Abstract

Increasing greenhouse gas emissions and more and more restrictive European Union regulations necessitate the reduction of energy demand in buildings, including hotels. A more economical way of managing and operating a facility may lead to competitive advantage and a reduction in the negative impact on the environment. This study indicated that the hotel facility wastes significant amounts of water and energy, and the main sources of losses were determined. The design assumption was to achieve savings by introducing technical improvements in the most energy and water-consuming areas. The modification consisted of replacing some of the lighting, fittings, and ventilation. The results of the achieved water and energy savings were compared with the consumption recorded in 2019. The very satisfactory final results were obtained, showing savings about 20% higher than assumed by the hotel management. Taking into account the replacement of lighting in staircases and underground garages, in addition to the replacement of ventilation in the hotel building, the maximum possible daily saving due to the changes mentioned is estimated at approximately 68% for lighting and ventilation.

1. Introduction

The effects of global warming and the huge costs that are incurred through mismanagement of natural resources are being increasingly felt [1,2,3,4,5]. Large facilities that absorb enormous amounts of water and energy are usually equipped with obsolete appliances without precise control of consumption [6,7]. This group includes five-star hotels that ensure the highest possible standard.

The use of various types of energy sources is the basis for the functioning of modern civilization. In the hotel industry, it is also a prerequisite for a comfortable stay and the use of accommodation and all other services. A hotel chain consumes large volumes of energy in its daily operations, for example, for lighting the rooms and restaurants, in addition to many other processes such as water management, air conditioning control, steam, and gas [8,9,10].

Until 2020, the hotel industry, both in Poland and in Europe, recorded dynamic growth in terms of guests visiting every year and newly built hotel facilities [11,12]. The hotel industry usually provides services 24 h a day, which, depending on the applicable standards, is associated with ensuring high quality, which usually does not go hand in hand with savings. One of the most common problems in hotel expense optimization is the dependence of the number of fixed costs (including electricity) on the occupancy rate [13]. The implementation of technical improvements to hotels is aimed at ensuring the current comfort of use with the lowest possible resource consumption. Innovative solutions and equipment that are available on the market are an opportunity for significant savings, both financial and environmental protection. By making low-cost investments that pay back quickly, water and energy consumption can be cut in half [14,15].

Polish consumers increasingly pay attention to the responsibility of companies in terms of their approach to ecology [16]. In a survey, 9 out of 10 people say they are willing to pay more for services from companies that care about the environment, and 21 percent will always choose a green brand, regardless of the price difference [17].

The main stimulus for pro-ecological activities in hotel facilities is the application of technical and organizational solutions conducive to environmental protection, which significantly reduce operating costs, especially in respect of energy, water, and waste management. Savings in water or energy consumption with the use of modern technology in hotels can now reach 30–50%, without reducing services. It is estimated that about 35% of the world’s hotels have comprehensive environmental programs [18,19].

Possible financial outlays for the modernization of hotel facilities result from the financial performance. These, in turn, depend on the interest in the property and its location by hotel guests, and with it the price per hotel room. The highest hotel room rates in the world, as in Q2 2019, were recorded in the US in New York (EUR 267, up 6%) and Washington DC (EUR 246, up 12%). Third place went to Tokyo, with a hotel rate of EUR 181 (up 7%). The average price for a hotel room in Warsaw in the second quarter of 2019 was EUR 81—this is EUR 6 less compared to the second quarter of 2018 [20].

A five-star hotel is a facility that provides guests with both short-term and longer stays in rooms or suites imitating an exclusive and cozy temporary residence [21,22]. The most common reasons for people using hotel services are business, recreational, training, family trips, or trips related to cultural events. During their stay, hotel guests want to feel relaxed, refreshed, and served at the highest level within the price they pay per night in a luxury hotel. Most people do not pay attention to the consumption of water or electricity, although they reduce consumption in their own homes due to costs and environmental factors. The occupancy rate of hotels and resorts during the holiday season often reaches 100%. The uninterrupted service of powerful tourist facilities is constantly consuming enormous water and energy [23,24]. The amount of water and energy used is influenced by many factors, e.g., the number of occupied rooms, the number of outside guests in the spa area, time of year, installed equipment, outside temperature, number of employees, number of meals prepared, and amount of laundry.

Standard actions that improve the efficiency and correct operation of the installation and consequently affect the energy balance of the heating system in the hotel building include insulation of heating pipes that pass through unheated areas or areas with lower temperatures (corridors, stairwells, basements of the building). In many buildings, lowered ceilings are used even in basements. In the space above them, heat pipes often run without proper insulation. Another activity influencing the energy balance of the facility is chemical flushing and sediment removal in order to restore the original patency of heat pipes and correct operation of thermostatic valves. The water used in the circuit causes scaling. It is necessary to replace the valves with new ones, after the heat pipes have been fully unblocked, and to seal the system by eliminating water losses and eliminating air from the system. The elimination of the collective venting system in favor of individual vents for each riser, the installation of modern thermostats at the radiators, and the retrofitting of automatic weather control devices also affect the energy balance.

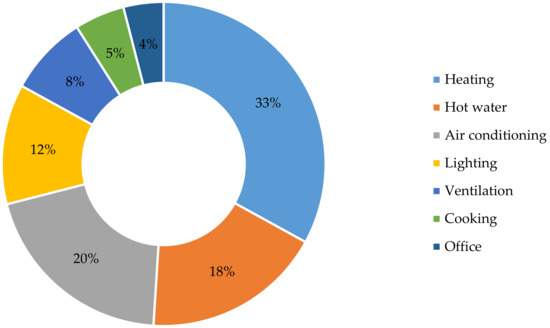

The season of the year, the outside temperature, and the number of people staying in the hotel are important. Heating (30%), ventilation (19%), and air conditioning (12%) account for more than half of the total energy consumption in hotels [25,26]. Next in the structure of energy consumption are the hot water provision (21%), lighting and electrical appliances (12%), and food preparation (6%).

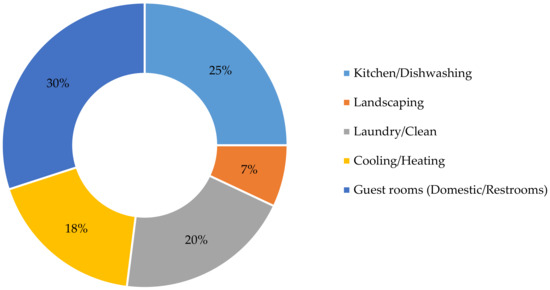

In the case of water consumption in hotels, more than half, as much as 51%, of the total water consumption is used for the daily toilet, i.e., flushing the toilet bowl and taking care of personal hygiene. The other half of the structure is related to food preparation (16%), laundry (14%), spa area operation (11%), and cleaning (8%) [27,28,29,30].

Electricity consumption in hotel facilities, as in the case of water consumption, depends on many factors, the most important of which are location, standard, and the number of guests. According to these criteria, the average energy consumption in hotels can be preliminarily assessed. For example, the energy consumption of elevators represents a significant portion (3–8%) of the total energy used to maintain a hotel building. The effectiveness of individual areas influencing the total energy consumption depends on the internal regulations and equipment of a given hotel. In order to provide guests with the greatest possible comfort, practicality, and safety, the authorities of hotel facilities introduce modern systems enabling the best quality of facility management.

