A Novel Optimal Charging Algorithm for Lithium-Ion Batteries Based on Model Predictive Control

Abstract

1. Introduction

2. Descriptions of the Proposed MPC Strategy

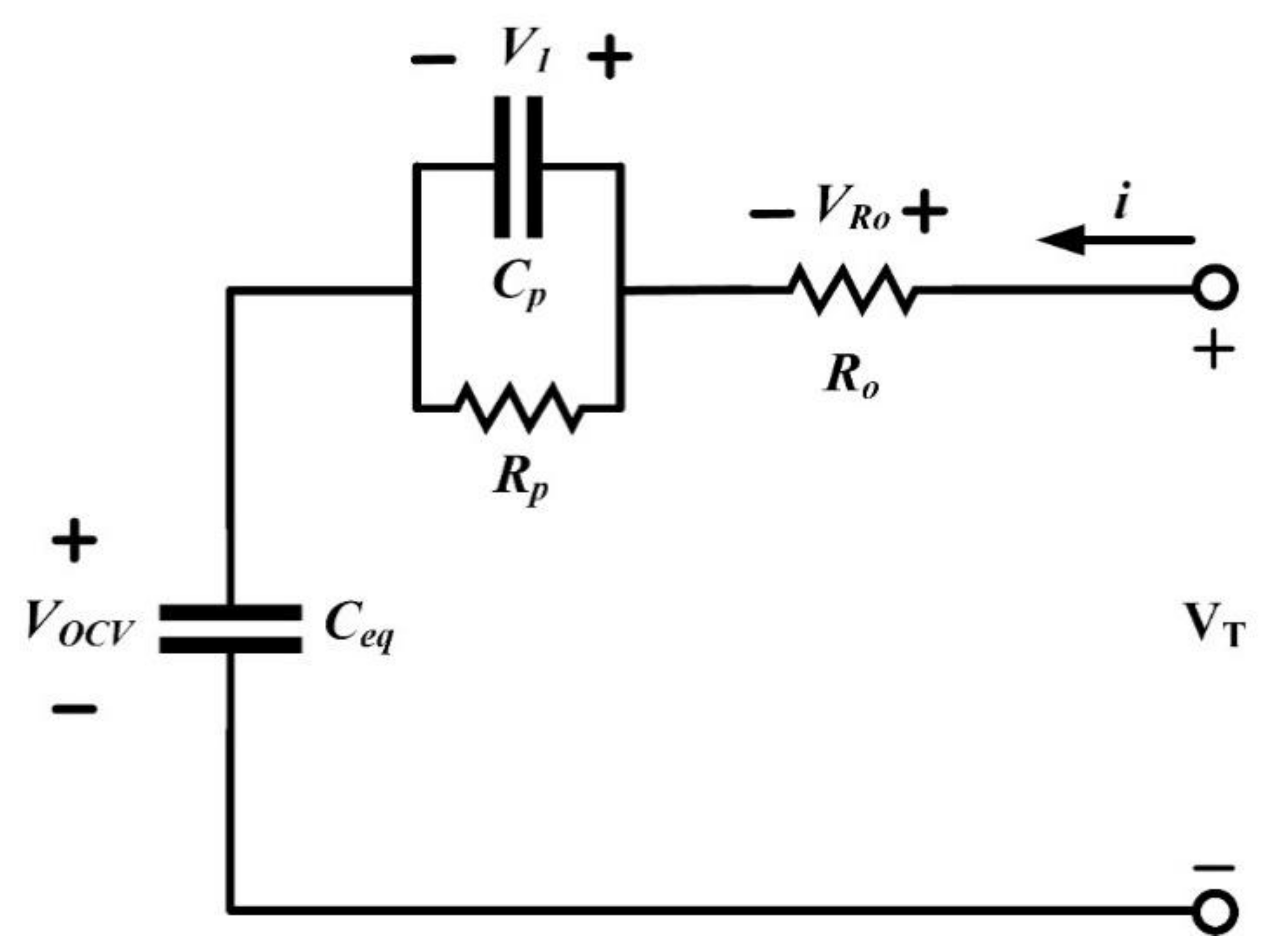

2.1. Battery Modeling

2.2. State-Space Representation of Li-Ion Battery Equivalent Circuit Model

2.3. Cost Function of the Proposed MPC

2.4. Derivation of the Proposed MPC Charging Algorithm

2.5. Constraints

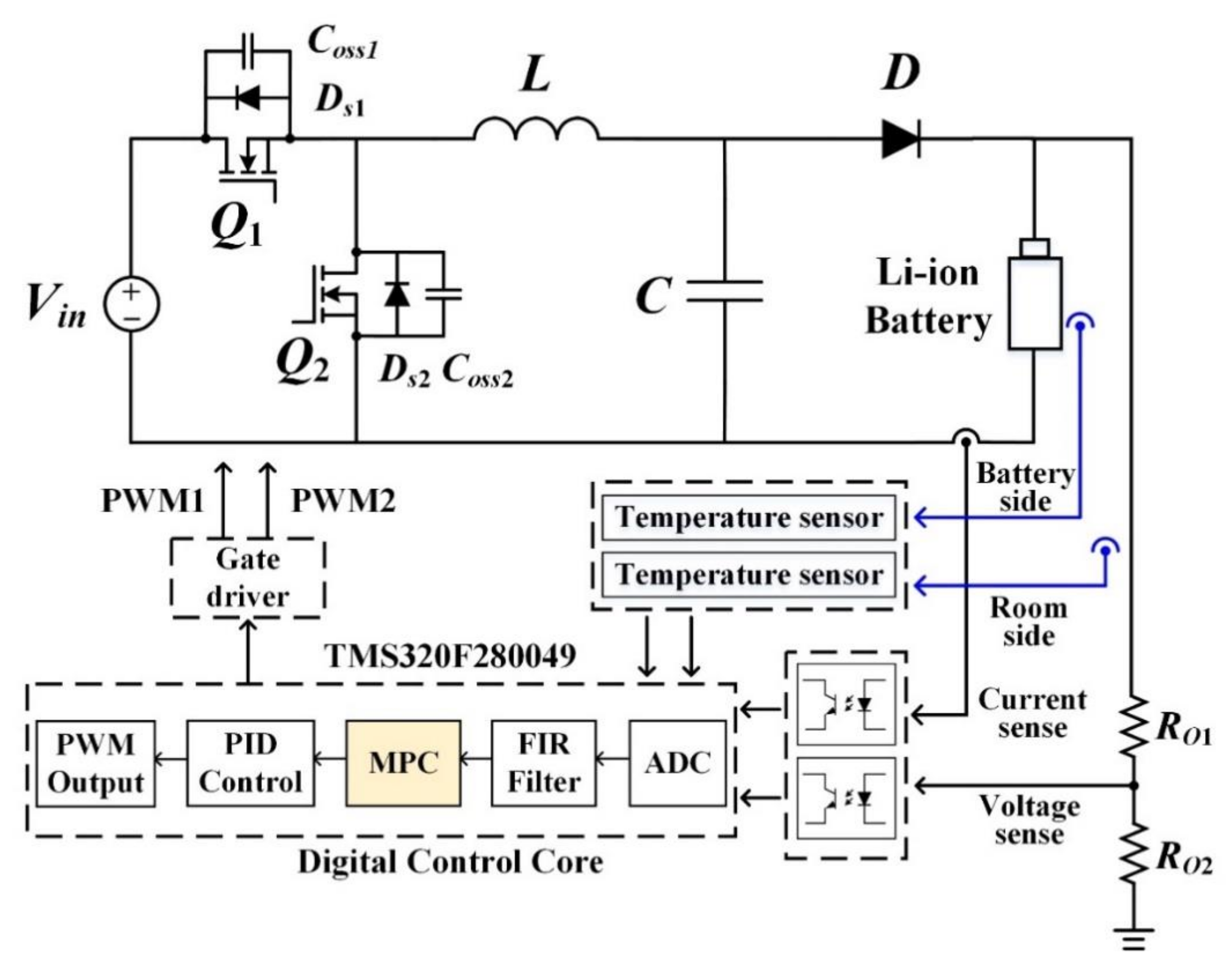

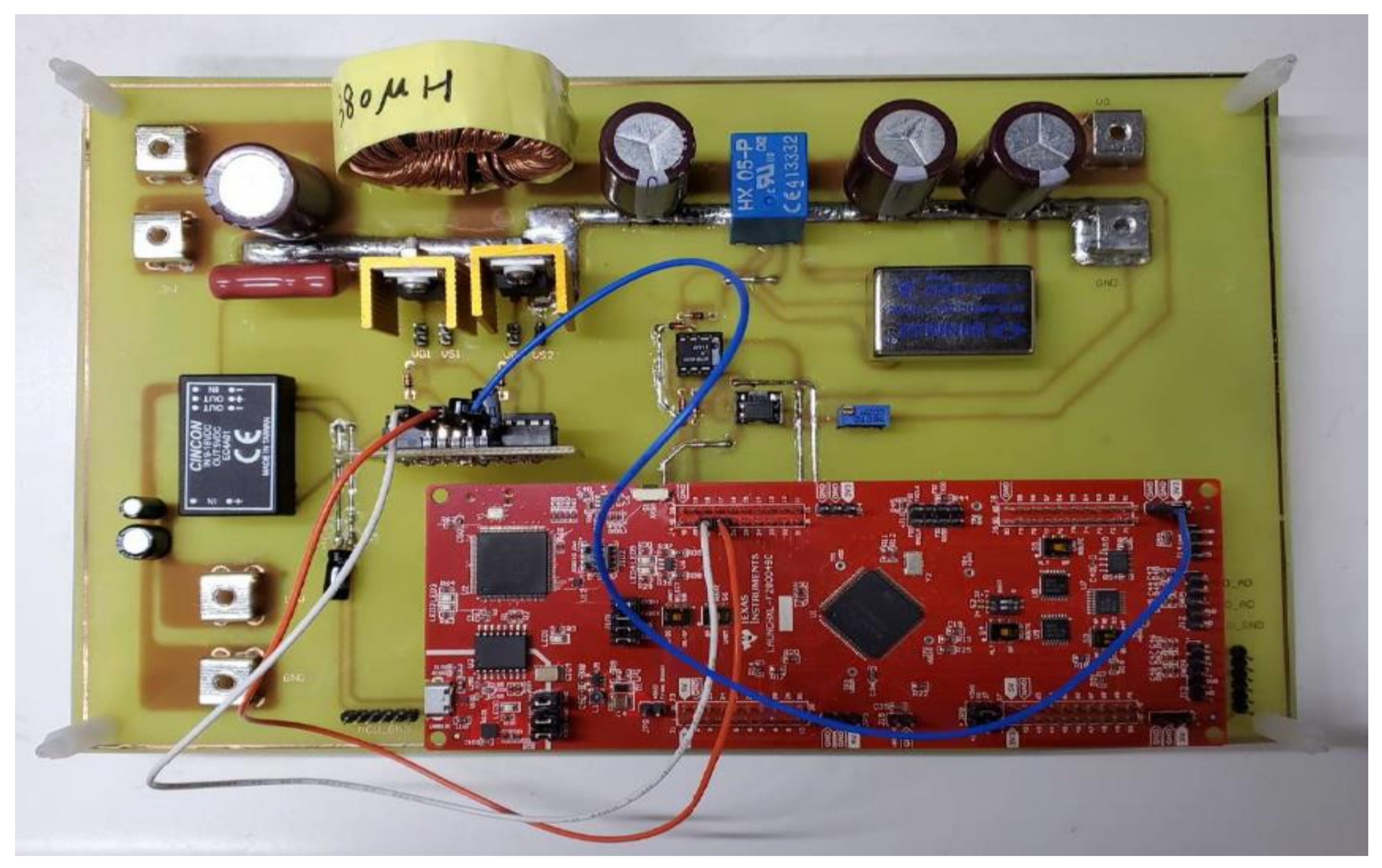

3. Realization of the Proposed MPC Charger

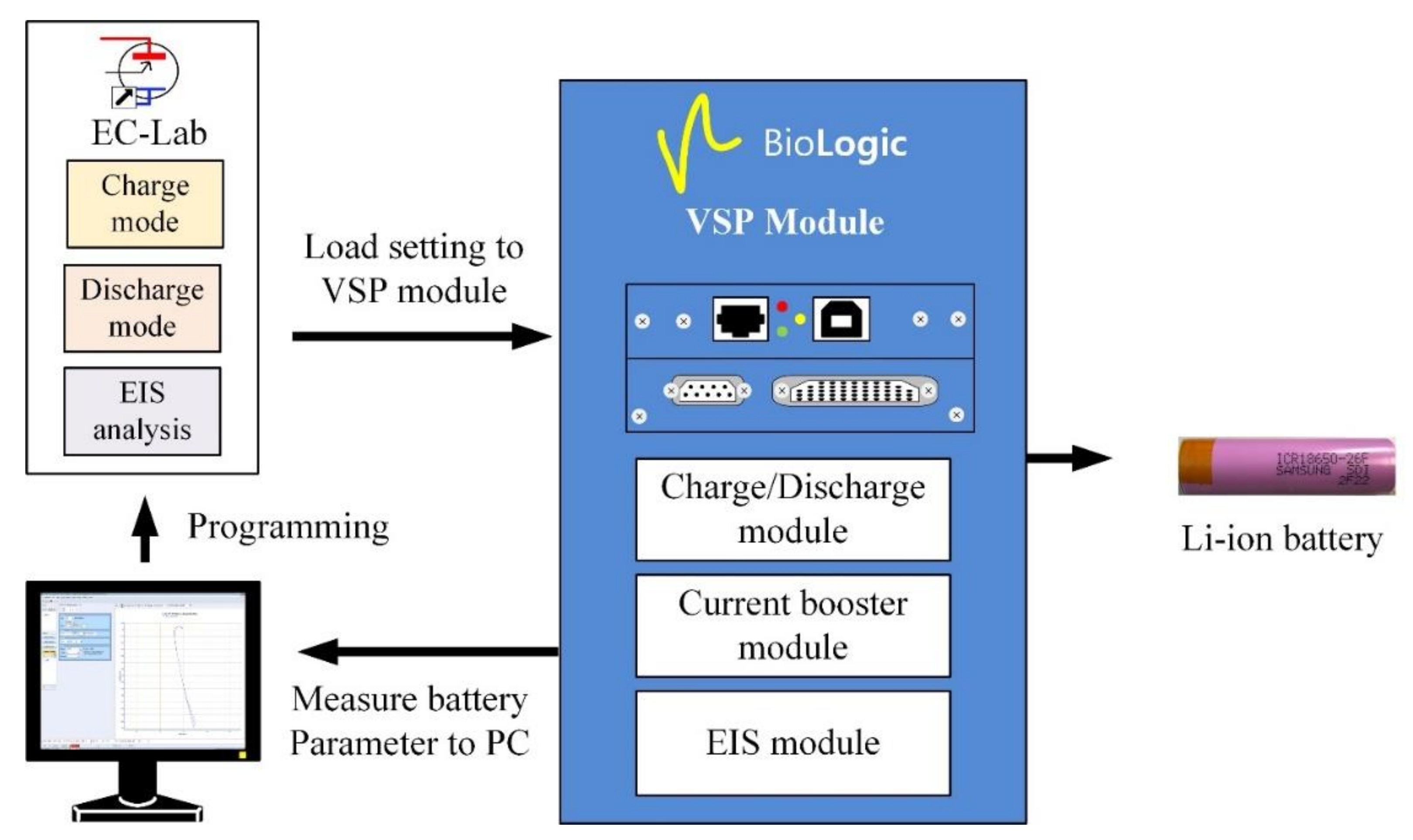

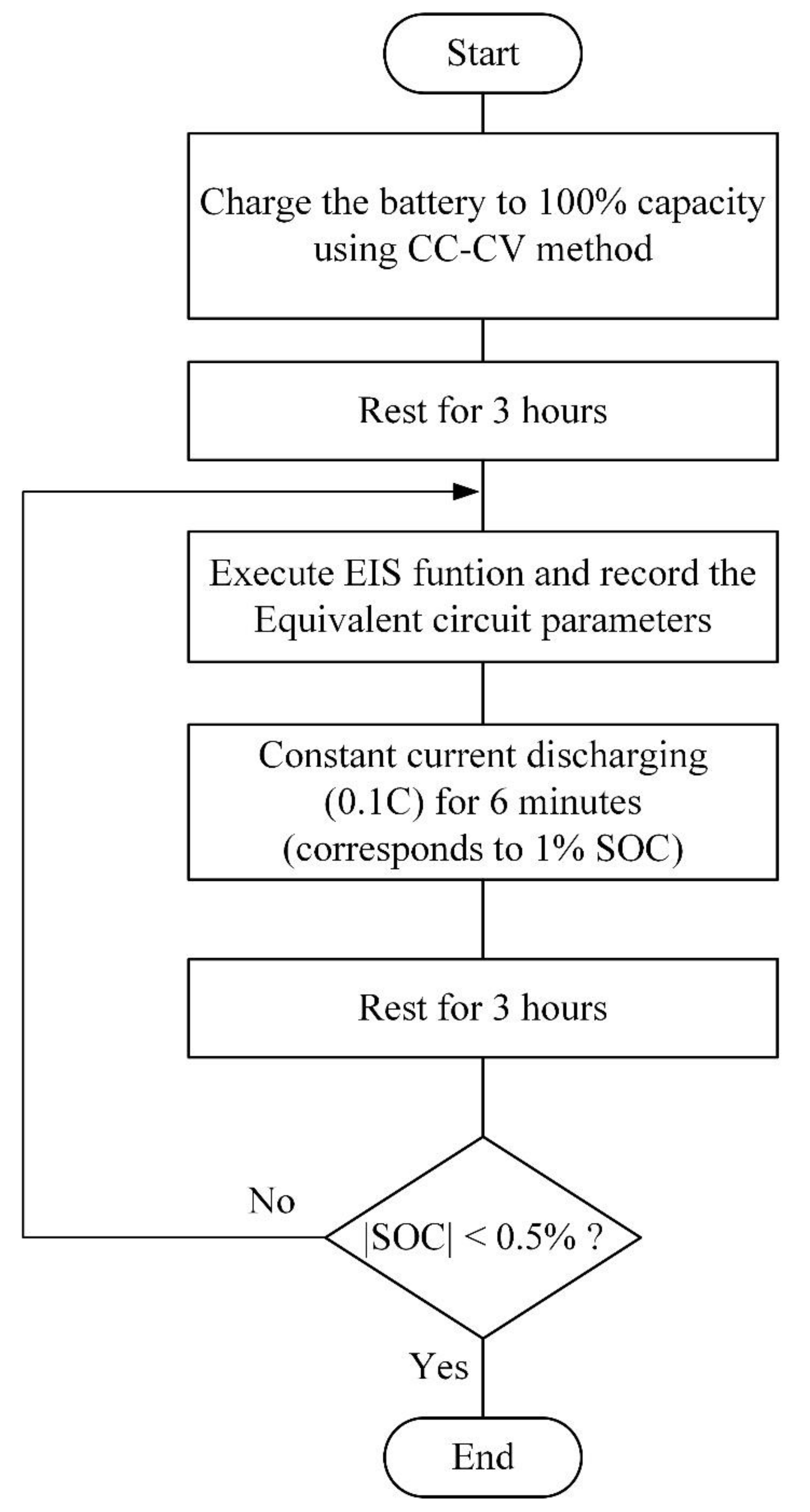

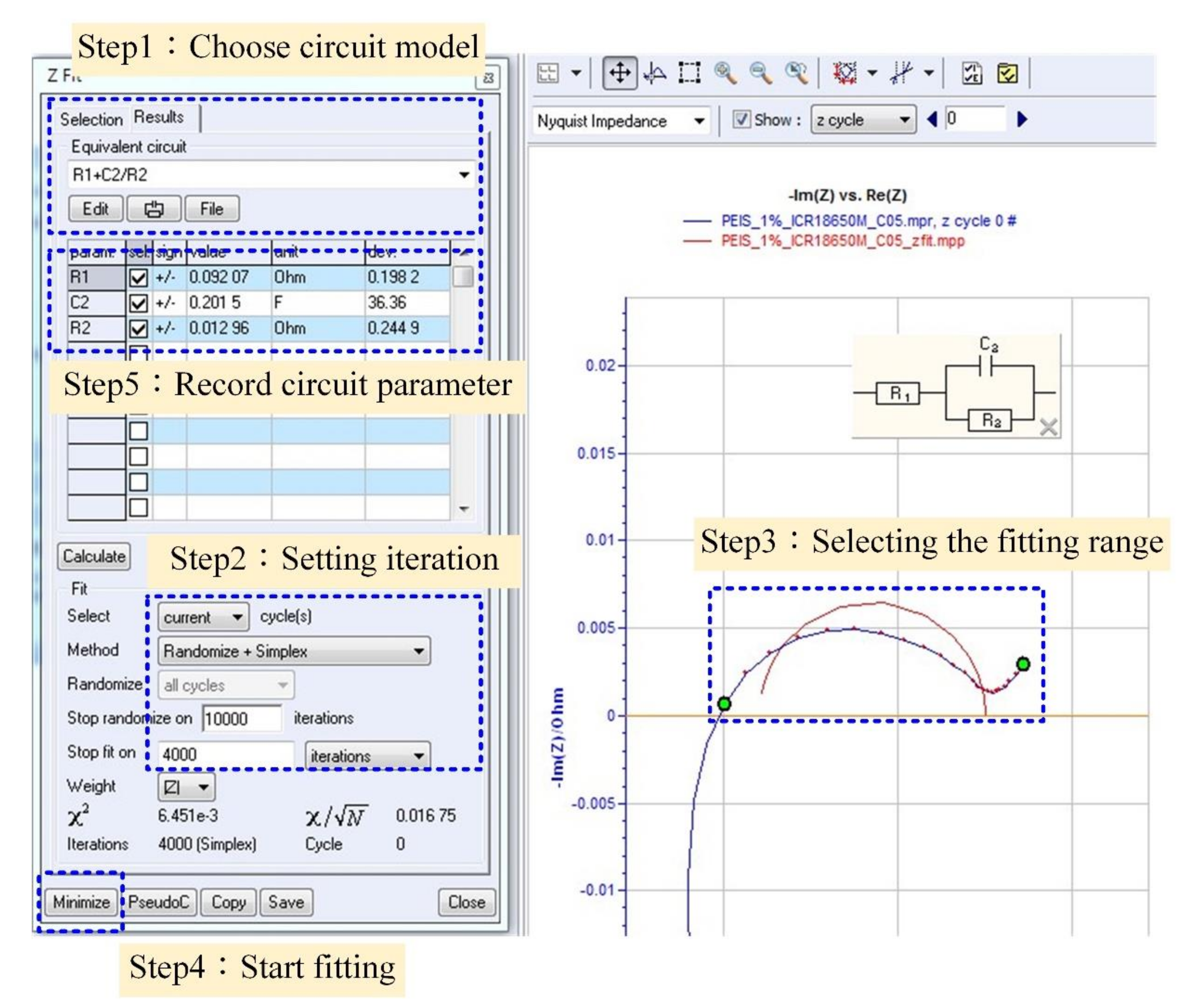

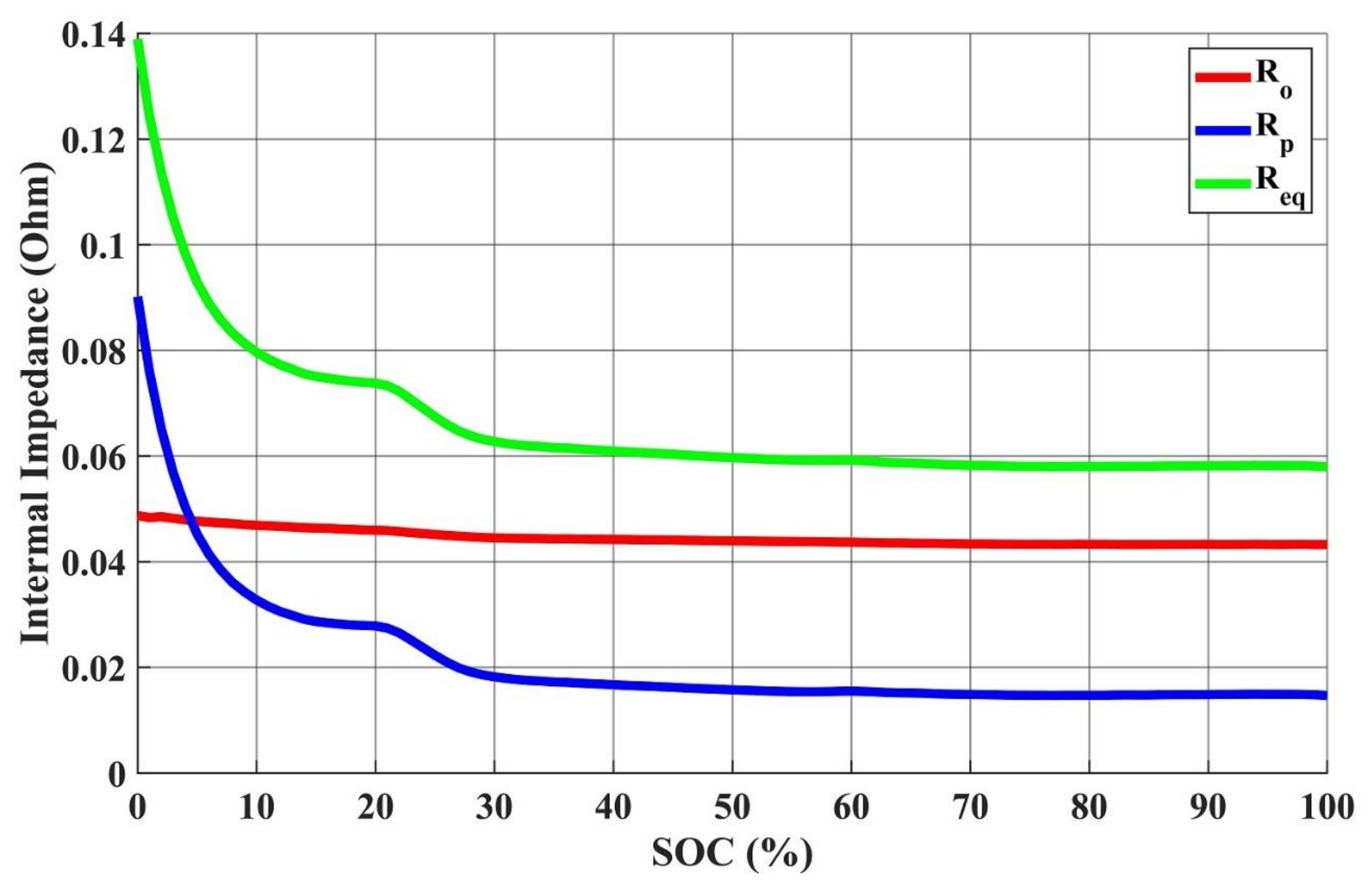

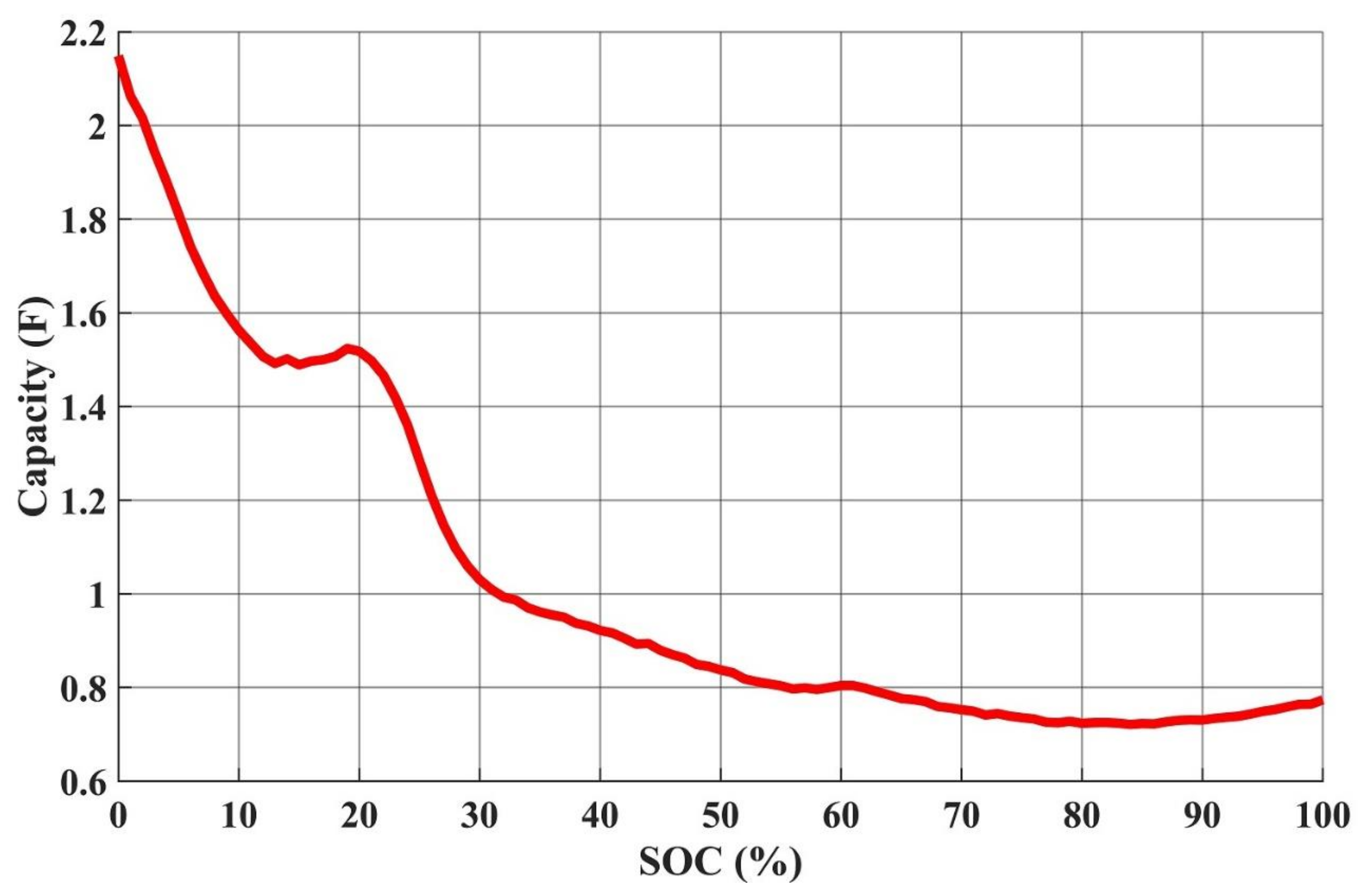

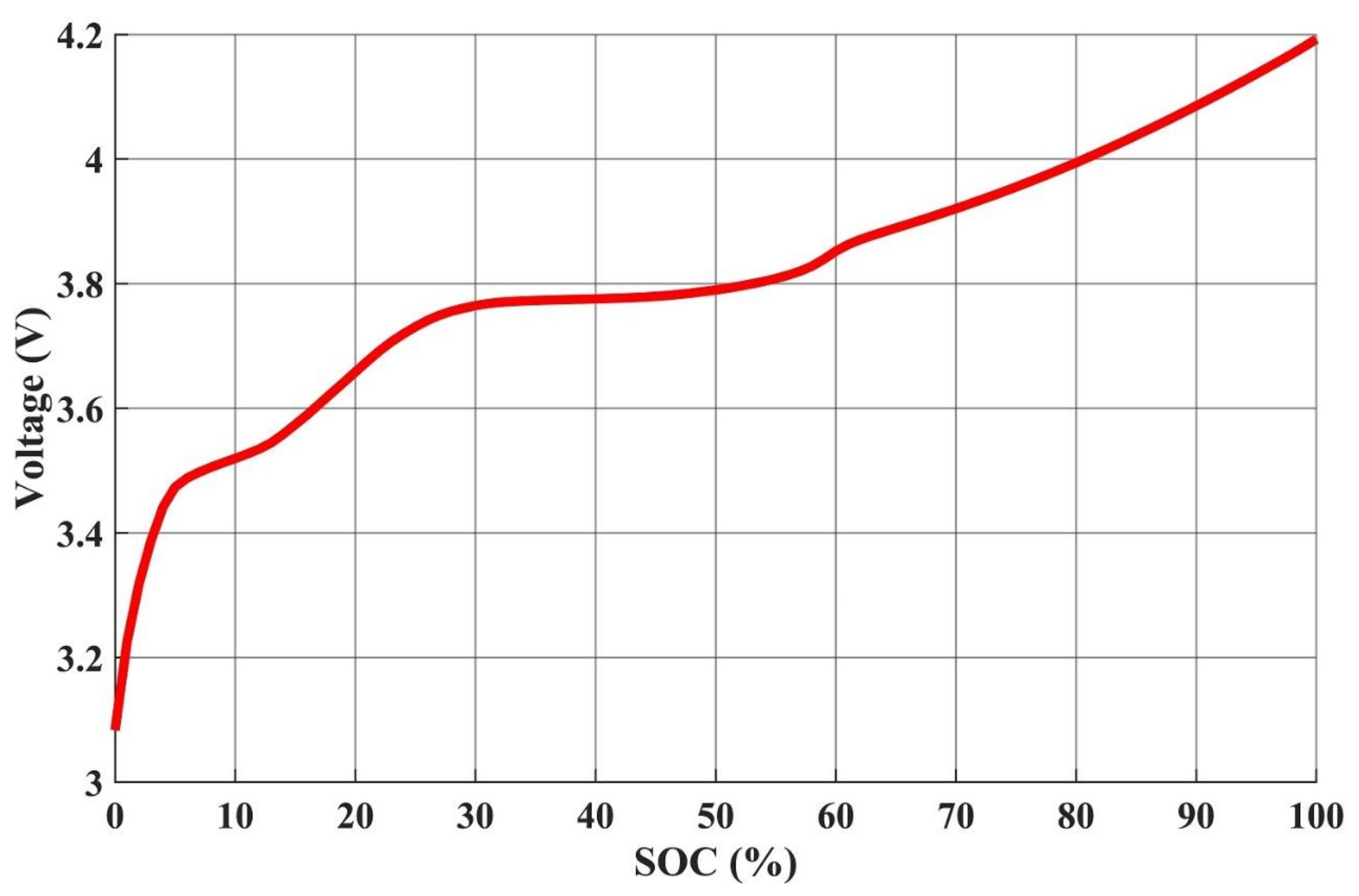

3.1. Identification of Parameters of the Utilized Li-Ion Battery

3.2. The Proposed MPC Charger

