Modelling and Environmental Assessment of a Stand-Alone Micro-Grid System in a Mountain Hut Using Renewables

Abstract

:1. Introduction

2. Micro-Grid System and Definition of the Simulated Scenarios

- (i)

- MEAS: system configuration after the upgrade, PV 3.7 kWp, batteries 38.4 kWh, gen-sets 12.8 + 22.4 kW, measurement results of actual 1-year operation of the hut.

- (ii)

- SOPE: system configuration after the upgrade, same as measured, used for validation of the custom computational model.

- (iii)

- SOPE+: system configuration after the upgrade, same as the SOPE and measured but with modified battery charging strategy to increase the use of renewable energy.

- (iv)

- SOPB: system configuration before the upgrade for comparison with current state, PV 0.5 kWp, batteries 38.4 kWh, gen-sets 12.8 + 22.4 kW.

- (v)

- SOPEx2: hypothetical configuration with double PV and battery capacity compared to the SOPE; improved battery charging strategy was employed as in the SOPE+.

- (vi)

- RES: hypothetical configuration with sufficient PV and battery capacity for fully renewable operation; improved battery charging strategy was employed as in the SOPE+.

3. Computational Model and Input Data

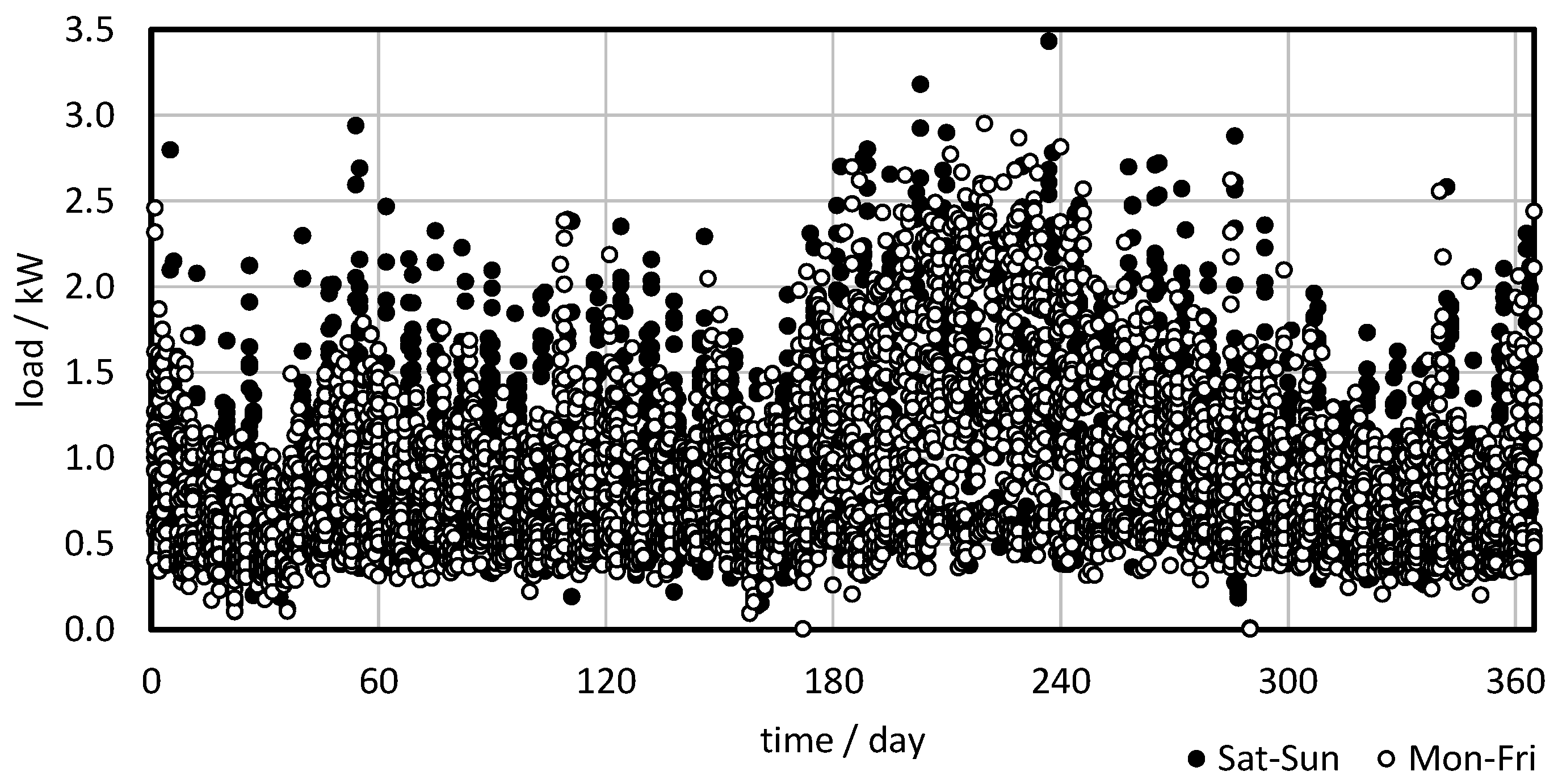

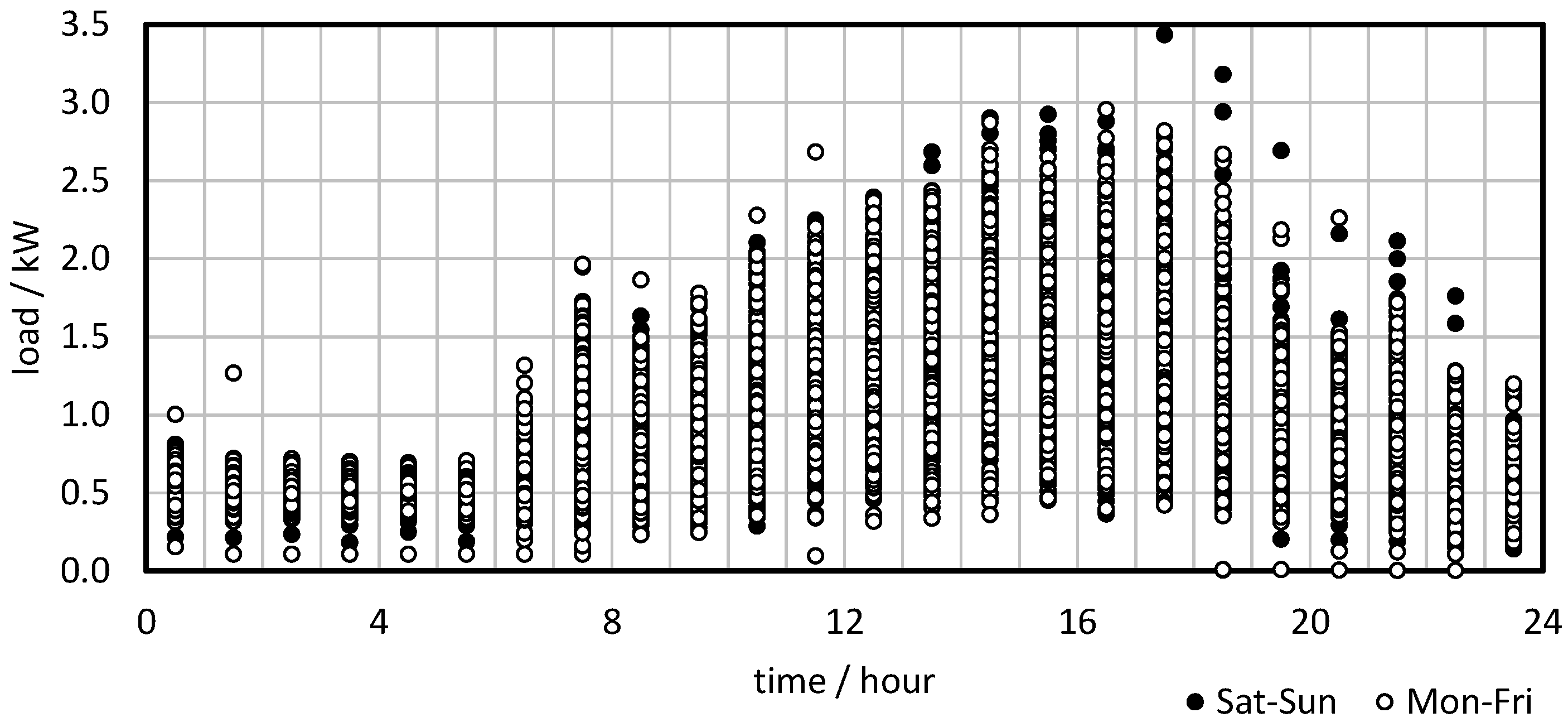

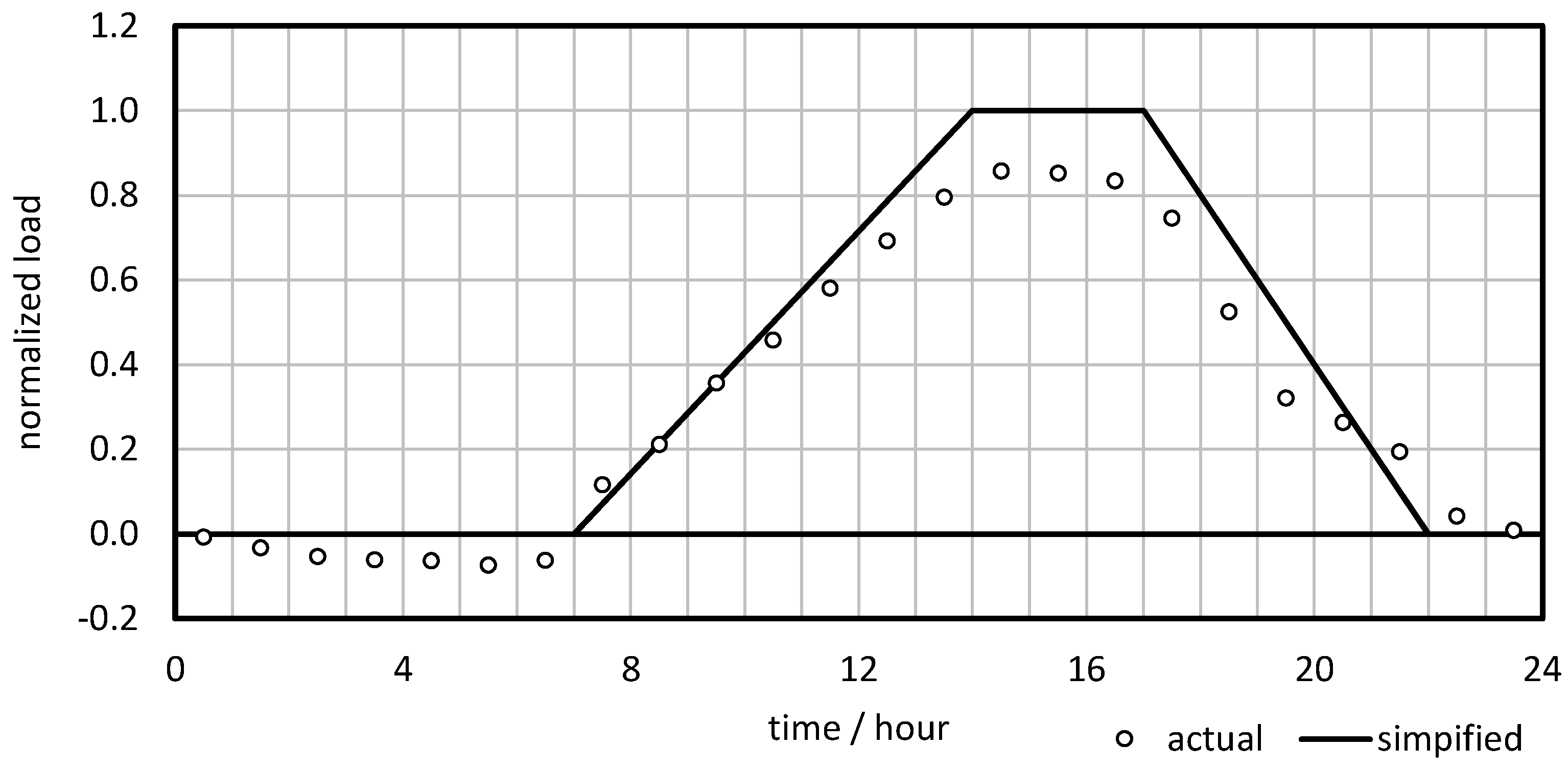

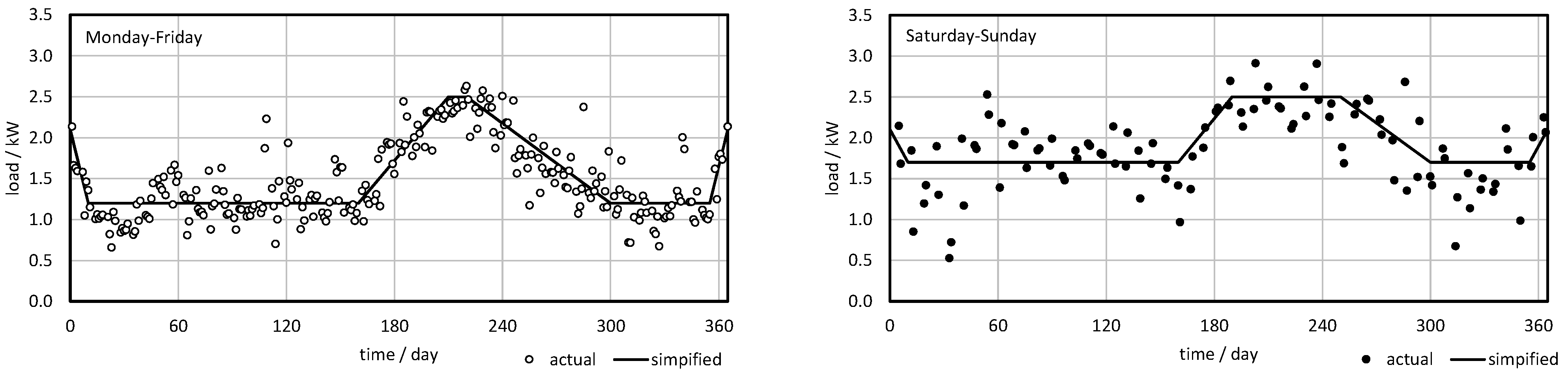

3.1. Input Data

- It is necessary to know whether the particular day is a working day or a weekend day.

- It is necessary to know to which of the intervals j shown in Figure 7 the particular day belongs, so that appropriate coefficients apeak,j and bpeak,j are selected.

- It is necessary to know to which of the intervals k shown in Figure 5 the particular hour belongs, so that appropriate coefficients anorm,k and bnorm,k are selected.

- Peak load of the day and normalized load of the hour are calculated according to Equations (2) and (3), respectively.