In Poland, the number of tourists arriving increases every year. This is closely related to the growth of the hotel industry. In most regions, there is an increase in the number of hotels and new accommodation places compared to the previous years. There are eight types of hotels. The main ones are hotels whose classification is indicated by stars that reflect the standard. Five-star hotels are of the highest quality and standard, represented by the facility, services, and staff. Other objects are motels, usually located by roads and designed to provide accommodation and rest for long-distance travelers. The other facilities are holiday or summer houses, guesthouses, campsites or and hostels.

The demand for water in hotels depends largely on the standard and location. In an exemplary Polish five-star hotel, the daily demand per person may be even over 1000 L. In the case of a three-star middle-class hotel, the daily consumption per person may amount to about 150 L.

Water consumption in hotels depends on the standard and location of the facility. Water consumption in hotels in Poland and the European Union does not seem to be particularly divergent [31,32]. Obviously, an unambiguous comparison cannot be made due to the insufficient amount of data presenting water consumption in most European Union countries. The above-mentioned example of a three-star hotel consuming about 150 L per day per person can be compared with the Mediterranean countries, in which, despite being middle class, hotels need up to 600 L of water per person per day. On the other hand, ecological hotels in the eagerly visited Greece present their daily consumption per person as about 250 L. Water consumption in 4–5 star hotels in Germany ranges from 120 to 780 L per person/day (at 70% occupancy) [33]. It is twice as small compared to an example hotel of the same class in Poland. Each consumption depends on many factors; therefore, the above comparison is only illustrative. Hotels that, in addition to the accommodation room, offer attractions outside the building, such as parks, golf courses, or gardens, absorb so much water that this consumption can account for even half of the cost of maintaining a given hotel. Hotel facilities located in city centers estimate water consumption on average up to 15–20% of the facility’s maintenance costs (in Tunisia, the cost of water can be up to 40% of the cost) [34,35].

In hotels, it is very important to create hygienic conditions (fresh air) and thermal comfort conditions. The supply and exhaust ventilation system should be arranged so that the introduced ventilation air does not cause local air velocities higher than 0.2 m/s. Requirements for the amount of fresh air are given in PN (Polish Standards)—EN (European Standards) 15251 [36]. The most convenient way to plan a supply grille is to share it with the circulation air. The air quality in a hotel room is directly dependent on the fresh (outdoor) air supply and the pollutant and odor streams released into the room. A fairly common problem in hotel rooms is the intense smell of room furnishings such as carpet, furniture. Unfortunately, this problem cannot be solved by increasing the operating efficiency of the ventilation system.

Heating, ventilation, and air conditioning make up the bulk of electricity consumption [37,38]. In an exemplary Polish hotel, this component may constitute up to 61% of energy consumption. Other factors influencing consumption are the provision of hot water (21%), lighting and electrical appliances (12%), and food preparation (6%). The main problem, and at the same time a very important issue, is to reduce and save utility consumption while ensuring the highest standard of the facility. Another factor faced by hotel management is energy management in individual departments such as the kitchen, laundry, or even the spa area. Exceeding the contractual power is a very common result of abuse by both hotel guests and the majority of hotel employees. Unfortunately, in order to ensure the highest quality of services, for which a guest staying at a hotel pays a considerable price, some departments cannot afford any savings. As a result, the hotel is charged very high fees by energy suppliers.

In hotel rooms, the main sources of noise are moving parts of air conditioning systems or air noise. The acoustic requirements for ventilation systems are defined in terms of the permissible sound level in rooms, given in decibels (dB). The sound level is a filter-weighted sound pressure level, which is an objective measurement of the loudness level perceived by the human ear.

Some European Union countries have a warmer climate compared to Poland. High outside temperature means that ventilation and air conditioning consume more energy than estimated in Poland. However during winter in Poland heating contributes to higher energy consumption. Therefore, the basic structure of energy consumption in most countries will be similar.

Extremely high requirements also apply to the air circulation, especially in high-rise hotel facilities with several or several dozen floors, where windows cannot be opened [39,40]. The indoor climate requirements in hotel rooms are regulated by the legal regulations on tourist services, which are binding in high standard hotels. According to the regulations, the facility is required to maintain the temperature from 18 to 21 degrees Celsius, ensure proper air exchange, and maintain a relative humidity of 45 to 60% in the hotel room and spaces such as the main lobby or gastronomy rooms.

For proper air exchange in the analyzed room, it is necessary to provide the so-called hygiene minimum, i.e., the minimum outside airflow rate to dilute pollutants in indoor air to an acceptable level. In the case of rooms such as hotel facilities, it is primarily carbon dioxide, which is a product of the process of human respiration. Hotels use air conditioning systems that use air- or air-and-chilled water to take away heat gains. A properly designed air conditioning system relies on a carefully calculated ventilation airflow. Its value results from the cooling load (heat gain) of the room. In air–water air-conditioning systems, when most of the heat gain is absorbed by the cooling water (e.g., in the case of chilled beams, a hygienic supply of outside air is usually sufficient). The required design assumptions for ventilation and air conditioning are regulated by the provisions of Polish standards PN-78/B-03421 [41], PN-83/B-03430/Az3:2000 [42], and PN-EN 15251:2012P [43]. According to the above-mentioned legal regulations in collective residence buildings, the minimum volume flow rate of external air should be as follows: for ventilated living rooms, 20 m3/h, but not less than one air exchange per hour; and for air-conditioned and ventilated rooms with non-opening windows, 30 m3/h; in the administrative part of the hotel, the minimum ventilation airflow rate with a smoking ban should be as follows: in ventilated rooms 20 m3/h for each person, and in air-conditioned and ventilated rooms with non-opening windows, 30 m3/h for each person. The following airflows should be removed from bathrooms and toilets intended for individual use: from a bathroom (with or without a toilet), 50 m3/h, from a separate toilet, 30 m3/h. The airflow rate for sanitary and hygienic rooms for common use shall be 100 m3/h for each toilet. In these rooms, separate supply and exhaust ventilation systems are designed.

The average operating time of fan coil units in a hotel room is approximately 80%, while for offices it is approximately 40%.

The highest annual energy consumption for air treatment occurs when outdoor air is supplied to a room at room temperature [44].

Regardless of nationality, while using the goods provided by various types of hotels, a statistical guest uses at least 50% more water and energy on a trip than at home on a daily basis [45,46]. Paying high prices for accommodation and stays, the potential guest does not pay attention to any savings. Tourist towns with as many hotels as residential houses consume up to seven times more water to host tourists than permanent residents. The projected increase in the number of hotels prompts the implementation of innovative solutions and investments aimed at reducing the so far excessively used water and energy [47,48,49].

The purpose of this study was to analyze water and energy consumption in a five-star hotel in the center of Europe. The manuscript proposes solutions to reduce media consumption. Based on data on media consumption in the analyzed hotel over the last 10 years, a detailed analysis and assessment of the current state of water and electricity consumption in the area of lighting, air conditioning, electrical installations, and fittings was performed. Then, modifications to the existing installations were proposed, and the optimization of water and electricity consumption was assessed. The design assumption was to achieve at least 20% savings after introducing technical improvements. This assumption was the minimum threshold that would ensure the reasonable time of the return of the entire investment and allow for noticeable savings in the future.