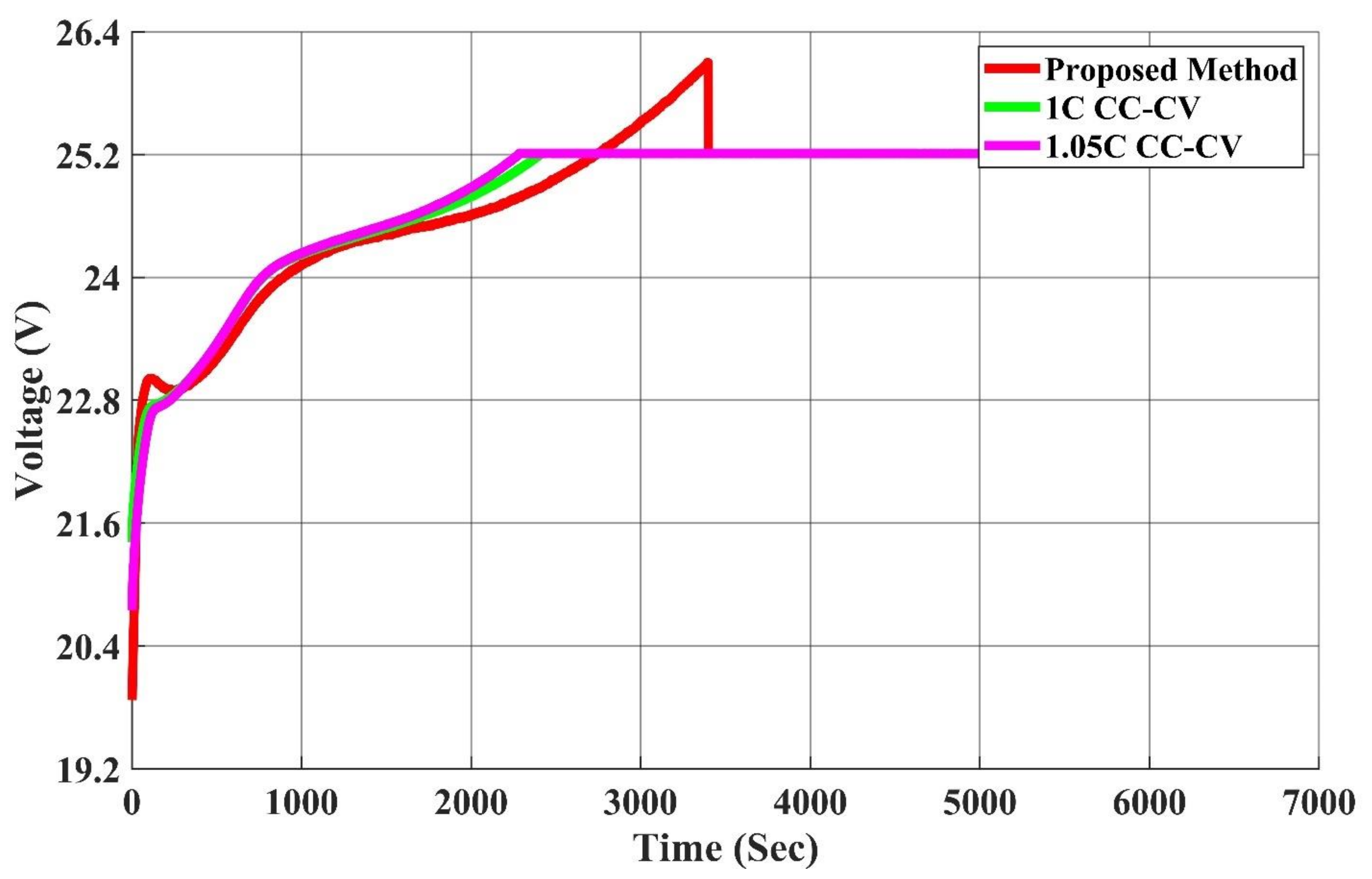

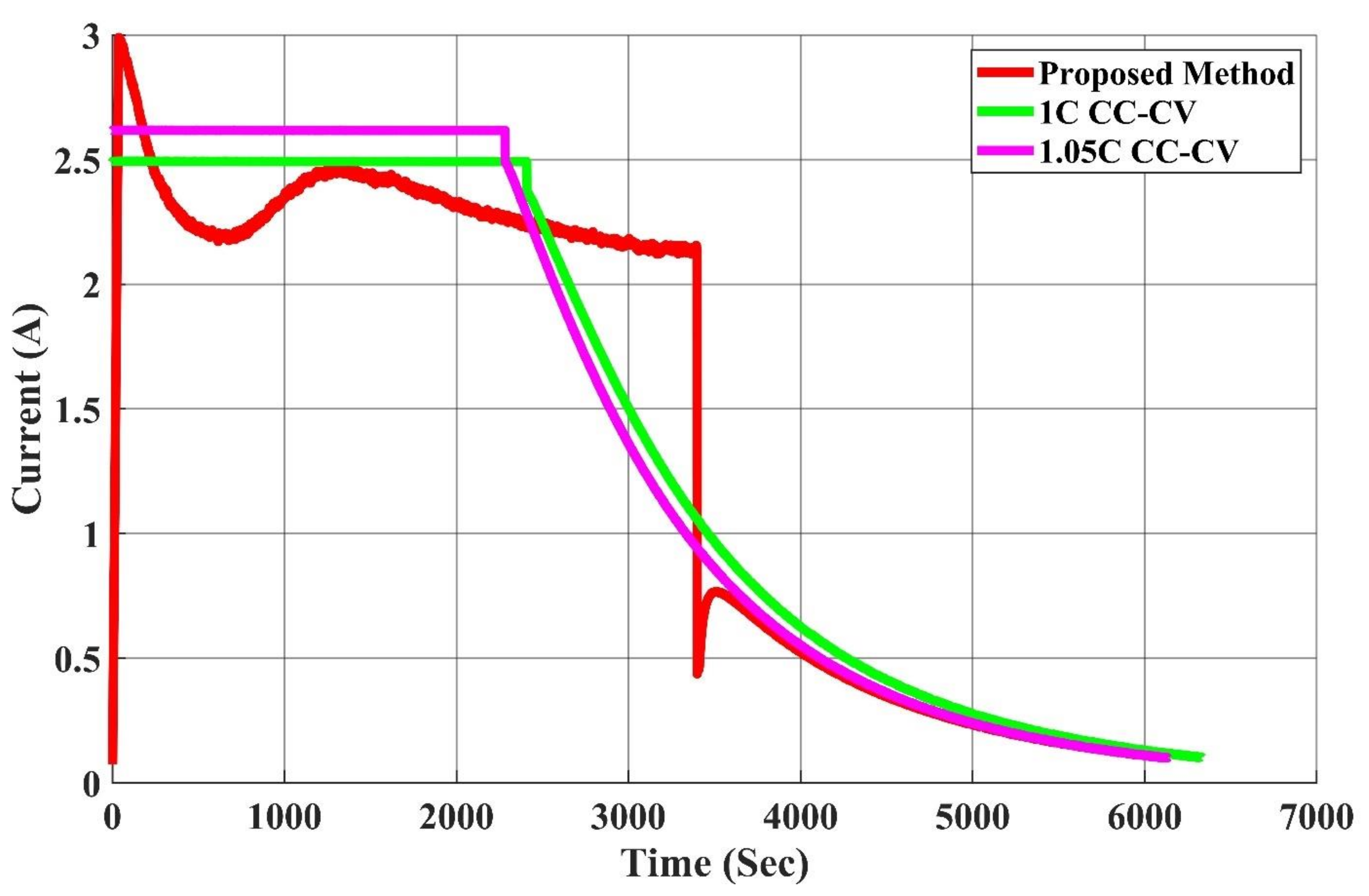

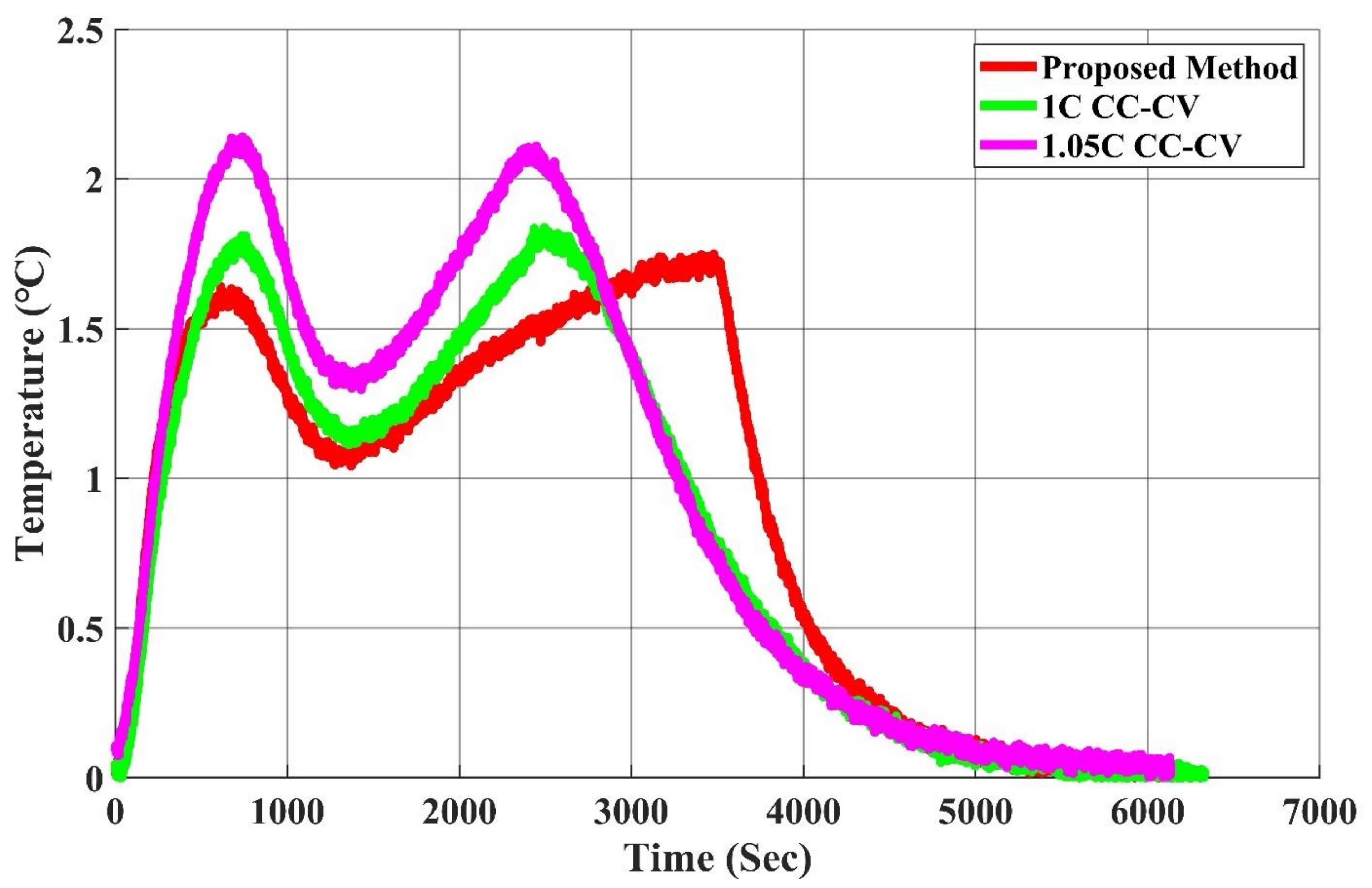

4. Experimental Results

5. Conclusions

- The optimal charging current can be calculated by the model predictive control, thereby achieving the optimal effect.

- Compared with the conventional CC-CV charging method, the model predictive charging method can effectively improve the charging temperature rise, charging speed, and charging efficiency.

- In comparison with the MPC method proposed in the literature, the model and constraint used in the proposed method are much more straightforward; thus, it is suitable for being realized by a low-cost MCU.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guan-Chyun, H.; Liang-Rui, C. Fuzzy controlled Lithium-Ion Battery Charge System with Active State of Charge Controller. Trans. Ind. Electron. 2001, 48, 585–593. [Google Scholar] [CrossRef]

