Sugar Beet Pulp in the Context of Developing the Concept of Circular Bioeconomy

Abstract

:1. Introduction

- Presenting the concept and meaning of circular bio-economy.

- Characterizing properties of the sugar beet pulp from the perspective of using them as feedstock.

- Determining the volume of production of the sugar beet pulp and the current methods of using them.

- Determining the methods of obtaining attractive bioproducts and renewable energy from sugar beet pulp.

2. Circular Bioeconomy—The Concept and Meaning

- (1)

- Technical cycle, encompassing non-renewable resources, meaning the resources that cannot be renewed as a result of natural processes, or it will take a very long time to do so.

- (2)

- Biological cycle, encompassing renewable resources meaning the resources that can be renewed on an ongoing basis, or the renewal happens very fast. The biological cycle also refers to:

- The biomass, that is the part of the product, waste, residues, which are biodegradable;

- Residues of biological origin;

- Industrial biomass.

- (1)

- Preserving natural capital by balancing natural resource flows (loops of natural resource cycles).

- (2)

- Optimizing the use of raw materials by maintaining finished products and components for their production in the cycles mentioned above (technical and biological).

- (3)

- The continuity of increasing the efficiency of the circular economy system through the constant identification, monitoring and removal of negative external consequences associated with flows of flows.

- Lignocelluloses,

- Algae (microalgae),

- Agricultural, municipal, industrial, and forest waste and residues such as, for example, manure, food, sludge [16].

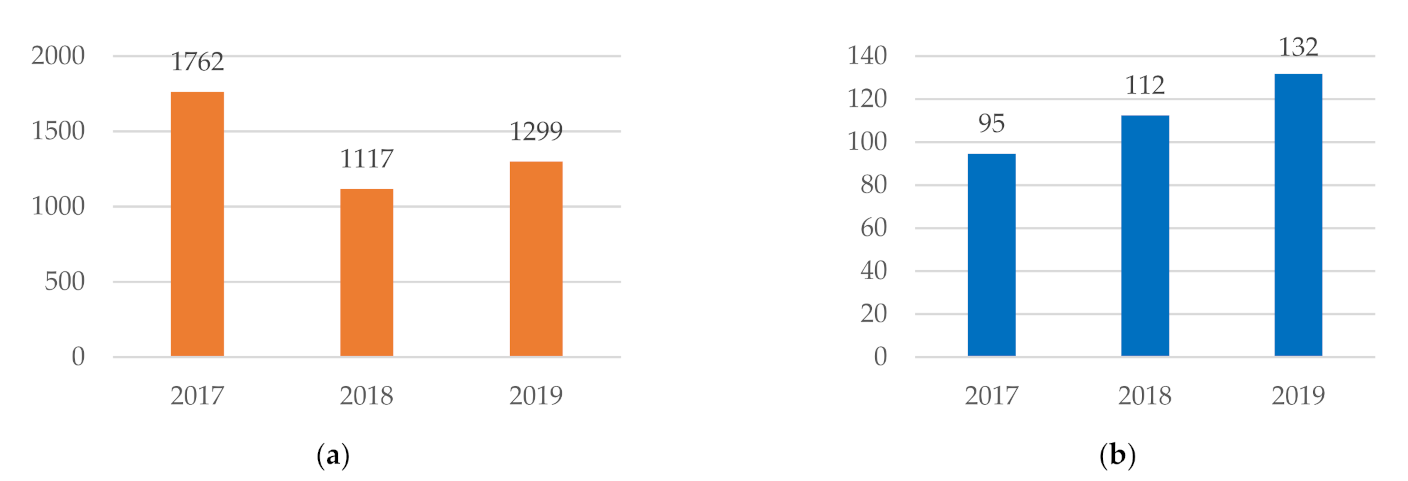

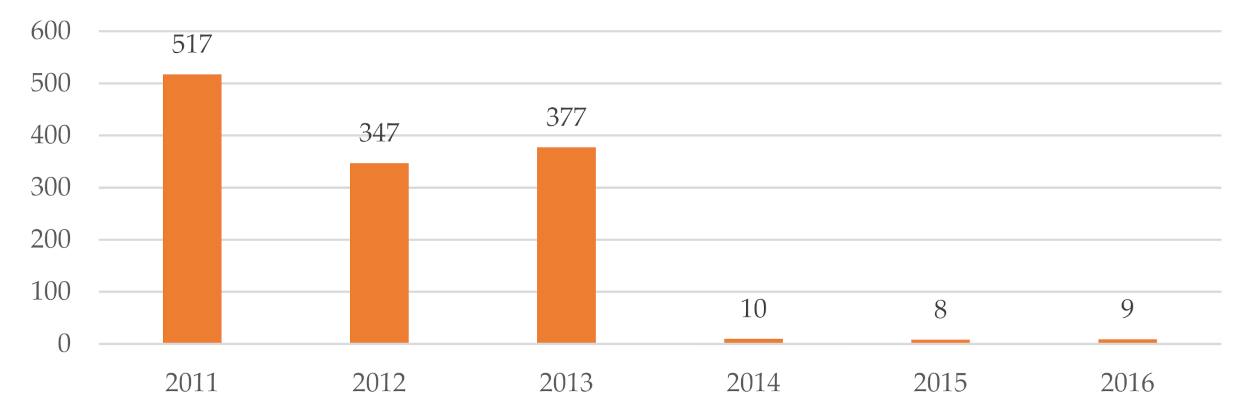

3. Production of Sugar Beet Pulp

4. Current Uses of Sugar Beet Pulp

5. New Applications of Sugar Beet Pulp as an Example of Implementing the Circular Bioeconomy Concept

- Biodegradable composites (thermoplastics) used as a lightweight construction material [142];

6. Energy

7. Discussion

- Preserves natural resources and reduces the amount of waste being landfilled by keeping bioresources in the loop [18].

- Reduces GHG and other emissions by producing biogas.

- Building a cohesive policy, which takes into account, when constructing the postulates, goals, and instruments within the framework of economic policy and sectoral policies, the premises of the concept of sustainable;

- Material investments, related to infrastructure and no-material investments, which are related to knowledge, qualifications, skills in the area of environmental protection, recycling, sustainable environmental technologies, biotechnology, and bioengineering etc.;

- Implementing the rules of participative management and dialog between the private, public, and non-governmental sector.

- Improving the information flows in the chains and networks of bioeconomy;

- Orienting the educational activity towards sustainable development, bioeconomy, biotechnology, and bioengineering;

- Launching the systems of financial and support and the tools promoting circular economy;

- Implementing the planning, monitoring, and evaluating systems in the chains and networks of bioeconomy;

- Interdisciplinarity of the work conducted in the R&D field;

- Initiating, supporting, and diffusing the research and development work;

- Creating a cooperation network and a network of clusters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Linder, M.; Sarasini, S.; van Loon, P. A Metric for Quantifying Product-Level Circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef] [Green Version]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017; p. 2544. Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 4 December 2021).