2. Materials and Methods

The technical parameters of the components of the modernized installation presented in the following analysis are exemplary. They are designed to show the impact of retrofitting on its overall cost-effectiveness. The parameters of other possible system components are presented in the catalog [50]. In addition, the manuscript’s analysis of retrofitting existing installations in a hotel facility is intended to make hotel owners aware that significant energy and financial benefits are achievable without completely replacing the installations. Modernization of elements of water installation, air conditioning, and lighting emphasizes the variability of proposed solutions.

The analyzed facility is a five-star hotel in central Europe. In this multistorey building, the underground floors are occupied by technical and installation rooms and parking lots. The hotel has a total of 414 rooms, including 76 suites, a swimming pool with a gym and an aerobics room, two restaurants, a cafe, a bar, and 14 conference rooms. The ground floor is largely occupied by the four-story lobby (approximately 17 m high), covered with a glass roof. The communication between floors is facilitated by 14 elevators. During the period of the last five years, the average occupancy was almost 100% of the booked rooms on weekends and about 60% from Monday to Friday. During holidays and long weekends, most of the rooms were free. Occupancy sometimes did not even reach 20% because guests prefer to spend holidays outside the city.

The hotel is of greatest interest from June to September. Energy-consuming systems in the analyzed hotel facility include heating, air conditioning, electrical installations, and a building management system (BMS).

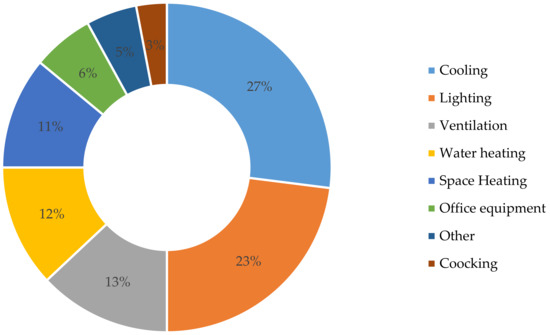

Figure 1 shows the total primary energy consumption of the analyzed hotel facility with the contribution of each energy use (space heating, space cooling, domestic hot water, lighting, and equipment).

Figure 1.

Structure of primary energy consumption in the analyzed hotel facility.

2.1. Heating Installation

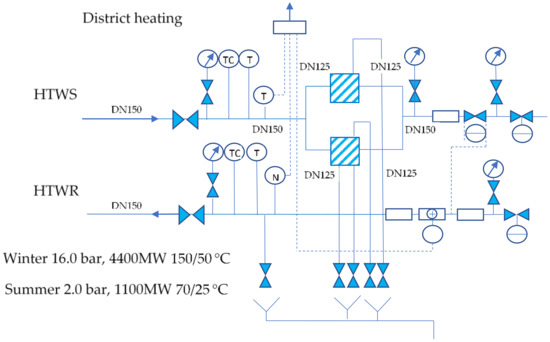

The facility is equipped with the main heat connection directly to the European district heating system, and a fuel oil boiler as a reserve. The internal installation distributes heating water from the first supply level on the second floor to the receiving devices and at the same time sends it to the second supply level located on the 21st floor, from where the further distribution of heating water takes place to floors 22–44. In case of interruptions in heat supply on the 42nd floor, a reserve oil boiler with a heating oil tank with a capacity of 3000 L was installed. There are several main heating circuits in the facility, including the supply of water heaters in air handling units; supply of water heaters in fan-coil units (FCUs); power supply to the underfloor heating system in the swimming pool part; supply of auxiliary radiator heating in conference and banquet rooms; supply of water heaters in air curtains supporting heating of the lobby during winter; and preparation of domestic hot water for the needs of guests and the kitchen.

The diagram below shows the main thermal connection (Figure 2), which shows high-temperature water supply (HTWS) temperature in the upper part, and in the lower part, high-temperature water return (HTWR) temperature.

Figure 2.

Diagram of the main thermal connection.

The amount of the heating medium supplying the internal central heating system is continuously regulated in relation to the outside temperature. The operating temperature of the installation on the primary side in winter under the design external temperature conditions is 130/55 °C, and in the summer period, 70/25 °C.

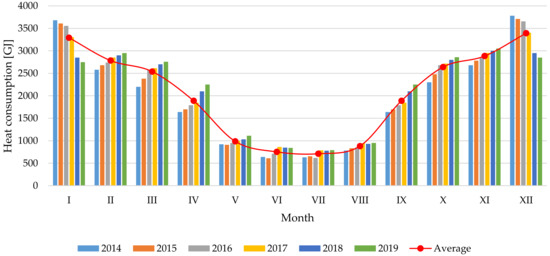

The heat consumption analysis carried out in 2018 shows the dependence of consumption on the season and the prevailing outside temperature (Figure 3). In the analyzed hotel, the month with the lowest heat consumption in a given year is June with a value of 610 GJ. The winter months of December and January are responsible for the highest heat consumption, ranging between 2850 and 3780 GJ.

Figure 3.

Measured heat consumption in 2014–2019.

The heat consumption shown in Figure 3 shall be based on final energy consumption as measured by metering equipment.

2.2. Installation of Air Conditioning, Water, and Sewage

The cooling system consists of 4 TRANE RTWB 220 compressor cooling units with a cooling capacity of 508.5 kW each, equipped with compressors with an electric power of 132 kW (175 kW including drives and auxiliary systems), producing chilled water distributed to air handling units and air convectors (FCUs). The heat is dissipated using the GUNTER GFH 092B/2 × 5 N (D)-G6/2P fan dry coolers in the glycol cycle. The system is equipped with a 3500 L chilled water buffer and a free-cooling exchanger that starts at an outside temperature of 8 °C.

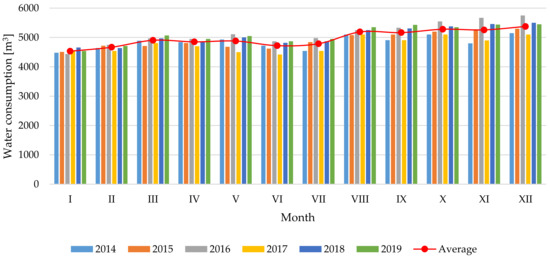

The water for the facility is taken from the municipal water supply using two Dn 100 connections. On the fourth floor, two firefighting tanks have been installed. with a capacity of 1000 m3 each. The water supplying the building’s water supply system is collected in a tank with a capacity of 80 m3. The installation is divided into four zones covering the same floors as the heating system. Each zone is powered by a separate pump hydrophore set equipped with frequency converters. The average cold water consumption is around 4700 m3 per month, which is approximately 156 m3 of water per day to meet all the needs of the facility (including kitchen and domestic hot water). The used water is discharged into the municipal sewage system. The current prices of the above-mentioned media are PLN 3.6/m3 for cold water and PLN 5.52/m3 for sewage, respectively.

The structure of average water consumption in the analyzed hotel facility is shown in Figure 4.

Figure 4.

Structure of water consumption in the analyzed hotel facility.

Figure 5 shows the average water consumption over the last 10 years. It can be seen that consumption increases in a slightly irregular manner, from 46,037 m3 in 2009 to 61,896 m3 in 2016.

Figure 5.

Measured water consumption in a hotel facility in 2014–2019.

