Bearing Fault Diagnosis under Time-Varying Speed and Load Conditions via Observer-Based Load Torque Analysis †

Abstract

:1. Introduction

2. Mathematical Model of Modified Natural Observer

- Record 30 historic values of the q-axis current command in an array.

- When a new q-axis current command is generated by the PI controller of the speed loop, the current commands that delay the 1-speed loop ago and delay the 30-speed loop ago, a.k.a. and , should be used to calculate the absolute value of errors and .

- Once each error exceeds a preset threshold , a transient flag should be set to TRUE to indicate that the motor is operating in the transient condition. The flag will return FALSE when both errors are under the threshold for a certain period of time.

- The coefficient of the differential component will be set to 0 when the transient flag is FALSE, and will be a tuned value if the transient flag is TRUE.

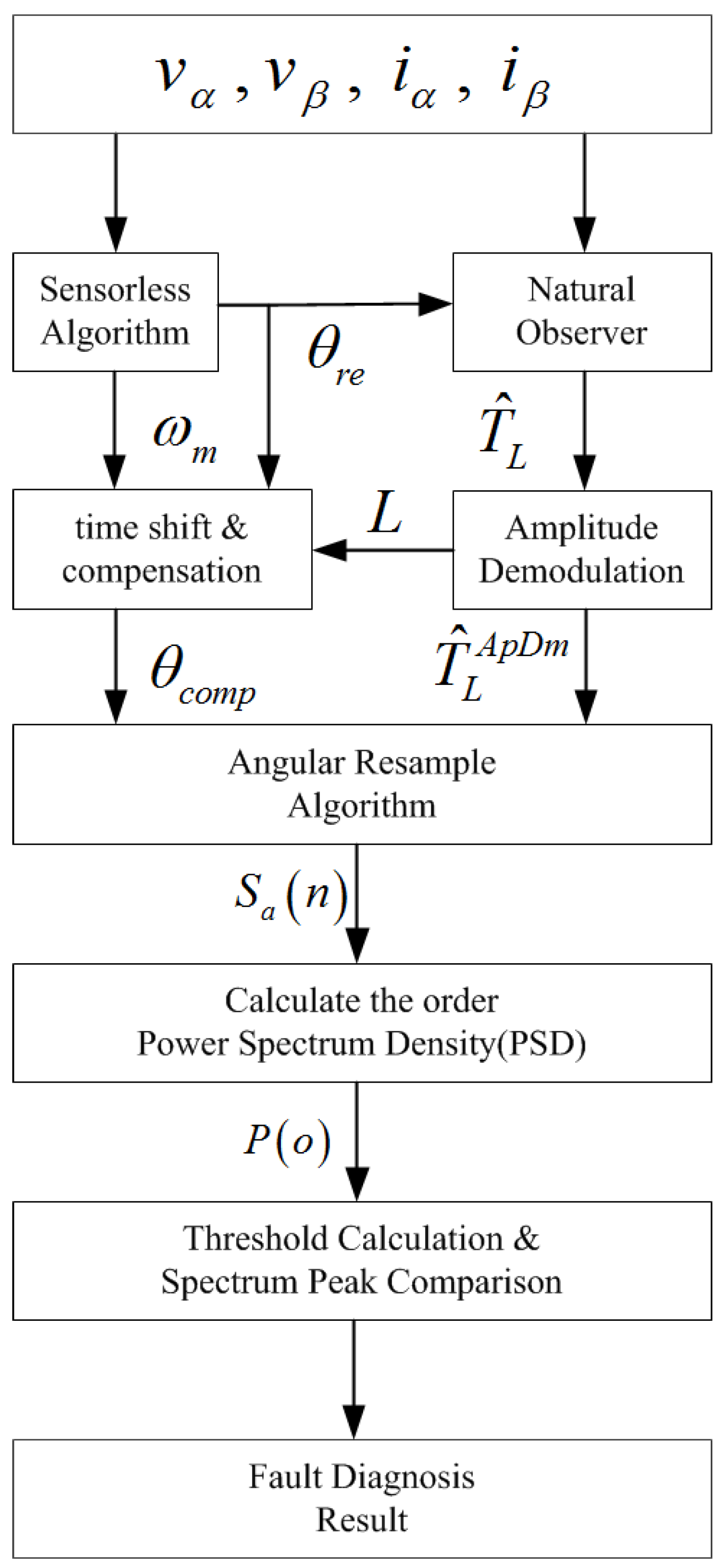

3. Bearing Fault Diagnosis under Non-Stationary Conditions

3.1. Bearing Fault Characteristic Frequency and Its Extension under Non-Stationary Conditions

3.2. Rotating Angle Estimation and Angle Compensation

3.3. The Moving Averaging Filter and Amplitude Demodulation

3.4. The Angular Resample (AR) Algorithm

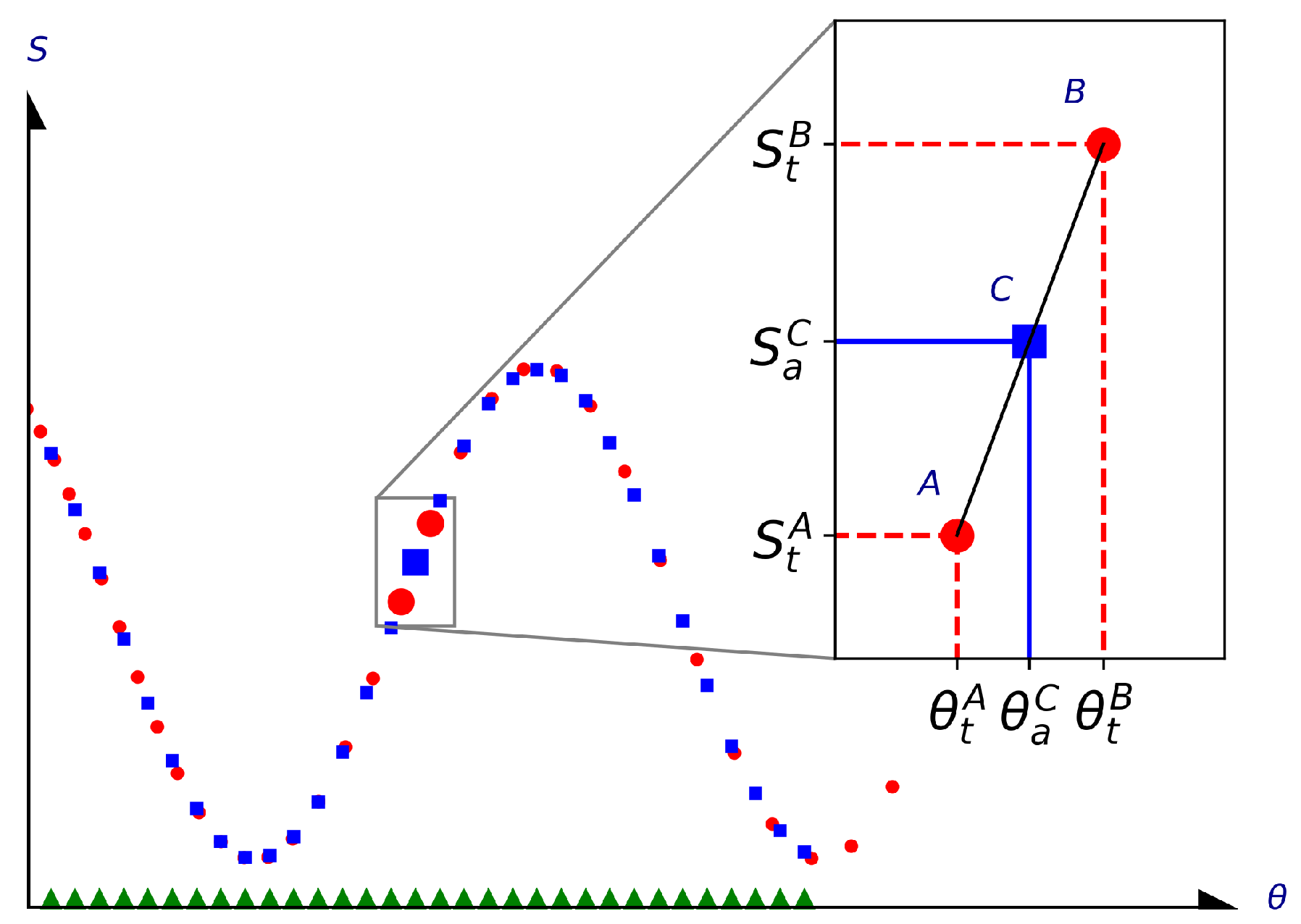

- The subscript “t” is used to indicate the series in the time domain. The time domain series is sampled at a constant sampling-rate with equal time intervals. They are basically non-stationary signals, which need to be resampled into the series with equal angular intervals. The rotor position angle series and the non-stationary load torque signal series are constructed using and , respectively.

- The subscript “a” is used to indicate the series in the angular domain. An angular domain series is created with equal angular intervals between each pair of adjacent points and drawn with “▲” markers in Figure 2where M denotes the sample number per revolution in the angular domain, which analogously resembles to the sampling frequency in the time domain. N represents the total number of revolutions in the angular domain, which, in the time domain, analogously resembles the time length of the series .

