The operational conditions of the shearer drive are specific, which practically makes correct (from the theoretical point of view) cooperation between the wheel and rack impossible. In such a situation, we look for a compromise solution, such as non-standard profiles, which would make it possible to slow down the wear of the track wheel and thus extend its service life. This is due to two basic factors, namely the parameters of the pressure forces between the surfaces of the teeth of the wheel and rack and the slippage between these surfaces during the intermeshing process. This part of the article describes the analysis of the slip differences between the toothed surfaces of the track wheel and the new rack design.

4.1. Theoretical Analysis of the Correct Cooperation of the Gear—Rack System

When selecting a profile for teeth of cooperating components, properties of existing gears of the profiles, called standard ones, were analyzed. These include cycloidal and involute profiles as well as less frequently used circularly arched profiles.

The advantages of cycloidal gearing are as follows: the concave tooth surface of one-wheel cooperates with the convex surface of the tooth of the other wheel and vice versa; there is a wide contact area and small unit surface pressure; there is low tooth wear, low slippage, and high gearing efficiency. On the other hand, the disadvantages of cycloidal gearing are as follows: the need to maintain a very precise interaxial distance as the sum of the theoretical radii of the rolling wheels, teeth machining using precise numerically controlled machines, and vibrations and additional dynamic loads caused by inaccuracy of the tooth pitch.

Due to the above-mentioned disadvantages, the cycloidal gear cannot be considered to be used in the shearer drive. However, it is possible to try to use some of its features to modify the currently used involute gearing. Therefore, its properties should be analyzed, and the advantages and disadvantages, as well as the impact of parameters on the shaping of slips and loads, should be assessed.

The features of the involute profile are generally well known, as it is the most commonly used type of intermeshing in machine drives. It is also used in rack and pinion haulage drives of longwall shearers. In these drives, the track wheels are the involute teeth wheels, while the rack profiles are often modified. An attempt to apply a rack with a concave tooth profile (Flextrack system) to minimize the forces of inter-teeth pressures was not fully successful; therefore, a modification was aimed at minimizing the defects of involute intermeshing.

Contrary to the cycloidal profile, the involute profile is not very sensitive to the change of the distance between the axles of the cooperating wheels. However, this has other consequences, which are referred to as involute intermeshing disadvantages, the impact of which should be minimized by appropriate selection of parameters.