2.3. Electrical Installations

The building is powered from two 15 KV lines, from which 0.4 kV receivers are supplied through 3 × 1600 kVA transformers. An 800-kW generator installed on the 44th floor is provided for emergency power supply.

Figure 6 shows the structure of electricity consumption in the analyzed hotel facility. Lighting, space heating and cooling, and water heating equipment use about 60% of the electricity consumed in the hotel. According to the information obtained from the representatives of the analyzed hotel facility, this usage ranges from 5 to 10% of the hotel’s revenue, and hence controlling electricity costs is a big factor affecting the profitability of the facility.

Figure 6.

Structure of electricity consumption in the analyzed hotel facility.

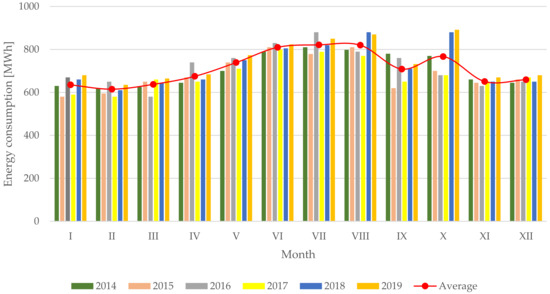

Electricity consumption from 2014 to 2016 was constantly increasing, which can be seen in the figure below (Figure 7). During this time, the hotel was gaining in popularity and its occupancy increased with each passing year. Since 2017, this consumption has remained at a similar level with an average permanent occupancy of 80%.

Figure 7.

Measured electricity consumption in a hotel facility in 2014–2019.

2.4. Building Management System

The facility has a building management system (BMS) by means of which it monitors the conditions prevailing in individual zones, and controls and remotely manages the operation of heating, ventilation, and air conditioning (HVAC) devices aimed at maintaining comfortable conditions for guests’ stay. Heat supply can be monitored and adjusted as needed. However, it is worth considering the expansion of the BMS, e.g., with the currently missing reading of many submeters, mainly electric ones. This would facilitate quick and current insight into the energy management of the facility and faster reaction and elimination of potential irregularities in this area. The BMS system is directly connected with the hotel’s Opera system monitoring reservations/occupancy of rooms. Therefore, it is possible to maintain three states of thermal comfort in the rooms—Prekomfort, Komfort, and BEMS (Building Energy Management Systems).

2.5. Additional Information

One of the main energy problems is the underheating of the lobby area in winter due to the number of entrance doors through which heat escapes, on the one hand, and the glass façade with low thermal insulation on the other. Moreover, in the summer season, there is a problem of overheating of the lobby and insufficient cooling capacity of the ventilation units serving this zone of the building. In order to prevent excessive heat gain through radiation, a reflective foil was glued directly on the outer side of the glass façade of the first floor, but this solution is still missing on the two upper floors. The second problem is the insufficient efficiency of the cooling system based on four compressor units and dry coolers placed on the roof. The fan coolers are installed on the southeast side, and for this reason, the air temperature around them is very high in summer. They are not shaded most of the day and are not able to dissipate the heat taken from the building.

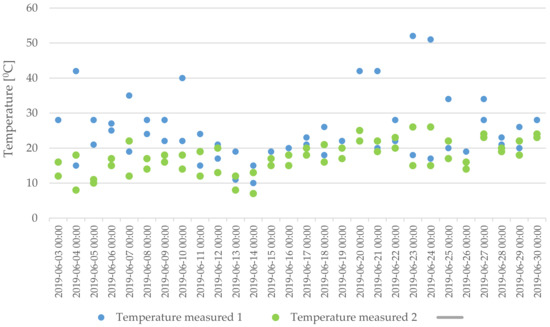

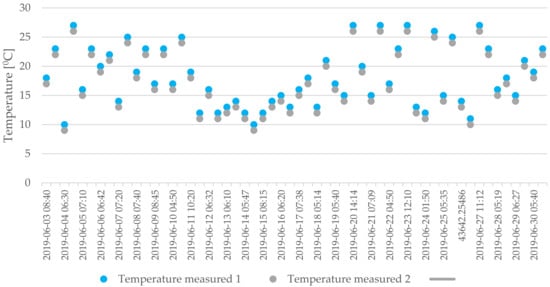

For the purposes of the analysis, the temperatures on the sunny side, where the fan coolers are located, and on the north (shaded) side were measured from 3 June to 30 June 2019 (Figure 8 and Figure 9). In Figure 8 and Figure 9, measured temperature 1 is the measured temperature outside the building but very close to the fan, and measured temperature 2 is the temperature outside (ambient) but away from the fan.

Figure 8.

Temperature registration on the sunny part of the roof.

Figure 9.

Temperature registration on the shaded part of the roof.

Figure 8 shows a large temperature discrepancy between the temperature measured close to the fan, and the outside air temperature (temperature prevailing outside the building) [51]. The temperature of the fan coolers on hot and sunny days was over 50 °C. After sunset or on cloudy days, the coolers did not heat up so drastically and their temperature was close to the temperature outside.

On the other hand, in the place where the fan coolers are not exposed to the sunny and heated part of the roof, the measured temperature mostly coincides with the external temperature. The data of both temperatures in Figure 9 coincide in almost 100% of the points.

3. Results

The results of the study concern the proposed solutions for savings in terms of the lighting of staircases of the hotel facility, lighting of underground garages, replacement of fans in the air handling units, and replacement of bathroom fittings.

3.1. Staircase Lighting Modernization

There are two staircases in the building, one with external windows and the other with no natural light, starting on the fifth floor and ending on the 44th floor. Right next to the staircase without access to daylight, there is one fire lift and two service lifts. Each staircase ends with an exit to the roof located on the 44th floor of the building. The exit from the staircase on each floor leads to the corridors intended for employees. Additionally, there are two additional staircases from floors −5 to +5 and one from the ground floor to the third floor. In addition, there is a staircase in the building that leads to underground garages located on floors −2 to −5.

The modernization of internal lighting will consist of replacing the existing fluorescent luminaires with energy-saving LED (Light Emitting Diode) luminaires. As part of the modernization, it is planned to replace the existing 2 × 36 W (i.e., 0.07 kW) fluorescent lamps located in staircases, equipped with an emergency module and a NiCd 6 V 4 ah battery. The modernization will cover the lighting of internal emergency staircases. In the place of fluorescent luminaires, new LED luminaires will be installed with a nominal power of 39 W with a built-in emergency module, a motion sensor, and a daylight sensor.

The current installed power in the base state, calculated on the basis of the actual state, was 9828 W. After taking into account the losses on ballasts, it amounts to 12,481.6 W. The ballasts are devices limiting the current in the electric circuit, and the losses in them were determined at the level of 27%.

The most important factor will be to reduce the lighting time of luminaires in the area of staircases. The new LED luminaires will be equipped with presence and daylight sensors; therefore, the lighting operation time will be significantly reduced. Due to the continuous nature of the hotel operation, requiring the building to be open and manned 24 h a day, it was assumed that fluorescent lamps in the staircases would operate 24 h a day. The lighting of these rooms is essential for the night shifts of hotel employees. With currently installed fluorescent luminaires, the daily energy consumption is almost 300 kWh. This is a great amount needed only to illuminate staircases. In some moments of operation of the analyzed hotel, the lights are used unnecessarily, which generates excessive power consumption and costs.