- The load torque signal time domain series is reallocated as the angular domain series , which is drawn in Figure 2 with “•” markers. should be resampled at specific angular values listed in to ensure an equal-angular-interval series in angular domain. As drawn in the zoom-in subplot of Figure 2, point with “■” markers refers to an interpolation example point. Its horizontal ordinate is in series , and its vertical ordinate is calculated using linear interpolation

3.5. Fault Threshold Determination Using Information Entropy

- Create two sliding windows, and , whose lengths are and respectively.

- Move the sliding window through the whole , and calculate the average of the values included in . A new order spectrum , called “average-value spectrum” can be obtained.

- Slide the window and calculate the median of the values included in . A new order spectrum , called “median-value spectrum”, can be obtained.

- Calculate the maximum value of . It is defined as the threshold of the original spectrum .

- If the amplitude of at the corresponding BFCO (or in its neighborhood) is higher than the , it indicates that the motor is in a bearing fault condition and is in demand of the maintenance.

- Locate the impulses that are dominant in the order spectra by the method of information entropy described in [37].where represents the share of , the sorted values of the order spectra, in the sum of all in the order spectra.To decide whether the impulses are “dominant” in the order spectra, the differential of is calculated:If becomes relatively small enough, all the should be regarded as “dominant impulses”.

- Calculate the weighted distances of the picked order spectrum value using the following expression:where indicates the distance between and

- Among the , the information entropy method is implemented again. If and , will be set as , the length of the average window.

- The length of the medium window, , should be greater than , and is set as .

