Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures

Abstract

:1. Introduction

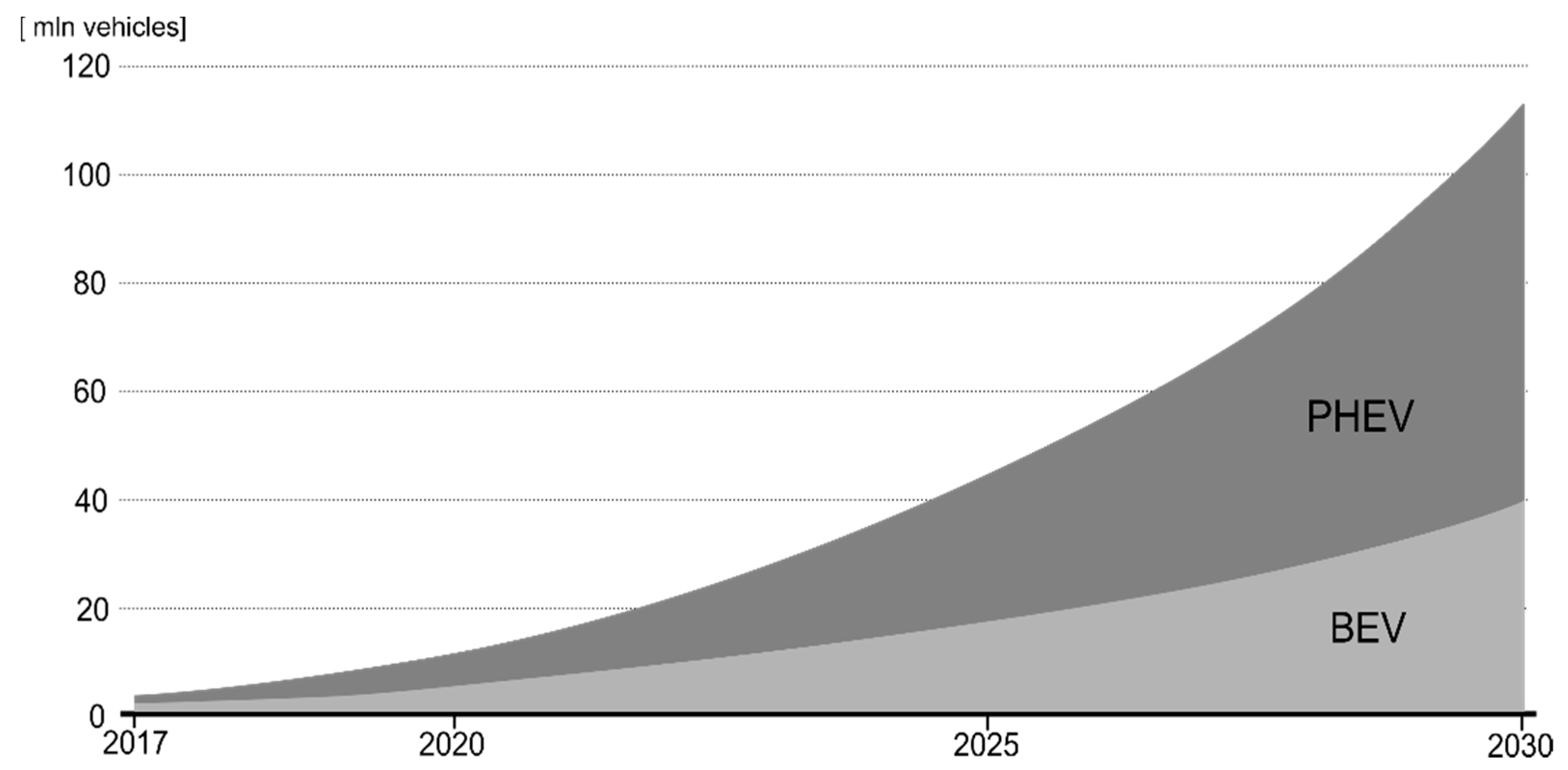

2. Market Situation and Forecast of Electric Vehicles

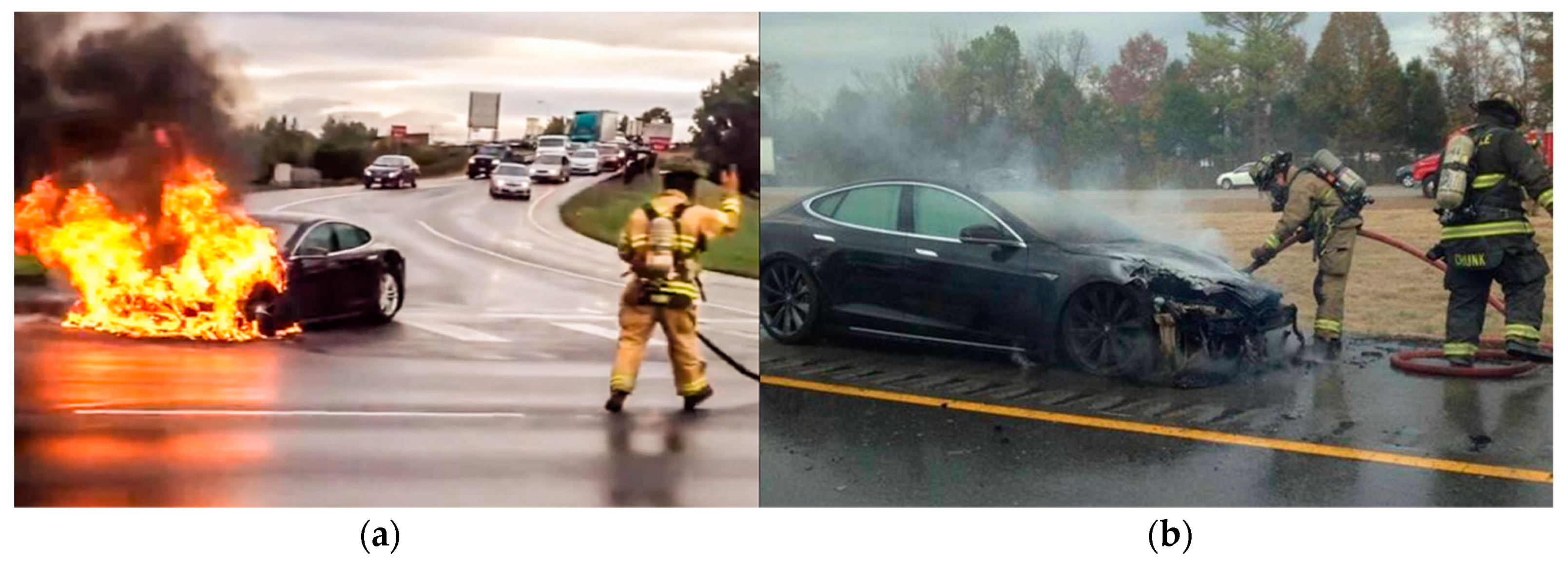

3. Electric Vehicle Fire Incidents

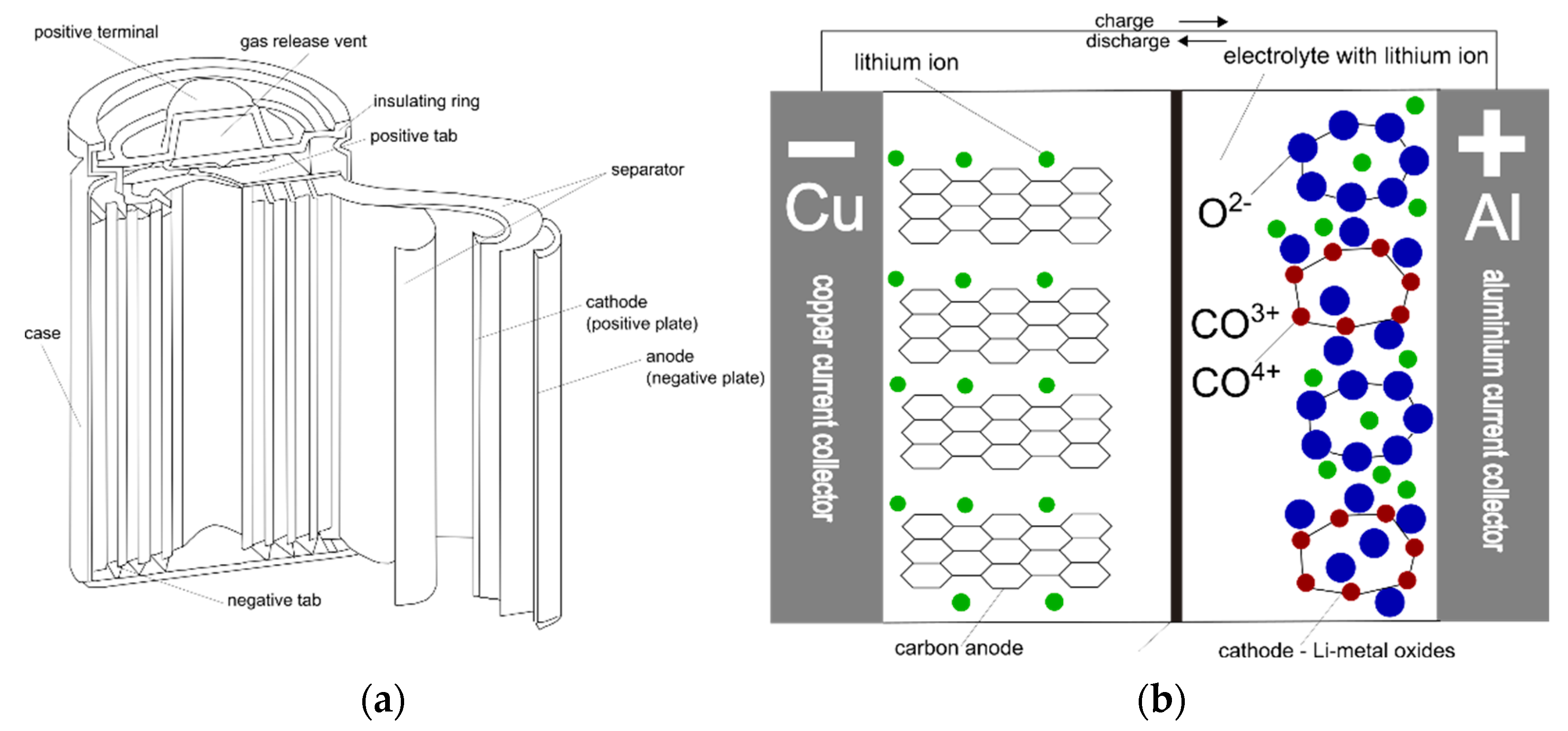

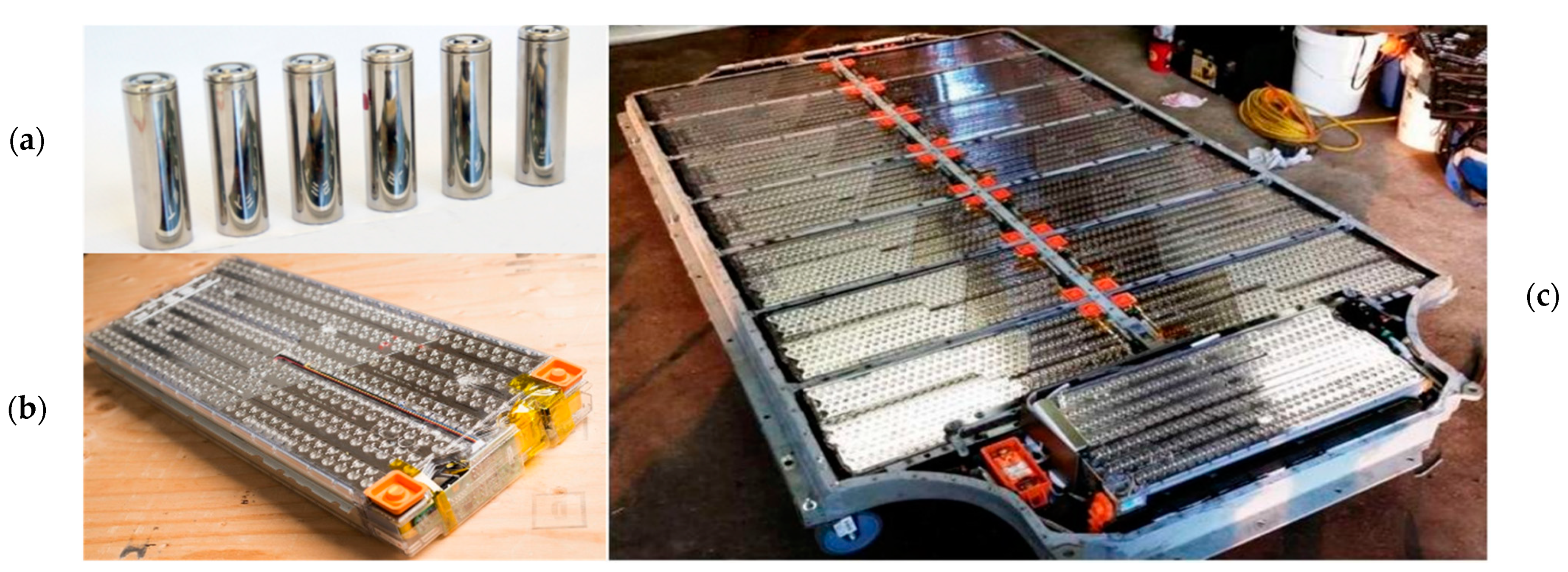

4. Lithium Ion Batteries

4.1. Basics, Principle of Work

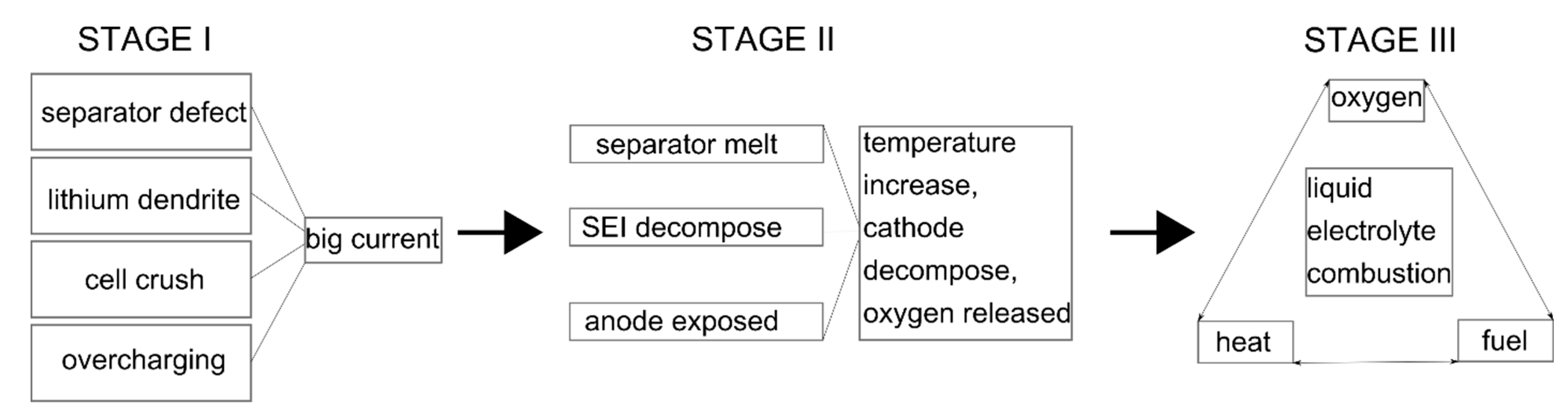

4.2. Safety of Operation and Fire Risk

- Thermal abuse: Li-ion cells demonstrate their best performance at temperatures between 20 and 30 °C [51]. With the global expansion of passenger electric cars equipped with Li-ion cells, it is not possible to guarantee operation in this temperature range without appropriate systems to help maintain proper operating temperatures. In the states of California or Arizona, air temperatures above 40 °C are not uncommon during the summer months, while in the northern parts of Norway or Sweden, temperatures below −10 °C prevail during the winter [74]. Sustained high temperatures can lead to undesirable chemical reactions whereby the battery can overheat [70,75]. Then, if the heat is not properly dissipated, the phenomenon of “thermal runaway” can occur, an uncontrolled temperature rise leading to cell ignition [70]. If the temperature acting on the cell is too low, the internal resistance increases significantly, which can contribute to an additional thermal effect that increases the likelihood of fire [70,76].

