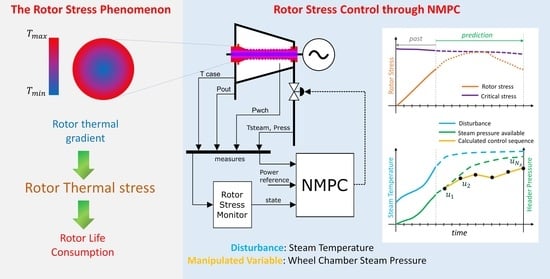

Steam Turbine Rotor Stress Control through Nonlinear Model Predictive Control

Abstract

:1. Introduction

2. Steam Turbine Modelling Approach and Rotor Stress Monitoring

- The state of the generator breaker that connects the electric generator to the network;

- The state of the ST startup;

- The rotor speed;

- The inlet, outlet, and wheel chamber pressures;

- The temperature of the steam in the inlet;

- The ST casing temperature;

- Some parameters describing the dependence of the rotor temperature on material properties, limits on pressures, temperatures, speeds, and coefficients to calibrate stress values.

- Calculation of rotor temperature;

- Calculation of rotor thermal stress;

- Derivation of boundary conditions for the thermal model.

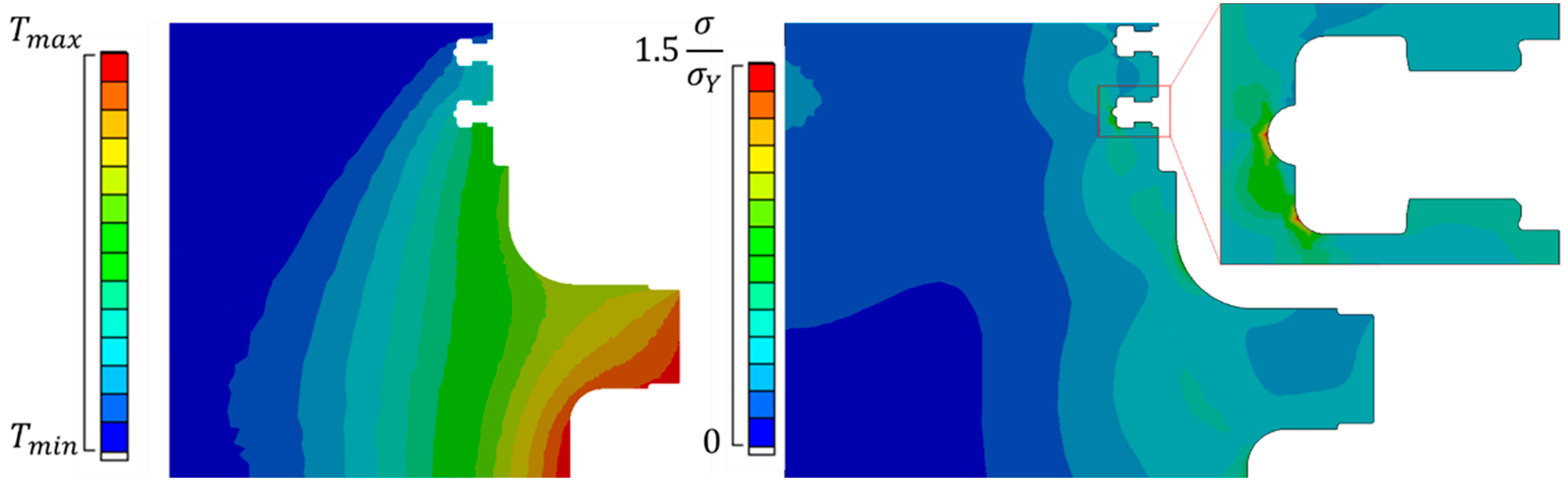

2.1. Thermal Model

- The main assumption is that the rotor geometry can be described by an infinitely extended cylinder excluding the dependency from the axial coordinate;

- Local variations of material properties are taken into account leading to a non-linear heat transfer equation with a non-homogeneous material;

- Since HTC and are time-dependent the model is suitable to complex heat transient scenarios.

