Stability Enhancement of a Single-Stage Transonic Axial Compressor Using Inclined Oblique Slots

Abstract

1. Introduction

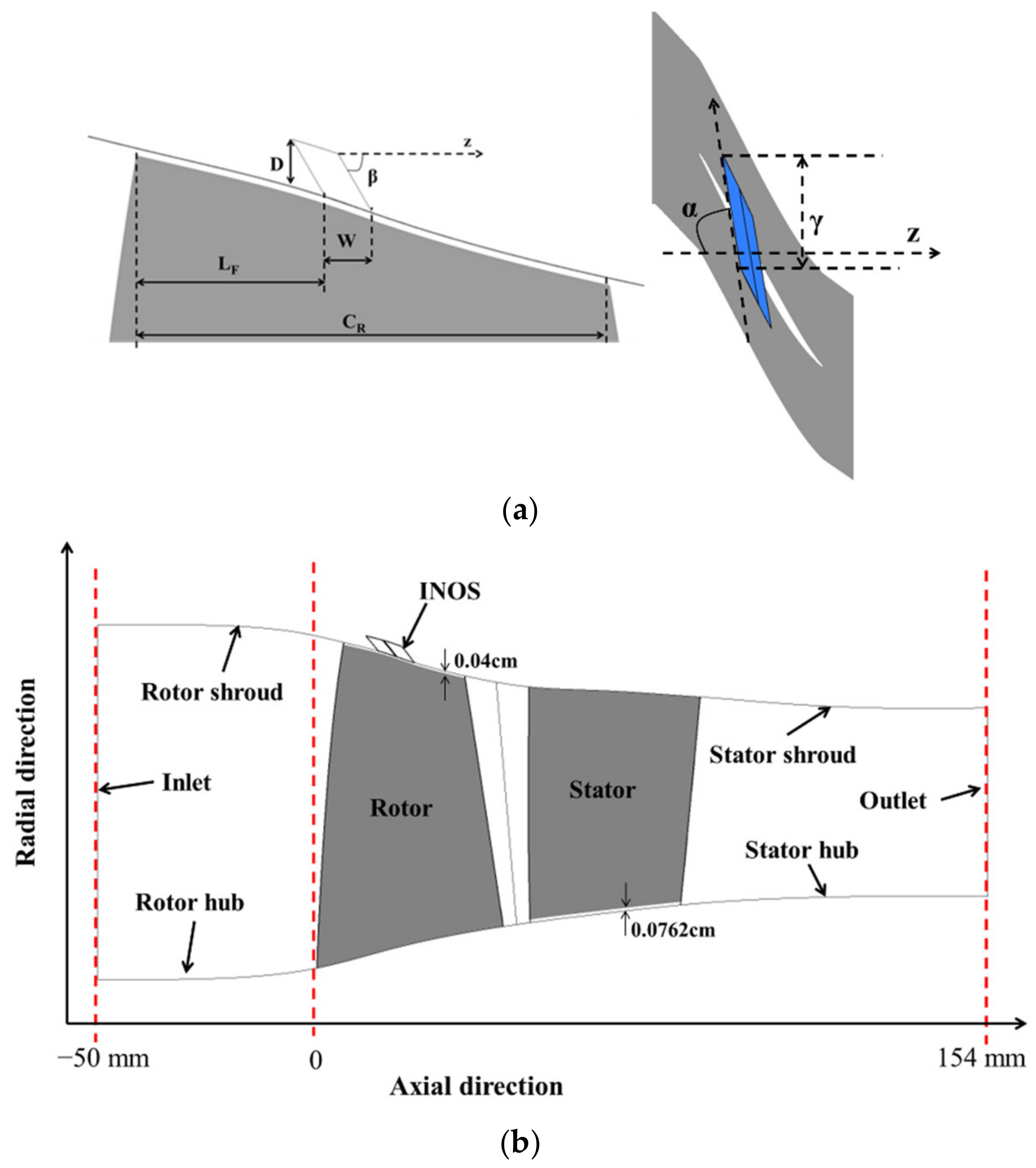

2. Compressor Model and Casing Treatment Design

3. Numerical Analysis

3.1. Numerical Method

3.2. Performance Parameters

3.3. Grid Dependency Test

3.4. Optimization Technique

4. Discussions

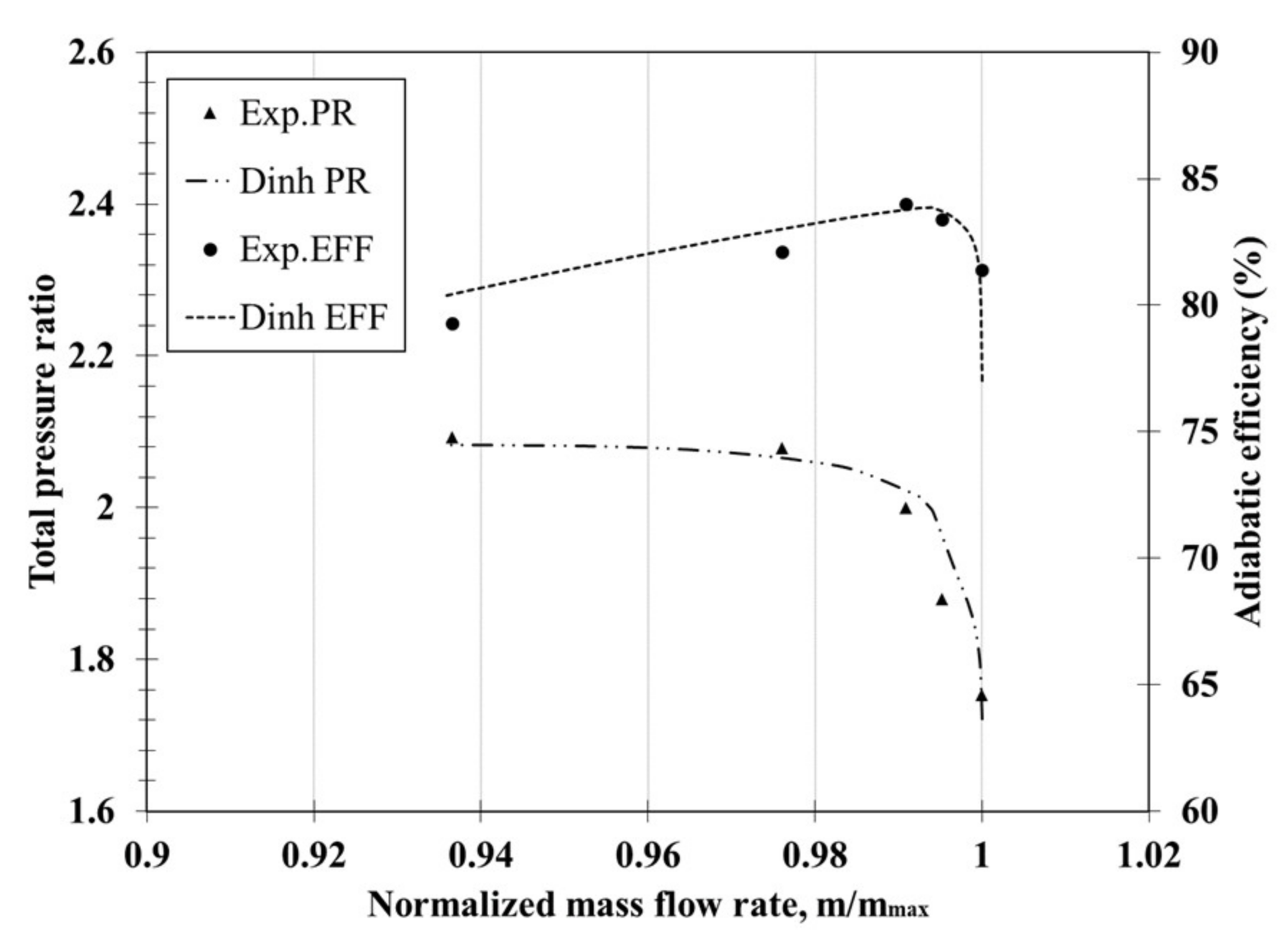

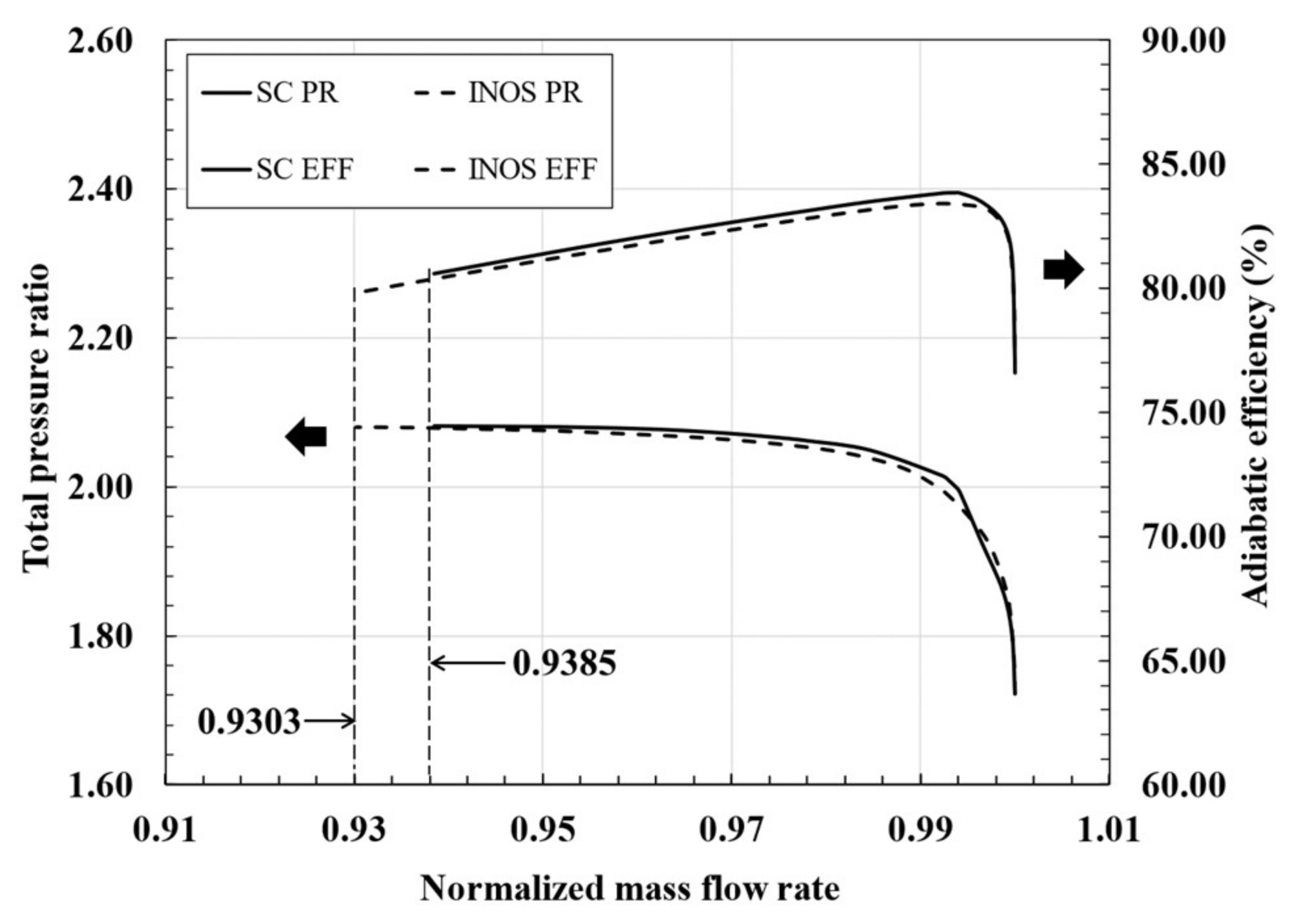

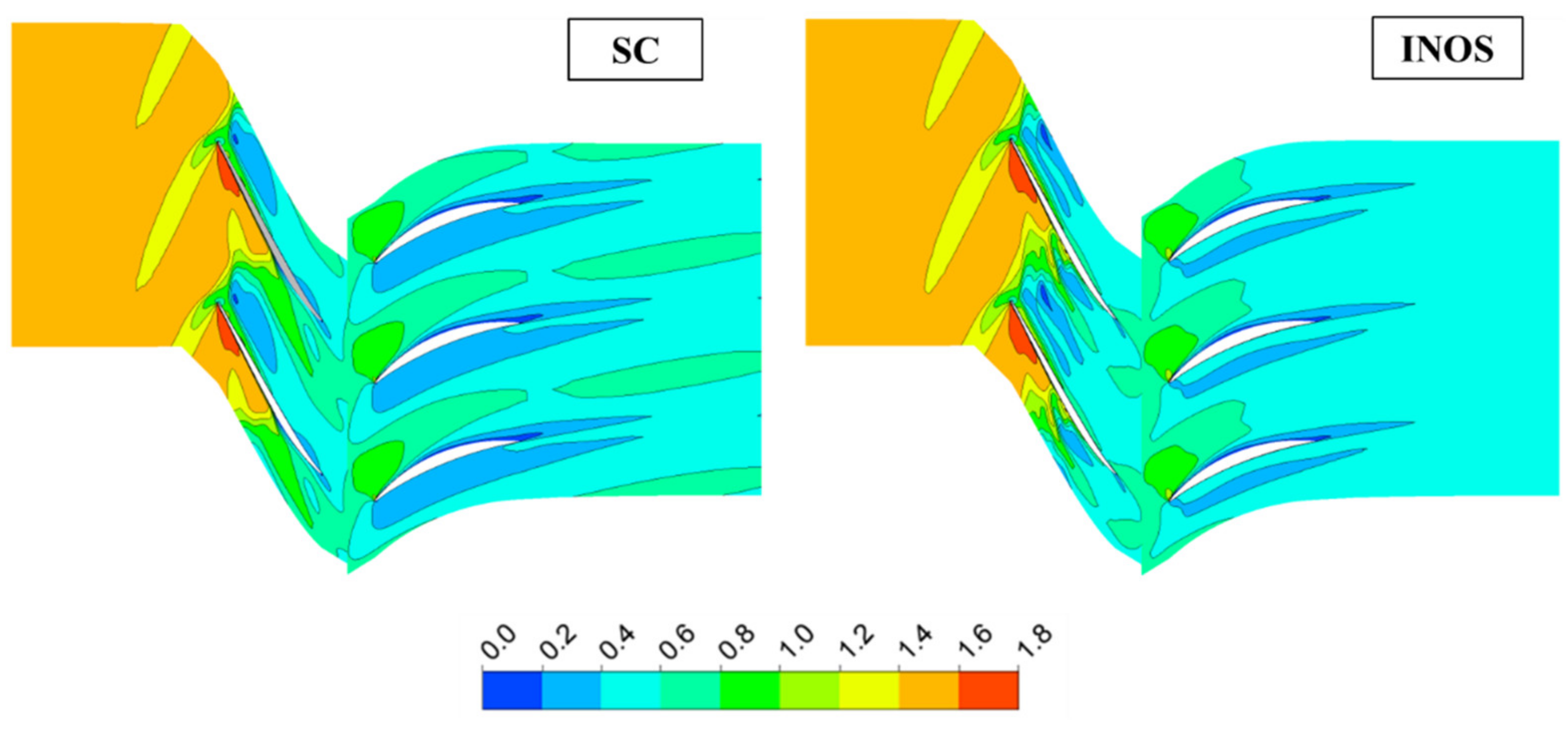

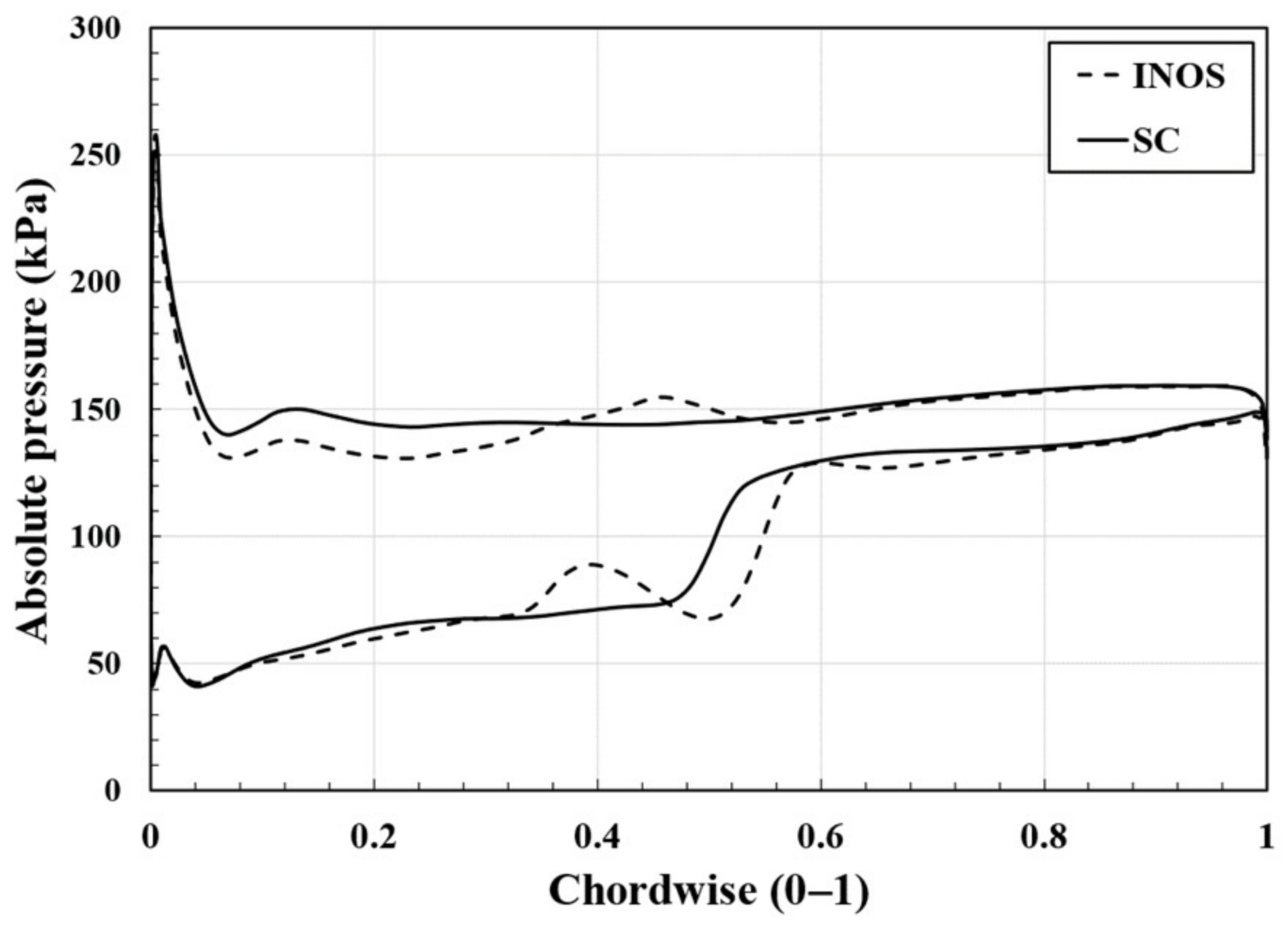

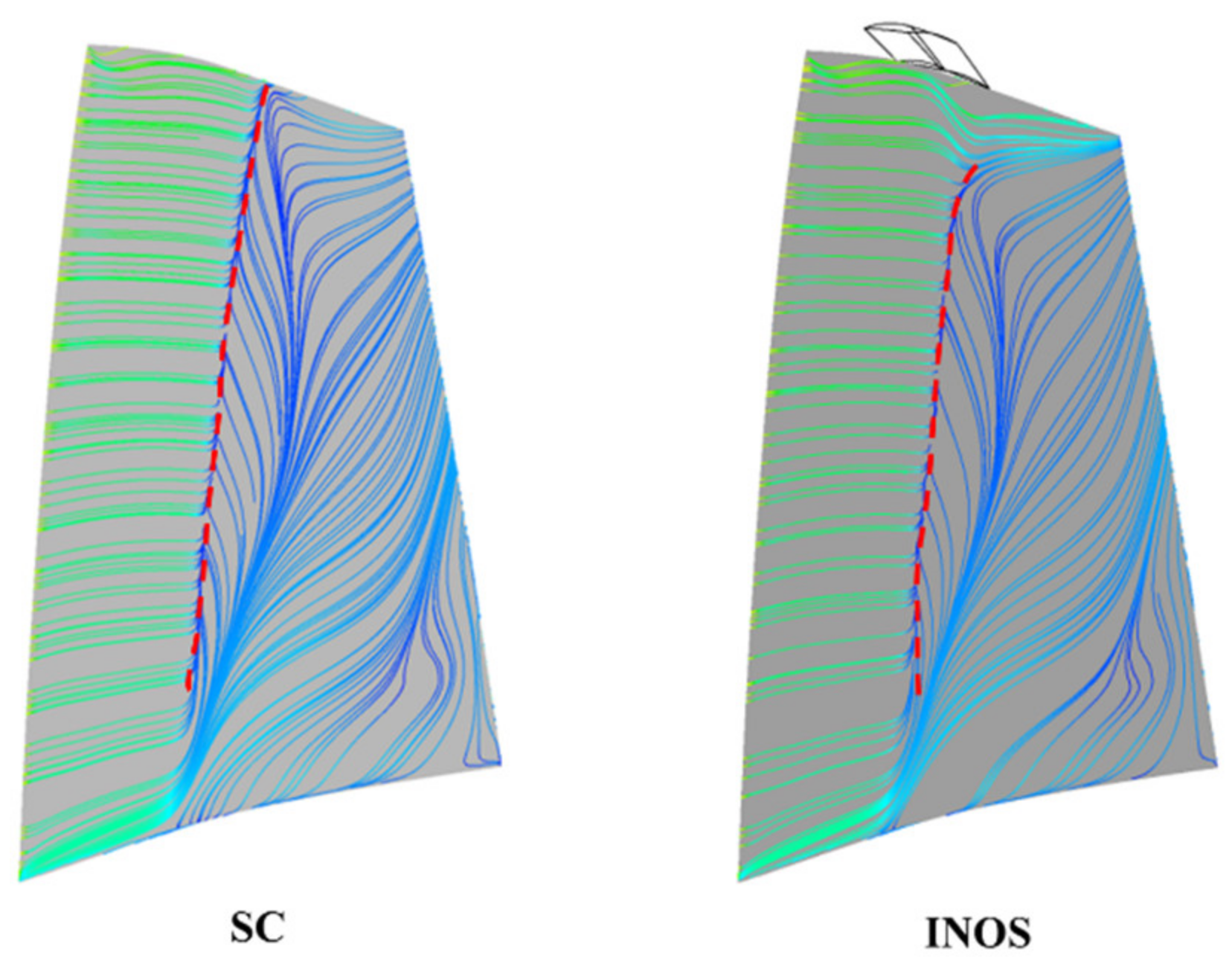

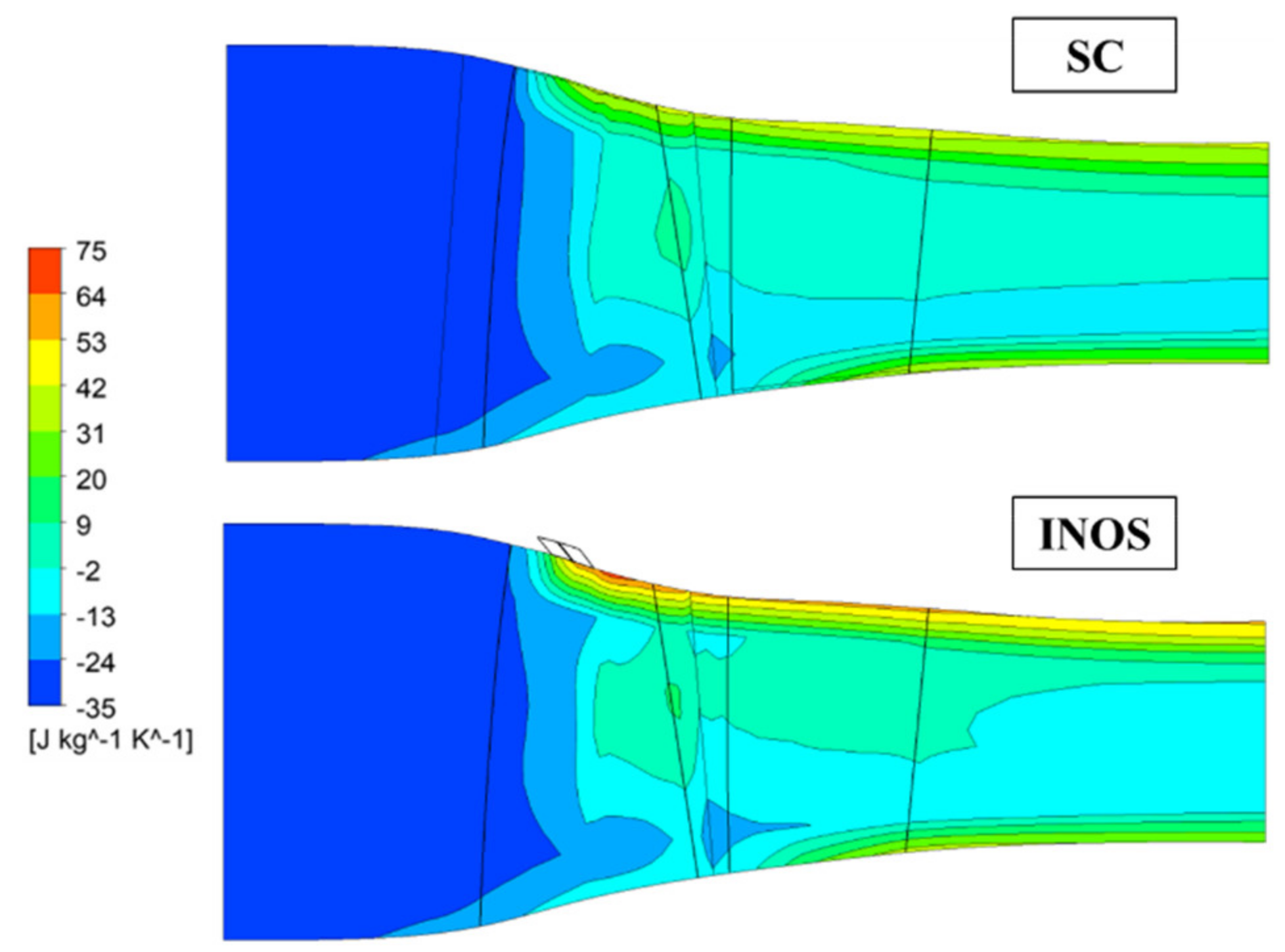

4.1. Results with the Reference INOS

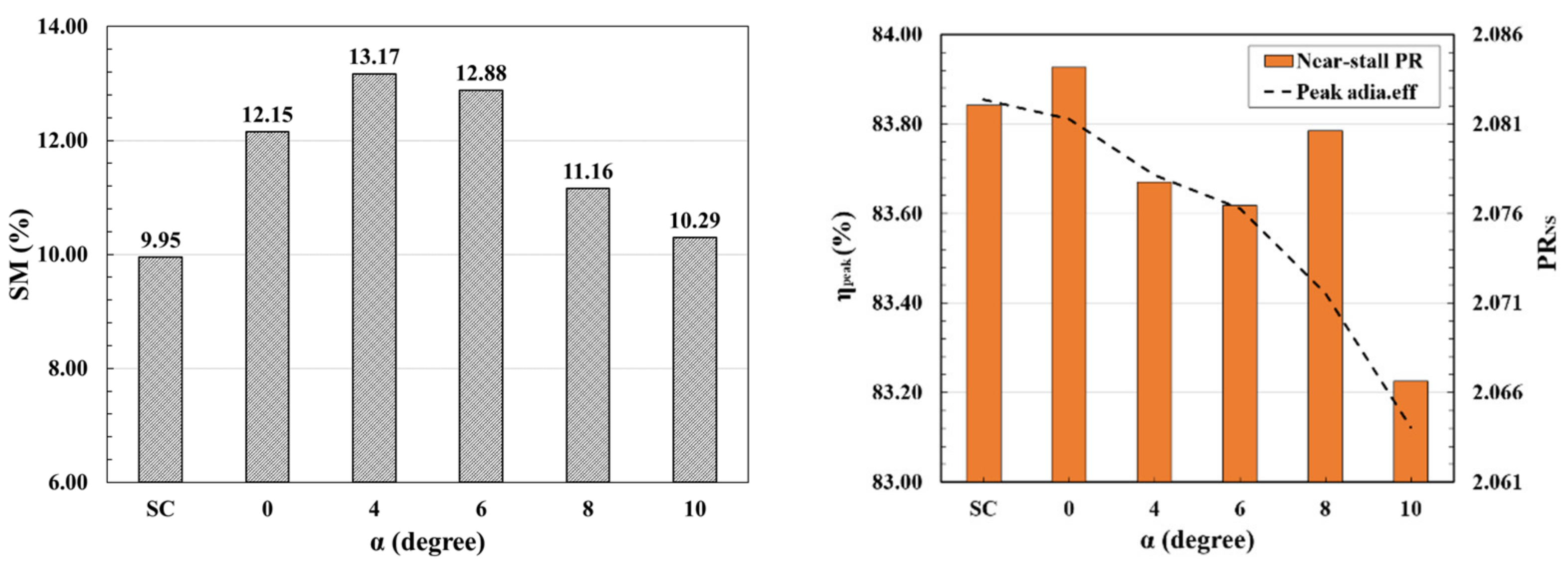

