategy for marine selective catalytic reduction system. ASME Trans. J. Dyn. Sys. Meas. Control 2019, 141, 011005. [Google Scholar] [CrossRef]

- Foteinos, M.I.; Konstantinidis, S.K.; Kyrtatos, N.P.; Busk, K.-V. Simulation of the transient thermal response of a high pressure selective catalytic reduction aftertreatment system for a Tier III two-stroke marine diesel engine. ASME Trans. J. Eng. Gas Turbines Power 2019, 141, 071001. [Google Scholar] [CrossRef]

- Xi, H.; Zhou, S.; Zhou, J. New experimental results of NO removal from simulated marine engine exhaust gases by Na2S2O8/urea solutions. Chem. Eng. J. 2019, 362, 12–20. [Google Scholar] [CrossRef]

- Choi, C.; Sung, Y.; Choi, G.-M.; Kim, D.-J. Numerical analysis of NOx reduction for compact design in marine urea-SCR system. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 1020–1033. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, R.; Zhou, S.; Huang, C.; Feng, Y.; Shreka, M.; Zhang, C. Performance optimization of high-pressure SCR system in a marine diesel engine. Part I: Flow optimization and analysis. Top. Catal. 2019, 62, 27–39. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, R.; Zhou, S.; Huang, C.; Feng, Y.; Shreka, M.; Zhang, C. Performance optimization of high-pressure SCR system in a marine diesel. Part II: Catalytic reduction and process. Top. Catal. 2019, 62, 40–48. [Google Scholar] [CrossRef]

- Kleinhenz, M.; Fiedler, A.; Lauer, P.; Döring, A. SCR coated DPF for marine engine applications. Top. Catal. 2019, 62, 282–287. [Google Scholar] [CrossRef]

- Ha, T.-H.; Nishida, O.; Fujita, H.; Wataru, H. Simultaneous removal of NOx and fine diesel particulate matter (DPM) by electrostatic water spraying scrubber. J. Mar. Eng. Technol. 2014, 8, 45–53. [Google Scholar] [CrossRef]

- Zis, T.; Psaraftis, H.N. Operational measures to mitigate and reverse the potential modal shifts due to environmental legislation. Marit. Policy Manag. 2019, 46, 117–132. [Google Scholar] [CrossRef]

- Lehtoranta, K.; Aakko-Saksa, P.; Murtonen, T.; Vesala, H.; Ntziachristos, L.; Rönkko, T.; Karjalainen, P.; Kuittinen, N.; Timonen, H. Particulate mass and nonvolatile particle number emissions from marine engines using low-sulfur fuels, natural gas, or scrubbers. Environ. Sci. Technol. 2019, 53, 3315–3322. [Google Scholar] [CrossRef] [PubMed]

- Greek Shipowner. Personal communication, 2020.

- DNV GL. Global Sulfur Cap 2020, Compliance Options and Implications for Shipping—Focus on Scrubbers. Available online: https://www.dnvgl.com/maritime/publications/global-sulfur-cap-2020.html (accessed on 2 April 2022).

- Yang, Z.L.; Zhang, D.; Caglayan, O.; Jenkinson, I.D.; Bonsall, S.; Wang, J.; Huang, M.; Yan, X.P. Selection of techniques for reducing shipping NOx and SOx emissions. Transp. Res. Part D Transp. Environ. 2012, 17, 478–486. [Google Scholar] [CrossRef]

- Claremar, B.; Haglund, K.; Rutgersson, A. Ship emissions and the use of current air cleaning technology: Contributions to air pollution and acidification in the Baltic Sea. Earth Syst. Dyn. 2017, 8, 901–919. [Google Scholar] [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Williams, P.J. Use of seawater as makeup water for wet flue gas desulfurization systems. In Proceedings of the EPRI-DOE-EPA Combined Utility Air Pollutant Control Symposium, Atlanta, GA, USA, 16–20 August 1999. [Google Scholar]

- International Maritime Organization. Investigation of Appropriate Control Measures (Abatement Technologies) to Reduce Black Carbon Emissions from International Shipping 2015. Available online: http://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Documents/Air%20pollution/Black%20Carbon.pdf (accessed on 2 April 2022).