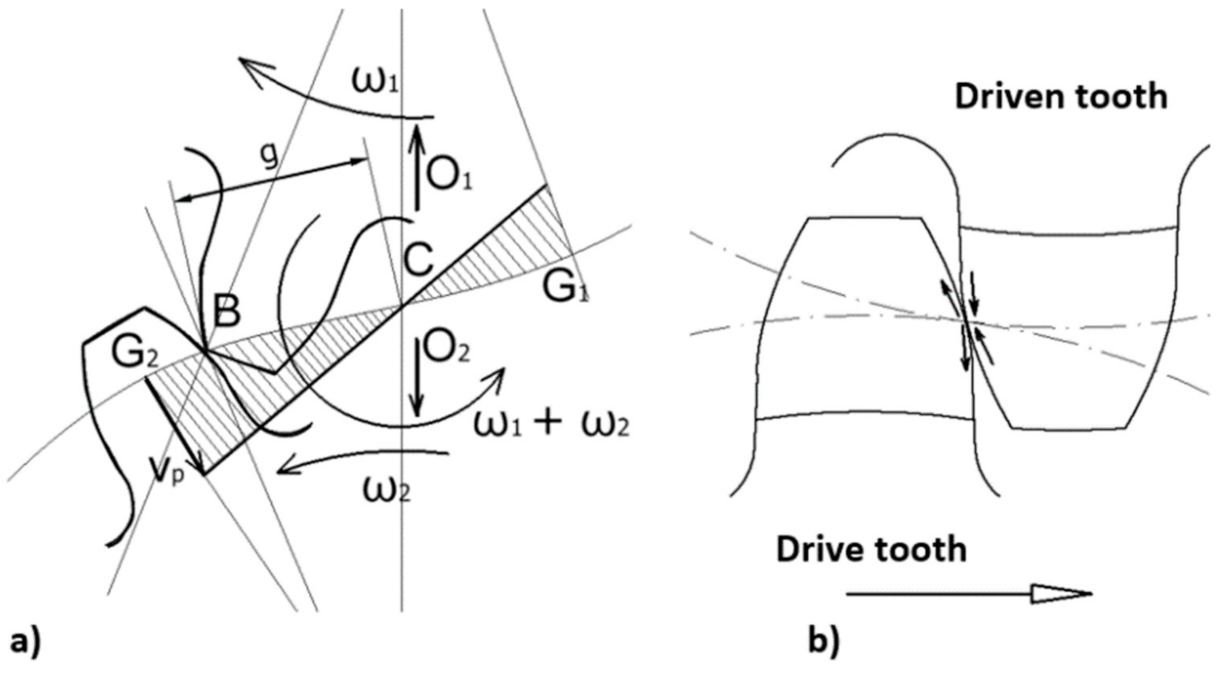

Complex rolling and sliding processes are found between the two involute sections in the buttress, in the result of different lengths of the cooperating involute sections. These sections responsible for the uniform rotations of the cooperating wheels can be regarded approximately as circular arcs, the radii of which are equal to the radii of curvature at the considered places. According to the diagram in

Figure 8a, the slip speed v

p at point B will be [

22]:

where:

ω1, ω2—angular speeds of cooperating gears,

CB = g—a distance of the discussed point B from the central point C.

The presented relationship shows that the slip speed is directly proportional to the segment g and to the sum of the angular speeds of the cooperating wheels. Assuming constant (unchanging) angular speeds, the greater the sliding speed, the greater the distance between the tooth side contact point and the central point C, equal to zero at point C. The sense of a slip speed vector on the tooth side surfaces is different on the tooth side of the driving wheel than on the tooth side of the driven wheel.

The method for determining the slip of the cooperating toothed wheels, presented in

Figure 8, can be used to determine the slip of toothed gear. The method for determining the slip of the cooperating gears presented in

Figure 8 can be used to determine the slip for a toothed gear. The situation is simplified because the rack is stationary, so only the rotational movement of the track wheel is considered, and the slip speed in this case will be g·ω

1.

Conclusions regarding the selection of intermeshing parameters can be drawn from the presented analyses allowing for reduction of the slip, which have a significant impact on the wear of the track wheel teeth, especially in their tips. Unfortunately, it shows that the bigger slip causes the greater nominal angle of the profile and the lower high of the tooth. Additionally, this operation reduces intermeshing, which may lead to situations where loads are transferred by one tooth, especially when using the bigger tooth clearances, which is intentional due to the above-mentioned characteristics of the shearer driving gearbox. These features are reasonable when selecting the intermeshing parameters but should be confronted with the advantages and disadvantages of the involute intermeshing listed below.

The advantages of the involute gearing include the following: it is practically insensitive to changes in the distance between the axels of the cooperating wheels. Direction and magnitude of the radial pressures and along the buttress line (gearing) are constant, so there are no additional load fluctuations and vibrations during operation, and there is the relatively high efficiency of intermeshing, although, in the case of a shearer drive, this advantage is not evident due to the specific working conditions. The disadvantages, however, include the following: quite a large surface pressure, especially in the area of the teeth tips, and slightly greater slip than in the cycloidal intermeshing.

Despite these disadvantages, the involute gearing is the only basic solution that meets technical and economic criteria and, after modifying the profile of the rack teeth, will make it possible to reduce wear on the shearer track wheels [

1,

2,

3,

4,

5,

6,

7,

8,

9].