4. Simulation and Experimental Results

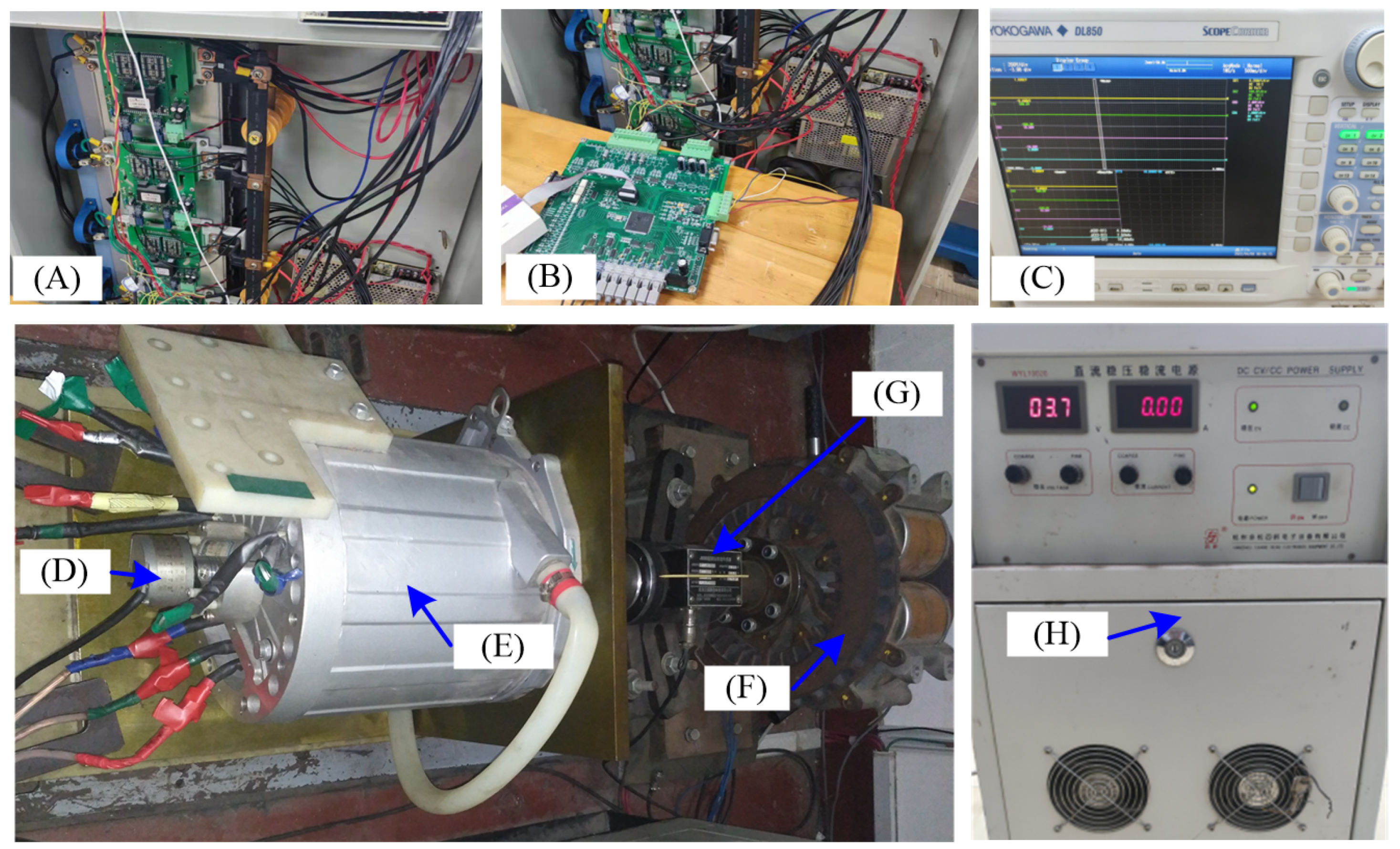

4.1. Experimental Setup

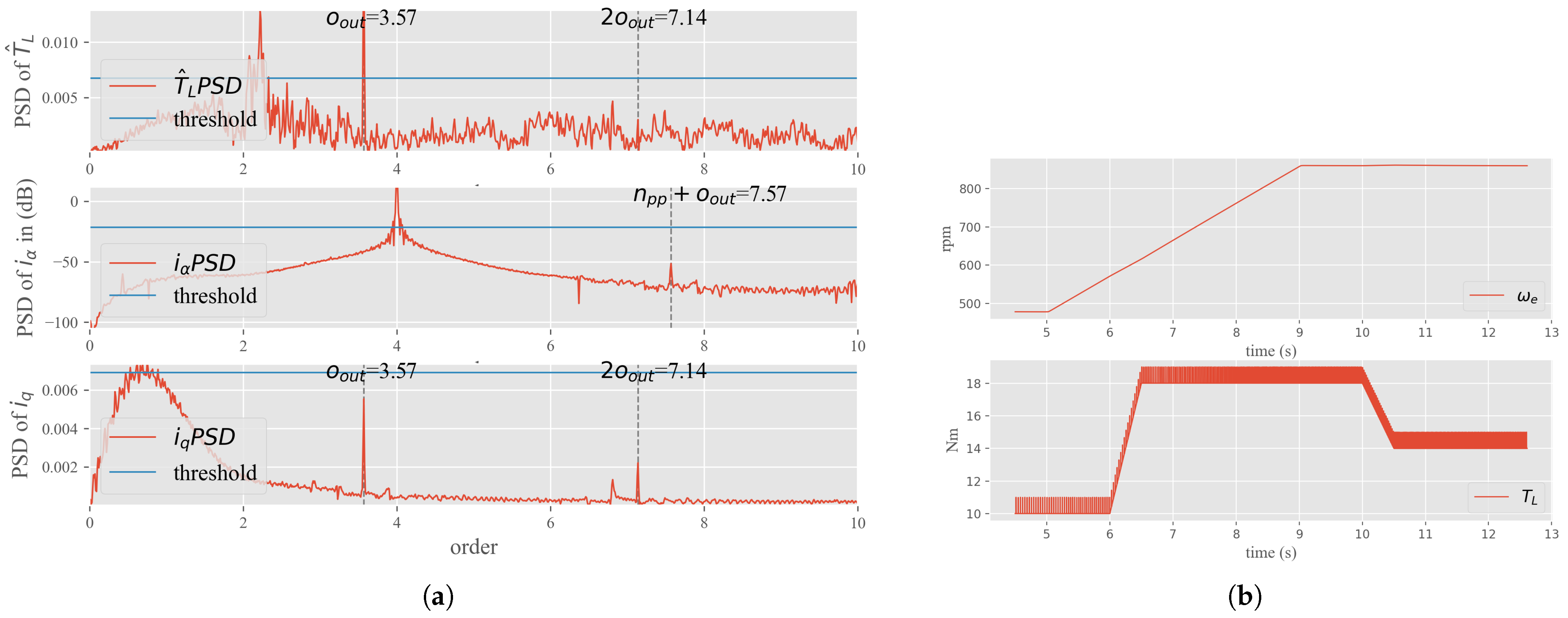

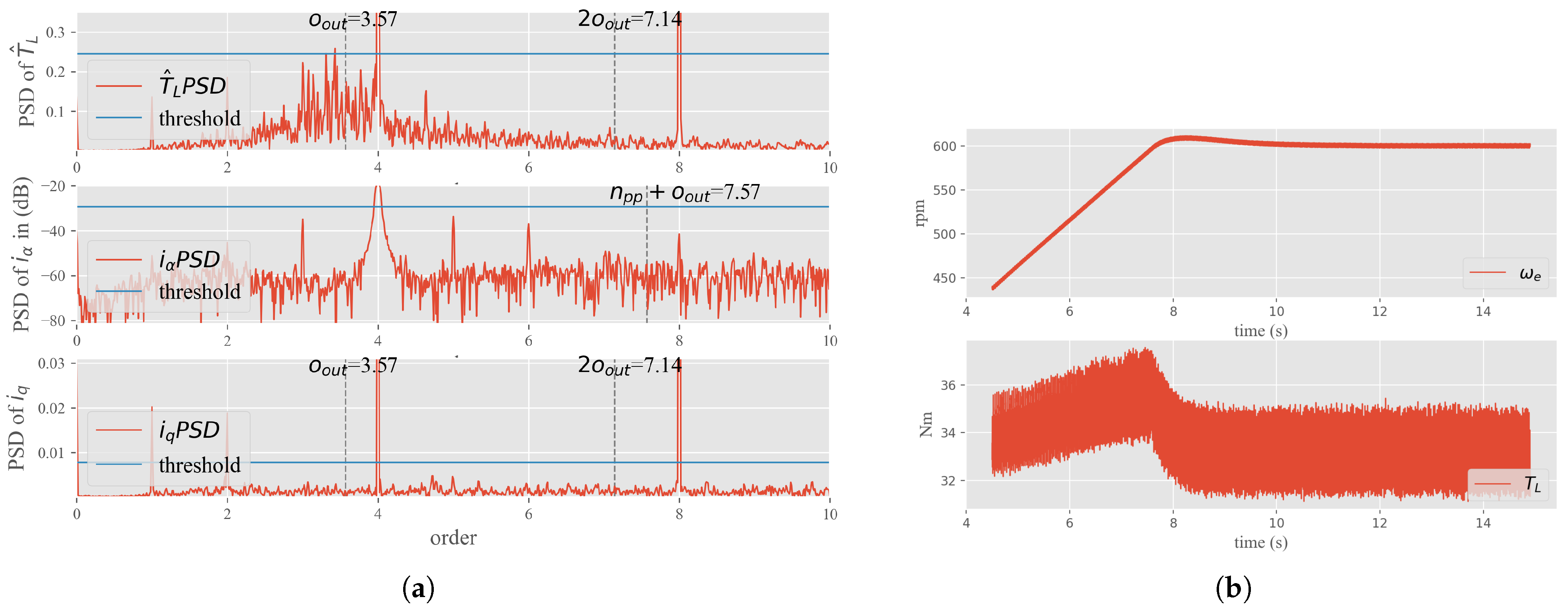