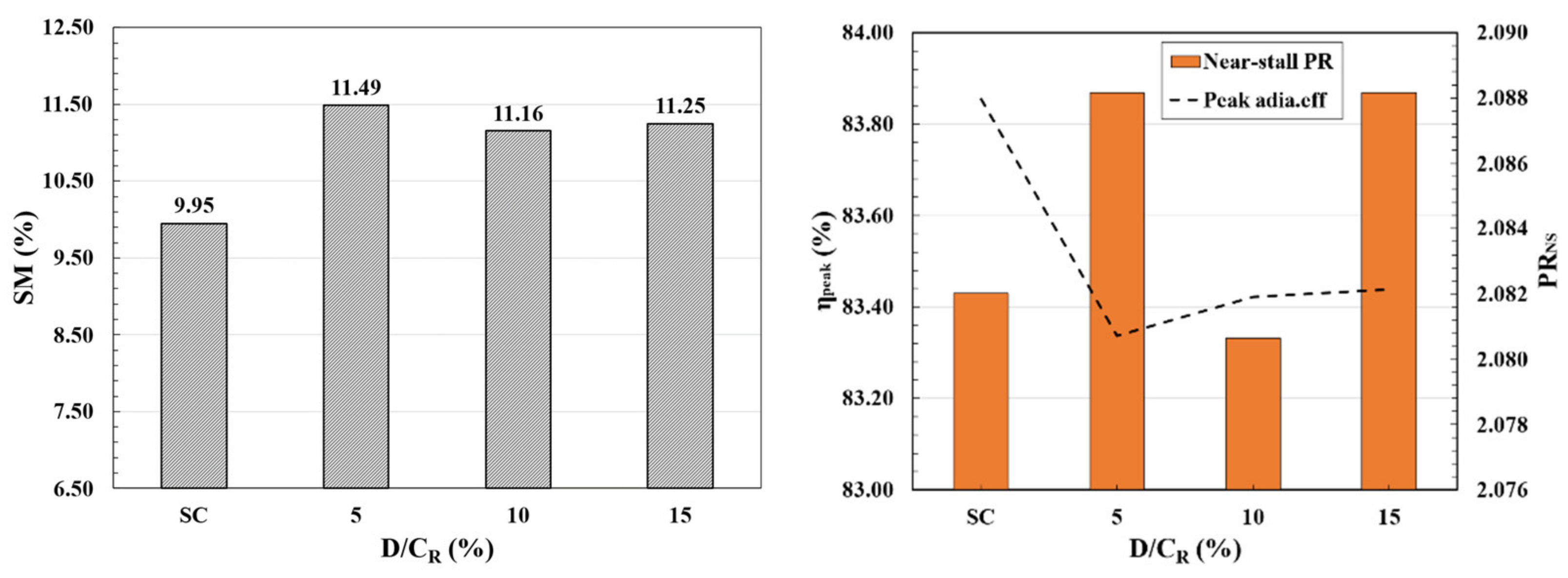

4.2. Parametric Study

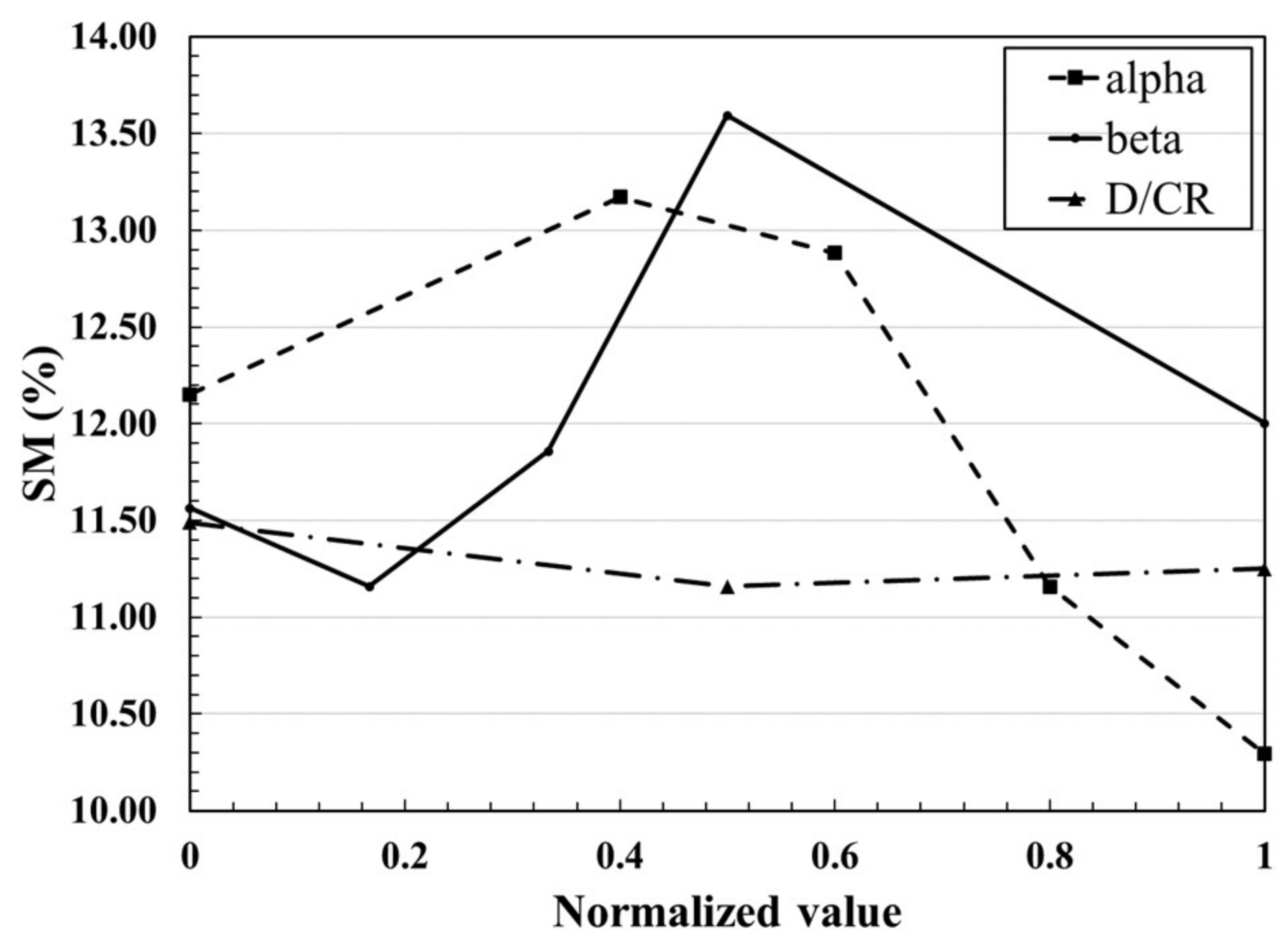

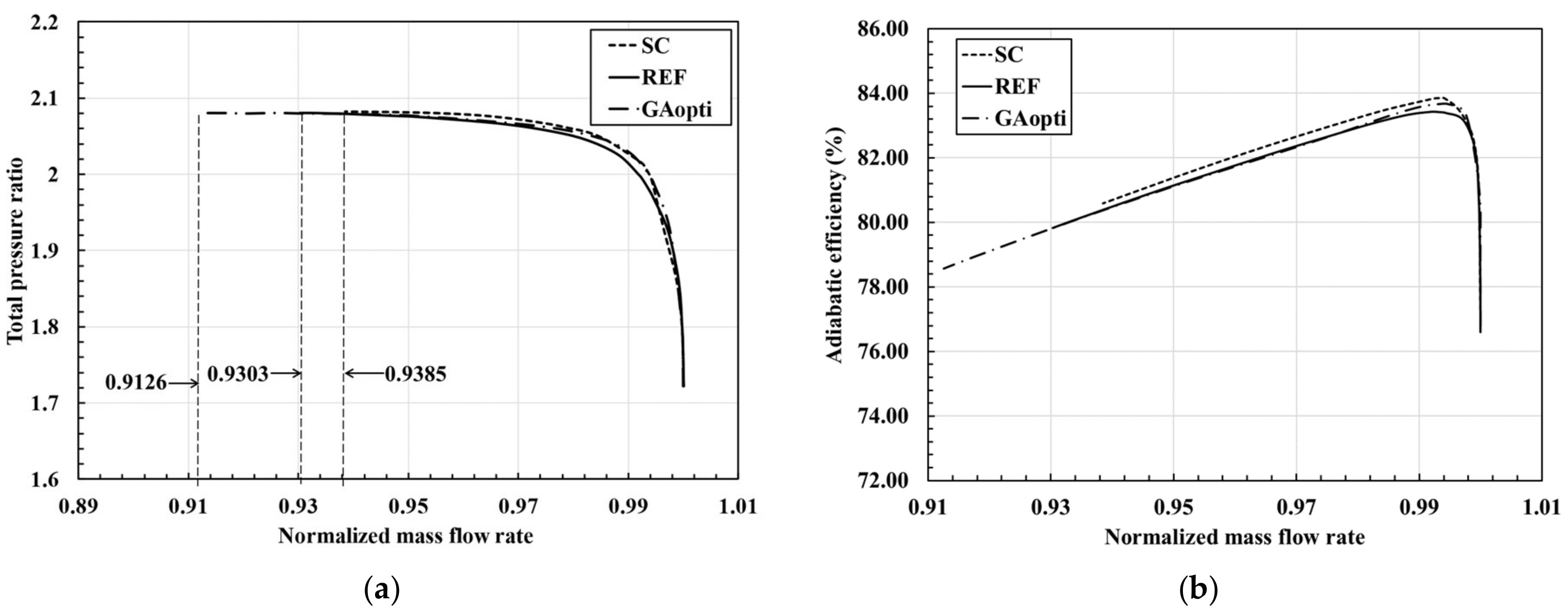

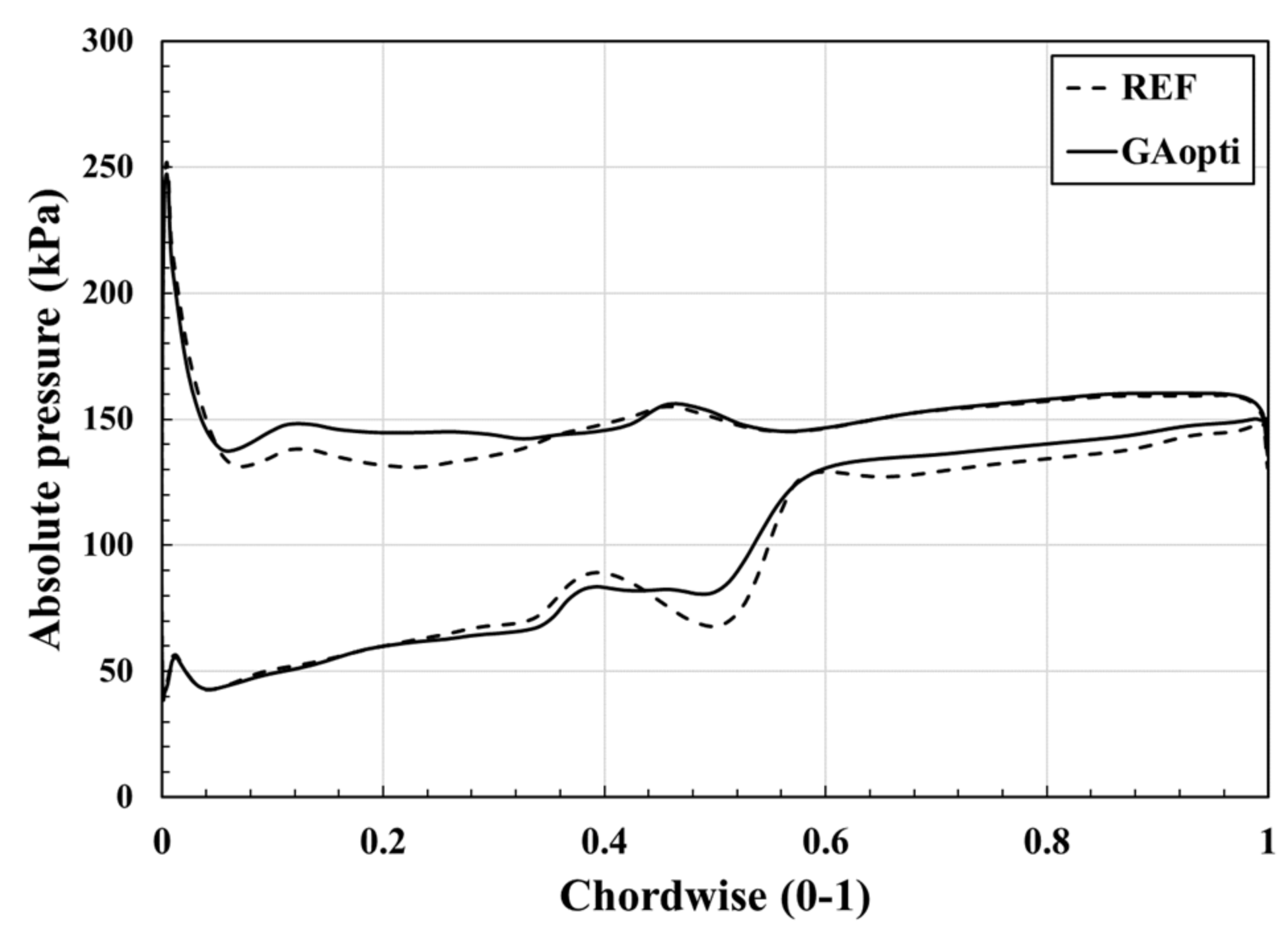

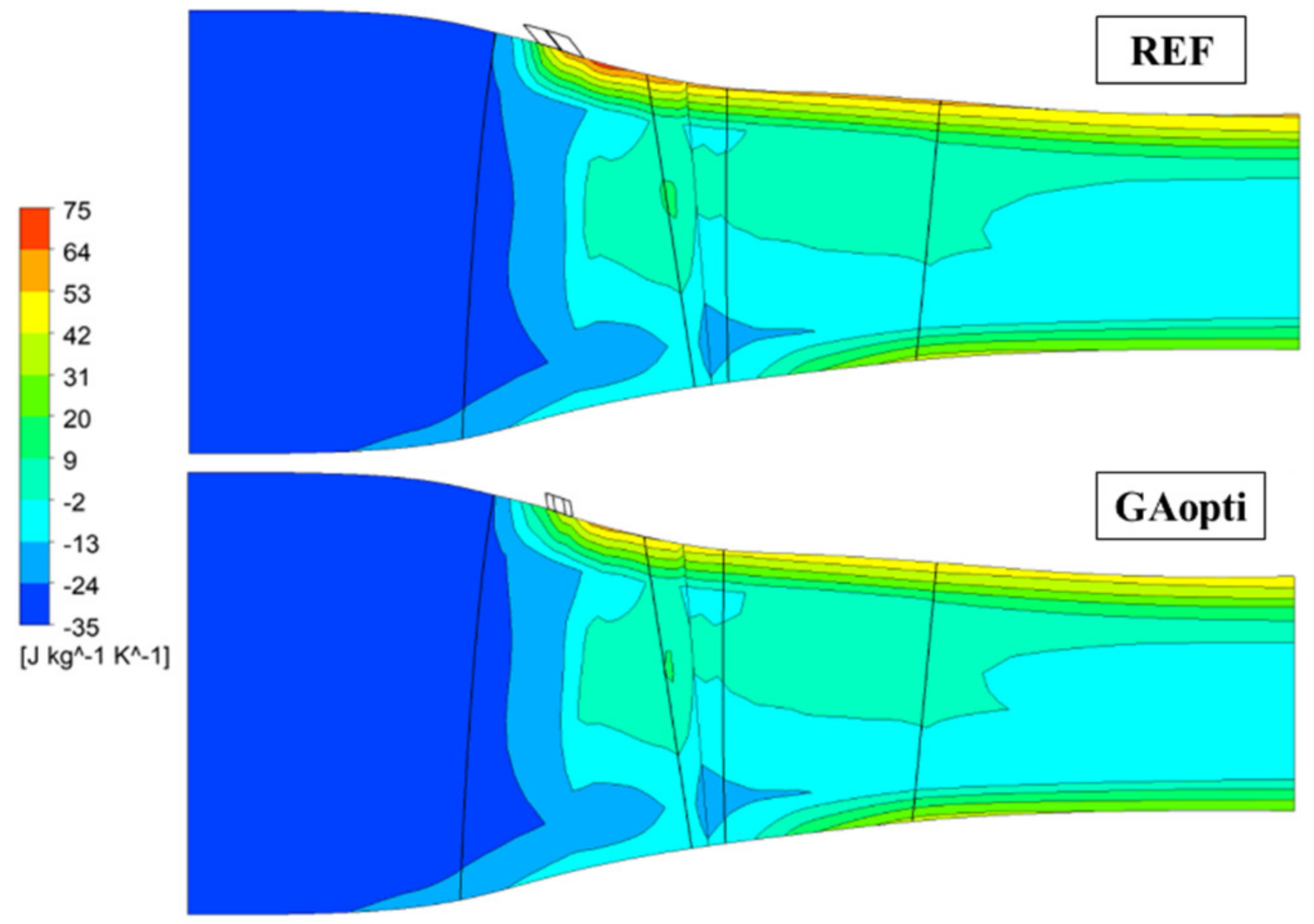

4.3. Optimization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Inoue, M.; Kuroumaru, M. Structure of tip clearance flow in an isolated axial compressor rotor. J. Turbomach. 1989, 111, 250–256. [Google Scholar] [CrossRef]

- Adamczyk, J.J.; Celestina, M.L.; Greitzer, E.M. The role of tip clearance in high-speed fan stall. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 1993; Volume 1. [Google Scholar] [CrossRef]