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- Liguori, R.; Faraco, V. Biological processes for advancing lignocellulosic waste biorefinery by advocating circular economy. Bioresour. Technol. 2016, 215, 13–20. [Google Scholar] [CrossRef]

- Guo, Z.; Yan, N.; Lapkin, A. Towards circular economy: Integration of bio-waste into chemical supply chain. Curr. Opin. Chem. Eng. 2019, 26, 148–156. [Google Scholar] [CrossRef]

- Attard, T.M.; Clark, J.H.; McElroy, C.R. Recent developments in key biorefinery areas. Curr. Opin. Green Sustain. Chem. 2020, 21, 64–74. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Patel, A.; Juneja, A.; Singh, R.P.; Yan, B.; Awasthi, S.K.; Jain, A.; Liu, T.; Duan, Y.; et al. Refining biomass residues for sustainable energy and bio-products: An assessment of technology, its importance, and strategic applications in circular bio-economy. Renew. Sustain. Energy Rev. 2020, 127, 109876. [Google Scholar] [CrossRef]

- Venkata Mohan, S.; Dahiya, S.; Amulya, K.; Katakojwala, R.; Vanitha, T.K. Can circular bioeconomy be fueled by waste biorefineries—A closer look. Bioresour. Technol. Rep. 2019, 7, 100277. [Google Scholar] [CrossRef]

- Birner, R. Bioeconomy Concepts. In Bioeconomy: Shaping the Transition to a Sustainable, Biobased Economy; Lewandowski, I., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 17–38. ISBN 978-3-319-68152-8. [Google Scholar]

- Chisika, S.N.; Park, J.; Yeom, C. Paradox of Deadwood Circular Bioeconomy in Kenya’s Public Forests. Sustainability 2021, 13, 7051. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation and McKinsey Growth within: A Circular Economy Vision for a Competitive Europe. Available online: https://www.sun-institute.org/media/growth_within_for_print1 (accessed on 15 March 2021).

- Woźniak, E.; Tyczewska, A.; Twardowski, T. Bioeconomy development factors in the European Union and Poland. New Biotechnol. 2021, 60, 2–8. [Google Scholar] [CrossRef] [PubMed]

- Ubando, A.T.; Felix, C.B.; Chen, W.-H. Biorefineries in circular bioeconomy: A comprehensive review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, A.; Mhatre, A.; Pandit, R.; Lali, A.M. Synergistic biorefinery of Scenedesmus obliquus and Ulva lactuca in poultry manure towards sustainable bioproduct generation. Bioresour. Technol. 2020, 297, 122462. [Google Scholar] [CrossRef]

- Stegmann, P.; Londo, M.; Junginger, M. The circular bioeconomy: Its elements and role in European bioeconomy clusters. Resour. Conserv. Recycl. X 2020, 6, 100029. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total Environ. 2020, 716, 137065. [Google Scholar] [CrossRef]

- Kardung, M.; Cingiz, K.; Costenoble, O.; Delahaye, R.; Heijman, W.; Lovrić, M.; van Leeuwen, M.; M’Barek, R.; van Meijl, H.; Piotrowski, S.; et al. Development of the Circular Bioeconomy: Drivers and Indicators. Sustainability 2021, 13, 413. [Google Scholar] [CrossRef]

- Smutka, L.; Pawlak, K.; Kotyza, P.; Svatoš, M. Polish Sugar Industry Development. Agris On-line Pap. Econ. Inform. 2018, 10, 71–90. [Google Scholar] [CrossRef] [Green Version]

- European Association of Sugar Manufacturers Statistics–CEFS. Available online: https://cefs.org/resources/statistics/ (accessed on 4 September 2020).

- Gumienna, M.; Szambelan, K.; Jeleń, H.; Czarnecki, Z. Evaluation of ethanol fermentation parameters for bioethanol production from sugar beet pulp and juice. J. Inst. Brew. 2014, 120, 543–549. [Google Scholar] [CrossRef]

- Dávila, I.; Remón, J.; Gullón, P.; Labidi, J.; Budarin, V. Production and characterization of lignin and cellulose fractions obtained from pretreated vine shoots by microwave assisted alkali treatment. Bioresour. Technol. 2019, 289, 121726. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Antikainen, R.; Bocken, N.; Dahlbo, H.; Aminoff, A. Do circular economy business models capture intended environmental value propositions? J. Clean. Prod. 2018, 171, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Jain, A.; Sarsaiya, S.; Kumar Awasthi, M.; Singh, R.; Rajput, R.; Mishra, U.C.; Chen, J.; Shi, J. Bioenergy and bio-products from bio-waste and its associated modern circular economy: Current research trends, challenges, and future outlooks. Fuel 2022, 307, 121859. [Google Scholar] [CrossRef]

- Velvizhi, G.; Balakumar, K.; Shetti, N.P.; Ahmad, E.; Kishore Pant, K.; Aminabhavi, T.M. Integrated biorefinery processes for conversion of lignocellulosic biomass to value added materials: Paving a path towards circular economy. Bioresour. Technol. 2022, 343, 126151. [Google Scholar] [CrossRef] [PubMed]

- Righetti, E.; Nortilli, S.; Fatone, F.; Frison, N.; Bolzonella, D. A Multiproduct Biorefinery Approach for the Production of Hydrogen, Methane and Volatile Fatty Acids from Agricultural Waste. Waste Biomass Valoriz. 2020, 11, 5239–5246. [Google Scholar] [CrossRef] [Green Version]

- Barreira, J.C.M.; Arraibi, A.A.; Ferreira, I.C.F.R. Bioactive and functional compounds in apple pomace from juice and cider manufacturing: Potential use in dermal formulations. Trends Food Sci. Technol. 2019, 90, 76–87. [Google Scholar] [CrossRef]

- Alexandri, M.; Schneider, R.; Papapostolou, H.; Ladakis, D.; Koutinas, A.; Venus, J. Restructuring the Conventional Sugar Beet Industry into a Novel Biorefinery: Fractionation and Bioconversion of Sugar Beet Pulp into Succinic Acid and Value-Added Coproducts. ACS Sustain. Chem. Eng. 2019, 7, 6569–6579. [Google Scholar] [CrossRef]

- Konwar, L.J.; Mikkola, J.-P.; Bordoloi, N.; Saikia, R.; Chutia, R.S.; Kataki, R. Chapter 3-Sidestreams From Bioenergy and Biorefinery Complexes as a Resource for Circular Bioeconomy. In Waste Biorefinery. Potential and Perspectives; Bhaskar, T., Pandey, A., Mohan, S.V., Lee, D.-J., Khanal, S.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 85–125. ISBN 978-0-444-63992-9. [Google Scholar]