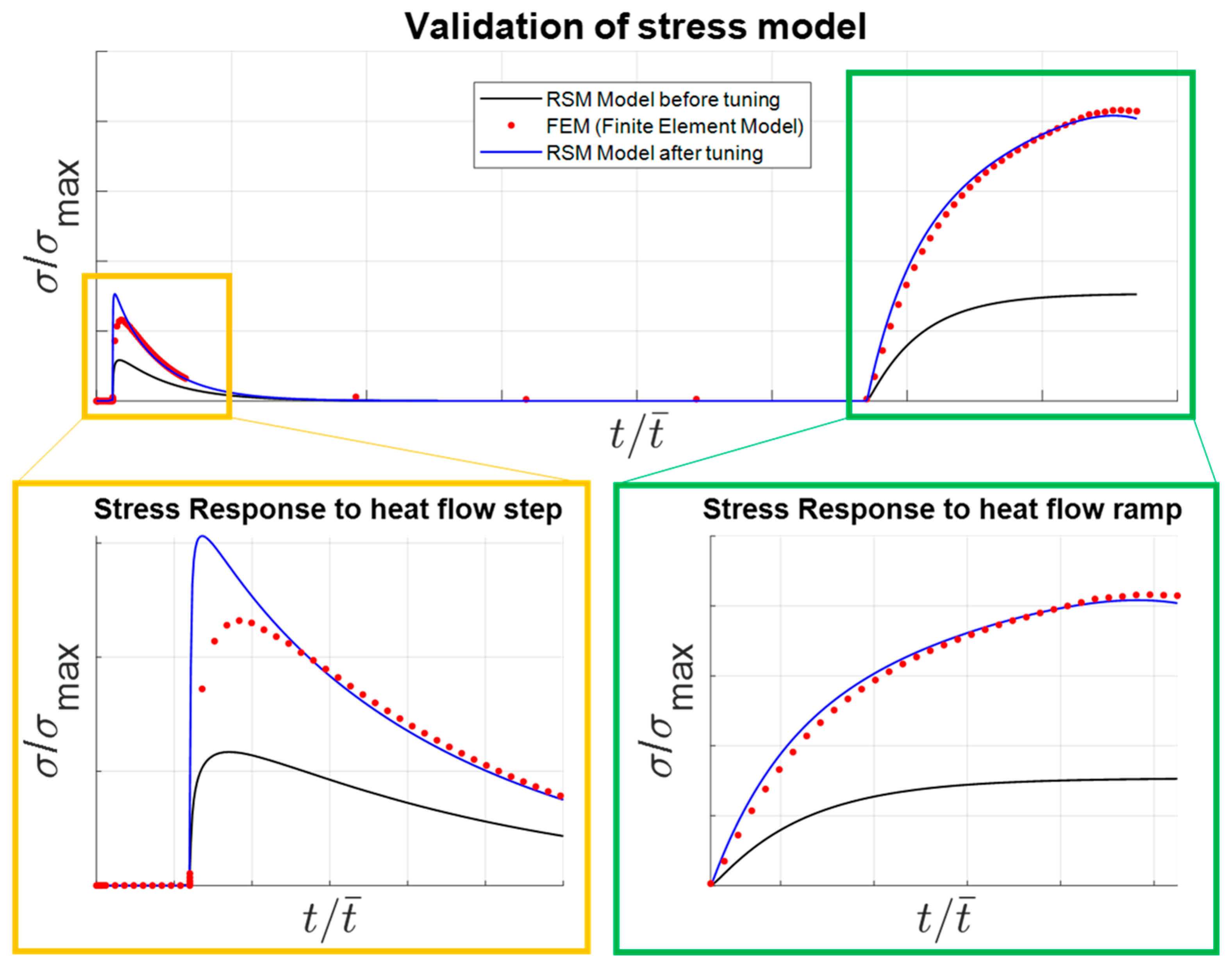

2.2. Rotor Stress Models

2.3. Power and HTC Calculation

3. Rotor Stress Control Strategies

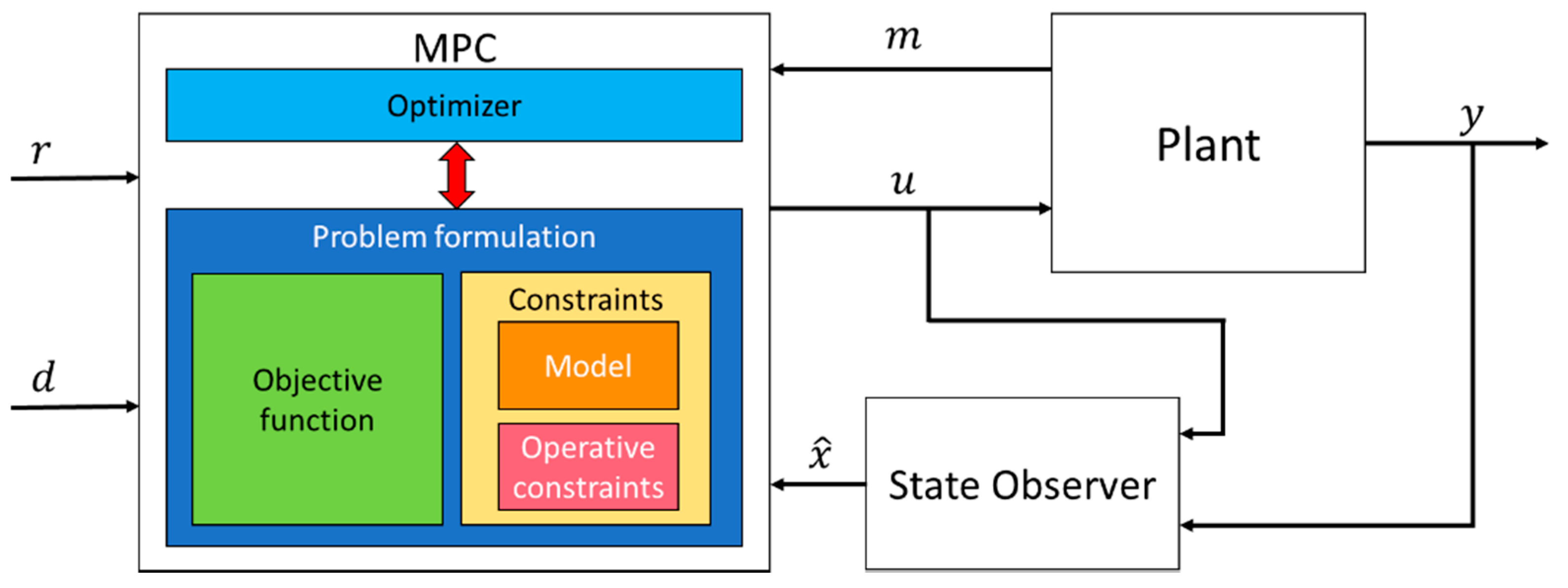

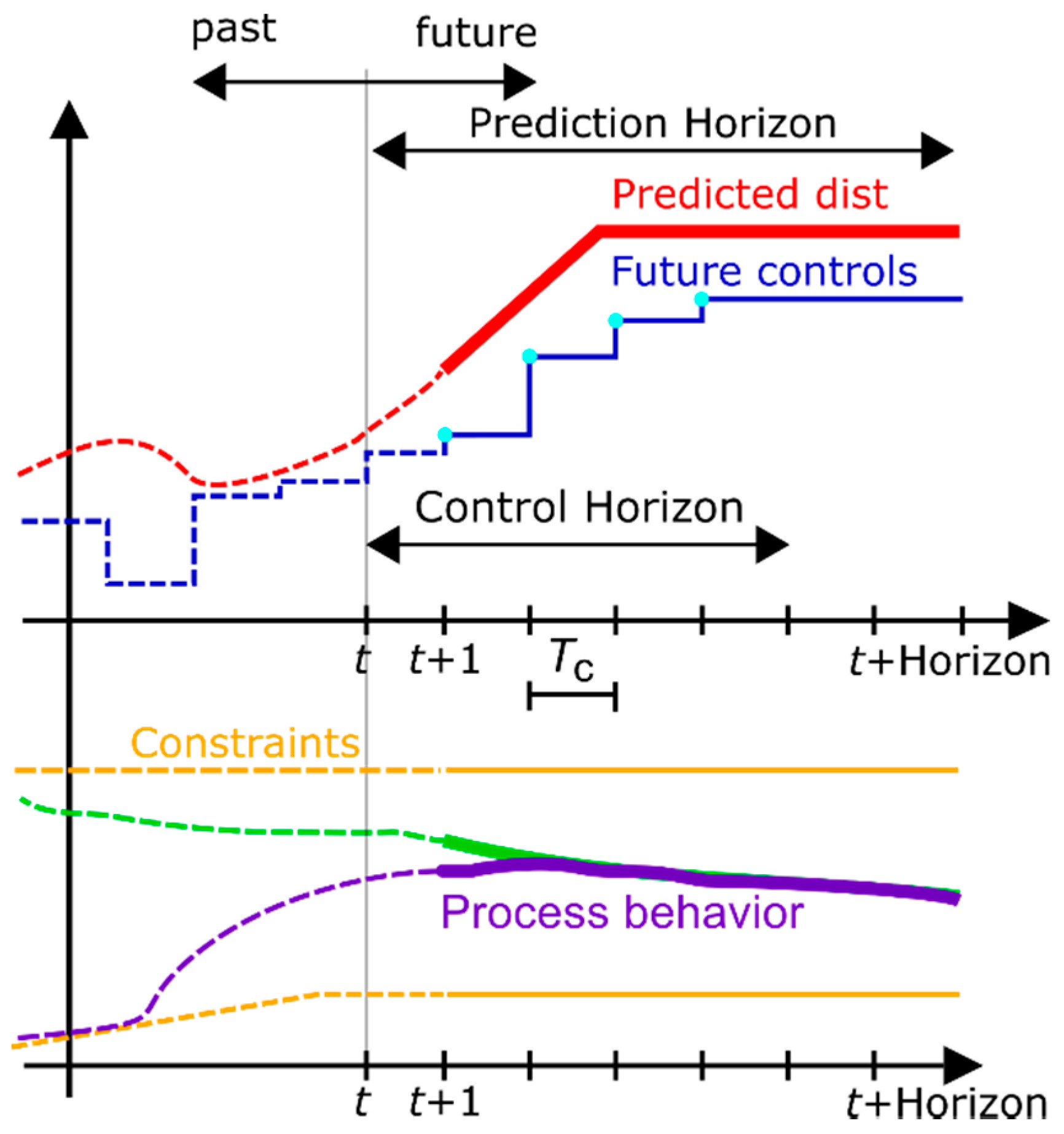

3.1. Background on PI and MPC Control Strategies

- A sufficiently accurate process model, i.e., the core of the MPC approach, whose complexity must balance two counteracting issues related to the accuracy of the short-long term dynamic predictions and the computation burden required to simulate it. In the literature, several realizations of the process models are proposed, starting from linear state space models, linear or nonlinear autoregressive exogenous models (ARX) [52], and Hammerstein Wiener models [53], which are considered the standard for industrial process modelling, up to ANNs [54,55], which are less widespread in control applications but particularly effective in modelling nonlinear behavior. Furthermore, the modelling objective it is not only related to the future behavior prediction, but also to the estimation of the current state of the controlled process, which might not be accessible or measurable.

- A cost function describing one or more indexes to be optimized. Such cost function depends on the specific task and in general is related to energy description of the system, economic costs, or particular specific mathematical relationships. From this point of view, the MPC can fundamentally be a single or a multi objective optimization problem.

- A set of constraints aimed at describing the operative boundaries of the system, including the process itself as well as actuators and related subsystems.

