Design and Analysis of Novel Synchronous Motion Technique for a Multi-Module Permanent Magnet Linear Synchronous Motor

Abstract

:1. Introduction

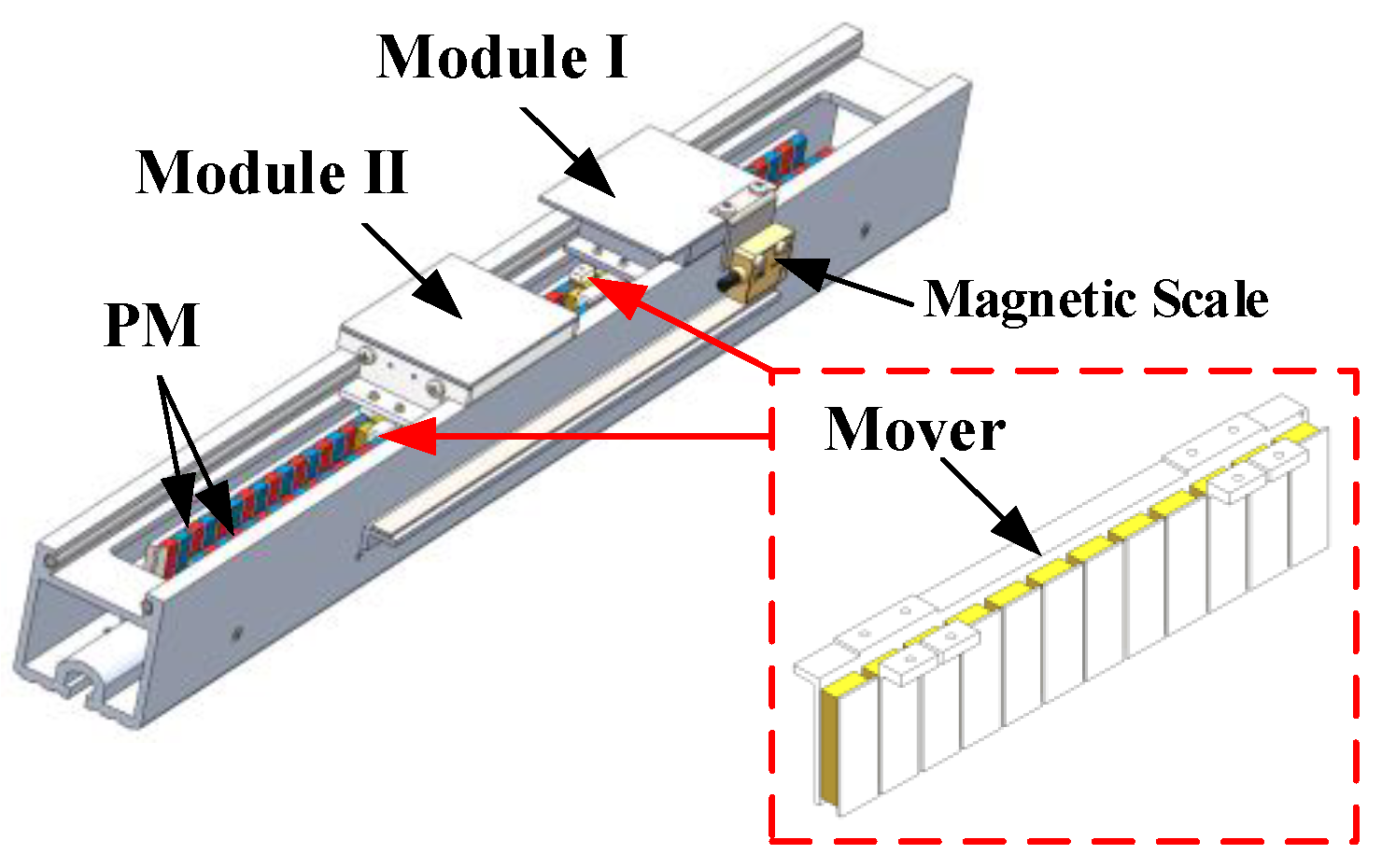

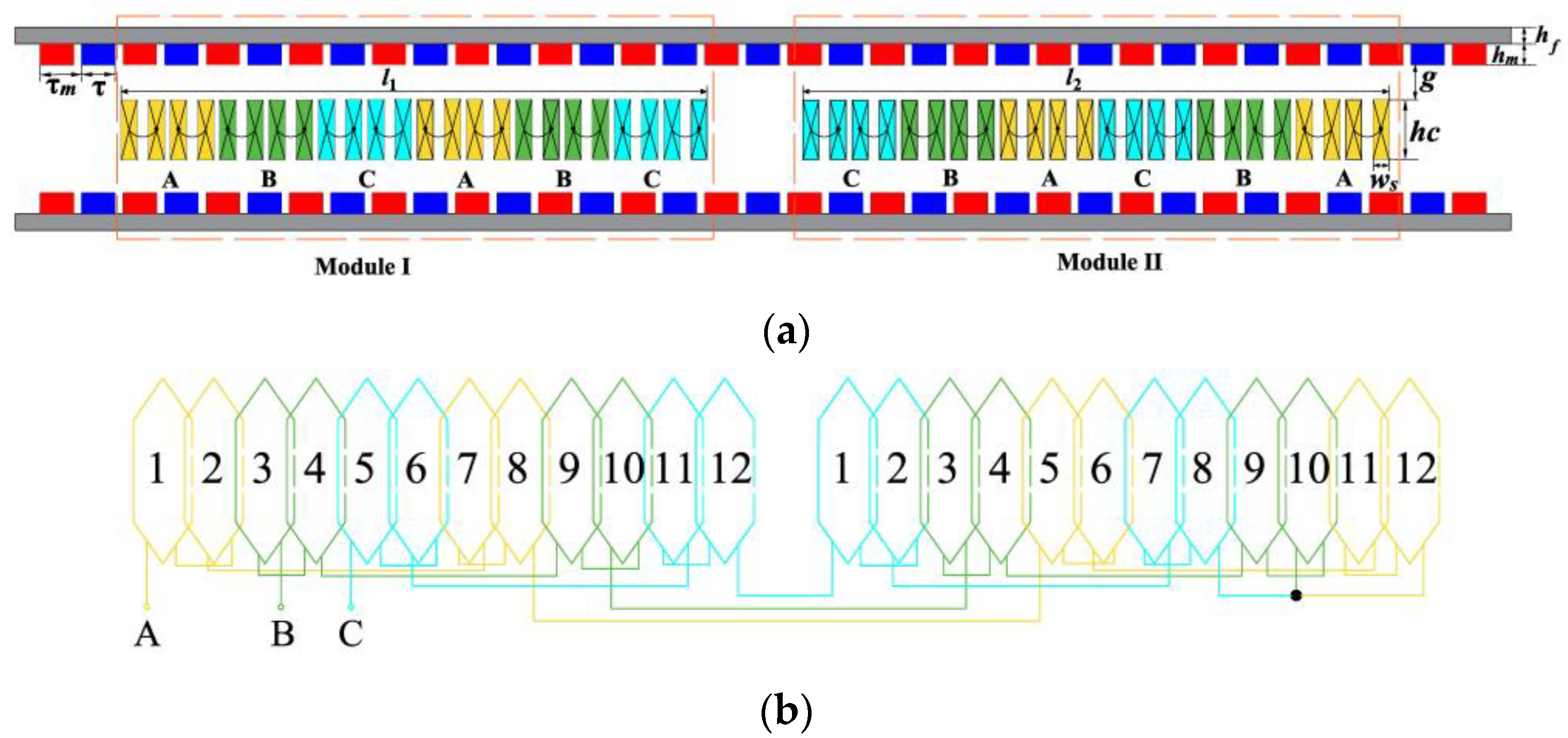

2. Motor Topology Structure

3. Mathematical Models of the Two-Module PMLSM

- (1)

- the three-phase windings are symmetrical, differing from each other by 120 degrees in space;

- (2)

- the magnetic circuit nonlinearity and PM eddy current loss are neglected;

- (3)

- flux linkage produced by windings and PMs is sinusoidal;

- (4)

- the temperature influence on electromagnetic parameters is dismissed.