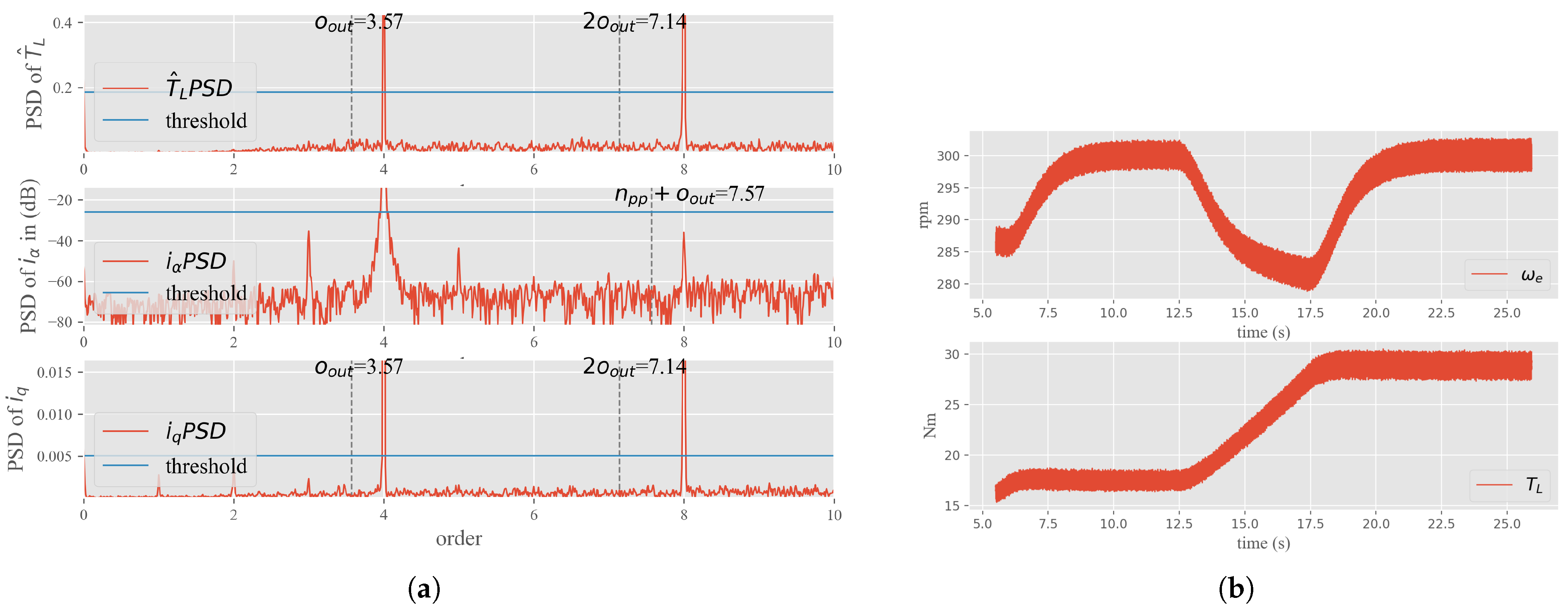

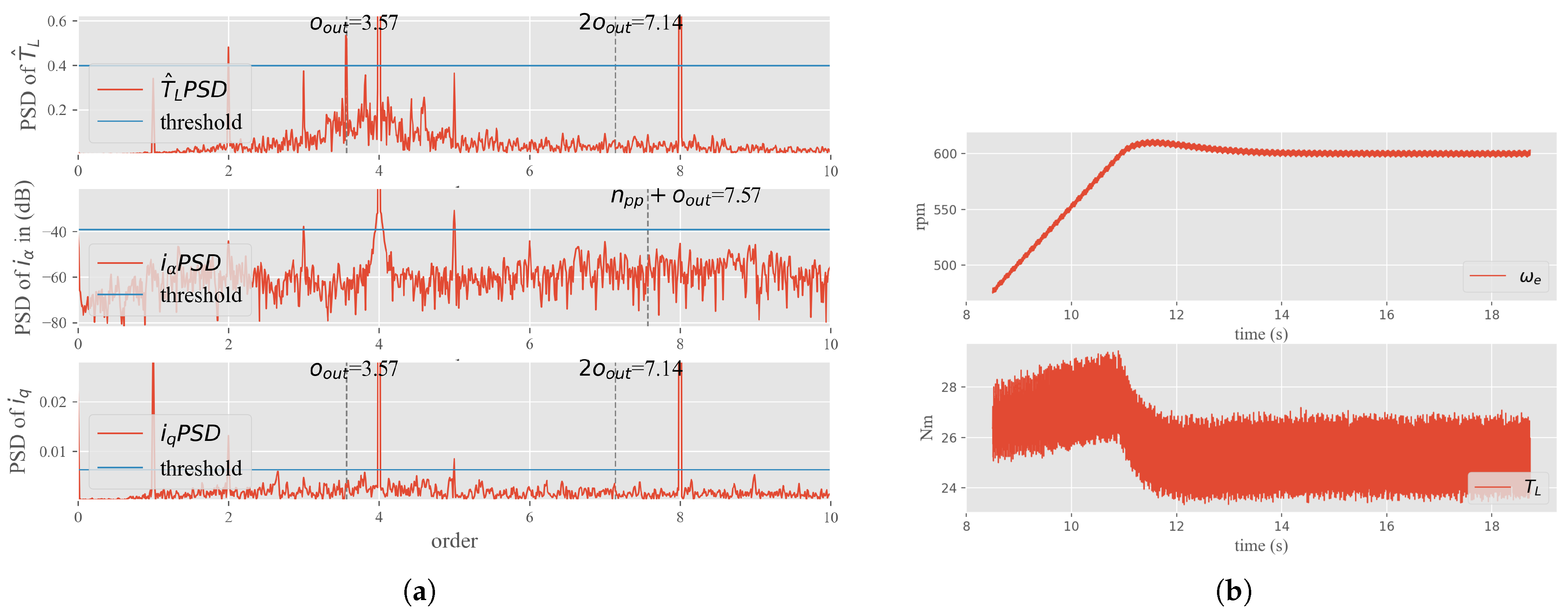

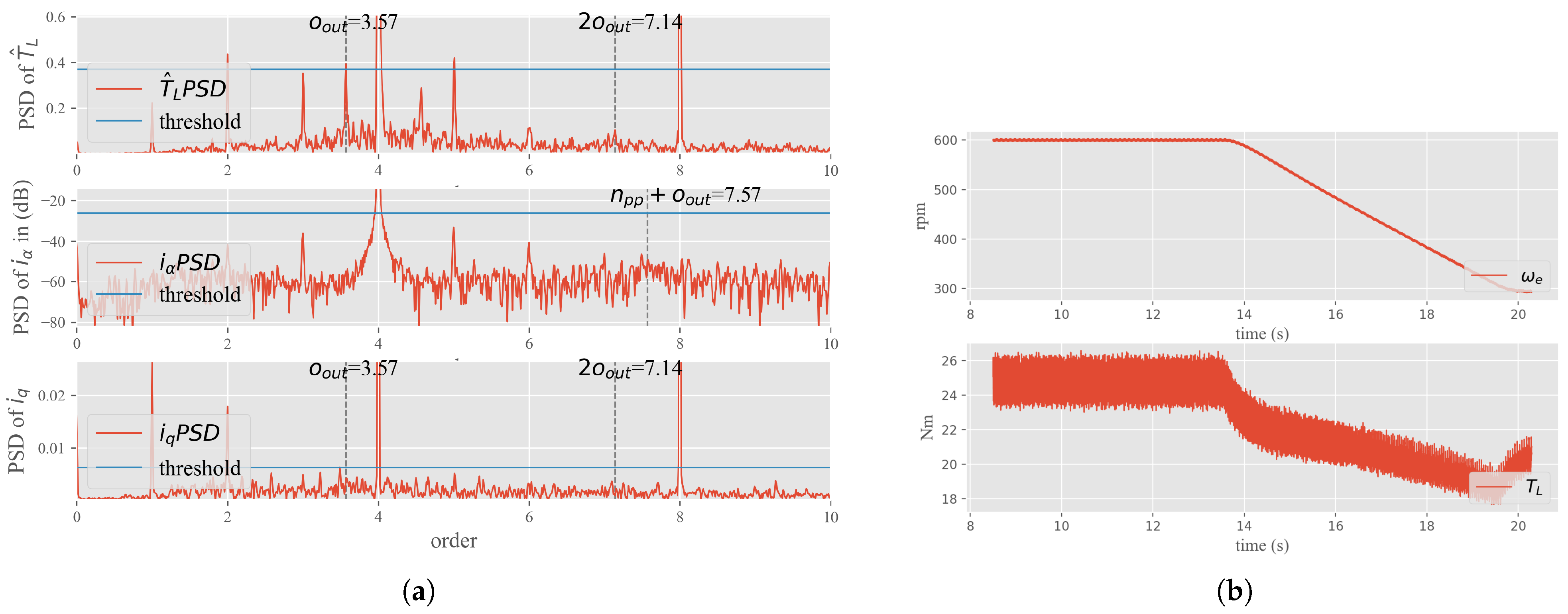

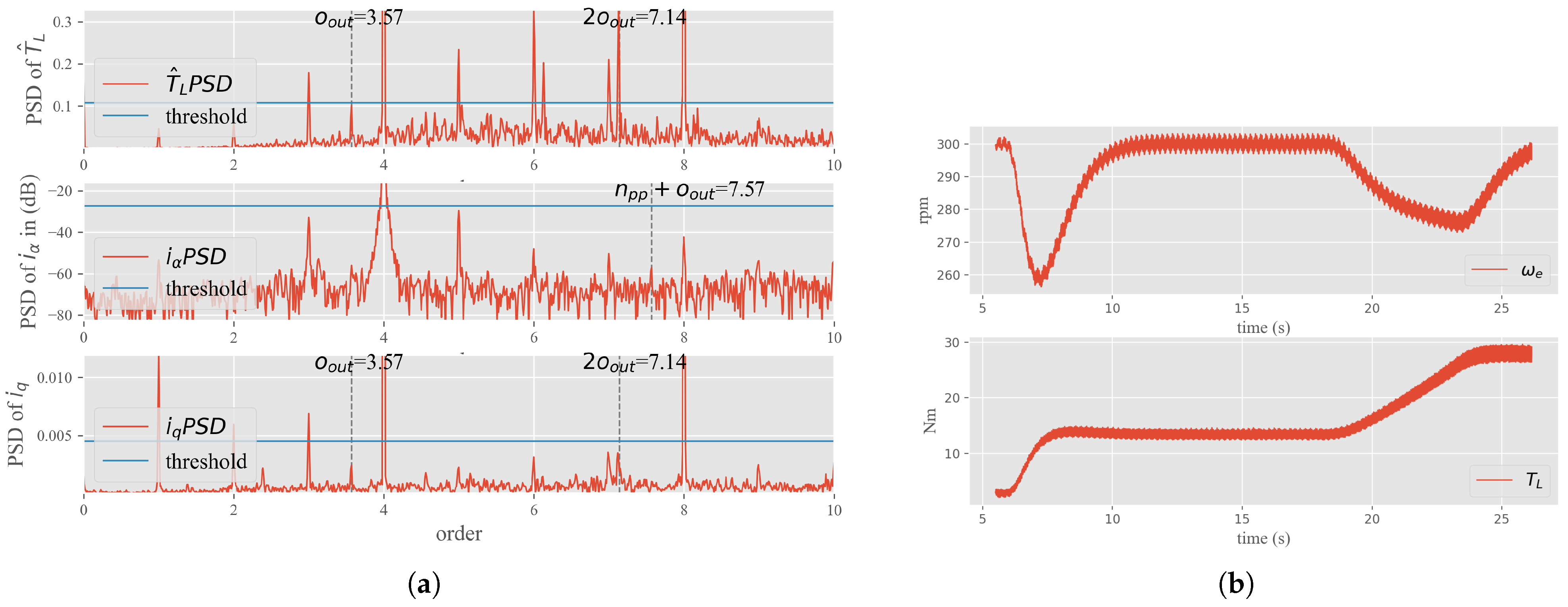

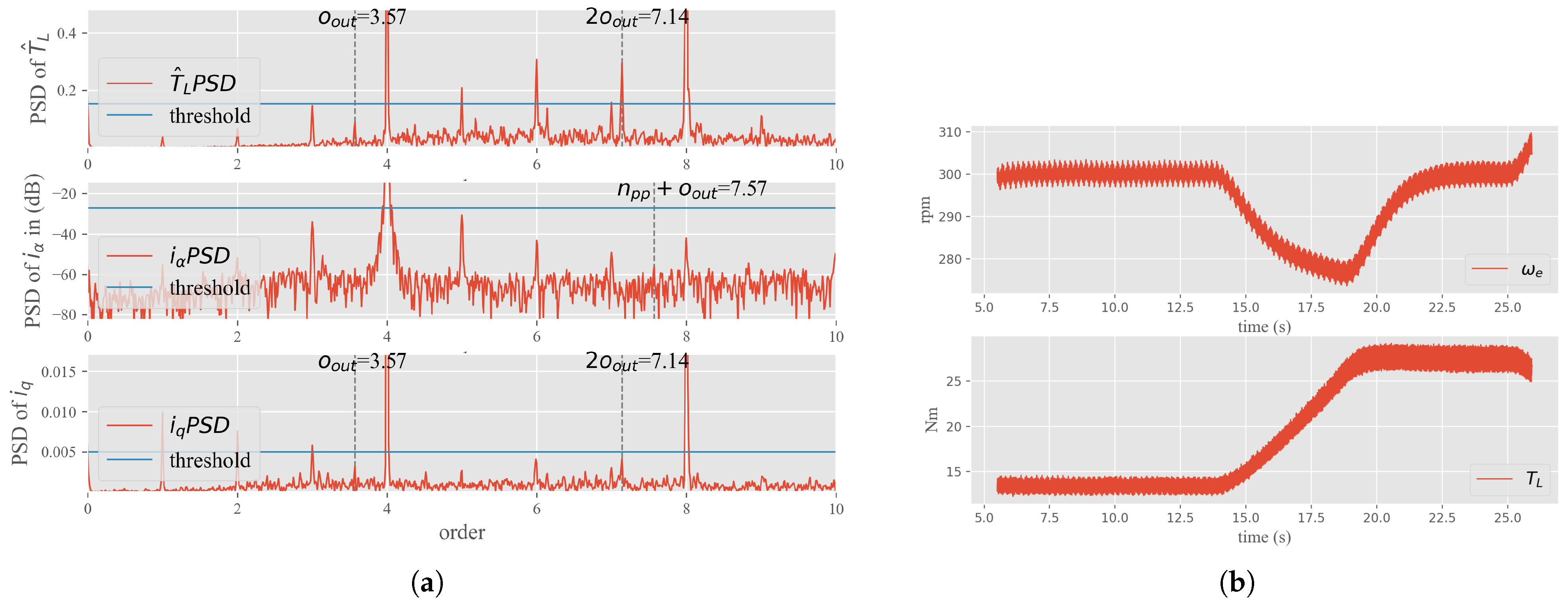

4.2. Simulation Results Using Natural Observer under Non-Stationary Conditions

4.3. Experimental Results Using the Natural Observer under Non-Stationary Conditions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Motor Reliability Working Group. Report of Large Motor Reliability Survey of Industrial and Commercial Installations. IEEE Trans. Ind. Appl. 1985, IA-21, 853–872. [Google Scholar] [CrossRef]