- Electrical overloading: mass-produced electric cars equipped with Li-ion cells are required to be rechargeable as quickly as possible and to have a high level of driving dynamics, all of which negatively affect the safe operation of the vehicle and increase the probability of spontaneous combustion of the cell as a result of too intensive charging or discharging of the cell. In such cases, the Joule effect generating additional heat and unwanted chemical reactions can occur which can lead to an internal short circuit. [77,78]. It is often pointed out that EV fires can be caused by improper servicing, improper manufacturing procedures or inadequate electronic safety and cell condition monitoring systems [79].

- Mechanical damage: another group of risks associated with the operation of LI-ion cells is damage caused by mechanical actions on the battery. The cells themselves, without special protection, are susceptible to mechanical damage, which is why special covers have been used in electric BEVs since the beginning of production to protect the cells against the effects of collisions. Most data show that minor collisions are harmless for the cells [80]; however, in the case of accidents involving vehicles moving at excessive speeds, the risk of a Li-ion battery fire significantly increases and seems to be unavoidable in the case of road incidents at very high speeds [81,82,83]. The tendency of individual LIBs to initiate TR mechanically is the subject of specific risk assessment tests, i.e., SAE J2464, SAEJ2929, ISO 12405-1, ISO12405-2, ISO 12405-3, SEC 62660-1, SEC 62660-2, SEC62660-3, UL 2580, KMVSS Article18-3, AIS-048, GB38031 [84].

