1. Introduction

Offshore wind generation is one of the fastest growing renewable sources in scale with an approximately 30% annual deployment increase since 2010 and is set to become the largest source of electricity in the European Union by 2040 [

1]. In addition, the traditional onshore wind power market remains strong and keeps expanding at a steady pace [

2]. Further success and the adoption of large-scale wind generation will be determined by its reliability and price. In this regard the high operation and maintenance (O&M) cost is one of the key challenges for modern wind turbines (WT), originating largely from their exposure to harsh ambient conditions in remote locations. This is especially pertinent to offshore WTs, where access is limited and maintenance costs high due to complicated repair infrastructure requirements imposed by the device location and scale. The O&M cost is estimated to account for up to 30% of entire offshore farm lifetime cost [

3]. To mitigate this problem, condition monitoring techniques are continuously being developed to enable lower costs, pre-scheduled maintenance, and thus reduce the downtime losses and avoid the high unplanned maintenance expense through a predictive maintenance approach. The key WT subassemblies that require effective monitoring in this respect are its drivetrain elements (e.g., bearings, generator, gearbox), which are in modern WT systems normally equipped with dedicated and costly condition monitoring systems [

4]. Improved monitoring of these components has thus attracted considerable research interest [

5,

6,

7].

The generator shaft misalignment is one of most common problems in practical WT drivetrains; this condition relates to appropriate alignment of its critical components, i.e., the WT rotor, gearbox (where present) and generator shafts [

8]. In general, shaft misalignment is characterised as a condition in which the shaft of the driving machine and that of the driven machine are not aligned with the same centerline. It is reported to be responsible for 50% of all rotating machinery problems [

9] and can in WT drivetrains result in undesired forces leading to damage or destruction of bearings, seals, and couplings, and thus eventually the gearbox and the generator failure [

8]. Therefore, the monitoring and diagnosis of shaft alignment is critical in WT drivetrains. This is especially pertinent to WTs located in harsh and remote environments, where effective misalignment monitoring could help reduce the associated downtime and repair cost implications [

10,

11].

The WT generator shaft alignment is typically inspected once a year utilizing costly laser alignment tools as part of a maintenance program to validate the existing misalignment levels and thus schedule the corresponding repair action [

8]. Furthermore, the laser tools employed for inspection are only suitable for use when the generator is not operating. These, therefore, cannot be used to enable online alignment monitoring [

12,

13]. Consequently, online vibration monitoring using piezoelectric accelerometers is generally employed in WT drivetrains to identify mechanical faults, including shaft misalignment; this is typically achieved by observing the relevant spectral components of vibration signals at multiples of shaft rotational speed [

9,

14]. However, vibration sensing systems are generally costly and invasive, requiring sensors to be in physical contact with the monitored device structure, and while effective, the vibration analysis based diagnostic reliability can be affected by the generator transient operation and limitations in dynamic range [

13]. Alternative approaches for shaft misalignment diagnosis are therefore constantly being investigated. These include methods based on the application of drivetrain thermal monitoring techniques [

15,

16,

17], where, for example, infrared thermometers observing the coupling temperature were employed in [

11] for misalignment detection; however, this was found to also be sensitive to other heat sources in the drivetrain. While the thermal monitoring methods can generally be effective in a known environment, they impose requirements for what can be costly and sensitive thermal monitoring devices and could be challenged in effective application in harsh and variable environmental conditions characteristic of WTs. A strain gauge was used in [

18] to predict shaft misalignment via measuring displacement in the vicinity of couplings, but this approach was shown to be constrained by the sensor location requirements. The Fiber Bragg grating (FBG) strain sensing application on the generator frame was investigated in [

19], where misalignment recognition was undertaken by observing different orientations of machine frame strain spectral components at multiples of shaft rotational speed; while promising, this method remains relatively invasive and relies on the usage of a costly FBG sensing system. The motor current signature analysis (MCSA) as a minimally sensor dependent and invasive diagnostic tool has been explored to diagnose shaft misalignment in conventional electric machines by investigating rotational speed related harmonic contents in the terminal current signals [