3.1. Three-Phase Flux Linkage

3.2. Three-Phase Winding Terminal Voltage

3.3. Input Power

3.4. Average Thrust

3.5. Motion Equation

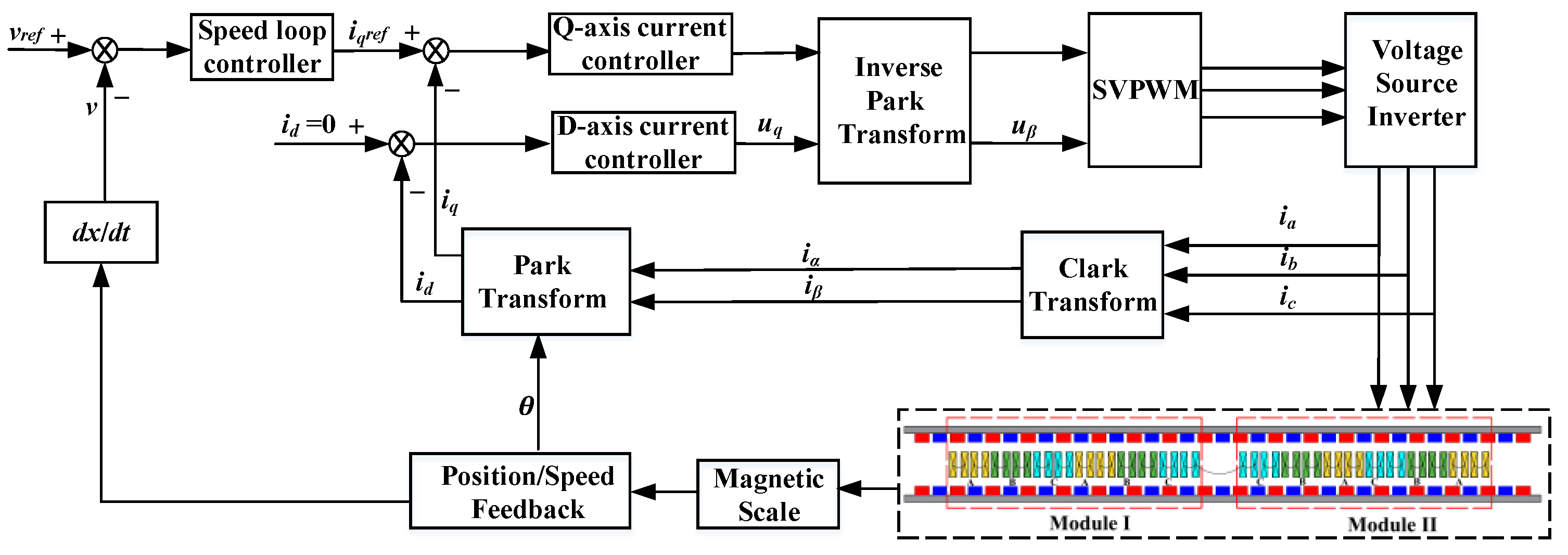

4. Vector Control Strategy for the Two-Module PMLSM

5. Experimental Verification and Results

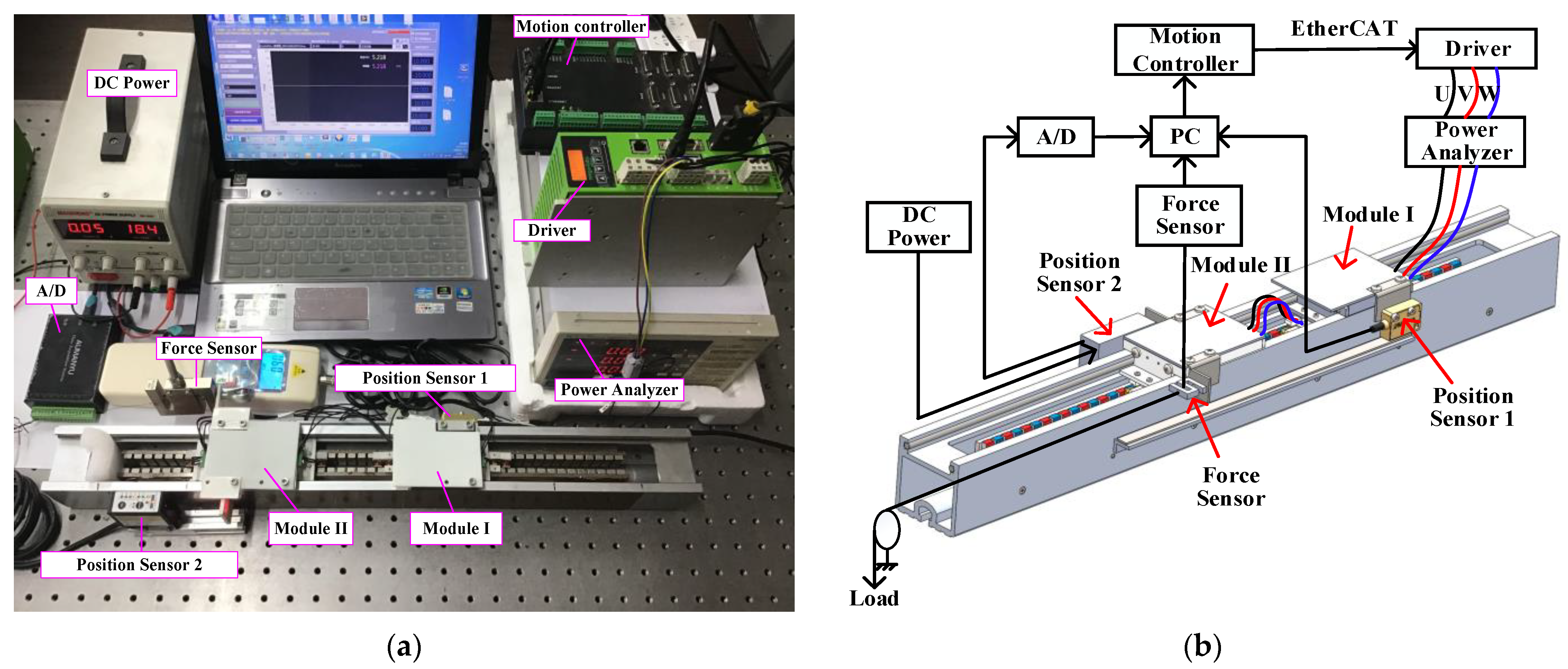

5.1. Experimental Setup

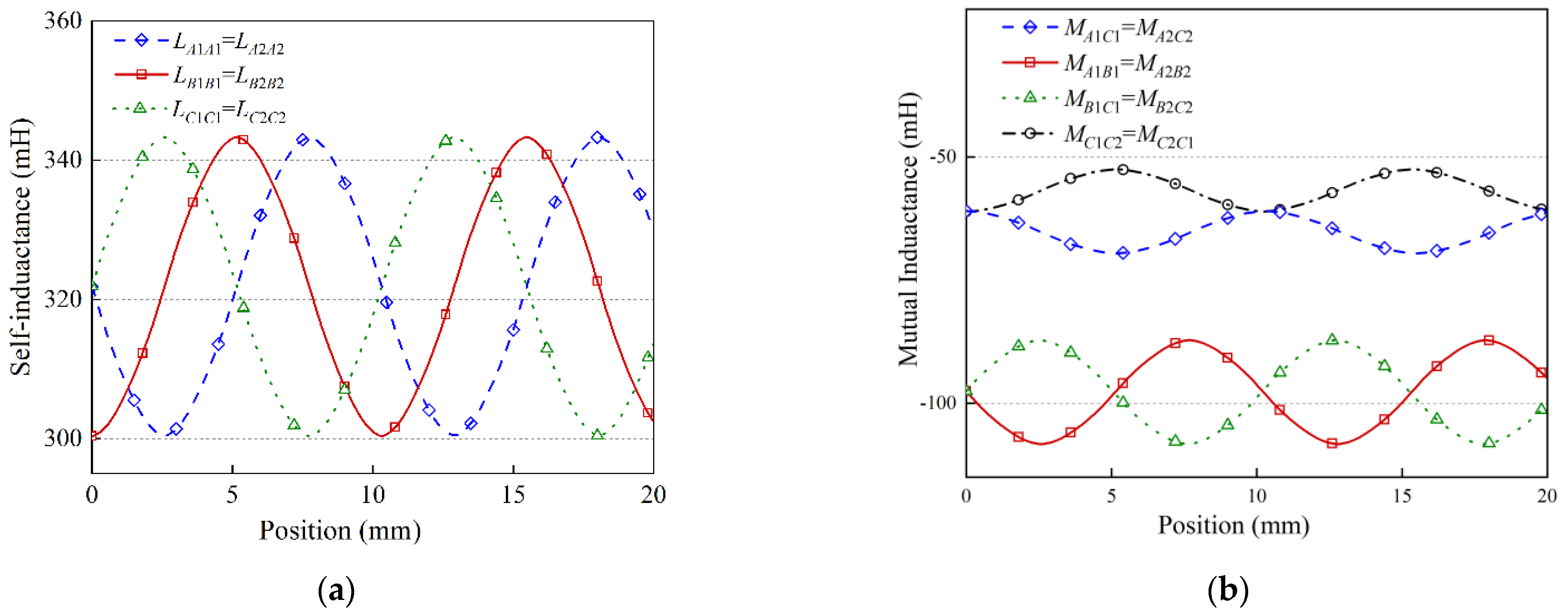

5.2. FEM Results of the PM Flux Linkage and Inductance

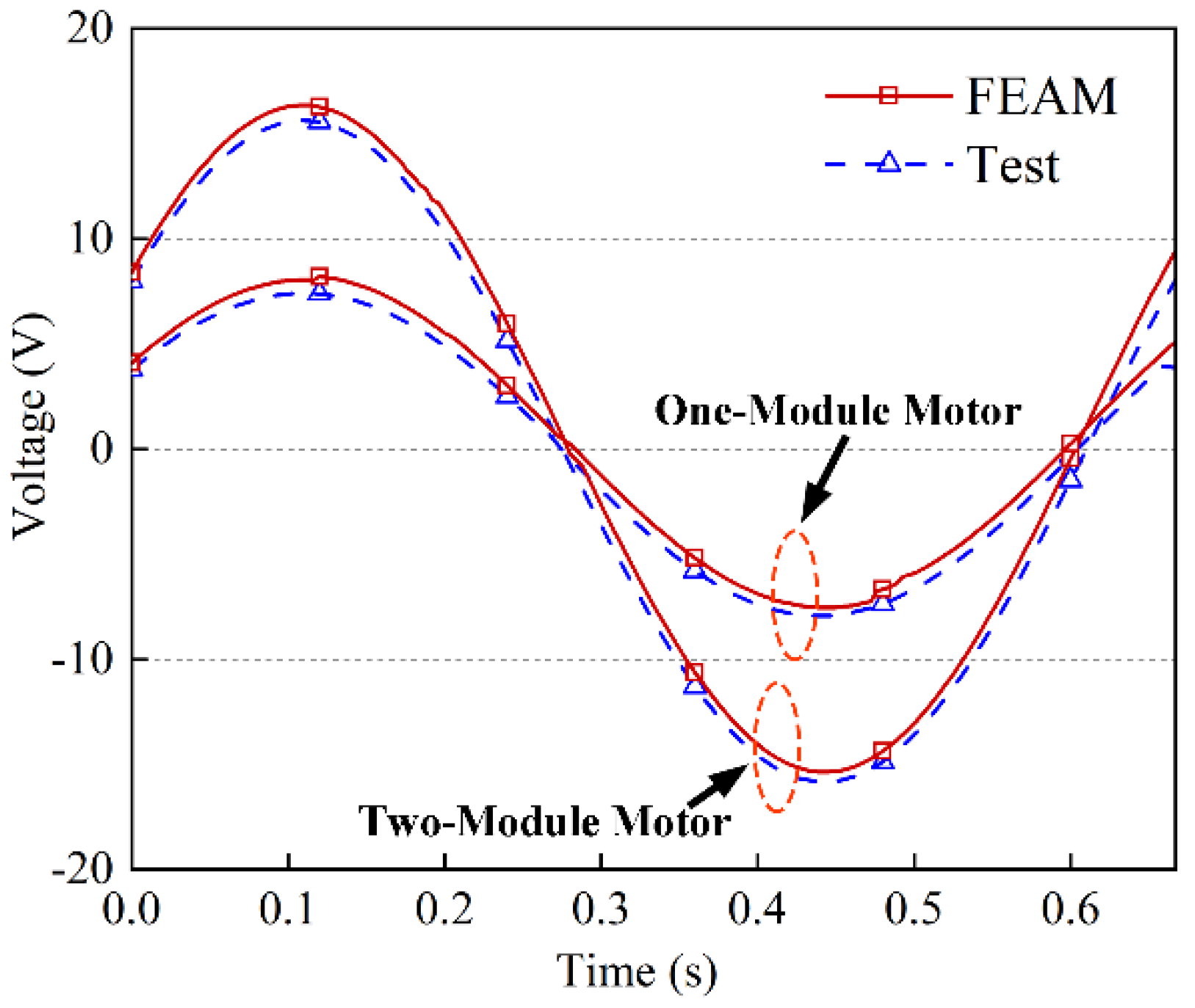

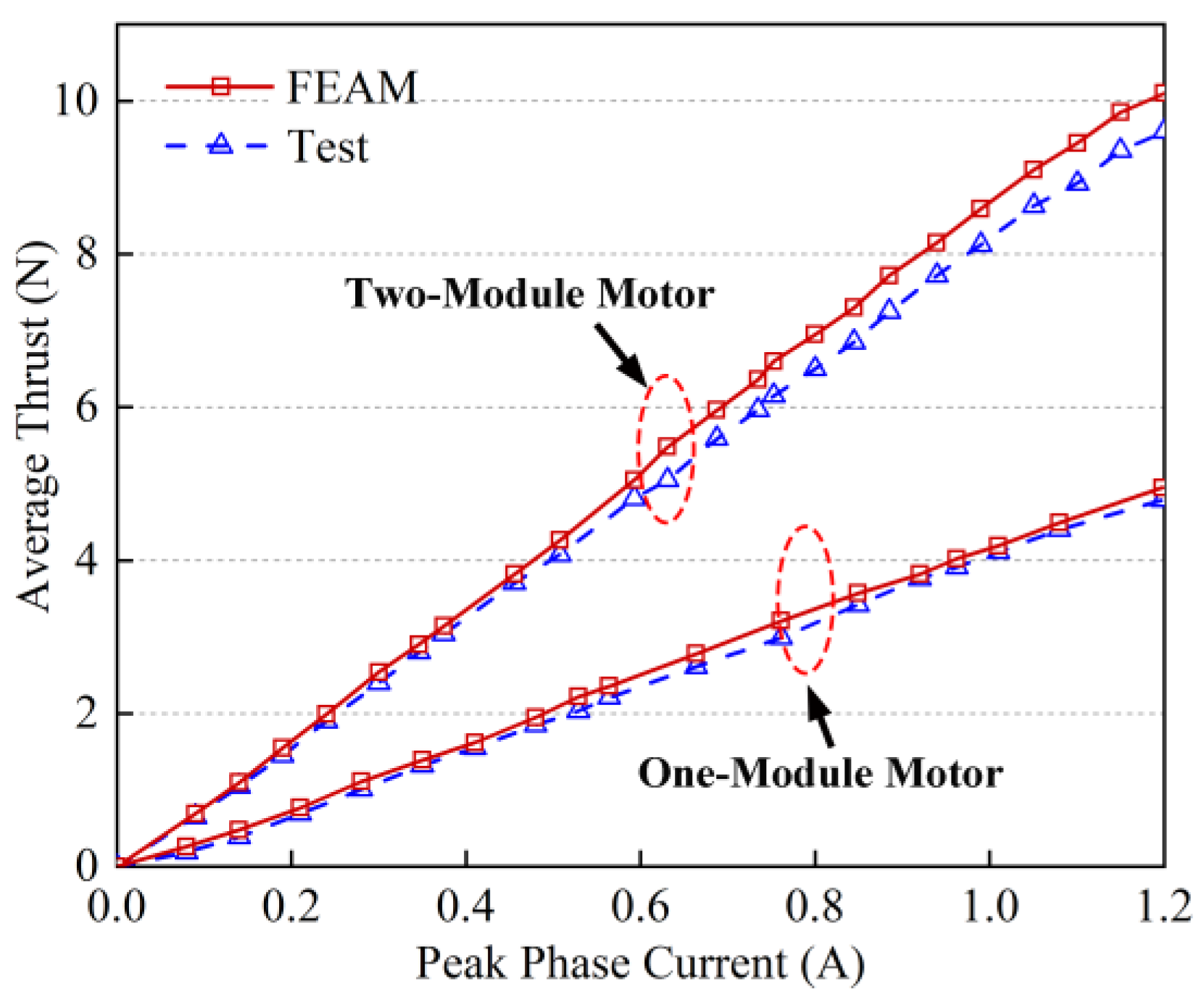

5.3. Voltage and Thrust Characteristics

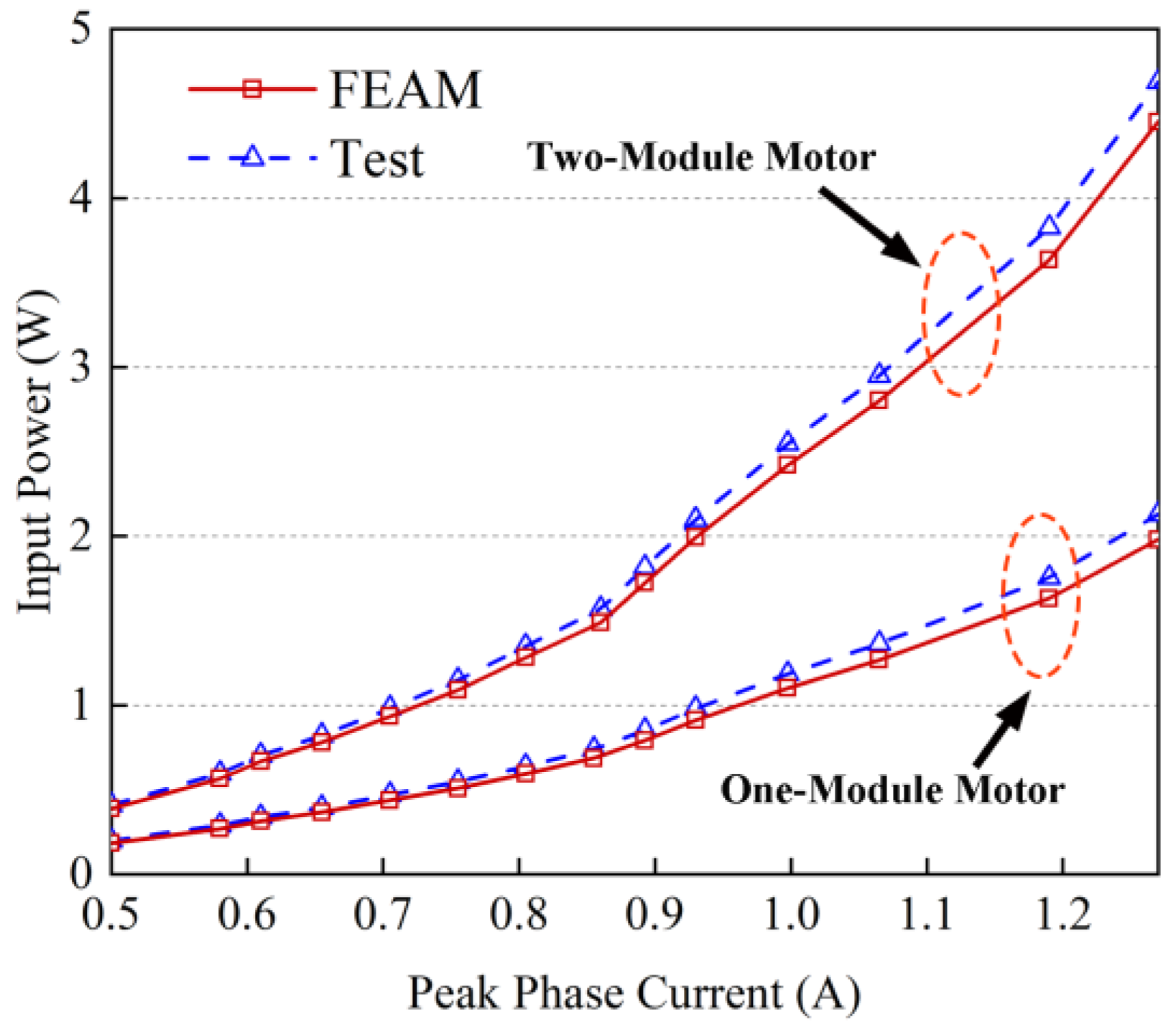

5.4. Input Power Characteristic