The new LED luminaire has a built-in RMS (Radio Motion Sensor) presence sensor and daylight sensor, which has an adjustable detection range, back-up time from 5 s to 30 min, and daylight threshold intensity. It is also equipped with an ON–OFF function, which allows to turn off the light after the disappearance of traffic and when the light intensity in a given room is higher than the selected level. The new LED fittings will have a nominal power of 39 W.

The new LED luminaires used in the modernization, as opposed to traditional fluorescent lamps, have better efficiency and durability. The light of LED luminaires shows a more precise orientation and allows for their more accurate and efficient use. Traditional fluorescent lamps use too much energy to generate heat, unlike LED sources. Energy savings with the use of modern LED sources are up to 50%.

The lighting power consumption in staircases before and after modernization is presented in Table 1. The installed wattage of internal light sources was calculated as the product of the bulb rating and the number of lamps installed. To calculate the daily energy consumption [kWh], the product of the installed power and the time during which the power is consumed was used [52,53].

Table 1.

The lighting of hotel staircases before and after modernization.

Due to the built-in daylight and motion sensors, after modernization, the estimated daily operating time of new luminaires can be reduced from 24 h by as much as half. The average lamp life is influenced by many factors, including hotel occupancy, employee efficiency, cloud cover outside the window, frequency of use of elevators, etc. Taking all this into account, it is possible to estimate the reduction of daily energy consumption from 299.56 kWh to 127.76 kWh. Savings that can be achieved are up to 58%.

Traditional linear fluorescent lamps are a functional and efficient light source. These are fluorescent lamps of the discharge lamp group—ultraviolet radiation is created by an electrical discharge in low-pressure mercury vapor; it is then converted into visible light by means of a phosphor. The use of modern lighting fixtures has made the choice between traditional fluorescent and LED a difficult decision. Improvements have eliminated light ripple, uncomfortable flickering when turned on, and buzzing. In addition, the time to light up and achieve full luminous flux has been shortened, and the luminaires do not require compensation. Fluorescent lamps emit a small amount of heat, are characterized by a long life (from several to tens of thousands of hours), and are also available in different color temperatures. High-quality LED bulbs can maintain 70% of their original brightness even after 50,000 h of operation. Manufacturers are still working on improving this parameter; in the market, fluorescent lamps have also appeared that operate for 90,000 h [54,55].

3.2. Underground Garage Lighting Modernization

In the underground garage, there are two types of fluorescent lamps with a power of 1 × 36 W and 2 × 36 W. Luminaires are located above the main communication routes and over parking spaces. Some of the above-mentioned luminaires have a built-in emergency module with a battery. The garage lighting circuits are equipped with motion sensors located in the vestibules of the elevators and above the entrance ramps. New LED fittings will be installed in place of the old fluorescent luminaires. Every second luminaire above the escape routes will be equipped with an emergency power supply module with a battery for 3 h of power backup.

The main objective of the modernization is to reduce the power of installed fluorescent lamps in underground garage areas. In the garages, floors −5 to −2 are identical. The scope of works does not include storage, technical, rest and refreshment, rooms, etc., whose lighting circuits are equipped with switches (rooms used occasionally), or corridors and passageways with motion/presence sensors. Overall, 410 old fluorescent luminaires will be replaced by new LEDs with a nominal power of 36 W and 27 W.

The daily energy consumption of currently installed fluorescent lamps is 442.80 kWh with the 24-h operation. As a result of the modernization, i.e., replacement of lighting with LEDs and installation of motion detectors, the garage lighting will consume 333.51 kWh per day, which translates into 109.29 kWh savings per day.

The lighting power consumption in staircases before and after modernization is presented in Table 2.

Table 2.

The lighting of underground garages before and after modernization.

3.3. Replacing Fans in Air Handling Units

Another modernization proposal is the replacement of supply and exhaust air handling units (AHUs). It is planned to install new fans equipped with AC motors, and partially with EC (Electronically Commutated) motors (in the case of fans that have not been continuously regulated with the use of inverters so far).

The effect of the proposed modernization is the reduction of electricity consumption by selected AHUs, reduction of the installed fan power, and improvement of their efficiency and performance (each of the proposed fans should have approximately 10–15% reserve capacity in case of future modernization or rebuilding of ventilation systems).

The AHU inlet exhaust air handling units have been characterized in the current state and after possible modernization in terms of power at the operating point. Replacing the current Rosenberg fans with radial fans allowed reducing the power at the operating point while maintaining the same parameters. Both before and after the modernization, one fan was used on the inlet and one on the exhaust. The parameters of the realized process were regulated by an inverter.

The comparison presented in Table 3 below shows the difference in air handling unit power at the operating point before and after the modernization. The total sum of the power of all air handling units in the current state in the analyzed accommodation facility is 335.93 kW, while after the proposed modernization, this sum is reduced to 276.72 kW. Energy savings when replacing the currently installed Rosenberg fans with radial fans are 59.21 kW at the operating point.

Table 3.

Comparison of power at the operating point before and after modernization.

The calculation of electricity savings before and after the modernization was carried out on the basis of the nominal power value of each of the 27 fans and their operating times during the year in accordance with the calendars currently operating in the facility. The working time of each fan was limited to the maximum number of hours, i.e., 8568. One week was planned for any technological or service breaks. In the case of fans with an inverter, operation at speed 1 means 70% of the nominal capacity of the fan operation and at speed 2 means the nominal power. These values were adopted on the basis of photographic documentation of the BMS system prepared during visits to the facility. The savings from replacing the fans were 59.21 kW at the operating point. With an additional shift from second gear to first gear, the savings increase up to 242.35 kW.

3.4. Replacement of Bathroom Fittings

Another proposal for modernization is the replacement of the classic fittings with a more economical one. The currently installed fittings use too much water. To a large extent, it depends on the high occupancy of the hotel often over 80%. The modernization will consist of installing new fittings with an aerator. It aims to reduce water consumption by up to half. If the condition of the present washbasin and shower faucets is reasonably good, it is possible to mount the aerator itself to the currently installed fittings. It is an economical solution in the event that the equipment is not worn out and is suitable for further use by guests without reducing the standards of a five-star hotel. However, 848 washbasin faucets and 446 shower and bathtub heads will be replaced.

Assuming that the average hotel occupancy is 80%, which is about 600 guests, we can estimate the approximate water consumption during their stay. Considering that the currently installed fittings have an economical class A, that consumes ≤0.25 L per second, i.e., a maximum of 15 L per minute, the newly installed tip will reduce its consumption from 1.8 to 8 L per minute. This is possible due to the regulation of the water flow and thus setting the appropriate pressure by turning the screw. It can be stated that one person uses approximately 170 L for washing hands, teeth, and taking a shower or bath. With 600 people staying overnight during one day, the consumption reaches approximately 102,000 L for the use of washbasins, showers, or bathtubs.

Taking into account the annual water consumption in the analyzed hotel facility, which in 2019 was 61,106,000 L, approximately 5,092,167 L were used during the month, and the daily average is 169,739 L. With the aforementioned average occupancy of 80%, assuming about 600 overnight guests, the amount of water used to service one person is 283 L.