- DNV GL. Global Sulfur Cap 2020. Get Insights on Compliance Options and Implications for Shipping. Focus on Scrubbers; DNV GL: Bærum, Norway, 2019. [Google Scholar]

- DNV GL. Global Sulfur Cap 2020. Know the Different Choices and Challenges for On-Time Compliance; DNV GL: Bærum, Norway, 2020. [Google Scholar]

- The Swedish Club, Sulfur Guide, Dealing with the Sulfur Cap 2020 and Beyond. Available online: https://www.swedishclub.com/media_upload/files/Publications/Loss%20Prevention/Sulfur-Guide%202019%20www.pdf (accessed on 2 April 2022).

- Cho, B.K.; Lee, J.H.; Crellin, C.C.; Olson, K.L.; Hilden, D.L.; Kim, M.K.; Kim, P.S.; Heo, I.; Oh, S.H.; Nam, I.-S. Selective catalytic reduction of NOx by diesel fuel: Plasma-assisted HC/SCR system. Catal. Today 2012, 191, 20–24. [Google Scholar] [CrossRef]

- Liu, B.; Wu, X.; Liu, X.; Gong, M. Assessment of ecological stress caused by maritime vessels based on a comprehensive model using AIS data: Case study of the Bohai Sea, China. Ecol. Indic. 2021, 126, 107592. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Brown, R.; Yang, L.; Morawska, L.; Ristovski, Z.; Fu, Q.; Huang, C. Shipping emissions and their impacts on air quality in China. Sci. Total Environ. 2017, 581–582, 186–198. [Google Scholar] [CrossRef]

| Year of Issue | Permitted Fuel Sulfur Content (% m/m) | |

|---|---|---|

| SECAs | Worldwide | |

| 2000 | 1.5% | 4.5% |

| 2010.07 | 1.0% | |

| 2012 | 3.5% | |

| 2015 | 0.1% | |

| 2020 | 0.5% | |

| Tier | Year of Issue | Nitrogen Oxides Concentration Limit, g/kWh | ||

|---|---|---|---|---|

| RPM ** < 130 | 130 ≤ RPM < 2000 | RPM ≥ 2000 | ||

| Tier I | 2000 | 17.0 | 45 * RPM−0.2 | 9.8 |

| Tier II | 2011 | 14.4 | 44 * RPM−0.23 | 7.7 |

| Tier III | 2016 * | 3.4 | 9 * RPM−0.2 | 1.96 |

| No. | Type of the Study | Main Objectives of the Study | Main Conclusions of the Study | Reference |

|---|---|---|---|---|

| 1 | Experimental | The polluting behavior of low-pressure an EGR system operating in combination with a seawater scrubber on a LPG carrier, which operated with HSFO. | (1) Increased back pressure due to the scrubber operation and small fuel penalty due combustion efficiency worsening from the use of EGR were evidenced. (2) A 70% NOx reduction and simultaneous dramatic reduction (98%) of SOx emissions, which was interpreted as compliance with NOx Tier III values and maritime fuel sulfur limits in ECAs were observed. (3) It was witnessed Adequate performance of the water wash treatment unit resulting in the receipt of good quality water samples compared to all measured compounds was witnessed. | [13] |

| 2 | Theoretical/Case Study | The environmental and economic repercussions from the implementation of fuel sulfur directive in the Scandinavian industry, i.e., transition from heavy fuel oil (HFO) to marine diesel oil (MDO). | It was found that before the decision of the industry and the owners, there was a profound requirement for extensive feasibility studies and elaborative research relevant to the upcoming environmental decisions for SOx ECAs and their repercussions on maritime logistics, economy, and environment. | [14] |

| 3 | Theoretical/Case Study | The economic burden and pollutant emissions as functions of the reduction choices in pollutant Emission Control Areas were thoroughly investigated. | (1) It was evidenced that the optimum solution is a function of the engine size, the engine fuel consumption inside ECAs and the projected future fuel prices. (2) It was found that the investment cost for the sulfur reduction technologies must be fully covered from fuel saving inside ECAs, which favors MGO or LFO compared to scrubbing systems or LNG. | [15] |