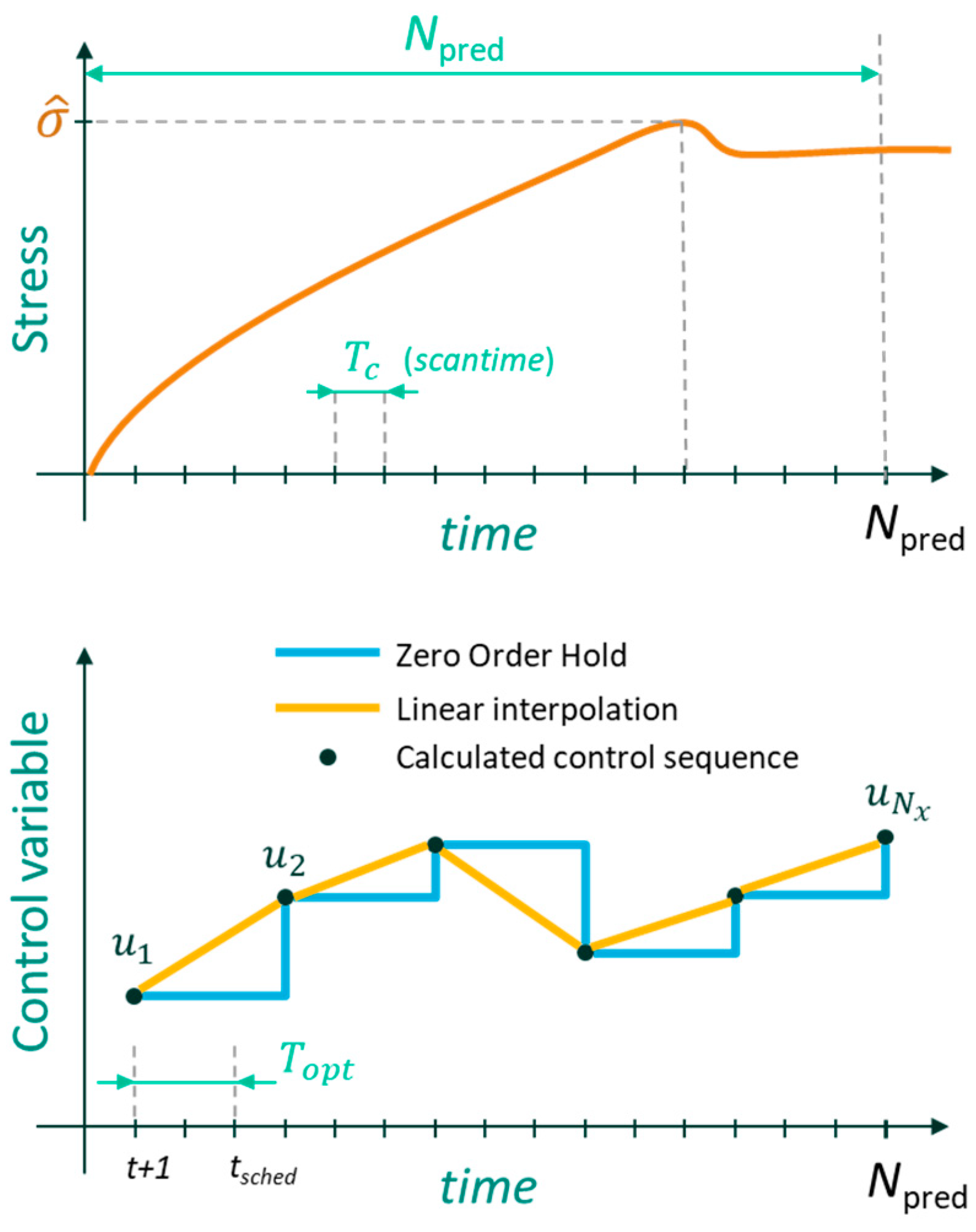

- At the control timestep , MPC reads the measurements and the estimate of the current state of the process. The initial state defines the simulation starting point of the controlled process;

- The optimization algorithm solves, in real time, the formulated problem for a prediction horizon of Np time steps ahead, generating a control sequence u, which minimize the objective function J(xt, Np, Nc), while respecting the constraints:

- The MPC acts on the controlled system, by implementing the first calculated control move u(1). The MPC keeps in memory the remaining control sequence () as a warm start of the optimization of the next control step.

- In the next control step, the MPC strategy comes back to step 1, by implementing a closed loop control, since the applied action on the controlled process is optimized starting from the measurement or the estimate of its current state.

3.2. PI Based Rotor Stress Controller

3.3. Nonlinear Model Predictive Rotor Stress Controller

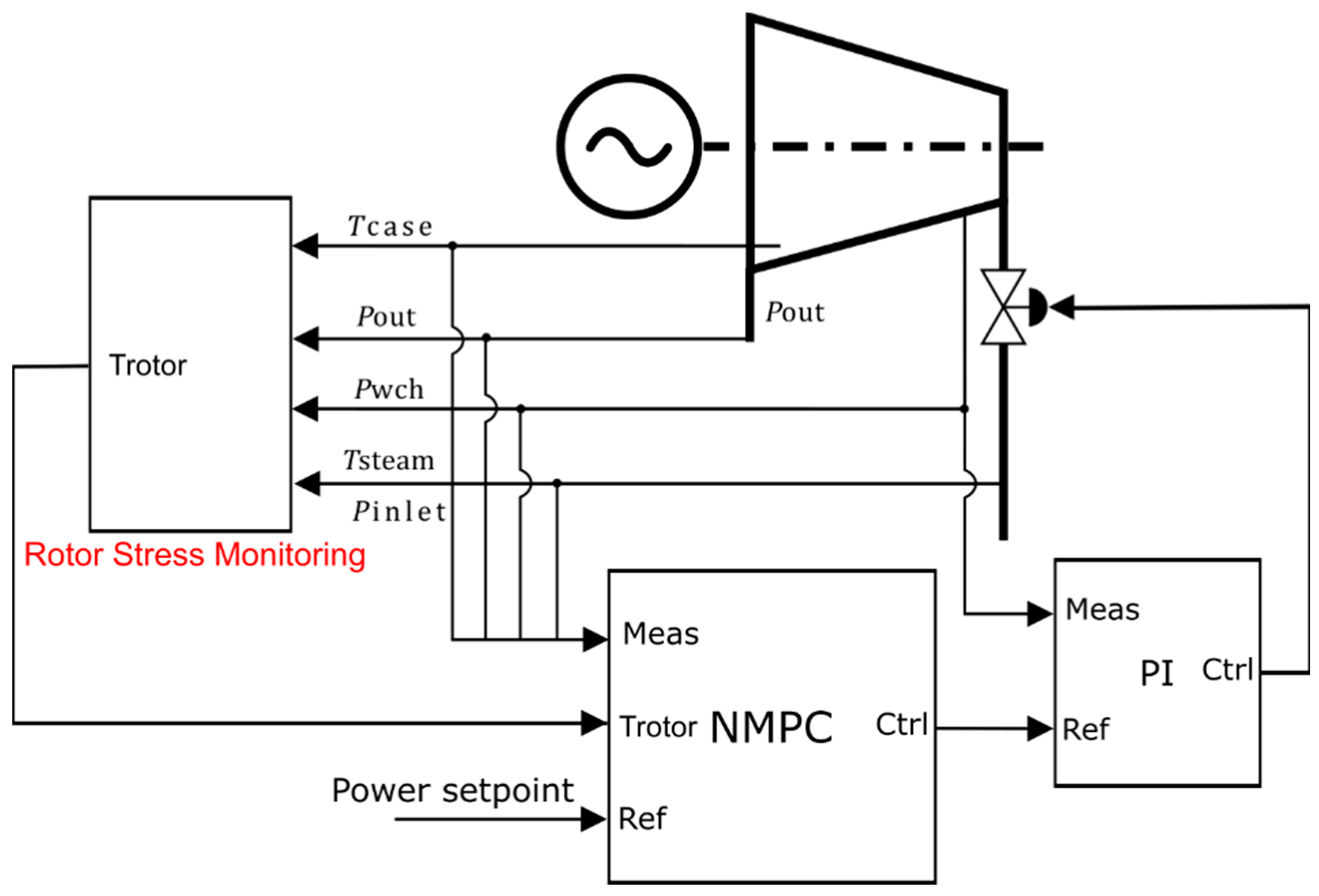

- The rotor stress monitor, i.e., the soft sensor presented in Section 2, which estimates the thermal status, focusing on the temperature of the rotor discretized in N points. The soft sensor is used as a state observer within the NMPC approach, externally installed in PLC platform as an integral part of the steam turbine governor. The block calculates the state of the machine, starting from some relevant inputs: The internal and external case temperature, the pressure and the temperature in the steam header, and the wheel-chamber and outlet pressures.

- The NMPC algorithm, which calculates a reference control action for the pressure in the wheel chamber.

- A PI controller, which directly acts on the inlet valve by following the reference from the NMPC algorithm. This particular control architecture aims at overcoming the issues related to the nonlinear behavior of the valve system, without including it in the modelling strategy formulated within the NMPC software.