- Tsang, K.M.; Chan, W.L. Current sensorless quick charger for lithiumion batteries. Energy Convers. Manag. 2011, 52, 1593–1595. [Google Scholar] [CrossRef]

- Chen, L.-R. PLL-Based Battery Charge Circuit Topology. IEEE Trans. Ind. Electron. 2004, 51, 1344–1346. [Google Scholar] [CrossRef]

- Chen, L.-R.; Chen, J.-J.; Chu, N.-Y.; Han, G.-Y. Current-Pumped Battery Charger. IEEE Trans. Ind. Electron. 2008, 55, 2482–2488. [Google Scholar] [CrossRef]

- Wang, S.-C.; Chen, G.-J.; Liu, Y.-H. Adaptive Charging Strategy With Temperature Rise Mitigation and Cycle Life Extension for Li-ion Batteries. CPSS Trans. Power Electron. Appl. 2018, 3, 202–212. [Google Scholar] [CrossRef]

- Chen, L.-R. A Design of an Optimal Battery Pulse Charge System by Frequency-Varied Technique. IEEE Trans. Ind. Electron. 2007, 54, 398–405. [Google Scholar] [CrossRef]

- Liang-Rui, C. A design of duty-varied voltage pulse charger for improving lithium-ion battery-charging response. Trans. Ind. Electron. 2009, 56, 480–487. [Google Scholar] [CrossRef]

- De Jongh, P.E.; Notten, P.H.L. Effect of current pulses on lithium intercalation batteries. Solid State Ion. 2002, 148, 259–268. [Google Scholar] [CrossRef]

- Li, J.; Murphy, E.; Winnick, J.; Kohl, P.A. The effects of pulse charging on cycling characteristics of commercial lithium-ion batteries. J. Power Sources 2001, 102, 302–309. [Google Scholar] [CrossRef]

- Isuru, N.S.M.; Siriroj, S. An Adaptive Pulse Charging Algorithm for Lithium Batteries. In Proceedings of the 14th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (EC-TI-CON), Phuket, Thailand, 27–30 June 2017; pp. 218–221. [Google Scholar]

- Huazhen, F.; Christopher, D.; Vadim, L. Optimal pulse-modulated Lithium-ion battery charging Algorithms. J. Energy Storage 2018, 15, 359–367. [Google Scholar]