| 4 | Theoretical/Case Study | (1) Two different SOx emission reduction technologies, namely, the use of low sulfur fuel oil and scrubbers, were comparatively evaluated from an economic and environmental perspective. (2) The effectiveness of the investments of SOx scrubbing system installations for compliance with the requirements of VI MARPOL 73/78 was analyzed. | It was found that the investments in exhaust gas scrubbing systems are effective under any fuel price option examined. | [16] |

| 5 | Experimental | (1) Construction of a selective catalytic reduction (SCR) system. (2) The on-board NOx reduction effectiveness of the investigated SCR module was examined. | The proposed SCR system is highly effective in reducing NOx emissions from the marine engines of the maritime vessel under examination. | [17] |

| 6 | Experimental | The relative influence of fuel sulfur content and water on the performance indicators and the effectiveness of a SCR system was investigated. The impact of fuel sulfur percentage on the NOx reduction potential of a commercial SCR catalyst fed with urea at low temperatures was analyzed. | (1) It was shown that the addition of SO2 in the absence of water enhances NOx reduction rates and promotes the conversion of NH3 with an increased N2O formation (This effect appeared to be independent from temperature). (2) It was found that the addition of H2O in the absence of SO2 results in NOx reduction and in the curtailment of N2O formation. (3) It was witnessed that in the presence of SO2 and water, NOx reduction potential is curtailed. | [18] |

| 7 | Experimental | The influence of the KCl poisoning on the performance indicators of MnOx catalyst, which is a key component of the SCR system, was investigated. | (1) It was shown that at low temperatures, MnO2-based catalysts indicate superior performance compared to conventional catalysts. (2) It was found that SCR catalytic performance was related directly to the oxygen availability of MnOx catalyst. (3) It was witnessed that the presence of KCl negatively affected the performance of SCR catalyst at low temperatures mainly due to oxygen mobility of MnOx species. | [19] |

| 8 | Experimental | The PM and SO2 emission reduction potential from a marine engine equipped with an open-loop seawater scrubber was examined. | (1) It was shown that a seawater scrubber effectively reduced SO2 emissions at levels like the ones corresponding to <0.1% fuel sulfur content (0.1% is the allowed fuel sulfur percentage in SECAs since 2015). (2) It was realized that the use of a seawater scrubber resulted in the reduction of PM emissions by 75% compared to conventional marine engine operation. (3) The use of a seawater scrubbing system also results in a significant reduction of polycyclic aromatic hydrocarbons (PAHs). (4) It was also found that the captured SO2 resulted in the reduction of pH and in a high sulfuric acids concentration in the water effluent. (5) PM emission reduction with a seawater scrubber is the same as with the one attained with a fuel transition from HFO to marine gas oil (MGO). | [20] |

| 9 | Experimental | The following three methodologies complying with both ECA regulations for sulfur and Tier III for NOx were evaluated: (a) heavy fuel oil (HFO) in combination with SCR and an open-loop seawater purifier, (b) marine gas oil (MGO) in combination with SCR, (c) liquefied natural gas (LNG). | (1) All methodologies reduce the impact on particles, photochemical ozone formation, acidification, and terrestrial eutrophication potential in the life cycle. (2) It was necessary to adjust the slip of ammonia from the use of SCR and the slip of methane from the LNG engine. (3) Methane slip could possibly be reduced by engine modifications or oxidation catalysts. | [21] |

| 10 | Theoretical/Case Study | The environmental impacts of the following exhaust gas reduction methodologies were compared: (a) selective catalytic reduction (SCR), (b) seawater treatment (SWS), (c) MGO, (d) LNG conversion. | (1) The use of LNG conversion or a combined system (SCR + SWS) or (SCR + MGO) can be applied to the ship. (2) High NOx and SOx emission reduction rates can be achieved using a combined system (SCR + SWS). (3) The LNG conversion process achieves the greatest reduction of PM emissions, while it is the only method that reduces CO2 emissions. (4) LNG conversion can economically achieve the required emission levels according to international regulations. | [22] |