The shower aerator is able to reduce consumption to 2 to 8 L per minute through a convenient knob. A currently installed classic hand shower can use up to 20 L per minute [56,57]. The use of the aerator does not reduce the comfort as it adapts to the needs of users. The installation of water stream aerators will save and reduce water consumption by at least half. It is associated with saving water consumption and reducing the costs of its heating and sewage disposal. Savings resulting from the modernization applied may even amount to over 50,000 L of water used daily.

The last proposal for a possibility to reduce water consumption is regarding changes to the toilet flushing units. Modernization will cover guest rooms and staff and public bathrooms located in the analyzed hotel. Each of the 414 rooms has one toilet, in addition, there are single toilets available for employees on 24 floors. There are 10 toilets in the public bathrooms and in the spa and wellness area. The total sum of the flushing cisterns covered by the modernization is 448. The installed flushing cisterns have a capacity of 9 L and have one button, when pressed, all the water collected in the flush flows out. The solution ensuring the reduction of this wear will be the installation of a mechanism with a double flushing system cooperating with a button consisting of two parts. Typically, one of the buttons is smaller to distinguish the use as needed. To perform this part of the modernization, it is necessary to replace the existing valves with special drain valves adapted to two-position operation, in this case for concealed cisterns.

Installing a two-way drain valve will allow you to regulate and reduce the amount of water used during flushing to 6 or 3 L instead of 9 (Table 4). This will allow you to save the water used for this purpose by half when using the appropriate button depending on the need. Most people are aware of the water deficit in the world and are willing to use the dual flush button in the right way, thus reducing water consumption.

Table 4.

Comparison of water consumption before and after modernization.

3.5. Summary of the Analysis Performed

In terms of energy consumption, the proposals for retrofitting and reducing energy consumption showed an estimated significant difference in watts that could be saved. If the current lighting is replaced with LED in staircases and underground garages, 281.1 kWh can be saved per day, as compared to the earlier consumption of 742.36 kWh per day. The estimated possible savings are shown in Table 5 indicate that after the proposed modernization, lighting in staircases will reduce energy consumption to 43%, and garages to 38% of the current consumption.

Table 5.

Proposed energy savings.

The energy savings for replacing LED lighting are surprisingly high. However, these values have been verified based on literature according to which the savings can exceed 70% depending on the lighting control system used [52].

Ventilation after modernization, with appropriate settings, can consume even only 29% of what is currently consumed. The quality of the devices mentioned and the comfort felt during their operation will remain unnoticeable. The maximum possible daily savings in the considered areas is estimated at approximately 68%. There is an imperceptibly smaller difference in water consumption. Table 6 shows the water consumption per minute. As the analyzed area constitutes 51% of the total consumption, taking into account other departments, the possible saving of the majority amounting to 61% is a very satisfactory result.

Table 6.

Proposed water savings.

4. Discussion

The several-year-old hotel facility that was described and analyzed in this study has equipment that has not been replaced since the hotel’s inception. Over time, innovative solutions have been introduced to the market, which are worth paying attention to, taking into account ecological aspects and possible financial savings.

According to the analyses presented in the manuscript and the available information in the literature, the energy consumption savings in the hotel can be at the levels shown in Table 7.

Table 7.

Savings on hotel energy consumption.

The applied technical improvements in the area of water consumption, i.e., replacement of washbasin and shower faucets and the installation of new economical drain valves in the flushing cisterns allowed for huge savings. The water consumption in the analyzed hotel facility in 2019 was 61,106,000 L. On average, this consumption amounted to 169,739 L. The overall savings achieved with the proposed water upgrade are estimated at 50,846 L per day, which is 30% less water used in relation to the total water consumption of the site. After replacing the bathroom fittings, the water used decreased by 30,477 L per day. Replacing the flush drain valves resulted in an average saving of 20,368 L.

The replacement of emergency lighting located in staircases and underground garages and the modernization of the fans brought also satisfactory results. The total energy consumption during the day decreased by 5847 kWh. Looking at the general structure of consumption in a given hotel facility, due to the improvements made to only a small part responsible for the total consumption, the achieved savings of 25% seems very satisfactory.

The results obtained at the level of 30% savings on the basis of the modernization of the part responsible for half of the water consumption in the analyzed hotel facility and 25% of energy savings achieved through the replacement of some equipment meet the design assumptions. The final results are satisfactory and prompt us to implement the proposed improvements as soon as possible.

5. Conclusions

The analyses presented in the manuscript, aimed at proposing solutions to increase energy efficiency, are proposals for modernization prepared on the basis of the analysis of the facility, the technical condition of the equipment, its operation, and the analysis of energy consumption in the hotel facility.

The conducted analysis of the technical aspects of energy and water waste resulting from the use of already obsolete elements showed the possibility of modernizing the installation in a way that reduces both energy and water consumption.

The reduction of energy consumption will result from the replacement of electrical equipment in the lighting, air conditioning, and ventilation systems of the building. Reducing water consumption will also be associated with the replacement of the most wasteful details of equipment. Mitigation of water consumption will also mean reducing the consumption of energy needed to heat and distribute water in the building. The implementation of the changes will also bring significant financial savings by reducing the costs of electricity and water charges from municipal networks. The costs of introducing changes will have to be assessed in a separate study. Nevertheless, it is suggested to gradually implement the modernization in the TPM (Total Productive Maintenance) mode. By using this approach, all activities necessary for the modernization will take place without disturbing the hotel operation mode. Thus, it will limit the potential losses related to a possible downtime.

Examples of how information technology, electronics, and management can work together to achieve the highest possible energy efficiency in hotel facilities are increasingly common in the market. They are used to manage buildings, rooms, network properties. Recently, the Hilton hotel chain has set a goal to reduce its energy-related costs, which are equivalent to as much as 5% of its revenue [52]. The goal set by Hilton was made possible by implementing EcoStruxure™ Resource Advisor, a scalable cloud-based platform. It shows, in real time, the prevailing prices and resource consumption for that property, allowing them to be compared with data from other Hilton properties around the world. To make this possible, smart controllers were installed in the hotels to collect information about the resources consumed. This solution requires a large one-time investment of financial resources.

The authors are quite convinced that a similar situation might occur in many enterprises of that type, and performing such retrofitting can lead to significant improvement in energy and water consumption. Moreover, the important factor is that retrofitting can be carried out almost without disturbances with respect to the business activities of the hotel. Actually, because of frequent lockdowns due to the COVID-19 pandemic, it can be performed quickly with limited contacts between working people and eventual guests, assuring workplaces for many persons.

The hospitality industry is among those most negatively affected by the COVID-19 pandemic. The key now is to focus on proper management. The future of business may be determined by, among other things, unusual solutions for optimizing existing energy consumption costs.

Running an accommodation facility involves a huge consumption of energy, etc. for air conditioning, heating, or lighting. The pandemic caused many plants to cease production and the demand for electricity fell dramatically. The energy exchange (Towarowa Giełda Energii (TGE)) has reacted to these changes, more specifically the TGeBase index (created on the basis of calculations based on weighted average hourly electricity prices). Consequently, by switching to one that uses TGE, hotels can now contract nearly 20% of their electricity several years ahead, which is cheaper in terms of the year-on-year comparison. As the economy unfreezes, prices on TGE are expected to rise.

In their references, the authors refer to specific price lists for the fittings used (e.g., LED and traditional fluorescent). Because the analyzed hotel facility has been operating on the market for many years, many of its existing solutions are no longer available on the market. It is therefore difficult for the authors to address the question of the costs required to maintain the previous and new fixtures. However, from the point of view of the lifespan of the new solutions, it can be assumed that they will require less maintenance work.