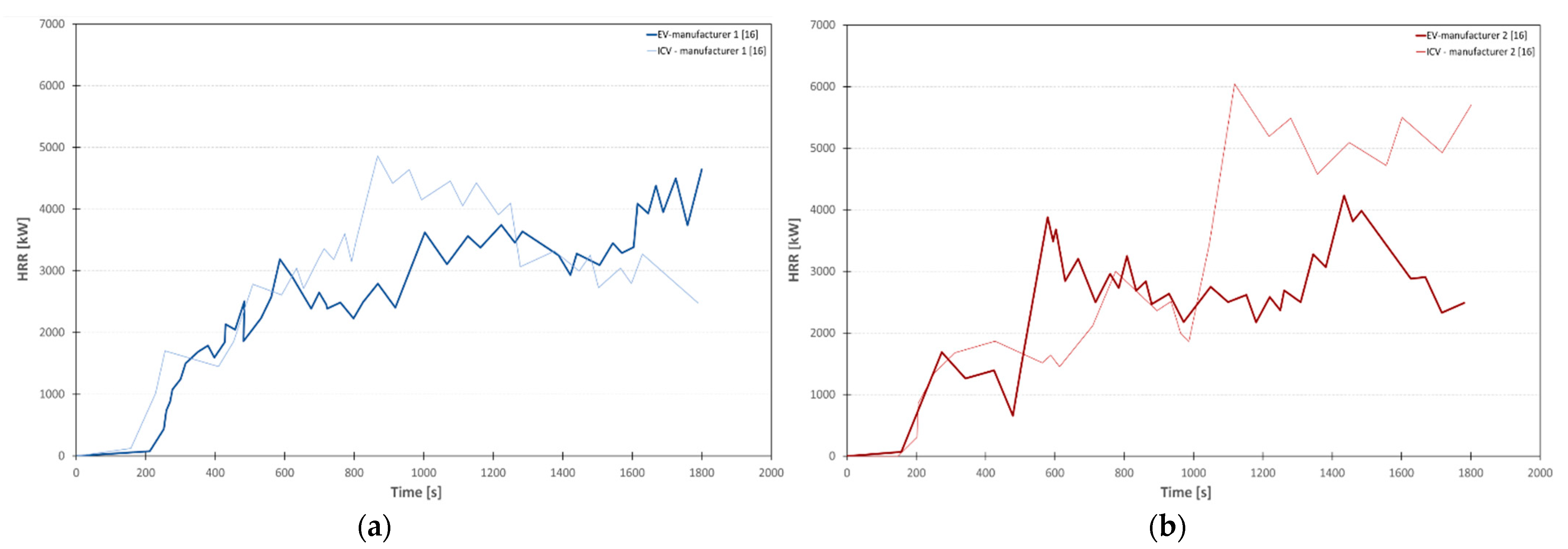

5. Characteristics of Electric Car Heat Release Rate (HRR) Fires

6. Extinguishing an Electric Car Fire

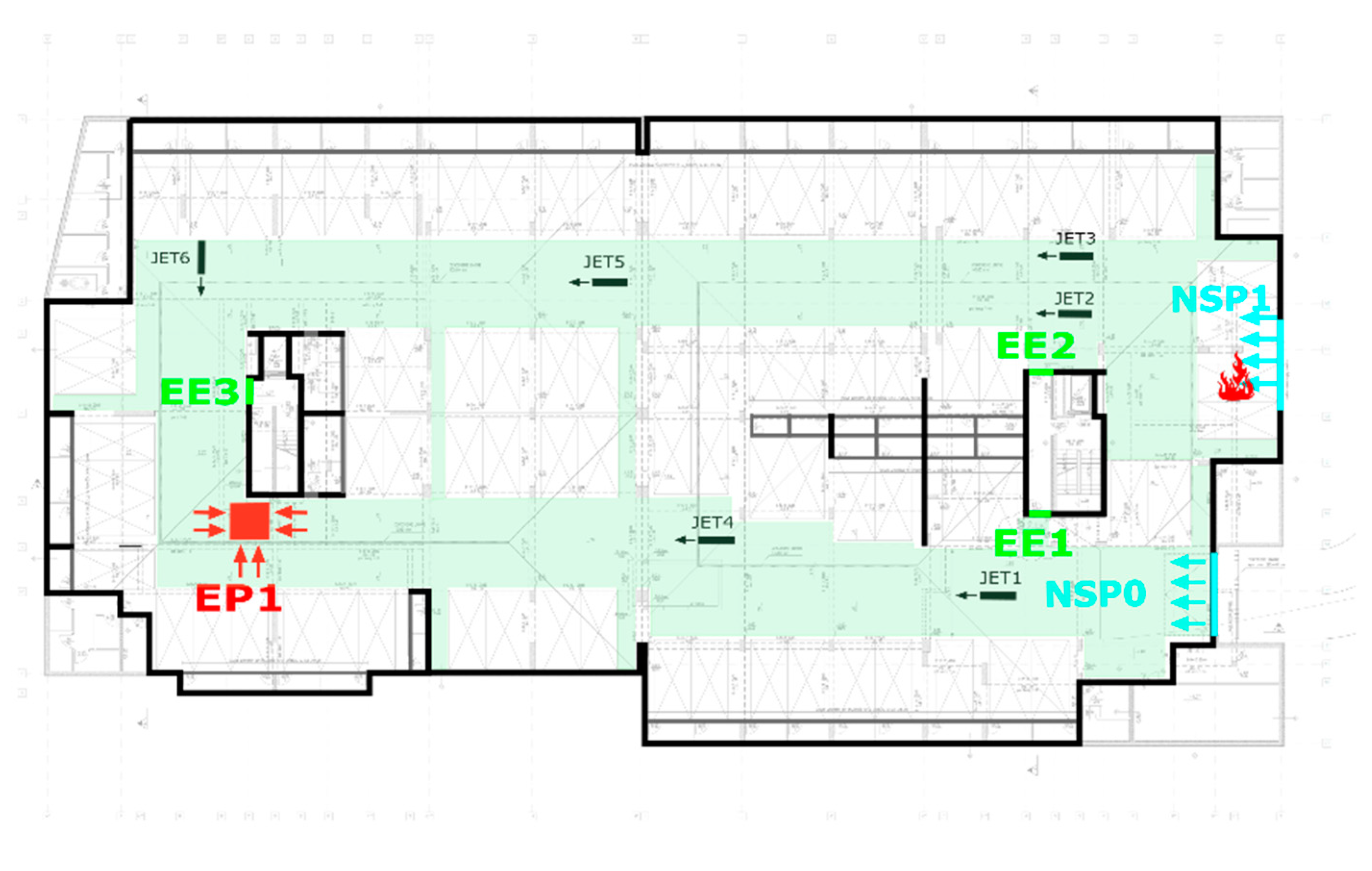

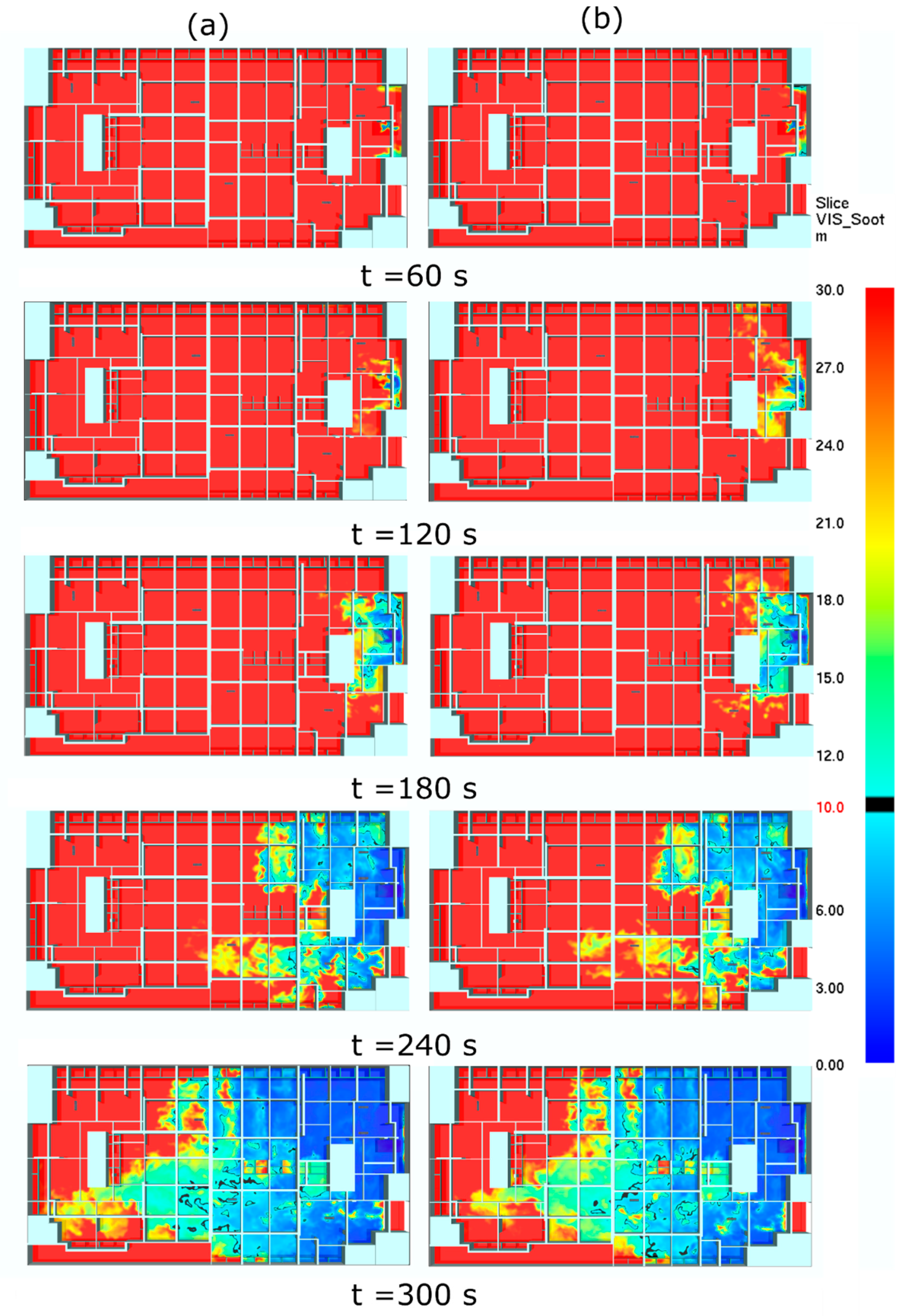

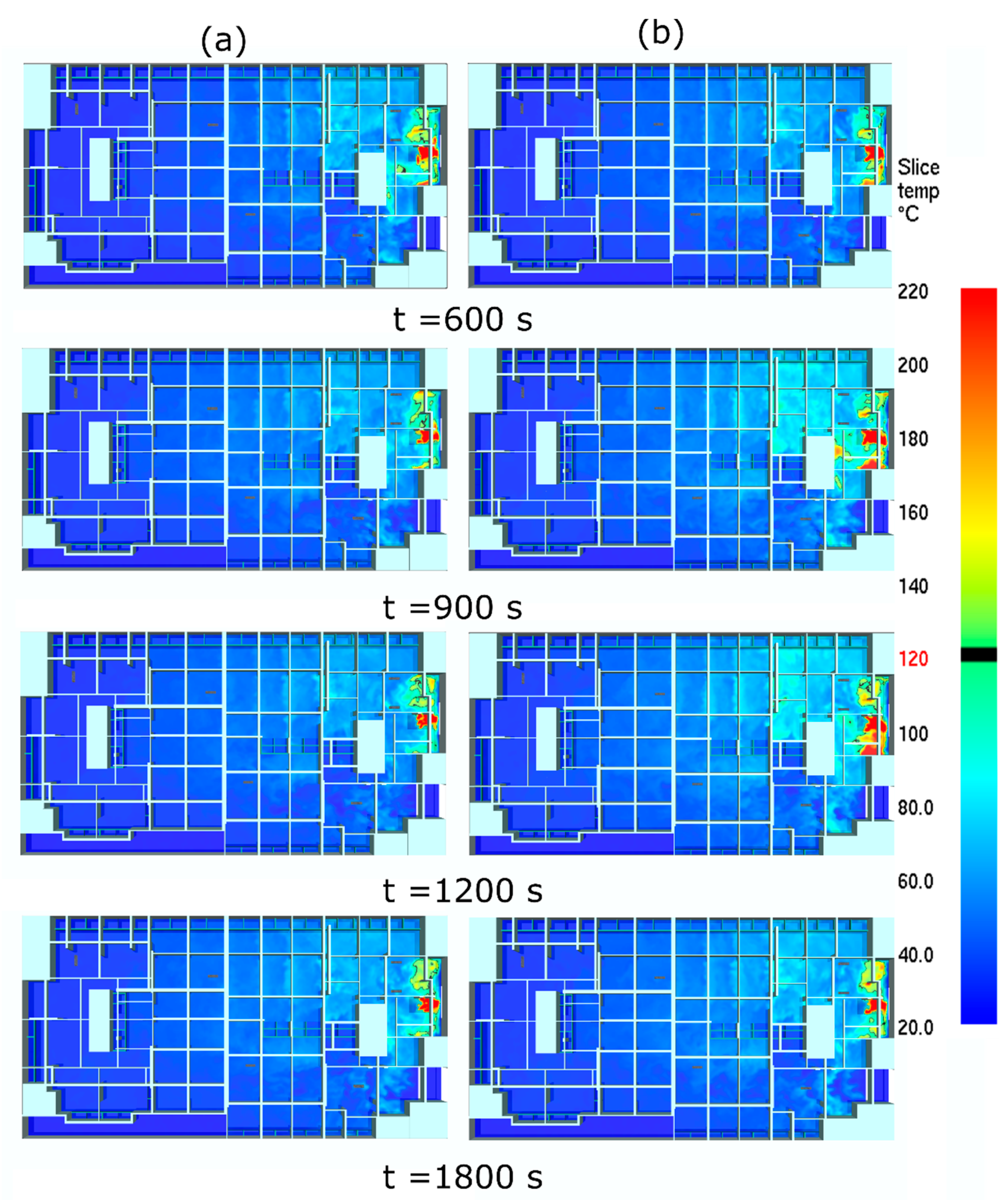

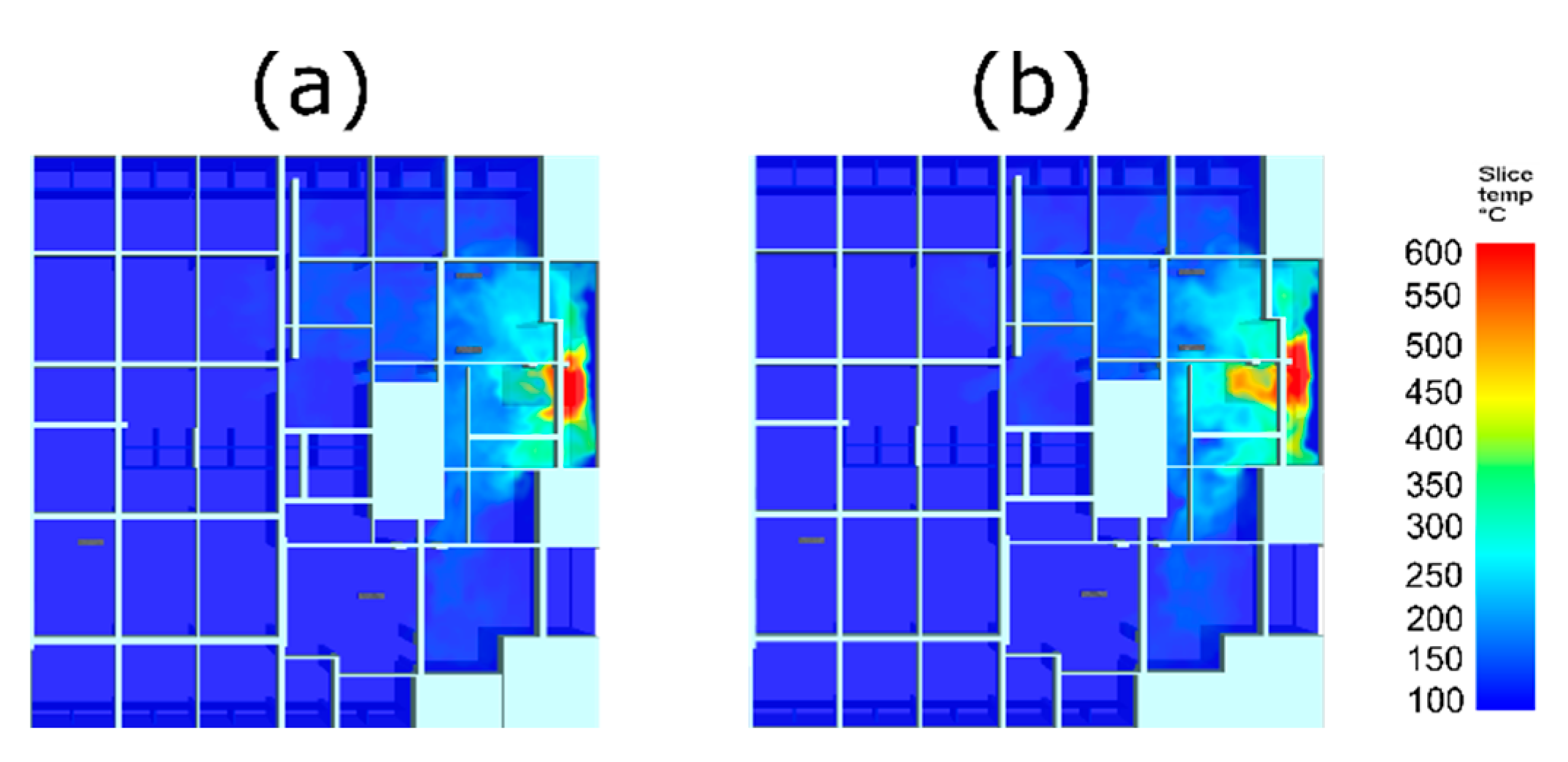

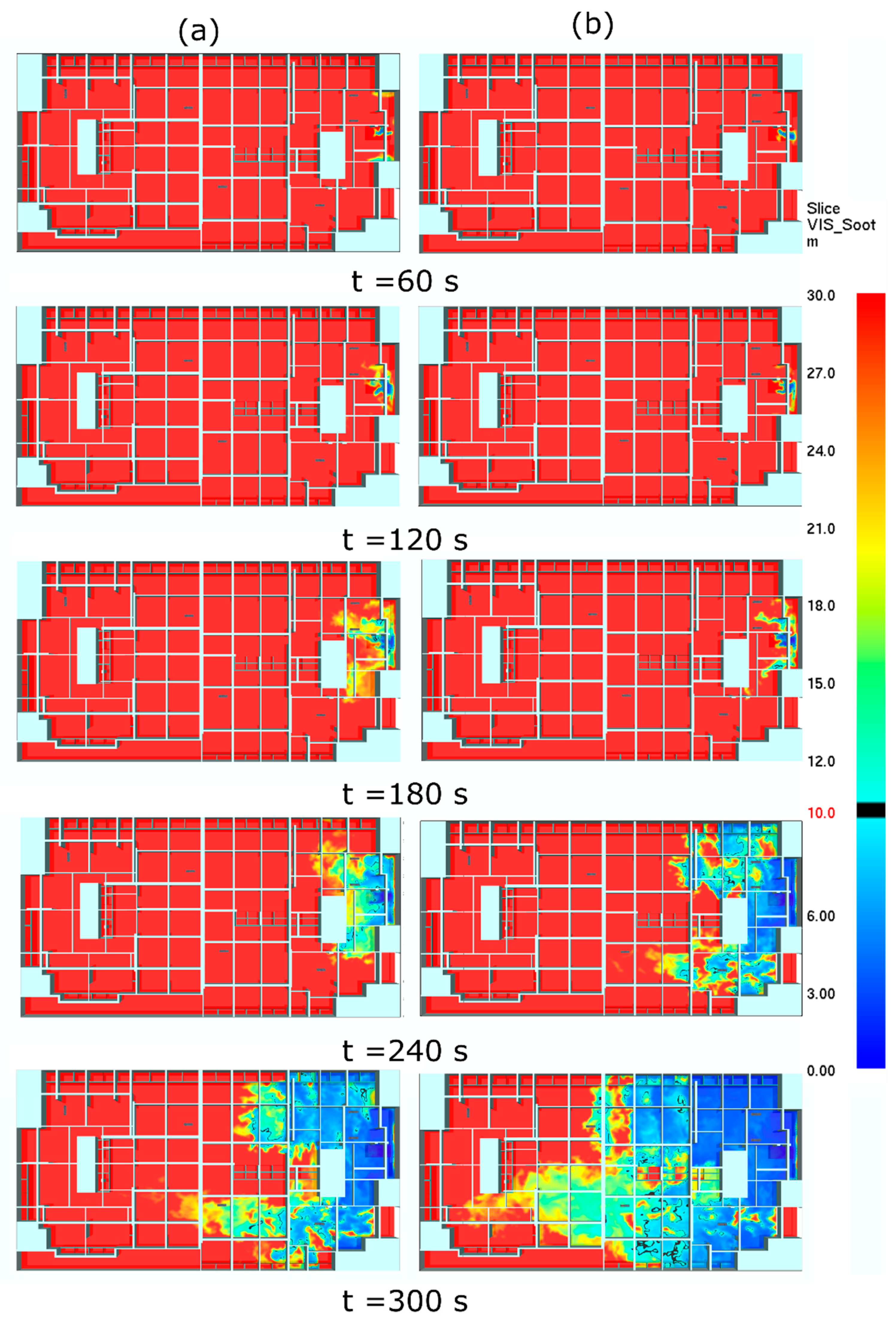

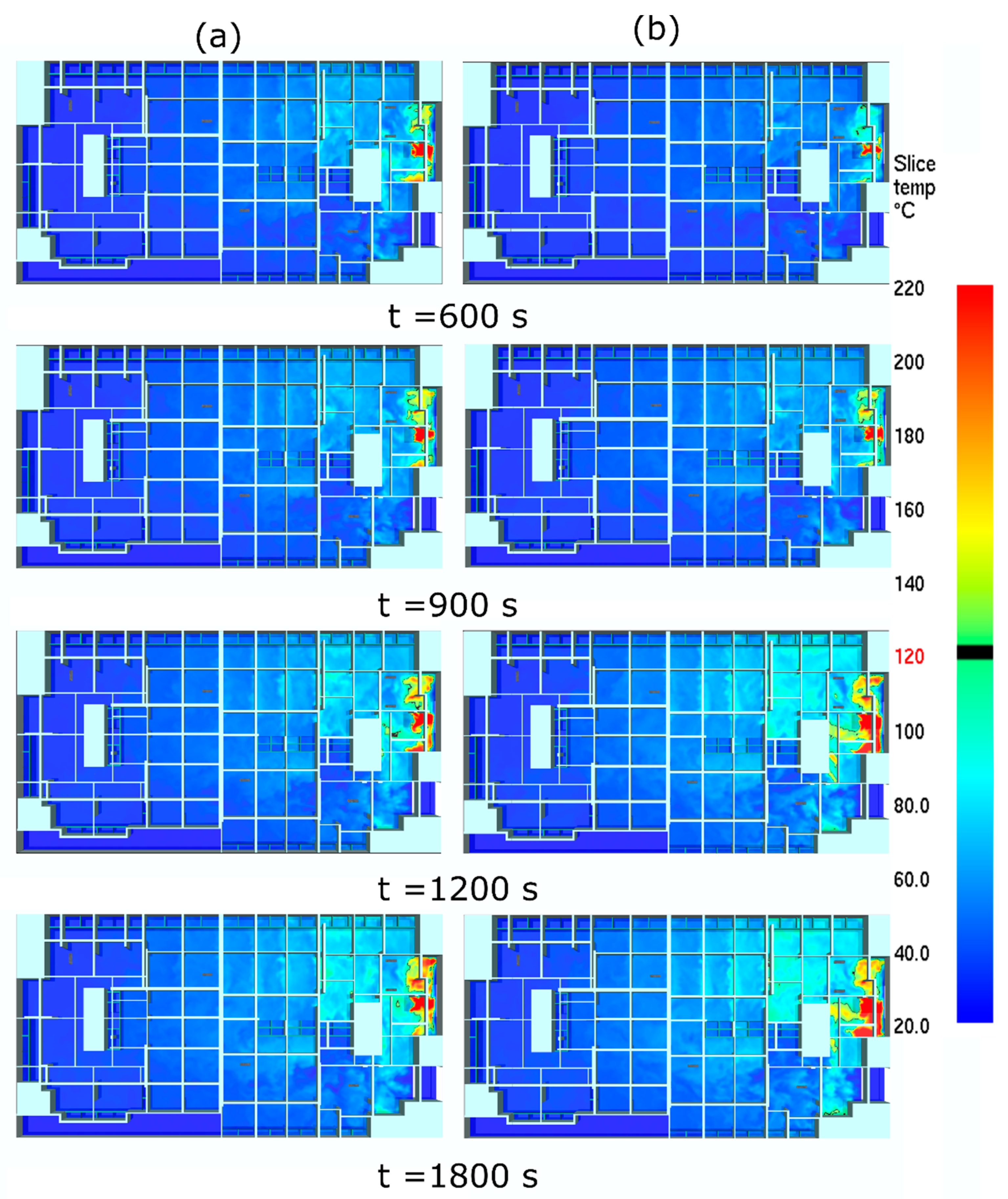

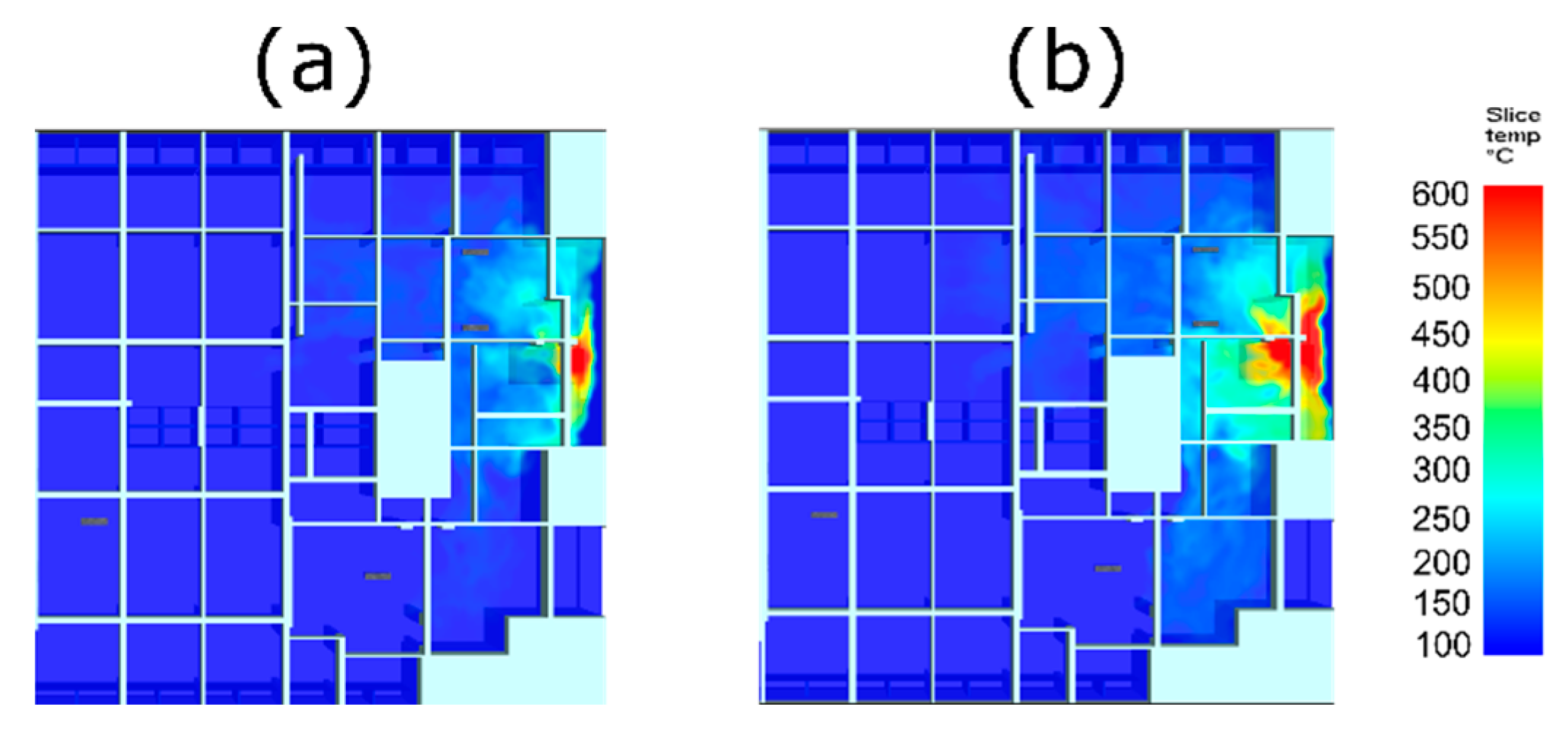

7. Fire Hazard of Electric Cars in Buildings

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Commission Regulation (EU) No 459/2012 of 29 May 2012 amending Regulation (EC) No 715/2007 of the European Parliament and of the Council and Commission Regulation (EC) No 692/2008 as regards emissions from light passenger and commercial vehicles (Euro 6). Off. J. Eur. Union 2012, 48, 258–266.

- Tsakalidis, A.; Thiel, C. Electric Vehicles in Europe from 2010 to 2017: Is Full-Scale Commercialisation Beginning? An Overview of the Evolution of Electric Vehicles in Europe, EUR 29401 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-96719-1. [CrossRef]

- Jiang, X.; Zhu, G.; Zhu, H.; Li, D. Full-scale Experimental Study of Fire Spread Behavior of Cars. Procedia Eng. 2018, 211, 297–305. [Google Scholar] [CrossRef]

- Spearpoint, M.; Mohd, T.M.Z. Distribution analysis of the fire severity characteristics of single passenger road vehicles using heat release rate data. Fire Sci. Rev. 2013, 2, 5. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.; Ryu, J.; Ryou, H.S. Experimental Study on the Fire-Spreading Characteristics and Heat Release Rates of Burning Vehicles Using a Large-Scale Calorimeter. Energies 2019, 12, 1465. [Google Scholar] [CrossRef] [Green Version]