- Kurian, J.K.; Nair, G.R.; Hussain, A.; Raghavan, G.S.V. Feedstocks, logistics and pre-treatment processes for sustainable lignocellulosic biorefineries: A comprehensive review. Renew. Sustain. Energy Rev. 2013, 25, 205–219. [Google Scholar] [CrossRef]

- Zuin, V.G.; Ramin, L.Z. Green and Sustainable Separation of Natural Products from Agro-Industrial Waste: Challenges, Potentialities, and Perspectives on Emerging Approaches. Top. Curr. Chem. 2018, 376, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- da Silva, T.L.; Moniz, P.; Silva, C.; Reis, A. The dark side of microalgae biotechnology: A heterotrophic biorefinery platform directed to ω-3 rich lipid production. Microorganisms 2019, 7, 670. [Google Scholar] [CrossRef] [Green Version]

- Yaashikaa, P.R.; Senthil Kumar, P.; Varjani, S. Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review. Bioresour. Technol. 2022, 343, 126126. [Google Scholar] [CrossRef] [PubMed]

- Ioannidou, S.M.; Pateraki, C.; Ladakis, D.; Papapostolou, H.; Tsakona, M.; Vlysidis, A.; Kookos, I.K.; Koutinas, A. Sustainable production of bio-based chemicals and polymers via integrated biomass refining and bioprocessing in a circular bioeconomy context. Bioresour. Technol. 2020, 307, 123093. [Google Scholar] [CrossRef] [PubMed]

- To, M.H.; Uisan, K.; Ok, Y.S.; Pleissner, D.; Lin, C.S.K. Recent trends in green and sustainable chemistry: Rethinking textile waste in a circular economy. Curr. Opin. Green Sustain. Chem. 2019, 20, 1–10. [Google Scholar] [CrossRef]

- Troiano, D.; Orsat, V.; Dumont, M.J. Status of filamentous fungi in integrated biorefineries. Renew. Sustain. Energy Rev. 2020, 117, 109472. [Google Scholar] [CrossRef]

- Belaud, J.P.; Prioux, N.; Vialle, C.; Sablayrolles, C. Big data for agri-food 4.0: Application to sustainability management for by-products supply chain. Comput. Ind. 2019, 111, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Hetemäki, L.; Hanewinkel, M.; Muys, B.; Ollikainen, M.; Palahí, M.; Trasobares, A. Leading the way to a European circular bioeconomy strategy. In From Science to Policy 5; European Forest Institute: Sarjanr, Finland, 2017. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Neves, R.C.; Klein, B.C.; da Silva, R.J.; Rezende, M.C.A.F.; Funke, A.; Olivarez-Gómez, E.; Bonomi, A.; Maciel-Filho, R. A vision on biomass-to-liquids (BTL) thermochemical routes in integrated sugarcane biorefineries for biojet fuel production. Renew. Sustain. Energy Rev. 2020, 119, 109607. [Google Scholar] [CrossRef]

- Innovating for Sustainable Growth: A Bioeconomy for Europe; European Commission: Luxembourg, 2012.

- Enriquez, J. Genomics and the World’s Economy. Science 1998, 281, 925–926. [Google Scholar] [CrossRef]

- Frisvold, G.B.; Moss, S.M.; Hodgson, A.; Maxon, M.E. Understanding the U.S. Bioeconomy: A New Definition and Landscape. Sustainability 2021, 13, 1627. [Google Scholar] [CrossRef]

- Barañano, L.; Garbisu, N.; Alkorta, I.; Araujo, A.; Garbisu, C. Contextualization of the Bioeconomy Concept through Its Links with Related Concepts and the Challenges Facing Humanity. Sustainability 2021, 13, 7746. [Google Scholar] [CrossRef]

- Holmgren, S.; D’Amato, D.; Giurca, A. Bioeconomy imaginaries: A review of forest-related social science literature. Ambio 2020, 49, 1860–1877. [Google Scholar] [CrossRef]

- OECD. The Bioeconomy to 2030: Designing a Policy Agenda; OECD Publishing: Paris, France, 2009. [Google Scholar] [CrossRef]

- McCormick, K.; Kautto, N. The Bioeconomy in Europe: An Overview. Sustainability 2013, 5, 2589–2608. [Google Scholar] [CrossRef] [Green Version]

- Golden, J.S.; Handfield, R.B. Why Biobased? Opportunities in the Emerging Bioeconomy. Available online: http://www.biopreferred.gov/files/WhyBiobased (accessed on 4 March 2021).

- Albrecht, J.; Carrez, D.; Cunningham, P.; Daroda, L.; Mancia, R.; Máthé, L.; Raschka, A.; Carus, M.; Piotrowski, S. The Knowledge Based Bio-Economy (KBBE) in Europe: Achievements and Challenges. 2010. Available online: https://www.vlaanderen.be/publicaties/the-knowledge-based-bio-economy-kbbe-in-europe-achievements-and-challenges (accessed on 4 September 2020).

- Global Bioeconomy Summit Global Bioeconomy Summit Communiqué. Available online: https://gbs2018.com/fileadmin/gbs2018/Downloads/GBS_2018_Communique (accessed on 4 March 2020).

- The White House. National Bioeconomy Blueprint; The White House: Washington, DC, USA, 2012. Available online: https://obamawhitehouse.archives.gov/sites/default/files/microsites/ostp/national_bioeconomy_blueprint_april_2012.pdf (accessed on 4 December 2021).

- Pfau, S.F.; Hagens, J.E.; Dankbaar, B.; Smits, A.J.M. Visions of Sustainability in Bioeconomy Research. Sustainability 2014, 6, 1222–1249. [Google Scholar] [CrossRef] [Green Version]

- Sidi-Yacoub, B.; Oudghiri, F.; Belkadi, M.; Rodríguez-Barroso, R. Characterization of lignocellulosic components in exhausted sugar beet pulp waste by TG/FTIR analysis. J. Therm. Anal. Calorim. 2019, 138, 1801–1809. [Google Scholar] [CrossRef]

- Kougias, P.G.; Angelidaki, I. Biogas and its opportunities—A review. Front. Environ. Sci. 2018, 12, 14. [Google Scholar] [CrossRef]

- Jarre, M.; Petit-Boix, A.; Priefer, C.; Meyer, R.; Leipold, S. Transforming the bio-based sector towards a circular economy-What can we learn from wood cascading? For. Policy Econ. 2020, 110, 101872. [Google Scholar] [CrossRef]

- Azapagic, A. Sustainability considerations for integrated biorefineries. Trends Biotechnol. 2014, 32, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Nolles, R.; Staps, F.; Van Engelen, G. The unbeatable beet: Biorefining of sugar beet pulp. Adv. Mater.-TechConnect Briefs 2016 2016, 2, 159–162. [Google Scholar]