Author Contributions

Conceptualization, O.O. and K.T.; methodology, K.T. and O.O.; validation, K.T. and O.O.; investigation, O.O. and K.T.; writing—original draft preparation, O.O. and K.T.; funding acquisition, O.O. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out under financial support obtained from the research subsidy of the Faculty of Engineering Management (WIZ) of the Bialystok University of Technology, grant No. WI/WIZ-INZ/4/2019 (Olga Orynycz).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in this article. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caban, J.; Vrábel, J.; Šarkan, B.; Kuranc, A.; Słowik, T. Operational Tests of Brake Fluid in Passenger Cars. Periodica Poly-Technica Transp. Eng. 2021, 49, 126–131. [Google Scholar] [CrossRef]

- Dzikuć, M.; Piwowar, A.; Szufa, S.; Adamczyk, J.; Dzikuć, M. Potential and Scenarios of Variants of Thermo-Modernization of Single-Family Houses: An Example of the Lubuskie Voivodeship. Energies 2021, 14, 191. [Google Scholar] [CrossRef]

- Nazarko, J.; Czerewacz-Filipowicz, K.; Kuźmicz, A.K. Comparative analysis of the Eastern European countries as participants of the new silk road. J. Bus. Econ. Manag. 2017, 18, 1212–1227. [Google Scholar] [CrossRef]

- Niemczuk, B.; Nieoczym, A.; Caban, J.; Marczuk, A. Analysis of chemical and energy properties of energy willow in the industrial burning. Przem. Chem. 2018, 97, 44–48. [Google Scholar]

- Nazarko, L. Responsible Research and Innovation in Enterprises: Benefits, Barriers and the Problem of Assessment. J. Open Innov. Technol. Mark. Complex. 2020, 6, 12. [Google Scholar] [CrossRef]

- Kampel, W.; Aas, B.; Bruland, A. Characteristics of energy-efficient swimming facilities—A case study. Energy 2014, 75, 508–512. [Google Scholar] [CrossRef]

- Han, H.; Lee, J.S.; Trang, H.L.T.; Kim, W. Water conservation and waste reduction management for increasing guest loyalty and green hotel practices. Int. J. Hosp. Manag. 2018, 75, 58–66. [Google Scholar] [CrossRef]

- Placet, M.; Katipamula, S.; Liu, B.; Dirks, J.; Xie, Y. Energy End-Use Patterns in Full-Service Hotels: A Case Study. Available online: https://www.aceee.org/files/proceedings/2010/data/papers/1984.pdf (accessed on 20 February 2021).

- Bohdanowicz, P.; Churie-Kallhauge, A.; Martinac, I. Energy-Efficiency and Conservation in Hotels—Towards Sustainable Turism. Available online: http://www.greenthehotels.com/eng/BohdanowiczChurieKallhaugeMartinacHawaii2001.pdf (accessed on 20 February 2021).

- Energy Use and Environmental Impact from Hotels on the Adriatic Coast in Croatia—Current Status and Future Possibilities for HVAC Systems. Available online: https://www.diva-portal.org/smash/get/diva2:10749/FULLTEXT01.pdf (accessed on 20 February 2021).

- Torres-Bagur, M.; Ribas, A.; Vila-Subirós, J. Incentives and Barriers to Water-Saving Measures in Hotels in the Mediterranean: A Case Study of the Muga River Basin (Girona, Spain). Sustainability 2019, 11, 3583. [Google Scholar] [CrossRef]

- Wei, W.; Wargocki, P.; Zirngibl, J.; Bendžalová, J.; Mandin, C. Review of parameters used to assess the quality of the indoor environment in Green Building certification schemes for offices and hotels. Energy Build. 2020, 209, 109683. [Google Scholar] [CrossRef]

- Klimek, B.; Szeląg, J. The Use of a Hotel—The Example of Cracow’s Hotel “Copernicus”. Zesz. Naukowe Uniw. Ekon. Krakowie 2010, 822, 59–76. [Google Scholar]

- Żogała, A.; Darul, H.; Głodniok, M.; Zawartka, P. Municipal wastewater as an source of waste heat—Case study. Ecol. Eng. 2016, 49, 208–212. [Google Scholar]

- Arnell, M.; Lundin, E.; Jeppsson, U. Sustainability Analysis for Wastewater Heat Recovery—Literature Review; Technical Report; Division of Industrial Electrical Engineering and Automation: Lund, Sweden, 2020; Available online: https://www.iea.lth.se/publications/Reports/LTH-IEA-7267.pdf (accessed on 12 January 2021).

- Green Energy as a Method of Cost Optimization. Available online: https://www.e-hotelarz.pl/artykul/69176/zielona-energia-metoda-optymalizacji-kosztow/ (accessed on 20 February 2021).

- Climate Change Awareness. Busradar.pl Study. Available online: https://www.slideshare.net/BusradarPL/wiadomo-zmian-klimatycznych-badanie-busradarpl (accessed on 20 February 2021).

- Hotel Energy Solutions, Key Energy Efficiency Solutions for SME Hotels, Hotel Energy Solutions Project Publications. 2011. Available online: https://www.e-unwto.org/doi/pdf/10.18111/9789284415038 (accessed on 20 February 2021).

- Rotimi, A.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Estimation and Validation of Energy Consumption in UK Existing Hotel Building Using Dynamic Simulation Software. Sustainability 2017, 9, 1391. [Google Scholar] [CrossRef]

- Analysis of Hotel Rates in the Second Quarter of 2019. Available online: https://www.hrs.com/pl/serwis-prasowy/informacje-prasowe/analiza-stawek-hotelowych-w-drugim-kwartale-2019-roku.html (accessed on 20 February 2021).

- Chang, H.P.; Ma, C.C. Managing the service brand value of the hotel industry in an emerging market. Int. J. Hosp. Manag. 2015, 47, 1–13. [Google Scholar] [CrossRef]

- Guerra-Montenegro, J.; JSanchez-Medina, J.; Laña, I.; DSanchez-Rodriguez, D.; Alonso-Gonzalez, I.; Del Ser, J. Computational Intelligence in the hospitality industry: A systematic literature review and a prospect of challenges. Appl. Soft Comput. 2021, 107082. [Google Scholar] [CrossRef]

- Wyngaard, A.T.; De Lange, R. The effectiveness of implementing eco initiatives to recycle water and food waste in selected Cape Town hotels. Int. J. Hosp. Manag. 2013, 34, 309–316. [Google Scholar] [CrossRef]

- Karagiorgas, M.; Tsoutsos, T.; Drosou, V.; Pouffary, S.; Pagano, T.; Lopez Lara, G.; Mendes, J.M.M. HOTRES: Renewable energies in the hotels. An extensive technical tool for the hotel industry. Renew. Sustain. Energy Rev. 2006, 10, 198–224. [Google Scholar] [CrossRef]

- Zarębski, P.; Borzyszkowski, J.; Marczak, M. Sustainable Development and Tourism. Example of Investments Connected with the Installation of Solar Collectors in Seaside Lodging Facilities. Rocz. Ochr. Środowiska 2015, 17, 143–164. [Google Scholar]

- Electricity Management in a Hotel Facility. Available online: http://www.monitorus.pl/artykuly/hotele/zarzadzanie-energia-elektryczna-w-obiekcie-hotelarskim (accessed on 1 February 2021).