- Okamoto, K.; Watanabe, N.; Hagimoto, Y.; Chigira, T.; Masano, R.; Miura, H.; Ochiai, S.; Satoh, H.; Tamura, Y.; Hayano, K.; et al. Burning behavior of sedan passenger cars. Fire Saf. J. 2009, 44, 301–310. [Google Scholar] [CrossRef]

- Mangs, J.; Keski-Rahkonen, O. Characterization of the fire behaviour of a burning passenger car. Part I: Car fire experiments. Fire Saf. J. 1994, 23, 17–35. [Google Scholar] [CrossRef]

- Spearpoint, M.; Tohir, M.; Zahirasri, M. Simplified approach to predict heat release rate curves from multiple vehicle fires in car parking buildings. Fires Veh. FIVE 2014, 2014, 173. [Google Scholar]

- PIARC. Technical Committee 3.3 Road Tunnel Operation. Design Fire Characteristics for Road Tunnels; World Road Association: Paris, France, 2017. [Google Scholar]

- Angel, T. Study of the fire dynamics in a burning car and analysis of the possibilities for transfer of fire to a nearby vehicle. E3S Web Conf. 2019, 112, 01015. [Google Scholar] [CrossRef]

- Li, D.; Zhu, G.; Zhu, H.; Yu, Z.; Gao, Y.; Jiang, X. Flame spread and smoke temperature of full-scale fire test of car fire. Case Stud. Therm. Eng. 2017, 10, 315–324. [Google Scholar] [CrossRef]

- Merci, B.; Shipp, M. Smoke and heat control for fires in large car parks: Lessons learnt from research? Fire Saf. J. 2013, 57, 3–10. [Google Scholar] [CrossRef] [Green Version]

- Deckers, X.; Haga, S.; Tilley, N.; Merci, B. Smoke control in case of fire in a large car park: CFD simulations of full-scale configurations. Fire Saf. J. 2013, 57, 22–34. [Google Scholar] [CrossRef] [Green Version]