- Schlechtriem, S.; Lotzerich, M. Breakdown of tip leakage vortices in compressors at flow conditions close to stall. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 1997; Volume 1, pp. 1–8. [Google Scholar] [CrossRef]

- Hofmann, W.; Ballmann, J. Tip clearance vortex development and shock-vortex-interaction in a transonic axial compressor rotor. In Proceedings of the 40th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 14–17 February 2002. [Google Scholar] [CrossRef]

- Wilke, I.; Kau, H.P. A numerical investigation of the flow mechanisms in a high pressure compressor front stage with axial slots. J. Turbomach. 2004, 126, 339–349. [Google Scholar] [CrossRef]

- Schnell, R.; Voges, M.; Mönig, R.; Müller, M.W.; Zscherp, C. Investigation of blade tip interaction with casing treatment in a transonic compressor—Part II: Numerical results. J. Turbomach. 2011, 133, 2011. [Google Scholar] [CrossRef]

- Wilke, I.; Kau, H.P.; Brignole, G. Numerically aided design of a high-efficient casing treatment for a transonic compressor. Part A. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 2005; Volume 6, pp. 353–364. [Google Scholar] [CrossRef]

- Lu, X.; Chu, W.; Zhang, Y.; Zhu, J. Experimental and numerical investigation of a subsonic compressor with bend-skewed slot-casing treatment. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2006, 220, 1785–1796. [Google Scholar] [CrossRef]