- de Souza Moreira, L.R.; Farinas, C.S.; de Aquino Ximenes, E.; Filho, E.X.F. Introduction. In Recent Advances in Bioconversion of Lignocellulose to Biofuels and Value-Added Chemicals within the Biorefinery Concept; Ferreira Filho, E.X., de Souza Moreira, L.R., de Aquino Ximenes, E., Farinas, C.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–4. ISBN 978-0-12-818223-9. [Google Scholar]

- European Commission, Directorate-General for Research and Innovation. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; Publications Office: Luxembourg, 2018. [Google Scholar]

- Venkata Mohan, S.; Amulya, K.; Annie Modestra, J. Urban biocycles–Closing metabolic loops for resilient and regenerative ecosystem: A perspective. Bioresour. Technol. 2020, 306, 123098. [Google Scholar] [CrossRef]

- di Bitonto, L.; Reynel-Ávila, H.E.; Mendoza-Castillo, D.I.; Bonilla-Petriciolet, A.; Pastore, C. Residual Mexican biomasses for bioenergy and fine chemical production: Correlation between composition and specific applications. Biomass Convers. Biorefinery 2021, 11, 619–631. [Google Scholar] [CrossRef]

- Bello, S.; Méndez-Trelles, P.; Rodil, E.; Feijoo, G.; Moreira, M.T. Towards improving the sustainability of bioplastics: Process modelling and life cycle assessment of two separation routes for 2,5-furandicarboxylic acid. Sep. Purif. Technol. 2020, 233, 116056. [Google Scholar] [CrossRef]

- Cárdenas-Fernández, M.; Bawn, M.; Hamley-Bennett, C.; Bharat, P.K.V.; Subrizi, F.; Suhaili, N.; Ward, D.P.; Bourdin, S.; Dalby, P.A.; Hailes, H.C.; et al. An integrated biorefinery concept for conversion of sugar beet pulp into value-added chemicals and pharmaceutical intermediates. Faraday Discuss. 2017, 202, 415–431. [Google Scholar] [CrossRef] [Green Version]

- Adiletta, G.; Brachi, P.; Riianova, E.; Crescitelli, A.; Miccio, M. A Simplified Biorefinery Concept for the Valorization of Sugar Beet Pulp: Ecofriendly Isolation of Pectin as a Step Preceding Torrefaction. Waste Biomass Valoriz. 2020, 11, 2721–2733. [Google Scholar] [CrossRef]

- Hotchkiss, A.; Fishman, M.; Liu, L. The role of sugar beet pulp polysaccharides in the sustainability of the sugar beet industry. Proc. ACS Symp. Ser. 2010, 1058, 283–290. [Google Scholar]

- Gheewala, S.H. Biorefineries for Sustainable Food-Fuel-Fibre Production: Towards a Circular Economy. E3S Web Conf. 2019, 125, 01002. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Rezicó, T.; Oros, D.; Markovicó, I.; Kracher, D.; Ludwig, R.; Šantek, B. Integrated hydrolyzation and fermentation of sugar beet pulp to bioethanol. J. Microbiol. Biotechnol. 2013, 23, 1244–1252. [Google Scholar] [CrossRef] [Green Version]

- Mohdaly, A.A.A.; Hassanien, M.F.R.; Mahmoud, A.; Sarhan, M.A.; Smetanska, I. Phenolics extracted from potato, sugar beet, and sesame processing by-products. Int. J. Food Prop. 2013, 16, 1148–1168. [Google Scholar] [CrossRef]

- Berlowska, J.; Cieciura-Włoch, W.; Kalinowska, H.; Kregiel, D.; Borowski, S.; Pawlikowska, E.; Binczarski, M.; Witonska, I. Enzymatic conversion of sugar beet pulp: A comparison of simultaneous saccharification and fermentation and separate hydrolysis and fermentation for lactic acid production. Food Technol. Biotechnol. 2018, 56, 188–196. [Google Scholar] [CrossRef]

- Berlowska, J.; Binczarski, M.; Dziugan, P.; Wilkowska, A.; Kregiel, D.; Witonska, I. Chapter 13-Sugar Beet Pulp as a Source of Valuable Biotechnological Products. In Handbook of Food Bioengineering; Holban, A.M., Grumezescu, A.M., Eds.; Academic Press: London, UK, 2018; pp. 359–392. ISBN 978-0-12-811443-8. [Google Scholar]

- Commission Regulation (EU). No 68/2013 of 16 January 2013 on the Catalogue of Feed Materials, OJ L 29. 30 January 2013. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32013R0068 (accessed on 9 September 2020).

- Abramczuk, W.; Spychała, W. Wysłodki buraczane–produkt uboczny w produkcji cukru, a jednocześnie doskonała i wartościowa pasza. Burak Cukrowy 2009, 4, 17–21. [Google Scholar]

- Kowalska-Wentel, M. Wysłodki Buraczane-Pasza, Odpad czy Surowiec? Available online: https://www.researchgate.net/profile/Monika_Kowalska-Wentel/publication/262662044_WYSLODKI_BURACZANE_-_PASZA_ODPAD_CZY_SUROWIEC/links/0deec5385bca65eb80000000/WYSLODKI-BURACZANE-PASZA-ODPAD-CZY-SUROWIEC (accessed on 4 September 2020).

- EU. Beet Sugar Sustainability Parnership Good Practices. Available online: http://www.sustainablesugar.eu/good-practices (accessed on 4 September 2020).

- Frape, D. Equine Nutrition and Feeding; John Wiley & Sons, Ltd.: Oxford, UK, 2007; ISBN 9780470751053. [Google Scholar]

- Zheng, Y.; Yu, C.; Cheng, Y.S.; Lee, C.; Simmons, C.W.; Dooley, T.M.; Zhang, R.; Jenkins, B.M.; VanderGheynst, J.S. Integrating sugar beet pulp storage, hydrolysis and fermentation for fuel ethanol production. Appl. Energy 2012, 93, 168–175. [Google Scholar] [CrossRef]

- Mesbahi, G.; Niakoosari, M.; Savadkoohi, S.; Farahnaky, A. An investigation on the functional properties of carboxymethyl cellulose (CMC) produced from sugar-beet pulp. In Gums and Stabilisers for the Food Industry 15; Williams, P.A., Phillips, G.O., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2010; pp. 323–329. ISBN 978-1-84755-199-3. [Google Scholar]

- Schmidt, S.C.; Gardiner, W.H. Nongrain Feeds: EC Trade and Policy Issues. Available online: https://ideas.repec.org/p/ags/uersfe/147988.html (accessed on 4 September 2020).