- Tran, M.Q.; Elsisi, M.; Mahmoud, K.; Liu, M.K.; Lehtonen, M.; Darwish, M.M.F. Experimental Setup for Online Fault Diagnosis of Induction Machines via Promising IoT and Machine Learning: Towards Industry 4.0 Empowerment. IEEE Access 2021, 9, 115429–115441. [Google Scholar] [CrossRef]

- Tran, M.Q.; Elsisi, M.; Liu, M.K.; Vu, V.Q.; Mahmoud, K.; Darwish, M.M.F.; Abdelaziz, A.Y.; Lehtonen, M. Reliable Deep Learning and IoT-Based Monitoring System for Secure Computer Numerical Control Machines Against Cyber-Attacks With Experimental Verification. IEEE Access 2022, 10, 23186–23197. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.Q.; Mahmoud, K.; Mansour, D.E.A.; Lehtonen, M.; Darwish, M.M.F. Towards Secured Online Monitoring for Digitalized GIS Against Cyber-Attacks Based on IoT and Machine Learning. IEEE Access 2021, 9, 78415–78427. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.; Mahmoud, K.; Mansour, D.E.A.; Lehtonen, M.; Darwish, M.M. Effective IoT-based deep learning platform for online fault diagnosis of power transformers against cyberattacks and data uncertainties. Measurement 2022, 190, 110686. [Google Scholar] [CrossRef]

- Stack, J.R.; Habetler, T.G.; Harley, R.G. Fault classification and fault signature production for rolling element bearings in electric machines. IEEE Trans. Ind. Appl. 2004, 40, 735–739. [Google Scholar] [CrossRef]

- Peeters, C.; Guillaume, P.; Helsen, J. A comparison of cepstral editing methods as signal pre-processing techniques for vibration-based bearing fault detection. Mech. Syst. Signal Process. 2017, 91, 354–381. [Google Scholar] [CrossRef]

- Pezzani, C.M.; Bossio, J.M.; Castellino, A.M.; Bossio, G.R.; Angelo, C.H.D. A PLL-based resampling technique for vibration analysis in variable-speed wind turbines with PMSG: A bearing fault case. Mech. Syst. Signal Process. 2017, 85, 354–366. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Zhang, Y.; Liu, Y.; Ma, Z.; Kusiak, A. Application of cyclic coherence function to bearing fault detection in a wind turbine generator under electromagnetic vibration. Mech. Syst. Signal Process. 2017, 87, 279–293. [Google Scholar] [CrossRef]

- Schoen, R.R.; Habetler, T.G.; Kamran, F.; Bartfield, R.G. Motor bearing damage detection using stator current monitoring. IEEE Trans. Ind. Appl. 1995, 31, 1274–1279. [Google Scholar] [CrossRef]

- Zhou, W.; Lu, B.; Habetler, T.G.; Harley, R.G. Incipient Bearing Fault Detection via Motor Stator Current Noise Cancellation Using Wiener Filter. IEEE Trans. Ind. Appl. 2009, 45, 1309–1317. [Google Scholar] [CrossRef]

- Hamadache, M.; Lee, D.; Veluvolu, K.C. Rotor Speed-Based Bearing Fault Diagnosis (RSB-BFD) Under Variable Speed and Constant Load. IEEE Trans. Ind. Electron. 2015, 62, 6486–6495. [Google Scholar] [CrossRef]

- Trajin, B.; Regnier, J.; Faucher, J. Comparison Between Stator Current and Estimated Mechanical Speed for the Detection of Bearing Wear in Asynchronous Drives. IEEE Trans. Ind. Electron. 2009, 56, 4700–4709. [Google Scholar] [CrossRef]

- Phung, V.T.; Pacas, M. Detection of bearing faults in repetitive mechanical systems by identification of the load torque. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 3089–3095. [Google Scholar] [CrossRef]

- Bouchikhi, E.H.E.; Choqueuse, V.; Benbouzid, M.E.H. Current Frequency Spectral Subtraction and Its Contribution to Induction Machines’ Bearings Condition Monitoring. IEEE Trans. Energy Convers. 2013, 28, 135–144. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.Z.; Yang, Q.; Huang, M.Y.; Yan, W.J. Sparse component analysis-based under-determined blind source separation for bearing fault feature extraction in wind turbine gearbox. IET Renew. Power Gener. 2017, 11, 330–337. [Google Scholar] [CrossRef]

- Escobar-Moreira, L.A. An approach to ultrasonic fault machinery monitoring by using the wigner-ville and choi-williams distributions. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Blodt, M.; Bonacci, D.; Regnier, J.; Chabert, M.; Faucher, J. On-Line Monitoring of Mechanical Faults in Variable-Speed Induction Motor Drives Using the Wigner Distribution. IEEE Trans. Ind. Electron. 2008, 55, 522–533. [Google Scholar] [CrossRef]

- Seshadrinath, J.; Singh, B.; Panigrahi, B.K. Investigation of Vibration Signatures for Multiple Fault Diagnosis in Variable Frequency Drives Using Complex Wavelets. IEEE Trans. Power Electron. 2014, 29, 936–945. [Google Scholar] [CrossRef]

- Watson, S.J.; Xiang, B.J.; Yang, W.; Tavner, P.J.; Crabtree, C.J. Condition Monitoring of the Power Output of Wind Turbine Generators Using Wavelets. IEEE Trans. Energy Convers. 2010, 25, 715–721. [Google Scholar] [CrossRef] [Green Version]

- Eren, L.; Devaney, M.J. Bearing damage detection via wavelet packet decomposition of the stator current. IEEE Trans. Instrum. Meas. 2004, 53, 431–436. [Google Scholar] [CrossRef]