- Finally, the load is calculated as

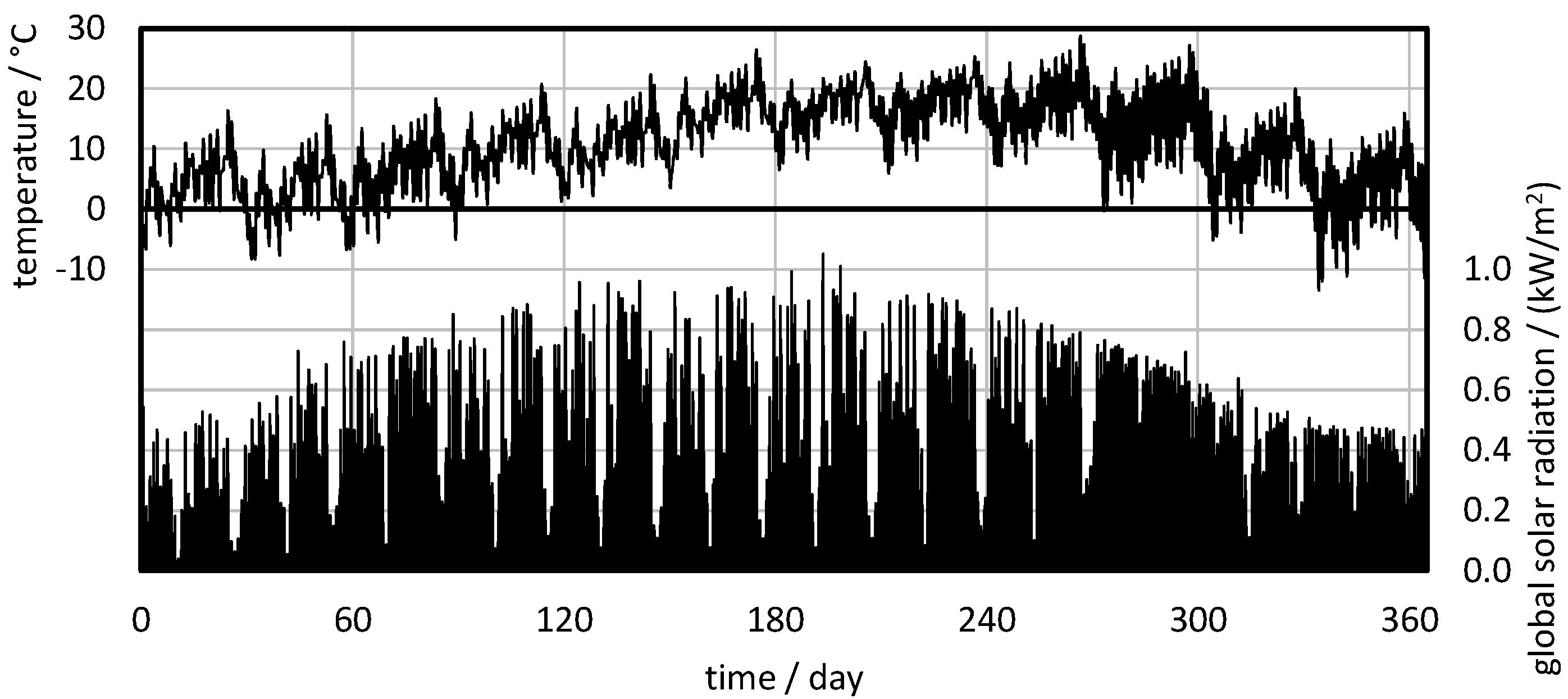

3.2. Weather Conditions

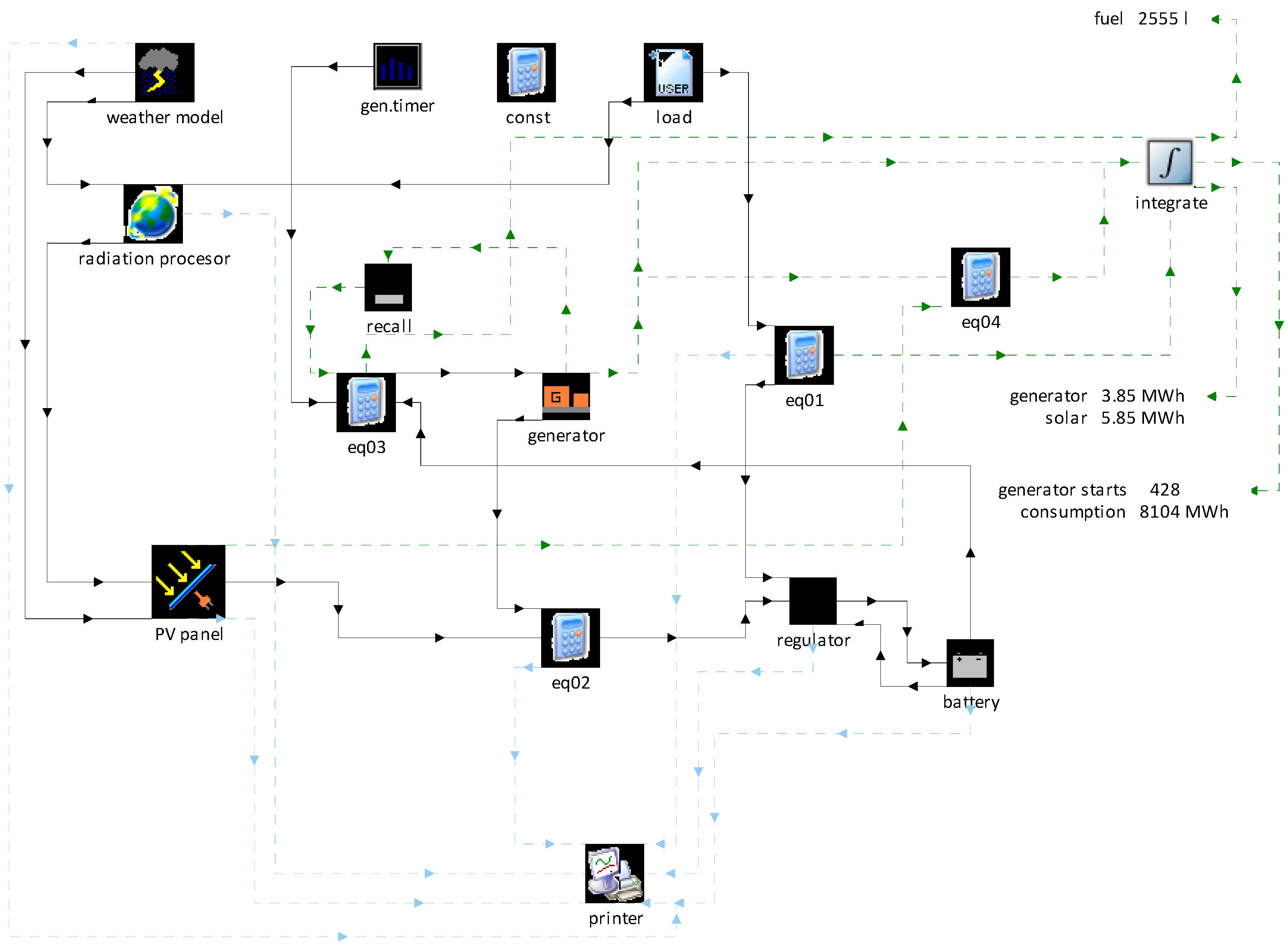

3.3. Energy System Model

4. Energy Balance of the Modelled Configurations

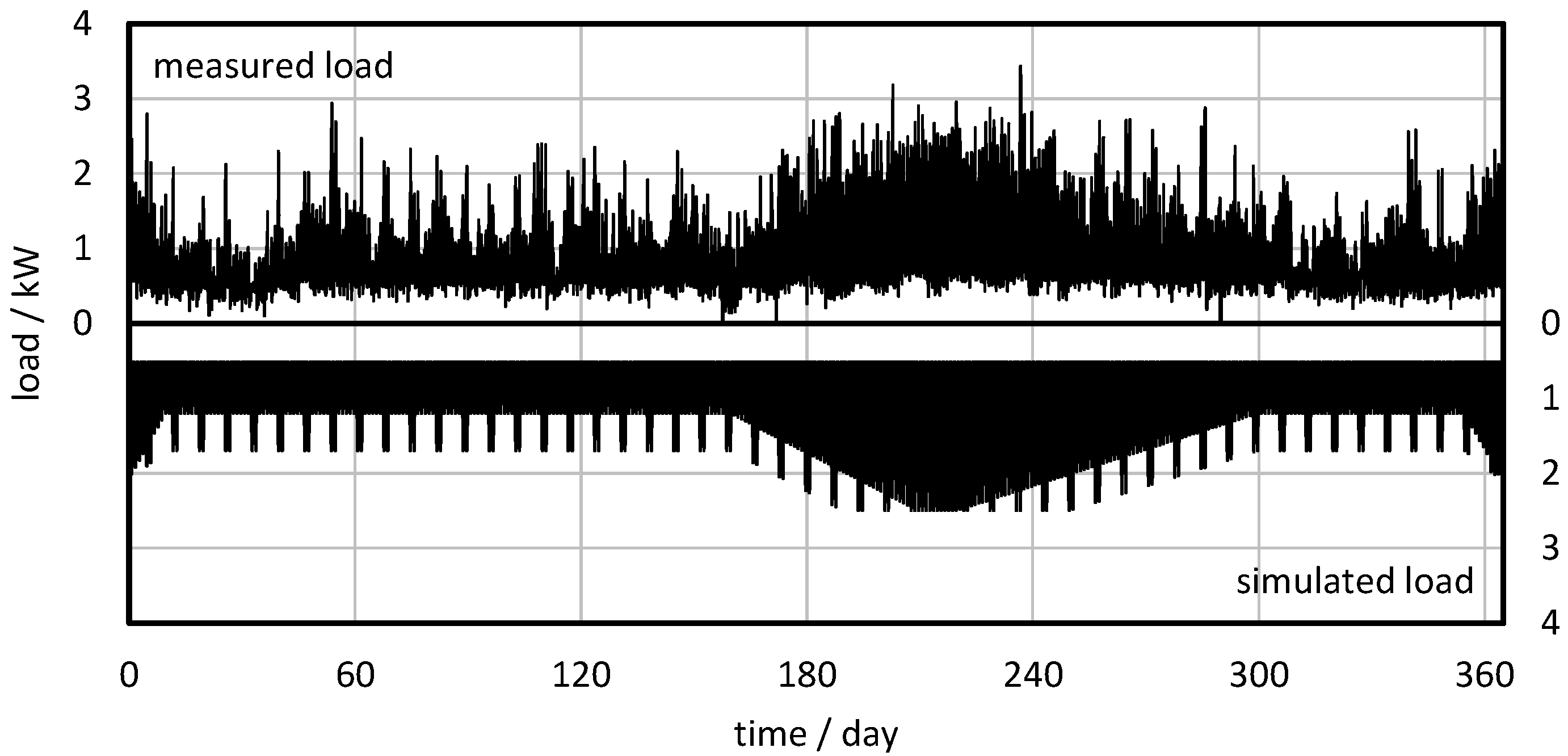

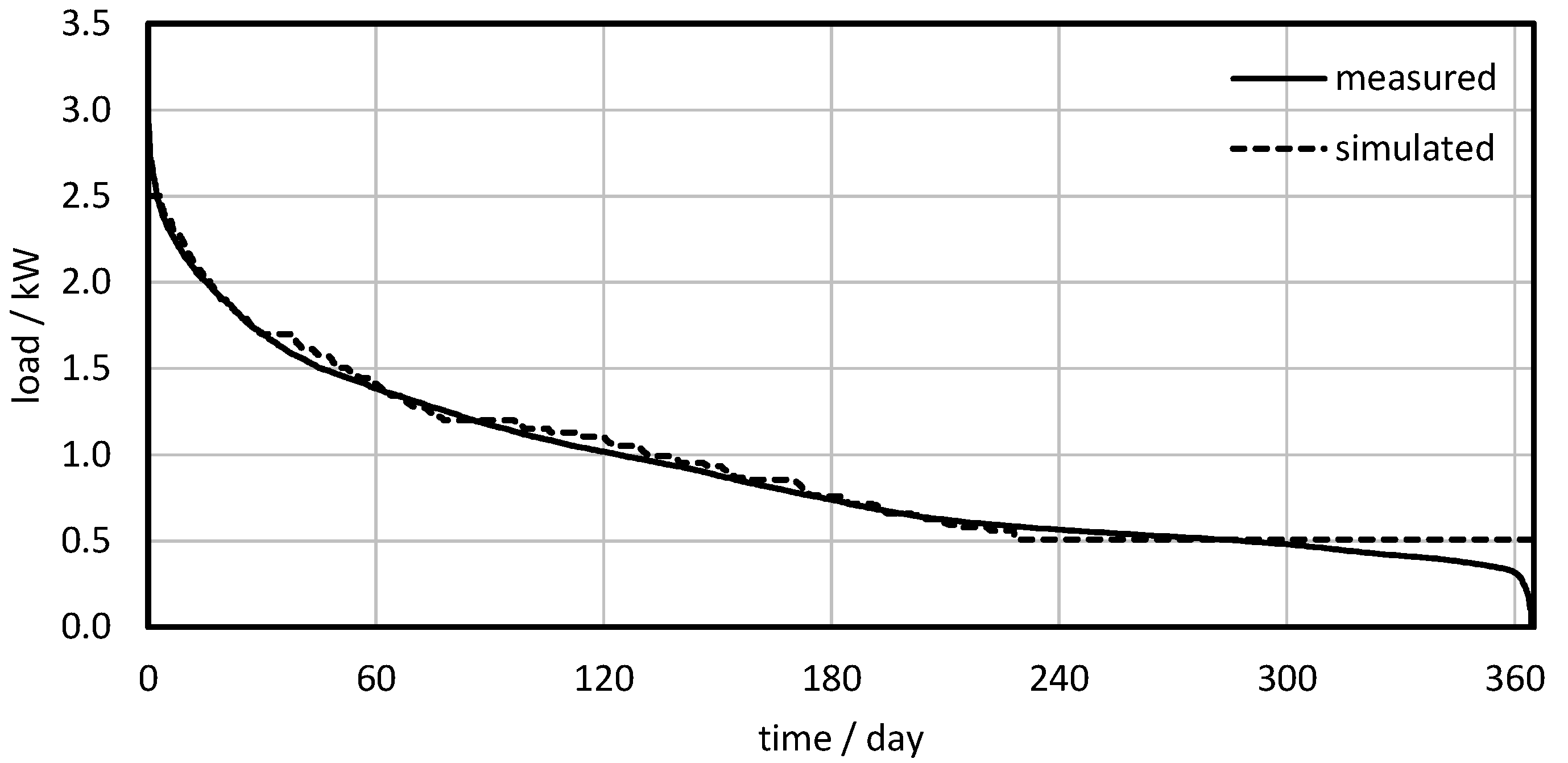

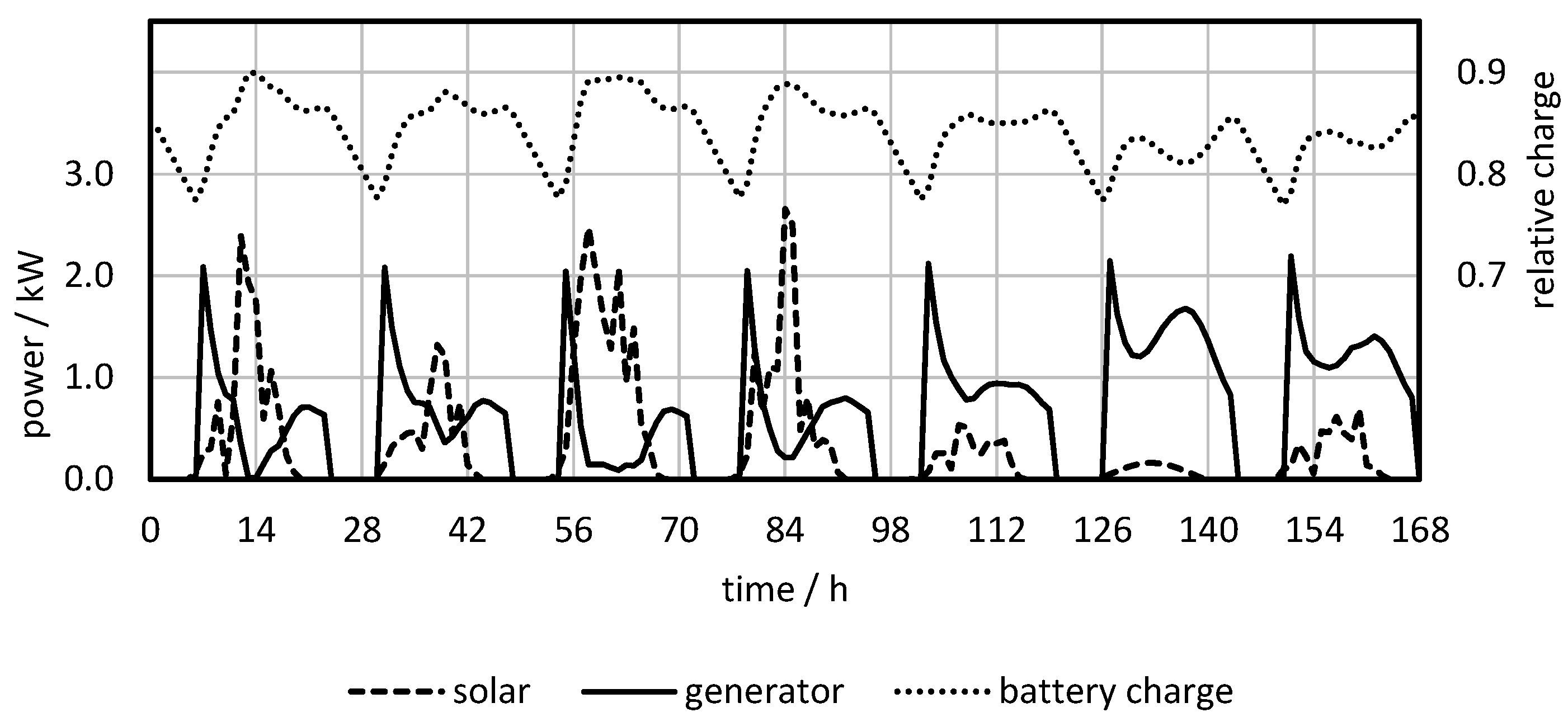

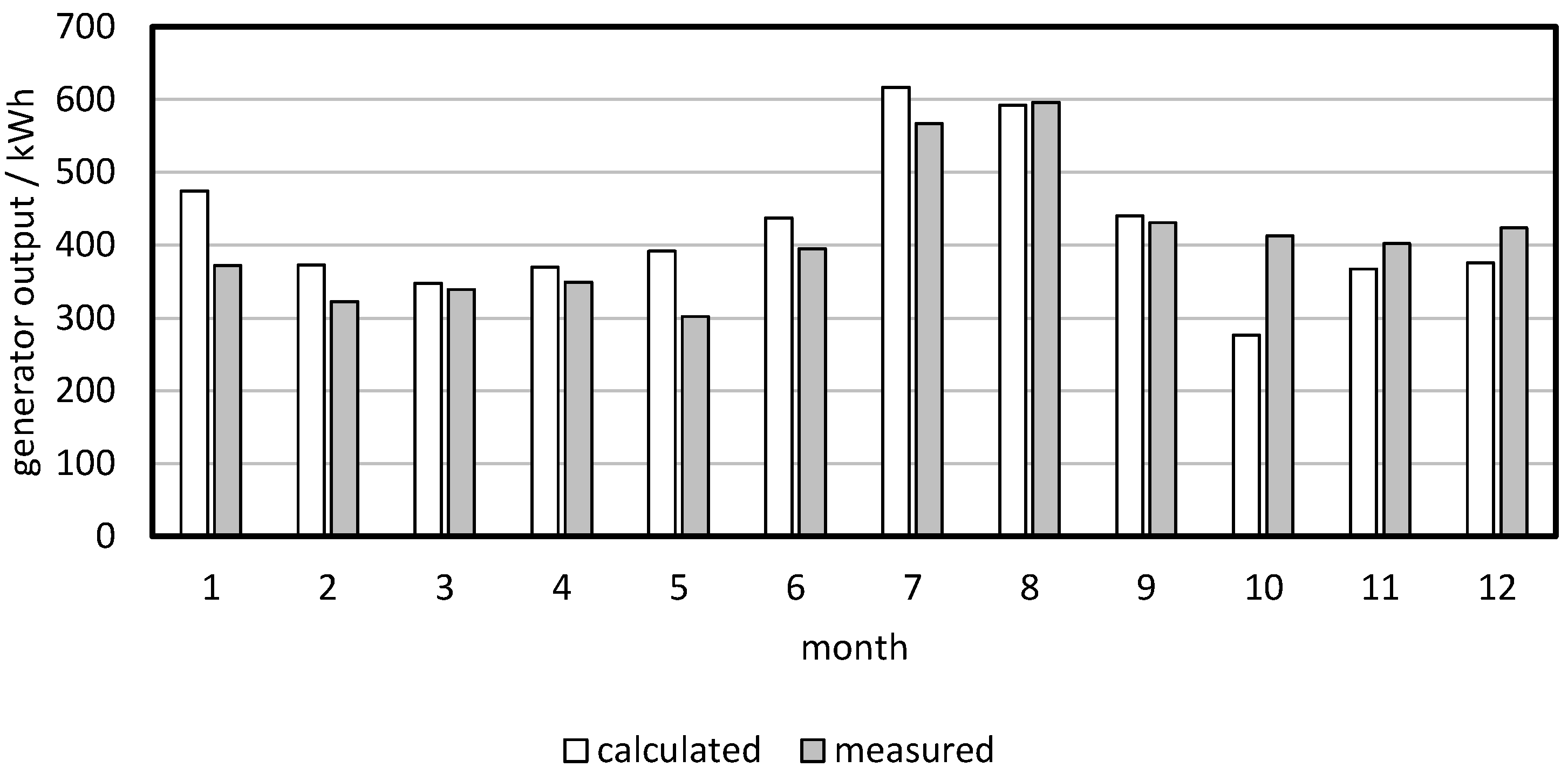

4.1. Custom Computational Model Validation with Experimental Data of the SOPE

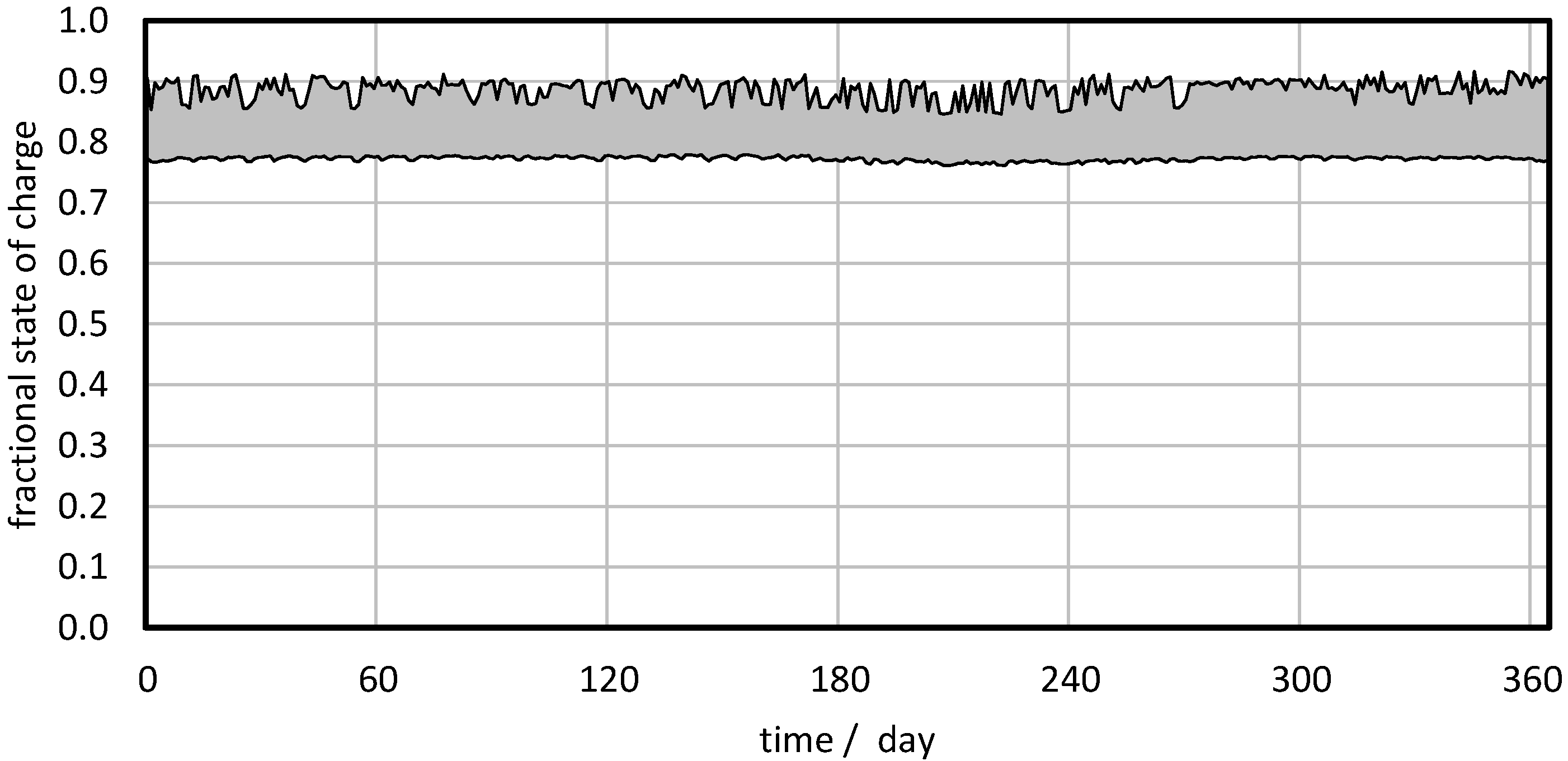

4.2. Improved Battery Charging Strategy in the SOPE+

4.3. The Simulation Results for the SOPB

4.4. Increased Power of the PV and Batteries’ Capacity to Increase Renewable Penetration

5. Environmental Assessment

5.1. Goal, Scope and Functional Unit

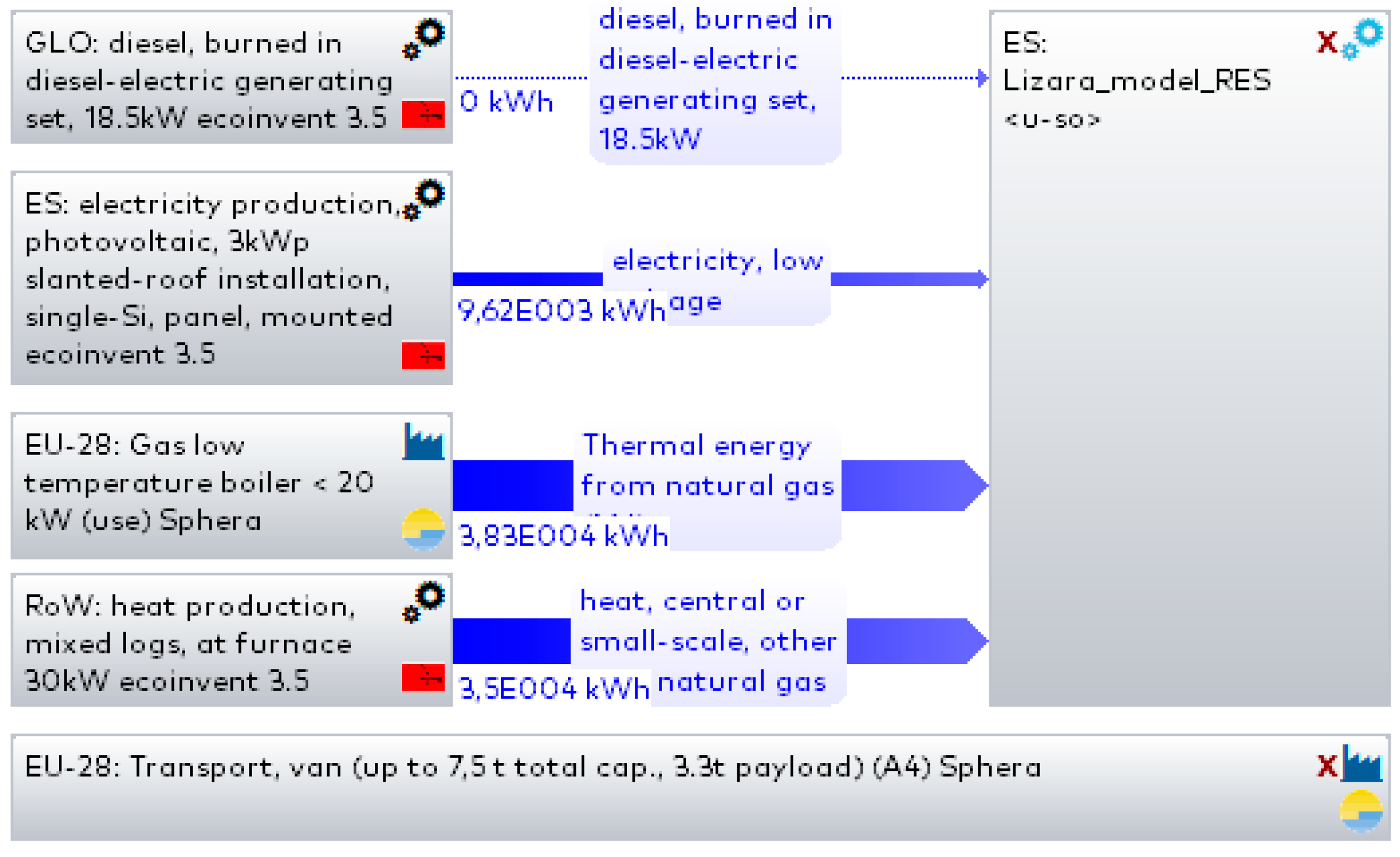

5.2. Life Cycle Inventory Analysis

5.2.1. Manufacturing and Operational Phase

5.2.2. Transport Phase

5.3. Lifecycle Impact Assessment Methodology

5.4. Interpretation of the Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mori, M.; Gutiérrez, M.; Casero, P. Micro-grid design and life-cycle assessment of a mountain hut’s stand-alone energy system with hydrogen used for seasonal storage. Int. J. Hydrogen Energy 2021, 46, 29706–29723. [Google Scholar] [CrossRef]

- Goymann, M.; Wittenwiler, M.; Hellweg, S. Environmental decision support for the construction of a “green” mountain hut. Environ. Sci. Technol. 2008, 42, 4060–4067. [Google Scholar] [CrossRef] [PubMed]