- Panagiotopoulos, I.A. Dark Fermentative Hydrogen Production from Lignocellulosic Biomass. In Production of Hydrogen from Renewable Resources; Fang, Z., Smith, R.L., Jr., Qi, X., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 3–40. ISBN 978-94-017-7330-0. [Google Scholar]

- Zheng, Y.; Lee, C.; Yu, C.; Cheng, Y.; Zhang, R.; Jenkins, B.M.; Vandergheynst, J.S. Dilute acid pretreatment and fermentation of sugar beet pulp to ethanol. Appl. Energy 2013, 105, 1–7. [Google Scholar] [CrossRef]

- Fišerová, M.; Gigac, J.; Boháček, Š. Application of pre-treated sugar beet pulp in paper manufacture. Cellul. Chem. Technol. 2007, 41, 283–289. [Google Scholar]

- Food and Agriculture Organization of the United Nations Faostat. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 4 December 2021).

- Berlowska, J.; Pielech-Przybylska, K.; Balcerek, M.; Cieciura, W.; Borowski, S.; Kregiel, D. Integrated bioethanol fermentation/anaerobic digestion for valorization of sugar beet pulp. Energies 2017, 10, 1255. [Google Scholar] [CrossRef] [Green Version]

- Spagnuolo, M.; Crecchio, C.; Pizzigallo, M.D.R.; Ruggiero, P. Synergistic effects of cellulolytic and pectinolytic enzymes in degrading sugar beet pulp. Bioresour. Technol. 1997, 60, 215–222. [Google Scholar] [CrossRef]

- Cárdenas-Fernández, M.; Hamley-Bennett, C.; Leak, D.J.; Lye, G.J. Continuous enzymatic hydrolysis of sugar beet pectin and L-arabinose recovery within an integrated biorefinery. Bioresour. Technol. 2018, 269, 195–202. [Google Scholar] [CrossRef]

- Gharib-Bibalan, S. High Value-added Products Recovery from Sugar Processing By-products and Residuals by Green Technologies: Opportunities, Challenges, and Prospects. Food Eng. Rev. 2018, 10, 95–111. [Google Scholar] [CrossRef]

- Główny Urząd Statystyczny. Produkcja Wyrobów Przemysłowych w 2017 r.; Statistics Poland: Warsaw, Poland, 2018. Available online: https://stat.gov.pl/obszary-tematyczne/przemysl-budownictwo-srodki-trwale/przemysl/produkcja-wyrobow-przemyslowych-w-2017-roku,3,15.html (accessed on 9 September 2020).

- Główny Urząd Statystyczny. Produkcja Wyrobów Przemysłowych w 2018 r.; Statistics Poland: Warsaw, Poland, 2019. Available online: https://stat.gov.pl/obszary-tematyczne/przemysl-budownictwo-srodki-trwale/przemysl/produkcja-wyrobow-przemyslowych-w-2018-roku,3,16.html (accessed on 9 September 2020).

- Główny Urząd Statystyczny. Produkcja Wyrobów Przemysłowych w 2019 r.; Statistics Poland: Warsaw, Poland, 2020. Available online: https://stat.gov.pl/obszary-tematyczne/przemysl-budownictwo-srodki-trwale/przemysl/produkcja-wyrobow-przemyslowych-w-2019-roku,3,17.html (accessed on 9 September 2020).

- Karpaky, H.; Maalouf, C.; Bliard, C.; Gacoin, A.; Lachi, M.; Polidori, G. Mechanical and thermal characterization of a beet pulp-starch composite for building applications. E3S Web Conf. 2019, 85, 08005. [Google Scholar] [CrossRef] [Green Version]

- P.W. “Agsol” Sp.J Wysłodki Buraczane. Available online: https://agsol.pl/produkt/wyslodki-buraczane/ (accessed on 26 December 2021).

- Czyżyk, F.; Strzelczyk, M. Rational utilization of production residues generated in agri-food. Arch. Waste Manag. Environ. Prot. 2015, 17, 99–106. [Google Scholar]

- Kühnel, S.; Schols, H.A.; Gruppen, H. Aiming for the complete utilization of sugar-beet pulp: Examination of the effects of mild acid and hydrothermal pretreatment followed by enzymatic digestion. Biotechnol. Biofuels 2011, 4, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- EU. Beet Sugar Sustainability Parnership Issue Brief-Resource Efficiency-Circular Economy. Available online: http://www.sustainablesugar.eu/news/2016/11/25/issue-brief-resource-efficiency-circular-economy (accessed on 4 September 2020).

- Südzucker Polska, S.A. Biogazownia-Środowisko-Zrównoważony, Rozwój. Available online: http://www.suedzucker.pl/pl/biogazownia,58.htm (accessed on 4 September 2020).

- Ogrodowczyk, D.; Olejnik, T.P.; Kaźmierczak, M.; Brzeziń, S.; Baryga, A. Economic analysis for biogas plant working at sugar factory. Biotechnol. Food Sci. 2016, 80, 129–136. [Google Scholar]

- Fritsch, C.; Staebler, A.; Happel, A.; Márquez, M.A.C.; Aguiló-Aguayo, I.; Abadias, M.; Gallur, M.; Cigognini, I.M.; Montanari, A.; López, M.J.; et al. Processing, valorization and application of bio-waste derived compounds from potato, tomato, olive and cereals: A review. Sustainability 2017, 9, 1492. [Google Scholar] [CrossRef] [Green Version]

- Fishman, M.L.; Chau, H.K.; Cooke, P.H.; Hotchkiss, A.T. Global structure of microwave-assisted flash-extracted sugar beet pectin. J. Agric. Food Chem. 2008, 56, 1471–1478. [Google Scholar] [CrossRef] [PubMed]

- Uchwała nr 88 Rady Ministrów z Dnia 1 Lipca 2016 r. w Sprawie Krajowego Planu Gospodarki Odpadami 2022, M.P. 2016 poz. 784. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WMP20160000784 (accessed on 9 September 2020).

- Minister Środowiska Sprawozdanie z Realizacji Krajowego Planu Gospodarki Odpadami za Okres od 1 Stycznia 2014 r. do 31 Grudnia 2016 r. Available online: https://bip.mos.gov.pl/strategie-plany-programy/krajowy-plan-gospodarki-odpadami/sprawozdania-z-realizacji-krajowego-planu-gospodarki-odpadami/ (accessed on 9 September 2020).

- Monitor Polski Obwieszczenie Ministra Środowiska z Dnia 4 Października 2010 r. w Sprawie Wysokości Stawek Opłat za Korzystanie ze Środowiska na rok 2011, M.P. 2010 nr 74 poz. 945. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WMP20100740945 (accessed on 9 September 2020).

- Monitor Polski Obwieszczenie Ministra Środowiska z Dnia 30 Sierpnia 2019 r. w Sprawie Wysokości Stawek Opłat za Korzystanie ze Środowiska na rok 2020, M.P. 2019 poz. 866. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WMP20190000866 (accessed on 9 September 2020).