- Lau, E.C.C.; Ngan, H.W. Detection of Motor Bearing Outer Raceway Defect by Wavelet Packet Transformed Motor Current Signature Analysis. IEEE Trans. Instrum. Meas. 2010, 59, 2683–2690. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Afshari, S.S.; Liang, X.; Chen, Z. Adaptive Cost Function Ridge Estimation for Rolling Bearing Fault Diagnosis Under Variable Speed Conditions. IEEE Trans. Instrum. Meas. 2022, 71, 1–12. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Wang, X. Two-Step Adaptive Chirp Mode Decomposition for Time-Varying Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Peng, Y.; Qiao, W. Current-Aided Order Tracking of Vibration Signals for Bearing Fault Diagnosis of Direct-Drive Wind Turbines. IEEE Trans. Ind. Electron. 2016, 63, 6336–6346. [Google Scholar] [CrossRef]

- Lu, S.; Guo, J.; He, Q.; Liu, F.; Liu, Y.; Zhao, J. A Novel Contactless Angular Resampling Method for Motor Bearing Fault Diagnosis Under Variable Speed. IEEE Trans. Instrum. Meas. 2016, 65, 2538–2550. [Google Scholar] [CrossRef]

- Wang, T.; Liang, M.; Li, J.; Cheng, W. Rolling element bearing fault diagnosis via fault characteristic order (FCO) analysis. Mech. Syst. Signal Process. 2014, 45, 139–153. [Google Scholar] [CrossRef]

- Bowes, S.; Sevinc, A.; Holliday, D. New natural observer applied to speed-sensorless DC servo and induction motors. IEEE Trans. Ind. Electron. 2004, 51, 1025–1032. [Google Scholar] [CrossRef]

- Chen, Z.; Tomita, M.; Doki, S.; Okuma, S. An extended electromotive force model for sensorless control of interior permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2003, 50, 288–295. [Google Scholar] [CrossRef]

- Chen, J.; Mei, J.; Yuan, X.; Zuo, Y.; Lee, C.H.T. Natural Speed Observer for Nonsalient AC Motors. IEEE Trans. Power Electron. 2022, 37, 14–20. [Google Scholar] [CrossRef]

- Ali, M.N.; Soliman, M.; Mahmoud, K.; Guerrero, J.M.; Lehtonen, M.; Darwish, M.M.F. Resilient Design of Robust Multi-Objectives PID Controllers for Automatic Voltage Regulators: D-Decomposition Approach. IEEE Access 2021, 9, 106589–106605. [Google Scholar] [CrossRef]

- Zhao, L.; Huang, J.; Liu, H.; Li, B.; Kong, W. Second-Order Sliding-Mode Observer With Online Parameter Identification for Sensorless Induction Motor Drives. IEEE Trans. Ind. Electron. 2014, 61, 5280–5289. [Google Scholar] [CrossRef]

- Li, B.; Chow, M.Y.; Tipsuwan, Y.; Hung, J.C. Neural-network-based motor rolling bearing fault diagnosis. IEEE Trans. Ind. Electron. 2000, 47, 1060–1069. [Google Scholar] [CrossRef] [Green Version]

- Fyfe, K.; Munck, E. Analysis of Computed Order Tracking. Mech. Syst. Signal Process. 1997, 11, 187–205. [Google Scholar] [CrossRef]

- Ye, M.; Huang, J. Bearing Fault Diagnosis Under Time-Varying Speed and Load Conditions via Speed Sensorless Algorithm and Angular Resample. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1775–1781. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W. Current-Based Mechanical Fault Detection for Direct-Drive Wind Turbines via Synchronous Sampling and Impulse Detection. IEEE Trans. Ind. Electron. 2015, 62, 1693–1702. [Google Scholar] [CrossRef]

- Romero-Troncoso, R.J.; Saucedo-Gallaga, R.; Cabal-Yepez, E.; Garcia-Perez, A.; Osornio-Rios, R.A.; Alvarez-Salas, R.; Miranda-Vidales, H.; Huber, N. FPGA-Based Online Detection of Multiple Combined Faults in Induction Motors Through Information Entropy and Fuzzy Inference. IEEE Trans. Ind. Electron. 2011, 58, 5263–5270. [Google Scholar] [CrossRef]

| Parameters | Notation | Values |

|---|---|---|

| Rated Power | 20 kW | |

| Number of Pole Pairs | 4 | |

| Stator Resistance | ||

| d-Axis Inductance | mH | |

| q-Axis Inductance | mH | |

| Rotor Flux | Wb | |

| Moment of Inertia |

| Motor Type | Faulty Motor | |||

|---|---|---|---|---|

| Time-Varying Condition | Speed (Case 1) | Speed (Case 2) | Torque (Case 1) | Torque (Case 2) |

| signal power of | ||||

| noise power of | 5.72 | 4.31 | 1.60 | 1.69 |

| SNR of | 9.786% | 6.140% | 11.085% | 8.226% |

| signal power of | ||||

| noise power of | ||||

| SNR of | 0.684% | 0.494% | 2.412% | 2.509% |

| Motor Type | Healthy Motor | Faulty Motor | ||||

|---|---|---|---|---|---|---|

| Time-Varying Condition | Speed | Torque | Speed (Case 1) | Speed (Case 2) | Torque (Case 1) | Torque (Case 2) |

| resampled | × | × | √ | √ | √ | √ |

| resampled phase- current | × | × | × | × | △ | × |

| resampled q-axis current | × | × | × | × | △ | △ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, M.; Zhang, J.; Yang, J. Bearing Fault Diagnosis under Time-Varying Speed and Load Conditions via Observer-Based Load Torque Analysis. Energies 2022, 15, 3532. https://doi.org/10.3390/en15103532

Ye M, Zhang J, Yang J. Bearing Fault Diagnosis under Time-Varying Speed and Load Conditions via Observer-Based Load Torque Analysis. Energies. 2022; 15(10):3532. https://doi.org/10.3390/en15103532

Chicago/Turabian StyleYe, Ming, Jian Zhang, and Jiaqiang Yang. 2022. "Bearing Fault Diagnosis under Time-Varying Speed and Load Conditions via Observer-Based Load Torque Analysis" Energies 15, no. 10: 3532. https://doi.org/10.3390/en15103532

APA StyleYe, M., Zhang, J., & Yang, J. (2022). Bearing Fault Diagnosis under Time-Varying Speed and Load Conditions via Observer-Based Load Torque Analysis. Energies, 15(10), 3532. https://doi.org/10.3390/en15103532