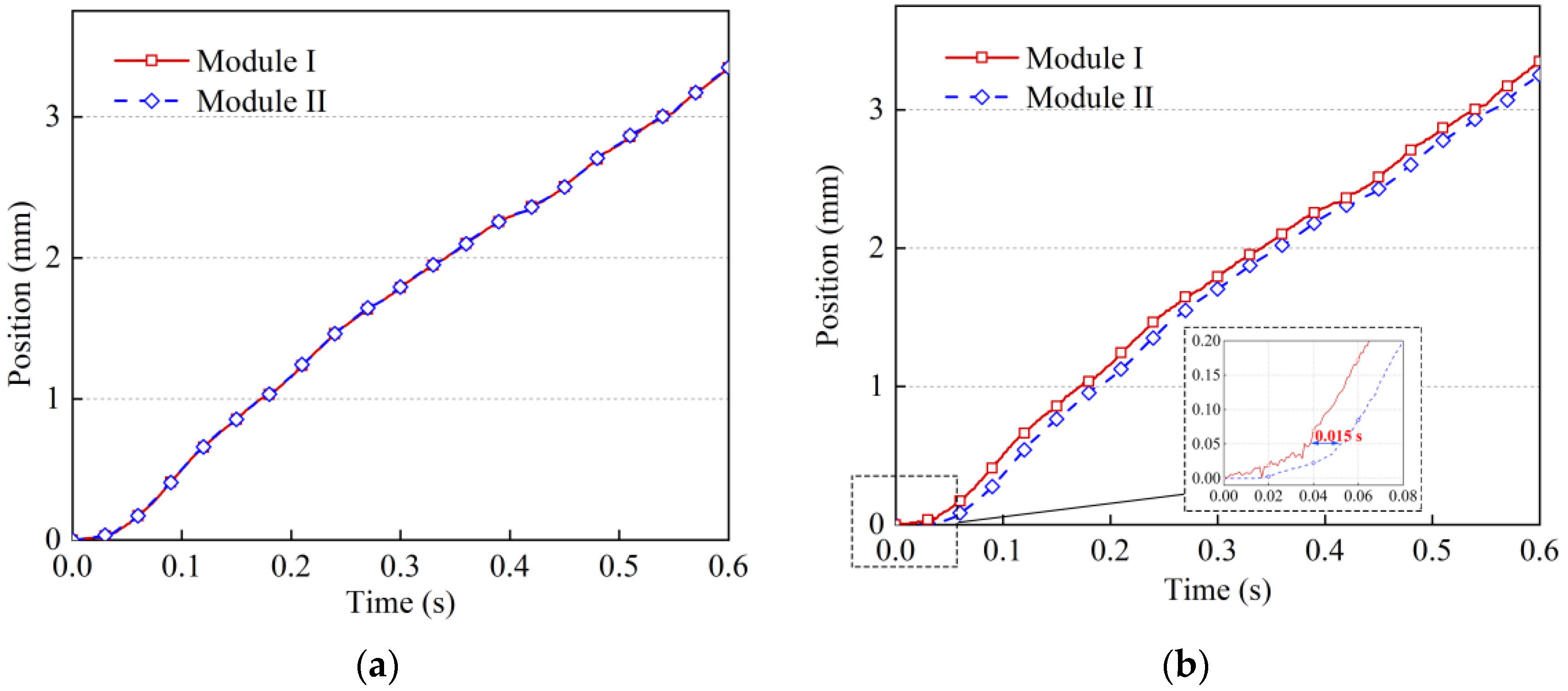

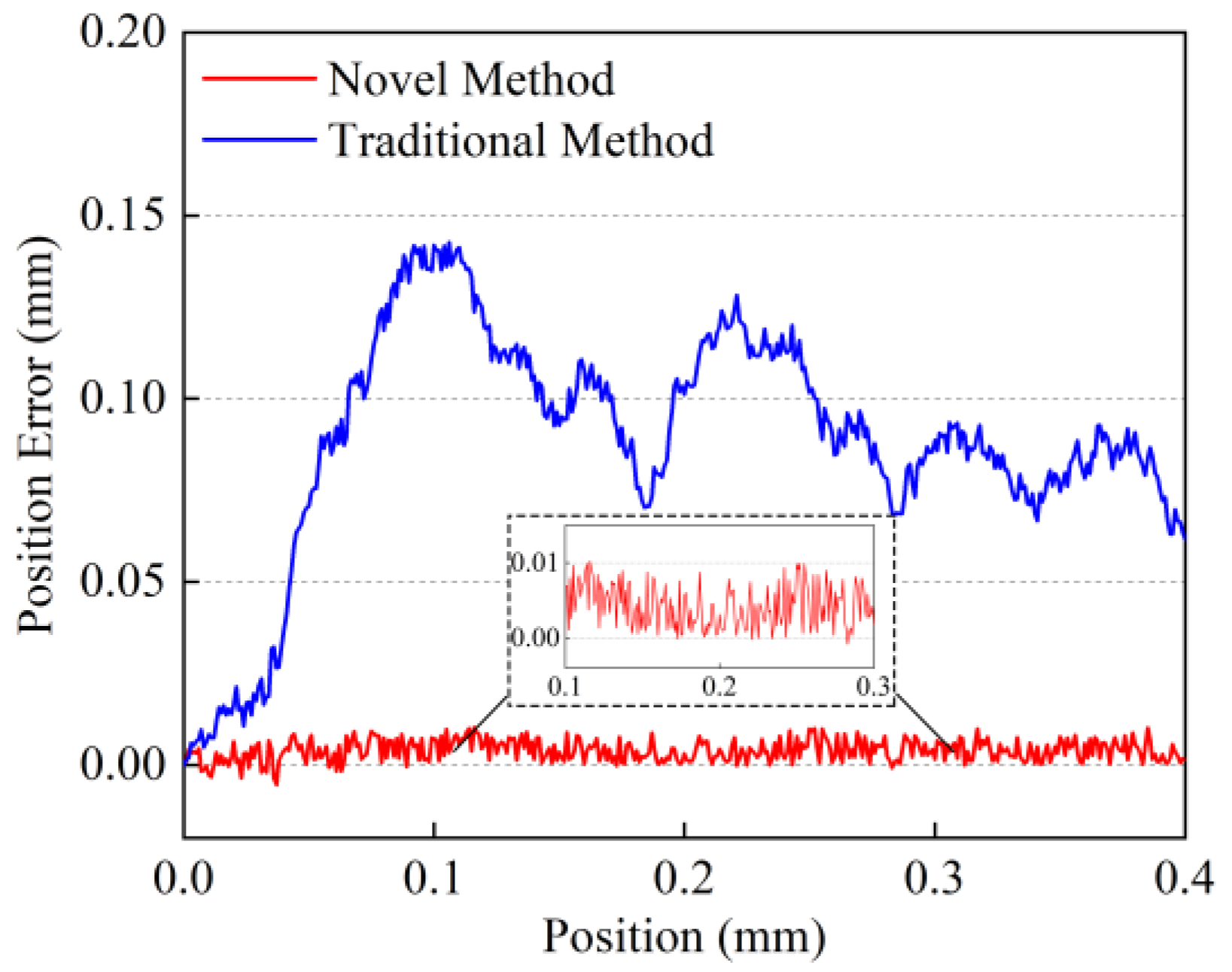

5.5. Synchronization Performance Comparison without External Disturbance

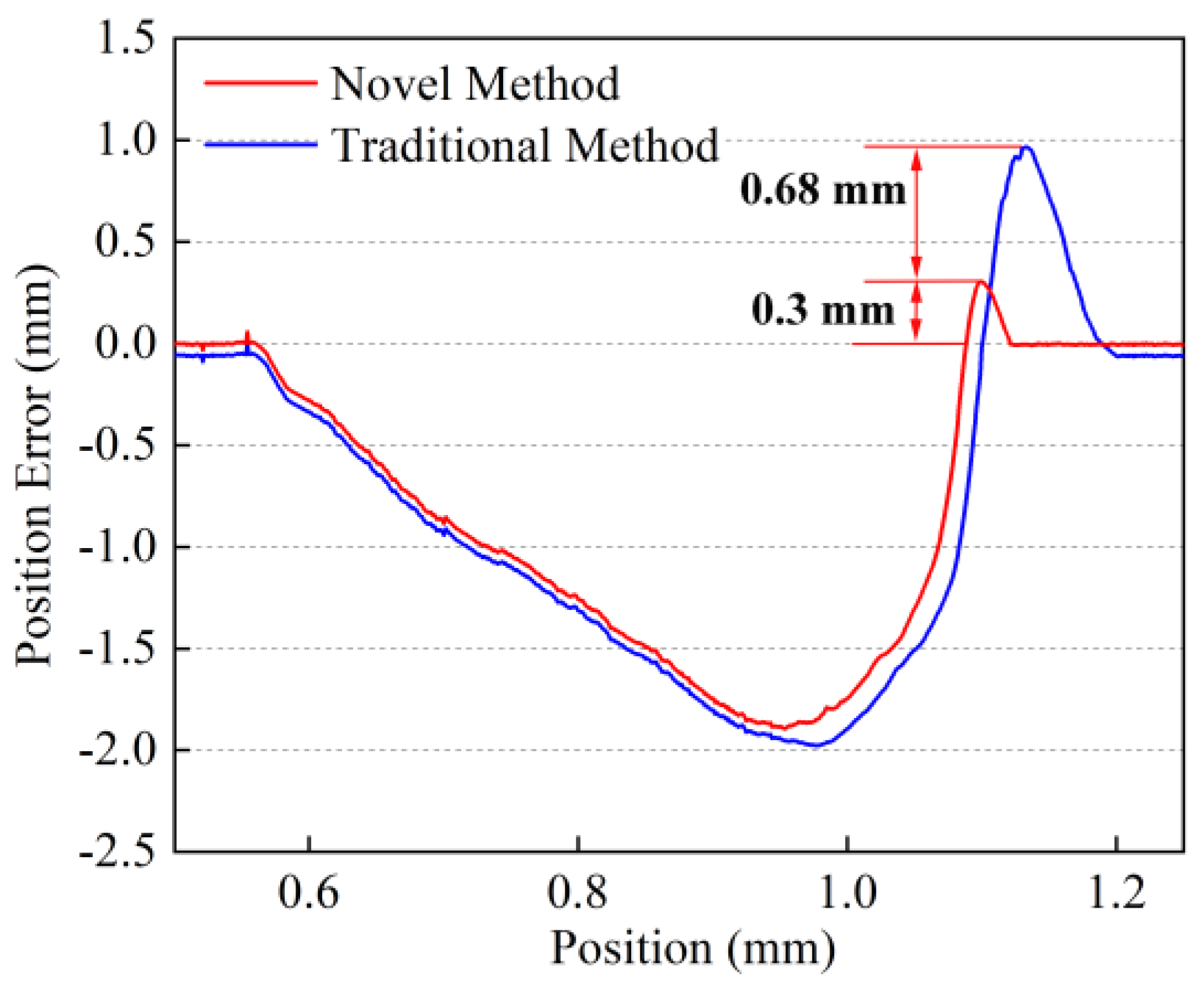

5.6. Synchronization Performance Comparison with External Disturbance

6. Conclusions

- (1)

- The proposed novel method can realize no control delay time between the two modules, thus improving the two-module synchronization performance. Furthermore, the proposed novel method has better dynamic response in the sudden change of external disturbance.

- (2)