- Zanzi, C.; Gómez, P.; López, J.; Hernández, J. Analysis of Heat and Smoke Propagation and Oscillatory Flow through Ceiling Vents in a Large-Scale Compartment Fire. Appl. Sci. 2019, 9, 3305. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.; Lee, Y.; Na, J.; Ryou, H.S. Numerical Study on the Effect of Tunnel Aspect Ratio on Evacuation with Unsteady Heat Release Rate Due to Fire in the Case of Two Vehicles. Energies 2019, 12, 133. [Google Scholar] [CrossRef] [Green Version]

- Lecocq, A.; Bertana, M.; Truchot, B.; Marlair, G. Comparison of the fire consequences of an electric vehicle and an internal combustion engine vehicle. In Proceedings of the International Conference on Fires in Vehicles—FIVE 2012, Chicago, IL, USA, 27–28 September 2012; pp. 183–194. [Google Scholar]

- Lecocq, A.; Bertana, M.; Truchot, B.; Marlair, G. Comparison of fire behaviours of an electric-battery-powered behicle and gasoline-powered vehicle in a real-scale fire test. In Proceedings of the Second International Conference on Fires in Vehicles, Chicago, IL, USA, 27–28 September 2012. [Google Scholar]

- Lam, C.; MacNeil, D.; Kroeker, R.; Lougheed, G.; Lalime, G. Full-scale fire testing of electric and internal combustion engine vehicles. In Proceedings of the Fourth International Conference on Fire in Vehicle, Baltimore, MD, USA, 5–6 October 2016. [Google Scholar]

- Lougheed, G.; Lam, C.; Carbonneau, G.; Kroeker, R.; Edwards, D.; Tompkins, J.; Lalime, G. Electric vehicle fire testing. In Proceedings of the 8th EVS-GTR Meeting, Washington, DC, USA, 1–5 June 2015. [Google Scholar]

- Mercedes EQS 450+. Available online: https://ev-database.org/car/1483/Mercedes-EQS-450plus (accessed on 9 September 2021).

- Tesla Model S Long Range. Available online: https://ev-database.org/car/1404/Tesla-Model-S-Long-Range (accessed on 9 September 2021).