- Özbaş, K.E.; Özbaş, Ö.Ö. Sugar beet pulp as biomass. Zuckerindustrie 2017, 142, 29–32. [Google Scholar] [CrossRef]

- Gonzalez-Garcia, S.; Gullón, B.; Moreira, M.T. Environmental assessment of biorefinery processes for the valorization of lignocellulosic wastes into oligosaccharides. J. Clean. Prod. 2018, 172, 4066–4073. [Google Scholar] [CrossRef] [Green Version]

- Martins, L.C.; Monteiro, C.C.; Semedo, P.M.; Sá-Correia, I. Valorisation of pectin-rich agro-industrial residues by yeasts: Potential and challenges. Appl. Microbiol. Biotechnol. 2020, 104, 6527–6547. [Google Scholar] [CrossRef]

- Bonnin, E.; Ralet, M.-C.; Thibault, J.-F.; Schols, H.A. 12-Enzymes for the valorisation of fruit- and vegetable-based co-products. In Handbook of Waste Management and Co-Product Recovery in Food Processing. Volume 2. Woodhead Publishing Series in Food Science, Technology and Nutrition; Waldron, K., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2009; pp. 257–285. ISBN 978-1-84569-391-6. [Google Scholar]

- Berlowska, J.; Binczarski, M.; Dudkiewicz, M.; Kalinowska, H.; Witonska, I.A.; Stanishevsky, A.V. A low-cost method for obtaining high-value bio-based propylene glycol from sugar beet pulp. RSC Adv. 2015, 5, 2299–2304. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Wu, S.X.; Ye, J. Non-airtight fermentation of sugar beet pulp with anaerobically digested dairy manure to provide acid-rich hydrolysate for mixotrophic microalgae cultivation. Bioresour. Technol. 2019, 278, 175–179. [Google Scholar] [CrossRef] [PubMed]

- Baciu, I.-E.; Jördening, H.-J. Kinetics of galacturonic acid release from sugar-beet pulp. Enzyme Microb. Technol. 2004, 34, 505–512. [Google Scholar] [CrossRef]

- Sun, R.; Hughes, S. Extraction and Physico-Chemical Characterization of Pectins from Sugar Beet Pulp. Polym. J. 1998, 30, 671–677. [Google Scholar] [CrossRef] [Green Version]

- Tebble, I.; Keech, A.; McDonell, J.; Punter, G. A method of preparation of L-arabinose World Intellectual Property Organization. International Bureau, WO/2005/052195. 2005. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2005052195&_fid=GB135016195 (accessed on 13 August 2020).

- Wu, R.; Zhang, H.; Zeng, X.; Zhang, J.; Xiong, H. L-arabinose and oligosaccharides production from sugar beet pulp by xylanase and acid hydrolysis. Afr. J. Biotechnol. 2011, 10, 1907–1912. [Google Scholar] [CrossRef] [Green Version]

- Sato, N.; Takano, Y.; Mizuno, M.; Nozaki, K.; Umemura, S.; Matsuzawa, T.; Amano, Y.; Makishima, S. Production of feruloylated arabino-oligosaccharides (FA-AOs) from beet fiber by hydrothermal treatment. J. Supercrit. Fluids 2013, 79, 84–91. [Google Scholar] [CrossRef]

- Elst, K.; Babbar, N.; Van Roy, S.; Baldassarre, S.; Dejonghe, W.; Maesen, M.; Sforza, S. Continuous production of pectic oligosaccharides from sugar beet pulp in a cross flow continuous enzyme membrane reactor. Bioprocess Biosyst. Eng. 2018, 41, 1717–1729. [Google Scholar] [CrossRef]

- Ferreira, P.; Diez, N.; Faulds, C.B.; Soliveri, J.; Copa-Patiño, J.L. Release of ferulic acid and feruloylated oligosaccharides from sugar beet pulp by Streptomyces tendae. Bioresour. Technol. 2007, 98, 1522–1528. [Google Scholar] [CrossRef]

- Peng, X.Y.; Mu, T.H.; Zhang, M.; Sun, H.N.; Chen, J.W.; Yu, M. Optimisation of production yield by ultrasound-/microwave-assisted acid method and functional property of pectin from sugar beet pulp. Int. J. Food Sci. Technol. 2015, 50, 758–765. [Google Scholar] [CrossRef]

- Brachi, P.; Riianova, E.; Miccio, M.; Miccio, F.; Ruoppolo, G.; Chirone, R. Valorization of Sugar Beet Pulp via Torrefaction with a Focus on the Effect of the Preliminary Extraction of Pectins. Energy Fuels 2017, 31, 9595–9604. [Google Scholar] [CrossRef]

- Thakur, B.R.; Singh, R.K.; Handa, A.K.; Rao, M.A. Chemistry and uses of pectin—A review. Crit. Rev. Food Sci. Nutr. 1997, 37, 47–73. [Google Scholar] [CrossRef] [PubMed]

- Spagnuolo, M.; Crecchio, C.; Pizzigallo, M.D.R.; Ruggiero, P. Fractionation of sugar beet pulp into pectin, cellulose, and arabinose by arabinases combined with ultrafiltration. Biotechnol. Bioeng. 1999, 64, 685–691. [Google Scholar] [CrossRef]

- Siew, C.K.; Williams, P.A. Emulsification Properties of Sugar Beet Pectin. In Gums and Stabilisers for the Food Industry 14; Williams, P.A., Phillips, G.O., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2008; pp. 257–263. ISBN 978-0-85404-461-0. [Google Scholar]

- Nuñez, A.; Fishman, M.L.; Fortis, L.L.; Cooke, P.H.; Hotchkiss, A.T. Identification of Extensin Protein Associated with Sugar Beet Pectin. J. Agric. Food Chem. 2009, 57, 10951–10958. [Google Scholar] [CrossRef]

- Mesbahi, G.; Jamalian, J.; Farahnaky, A. A comparative study on functional properties of beet and citrus pectins in food systems. Food Hydrocoll. 2005, 19, 731–738. [Google Scholar] [CrossRef]

- Mata, Y.N.; Blázquez, M.L.; Ballester, A.; González, F.; Muñoz, J.A. Sugar-beet pulp pectin gels as biosorbent for heavy metals: Preparation and determination of biosorption and desorption characteristics. Chem. Eng. J. 2009, 150, 289–301. [Google Scholar] [CrossRef]

- Grassino, A.N.; Halambek, J.; Djaković, S.; Rimac Brnčić, S.; Dent, M.; Grabarić, Z. Utilization of tomato peel waste from canning factory as a potential source for pectin production and application as tin corrosion inhibitor. Food Hydrocoll. 2016, 52, 265–274. [Google Scholar] [CrossRef]

- Leijdekkers, A.G.M.; Bink, J.P.M.; Geutjes, S.; Schols, H.A.; Gruppen, H. Enzymatic saccharification of sugar beet pulp for the production of galacturonic acid and arabinose; a study on the impact of the formation of recalcitrant oligosaccharides. Bioresour. Technol. 2013, 128, 518–525. [Google Scholar] [CrossRef]

- The Bio-Based Industries Joint Undertaking (BBI JU). BBI JU PULP2VALUE Project: Sustainable Extraction of High-Value Products from Sugar Beet Pulp|Bio-Based Industries-Public-Private Partnership. Available online: https://www.bbi-europe.eu/bbi-ju-pulp2value-project-sustainable-extraction-high-value-products-sugar-beet-pulp (accessed on 4 September 2020).