20,

21,

22]. The available MCSA academic studies were however undertaken on small scale machinery, and larger test systems are needed to contribute better understanding of possible fault effects manifestation and its generality. An investigation on a 30 kW doubly fed induction generator (DFIG) was reported in [

23], where terminal currents and controller loops signals were evaluated, but no significant or consistent signature at rotational speed sidebands, generally deemed characteristic of shaft misalignment, could be observed in the spectrum with the presence of fault. The general interest in development of noninvasive and competent condition monitoring methods for shaft misalignment in wind generator systems and other rotary electric machine applications remains strong but further research is needed to explore the potential of using electrical signal embedded changes for fault monitoring purposes.

Machine Learning (ML) is a method used to generalise data by learning from a set of features to find the underlying correlation between them and thus predict new labels. This offers new opportunities for classification and understanding of diagnostic information in electric machinery condition monitoring applications. A number of machine fault diagnosis applications reported in the literature applied unsupervised learning, such as successful fault detection using advanced AI clustering applied in [

24] to detect rotor broken bars and bearing failures via MCSA at different operating conditions. Furthermore, a study in [

25] applied successful clustering techniques on vibration data from different rolling bearing elements by using principal component analysis to detect the type of faults with respect to the change in rotational frequency. A further paper shown in [

26] used unsupervised clustering technique to identify stator-winding short, rotor-winding short, and brush faults on a wound-rotor induction generator using stator and rotor current and voltage signatures. On the other hand, supervised learning has been used in [

27]: regression and a non-linear artificial neural network (ANN) were applied to detect generator failures in wind turbines. It was established that the ANN performed better than the regression models. Furthermore, a novel methodology in [

28] applied multi-label classification for diagnosing and classifying the severity of misalignment and imbalance via vibration and current signatures on an inverter-driven cage induction machine. The dataset was processed, and two models were developed to detect the type and severity of faults by using a decision tree, classifier chain, and K-Nearest Neighbor (KNN). It was found that the classifier chain and KNN performed better than the decision tree in fault diagnosis, achieving a 99% accuracy for predicting the severity of the faults.

Santos et al. [

29] considered using a Support Vector Machine (SVM) and ANN classification to detect rotor misalignment and imbalance in variable speed and load conditions. Vibration, electrical torque and mechanical signals, including speed measurements, were acquired at two-levels of misalignment and four levels of imbalance introduced on a test system using an induction motor electrical drive and a parallel and planetary gearbox. It was determined that linear SVM performed better than ANN and other SVM’s kernels (e.g., Gaussian and Stamp) with an accuracy of 98%. In addition, ANN takes longer to train and tune compared to SVM, suggesting that it is computationally costly. Moreover, the SVM and decision tree were used in [

30] for the diagnosis of mechanical faults related to bearing and shaft on a test system utilising a variable speed DC motor with a flexibly coupled shaft. The shaft is supported with two ball bearings at the end. It was noted that classifiers performed well in diagnosing faults associated with 12 different conditions and reported an accuracy between 93 and 99%; however, the findings need further validation in the transient state.

The study in [

31] applied the ANN with the CSA framework to diagnose mechanical rotor eccentricity for variable speed conditions. It was discovered that the ANN performed well in diagnosing healthy and faulty conditions with an accuracy between 93 and 98%, although lower accuracy was reported when predicting increasing severity. However, validation of this method is required in real case data. Likewise, [

32] proposed a methodology for detecting wear and misalignment in a journal bearing. It revealed that ANN performed well in diagnosing a faulty condition with further work planned on modelling with different parameters to distinguish between misalignment and bearing wear.

Conversely, various papers reported WT fault detection using existing data from the turbine’s Supervisory Control and Data Acquisition System (SCADA). For example, fault detection and diagnosis of excitation error, feeding fault, generator heating faults, and air cooling malfunction were examined in [

33] on WTs in Ireland using generator SCADA data. Fault detection was based on two classes (healthy and faulty). The Support Vector Machine (SVM) was applied, and promising results obtained in relation to distinguishing between healthy and faulty conditions, with recall scores above 80% and advanced detection claimed of up to 24 h before the occurrence of failures. Furthermore, in [

34], a study was conducted to develop generator brush fault diagnostic models based on boosting tree and ensemble models such as Random Forest. The data are extracted from the SCADA of 27 WTs with sampling performed every 10 min. Accuracy between 82 and 97% was observed and advanced detection of up to 12 h reported. These studies clearly indicate considerable interest exists in the intelligent application of ML methods for practical condition monitoring purposes in wind turbine systems.