- Porsche Taycan Plus. Available online: https://ev-database.org/car/1394/Porsche-Taycan-Plus (accessed on 9 September 2021).

- Iclodean, C.; Varga, B.; Burnete, N.; Cimerdean, D.; Jurchiș, B. Comparison of Different Battery Types for Electric Vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012058. [Google Scholar] [CrossRef] [Green Version]

- Larminie, J.; Lowry, J. Electric Vehicle Technology Explained; John Wiley & Sons Ltd.: Chichester, UK, 2003; pp. 183–187. [Google Scholar]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Source 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Kong, L.; Li, C.; Jiang, J.; Pecht, M.G. Li-Ion Battery Fire Hazards and Safety Strategies. Energies 2018, 11, 2191. [Google Scholar] [CrossRef] [Green Version]

- Feng, X.; Zheng, S.; He, X.; Wang, L.; Wang, Y.; Ren, D.; Ouyang, M. Time Sequence Map for Interpreting the Thermal Runaway Mechanism of Lithium-Ion Batteries with LiNixCoyMnzO2 Cathode. Front. Energy Res. 2018, 6, 126. [Google Scholar] [CrossRef] [Green Version]

- Hou, J.; Lu, L.; Wang, L.; Ohma, A.; Ren, D.; Feng, X.; Li, Y.; Li, Y.; Ootani, I.; Han, X.; et al. Thermal runaway of Lithium-ion batteries employing LiN(SO2F)2-based concentrated electrolytes. Nat. Commun. 2020, 11, 5100. [Google Scholar] [CrossRef]

- Golubkov, A.W.; Planteu, R.; Krohn, P.; Rasch, B.; Brunnsteiner, B.; Thaler, A.; Hacker, V. Thermal runaway of large automotive Li-ion batteries. RSC Adv. 2018, 8, 40172. [Google Scholar] [CrossRef] [Green Version]

- Bisschop, R.; Willstrand, O.; Rosengren, M. Handling Lithium-Ion Batteries in Electric Vehicles: Preventing and Recovering from Hazardous Events. Fire Technol. 2020, 56, 2671–2694. [Google Scholar] [CrossRef]