- Influenced by the coupling inductance between the two modules, the two-module motor’s peak voltage, average thrust, and input power are 1.9%, 2.7%, and 4.5% larger than those of two times the one-module motor, respectively. Furthermore, accurate mathematical models are significant to the design and control of the two-module PMLSM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, C.; Li, C.; Chen, Z.; Yao, B. Advanced synchronization control of a dual-linear-motor-driven gantry with rotational dynamics. IEEE Trans. Ind. Electron. 2018, 65, 7526–7535. [Google Scholar] [CrossRef]

- Wang, B.; Iwasaki, M.; Yu, J. Command filtered adaptive backstepping control for dual-motor servo systems with torque disturbance and uncertainties. IEEE Trans. Ind. Electron. 2022, 69, 1773–1781. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Li, Y.; Luo, W. Reference trajectory modification based on spatial iterative learning for contour control of two-axis NC systems. IEEE/ASME Trans. Mechatron. 2020, 25, 1266–1275. [Google Scholar] [CrossRef] [Green Version]

- Ghaffari, A.; Ulsoy, A.G. Dynamic contour error estimation and feedback modification for high-precision contouring. IEEE/ASME Trans. Mechatron. 2016, 21, 1266–1275. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Zhang, W.-A.; Yu, L. A Linear Active Disturbance Rejection Control Approach to Position Synchronization Control for Networked Interconnected Motion System. IEEE Trans. Control Netw. Syst. 2020, 7, 1746–1756. [Google Scholar] [CrossRef]

- Kuang, Z.; Gao, H.; Tomizuka, M. Precise linear-motor synchronization control via cross-coupled second-order discrete-time fractional-order sliding mode. IEEE/ASME Trans. Mechatron. 2021, 26, 358–368. [Google Scholar] [CrossRef]

- Barton, K.L.; Alleyne, A.G. A cross-coupled iterative learning control design for precision motion control. IEEE Trans. Control Syst. Technol. 2008, 16, 1218–1231. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, J.H.; He, D.S.; Zhang, B. Based on Adjacent Cross-Coupling of Multi-Motor Synchronous Drive. Adv. Mater. Res. 2011, 201–203, 1093–1097. [Google Scholar] [CrossRef]

- Li, J.; Fang, Y.; Huang, X.; Li, J. Comparison of synchronization control techniques for traction motors of high-speed trains. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 2114–2119. [Google Scholar]

- Shi, T.; Liu, H.; Geng, Q.; Xia, C. Improved relative coupling control structure for multi-motor speed synchronous driving system. IET Electr. Power Appl. 2016, 10, 451–457. [Google Scholar] [CrossRef]