- Schweizer-Ries, P. Decentralized Energy Use in Mountain Regions. Mt. Res. Dev. 2001, 21, 25–29. [Google Scholar] [CrossRef]

- Tong, Z.; Zhang, K.M. The near-source impacts of diesel backup generators in urban environments. Atmos. Environ. 2015, 109, 262–271. [Google Scholar] [CrossRef]

- Shah, S.D.; Cocker, D.R.; Johnson, K.C.; Lee, J.M.; Soriano, B.L.; Miller, J.W. Emissions of regulated pollutants from in-use diesel back-up generators. Atmos. Environ. 2006, 40, 4199–4209. [Google Scholar] [CrossRef]

- Günkaya, Z.; Özdemir, A.; Özkan, A.; Banar, M. Environmental Performance of Electricity Generation Based on Resources: A Life Cycle Assessment Case Study in Turkey. Sustainability 2016, 8, 1097. [Google Scholar] [CrossRef] [Green Version]

- Smith, C.; Burrows, J.; Scheier, E.; Young, A.; Smith, J.; Young, T.; Gheewala, S.H. Comparative Life Cycle Assessment of a Thai Island’s diesel/PV/wind hybrid microgrid. Renew. Energy 2015, 80, 85–100. [Google Scholar] [CrossRef]

- Communication from the Commision: A Roadmap for Moving to a Competitive Low Carbon Economy in 2050; European Commission: Brussels, Belgium, 2011; Volume 34, pp. 1–34, COM (2011) 112 Final.

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019; Volume 53. [Google Scholar]