- Yi-Hwa, L.; Ching-Hsing, H.; Yi-Feng, L. Search for an optimal rapid charging pattern for Li-ion batteries using consecutive orthogonal arrays. IEEE Trans. Energy Convers. 2011, 26, 654–661. [Google Scholar]

- Thanh, T.V.; Xiaopeng, C.; Weixiang, S.; Ajay, K.; Joe-Air, J. New charging strategy for lithium-ion bat-teries based on the integration of taguchi method and state of charge estimation. J. Power Sources 2015, 273, 413–422. [Google Scholar]

- Liu, Y.-H.; Luo, Y.-F. Search for an optimal rapid-charging pattern for li-ion batteries using the taguchi approach. IEEE Trans. Ind. Electron. 2010, 57, 3963–3971. [Google Scholar] [CrossRef]

- Wang, S.-C.; Liu, Y.-H. A PSO-Based Fuzzy-controlled searching for the optimal charge pattern of li-ion batteries. IEEE Trans. Ind. Electron. 2015, 62, 2983–2993. [Google Scholar] [CrossRef]

- Yi-Hwa, L.; Jen-Hao, T.; Yu-Chung, L. Search for an optimal rapid charging pattern for Li-ion batteries using ant colony system algorithm. IEEE Trans. Ind. Electron. 2005, 52, 1328–1336. [Google Scholar]