| 11 | Theoretical/Case Study | Various ship emission reduction strategies were compared for compliance with the IMO SOx and NOx emission standards. | (1) The use of SCR and seawater purification seemed to be the best on-board reduction technologies. (2) LNG appears to be the most efficient type of fuel. (3) The type of ship and the operation area play an important role in choosing the appropriate strategy. | [23] |

| 12 | Theoretical/Literature review | The effects of maritime emissions (i.e., particulate matter, gaseous pollutants, etc.) on urban air quality in Europe’s coastal areas were examined. | (1) Emissions from shipping contribute to 1–7% of ambient air. (2) Contributions to environmental NO2 levels range between 7% and 24%. | [24] |

| 13 | Theoretical/Simulation Model | (1) It was estimated the incremental cost of reducing NOx and SOx from maritime vessels working in Emission Control Areas (ECAs). (2) It was comparatively evaluated the following five emission abatement methods: (a) SCR, (b) Humid Air Motor and Internal Engine Modification (HAM/IEM), (c) scrubbers, (d) marine gas oil (MGO), and (e) wet scrubbers and LNG. | (1) Increased sensitivity of NOx reduction methods to functional behavior, with the HAM/IEM combination performing well for exclusive circulation. (2) A Tier-III HAM / IEM combination can prove to be a worthwhile investment for technology vendors. (3) SOx reduction methods are generally independent of functional behavior. (4) MGO is the most expensive solution but simple to operate. (5) The scrubbing system is economical and relatively insensitive to operating behavior. (6) LNG successfully competes with MGO and scrubber. (7) LNG performs better in terms of cost. | [25] |

| 14 | Experimental | The abatement potential of a combined system comprised of catalyst and seawater scrubber was examined. | (1) A significant reduction in emissions was achieved. (2) The proposed emission abatement system can be used with sulfur fuel content up to 0.4%, whereas problems occurred when 2% fuel sulfur percentage was used. (3) Manipulation of scrubber operation is necessary to improve NOx reduction through the catalyst. | [26] |

| 15 | Theoretical/Simulation Model | The requirements for the reduction of harmful emissions in ports and coastal areas without investigating the overall cooling effect of maritime transport were investigated. | (1) The use of 2.7% sulfur HFO outside the ECA in combination with clean fuels within the ECA is appropriate both to maintain the global cooling effect of shipping and to reduce harmful emissions near land. (2) Combustion of low-grade fuels on the high seas offers cooling benefits. (3) Hybrid power settings have a lower environmental impact than standard engine solutions and a lower annual fuel bill. | [27] |

| 16 | Theoretical/Simulation Model + Literature Review | How changes in CO2 taxation may affect the time schedule and routing of maritime vessels was examined. | The increase of the carbon tax can substantially change the planning of ship services, incur additional costs for route services and improve environmental sustainability. | [28] |

| Pollutant | Aqueous Exhaust Gas Processing System | Capture Rate (%) |

|---|---|---|

| PM | Hybrid system | 60 to >90 |

| Seawater scrubber | 70 to 90 | |

| Freshwater scrubber | 65 to 95 | |

| NOx | Hybrid system | 0 up to “less than 10” |

| Seawater scrubber | 0 to 2.5 | |

| Freshwater scrubber | 7 | |

| CO2 | Hybrid system | 0 to 15 |

| Seawater scrubber | 0 | |

| Freshwater scrubber | 0 |

| No. | Type of the Study | Main Objectives of the Study | Main Conclusions of the Study | Reference |

|---|---|---|---|---|

| 1 | Theoretical/Simulation Model | The effect of (a) using sodium persulfate aqueous scrubbing, (b) temperature and (c) Na2S2O8, FeSO4 and H2O2 concentrations on NO and SO2 emission concentrations was examined. | (1) Increased persulfate concentration leads to an increase in NO removal at various temperatures. (2) SO2 was almost completely eliminated in the range of 55–85 °C. (3) NO removal of 93.5–99% with the addition of Na2S2O8 and Fe2+. (4) SO2 removal was as high as 98.4% both at 35 °C and at 80 °C. | [62] |

