Reliability Analysis of Bifacial PV Panel-Based Inverters Considering the Effect of Geographical Location

Abstract

1. Introduction

2. Reliability Analysis of PV Inverter

2.1. Mission Profile

2.2. Junction Temperature Estimation

2.3. Rainflow Counting Analysis

2.4. Lifetime Model

2.5. Reliability Analysis Using Monte Carlo Simulation

3. Results and Discussion

3.1. Estimation of Junction Temperature

3.2. Rainflow Counting Analysis

3.3. Lifetime Evaluation

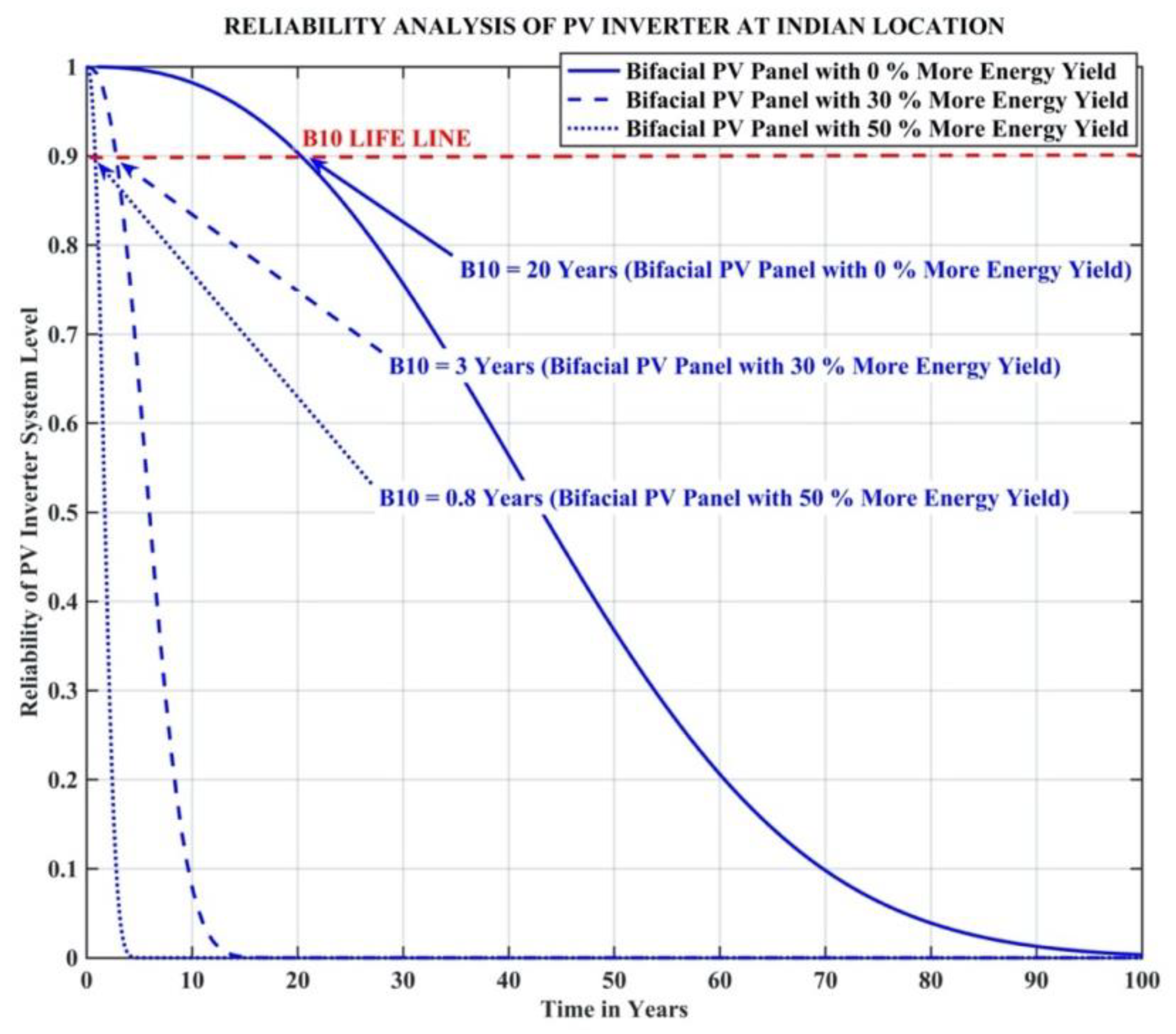

3.4. Reliability Analysis of PV Inverter Considering a Bifacial PV Panel

3.4.1. Estimation of Junction Temperature

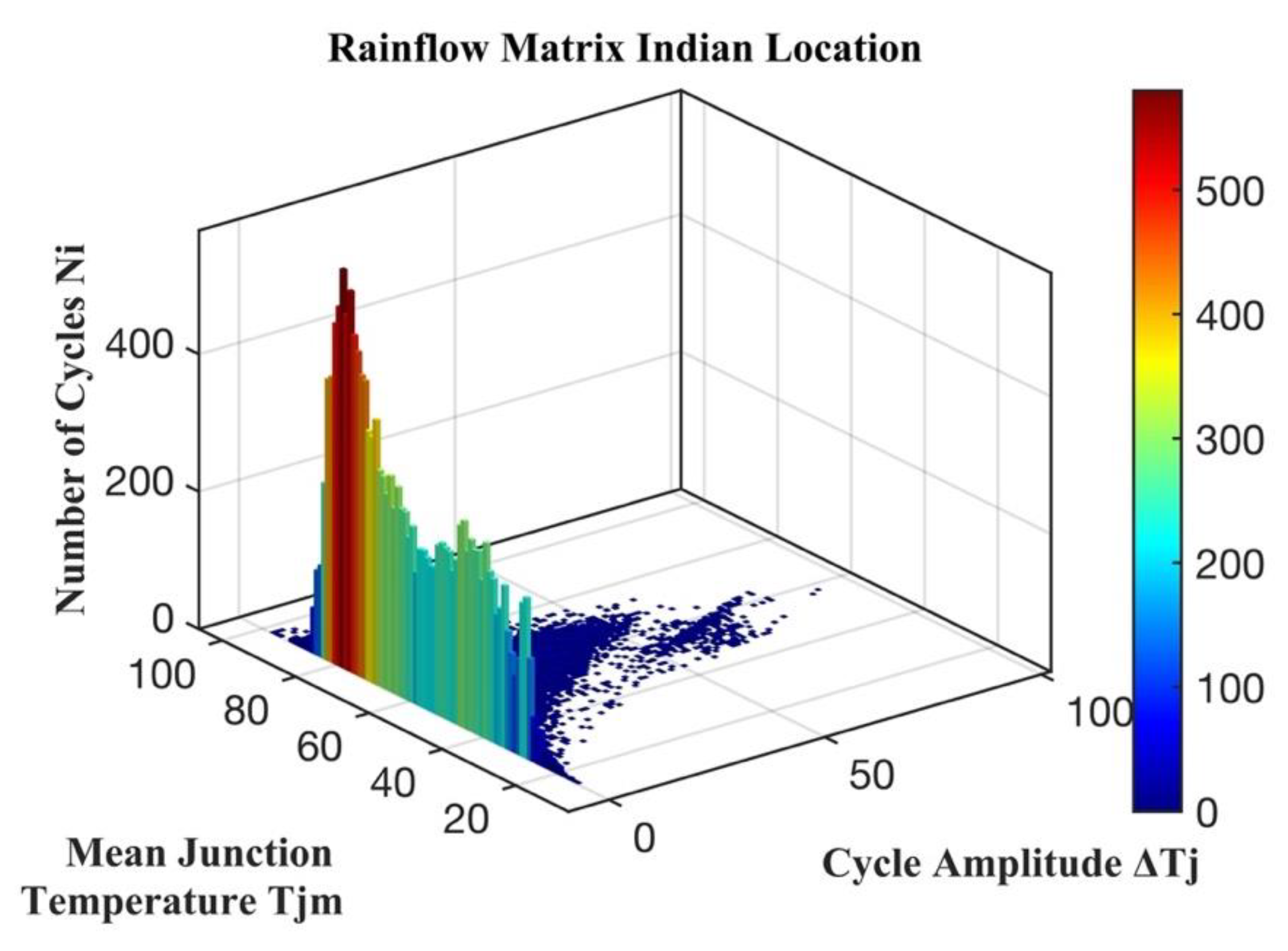