While the reported literature confirms the potential of supervised and unsupervised learning application for analysis of diagnostic signals, and thus diagnosis of WT drivetrain and general electric machinery faults, considerable further work is needed to explore the full potential of this approach. Of particular interest is to advance the non-invasive nature of diagnosis through analysis of those diagnostic signals that are readily available in electric drives and require no additional sensing hardware for monitoring. In this regard the signals embedded in the WT generator controller loops provide an attractive opportunity for minimally invasive condition monitoring as they are already monitored and recorded by the controller hardware and logic. They hence require no further hardware nor impose extra expense to access for diagnostic purposes but can, in practical applications, be challenging to access due to manufacturer imposed logic restrictions on drive controller design, which has partly impaired research efforts on their diagnostic exploration. Furthermore, the diagnostic signatures in the controller signals require further understanding; while they have been explored for signature analysis-based electrical fault monitoring in widely used WT DFIGs [

35,

36,

37], their application for misalignment fault detection remains largely unresearched. The existing limited research [

23] demonstrates that conventional fault physics-based signature analysis in DFIG controller signals is of very restricted potential for effective misalignment fault diagnosis and that more advanced data analysis methods are needed to ascertain and explore their diagnostic potential.

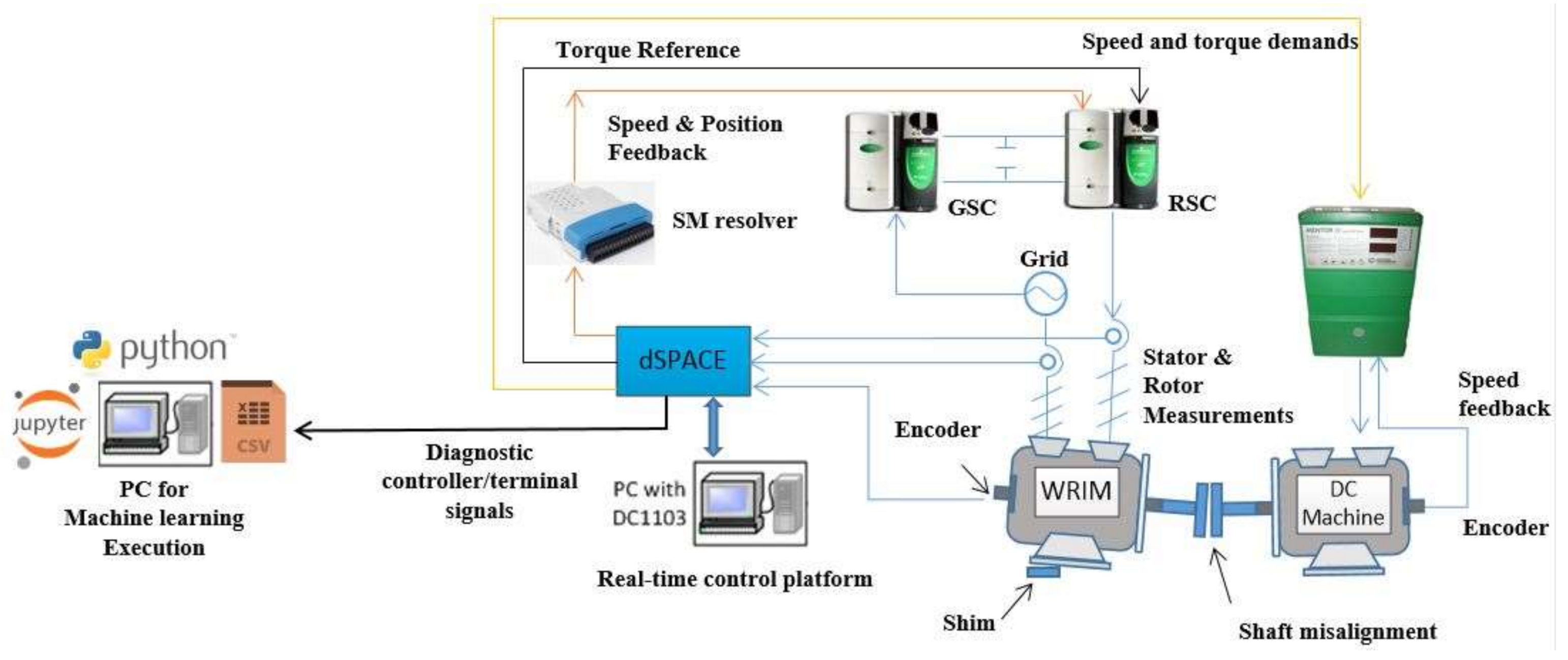