| 2 | Theoretical/Case Study | An extensive and detailed report providing information on various methods for compliance with the IMO sulfur content standards, including alternative fuels such as LNG, LPG, CNG, biofuels, ammonia, and hydrogen and EGTS. | Provides detailed information on how the specific class can support owners and operators during the decision-making process of the suitable SOx abatement technique. | [63] |

| 3 | Experimental | The operational behavior and the SO2 capture efficiency of a seawater scrubber located on a marine application was examined. | (1) Seawater indicated superior performance compared to distilled water. (2) The efficiency of the scrubber was enhanced by increasing the liquid flow rate and the gas residence time, (3) SO2 capture efficiencies up to 93% were realized. | [64] |

| 4 | Experimental/Detailed Report | The effect of fuel sulfur content on marine engine lubrication was investigated, and it specific suggestions concerning the most suitable lubricant oils that should be used were provided. | (1) Fuels with lower than 0.50% sulfur content will drive demand towards lower base number (BN) cylinder oils. (2) The use of HSFO with sulfur content potentially higher than 3.5% coupled with the use of scrubber technology will drive the demand towards higher BN cylinder oils. | [65] |

| 5 | Theoretical/Simulation Model | The environmental policy constraints for acidic exhaust gas of open-loop marine scrubbers’ discharges from ships was examined. The focus was on the underlying phenomena that primarily affect the disposal of acidic discharges in seawater. | Significant jet deflection was observed during an open-loop scrubber discharge. | [66] |

| 6 | Experimental & Theoretical/Simulation Model | The ability of an open-loop seawater scrubber for sulfur dioxide removal from exhaust gas was investigated. The investigation was focused on the examination of the following three absorbing methodologies: (a) seawater; (b) NaOH addition to seawater; and (c) by using distilled water as benchmark. | (1) The seawater was able to absorb a limited quantity of SO2 at very low equilibrium partial pressure. (2) The addition of NaOH allowed slightly higher solubility levels compared with only seawater. (3) For SO2 concentration up to 500 ppmv, an absorption efficiency above 98% can be achieved. | [67] |

| 7 | Theoretical/Case Study-Stochastic Model | How the existing fleet can be adapted to the new emission regulations was explored. The following techniques were considered: (a) the use of low-sulfur marine diesel oils and (b) the installation of scrubbers. | (1) The net present value of the scrubbers’ investment and the investment in the change of fuel types for different assumptions depends on the mode of operation of the vessels. (2) Significant data were provided on the relationship between increases in fuel consumption and CO2 emissions due to the use of scrubbing systems and how these affect the financial analysis of whether these incremental emissions are to be compensated under a CO2 pricing mechanism. | [68] |

| 8 | Theoretical & Experimental Report | An extensive and detailed report providing information about the decisions taken during the recent IMO committee meetings. | (1) The 0.5% fuel sulfur limit is a significant reduction from the current global limit of 3.50% m/m which has been established since 2012. (2) The only regular exception to the use of 0.50% fuel sulfur will be for the relatively small number of ships that choose to use the ‘equivalent’ compliance mechanisms in accordance with Regulation 4 of MARPOL Annex VI such as LNG fuel or the fitting of an exhaust gas treatment system. | [69] |

| 9 | Theoretical/Case Study | The impact of the “global sulfur cap” on the tribological behavior of two-stroke marine diesel engines was examined. | (1) The operation with high-sulfur residual fuels allows a smooth transition for marine diesel engines in 2020 and beyond. (2) Cylinder lubrication systems might be optimized by new parameter settings for the extended residence time of the lubricant instead of aiming at constantly feeding fresh lubricant for acid neutralization onto the cylinder liner running surface. (3) Reduced additivation needed for acid neutralization in cylinder lubricants is providing potential to focus on higher oxidation stability, deposit control, and lubricity for difficult operating conditions. | [70] |

| 10 | Theoretical/Simulation Model | The fluid dynamics and SO2 absorption in an open spray tower desulfurization reactor was investigated. | The proposed model is a powerful tool for designing and optimizing an open spray desulfurization tower, e.g., enabling the numerical evaluation of the best position of the spray nozzles, the distance between the spray plumes, the size of the wall rings, the number of operating spray jets and other critical parameters. | [71] |