- Tuz, P.K.; Gwoździej-Mazur, J. Analysis of flow in water supply systems in hotel buildings. Bud. Inż. Środowiska 2012, 3, 225–229. [Google Scholar]

- Management and Recovery of Rainwater and Grey Water. Available online: http://www.rynekinstalacyjny.pl/artykul/id4943,zagospodarowanie-i-odzysk-wody-deszczowej-i-szarej?p=2 (accessed on 1 February 2021).

- Shaw, G.; Bailey, A.; Williams, A. Aspects of service-dominant logic and its implications for tourism management: Examples from the hotel industry. Tour. Manag. 2011, 32, 207–214. [Google Scholar] [CrossRef]

- Tsagarakis, K.P.; Bounialetou, F.; Gillas, K.; Profylienou, M.; Pollaki, A.; Zografakis, N. Tourists’ attitudes for selecting accommodation with investments in renewable energy and energy saving systems. Renew. Sustain. Energy Rev. 2011, 15, 1335–1342. [Google Scholar] [CrossRef]

- Zeineb, H.; El Aissi, I. Determinants of Innovation in Tunisian Hotels. J. Tour. Hosp. 2020, 9. [Google Scholar] [CrossRef]

- Moreno-Perdigón, M.C.; Guzmán-Pérez, B.; Mesa, R.T. Guest satisfaction in independent and affiliated to chain hotels. Int. J. Hosp. Manag. 2021, 94, 102812. [Google Scholar] [CrossRef]

- KOMPLETT—Innovative Water Recycling Solution for Hotels. Available online: https://instalreporter.pl/ogolna/komplett-innowacyjne-rozwiazanie-recyklingu-wody-do-hoteli/ (accessed on 1 February 2021).

- Directions of Commercial Real Estate Market Development in Poland with Experts’ Comments. Available online: https://www.innogy.pl/pl/~/media/Innogy-Group/Innogy/Polska/Dokumenty/Raporty/Kierunki-rozwoju-rynku-nieruchomosci-komercyjnych-w-Polsce.pdf (accessed on 1 February 2021).

- Park, J.; Lee, B.K. An opinion-driven decision-support framework for benchmarking hotel service. Omega 2021, 102415. [Google Scholar] [CrossRef]

- PN-B-02151-2:2018-01 Building Acoustics. Noise Protection of Rooms in Buildings. Available online: https://komfortciszy.pl/przepisy/budynki-mieszkalne/polska-norma-pn-87b-0215102/ (accessed on 20 February 2021).

- Jiang, W.; Wang, L.; Zhou, K.Z.; Guo, Z. How managerial ties affect hotels’ proactive environmental practices in China: The contingent role of institutional environments. Int. J. Hosp. Manag. 2020, 102756. [Google Scholar] [CrossRef]

- Salehi, M.; VFilimonau, V.; Asadzadeh, M.; Ghaderi, E. Strategies to improve energy and carbon efficiency of luxury hotels in Iran. Sustain. Prod. Consum. 2021, 26, 1–15. [Google Scholar] [CrossRef]

- Barańska, P.; Zając, A. Analysis of fresh air temperatures for air conditioning system in a hotel. Instal 2020, 9, 38–43. [Google Scholar]

- Yu, F.W.; Chan, K.T. Economic benefits of improved condenser features for air-cooled chillers serving an air-conditioned hotel. Appl. Therm. Eng. 2006, 26, 1063–1073. [Google Scholar] [CrossRef]

- PN-78/B-03421. Available online: https://www.instalacjebudowlane.pl/196-33-78-wentylacja--wymogi-prawne.html (accessed on 12 February 2021).

- PN-83/B-03430/Az3:2000. Available online: https://www.pro-vent.pl/wymagania-dla-wentylacji/ (accessed on 12 February 2021).

- PN-EN 15251:2012P. Available online: http://www.rynekinstalacyjny.pl/artykul/id515,wentylacja-w-budynkach-niemieszkalnych-wg-pn-en-15251 (accessed on 12 February 2021).

- Rasheduzzaman, M.; Singh, R.; Haas, C.N.; Gurian, P.L. Required water temperature in hotel plumbing to control Legionella growth. Water Res. 2020, 182, 115943. [Google Scholar] [CrossRef]

- Ivanko, D.; Sørensen, A.L.; Nord, N. Splitting measurements of the total heat demand in a hotel into domestic hot water and space heating heat use. Energy 2021, 219, 119685. [Google Scholar] [CrossRef]

- Arora, S.D.; Mathur, S. Hotel pricing at tourist destinations—A comparison across emerging and developed markets. Tour. Manag. Perspect. 2020, 35, 100724. [Google Scholar] [CrossRef]

- Cazaubiel, A.; Cure, M.; Johansen, B.O.; Vergé, T. Substitution between online distribution channels: Evidence from the Oslo hotel market. Int. J. Ind. Organ. 2020, 69, 102577. [Google Scholar] [CrossRef]

- Make the Best Use of the Energy. Energy Efficiency Solution Catalogue. Available online: https://www.dorian.com.pl/sites/default/files/zalaczniki/efektywnosc_energetyczna_-_przykladowe_rozwiazania.pdf (accessed on 20 February 2021).

- Pascual-Fernández, P.; Santos-Vijande, M.L.; López-Sánchez, J.A.; Molina, A. Key drivers of innovation capability in hotels: Implications on performance. Int. J. Hosp. Manag. 2021, 94, 102825. [Google Scholar] [CrossRef]

- Specjał, A.; Bartosz, D. Balance method for determining the seasonal heat demand on the basis of two weeks heat consumption measurements in the building. Instal 2014, 12, 37–43. Available online: https://www.cire.pl/pliki/2/specjal.pdf (accessed on 1 February 2021).

- Żagan, W. Honestly and prudently about LED—Future and present state of LED application in lighting. Prz. Elektrotech. 2008, 84, 1–7. [Google Scholar]

- Lighting Technology. Available online: https://www.moeller.pl/Documentation/Katalogi/Technika_o%C5%9Bwietleniowa_2017.pdf (accessed on 1 February 2021).

- Rainshower and Traditional Shower—The Modern Shower Set. Available online: https://muratordom.pl/wnetrza/lazienka/deszczownica-i-tradycyjny-natrysk-czyli-nowoczesny-zestaw-prysznicowy-aa-NhaX-MomN-CQBp.html (accessed on 1 February 2021).

- Philips Lighting. Available online: http://images.philips.com/is/content/PhilipsConsumer/Campaigns/LI20160318_polish-newsletter/LI20160318_001_newsletter_lighting_Cennik_Philips_Lighting_Poland_Kwiecien_2016.pdf (accessed on 12 February 2021).

- PXF Lighting. Available online: https://www.pxf.pl/pl/produkty/plafoniery/variant/PX0906636 (accessed on 12 February 2021).

- Household Water Consumption Facts. Available online: https://gallantplumbing.com.au/household-water-consumption-facts/ (accessed on 1 February 2021).

- Efficiency Checks in at Hilton. Available online: https://www.se.com/pl/pl/download/document/998-1965259-GMA-US/ (accessed on 20 February 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).