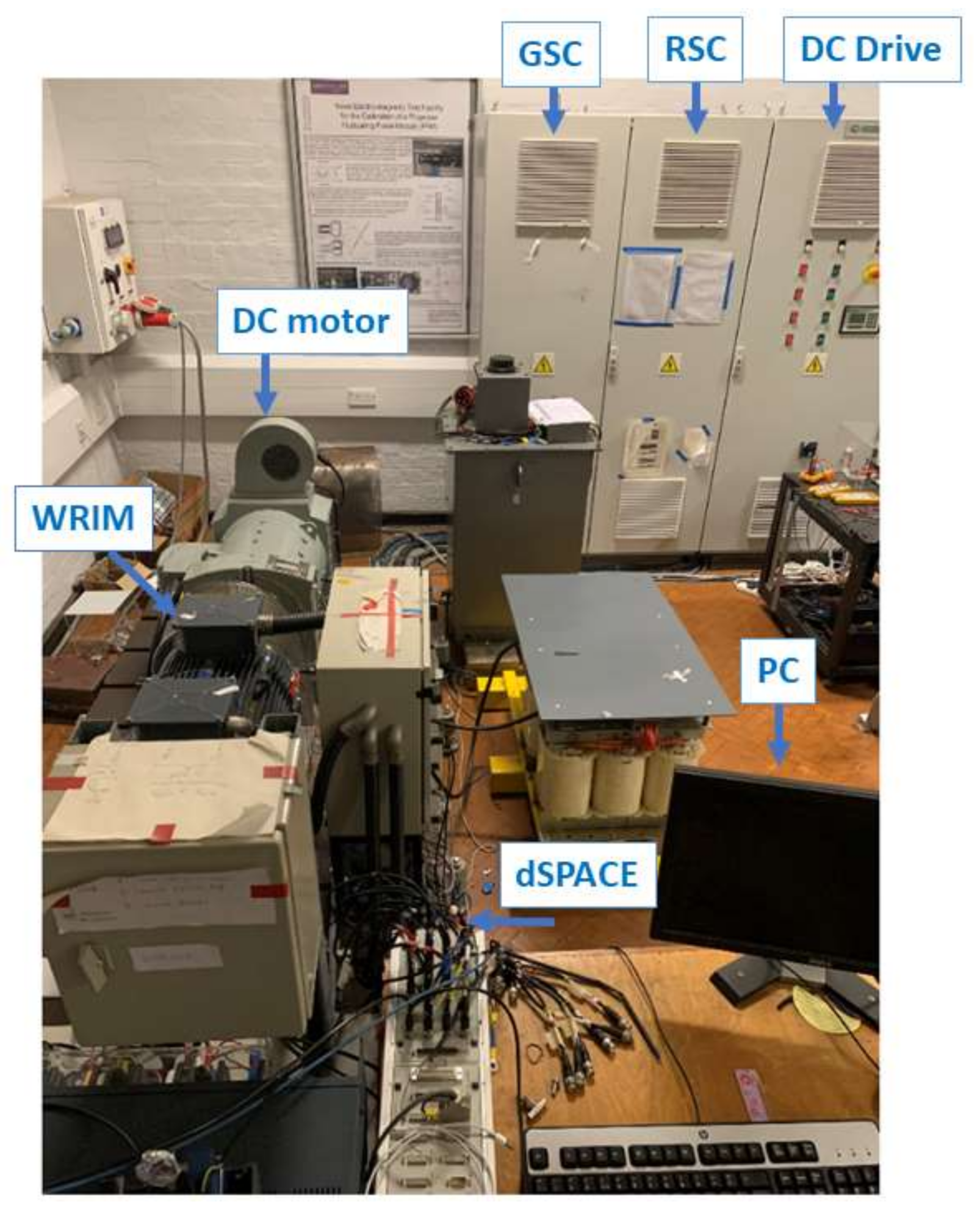

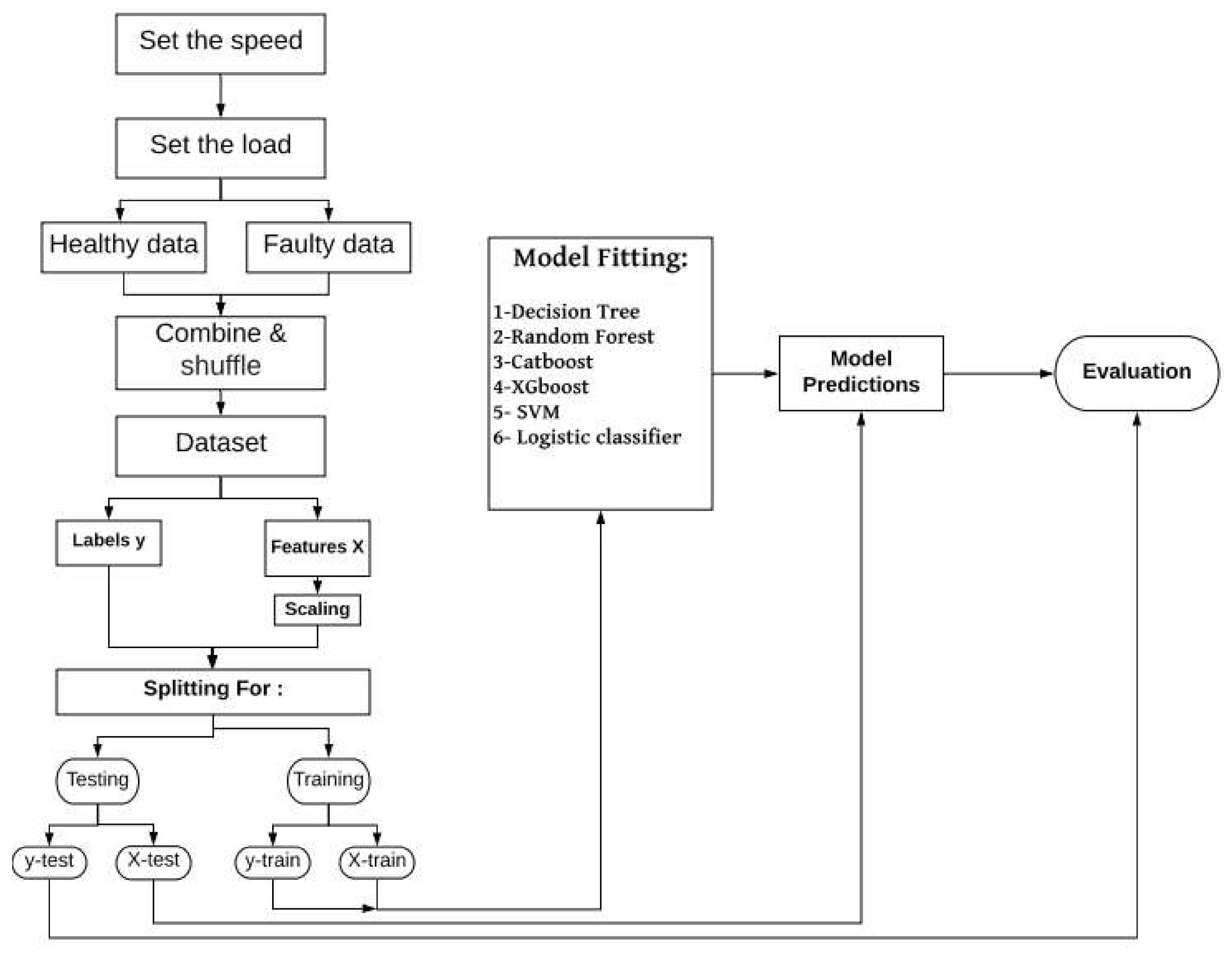

This study investigates the potential of supervised machine learning models’ application for identification of misalignment fault specific changes in WT DFIG controller loops’ signals and hence controller signal based misalignment fault diagnosis. To this end, a specialized purpose built DFIG experimental system that allows full access to controller signals and experimental emulation of the shaft angular misalignment fault is used in this work to obtain the datasets of healthy and faulty conditions signals in a range of typical operating points. These are then analyzed by a number of different supervised machine learning techniques to extract fault specific data classifiers that can be employed to enable misalignment fault diagnosis. The diagnostic performance of individual machine learning techniques is then compared to identify the best performing ones, and further analysis undertaken on training dataset volume requirements and diagnostic feature importance of controller signals for required dataset size reduction. The results demonstrate that an average misalignment fault recognition accuracy of up to 98.8% is possible through machine learning analysis of a key feature subset of DFIG controller signals in the current control loop.

4. Conclusions

This study demonstrates the general feasibility of a highly noninvasive methodology for monitoring wind generator shaft misalignment through supervised machine learning analysis of the readily available generator controller signals. The study is undertaken on a medium scale doubly fed induction generator laboratory test rig allowing practical emulation of the angular shaft misalignment and full access to controller signals.