| 11 | Theoretical/Simulation Model | The operational performance of a SO2 scrubber was examined and optimized. The results of the specific study represent a preliminary work for SO2 removal based on different nozzle designs. | (1) The slurry injection quantity considerably affects the improvement of the scrubber efficiency. (2) The high inlet velocity of the slurry flow positively affects the SO2 removal efficiency. | [72] |

| 12 | Theoretical/Simulation Model | The desulfurization efficiency of an integrated magnesium-based seawater scrubber was investigated. Various parameters were considered such as: (a) the ratio of liquid to gas (VL/VG), (b) the pH and (c) the velocity of the empty container. | (1) The VL/VG and pH parameters are the most effective factors influencing the desulfurization performance. (2) The desulfurization efficiency is greater than 90% under optimized conditions VL/VG = 10.39 L/m3 and pH = 7.66. | [73] |

| 13 | Theoretical/Case Study | The effect of the following alternatives used to reduce sulfur emissions on the investment and operating costs of a ship and a shipping company was investigated financially. Solutions: (a) switch to higher quality and lower sulfur fuels (referred to as distillates), (b) install flue gas cleaning facilities (referred to as scrubbers) and (c) retrofit of an existing LNG engine. | (1) There is a difference in the direction of recognition and response regarding SOx regulation between LC and SMC shipping companies. (2) SOx regulations affect the activities of a shipping company. (3) Governments and related bodies may lead active investment in shipping companies through reasonable political incentives such as the Green Shipping Award, the Green Award Certification and the NOx Fund. | [74] |

| 14 | Theoretical/Simulation Model | The lifetime cost of a scrubbing system and a fuel change approach were compared. | (1) The scrubber system seems to be more attractive to shipping companies that have a higher ECA port call density on their commercial lines, while the fuel change approach is more suitable for ships operating in loops with fewer ECA port calls. (2) There is a knowledge gap in the literature, namely that a ship’s sailing plan should be included in the evaluation of sulfur emission control methods for the ECA regulation and different methods of compliance. | [75] |

| 15 | Theoretical/Case Study | (1) The study examined the link between innovation policy and environmental legislation. (2) The study applied technological and legal material that illustrates the context of marine laundry systems as technological responses to more rigid environmental regulations, examining their impact on market potential and change. | (1) Demand for environmental innovation has gradually increased as the date for the IMO regulations expired due to the need and government support for the adoption of this technology. (2) Environmental regulations can lead to innovation, and for this reason government support in R&D to produce innovative products is extremely important, as market demand alone may not be enough—before environmental regulations—to persuade manufacturers to develop new environmentally sound technologies. (3) In cases where innovation is driven by environmental regulations, government support is also required for its adoption and implementation, as higher initial market prices usually complicate the assessment of the economic feasibility of environmental innovation compared to established technologies, leading to a resistance to adopt or implement them. | [76] |

| 16 | Theoretical/Financial Simulation Models | The limitations of the financial evaluation of technologies assisting compliance with the sulfur regulations in MARPOL Annex VI were identified. | The proposed methodology could improve the understanding of the problem and support decisions and could help operators select the necessary technical alternatives in a better way. | [77] |

| 17 | Experimental & Theoretical/Simulation Model | The following were investigated: (1) the removal of SO2 from seawater in a spray tower, (2) the effect of: (a) the flow rate of liquid to gas, (b) the initial concentration of SO2 in the gaseous phase, (c) the initial gas temperature and (d) the nozzle type, relative to the SO2 removal efficiency. | (1) The effective factors in order of importance are: (a) the liquid flow, (b) the gas flow, (c) the SO2 concentration in gas phase and (d) the inlet gas temperature. (2) At high gas temperatures, an increase in evaporation rate leads to an increase in resistance against SO2 transfer from gas to liquid phase up to a distinctive temperature. (3) The suitability of seawater for SO2 absorption in spray towers was revealed. | [78] |

| 18 | Theoretical/Cost-benefit analysis. | The costs and benefits of the two SOx reduction methodologies were examined: (a) SOx scrubbers and (b) use of MGO. | (1) Investing in MGO on a container ship tends to be more attractive than SWS. (2) The SWS installed on a new ship is generally more attractive than on an ex-post. (3) An old ship is not suitable for scrubber installation when its remaining life is less than 4 years. | [79] |