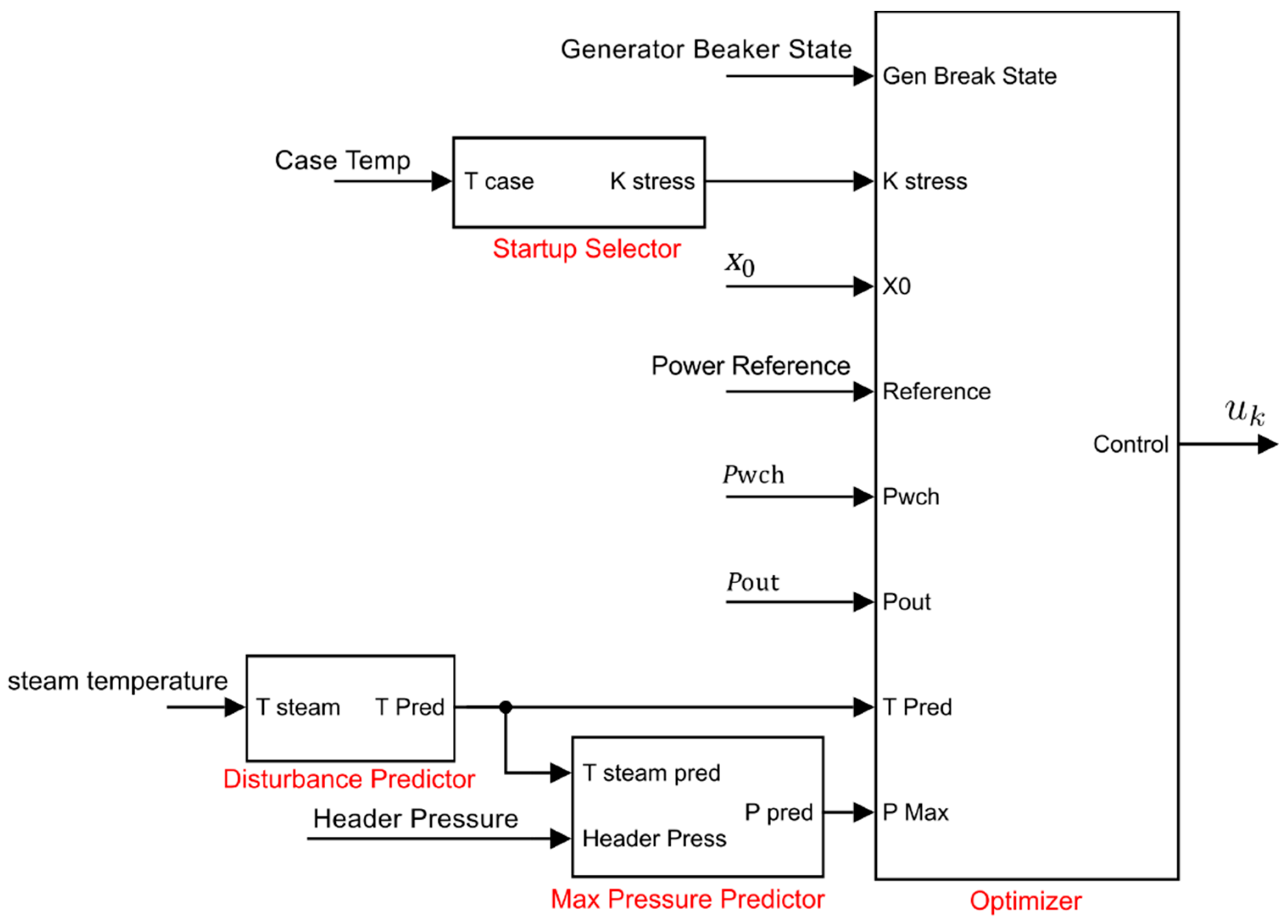

- A Startup Selector for selecting the parameters related to the maximum allowable stress according to the casing temperature and type of startup (cold, warm, hot).

- A Disturbance Predictor and a Max Pressure Predictor, which estimate, respectively, the future steam temperatures and the pressure available at the header. The steam temperature acts on the thermal dynamics as a non-controllable variable (disturbance). The predicted future header pressure is necessary to estimate its maximum constraints within the problem formulated in the NMPC. In deeper detail, the future predictions are calculated starting from the related current through a linear extrapolation. The linear extrapolation is saturated between a minimum and a maximum allowable value.

- The Optimizer, the main block of the NMPC algorithm, which implements the optimization problem, routines, and specific logics for calculating the control action. The optimization problem, formulated for a receding horizon problem, is described by the following equations:

3.4. Tailored SQP Algorithm

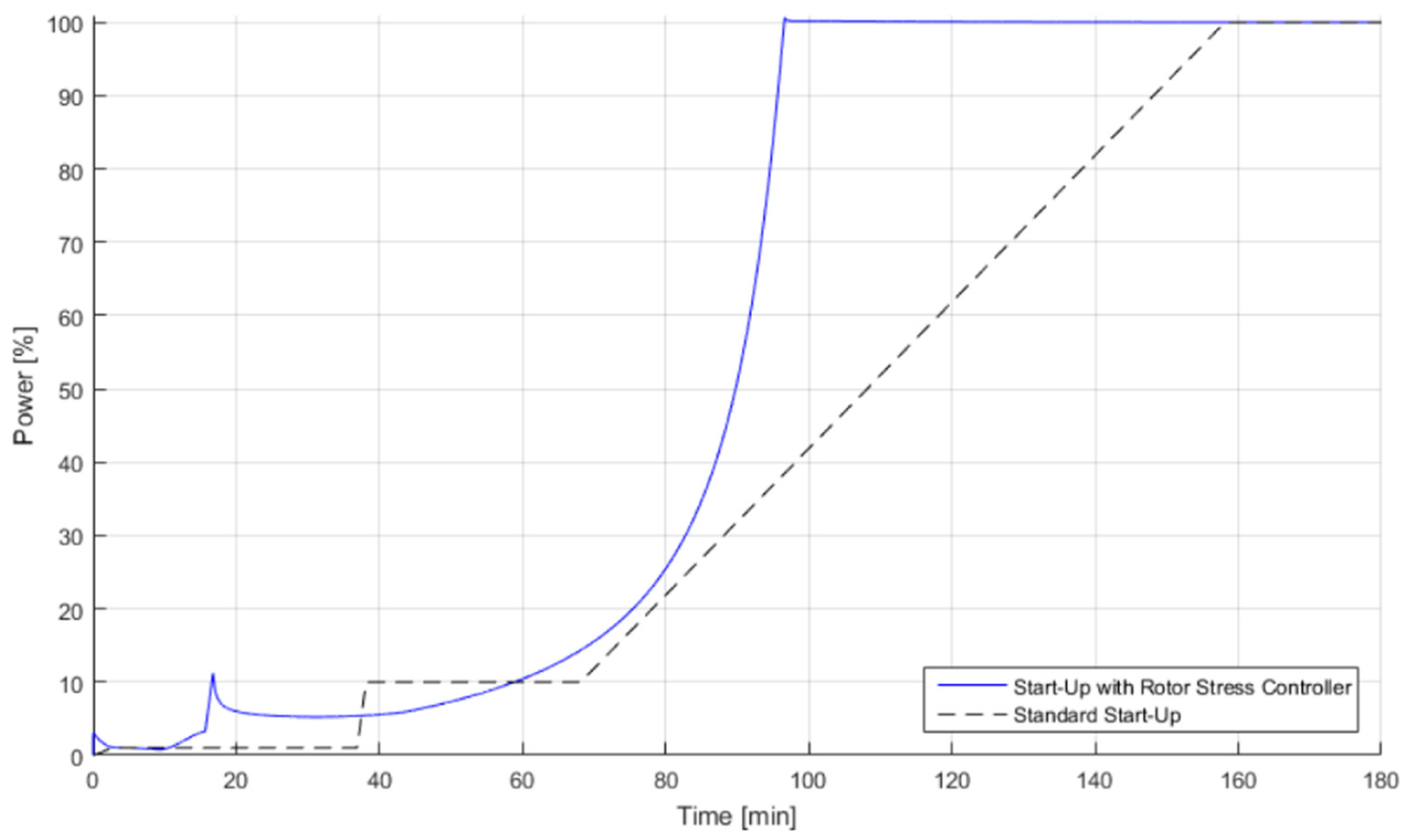

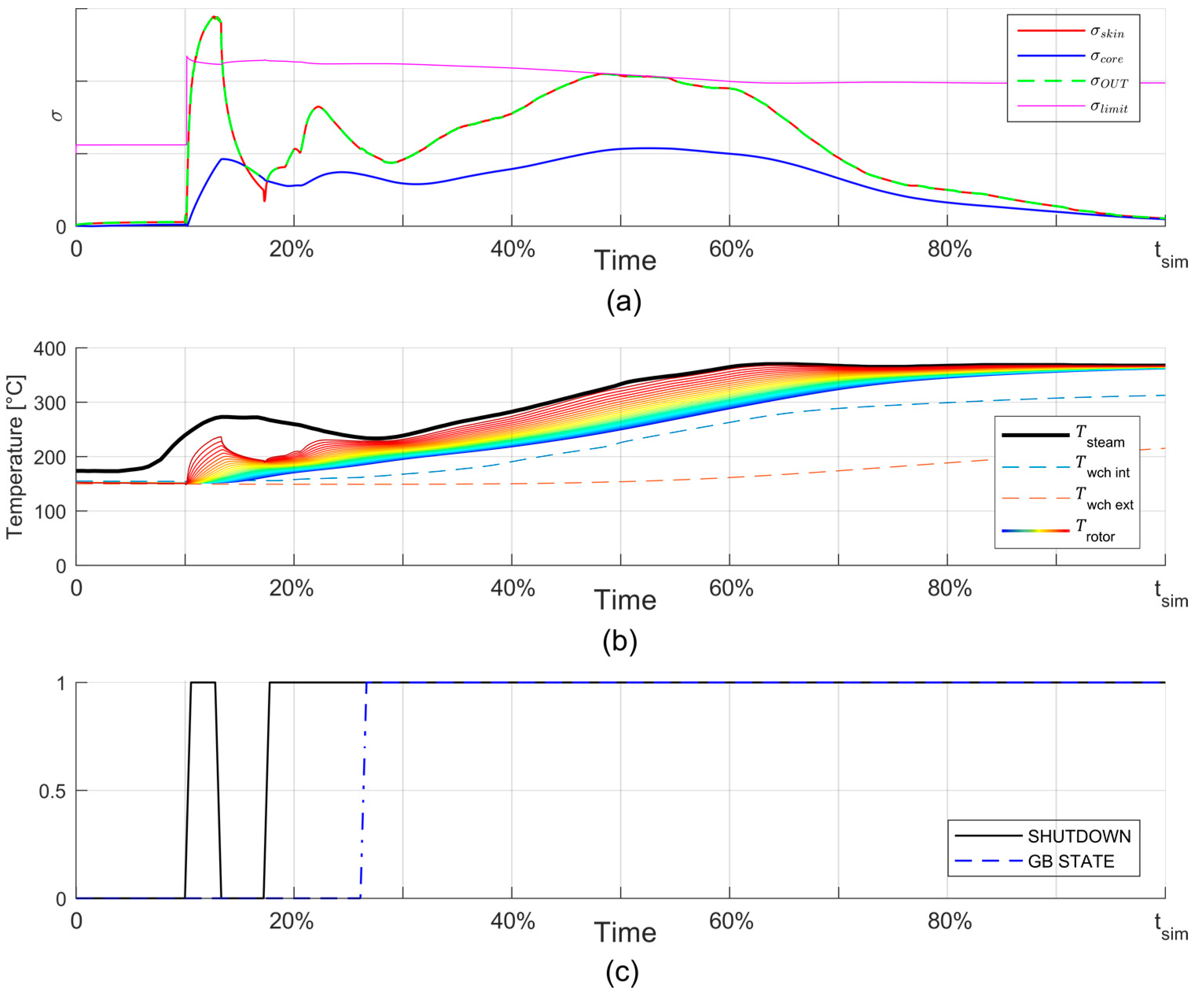

4. Results

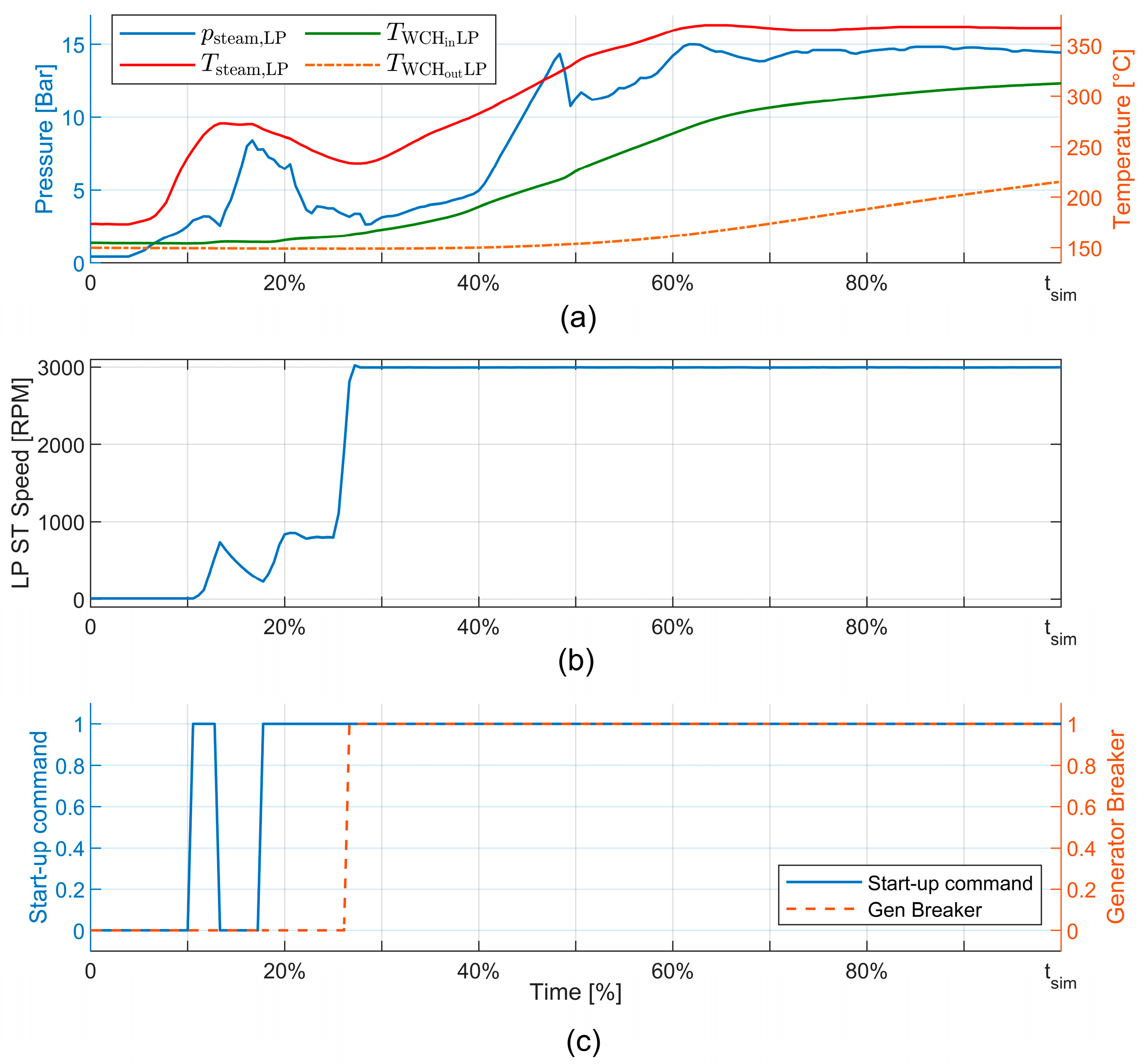

4.1. PI Control Results

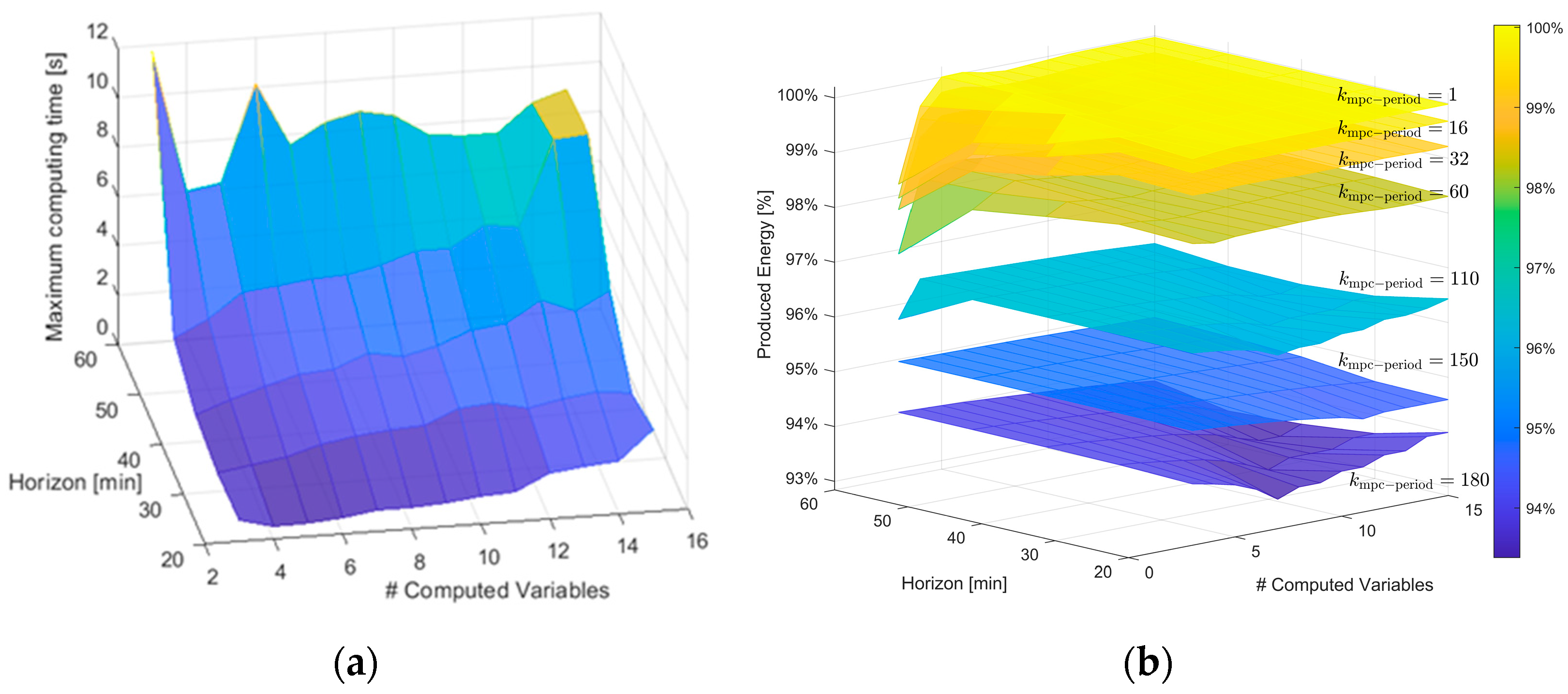

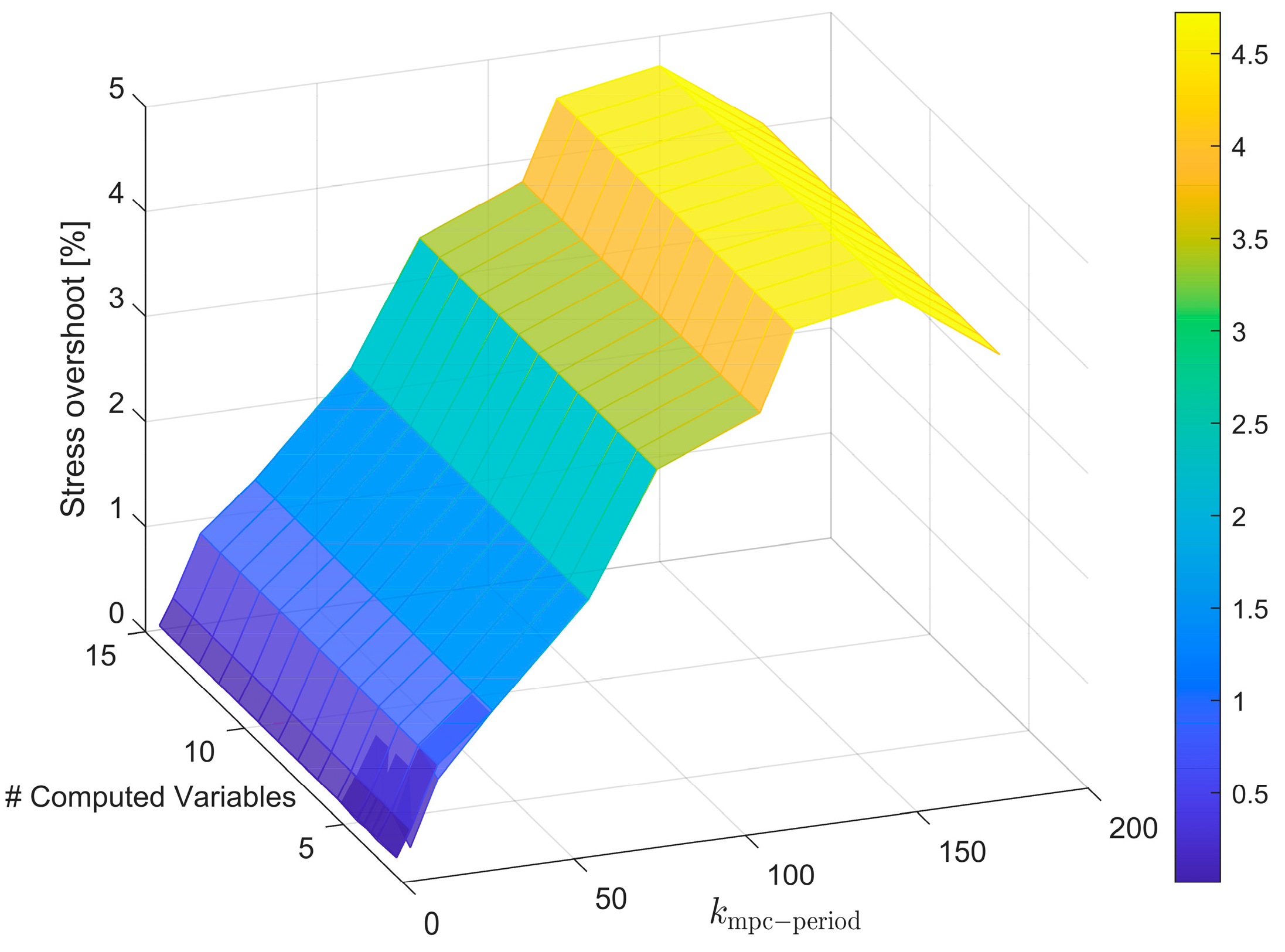

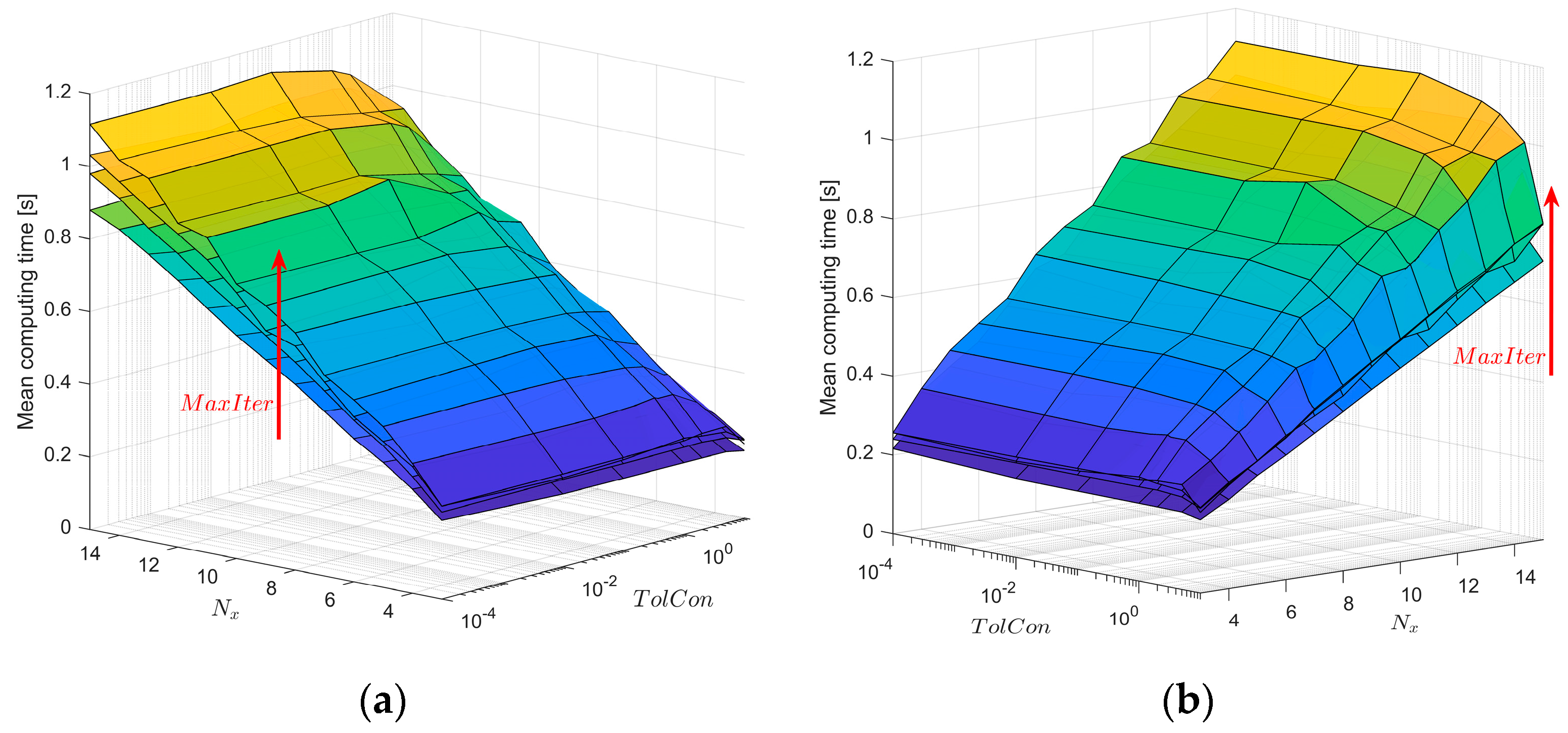

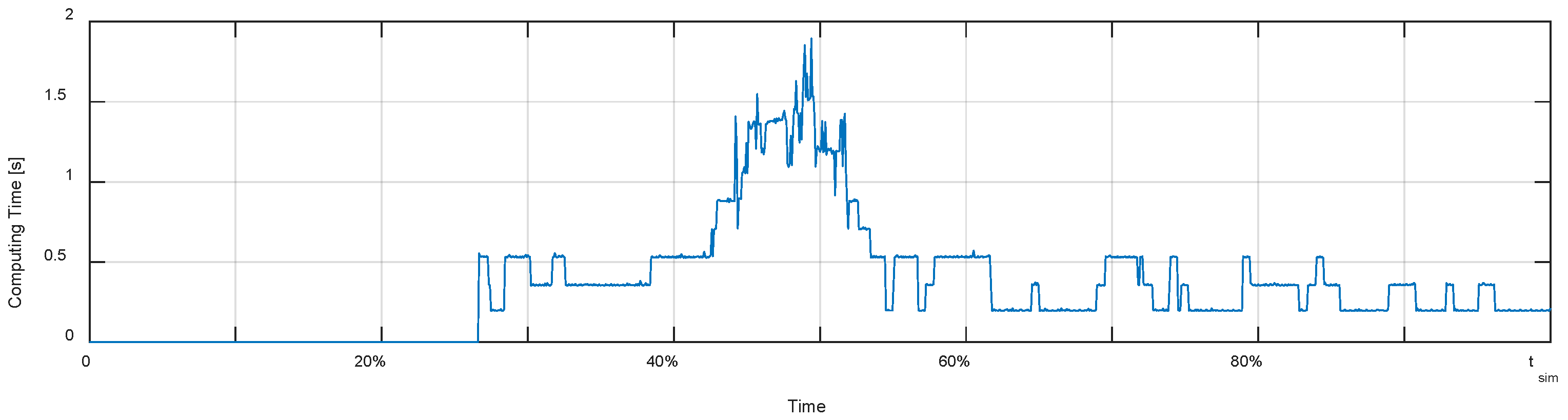

4.2. DOEs NMPC

- Time-related parameters , in which, when (the optimizer is not scheduled every control step), the control action is kept constant through a sample and hold strategy;

- Main optimizer parameters , MaxIter and TolCon;

- Cost function weights, and , where and have been varied according to the relationships: ,

4.3. Guidelines for Controller Parameters Tuning and Discussion of Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Kondziella, H.; Bruckner, T. Flexibility requirements of renewable energy based electricity systems—A review of research results and methodologies. Renew. Sustain. Energy Rev. 2016, 53, 10–22. [Google Scholar] [CrossRef]

- Siano, P. Demand response and smart grids—A survey. Renew. Sustain. Energy Rev. 2014, 30, 461–478. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H.; Connolly, D.; Wenzel, H.; Østergaard, P.A.; Möller, B.; Nielsen, S.; Ridjan, I.; Karnøe, P.; Sperling, K.; et al. Smart energy systems for coherent 100% renewable energy and transport solutions. Appl. Energy 2015, 145, 139–154. [Google Scholar] [CrossRef]

- Tascioni, R.; Arteconi, A.; Del Zotto, L.; Cioccolanti, L. Fuzzy logic energy management strategy of a multiple latent heat thermal storage in a small-scale concentrated solar power plant. Energies 2020, 13, 2733. [Google Scholar] [CrossRef]

- Badami, V.; Chiang, K.; Houpt, P.; Bonisonne, P. Fuzzy logic supervisory control for steam turbine prewarming automation. In Proceedings of the 1994 IEEE 3rd International Fuzzy Systems Conference, Orlando, FL, USA, 26–29 June 1994; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2002. [Google Scholar]

- Carnero, A.P.; Serrano, L.R.; Nebradt, J.G.; Leyva, L.M. Integration of thermal stress and lifetime supervision system of steam turbine rotors. Combust. Fuels Emiss. Parts A B 2008, 3, 1035–1044. [Google Scholar] [CrossRef]

- Sun, Y.-J.; Liu, X.-Q.; Hu, L.-S.; Tang, X.-Y. Online life estimation for steam turbine rotor. J. Loss Prev. Process. Ind. 2013, 26, 272–279. [Google Scholar] [CrossRef]