4.2. Simulation Tests of the Slip during the Co-Operation of the Track Wheel and New Rack Solutions

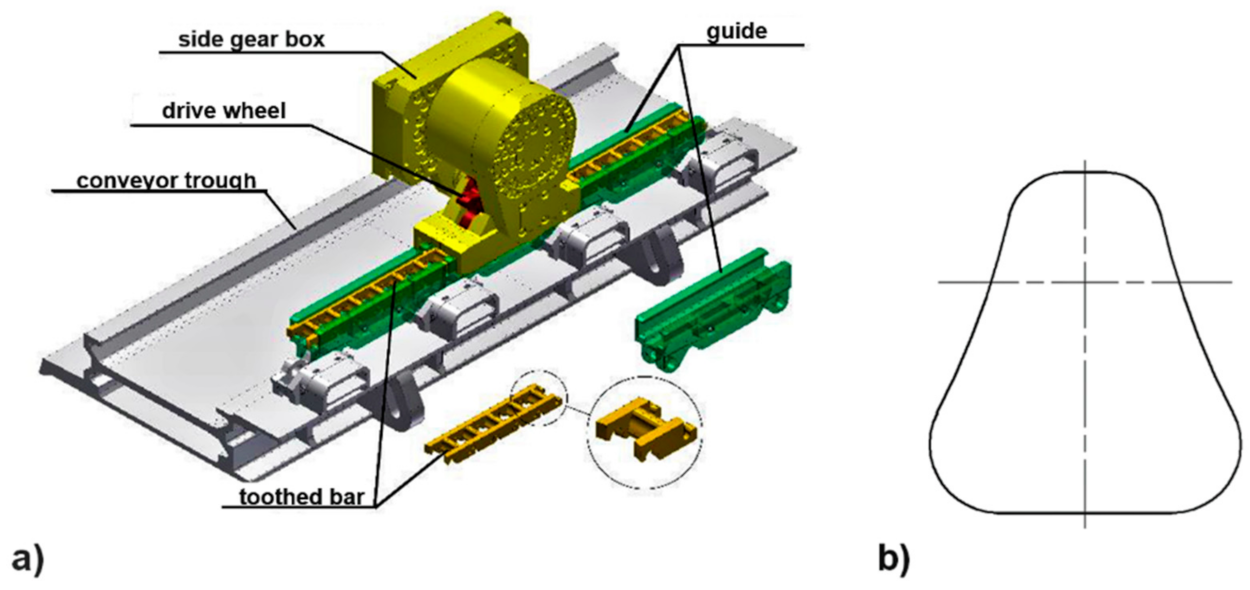

Considering the above information and the results of work with the Flextrack haulage system, three new design solutions for rack segments were developed for the simulation tests,

Figure 9. The basic rack for involute intermeshing, i.e., a rack with straight teeth, is presented as Type V1 in

Figure 9a. The following are racks with modified profiles. A segment with a tooth with a mixed arch profile Type V2 is shown in

Figure 9b, and Type V3 in

Figure 9c is a segment with a modified tooth profile, used in liner racks for the Eicotrack system manufactured by Ryfama.

The results of simulation tests carried out in accordance with the suggested methodology in Autodesk Inventor-Dynamic Analysis Environment are shown in

Figure 10. Three kinematic parameters, such as the angular speed of the frame wheel ω, assumed to be a constant (kinematic motion excitation), the displacement L of the model of the wheel drive, and the linear speed of this displacement Vs, are shown in graphs.

By comparing the diagrams, it is possible to assess the impact of the shape of the rack profile on disturbances in the gear ratio, mainly resulting from the slip between the teeth. This is precisely illustrated by the linear speed of displacement of the track wheel model of the drive Vs. In the case of the segment with a Type V3 tooth with a mixed arcuate profile, after the initial change of the speed, its stabilization can be observed. As for the two remaining segments, changes in the displacement speed are visible throughout the simulation. The impact of segment profiles on movement disturbances manifested as changes in the linear speed of displacement, assuming that the nature of periodically variable movements with variable amplitude is not stable. It can be concluded that the gaps between the teeth during intermeshing and disengagement of the gear teeth with the rack teeth have an impact on the process. Disturbances in the distance of the teeth increase the resistance to movement and pressure, and thus the friction forces at these moments. The type of profile and its geometrical parameters manifest themselves in periodic excitation of vibrations with variable amplitude.

The least favorable situation is in the case of the V1 straight-toothed rack, where these speed changes have the greatest dynamics, and therefore the most significant amplitude and duration. The load to the tips of the rack teeth, where there are the greatest pressures and at the same time the greatest slip, is important.

The situation is most favorable for teeth with a modified profile marked as Type V3. This is due to the fact that the modification of the profile mainly consisted in rounding the tooth head. The profile was modified with arcs of larger radii. Based on the presented diagrams, it can be assessed that the change of the rack profile causes that the gear ratio is not constant, irrespective of the impact of other factors, such as tooth clearances and changes in the distance between the rack wheel axis and the rack line. It should be emphasized that the presented simulation results are of comparative importance, and the conditions of the gear displacement and all parameters adopted for the simulation were identical for each case of the rack profile.

Regardless of the analysis of the impact of gear ratio disturbances, the result of which showed a significant improvement in the cooperation of the wheel with the rack by modifying the teeth geometry, the trajectory and speed of movement of the wheel tooth tips was also analyzed, enabling directly assessing the slip speed. Comparative analysis was also carried out regarding the tooth profile in the currently used Eicotrack rack system to verify the advisability of modifying the tooth profile of the rack. The parameters were determined in the same way as for the tests of racks suggested for the KOMTRACK system. The selected results of this analysis as screen shots are presented in

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15, successively for each KOMTRACK rack segment and Eicotrack linear rack. The arrows show the values (length of the arrow) and directions of the slip speed for successive positions of the track wheel in relation to the rack—the first position is marked in red, the next in green, and the last in pink.