| 19 | Theoretical/Cost-benefit analysis. | The main goal of the study was to identify the best options, i.e., the lowest reduction costs depending on its type, size and functional model. | (1) For ships with high fuel consumption, on-board cleaning and continuous HFO use provide the lowest cost. (2) In a case with crude oil prices below USD 50 per barrel, diesel is an interesting reduction option for smaller vessels currently using HFO. (3) The desulfurized HFO has production costs which make it a competitive reduction option for all ships except the largest fuel consumers. (4) With scrubber systems, it encourages the operation of vessels at higher speeds. Fuel consumption and CO2 emissions per ton increase as higher speeds require more power input in proportion to the transport work performed. | [80] |

| 20 | Theoretical/Literature Review | The environmental impacts of exhaust gas scrubber discharge were investigated. | (1) It is not clear whether scrubbers will become the standard way to reduce air pollution from shipping for decades to come. (2) It is not clear whether scrubbing systems are currently the most environmentally friendly technology. (3) Important information is provided on policy recommendations and on removing operational and investment uncertainty for the shipping industry. | [81] |

| 21 | Theoretical/Case Study | Two technologies used for reduction SOx emissions, i.e., (a) low sulfur fuel and (b) scrubber were elaboratively examined. | Comparing the technologies, it is observed that: (1) the technology chosen does not matter because each will require additional costs, i.e., capital cost and operating cost, loss of profits due to reduced load capacity; (2) the evaluation of the return on investment should be carried out by comparing the different technologies (in this case scrubber and low sulfur fuel) that meet the requirements of MARPOL 73/78; (3) the effectiveness of the investment in technology was assessed by cash flow modeling during the invoicing period covering the period from the introduction of the technology to the completion of the fiscal year. | [82] |

| 22 | Theoretical/Case Study | The repercussions of smokestack and scrubber release of acidic oxides in the Baltic Sea were thoroughly examined. | (1) As shipping is projected to become a major source of strong acid deposition in the Baltic Sea, the long-term effects on pH and alkalinity have been shown to be significantly lower than estimated from previous scope studies. (2) An important contribution to this difference is the effective extraction of acidification of surface waters. | [83] |

| 23 | Theoretical/Case Study | The well-to-wake energy consumption and GHG emissions of several major SOx abatement solutions used in marine transportation were investigated. | (1) An HFO scrubbing system has the potential to reduce SOx emissions with lower energy consumption and greenhouse gas emissions compared to the transition to low sulfur fuel production at the refinery. (2) A sensitivity analysis covering a number of system parameters revealed that fluctuations in the intensity of greenhouse gas emissions from the tank and the energy efficiency of the main engine have the highest effects on emissions. | [84] |

| 24 | Theoretical/Report | All available restrictions on the process of selecting fuels and propulsion equipment for maritime compliance with the IMO regulations on SOx emissions were examined. | The specific study: (a) provides various alternatives for compliance with “global sulfur cap 2020”, and (b) the advantages and disadvantages of each method were highlighted. | [85] |

| 25 | Experimental | The following methodologies used to control exhaust emissions in marine diesel engines were examined, i.e., (a) using only seawater, (b) electrolysis with electrolyzed alkaline seawater. | (1) With a seawater scrubber system. SOx removal could be achieved nearly perfectly leading to a sufficient reduction of PM. (2) Seawater electrolysis is more suitable for absorption of NOx and CO2. | [86] |

| 26 | Theoretical/Simulation Model | The mechanism of SO2 seawater absorption was investigated. | (1) The absorption capacity of typical seawater is about twice that of brackish water with almost zero salinity. (2) The absorption capacity decreases with both salinity and alkalinity. (3) The cleaning efficiency of 66%, which corresponds to compliance with the limits of the SOx emission control zones (SECA) when operating on fuel containing 4.5% w/w sulfur, requires a minimum water flow rate of 40–63 kg/(kWh depending on the composition of the seawater in terms of salinity and alkalinity. | [87] |