- Lee, C.-H.; Chen, M.-Y.; Hsu, S.-H.; Jiang, J.-A. Implementation of an SOC-based four-stage constant current charger for Li-ion batteries. J. Energy Storage 2018, 18, 528–537. [Google Scholar] [CrossRef]

- Lee, C.-H.; Chang, T.-W.; Hsu, S.-H.; Jiang, J.-A. Taguchi-based PSO for searching an optimal four-stage charge pattern of Li-ion batteries. J. Energy Storage 2019, 21, 301–309. [Google Scholar] [CrossRef]

- Khan, A.B.; Choi, W. Optimal Charge Pattern for the High-Performance Multistage Constant Current Charge Method for the Li-Ion Batteries. IEEE Trans. Energy Convers. 2018, 33, 1132–1140. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Cotorruelo, A.; Limon, D.; Garone, E. Constrained Control of Linear Systems Subject to Combinations of Intersections and Unions of Concave Constraints. IEEE Control. Syst. Lett. 2019, 3, 571–576. [Google Scholar] [CrossRef]

- Dan, H.; Yamauchi, J.; Hatanaka, T.; Fujita, M. Control Barrier Function-Based Persistent Coverage with Performance Guarantee and Application to Object Search Scenario. 2020 IEEE Conf. Control. Technol. Appl. (Ccta) 2020, 640–647. [Google Scholar] [CrossRef]

- Yan, J.; Xu, G.; Qian, H.; Xu, Y.; Song, Z. Model predictive control-based fast charging for vehicular batteries. Energies 2011, 4, 1178–1196. [Google Scholar] [CrossRef]

- Xavier, M.A.; Trimboli, M.S. Lithium-ion battery cell-level control using constrained model predictive control and equivalent circuit models. J. Power Sources 2015, 285, 374–384. [Google Scholar] [CrossRef]

- Torchio, M.; Magni, L.; Braatz, R.; Raimondo, D. Optimal Health-aware Charging Protocol for Lithium-ion Batteries: A Fast Model Predictive Control Approach. IFAC-Pap. 2016, 49, 827–832. [Google Scholar] [CrossRef]