Figure 11 shows the situation before the track wheel enters the buttress with a rack, which is analogous for all analyzed cases. On the other hand,

Figure 12 and

Figure 13 show the situation of starting the slip process; the wheel enters the buttresses with Type V1 and V2 toothed gear, and in

Figure 14 and

Figure 15, the moment of starting the slip process when entering the buttress with toothed gears is shown for the Type V3 toothed gear and the Eicotrack linear rack, and slippage of the track wheel while moving over the rack surface is shown. The presented slip velocity vectors, marked in red, pink, and green in the Figures, are proportional to the values of these speeds.

When analyzing the cooperation between the track wheel of the involute profile of teeth and gears with the modified tooth profile, it can be stated that minor modifications that can be allowed to not deteriorate the cooperation of the gear-rack pair have a relatively small effect on the change in the value of slips. In a specific case, the variations in the slip range from 9.0 to 21.3 mm/s. These are approximate and comparative values, useful when selecting the direction of changes regarding the modification the rack tooth profile. It should be emphasized that the assumption that the profile of teeth of the track wheel cannot be changed imposes significant limitations in modification of the parameters of the toothed segment teeth profiles. It should be remembered that the specific operating conditions of the shearer haulage drive and its related structure and the need to accept large manufacturing tolerances and tooth clearances do not allow for the unverified application of the principles resulting from the theory of toothed gear operation.

It should be noted that a reduction in slips causes a reduction of the intermeshing surface area. In the analyzed case, the best result was obtained for the version of the rack profile marked as Type V3. The cost of this is reduction in the contact surface area of the gear teeth cooperating with the rack, thus eliminating the areas near the apexes and near the tooth base from cooperation. This will have consequences such as the deterioration of the cooperation conditions as the teeth wear.

Analysis of the tooth profile of the rack, which was used in the modified version of the Komtrack system, led to the conclusion that by modifying the tooth profile, the slip can be reduced. However, it should be noted that this is the result of the theoretical analysis of cooperation, and that the reduction of slippage reduces the degree of coverage for intermeshing. Consequently, the risk that a single tooth is carrying a heavy load increase. In the case of the shearer drive, it cannot be ruled out that a single tooth will bear the entire load of the shearer, assuming high rack stiffness. Partition of the rack into segments reduces this risk by increasing its longitudinal flexibility. Therefore, the analysis of loads to teeth will be of the greatest importance, taking into account various conditions of the route configuration.

Later, the cooperation of the selected kinematic pair, the track wheel and the Type V3 gear segments, was analyzed in the Autodesk Inventor, AutoCAD Mechanical, and Microsoft Excel software environment in terms of slippage during the total rolling of the wheel through the toothed segment. Simplified 3D models of Type V3 toothed segments without casting beams and a simplified 3D model of a track wheel of a nominal width 76 mm was used for the analysis. For this type of analysis, only the profiles of the tooth flanks of the cooperating kinematic pairs are important. The entire length of the contact between the kinematic pair was analyzed, which translates into the angle of rotation of the track wheel by 30°. This angle results from the number of teeth on the frame wheel z = 12. After rotating the track wheel by 30°, the intermeshing conditions are repeated cyclically. The gear axis is 262 mm from the upper surface of the sidewalls of the gear segments. The general isometric view and the cross-section of the track wheel connection with toothed segments developed to analyze slips in the kinematic pair of the KOMTRACK feed system is shown in

Figure 16.

The analysis began with intermeshing at the moment when two teeth of the track wheel were in contact with two teeth of neighboring toothed segments. This intermeshing of the kinematic pair was taken as the beginning of the meshing and a track wheel rotation angle of 0° was assigned to it. Then the track wheel was rotated by 1° with the simultaneous contact of the corresponding tooth surfaces. Successive rotations of the track wheel by an angular increment of 1° were repeated until the wheel rotation by 30° was achieved. A view of the analyzed positions of the track wheel for the selected angular positions 0°, 5°, 10°, 15°, 20°, 25°, and 30° in relation to the toothed segments is given in

Figure 17.

Figure 18 shows the results of the analysis of slippage of the track wheel flank in relation to the toothed segment flank. The study shows that starting from the moment of intermeshing, the slip of the toothed segment flank in relation to the track wheel flank increases, reaching a maximum value of about 8 mm in the middle of the intermeshing length (angle of rotation of the track wheel about 15°). Thereafter, the slip of the toothed segment flank decreases until it reaches a non-slip condition corresponding to a track wheel rotation angle of approximately 28°. From this moment until the gearing out, the flank of the track wheel begins to “accelerate” in relation to the flank of the toothed segment—slippage of the analyzed kinematic pair results from the differences in the active length of the cooperating teeth. The active length of the track wheel flank is approximately 39.3 mm, while the corresponding length of the toothed segment flank is less than 37.5 mm. The identified differences in the active length of the two buttress surfaces are one of the main causes of the frictional wear of the shearer’s haulage system components. Based on the determined slip, a diagram was drawn up (

Figure 19), illustrating the changes depending on the track wheel angle of rotation.