- Rusin, A.; Nowak, G.; Lipka, M. Practical algorithms for online thermal stress calculations and heating process control. J. Therm. Stress. 2014, 37, 1286–1301. [Google Scholar] [CrossRef]

- Banaszkiewicz, M. Online monitoring and control of thermal stresses in steam turbine rotors. Appl. Therm. Eng. 2016, 94, 763–776. [Google Scholar] [CrossRef]

- Banaszkiewicz, M.; Dominiczak, K. A methodology for online rotor stress monitoring using equivalent Green’s function and steam temperature model. Trans. Inst. Fluid-Flow Mach. 2016, 133, 13–37. [Google Scholar]

- Dominiczak, K.; Rządkowski, R.; Radulski, W.; Szczepanik, R. Online prediction of temperature and stress in steam turbine components using neural networks. J. Eng. Gas Turbines Power 2016, 138, 052606. [Google Scholar] [CrossRef]

- Casella, F.; Pretolani, F. Fast start-up of a combined-cycle power plant: A simulation study with Modelica. In Modelica Conference; The Modelica Association: Linköping, Sweeden, 2006; Volume 4. [Google Scholar]

- Faille, D.; Davelaar, F. Model based start-up optimization of a combined cycle power plant. IFAC Proc. Vol. 2009, 42, 197–202. [Google Scholar] [CrossRef]

- Sun, Y.-J.; Wang, Y.-L.; Li, M.; Wei, J. Performance assessment for life extending control of steam turbine based on polynomial method. Appl. Therm. Eng. 2016, 108, 1383–1389. [Google Scholar] [CrossRef]

- Boulos, A.M.; Burnham, K.J. A fuzzy logic approach to accommodate thermal stress and improve the start-up phase in combined cycle power plants. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 945–956. [Google Scholar] [CrossRef]

- Matsumoto, H.; Ohsawa, Y.; Takahasi, S.; Akiyama, T.; Hanaoka, H.; Ishiguro, O. Startup optimization of a combined cycle power plant based on cooperative fuzzy reasoning and a neural network. IEEE Trans. Energy Convers. 1997, 12, 51–59. [Google Scholar] [CrossRef]

- Nakai, A.M.; Nakamoto, M.; Kakehi, A.; Hayashi, S. Turbine start-up algorithm based on prediction of rotor thermal stress. In SICE ’95. Proceedings of the 34th SICE Annual Conference, International Session Papers, Hokkaido, Japan, 26–28 July 1995; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2002; pp. 1561–1564. [Google Scholar]

- Gallestey, E.; Stothert, A.; Antoine, M.; Morton, S. Model predictive control and the optimization of power plant load while considering lifetime consumption. IEEE Trans. Power Syst. 2002, 17, 186–191. [Google Scholar] [CrossRef]