- Hu, B.; Li, H.; Wang, Q.; Tan, Y.; Chen, R.; Li, J.; Ban, W.; Liang, L. Production and Utilization of L-Arabinose in China. World J. Eng. Technol. 2018, 6, 24–36. [Google Scholar] [CrossRef] [Green Version]

- Bawn, M.; Subrizi, F.; Lye, G.J.; Sheppard, T.D.; Hailes, H.C.; Ward, J.M. Enzyme and Microbial Technology One-pot, two-step transaminase and transketolase synthesis of L-gluco-heptulose from L-arabinose. Enzyme Microb. Technol. 2018, 116, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Pérez, A.F.; Jofre, F.M.; de Souza Queiroz, S.; Vaz de Arruda, P.; Chandel, A.K.; das Gracas de Almeida Felipe, M. Chapter 9-Biotechnological production of sweeteners. In Biotechnological Production of Bioactive Compounds; Verma, M., Chandel, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 261–292. ISBN 978-0-444-64323-0. [Google Scholar]

- Loman, A.A.; Islam, S.M.M.; Ju, L.-K. Production of arabitol from enzymatic hydrolysate of soybean flour by Debaryomyces hansenii fermentation. Appl. Microbiol. Biotechnol. 2018, 102, 641–653. [Google Scholar] [CrossRef]

- Kordowska-Wiater, M. Production of arabitol by yeasts: Current status and future prospects. J. Appl. Microbiol. 2015, 119, 303–314. [Google Scholar] [CrossRef]

- Modelska, M.; Berlowska, J.; Kregiel, D.; Cieciura, W.; Antolak, H.; Tomaszewska, J.; Binczarski, M.; Szubiakiewicz, E.; Witonska, I.A. Concept for recycling waste biomass from the sugar industry for chemical and biotechnological purposes. Molecules 2017, 22, 1544. [Google Scholar] [CrossRef] [Green Version]

- Saija, A.; Tomaino, A.; Lo Cascio, R.; Trombetta, D.; Proteggente, A.; De Pasquale, A.; Uccella, N.; Bonina, F. Ferulic and caffeic acids as potential protective agents against photooxidative skin damage. J. Sci. Food Agric. 1999, 79, 476–480. [Google Scholar] [CrossRef]

- Takkellapati, S.; Li, T.; Gonzalez, M.A. An overview of biorefinery-derived platform chemicals from a cellulose and hemicellulose biorefinery. Clean Technol. Environ. Policy 2018, 20, 1615–1630. [Google Scholar] [CrossRef]

- Toǧrul, H.; Arslan, N. Production of carboxymethyl cellulose from sugar beet pulp cellulose and rheological behaviour of carboxymethyl cellulose. Carbohydr. Polym. 2003, 54, 73–82. [Google Scholar] [CrossRef]

- Olaru, N.; Olaru, L.; Stoleriu, A.; Ţi˘mpu, D. Carboxymethylcellulose synthesis in organic media containing ethanol and/or acetone. J. Appl. Polym. Sci. 1998, 67, 481–486. [Google Scholar] [CrossRef]

- Nolles, R.; Staps, F. The unbeatable beet: The power of microcellulosic fibers unraveled. Adv. Mater.-TechConnect Briefs 2016 2016, 1, 188–191. [Google Scholar]

- Liu, L.S.; Fishman, M.L.; Hicks, K.B.; Liu, C.K. Biodegradable composites from sugar beet pulp and poly (lactic acid). J. Agric. Food Chem. 2005, 53, 9017–9022. [Google Scholar] [CrossRef]

- Li, M.; Wang, L.; Li, D.; Cheng, Y.; Adhikari, B. Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohydr. Polym. 2014, 102, 136–143. [Google Scholar] [CrossRef]

- Vaccai, G.; Nicolucci, C.; Mantovani, G.; Monegato, A. Industrial production of paper using integral pulp from sugar beet. Zuckerindustrie 1994, 119, 855–859. [Google Scholar]

- Vaccari, G.; Tamburini, E.; Sgualdino, G.; Urbaniec, K.; Klemeš, J. Overview of the environmental problems in beet sugar processing: Possible solutions. J. Clean. Prod. 2005, 13, 499–507. [Google Scholar] [CrossRef]

- Tonini, D.; Hamelin, L.; Astrup, T.F. Environmental implications of the use of agro-industrial residues for biorefineries: Application of a deterministic model for indirect land-use changes. GCB Bioenergy 2016, 8, 690–706. [Google Scholar] [CrossRef] [Green Version]

- Câmara-Salim, I.; Conde, P.; Feijoo, G.; Moreira, M.T. The use of maize stover and sugar beet pulp as feedstocks in industrial fermentation plants–An economic and environmental perspective. Clean. Environ. Syst. 2021, 2, 100005. [Google Scholar] [CrossRef]

- Chauhan, M.K.; Varun; Chaudhary, S.; Kumar, S. Samar Life cycle assessment of sugar industry: A review. Renew. Sustain. Energy Rev. 2011, 15, 3445–3453. [Google Scholar] [CrossRef]

- Pińkowska, H.; Krzywonos, M.; Wolak, P.; Złocińska, A. Pectin and Neutral Monosaccharides Production during the Simultaneous Hydrothermal Extraction of Waste Biomass from Refining of Sugar—Optimization with the Use of Doehlert Design. Molecules 2019, 24, 472. [Google Scholar] [CrossRef] [Green Version]

- Abou-Elseoud, W.S.; Hassan, E.A.; Hassan, M.L. Extraction of pectin from sugar beet pulp by enzymatic and ultrasound-assisted treatments. Carbohydr. Polym. Technol. Appl. 2021, 2, 100042. [Google Scholar] [CrossRef]

- OECD/FAO. OECD-FAO Agricultural Outlook 2021–2030; OECD Publishing: Paris, France, 2021; ISBN 9789264436077. [Google Scholar] [CrossRef]

- Märländer, B.; Hoffmann, C.; Koch, H.-J.; Ladewig, E.; Merkes, R.; Petersen, J.; Stockfisch, N. Environmental situation and yield performance of the sugar beet crop in Germany: Heading for sustainable development. J. Agron. Crop Sci. 2003, 189, 201–226. [Google Scholar] [CrossRef]