- Mori, M.; Sekavčnik, M.; Drobnič, B. Integration of numerical and experimental approach in life cycle assessment of stand-alone microgrid system. In Proceedings of the 16th SDEWES Conference on Sustainable Development of Energy, Water and Environment Systems; Ban, M., Ed.; Faculty of Mechanical Engineering and Naval Architecture: Dubrovnik, Croatia, 2021; pp. 1–14. [Google Scholar]

- Chauhan, A.; Saini, R.P. Renewable energy based power generation for stand-alone applications: A review. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; pp. 424–428. [Google Scholar] [CrossRef]

- Khatib, T.; Ibrahim, I.A.; Mohamed, A. A review on sizing methodologies of photovoltaic array and storage battery in a standalone photovoltaic system. Energy Convers. Manag. 2016, 120, 430–448. [Google Scholar] [CrossRef]

- Zomer, C.; Custódio, I.; Goulart, S.; Mantelli, S.; Martins, G.; Campos, R.; Pinto, G.; Rüther, R. Energy balance and performance assessment of PV systems installed at a positive-energy building (PEB) solar energy research centre. Sol. Energy 2020, 212, 258–274. [Google Scholar] [CrossRef]

- Delille, G.; François, B.; Malarange, G. Dynamic frequency control support by energy storage to reduce the impact of wind and solar generation on isolated power system’s inertia. IEEE Trans. Sustain. Energy 2012, 3, 931–939. [Google Scholar] [CrossRef]