- Shirakawa, M.; Yun, Y.; Arakawa, M. Intelligent multi-objective model predictive control applied to steam turbine start-up. J. Adv. Mech. Des. Syst. Manuf. 2018, 12. [Google Scholar] [CrossRef]

- Larsson, P.-O.; Casella, F.; Magnusson, F.; Andersson, J.; Diehl, M.; Åkesson, J. A framework for nonlinear model-predictive control using object-oriented modeling with a case study in power plant start-up. In Proceedings of the 2013 IEEE Conference on Computer Aided Control System Design (CACSD), Hyderabad, India, 28–30 August 2013; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2013; pp. 346–351. [Google Scholar]

- Lopez-Negrete, R.; D’Amato, F.J.; Biegler, L.T.; Kumar, A. Fast nonlinear model predictive control: Formulation and industrial process applications. Comput. Chem. Eng. 2013, 51, 55–64. [Google Scholar] [CrossRef]

- D’Amato, F.J. Industrial application of a model predictive control solution for power plant startups. In Proceedings of the IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2006; pp. 243–248. [Google Scholar]

- Rúa, J.; Nord, L.O. Optimal control of flexible natural gas combined cycles with stress monitoring: Linear vs nonlinear model predictive control. Appl. Energy 2020, 265, 114820. [Google Scholar] [CrossRef]

- Dettori, S.; Iannino, V.; Colla, V.; Signorini, A. An adaptive Fuzzy logic-based approach to PID control of steam turbines in solar applications. Appl. Energy 2018, 227, 655–664. [Google Scholar] [CrossRef]

- Iannino, V.; Colla, V.; Innocenti, M.; Signorini, A. Design of a H∞ robust controller with μ-analysis for steam turbine power generation applications. Energies 2017, 10, 1026. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Li, Y. Transient analysis and execution-level power tracking control of the concentrating solar thermal power plant. Energies 2019, 12, 1564. [Google Scholar] [CrossRef] [Green Version]

- Bucciarelli, F.; Checcacci, D.; Girezzi, G.; Signorini, A. Operation and maintenance improvements of steam turbines subject to frequent start by rotor stress monitoring. In Volume 9: Oil and Gas Applications; Organic Rankine Cycle Power Systems; Steam Turbine; ASME International: New York, NY, USA, 2020. [Google Scholar]

- Checcacci, D.; Cosi, L.; Sah, S.K. Rotor life prediction and improvement for steam turbines under cyclic operation. Turbomach. Parts A B C 2011, 7, 2371–2379. [Google Scholar] [CrossRef]

- Ang, K.H.; Chong, G.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar] [CrossRef] [Green Version]