The paper utilizes the datasets of signals, measured in healthy and misalignment fault operating conditions in a number of operating points on the examined test system to classify the misalignment condition specific features in three generator signals group subsets, namely, the controller loops signals, the terminal signals, and the mechanical signals. The analysis employs a number of leading classifiers to evaluate the individual groups of signals diagnostic potential and cross compare it, with the main focus on diagnostic exploitation of the controller signals. It was found that, overall, misalignment condition detection using controller loop signals achieved by far the best validation accuracy, observed at a level of up to 98.8% average accuracy with consistent diagnosis. Moreover, using the embedded feature selection method to select the most appropriate set of features allowed consistent results to be achieved while maintaining high average accuracy levels by using only Iqr and Iqrerr controller loop signals for misalignment detection. This allows for a less computationally demanding establishment of the proposed diagnostic scheme. Conversely, machine learning analysis of neither the terminal nor mechanical signals was able to provide consistently high accuracy in recognition of misalignment fault and showed very limited potential for this application. In addition, it was noted that models can still perform well with a smaller training dataset, with an approximately 1% accuracy rate reduction observed for most of the classifiers with the reduction in the training dataset size. This suggests that their practical implementation would not be expected to impose significant training data requirements.

The findings of this study indicate that supervised machine learning application of DFIG controller loop signals may have potential to provide a reliable and highly non-invasive approach to monitoring shaft misalignment; the method would require no additional sensing to be established as it utilizes signals that are readily available within controller loops and necessitate no additional expense to capture. The practical application of the examined diagnostic scheme in a wind turbine system would be expected to impose a modest cost requirement. This would exclusively be related to the need for ensuring the availability of generator drive PLC computational capacity required to enable the ML based diagnostic analysis of the controller loop signals; these are already monitored and manipulated within the PLC registers for the purpose of achieving real time control. The extracted diagnostic information could effectively be integrated into the drive’s existing communication protocols and fed to an external wind turbine or farm level supervisory medium using existing hardware. The implementation expense of an ML based diagnostic scheme utilizing controller signals would thus be expected to compare very favorably to that of the current field practice that relies on utilization of dedicated and costly drivetrain acceleration monitoring and analysis platforms.

Future research needed to further explore the potential of this work in WT generators and establish its generality would involve the analysis of misalignment fault signals from a range of different practical DFIG system designs, including analysis of different levels and types of misalignment (e.g., offset misalignment) and generator dynamic operating regimes.