- Bernal-Agustín, J.L.; Dufo-López, R. Simulation and optimization of stand-alone hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2009, 13, 2111–2118. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H. Comparative analyses of seven technologies to facilitate the integration of fluctuating renewable energy sources. IET Renew. Power Gener. 2009, 3, 190–204. [Google Scholar] [CrossRef]

- Lacko, R.; Drobnič, B.; Mori, M.; Sekavčnik, M.; Vidmar, M. Stand-alone renewable combined heat and power system with hydrogen technologies for household application. Energy 2014, 77, 164–170. [Google Scholar] [CrossRef]

- Lacko, R.; Drobnič, B.; Sekavčnik, M.; Mori, M. Hydrogen energy system with renewables for isolated households: The optimal system design, numerical analysis and experimental evaluation. Energy Build. 2014, 80, 106–113. [Google Scholar] [CrossRef]

- Bojić, M.; Nikolić, N.; Nikolić, D.; Skerlić, J.; Miletić, I. Toward a positive-net-energy residential building in Serbian conditions. Appl. Energy 2011, 88, 2407–2419. [Google Scholar] [CrossRef]

- Mulleriyawage, U.G.K.; Shen, W.X. Optimally sizing of battery energy storage capacity by operational optimization of residential PV-Battery systems: An Australian household case study. Renew. Energy 2020, 160, 852–864. [Google Scholar] [CrossRef]

- Ramirez Camargo, L.; Nitsch, F.; Gruber, K.; Dorner, W. Electricity self-sufficiency of single-family houses in Germany and the Czech Republic. Appl. Energy 2018, 228, 902–915. [Google Scholar] [CrossRef]