Based on the relationships given in [

3], the pulling force, the meshing force, and the vertical component Y were also determined for the analyzed system. The obtained results are presented in the form of a graph for three consecutive intermeshings in

Figure 20. The analysis of the results shows that for the angle of rotation of the track wheel in the range between the 7–20°, the traction force, and the vertical component Y remain at the same level. During one cycle of meshing, the pulling force increases, reaching its maximum value at the moment of gearing out.

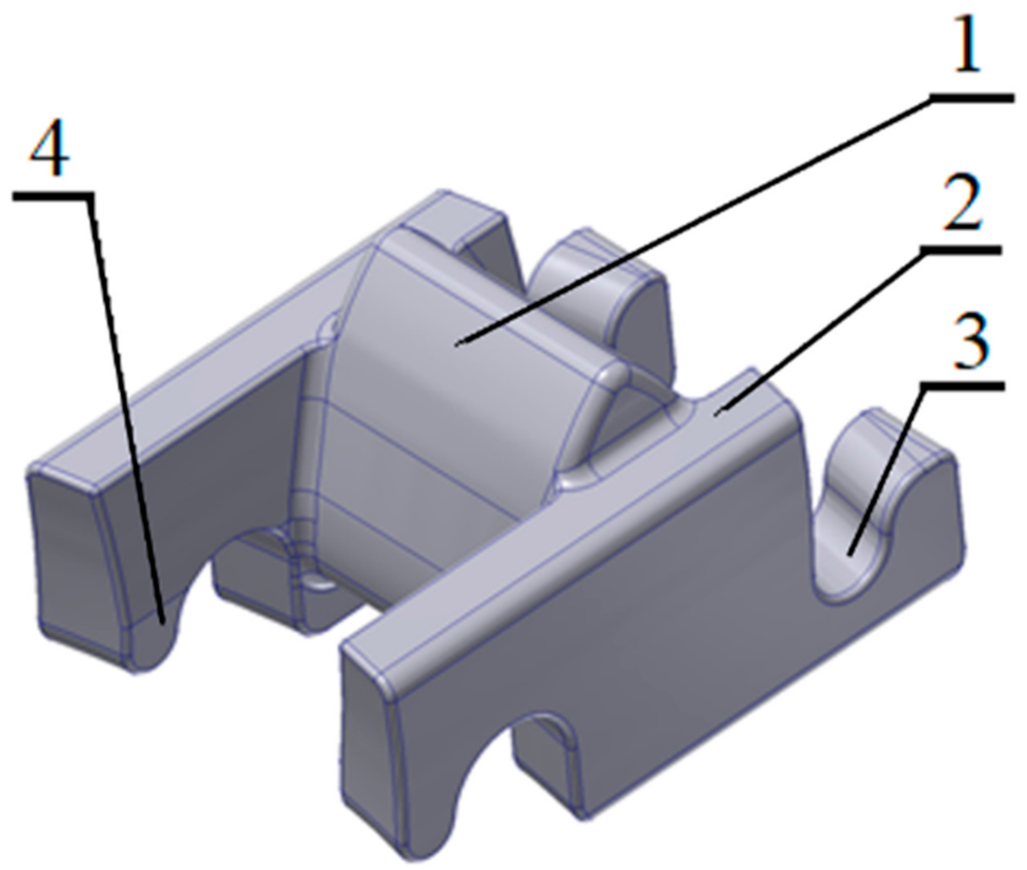

The selected design of the Type V3 toothed segments was manufactured in a prototype version, and initial functional tests of the suggested system were carried out on a test stand built on the storage yard of one of the mines belonging to PGG S.A.

The results were satisfactory. The high flexibility of the rack during the shearer movement along the curved route of AFC was obtained. On the other hand, plastic bending of the toothed segment catches as well as their breaking at the point of the smallest cross-section surface area were reported in a few cases, as shown in

Figure 21.

To avoid this type of damage, it was suggested to introduce changes to the design of the toothed segment. A solution of the toothed segment was developed, the 3D model of which is shown in

Figure 22. The profile of the tooth flanks is the same as for the previous solution of the V3 type toothed segment, the difference is only in the height of the tooth (lower by 10 mm) and in the absence of catches. The tests concerning the slippage during the cooperation of the track wheel with the new solution of the toothed segment gave the results analogous to the results obtained for the previous version of the segment with catches. A new solution of the toothed segment without catches was used for further tests.