- Essl1, A.; Golubkov, W.; Fuchs, A. Comparing Different Thermal Runaway Triggers for Two Automotive Lithium-Ion Battery Cell Types C. J. Electrochem. Soc. 2020, 167, 130542. [Google Scholar] [CrossRef]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Essl, C.; Golubkov, A.W.; Gasser, E.; Nachtnebel, M.; Zankel, A.; Ewert, E.; Fuchs, A. Comprehensive Hazard Analysis of Failing Automotive Lithium-Ion Batteries in Overtemperature Experiments. Batteries 2020, 6, 30. [Google Scholar] [CrossRef]

- Larsson, F. Assessment of Safety Characteristics for Li-Ion Battery Cells by Abuse Testing; Chalmers University of Technology: Göteborg, Sweden, 2014. [Google Scholar]

- Wang, Z.; Ouyang, D.; Chen, M.; Wang, X.; Zhang, Z.; Wang, J. Fire behavior of lithium-ion battery with different states of charge induced by high incident heat fluxes. J. Therm. Anal. Calorim. 2018, 136, 2239–2247. [Google Scholar] [CrossRef]

- Ren, D.; Hsu, H.; Li, R.; Feng, X.; Guo, D.; Han, X.; Lu, L.; He, X.; Gao, S.; Hou, J.; et al. A comparative investigation of aging effects on thermal runaway behavior of lithium-ion batteries. eTransportation 2019, 2, 100034. [Google Scholar] [CrossRef]

- Feng, X.; Zheng, S.; Ren, D.; He, X.; Wang, L.; Liu, X.; Li, M.; Ouyang, M. Key Characteristics for Thermal Runaway of Li-ion Batteries. Energy Procedia 2019, 158, 4684–4689. [Google Scholar] [CrossRef]

- Guo, L.S.; Wang, Z.R.; Wang, J.H.; Luo, Q.K.; Liu, J.J. Effects of the environmental temperature and heat dissipation condition on the thermal runaway of lithium ion batteries during the charge-discharge process. J. Loss Prev. Process. Ind. 2017, 49, 953–960. [Google Scholar] [CrossRef]

- Truchot, B.; Fouillen, F.; Collet, S. An experimental evaluation of toxic gas emissions from vehicle fires. Fire Saf. J. 2018, 97, 111–118. [Google Scholar] [CrossRef]

- IIEA. Global EV Outlook 2021; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/global-ev-outlook-2021 (accessed on 21 September 2021).

- Tesla Says Car Fire Started in Battery. Available online: https://wheels.blogs.nytimes.com/2013/10/02/highway-fire-of-tesla-model-s-included-its-lithium-battery/ (accessed on 21 May 2020).

- UPDATE 5-Tesla Reports Third Fire Involving Model S Electric Car. Available online: https://www.reuters.com/article/autos-tesla-fire-idUSL2N0IS0TL20131107 (accessed on 21 May 2020).

- Latest Tesla Fire Caused by Running over a Metal Object. Available online: https://money.cnn.com/2013/11/08/autos/tesla-fire-details/index.html (accessed on 21 May 2020).

- Tesla’s Third Model S Fire Brings Call for U.S. Inquiry. Available online: https://www.bloomberg.com/news/articles/2013-11-07/tesla-s-third-model-s-fire-brings-call-for-u-s-inquiry (accessed on 21 May 2020).

- Exclusive: Tesla Model S Charging System May Have Started Garage Fire—California Fire Dept. Available online: https://www.reuters.com/article/us-autos-tesla-fire/exclusive-tesla-model-s-charging-system-may-have-started-garage-fire-california-fire-dept-idUSBRE9BH1J020131218 (accessed on 21 May 2020).

- Linette, L. Another Tesla Caught on Fire While Sitting in a Toronto Garage This Month. Business Insider, 16 February 2014. [Google Scholar]

- Nygaard, K. “Tesla Antente under Lading og Brant opp” [A Tesla Caught Fire during Charging and Burned Out]. Aftenposten, 1 January 2016. (In Norwegian) [Google Scholar]

- A Tesla Model S Burst into Flames during a Test Drive in France. Available online: https://businessinsider.com.pl/international/a-tesla-model-s-burst-into-flames-during-a-test-drive-in-france/j4p2dh6 (accessed on 22 May 2020).

- NTSB: Tesla Was Going 116 Mph at Time of Fatal Florida Accident, Battery Pack Reignited Twice Afterwards. Available online: https://www.foxnews.com/auto/ntsb-tesla-was-going-116-mph-at-time-of-fatal-florida-accident-battery-pack-reignited-twice-afterwards (accessed on 25 June 2020).

- Tesla en feu sur l'A2: La batterie serait en cause. Available online: https://www.24heures.ch/suisse/tesla-feu-a2-batterie-cause/story/13942273 (accessed on 25 August 2021).

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- CGTN. Tesla Car Catches Fire in China, Investigation Underway. 2019. Available online: https://news.cgtn.com/news/3d3d514d7a416a4d34457a6333566d54/index.html (accessed on 25 June 2020).

- Scurtu, I.-L.; Szabo, I.; Mariasiu, F.; Moldovanu, D.; Mihali, L.; Jurco, A.-N. Numerical analysis of the influence of mechanical stress on the battery pack’s housing of an electric vehicle. IOP Conf. Ser. Mater. Sci. Eng. 2019, 568, 012054. [Google Scholar] [CrossRef] [Green Version]

- Bangkok Post. Porsche Catches Fire While Charging. 2018. Available online: https://www.bangkokpost.com/thailand/general/1429518/porsche-catches-fire-while-charging (accessed on 26 June 2020).

- National Transportation Safety Board. Preliminary Report: Crash and Post-crash Fire of Electric-powered Passenger Vehicle; National Transportation Safety Board: Denver, CO, USA, 2018.

- NTSB to Investigate Fiery Tesla Crash in Coral Gables That Killed 2. Available online: https://wsvn.com/news/local/miami-dade/ntsb-to-investigate-fiery-tesla-crash-in-coral-gables-that-killed-2/9 (accessed on 9 September 2021).

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Wu, X.; Song, K.; Zhang, X.; Hu Naifang Li, L.; Li, W.; Zhang, L.; Zhang, H. Safety Issues in Lithium Ion Batteries: Materials and Cell Design. Front. Energy Res. 2019, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- Tesla Model S Plaid Caught Fire While Driver Was at the Wheel, Says Fire Chief. Available online: https://www.cnbc.com/2021/07/01/tesla-model-s-plaid-caught-fire-while-being-driven-fire-chief.html (accessed on 24 September 2021).

- GM to Begin Fixing Chevy Bolt EVs, Recalled Due to Fire Risk, as Soon as Next Month. Available online: https://www.cnbc.com/2021/09/20/gm-to-begin-fixing-recalled-chevy-bolt-evs-next-month-due-to-fire-risk.html (accessed on 24 September 2021).

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2012, 226, 272. [Google Scholar] [CrossRef]

- Gerssen-Gondelach, S.J.; Faaij, A.P.C. Performance of batteries for electric vehicles on short and longer term. J. Power Sources 2012, 212, 111. [Google Scholar] [CrossRef]

- MLA Style: The Nobel Prize in Chemistry 2019. NobelPrize.org. Nobel Media AB 2020. Sun. 3 May 2020. Available online: https://www.nobelprize.org/prizes/chemistry/2019/summary/ (accessed on 4 July 2021).

- Blomgren, G.E. The development and future of lithium ion batteries. J. Electrochem. Soc. 2017, 164, A5019. [Google Scholar] [CrossRef] [Green Version]

- Compare Electric Cars: EV Range, Specs, Pricing & More. Available online: https://insideevs.com/reviews/344001/compare-evs/ (accessed on 9 September 2021).

- Joo, S.-H.; Shin, S.; Shin, D.-J.; Wang, J.-P. Development of recycling technology to recover valuable metals from lithium primary and ion batteries. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 212–220. [Google Scholar] [CrossRef]

- Deng, D. Li-ion batteries: Basics, progress, and challenges. Energy Sci. Eng. 2015, 3, 385–418. [Google Scholar] [CrossRef]

- Duan, J.; Tang, X.; Dai, H.; Yang, Y.; Wu, W.; Wei, X.; Huang, Y. Building Safe Lithium-Ion Batteries for Electric Vehicles: A Review. Electrochem. Energ. Rev. 2020, 3, 1–42. [Google Scholar] [CrossRef] [Green Version]

- Verma, K.D.; Banerjee, S.; Kar, K.K. Characteristics of electrolytes. In Handbook of Nanocomposite Supercapacitor Materials I; Kar, K., Ed.; Springer Series in Materials Science; Springer: Cham, Switzerland, 2020; Volume 300. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, B.; Stoliarov, S.I.; Sun, J. A review of lithium ion battery failure mechanisms and fire prevention strategies. Prog. Energy Combust. Sci. 2019, 73, 95–131. [Google Scholar] [CrossRef]

- Zubia, G.; Dufo-Lópeza, R.; Carvalhob, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Cuma, M.U.; Yirik, E.; Dericioğlu, Ç.; Ünal, E.; Onur, B.; Tumay, M. Design considerations of high voltage battery packs for electric buses. Int. J. Adv. Automot. Technol. 2017, 1, 73–79. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Sun, P.; Niu, H.; Huang, X.; Rein, G. Propensity to self-heating ignition of open-circuit pouch lithium-ion battery pile on a hot boundary. Fire Saf. J. 2020, 120, 103081. [Google Scholar] [CrossRef]