- Goinis, G.; Voß, C.; Aulich, M. Automated optimization of an axial-slot type casing treatment for a transonic compressor. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 2013; Volume 6B, pp. 1–13. [Google Scholar] [CrossRef]

- Streit, J.A.; Heinichen, F.; Kau, H.P. Axial-slot casing treatments improve the efficiency of axial flow compressors: Aerodynamic effects of a rotor redesign. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 2013; Volume 6A. [Google Scholar] [CrossRef]

- Ma, N.; Nan, X.; Lin, F. Numerical study on effects of axial-slot casing treatment on peak efficiency of axial compressors. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 2016; Volume 2A-2016, pp. 1–11. [Google Scholar] [CrossRef]

- Inzenhofer, A.; Guinet, C.; Hupfer, A.; Becker, B.; Grothe, P.; Heinichen, F. Difference in the working principle of axial slot and tip blowing casing treatments. In Proceedings of the ASME Turbo Expo; ASME: New York, NY, USA, 2016; Volume 2A-2016. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Wang, E.; Chu, W.; Ding, K.; Yan, S. Effect of inverse blade angle slots on a transonic rotor performance and stability. Aerosp. Sci. Technol. 2020, 96, 105596. [Google Scholar] [CrossRef]

- Samad, A.; Kim, K.Y. Shape optimization of an axial compressor blade by multi-objective genetic algorithm. Proc. Inst. Mech. Eng. Part A J. Power Energy 2008, 222, 599–611. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 2. [Google Scholar] [CrossRef]

- Lucas, J.M. Response surface methodology: Process and product optimization using designed experiments, 3rd edition. J. Qual. Technol. 2010, 42, 228–230. [Google Scholar] [CrossRef]

- Kim, J.-H.; Choi, J.-H.; Kim, K.-Y. Surrogate modeling for optimization of a centrifugal compressor impeller. Int. J. Fluid Mach. Syst. 2010, 3, 29–38. [Google Scholar] [CrossRef]

- MATLAB. The Language of Technical Computing-Release 14; Mathworks: Natick, MA, USA, 2004. [Google Scholar]

- Orr, M.J.L. Introduction to radial basis function networks. Network 1996. Available online: https://www.cc.gatech.edu/~isbell/tutorials/rbf-intro.pdf (accessed on 10 January 2021).