- Cabezas, M.D.; Wolfram, E.A.; Franco, J.I.; Fasoli, H.J. Hydrogen vector for using PV energy obtained at Esperanza Base, Antarctica. Int. J. Hydrog. Energy 2017, 42, 23455–23463. [Google Scholar] [CrossRef]

- Ulleberg, Ø.; Nakken, T.; Eté, A. The wind/hydrogen demonstration system at Utsira in Norway: Evaluation of system performance using operational data and updated hydrogen energy system modeling tools. Int. J. Hydrog. Energy 2010, 35, 1841–1852. [Google Scholar] [CrossRef]

- Bourdeau, M.; Basset, P.; Beauchêne, S.; Da Silva, D.; Guiot, T.; Werner, D.; Nefzaoui, E. Classification of daily electric load profiles of non-residential buildings. Energy Build. 2021, 233, 110670. [Google Scholar] [CrossRef]

- Benlahbib, B.; Bouarroudj, N.; Mekhilef, S.; Abdeldjalil, D.; Abdelkrim, T.; Bouchafaa, F.; Lakhdari, A. Experimental investigation of power management and control of a PV/wind/fuel cell/battery hybrid energy system microgrid. Int. J. Hydrog. Energy 2020, 45, 29110–29122. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, W. Model construction and energy management system of lithium battery, PV generator, hydrogen production unit and fuel cell in islanded AC microgrid. Int. J. Hydrog. Energy 2020, 45, 16381–16397. [Google Scholar] [CrossRef]

- Paul Ayeng’o, S.; Axelsen, H.; Haberschusz, D.; Sauer, D.U. A model for direct-coupled PV systems with batteries depending on solar radiation, temperature and number of serial connected PV cells. Sol. Energy 2019, 183, 120–131. [Google Scholar] [CrossRef]

- Cho, D.; Valenzuela, J. Optimization of residential off-grid PV-battery systems. Sol. Energy 2020, 208, 766–777. [Google Scholar] [CrossRef]

- Soudan, B.; Darya, A. Autonomous smart switching control for off-grid hybrid PV/battery/diesel power system. Energy 2020, 211, 118567. [Google Scholar] [CrossRef]

- Haratian, M.; Tabibi, P.; Sadeghi, M.; Vaseghi, B.; Poustdouz, A. A renewable energy solution for stand-alone power generation: A case study of KhshU Site-Iran. Renew. Energy 2018, 125, 926–935. [Google Scholar] [CrossRef]

- EU Project: Sustainhuts-Demonstrative Project Which Aims to Reduce CO2 Emissions in Natural Environments Acting in Huts; G.A. LIFE15 CCA/ES/000058; European Commission: Brussels, Belgium, 2016.

- Mori, M. Life Cycle Model (LCA) of RE Technologies Implementation and Sensitivity Analysis: Life Sustainhuts: Sustainable Mountain Huts in Europe: Life Cycle Assessment and Environmental Analysis; Faculty of Mechanical Engineering: Ljubljana, Slovenia, 2020. [Google Scholar]

- Mori, M. LCA Model of Case Study with All Listed Technologies Implemented: Life Sustainhuts: Sustainable Mountain Huts in Europe: Life Cycle Assessment and Environmental Analysis; Faculty of Mechanical Engineering: Ljubljana, Slovenia, 2020. [Google Scholar]

- Casero, P. Sustainable Mountainhuts in Europe, LIFE15 CCA/ES/000058; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Global Solar Atlas. Available online: https://globalsolaratlas.info/map (accessed on 17 July 2021).

- Bourdeau, M.; Nefzaoui, E.; Guo, X.; Chatellier, P. Modeling and forecasting building energy consumption: A review of data- driven techniques. Sustain. Cities Soc. 2019, 48, 101533. [Google Scholar] [CrossRef]

- Panapakidis, I.P.; Papadopoulos, T.A.; Christoforidis, G.C.; Papagiannis, G.K. Pattern recognition algorithms for electricity load curve analysis of buildings. Energy Build. 2014, 73, 137–145. [Google Scholar] [CrossRef]

- Gutiérrez, M.; Casero, P. Life15 CCA/ES/000058 Life Sustainhuts: Sustainable Mountain Huts in Europe D1.4 Third Monitoring Report_Spanish Huts; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Knight, K.M.; Klein, S.A.; Duffie, J.A. A methodology for the synthesis of hourly weather data. Sol. Energy 1991, 46, 109–120. [Google Scholar] [CrossRef]

- Graham, V.A.; Hollands, K.G.T.; Unny, T.E. Stochastic variation of hourly solar radiation over the day. Adv. Sol. Energy Technol. 1988, 3796–3800. [Google Scholar] [CrossRef]

- Degelman, L.O. A Weather Simulation Model for Building Energy Analysis. In Proceedings of the ASHRAE Transaction, Symposium on Weather Data; Pennsylvania State University: State College, PA, USA, 1976; pp. 435–447. [Google Scholar]

- Gansler, R.A.; Klein, S.A.; Beckman, W.A. Assessment of the accuracy of generated meteorological data for use in solar energy simulation studies. Sol. Energy 1994, 53, 279–287. [Google Scholar] [CrossRef]

- TESS Component Library Package—TESS Libraries|TRNSYS: Transient System Simulation Tool; TESS-Thermal Energy Systems Specialists: Madison, WI, USA, 2012.

- Renewables.ninja. Available online: https://www.renewables.ninja/ (accessed on 10 December 2021).

- Molod, A.; Takacs, L.; Suarez, M.; Bacmeister, J. Development of the GEOS-5 atmospheric general circulation model: Evolution from MERRA to MERRA2. Geosci. Model Dev. 2015, 8, 1339–1356. [Google Scholar] [CrossRef] [Green Version]

- Welcome|TRNSYS: Transient System Simulation Tool. Available online: http://www.trnsys.com/ (accessed on 17 July 2021).

- International Organisation for Standardisation. ISO 14040 (2006a): Environmental Management—Life Cycle Assessment—Principles and Framework; International Organisation for Standardisation: Geneva, Switzerland, 2006. [Google Scholar]

- International Organisation for Standardisation. ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organisation for Standardisation: Geneva, Switzerland, 2006. [Google Scholar]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010; ISBN 978-92-79-19092-6. [Google Scholar]

- GaBi Databases: Professional Database; Sphera Solutions: Leinfelden-Echterdingen, Germany, 2018.

- Ecoinvent 3.6: The Latest Version of the Ecoinvent Database Features More Than 2200 New and 2500 Updated Datasets; Ecoinvent: Zurich, Switzerland, 2019.

- Mori, M.; Lotrič, A.; Stropnik, R.; Drobnič, B.; Sekavčnik, M. LIFE15 CCA/ES/000058 LIFE SUSTAINHUTS: Life Cycle Assessment and Environmental Analysis, C5.2 Life Cycle Inventory Analysis (LCIA): Mass and Energy Balances of Mountain Huts; Faculty of Mechanical Engineering: Ljubljana, Slovenia, 2017. [Google Scholar]

- Federación Aragonesa de Montañismo. Available online: https://www.fam.es/ (accessed on 6 September 2021).

| SOPB | SOPE | |

|---|---|---|

| Diesel generator (kWp) | 22.4 + 12.8 | 22.4 + 12.8 |

| PV (kWp) | 0.53 | 3.7 |

| Batteries (kWh) | 38.4 | 38.4 |

| Chimney | Open chimney | Heat recuperation |

| Micro-grid control | Manual | Manual |

| Diesel (L/year) | 5774 | 4511 |

| LPG (kg/year) | 6568 | 3140 |

| Mixed wood (kg/year) | 700 | 5000 |

| Description | Unit | SOPB | MEAS * | SOPE | SOPE+ | SOPEx2 | RES |

|---|---|---|---|---|---|---|---|

| total consumption | kWh | 8105 | 7842 | 8105 | 8105 | 8105 | 8105 |

| generator output | kWh | 8284 | 4913 | 5064 | 3348 | 638 | 0 |

| total fuel consumption, single phase | L | 3408 | 2021 | 2083 | 1378 | 262 | 0 |