3.4.2. Rainflow Counting Analysis

3.5. Lifetime Evaluation

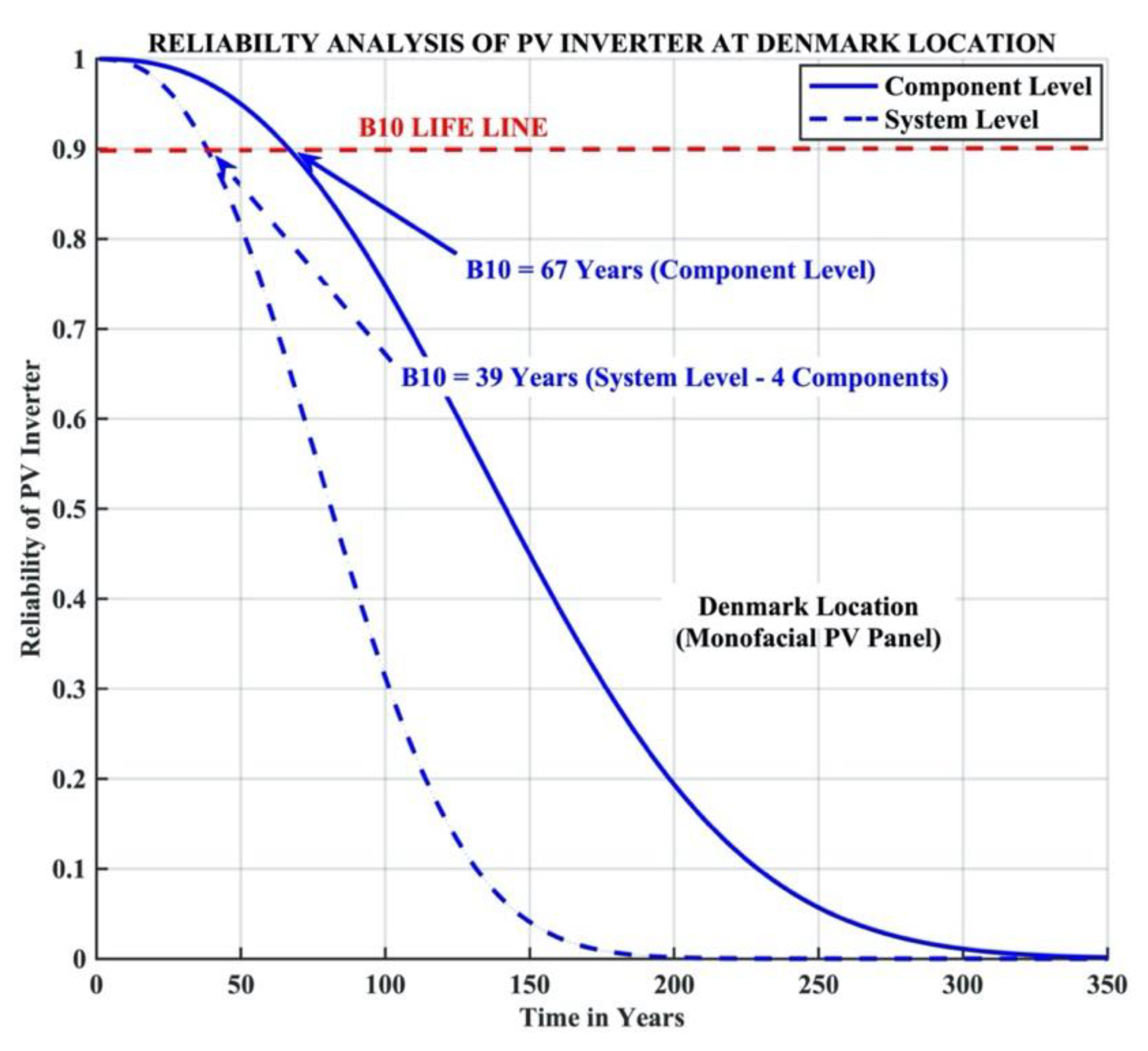

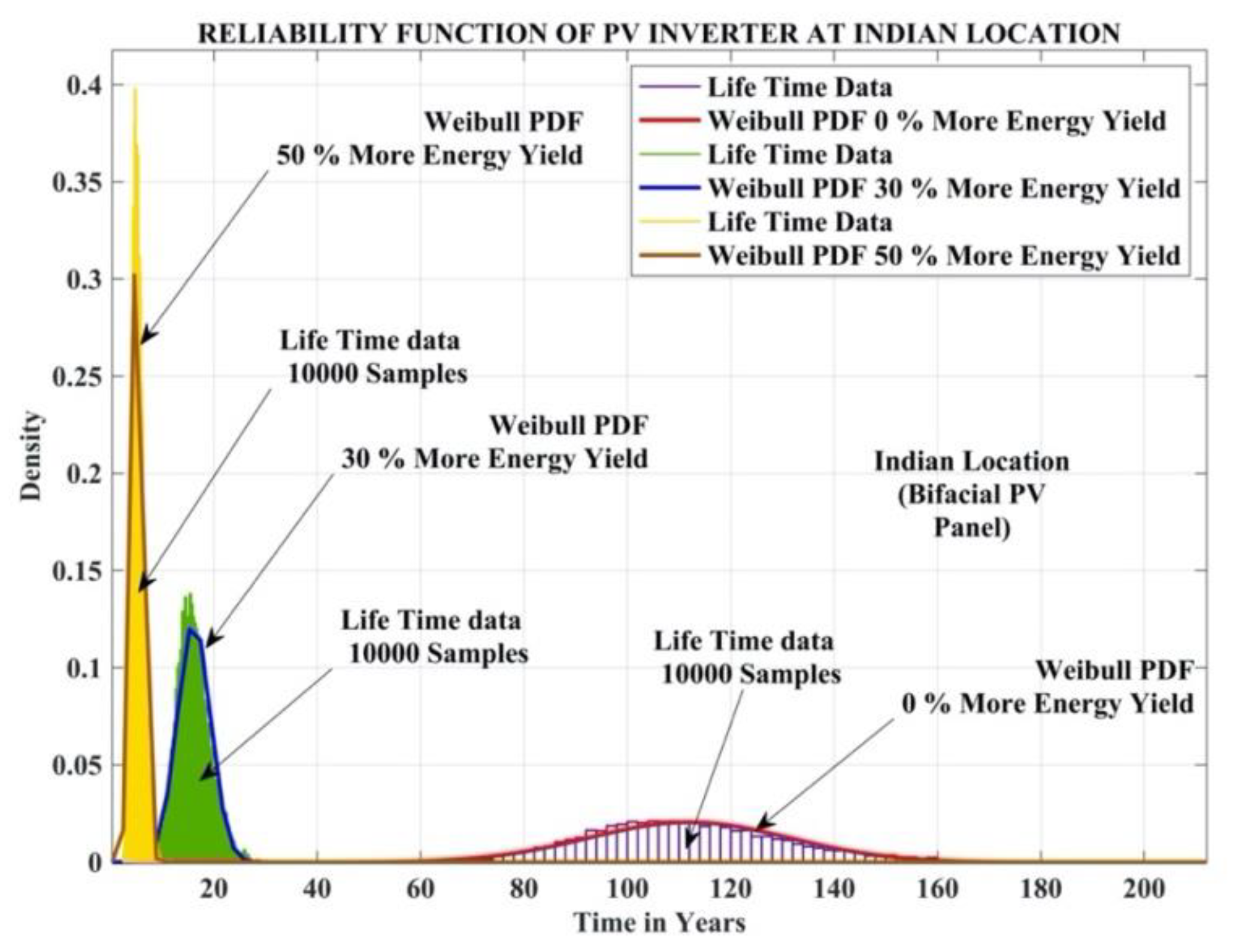

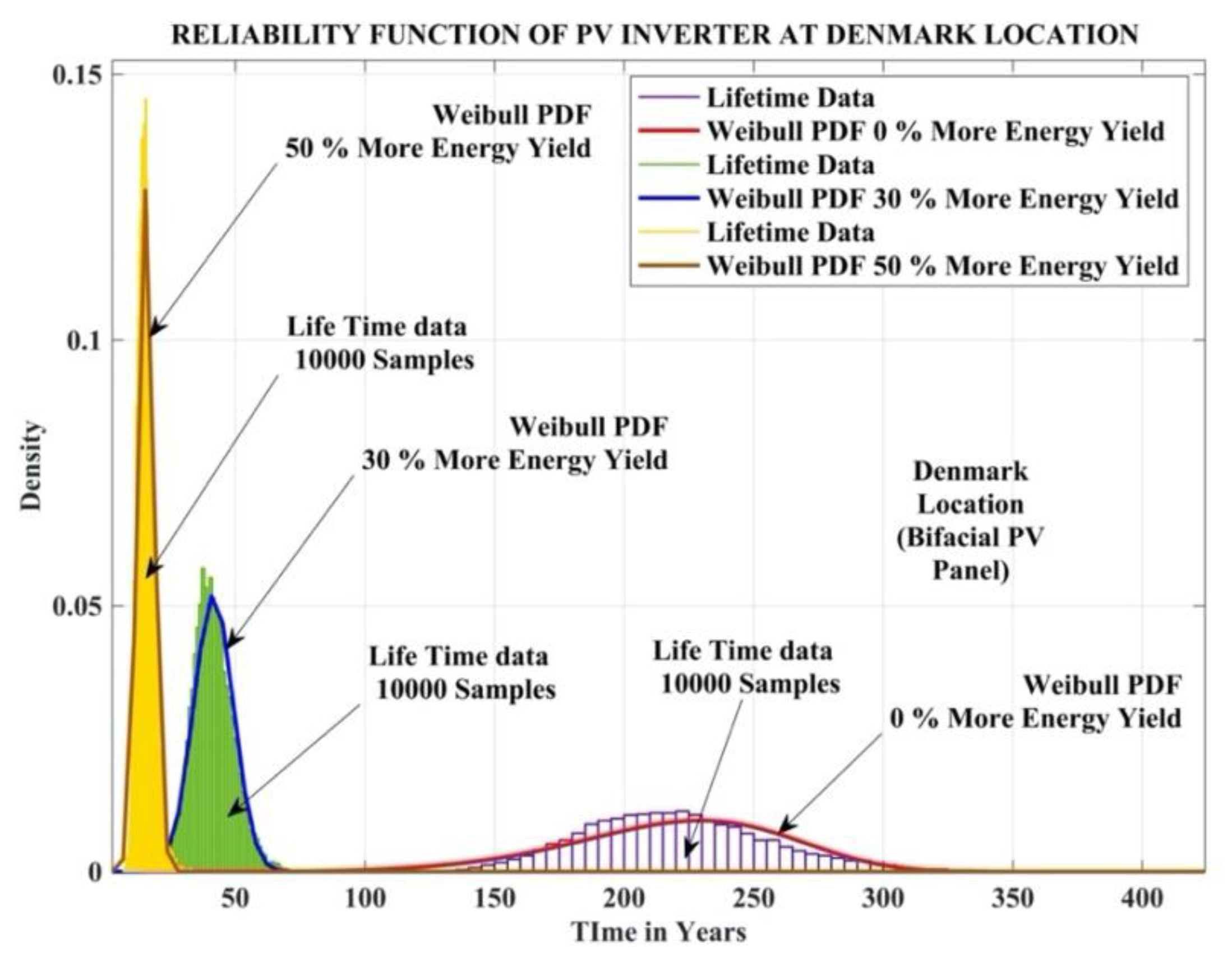

3.6. Reliability Analysis Using Monte Carlo Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- ETEnergyWorld. Solar Power Cost Will Fall to Rs 1.9 Per Unit in India by 2030: TERI Study; India TImes: New Delhi, India, 2019. [Google Scholar]