- Zeng, Z.; Shen, Y.; Lu, Q.; Wu, B.; Gerada, D.; Gerada, C. Investigation of a Partitioned-Primary Hybrid-Excited Flux-Switching Linear Machine with Dual-PM. IEEE Trans. Ind. Appl. 2019, 55, 3649–3659. [Google Scholar] [CrossRef]

- Li, J.; Huang, X.; Zhou, B.; Yu, H.; Huang, Q. Design principle of a 16-pole 18-slot two-sectional modular permanent magnet linear synchronous motor with optimisation of its end tooth. IET Electr. Power Appl. 2020, 14, 441–447. [Google Scholar] [CrossRef]

- Shi, T.; Zhang, X.; Zhou, Z.; Xia, C. Precise Contour Control of Biaxial Motion System Based on MPC. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1711–1721. [Google Scholar] [CrossRef]

- Xiong, H.; Zhang, M.; Zhang, R.; Zhu, X.; Yang, L.; Guo, X.; Cai, B. A new synchronous control method for dual motor electric vehicle based on cognitive-inspired and intelligent interaction. Future Gener. Comput. Syst. 2018, 94, 536–548. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, Y.; Wang, Y. Research on a Multi-Motor Coordinated Control Strategy Based on Fuzzy Ring Network Control. IEEE Access 2020, 8, 39375–39388. [Google Scholar] [CrossRef]

- Bian, C.; Hua, M.; Zheng, D. Cross-coupling synchronous control of dual-motor networked motion control system. In Proceedings of the Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017; pp. 7628–7633. [Google Scholar] [CrossRef]

- Zhong, G.; Shao, Z.; Deng, H.; Ren, J. Precise Position Synchronous Control for Multi-Axis Servo Systems. IEEE Trans. Ind. Electron. 2017, 64, 3707–3717. [Google Scholar] [CrossRef]

- Shen, H.; Li, P.; Luo, X. Synchronous multi-axis motion control based on modified EtherCAT distributed clock. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 3674–3678. [Google Scholar] [CrossRef]

- Li, G.-J.; Ren, B.; Zhu, Z.Q.; Foster, M.P.; Stone, D.A. Demagnetization Withstand Capability Enhancement of Surface Mounted PM Machines Using Stator Modularity. IEEE Trans. Ind. Appl. 2017, 54, 1302–1311. [Google Scholar] [CrossRef] [Green Version]

- Tan, Q.; Huang, X.Z.; Li, L.; Wang, M. Magnetic Field Analysis and Flux Barrier Design for Modular Permanent Magnet Linear Synchronous Motor. IEEE Trans. Ind. Electron. 2019, 67, 3891–3900. [Google Scholar] [CrossRef]

- Zheng, M.; Zhu, Z.Q.; Cai, S.; Xue, S.S. A Novel Modular Stator Hybrid-Excited Doubly Salient Synchronous Machine With Stator Slot Permanent Magnets. IEEE Trans. Magn. 2019, 55, 8104409. [Google Scholar] [CrossRef] [Green Version]

- Ma, M.; Li, L.; Zhang, J.; Yu, J.; Zhang, H.; Mingna, M. Investigation of Cross-Coupling Inductances for Long-stator PM Linear Motor Arranged in Multiple Segments. IEEE Trans. Magn. 2015, 51, 8205304. [Google Scholar] [CrossRef]

- Bang, D.-J.; Hwang, S.-H. Wide Air-gap Control for Multi-module Permanent Magnet Linear Synchronous Motors without Magnetic Levitation Windings. J. Power Electron. 2016, 16, 1773–1780. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Huang, K.; Sun, P.; Dong, R. Analytical Calculation of Performance of Line-Start Permanent-Magnet Synchronous Motors Based on Multidamping-Circuit Model. IEEE Trans. Power Electron. 2020, 36, 4410–4419. [Google Scholar] [CrossRef]

- Liu, J.; Bai, J.; Zheng, P.; Zhang, S.; Wang, M.; Yin, Z. Torque analysis of magnetic-field-modulated double-rotor machines with virtual work method. In Proceedings of the International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2018; pp. 1885–1889. [Google Scholar]

- Neyman, V.Y.; Markov, A.V. Model of electromechanical energy converter with variable inductance. In Proceedings of the 2019 20th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices (EDM), Erlagol, Russia, 29 June–3 July 2019; pp. 765–769. [Google Scholar]

- Kazan, E.; Onat, A. Modeling of Air Core Permanent-Magnet Linear Motors with a Simplified Nonlinear Magnetic Analysis. IEEE Trans. Magn. 2011, 47, 1753–1762. [Google Scholar] [CrossRef]

| Symbol | Quantity | Value |

|---|---|---|

| p | Pole pairs | 14 |

| τ | Pole pitch | 8 mm |

| Q | Virtual slots | 24 |

| hf | Height of secondary iron | 5 mm |

| τm | Width of PM | 10 mm |

| hm | Height of PM | 5 mm |

| hc | Height of coil | 5.4 mm |

| ws | Width of coil | 3.75 mm |

| g | Length of the sided air-gap | 1 mm |

| L | Longitudinal length | 55 mm |

| N | Number of turns per coil | 105 |

| R | Phase resistance | 7.6 Ω |

| l1 | Length of Module I | 79 mm |

| l2 | Length of Module II | 79 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Yin, H.; Zhang, H. Design and Analysis of Novel Synchronous Motion Technique for a Multi-Module Permanent Magnet Linear Synchronous Motor. Energies 2022, 15, 3617. https://doi.org/10.3390/en15103617

Zhang F, Yin H, Zhang H. Design and Analysis of Novel Synchronous Motion Technique for a Multi-Module Permanent Magnet Linear Synchronous Motor. Energies. 2022; 15(10):3617. https://doi.org/10.3390/en15103617

Chicago/Turabian StyleZhang, Fugang, Haibin Yin, and Han Zhang. 2022. "Design and Analysis of Novel Synchronous Motion Technique for a Multi-Module Permanent Magnet Linear Synchronous Motor" Energies 15, no. 10: 3617. https://doi.org/10.3390/en15103617

APA StyleZhang, F., Yin, H., & Zhang, H. (2022). Design and Analysis of Novel Synchronous Motion Technique for a Multi-Module Permanent Magnet Linear Synchronous Motor. Energies, 15(10), 3617. https://doi.org/10.3390/en15103617