| nominal photovoltaic power | kW | 0.5 | 3.7 | 3.7 | 3.7 | 7.4 | 11.1 |

| available solar energy | kWh | 791 | - | 5852 | 5852 | 11,704 | 17,556 |

| battery capacity | kWh | 38.4 | 38.4 | 38.4 | 38.4 | 76.8 | 192.0 |

| excess energy | kWh | 0 | - | 1734 | 59 | 2996 | 7941 |

| renewable penetration | % | 8.7 | - | 44.9 | 63.4 | 93.2 | 100.0 |

| SOPB | SOPE | SOPE+ | SOPEx2 | RES | Process from Generic Database | |

|---|---|---|---|---|---|---|

| Electricity (kWh) | ||||||

| PV slanted roof | 791 | 4118 | 5793 | 8708 | 9615 | ES: el. Prod., photovoltaic, 3 kWp slanted-roof installation, single-Si, panel, mounted, Ecoinvent 3.5 |

| Diesel, 1-phase | 8284 | 5064 | 3348 | 638 | 0 | GLO: diesel, burned in diesel-electric generating set, 18.5 kW, Ecoinvent 3.5 |

| Diesel, 3-phase | 6439 | 6439 | 6439 | 6439 | 6439 | |

| Heat (kWh) | ||||||

| LPG boiler | 73,292 | 35,040 | 35,040 | 35,040 | 35,040 | EU-28: gas low-temperature boiler < 20 kW (use), Sphera |

| Mixed log chimney | 350 | 38,252 | 38,252 | 38,252 | 38,252 | RoW: heat production, mixed logs, 30 kW, Ecoinvent 3.5 |

| Unit | SOPB | SOPE | SOPE+ | SOPEx2 | RES | |

|---|---|---|---|---|---|---|

| Diesel, 1-phase | kg | 2761.4 | 1687.7 | 1116.2 | 212.6 | 0.0 |

| Diesel, 3-phase | kg | 4907.7 | 3834.0 | 3262.5 | 2358.9 | 2146.3 |

| Factor, diesel | km·kg | 613,455 | 771,241 | 687,459 | 554,991 | 523,824 |

| LPG | kg | 6568 | 3140 | 3140 | 3140 | 3140 |

| Factor, LPG | km·kg | 1,944,128 | 929,440 | 929,440 | 929,440 | 929,440 |

| Factor, total | km·kg | 2,557,583 | 1,700,681 | 1,616,899 | 1,484,431 | 1,453,264 |

| Abbr. | Name | Indicator | Units | |

|---|---|---|---|---|

| Air/ Climate | GWP | Global Warming Potential | Greenhouse gas emissions | kg CO2-eq. |

| AP | Acidification Potential | Air pollution | kg SO2-eq. | |

| POCP | Photochemical Ozone Creation Potential | Air pollution | kg Ethene-eq. | |

| ODP | Ozone-Layer Depletion Potential | Air pollution | kg R11-eq. | |

| HTP | Human Toxicity Potential | Toxicity | kg 1,4-DCB-eq. | |

| Water | FAETP | Freshwater Aquatic Ecotoxicity Potential | Water pollution | kg 1,4-DCB-eq. |

| MAETP | Marine Aquatic Ecotoxicity Potential | Water pollution | kg 1,4-DCB-eq. | |

| EP | Eutrophication Potential | Water pollution | kg PO4-eq. | |

| Soil | TETP | Terrestrial Ecotoxicity Potential | Soil degradation and contamination | kg 1,4-DCB-eq. |

| Resources | ADP elem. | Abiotic depletion potential, elements | Resource depletion | kg Sb-eq. |

| ADP fossil | Abiotic depletion potential, fossil | Resource depletion | MJ |

| Air/Climate | Water | Soil | Resources | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| GWP 100 Years (kg CO2 eq.) | AP (kg SO2 eq.) | POCP (kg Ethene eq.) | ODP, Steady State (kg R11 eq.) | HTP inf. (kg DCB eq.) | FAETP inf. (kg DCB eq.) | MAETP inf. (kg DCB eq.) | EP (kg Phosphate eq.) | TETP inf. (kg DCB eq.) | ADP Elements (kg Sb eq.) | ADP Fossil (MJ) | |

| SOPB | 3.45 × 104 | 149 | 13.9 | 0.00246 | 2.90 × 103 | 1.68 × 103 | 3.32 × 106 | 37.4 | 52.6 | 0.0222 | 5.49 × 105 |

| SOPE | 2.26 × 104 | 130 | 21.4 | 0.00207 | 4.65 × 103 | 2.48 × 103 | 4.51 × 106 | 35.6 | 116.0 | 0.0296 | 3.42 × 105 |

| SOPE+ | 2.11 × 104 | 115 | 20.0 | 0.00180 | 4.60 × 103 | 2.58 × 103 | 4.54 × 106 | 32.0 | 114.0 | 0.0314 | 3.21 × 105 |

| SOPEx2 | 1.88 × 104 | 90.6 | 17.7 | 0.00136 | 4.56 × 103 | 2.78 × 103 | 4.64 × 106 | 26.3 | 111.0 | 0.0349 | 2.88 × 105 |

| RES | 1.83 × 104 | 85 | 17.1 | 0.00126 | 4.59 × 103 | 2.86 × 103 | 4.72 × 106 | 25.1 | 110.0 | 0.0363 | 2.80 × 105 |

| CO2, kg | CO2, % | SOX, kg | SOX, % | NOX, kg | NOX, % | ppm2.5, kg | ppm2.5, % | |

|---|---|---|---|---|---|---|---|---|

| SOPB | 3.30 × 104 | 100 | 27.3 | 100 | 232 | 100 | 27.4 | 100 |

| SOPE | 2.11 × 104 | 64 | 24.8 | 91 | 198 | 85 | 31.3 | 114 |

| SOPE+ | 1.97 × 104 | 60 | 22.3 | 82 | 173 | 75 | 28.3 | 103 |

| SOPEx2 | 1.74 × 104 | 53 | 18.6 | 68 | 134 | 58 | 23.6 | 86 |

| RES | 1.69 × 104 | 51 | 17.8 | 65 | 125 | 54 | 22.5 | 82 |

| Air/Climate | Water | Soil | Resources | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| GWP 100 Years | AP | POCP | ODP, Steady State | HTP inf. | FAETP inf. | MAETP inf. | EP | TETP inf. | ADP Elements | ADP Fossil | |

| SOPB | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

| SOPE | 66% | 87% | 154% | 84% | 160% | 148% | 136% | 95% | 221% | 133% | 62% |

| SOPE+ | 61% | 77% | 144% | 73% | 159% | 154% | 137% | 86% | 217% | 141% | 58% |

| SOPEx2 | 54% | 61% | 127% | 55% | 157% | 165% | 140% | 70% | 211% | 157% | 52% |

| RES | 53% | 57% | 123% | 51% | 158% | 170% | 142% | 67% | 209% | 164% | 51% |

| SOPE | SOPE+ | SOPEx2 | RES | |

|---|---|---|---|---|

| PV panels with regulator | 5373.6 € | 5373.6 € | 12,311.1 € | 18,466.6 € |

| Lead–acid batteries | 9011.4 € | 9011.4 € | 18,022.7 € | 45,056.8 € |

| Inverter unit | 4975.2 € | 4975.2 € | 5475.2 € | 6475.2 € |

| Improved charging strategy * | - | 3000.0 € | 3000.0 € | 3000.0 € |

| Thermo-chimney with heat exchanger | 5970.1 € | 5970.1 € | 5970.1 € | 5970.1 € |

| Labor costs | 968.0 € | 968.0 € | 1490.0 € | 2215.0 € |

| TOTAL | 26,298.3 € | 29,298.3 € | 46,269.1 € | 81,183.7 € |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mori, M.; Gutiérrez, M.; Sekavčnik, M.; Drobnič, B. Modelling and Environmental Assessment of a Stand-Alone Micro-Grid System in a Mountain Hut Using Renewables. Energies 2022, 15, 202. https://doi.org/10.3390/en15010202

Mori M, Gutiérrez M, Sekavčnik M, Drobnič B. Modelling and Environmental Assessment of a Stand-Alone Micro-Grid System in a Mountain Hut Using Renewables. Energies. 2022; 15(1):202. https://doi.org/10.3390/en15010202

Chicago/Turabian StyleMori, Mitja, Manuel Gutiérrez, Mihael Sekavčnik, and Boštjan Drobnič. 2022. "Modelling and Environmental Assessment of a Stand-Alone Micro-Grid System in a Mountain Hut Using Renewables" Energies 15, no. 1: 202. https://doi.org/10.3390/en15010202

APA StyleMori, M., Gutiérrez, M., Sekavčnik, M., & Drobnič, B. (2022). Modelling and Environmental Assessment of a Stand-Alone Micro-Grid System in a Mountain Hut Using Renewables. Energies, 15(1), 202. https://doi.org/10.3390/en15010202