- Woodhouse, M.; Jones-Albertus, R.; Feldman, D.; Fu, R.; Horowitz, K.; Chung, D.; Jordan, D.; Kurtz, S. On the Path to SunShot: The Role of Advancements in Solar Photovoltaic Efficiency, Reliability, and Costs; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Mackenzie, W. Global Bifacial Module Market Report 2019; Wood Mackenzie: Edinburgh, UK, 2019. [Google Scholar]

- Global Modelling and Assimilation Offfice. MERRA-2 Re-Analysis; Global Modelling and Assimilation Offfice: Washington, DC, USA, 2018. [Google Scholar]

- Yang, S.; Bryant, A.; Mawby, P.; Xiang, D.; Ran, L.; Tavner, P. An industry-based survey of reliability in power electronic converters. IEEE Trans. Ind. Appl. 2011, 47, 1441–1451. [Google Scholar] [CrossRef]

- Wang, H.; Liserre, M.; Blaabjerg, F.; de Place Rimmen, P.; Jacobsen, J.B.; Kvisgaard, T.; Landkildehus, J. Transitioning to physics-of-failure as a reliability driver in power electronics. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 97–114. [Google Scholar] [CrossRef]

- Upadhyayula, K.; Dasgupta, A. Guidelines for physics-of-failure based accelerated stress testing. Proc. Annu. Reliab. Maintainab. Symp. 1998, 1, 345–357. [Google Scholar] [CrossRef]

- Reichelt, J.; Gromala, P.; Rzepka, S. Accelerating the temperature cycling tests of FBGA memory components with lead-free solder joints without changing the damage mechanism. In Proceedings of the 2009 European Microelectronics and Packaging Conference, EMPC 2009, Rimini, Italy, 15–18 June 2009. [Google Scholar]

- Norris, K.C.; Landzberg, A.H. Reliability of Controlled Collapse Interconnections. IBM J. Res. Dev. 2010, 13, 266–271. [Google Scholar] [CrossRef]

- Infineon Technologies. Transient Thermal Measurements and Thermal Equivalent Circuit Models; Appllication Note AN 2015-10; Infineon Technologies: Neubiberg, Germany, 2018. [Google Scholar]

- Gatla, R.K.; Chen, W.; Zhu, G.; Wang, J.V.; Kshatri, S.S. Lifetime comparison of IGBT modules in Grid-connected Multilevel PV inverters Considering Mission Profile. In Proceedings of the ICPE 2019—ECCE Asia—10th International Conference on Power Electronics—ECCE Asia, Busan, Korea, 27–30 May 2019. [Google Scholar]

- Bayerer, R.; Herrmann, T.; Licht, T.; Lutz, J.; Feller, M. Model for power cycling lifetime of IGBT Modules? Various factors influencing lifetime. In Proceedings of the 2008 5th International Conference on Integrated Power Systems, CIPS 2008, Nuremberg, Germany, 11–13 March 2008. [Google Scholar]

- Yang, Y.; Sangwongwanich, A.; Blaabjerg, F. Design for reliability of power electronics for grid-connected photovoltaic systems. CPSS Trans. Power Electron. Appl. 2016, 1, 92–103. [Google Scholar] [CrossRef]