- Kujundžić, G.; Ileš, Š.; Matuško, J.; Vašak, M. Optimal charging of valve-regulated lead-acid batteries based on model predictive control. Appl. Energy 2017, 187, 189–202. [Google Scholar] [CrossRef]

- Goran, K.; Šandor, I.; Jadranko, M.; Mario, V. Electrothermal dynamics-conscious lithium-ion battery cell-level charging management via state-monitored predictive control. Energy 2017, 141, 250–259. [Google Scholar]

- Zou, C.; Manzie, C.; Nesic, D. Model predictive control for lithium-ion battery optimal charging. IEEE/ASME Trans. Mechatron. 2018, 23, 947–957. [Google Scholar] [CrossRef]

- Resmi, S.; Raghunathan, R. Modeling and contorl of battery systems. PartII: A model predictive controller for optimal charging. Comput. Chem. Eng. 2018, 119, 326–335. [Google Scholar]

- Pozzi, A.; Torchio, M.; Braatz, R.D.; Raimondo, D.M. Optimal charging of an electric vehicle battery pack: A real-time sensitivity-based model predictive control approach. J. Power Sources 2020, 461, 228133. [Google Scholar] [CrossRef]

- Yin, Y.; Choe, S.-Y. Actively temperature controlled health-aware fast charging method for lithium-ion battery using nonlinear model predictive control. Appl. Energy 2020, 271, 115232. [Google Scholar] [CrossRef]

- Bor, Y.L.; Ganesan, N.; Rudolph, G.J.; Daniel, H.D. Modeling of lithium ion cells—A simple equivalent-circuit model approach. Solid State Ionics 2004, 175, 835–839. [Google Scholar]

- Dubarry, M.; Vuillaume, N.; Liaw, B.Y. From single cell model to battery pack simulation for Li-ion batteries. J. Power Sources 2009, 186, 500–507. [Google Scholar] [CrossRef]

- Chiang, Y.-H.; Sean, W.-Y.; Ke, J.-C. Online estimation of internal resistance and open-circuit voltage of lithium-ion batteries in electric vehicles. J. Power Sources 2011, 196, 3921–3932. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Liuping, W. Model Predictive Control System Design and Implementation Using MATLAB®; Springer: Berlin, Germany, 2009. [Google Scholar]

- Sanyo. UR18650ZY Datasheet. Available online: https://www.rowa.co.jp/data/img/UR18650ZY.pdf (accessed on 19 March 2021).

| Ref. | Utilized Model | Optimization Method | Realization Platform | Experimentally Validated? |

|---|---|---|---|---|

| [22] | ECM and thermal model based on neural network | Genetic algorithm | PC | Yes |

| [23] | ECM (1RC model) | Solve pseudo minimum-time problem | PC | No |

| [24] | Linearized P2D model | Solve quadratic program | PC/MATLAB | No |

| [25] | Hybrid electrical (2RC) and temperature model | Solve quadratically constrained quadratic program | PC/MATLAB | Yes |

| [26] | Electrical-thermal model and AEKF for SOC estimation | Minimize the difference between SOC and optimal SOC trajectory | PC/MATLAB | No |

| [27] | Reduced-order PDE model | Minimize the difference between SOC/SOH and optimal SOC/SOH trajectory | PC/MATLAB | No |

| [28] | Simple lumped PDE model | Solve quadratic program | PC/MATLAB | No |

| [29] | Single-particle model (PDE) | Solve sensitivity-based MPC quadratic program | PC/MATLAB | No |

| [30] | Reduced-order electrochemical life model | Two offline optimizations and one online optimization | PC/MATLAB | No |

| SANYO UR18650ZY Lithium-Ion Battery | |

|---|---|

| Rated Capacity | 2600 mAh |

| Minimum Rated Capacity | 2500 mAh |

| Rated Voltage | 3.7 V |

| Cutoff Voltage | 3 V |

| Specification | 18.4 mm—diameter, 65 mm—height |

| Standard Charging Condition | CC-CV, 1250 mA, 4.2 V |

| Weight | 43.5 g |

| Charging Temperature | 0~40 °C |

| Discharging Temperature | −20~60 °C |

| a | b | c | d | e | |

|---|---|---|---|---|---|

| OCV | −482.5 | 6886 | −3.659 × 104 | 8.592 × 104 | −7.526 × 104 |

| RO | 9.695 × 10−11 | −2.908 × 10−8 | 3.528 × 10−6 | −0.0002139 | 0.04876 |

| RP | 5.61 × 10−9 | −1.35 × 10−6 | 0.0001153 | −0.004163 | 0.07031 |

| CP | −1.988 × 10−9 | −1.392 × 10−6 | 0.0004701 | −0.04417 | 2.056 |

| Input voltage (Vin) | 72 V |

| Output voltage (Vout) | 25.2 V |

| Output power (Pout) | 100 W |

| Efficiency (η) | >90% |

| Switching frequency (fs) | 100k Hz |

| Output voltage ripple (ΔVo/Vo) | <1% |

| Output current ripple (ΔIo/Io) | <10% |

| Ts | NP | NC | rw | WT | Imax |

|---|---|---|---|---|---|

| 1 s | 10 | 4 | 1 | 0.5 | 3 A |

| MPC | 1 C CC-CV | 1.05 C CC-CV | |

|---|---|---|---|

| Average Temperature Rise * (°C) | 1.30 | 1.31 | 1.53 |

| Maximum Temperature Rise * (°C) | 1.74 | 1.81 | 2.14 |

| Charging Time (Sec) | 6126 | 6332 | 6134 |

| Efficiency (%) | 99.62 | 99.65 | 99.59% |

| 1 C CC-CV | 1.05 C CC-CV | |

|---|---|---|

| Average Temperature Rise (%) | 0.76% | 15.03% |

| Maximum Temperature Rise (%) | 3.87% | 18.69% |

| Charging Time (%) | 3.25% | 0.13% |

| Ref | Complexity of MPC Solver | Model Complexity | Computation Time | Additional Requirement | Hardware Realization | Performance |

|---|---|---|---|---|---|---|

| proposed method | Low | Low | Fast | - | Yes | Suboptimal |

| [22] | Medium | Medium | Medium | GA, NN | No | Optimal |

| [24] | Low | High | Medium | - | No | Optimal |

| [26] | High | Medium | Slow | Extended Kalman Filter | No | Optimal |

| [29] | Medium | High | Slow | - | No | Optimal |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.-J.; Liu, Y.-H.; Cheng, Y.-S.; Pai, H.-Y. A Novel Optimal Charging Algorithm for Lithium-Ion Batteries Based on Model Predictive Control. Energies 2021, 14, 2238. https://doi.org/10.3390/en14082238

Chen G-J, Liu Y-H, Cheng Y-S, Pai H-Y. A Novel Optimal Charging Algorithm for Lithium-Ion Batteries Based on Model Predictive Control. Energies. 2021; 14(8):2238. https://doi.org/10.3390/en14082238

Chicago/Turabian StyleChen, Guan-Jhu, Yi-Hua Liu, Yu-Shan Cheng, and Hung-Yu Pai. 2021. "A Novel Optimal Charging Algorithm for Lithium-Ion Batteries Based on Model Predictive Control" Energies 14, no. 8: 2238. https://doi.org/10.3390/en14082238

APA StyleChen, G.-J., Liu, Y.-H., Cheng, Y.-S., & Pai, H.-Y. (2021). A Novel Optimal Charging Algorithm for Lithium-Ion Batteries Based on Model Predictive Control. Energies, 14(8), 2238. https://doi.org/10.3390/en14082238