- Fliess, M.; Join, C. Model-free control. Int. J. Control 2013, 86, 2228–2252. [Google Scholar] [CrossRef] [Green Version]

- Astrom, K.; Johansson, K.; Wang, Q.-G. Design of decoupled PID controllers for MIMO systems. In Proceedings of the 2001 American Control. Conference. (Cat. No.01CH37148), Arlington, VA, USA, 25–27 June 2001; Volume 3. [Google Scholar] [CrossRef] [Green Version]

- Gargari, E.A. Colonial competitive algorithm: A novel approach for PID controller design in MIMO dis-tillation column process. Int. J. Intell. Comput. Cybern. 2008, 1, 337–355. [Google Scholar] [CrossRef] [Green Version]

- Cominos, P.; Munro, N. PID controllers: Recent tuning methods and design to specification. IEEE Proc. Control Theory Appl. 2002, 149, 46–53. [Google Scholar] [CrossRef]

- Åström, K.; Hägglund, T. Revisiting the Ziegler–Nichols step response method for PID control. J. Process. Control 2004, 14, 635–650. [Google Scholar] [CrossRef]

- Åström, K.; Hägglund, T. Automatic tuning of simple regulators with specifications on phase and amplitude margins. Automatica 1984, 20, 645–651. [Google Scholar] [CrossRef] [Green Version]

- Skogestad, S. Simple analytic rules for model reduction and PID controller tuning. J. Process. Control 2003, 13, 291–309. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, M.; Atherton, D. Automatic tuning of optimum PID controllers. IEE Proc. D Control Theory Appl. 1993, 140, 216–224. [Google Scholar] [CrossRef]

- Åström, K.; Hägglund, T. The future of PID control. Control Eng. Pr. 2001, 9, 1163–1175. [Google Scholar] [CrossRef]

- Propoi, A.I. Use of LP methods for synthesizing sampled-data automatic systems. Automn Remote Control 1963, 24, 837. [Google Scholar]

- Cutler, C.; Brian, R.; Ramaker, L. Dynamic matrix control. A computer control algorithm. Jt. Autom. Control Conf. 1980, 17. [Google Scholar] [CrossRef]

- Richalet, J.; Rault, A.; Testud, J.; Papon, J. Model predictive heuristic control: Applications to industrial processes. Automatica 1978, 14, 413–428. [Google Scholar] [CrossRef]

- Clarke, D.; Mohtadi, C.; Tuffs, P. Generalized predictive control—Part I. The basic algorithm. Automatica 1987, 23, 137–148. [Google Scholar] [CrossRef]

- Clarke, D.; Mohtadi, C.; Tuffs, P. Generalized predictive control—Part II extensions and interpretations. Automatica 1987, 23, 149–160. [Google Scholar] [CrossRef]

- García, C.E.; Prett, D.M.; Morari, M. Model predictive control: Theory and practice—A survey. Automatica 1989, 25, 335–348. [Google Scholar] [CrossRef]

- Camacho, E.; Bordons-Alba, C. Model. Predictive Control in the Process. Industry; Springer Science and Business Media LLC: Secaucus, NJ, USA, 1995. [Google Scholar]

- Qin, S.; Badgwell, T.A. A survey of industrial model predictive control technology. Control Eng. Pr. 2003, 11, 733–764. [Google Scholar] [CrossRef]

- Lee, J.H. Model predictive control: Review of the three decades of development. Int. J. Control Autom. Syst. 2011, 9, 415–424. [Google Scholar] [CrossRef]

- Xi, Y.-G.; Li, D.-W.; Lin, S. Model predictive control—Status and challenges. Acta Autom. Sin. 2013, 39, 222–236. [Google Scholar] [CrossRef]

- Camacho, E.F.; Gallego, A.J.; Escaño, J.M.; Sánchez, A.J. Hybrid nonlinear MPC of a solar cooling plant. Energies 2019, 12, 2723. [Google Scholar] [CrossRef] [Green Version]

- Kong, X.; Ma, L.; Liu, X.; Abdelbaky, M.A.; Wu, Q. Wind turbine control using nonlinear economic model predictive control over all operating regions. Energies 2020, 13, 184. [Google Scholar] [CrossRef] [Green Version]

- Darwish, S.; Pertew, A.; ElHaweet, W.; Mokhtar, A. Advanced boiler control system for steam power plants using modern control techniques. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, SC, Canada, 12–14 June 2019. [Google Scholar] [CrossRef]

- Geng, X.; Zhu, Q.; Liu, T.; Na, J. U-model based predictive control for nonlinear processes with input delay. J. Process. Control 2019, 75, 156–170. [Google Scholar] [CrossRef] [Green Version]

- Tsay, C.; Kumar, A.; Flores-Cerrillo, J.; Baldea, M. Optimal demand response scheduling of an industrial air separation unit using data-driven dynamic models. Comput. Chem. Eng. 2019, 126, 22–34. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Rincón, F.D.; Christofides, P.D. Real-time adaptive machine-learning-based predictive control of nonlinear processes. Ind. Eng. Chem. Res. 2020, 59, 2275–2290. [Google Scholar] [CrossRef]

- Wu, Z.; Tran, A.; Rincon, D.; Christofides, P.D. Machine-learning-based predictive control of nonlinear processes. Part II: Computational implementation. AIChE J. 2019, 65. [Google Scholar] [CrossRef]

- Rawlings, J. Tutorial overview of model predictive control. IEEE Control Syst. 2000, 20, 38–52. [Google Scholar] [CrossRef] [Green Version]

- Scokaert, P.; Mayne, D.; Rawlings, J. Suboptimal model predictive control (feasibility implies stability). IEEE Trans. Autom. Control 1999, 44, 648–654. [Google Scholar] [CrossRef] [Green Version]

- Gros, S.; Zanon, M.; Quirynen, R.; Bemporad, A.; Diehl, M. From linear to nonlinear MPC: Bridging the gap via the real-time iteration. Int. J. Control 2016, 93, 62–80. [Google Scholar] [CrossRef]

- Tavernini, D.; Vacca, F.; Metzler, M.; Savitski, D.; Ivanov, V.; Gruber, P.; Hartavi, A.E.; Dhaens, M.; Sorniotti, A. An explicit nonlinear model predictive abs controller for electro-hydraulic braking systems. IEEE Trans. Ind. Electron. 2019, 67, 3990–4001. [Google Scholar] [CrossRef]

- Escaño, J.M.; Sánchez, A.J.; Witheephanich, K.; Roshany-Yamchi, S.; Bordons, C. Explicit simplified MPC with an adjustment parameter adapted by a fuzzy system. J. Intell. Fuzzy Syst. 2019, 37, 1287–1298. [Google Scholar] [CrossRef]

- Schittkowski, K.; Yuan, Y. Sequential quadratic programming methods. In Wiley Encyclopedia of Operations Research and Management Science; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Han, S.P. A globally convergent method for nonlinear programming. J. Optim. Theory Appl. 1977, 22, 297–309. [Google Scholar] [CrossRef] [Green Version]

- Kraft, D. A software package for sequential quadratic programming. In Deutsche Forschungs- und Versuchsanstalt für Luft- und Raumfahrt Köln: Forschungsbericht; Deutsche Forschungs-und Versuchsanstalt für Luft- und Raumfahrt Köln: Koln, Germany, 1988; Volume 88. [Google Scholar]

| Case Study | NPIAE | NPC |

|---|---|---|

| PI RSC with overshoot | 4.77 | 95.23 |

| PI RSC no overshoot | 5.30 | 94.70 |

| Tuned NMPC | 2.49 | 97.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dettori, S.; Maddaloni, A.; Galli, F.; Colla, V.; Bucciarelli, F.; Checcacci, D.; Signorini, A. Steam Turbine Rotor Stress Control through Nonlinear Model Predictive Control. Energies 2021, 14, 3998. https://doi.org/10.3390/en14133998

Dettori S, Maddaloni A, Galli F, Colla V, Bucciarelli F, Checcacci D, Signorini A. Steam Turbine Rotor Stress Control through Nonlinear Model Predictive Control. Energies. 2021; 14(13):3998. https://doi.org/10.3390/en14133998

Chicago/Turabian StyleDettori, Stefano, Alessandro Maddaloni, Filippo Galli, Valentina Colla, Federico Bucciarelli, Damaso Checcacci, and Annamaria Signorini. 2021. "Steam Turbine Rotor Stress Control through Nonlinear Model Predictive Control" Energies 14, no. 13: 3998. https://doi.org/10.3390/en14133998

APA StyleDettori, S., Maddaloni, A., Galli, F., Colla, V., Bucciarelli, F., Checcacci, D., & Signorini, A. (2021). Steam Turbine Rotor Stress Control through Nonlinear Model Predictive Control. Energies, 14(13), 3998. https://doi.org/10.3390/en14133998