- Novak, M.; Sangwongwanich, A.; Blaabjerg, F. Monte Carlo Based Reliability Estimation Methods in Power Electronics. In Proceedings of the 2020 IEEE 21st Workshop on Control and Modeling for Power Electronics (COMPEL), Aalborg, Denmark, 9–12 November 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Sangwongwanich, A.; Yang, Y.; Sera, D.; Blaabjerg, F. Lifetime Evaluation of Grid-Connected PV Inverters Considering Panel Degradation Rates and Installation Sites. IEEE Trans. Power Electron. 2018, 33, 1225–1236. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Parameter A | 9.3400 × 1014 |

| Parameter β1 | −4.41600 |

| Parameter β2 | 1285.00 |

| Parameter β3 | −0.46300 |

| Parameter β4 | −0.71600 |

| Parameter β5 | −0.76100 |

| Parameter β6 | −0.500 |

| Parameter I | 3.0–23.00 A |

| Parameter V | 6.00–33.00 V |

| Parameter D | 75.0–500.0 µm |

| Parameter | Specification |

|---|---|

| Rated Power of Inverter | 3-kW |

| Supply Grid Voltage | 230 V |

| Supply Grid Frequency | 50 Hz |

| Capacitance of DC Link | 1.5 × 10−3 F |

| Country | Mean Junction Temperature (Tjm) | Cycle Amplitude (ΔTj) | Life Consumption (LC) | Lifetime in Years (LF) |

|---|---|---|---|---|

| India | 59.77 °C | 5.95 °C | 0.00908588 | 110.06 |

| Denmark | 19.23 °C | 4.69 °C | 0.00460278 | 217.26 |

| Country | Component Level B10 Lifetime (Years) | System Level B10 Lifetime: 4 Components (Years) |

|---|---|---|

| India | 35 | 20 |

| Denmark | 67 | 39 |

| Country | Bifacial PV Panel % Additional Energy Yield | Mean Junction Temperature (Tjm) | Cycle Amplitude (ΔTj) | Life Consumption (LC) | Lifetime in Years (LF) |

|---|---|---|---|---|---|

| India | 0% | 59.77 °C | 5.95 °C | 0.00908588 | 110.06 |

| 30% | 8.95 | 72.84 | 0.06309605 | 15.85 | |

| 50% | 11.30 | 82.85 | 0.19576864 | 5.11 | |

| Denmark | 0% | 19.23 °C | 4.69 °C | 0.00460278 | 217.26 |

| 30% | 6.77 | 21.98 | 0.02440063 | 40.98 | |

| 50% | 8.42 | 24.14 | 0.06577629 | 15.20 |

| Country | Bifacial PV Panel % Additional Energy Yield | Component Level B10 Lifetime (Years) | System Level B10 Lifetime: 4 Components (Years) |

|---|---|---|---|

| India | 0% | 35 | 20 |

| 30% | 5 | 3 | |

| 50% | 1.5 | 0.8 | |

| Denmark | 0% | 67 | 39 |

| 30% | 13 | 8 | |

| 50% | 5 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kshatri, S.S.; Dhillon, J.; Mishra, S.; Tariq, R.; Sharma, N.K.; Bajaj, M.; Rehman, A.U.; Shafiq, M.; Choi, J.-G. Reliability Analysis of Bifacial PV Panel-Based Inverters Considering the Effect of Geographical Location. Energies 2022, 15, 170. https://doi.org/10.3390/en15010170

Kshatri SS, Dhillon J, Mishra S, Tariq R, Sharma NK, Bajaj M, Rehman AU, Shafiq M, Choi J-G. Reliability Analysis of Bifacial PV Panel-Based Inverters Considering the Effect of Geographical Location. Energies. 2022; 15(1):170. https://doi.org/10.3390/en15010170

Chicago/Turabian StyleKshatri, Sainadh Singh, Javed Dhillon, Sachin Mishra, Rizwan Tariq, Naveen Kumar Sharma, Mohit Bajaj, Ateeq Ur Rehman, Muhammad Shafiq, and Jin-Ghoo Choi. 2022. "Reliability Analysis of Bifacial PV Panel-Based Inverters Considering the Effect of Geographical Location" Energies 15, no. 1: 170. https://doi.org/10.3390/en15010170

APA StyleKshatri, S. S., Dhillon, J., Mishra, S., Tariq, R., Sharma, N. K., Bajaj, M., Rehman, A. U., Shafiq, M., & Choi, J.-G. (2022). Reliability Analysis of Bifacial PV Panel-Based Inverters Considering the Effect of Geographical Location. Energies, 15(1), 170. https://doi.org/10.3390/en15010170