- National Climatic Data Center. State Climate Extremes Committee (SCsEC); National Climatic Data Center: Asheville, NC, USA, 2016. [Google Scholar]

- Tobishima, S.I.; Yamaki, J.I. A consideration of lithium cell safety. J. Power Sources 1999, 81–82, 882–886. [Google Scholar] [CrossRef]

- Hao, M.; Li, J.; Park, S.; Moura, S.; Dames, C. Efficient thermal management of Li-ion batteries with a passive interfacial thermal regulator based on a shape memory alloy. Nat. Energy 2018, 3, 899–906. [Google Scholar] [CrossRef]

- Zheng, J.; Engelhard, M.H.; Mei, D.; Jiao, S.; Polzin, B.J.; Zhang, J.; Xu, W. Electrolyte additive enabled fast charging and stable cycling lithium metal batteries. Nat. Energy 2017, 2, 17012. [Google Scholar] [CrossRef]

- Fairley, P. Speed bumps ahead for electric-vehicle charging. IEEE Spectr. 2010, 47, 13–14. [Google Scholar] [CrossRef]

- Larsson, F.; Mellander, B.-E. Lithium-Ion Batteries Used in Electrified Vehicles—General Risk Assessment and Construction Guidelines from a Fire and Gas Release Perspective; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2017. [Google Scholar]

- Justen, R.; Schöneburg, R. Crash safety of hybrid and battery electric vehicles. In Proceedings of the 22nd Enhanced Safety of Vehicles Conference, Washington, DC, USA, 13–16 June 2011. [Google Scholar]

- Liu, K.; Liu, Y.; Lin, D.; Pei, A.; Cui, Y. Materials for lithium-ion battery safety. Sci. Adv. 2018, 4, eaas9820. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Menale, C.; D’Annibale, F.; Mazzarotta, B.; Bubbico, R. Thermal management of lithium-ion batteries: An experimental investigation. Energy 2019, 182, 57–71. [Google Scholar] [CrossRef]

- Chombo, P.V.; Laoonual, Y. A review of safety strategies of a Li-ion battery. J. Power Sources 2020, 478, 228649. [Google Scholar] [CrossRef]

- Victor Chombo, P.; Laoonual, Y.; Wongwises, S. Lessons from the Electric Vehicle Crashworthiness Leading to Battery Fire. Energies 2021, 14, 4802. [Google Scholar] [CrossRef]

- Ghiji, M.; Edmonds, S.; Moinuddin, K. A Review of Experimental and Numerical Studies of Lithium Ion Battery Fires. Appl. Sci. 2021, 11, 1247. [Google Scholar] [CrossRef]

- Said, A.O.; Lee, C.; Stoliarov, S.I.; Marshall, A.W. Comprehensive analysis of dynamics and hazards associated with cascading failure in 18650 lithium ion cell arrays. Appl. Energy 2019, 248, 415–428. [Google Scholar] [CrossRef]

- Vytenis Babrauskas, R.D.P. Heat release rate: The single most important variable in fire hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Y.; Duan, Q.; Wu, T.; Sun, J.; Wang, Q. Fault detection of the connection of lithium-ion power batteries in series for electric vehicles based on statistical analysis. Energy 2018, 164, 745–756. [Google Scholar] [CrossRef]

- BS 7346-7:2013; Components for Smoke and Heat Control Systems—Part 7: Code of Practice on Functional Recommendations and Calculation Methods for Smoke and Heat Control Systems for Covered Car Parks. British Standards Institution: London, UK, 2013.

- NEN 6098:2010; Rookbeheersingssystemen Voor Mechanisch Geventileerde Parkeergarages. Royal Netherlands Standardization Institute: Delft, The Netherlands, 2010.

- Verification Method C/VM2, Framework for Fire Safety Design; New Zealand Building Code Clauses C1–C6 Protection from Fire, A3 Building Importance Levels; Ministry of Business Innovation & Employment: Wellington, New Zealand, 2013.

- Schleich, J.B.; Cajot, L.G.; Pierre, M.; Brasseur, M. Development of Designa Rules for Steel Structures Subjected to Natural Fires in Closed Car Parks; European Commission: Luxembourg, 1999. [Google Scholar]

- NFPA 502:2020; Standard for Road Tunnels, Bridges, and Other Limited Access Highways. National Fire Protection Association: Quincy, MA, USA, 2020.

- Colella, F. Understanding Electric Vehicle Fires; Fire Protection and Safety in Tunnels: Stavanger, Norway, 2016. [Google Scholar]

- Long, R.T.; Blum, A.F.; Bress, T.J.; Cotts, B.R.T. Best Practices for Emergency Response to Incidents Involving Electric Vehicles Battery Hazards: A Report on Full-Scale Testing Results; Fire Protection Research Foundation: Quincy, MA, USA, 2013. [Google Scholar]

- Emergency Response Guide Tesla Model S 2016. Available online: https://www.tesla.com/sites/default/files/downloads/2016_Model_S_Emergency_Response_Guide_en.pdf (accessed on 9 September 2021).

- Ghiji, M.; Novozhilov, V.; Moinuddin, K.; Joseph, P.; Burch, I.; Suendermann, B.; Gamble, G. A Review of Lithium-Ion Battery Fire Suppression. Energies 2020, 13, 5117. [Google Scholar] [CrossRef]

- Un, C.; Aydın, K. Thermal Runaway and Fire Suppression Applications for Different Types of Lithium Ion Batteries. Vehicles 2021, 3, 480–497. [Google Scholar] [CrossRef]

- Said, A.O.; Stoliarov, S.I. Analysis of effectiveness of suppression of lithium ion battery fires with a clean agent. Fire Saf. J. 2021, 121, 103296. [Google Scholar] [CrossRef]

- Willstrand, O. Fire Suppression Tests for Vehicle Battery Pack; Test Report 8P03983-03; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2019. [Google Scholar]

- SAE. Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler; SAE Int. Std. J1772-2017; SAE International: Warrendale, PA, USA, 2017; pp. 1–116. [Google Scholar]

- Wang, B.; Dehghanian, P.; Wang, S.; Mitolo, M. Electrical Safety Considerations in Large-Scale Electric Vehicle Charging Stations. IEEE Trans. Ind. Appl. 2019, 55, 6603–6612. [Google Scholar] [CrossRef]

- Chen, F.; Leong, J. Smoke flow phenomena and turbulence characteristics of tunnel fires. Appl. Math. Model. 2011, 35, 4554–4566. [Google Scholar] [CrossRef]

- McGrattan, K.; McDermott, R.; Hostikka, S.; Floyd, J.; Weinschenk, C.; Overholt, K. Volume 1: Mathematical model. In Fire Dynamics Simulator Technical Reference Guide, 6th ed.; NIST Special Publication 1018-1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Gager, A.H., III; Dominguez, G. Tenability Criteria in Unique Situations and Atypical Buildings; FEMTC: Manhattan, KS, USA, 2016. [Google Scholar]

- Poh, W. Tenability Criteria for Design of Smoke Hazard Management Systems; Ecolibrium: Ahmedabad, India, 2011. [Google Scholar]

- Hopkin, C.; Spearpoint, M.; Henderson, A.; Hopkin, D. Smoke Control Association Guide: Benchmarking firefighting tenability criteria against accepted designs. Int. Fire Prof. J. 2017. Available online: https://www.researchgate.net/publication/325049474_Smoke_Control_Association_Guide_Benchmarking_firefighting_tenability_criteria_against_accepted_designs (accessed on 10 October 2021).

| Type of Passenger Electric Car | Minimum Capacity of Li-Ion Battery [kWh] | Average Li-Ion Battery Capacity [kWh] | Maximum Battery Capacity Li-Ion [kWh] |

|---|---|---|---|

| HEV | 0.9 (1) | 1.4 (2) | 1.6 (3) |

| PHEV | 8.9 (4) | 13.8 (5) | 42.2 (6) |

| BEV | 32.6 (7) | 82 (8) | 200 (9) |

| Cell Type | LCO | LMO | LFP | NMC | NCA |

|---|---|---|---|---|---|

| life cycle length | ++ (3) | + (4) | +++ (2) | ++ (1) | ++ (1) |

| safety | + (4) | +++ (2) | ++++ (1) | +++ (2) | ++ (3) |

| energy density | +++ (2) | + (4) | + (4) | +++ (2) | +++ (2) |

| cost | +++ (2) | ++ (3) | +++ (2) | ++ (3) | ++ (3) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorsz, A.; Lewandowski, M. Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures. Energies 2022, 15, 11. https://doi.org/10.3390/en15010011

Dorsz A, Lewandowski M. Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures. Energies. 2022; 15(1):11. https://doi.org/10.3390/en15010011

Chicago/Turabian StyleDorsz, Adam, and Mirosław Lewandowski. 2022. "Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures" Energies 15, no. 1: 11. https://doi.org/10.3390/en15010011

APA StyleDorsz, A., & Lewandowski, M. (2022). Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures. Energies, 15(1), 11. https://doi.org/10.3390/en15010011