- Urbaniec, K.; Grabowski, M.; Wernik, J. 29-Applications of Process Integration Methodologies in Beet Sugar Plants. In Handboook of Process Integration (PI); Minimisation of Energy and Water Use, Waste and Emissions; Klemeš, J.J., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 883–913. ISBN 978-0-85709-593-0. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Sadeghzadeh Hemayati, S.; Tabatabaei, M.; Aghbashlo, M.; Mahmoudi, S.B. A review on beet sugar industry with a focus on implementation of waste-to-energy strategy for power supply. Renew. Sustain. Energy Rev. 2019, 103, 423–442. [Google Scholar] [CrossRef]

- Fikry, I.; Gheith, M.; Eltawil, A. An integrated production-logistics-crop rotation planning model for sugar beet supply chains. Comput. Ind. Eng. 2021, 157, 107300. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Jafarzadeh-Moghaddam, M.; Pateiro, M.; Lorenzo, J.M.; Domínguez, R. Physicochemical, Thermal and Rheological Properties of Pectin Extracted from Sugar Beet Pulp Using Subcritical Water Extraction Process. Molecules 2021, 26, 1413. [Google Scholar] [CrossRef]

- Pacheco, M.T.; Villamiel, M.; Moreno, R.; Moreno, F.J. Structural and Rheological Properties of Pectins Extracted from Industrial Sugar Beet By-Products. Molecules 2019, 24, 392. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Fu, X.; Luo, Z. Effect of molecular structure on emulsifying properties of sugar beet pulp pectin. Food Hydrocoll. 2016, 54, 99–106. [Google Scholar] [CrossRef]

- Chen, H.; Niu, H.; Zhang, H.; Yun, Y.; Chen, W.; Zhong, Q.; Chen, W.; Fu, X. Preparation and properties of ferulic acid-sugar beet pulp pectin ester and its application as a physical and antioxidative stabilizer in a fish oil-water emulsion. Int. J. Biol. Macromol. 2019, 139, 290–297. [Google Scholar] [CrossRef]

- Zhou, Y.; Mei, Y.; Luo, T.; Chen, W.; Zhong, Q.; Chen, H.; Chen, W. Study on the Relationship between Emulsion Properties and Interfacial Rheology of Sugar Beet Pectin Modified by Different Enzymes. Molecules 2021, 26, 2829. [Google Scholar] [CrossRef]

- Lara-Espinoza, C.; Carvajal-Millán, E.; Balandrán-Quintana, R.; López-Franco, Y.; Rascón-Chu, A. Pectin and Pectin-Based Composite Materials: Beyond Food Texture. Molecules 2018, 23, 942. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prandi, B.; Baldassarre, S.; Babbar, N.; Bancalari, E.; Vandezande, P.; Hermans, D.; Bruggeman, G.; Gatti, M.; Elst, K.; Sforza, S. Pectin oligosaccharides from sugar beet pulp: Molecular characterization and potential prebiotic activity. Food Funct. 2018, 9, 1557–1569. [Google Scholar] [CrossRef] [PubMed]

- Bellisle, F.; Hébel, P.; Fourniret, A.; Sauvage, E. Consumption of 100% pure fruit juice and dietary quality in french adults: Analysis of a nationally representative survey in the context of the WHO recommended limitation of free sugars. Nutrients 2018, 10, 459. [Google Scholar] [CrossRef] [Green Version]

- Wong, T.H.T.; Mok, A.; Ahmad, R.; Rangan, A.; Louie, J.C.Y. Intake of free sugar and micronutrient dilution in Australian children and adolescents. Eur. J. Nutr. 2019, 58, 2485–2495. [Google Scholar] [CrossRef]

- Fujiwara, A.; Okada, E.; Okada, C.; Matsumoto, M.; Takimoto, H. Association between free sugars intake and nutrient dilution among Japanese adults: The 2016 National Health and Nutrition Survey, Japan. Eur. J. Nutr. 2020, 59, 3827–3839. [Google Scholar] [CrossRef]

- Mok, A.; Ahmad, R.; Rangan, A.; Louie, J.C.Y. Intake of free sugars and micronutrient dilution in Australian adults. Am. J. Clin. Nutr. 2018, 107, 94–104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adamowicz, M. Bioeconomy as a concept for the development of agriculture and agribusiness. Probl. Agric. Econ. 2020, 365, 135–155. [Google Scholar] [CrossRef]

- Bio-Economy Technology Platforms (BECOTEPS). The European Bioeconomy in 2030: Delivering Sustainable Growth by Addressing the Grand Societal Challenges. Available online: https://www.greengrowthknowledge.org/resource/european-bioeconomy-2030-delivering-sustainable-growth-addressing-grand-societal-challenges (accessed on 4 September 2020).

| Effects of the Linear Economy | Effects of the Circular Economy |

|---|---|

|

|

| Economic Benefits | Social Benefits | Environmental Benefits |

|---|---|---|

|

|

|

| Nature of Barriers and Limitations | Examples |

|---|---|

| Market |

|

| Regulatory |

|

| Technological |

|

| Cultural |

|

| Environmental |

|

| Products | Extraction Method/Technology | Reference |

|---|---|---|

| Pectin | Different extraction procedures, including acid (HCl) extraction | [114] |

| Pectin | Microwave-assisted extraction | [68] |

| Galacturonic acid | Enzymatic release of galacturonic acid | [113] |

| L-arabinose | Few steps, including treatment with aqueous alkali | [115] |

| L-Arabinose and oligosaccharides | Xylanase and acid hydrolysis | [116] |

| L-arabinose and a galacturonic acid-rich backbone | Enzymatic hydrolysis of sugar beet pulp | [89] |

| Arabino-oligosaccharides | Hydrothermal treatment | [117] |

| Pectic oligosaccharides | Enzyme membrane reactor technology | [118] |

| Succinic acid | Fed-batch fermentations with the bacterial strain Actinobacillus succinogenes | [31] |

| Ferulic acid and feruloylated oligosaccharides | The release of products from sugar beet pulp was carried out with the actinomycete strains | [119] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ptak, M.; Skowrońska, A.; Pińkowska, H.; Krzywonos, M. Sugar Beet Pulp in the Context of Developing the Concept of Circular Bioeconomy. Energies 2022, 15, 175. https://doi.org/10.3390/en15010175

Ptak M, Skowrońska A, Pińkowska H, Krzywonos M. Sugar Beet Pulp in the Context of Developing the Concept of Circular Bioeconomy. Energies. 2022; 15(1):175. https://doi.org/10.3390/en15010175

Chicago/Turabian StylePtak, Michał, Agnieszka Skowrońska, Hanna Pińkowska, and Małgorzata Krzywonos. 2022. "Sugar Beet Pulp in the Context of Developing the Concept of Circular Bioeconomy" Energies 15, no. 1: 175. https://doi.org/10.3390/en15010175

APA StylePtak, M., Skowrońska, A., Pińkowska, H., & Krzywonos, M. (2022). Sugar Beet Pulp in the Context of Developing the Concept of Circular Bioeconomy. Energies, 15(1), 175. https://doi.org/10.3390/en15010175