| 27 | Experimental | (1) A comparative study between seawater and distilled water was carried out to examine the effect of seawater alkalinity. (2) The liquid phase was analyzed for alkalinity, pH and sulfate content before and after the tests. (3) The spray droplet size distribution was measured as a function of fluid flow rate. | (1) Seawater performed better than distilled water, taking advantage of its inherent alkalinity. (2) The desulfurization efficiency was improved by increasing the liquid flow rate and gas residence time and by decreasing the SO2 concentration. | [88] |

| 28 | Theoretical/Simulation Model | The heat and mass transfer process occurring in a seawater scrubber for marine application was comparatively investigated. | (1) A DPM (discrete phase model) was chosen for this case to simulate a real scrubber prototype. (2) Important information was given concerning the droplets trajectory, the velocity and the temperature inside the scrubber system. | [89] |

| No. | Type of the Study | Main Objectives of the Study | Main Conclusions of the Study | Reference |

|---|---|---|---|---|

| 1 | Experimental | The performance indicators of a marine SCR catalyst was investigated. | (1) Substrates must be durable to: (a) survive the high sulfur content of marine fuels and (b) provide cost and pressure drop benefits. (2) Extruded honeycomb substrates offer advantages in system volume and provide increased catalyst surface (in direct compensation with increased pressure drop). (3) Higher cell densities can be more easily clogged by the deposition of soot and/or sulfate particles on the inlet surface of the monolithic converter as well as on the channel walls and catalyst coating, ultimately leading to unacceptable flow restriction or catalytic flow suppression. | [106] |

| 2 | Theoretical/Simulation Model | The control rules in an SCR-DeNOx installation for a marine diesel engine working at full load conditions were elaborated. | The velocity distribution at the inlet of the catalyst layers, which can be affected by the position, size and angle of the gate leaves, plays an important role in the NOx removal efficiency of SCR systems. | [107] |

| 3 | Theoretical/Simulation Model | The operational performance of a compact diesel after-treatment system combining an SCR system with a reactive muffler was investigated. | (1) The system is capable of increasing NH3 homogeneity and improving NOx reduction efficiency. (2) In the integrated SCR—muffler, the pressure loss was significantly increased compared to a simple SCR system. | [108] |

| 4 | Theoretical/Assessment Study | The effects of the main important characteristics (i.e., composition, temperature, etc.) of the exhaust gases from a low-speed marine diesel engine on the performance characteristics of a SCR system were investigated. | (1) The weighted average NOx value of the low sulfur exhaust gas complied with the requirements of the IMO Tier III regulations when the low speed diesel engine was mated to the high pressure SCR system. (2) The weighted average NOx value under the high sulfur exhaust was slightly higher than that required by the IMO Tier III. (3) For both strategies, the engine exhaust performance meets the requirements of the IMO Tier III. (4) The cleaning bypass configuration design appears to have less impact on the initial performance of the engine. | [109] |

| 5 | Theoretical/Simulation Model | For marine SCR applications, the effect of static mixer geometry on flow mixing and pressure drop was investigated. | (1) Regardless of the type, the presence of a mixer leads to an improvement of the mixing efficiency by about 20%. (2) There was a compensatory relationship between uniformity and pressure drop. (3) In terms of mixing efficiency and pressure drop, the vortex type stirrer seems to be more suitable than the line type mixer. | [110] |

| 6 | Experimental and Theoretical/Simulation Model | The operational impact of a marine SCR-urea system on the reduction of NOx emissions was examined. | (1) The increase of the catalyst length leads to an increased total denitrification rate. (2) The increased length of the catalyst negatively affects the oxidation reaction rate of ammonia. | [111] |

| 7 | Experimental | The operating principles (a) and the behavior concerning the NOx reduction, of a scrubber system (components: exhaust heat exchangers, catalyzed particulate filter (CPF), diesel oxidation catalyst (DOC), packed bed wet scrubber), working on the principle of absorption of NOx species into water (b) were examined. | (1) NOx emissions absorption ranged from 4–66%. (2) The average NOx absorption of the cycle ranged from 15–58%. (3) NOx absorption varies depending on: (a) the residence time of the gas, (b) the absorption surface, (c) the temperature and (d) the NOx concentration. | [112] |