- Deb, K. Multi-Objective Optimisation Using Evolutionary Algorithms: An Introduction BT-Multi-Objective Evolutionary Optimisation for Product Design and Manufacturing; Wang, L., Ng, A.H.C., Deb, K., Eds.; Springer: London, UK, 2011; pp. 3–34. [Google Scholar]

- Kim, J.-H.; Ovgor, B.; Cha, K.H.; Kim, J.H.; Lee, S.; Kim, K.Y. Optimization of the aerodynamic and aeroacoustic performance of an axial-flow fan. AIAA J. 2014, 52, 2032–2044. [Google Scholar] [CrossRef]

- Khalfallah, S.; Ghenaiet, A.; Benini, E.; Bedon, G. Surrogate-based shape optimization of stall margin and efficiency of a centrifugal compressor. J. Propuls. Power 2015, 31, 1607–1620. [Google Scholar] [CrossRef]

- Ma, S.B.; Afzal, A.; Kim, K.Y. Optimization of ring cavity in a centrifugal compressor based on comparative analysis of optimization algorithms. Appl. Therm. Eng. 2018, 138, 633–647. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization and Machine Learning, 1st ed.; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1989. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar] [CrossRef]

- Van Laarhoven, P.J.M.; Aarts, E.H.L. Simulated Annealing BT-Simulated Annealing: Theory and Applications; van Laarhoven, P.J.M., Aarts, E.H.L., Eds.; Springer: Dordrecht, The Netherlands, 1987; pp. 7–15. [Google Scholar]

- Reid, L.; Moore, R.D. Design and Overall Performance of Four Highly Loaded, High Speed Inlet Stages for an Advanced High-Pressure-Ratio Core Compressor; NASA Technical Paper 1337; NASA: Washington, DC, USA, 1978.

- ANSYS. ANSYS CFX-Solver Theory Guide Release 15.0; ANSYS: Canonsburg, PA, USA, 2014. [Google Scholar]

- Dinh, C.T.; Ma, S.B.; Kim, K.Y. Effects of a circumferential feed-back channel on aerodynamic performance of a single-stage transonic axial compressor. Proc. ASME Turbo Expo. 2017, 2A-2017, 57–65. [Google Scholar] [CrossRef]

- Barth, T.; Jespersen, D. The design and application of upwind schemes on unstructured meshes. In Proceedings of the 27th Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1989; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 1989. [Google Scholar]

- Shim, H.-S.; Kim, S.-H.; Kim, K.-Y. Analysis and optimization of staggered partial diffuser vanes in a centrifugal pump. J. Fluids Eng. 2020, 142. [Google Scholar] [CrossRef]

- Chen, H.; Huang, X.; Fu, S. CFD investigation on stall mechanisms and casing treatment of a transonic compressor. In Collection of Technical Papers-AIAA/ASME/SAE/ASEE 42nd Joint Propulsion Conference; ASME: New York, NY, USA, 2006; Volume 6, pp. 4789–4798. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, K.J.; Kim, K.Y. Performance evaluation of a transonic axial compressor with circumferential casing grooves. Proc. Inst. Mech. Eng. Part A J. Power Energy 2012, 226, 218–230. [Google Scholar] [CrossRef]

- Dinh, C.T.; Heo, M.W.; Kim, K.Y. Aerodynamic performance of transonic axial compressor with a casing groove combined with blade tip injection and ejection. Aerosp. Sci. Technol. 2015, 46, 176–187. [Google Scholar] [CrossRef]

- Celik, I.; Karatekin, O. Numerical experiments on application of richardson extrapolation with nonuniform grids. J. Fluids Eng. Trans. ASME 1997, 119, 584–590. [Google Scholar] [CrossRef]

- McKay, M.D.; Beckman, R.J.; Conover, W.J. A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 1979, 21, 239–245. [Google Scholar] [CrossRef]

- Vuong, T.; Kim, K.; Dinh, C. Recirculation-groove coupled casing treatment for a transonic axial compressor. Aerosp. Sci. Technol. 2021, 111, 106556. [Google Scholar] [CrossRef]

| Parameters | LF/CR (%) | D/CR (%) | W/CR (%) | α (°) | β (o) | γ (°) |

|---|---|---|---|---|---|---|

| Values | 40 | 10 | 10 | 8 | 60 | 4 |

| Parameters | Symbols | Values |

|---|---|---|

| Numbers of mesh elements | S1/S2/S3 | 87780/38353/17820 |

| Grid refinement factors | r21/r32 | 1.3/1.3 |

| Stall margins corresponding to S1/S2/S3 | SM1/SM2/SM3 | 11.15/11.16/11.18 |

| Apparent order | p | 0.97 |

| Extrapolated value | 11.14 | |

| Approximated relative error | 0.0897% | |

| Extrapolated relative error | 0.0727% | |

| Grid convergence index | 0.0908% |

| Parameters | Lower Bound | Reference Value | Upper Bound |

|---|---|---|---|

| α (°) | 0 | 8 | 10 |

| β (°) | 45 | 60 | 135 |

| D/CR (%) | 5 | 10 | 15 |

| α (°) | β (°) | Objective Function (SM) | Error (%) | Improvement (%) | |||

|---|---|---|---|---|---|---|---|

| Prediction | RANS | vs. SC | vs. REF | ||||

| SC | - | - | - | 9.95 | - | - | - |

| REF | 8.00 | 60.00 | - | 11.16 | - | 12.14 | - |

| GAopti | 3.58 | 82.22 | 13.52 | 13.64 | 0.86 | 37.05 | 22.19 |

| PRNS | ηpeak | Change (%) | ||

|---|---|---|---|---|

| PRNS | ηpeak | |||

| SC | 2.08203 | 83.85 | - | - |

| REF | 2.08065 | 83.42 | −0.07 | −0.51 |

| GAopti | 2.08023 | 83.68 | −0.09 | −0.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vuong, T.-D.; Kim, K.-Y. Stability Enhancement of a Single-Stage Transonic Axial Compressor Using Inclined Oblique Slots. Energies 2021, 14, 2346. https://doi.org/10.3390/en14092346

Vuong T-D, Kim K-Y. Stability Enhancement of a Single-Stage Transonic Axial Compressor Using Inclined Oblique Slots. Energies. 2021; 14(9):2346. https://doi.org/10.3390/en14092346

Chicago/Turabian StyleVuong, Tien-Dung, and Kwang-Yong Kim. 2021. "Stability Enhancement of a Single-Stage Transonic Axial Compressor Using Inclined Oblique Slots" Energies 14, no. 9: 2346. https://doi.org/10.3390/en14092346

APA StyleVuong, T.-D., & Kim, K.-Y. (2021). Stability Enhancement of a Single-Stage Transonic Axial Compressor Using Inclined Oblique Slots. Energies, 14(9), 2346. https://doi.org/10.3390/en14092346